Method for low energy consumption preparation of dimethyl ether from methanol

A technology for methanol preparation and dimethyl ether, which is applied in the directions of dehydration of hydroxyl-containing compounds to prepare ether, ether preparation, ether separation/purification, etc., to achieve the effects of operating pressure and stable reduction, increasing stability, and saving energy and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

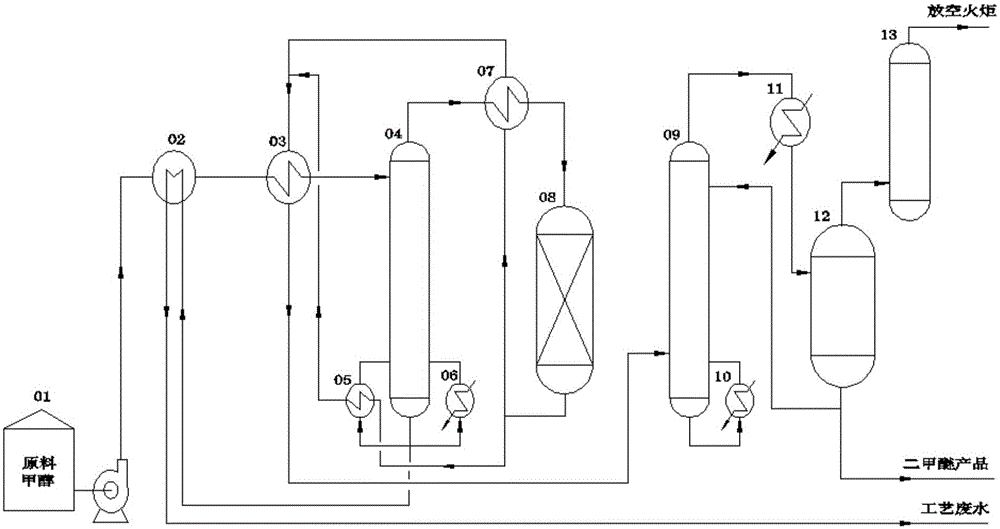

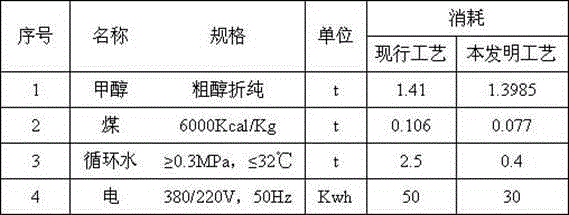

[0034] As shown in Fig. 1, the methanol with a purity of 99% (wt) is selected as the feed methanol, and it enters the reactor after two-stage heat exchange gasification and temperature rise, and the dehydration reaction is carried out at 300-350°C and a pressure of 0.78 MPa. The reaction product is fed into the gas phase at the bottom of the rectification tower, and the heat carried by itself is used to separate dimethyl ether from methanol and water. A mixture mainly containing methanol and water is obtained in the bottom of the tower. The top product is cooled by a condenser to obtain liquid phase two. Methyl ether and non-condensable gas containing a small amount of dimethyl ether and other light components, a part of liquid dimethyl ether is refluxed and a part is produced as a product after passing the test. Among them, the non-condensable gas goes to the scrubber to recover dimethyl ether, and the top of the scrubber contains light components such as carbon dioxide and ven...

Embodiment 2

[0036] According to the conditions and steps of Example 1, keep the operating conditions of the vaporization tower, reaction system and washing tower unchanged, only change the dimethyl ether feed position of the rectification tower, and the second plate counted from the bottom of the rectification tower is fed. The heat transfer oil valve outside the reboiler of the distillation tower can be fully closed, the pressure at the top of the tower is 0.7MPa, the temperature is 35°C, and the purity of the dimethyl ether product is 99.8%.

Embodiment 3

[0038] According to the conditions and steps of Example 1, the operating conditions of the vaporization tower, reaction system and washing tower were kept unchanged, and only the dimethyl ether feed position of the rectification tower was changed. The fourth plate counted from the bottom of the rectification tower was fed. The heat transfer oil valve outside the reboiler of the distillation column needs to be opened by one-fifth, the top pressure is 0.73 MPa, the temperature is 38°C, and the purity of the dimethyl ether product is 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com