Pressurized oxidation chemical chain air separation oxygen producing device and oxygen producing method

An oxygen production method and technology of an oxygen production device, applied in chemical instruments and methods, oxygen/ozone/oxide/hydroxide, inorganic chemistry, etc., can solve the problem of reducing the external heat energy of the oxygen carrier, excessive external heat energy supply, etc. problems, to achieve the effect of improving oxygen production efficiency and reducing external heat supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

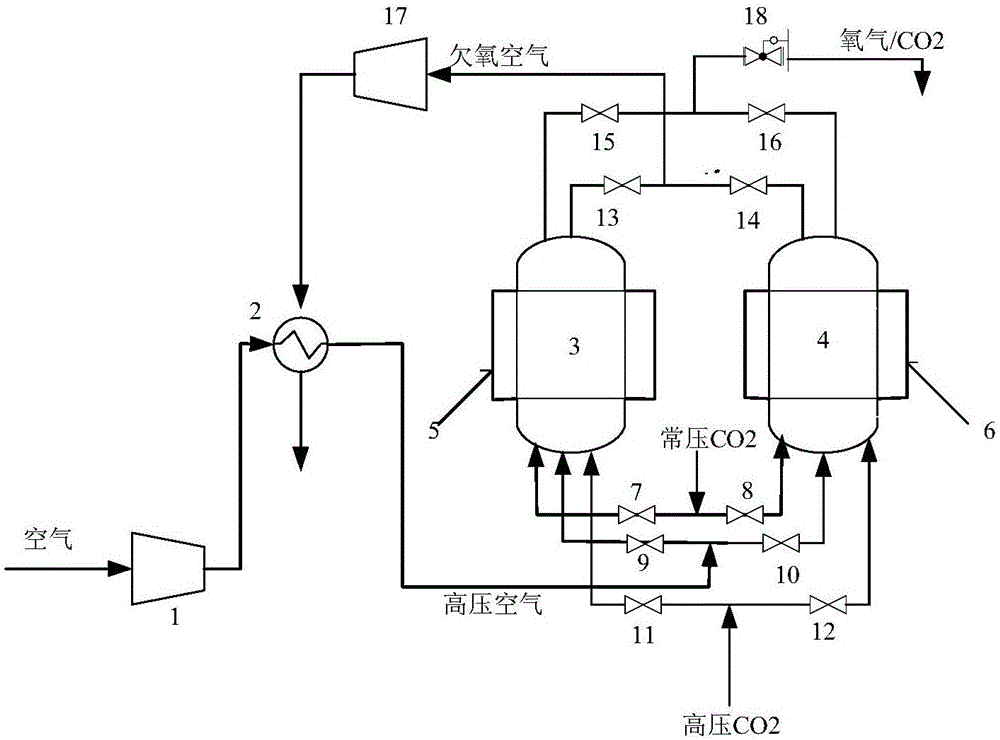

[0025] Such as figure 1 A kind of preparation method of oxygen-enriched flue gas shown, comprises the following steps:

[0026] Step 1: After the air is pressurized by the air compressor 1, it exchanges heat with the oxygen-poor air through the heat exchanger 2, and the high-pressure air after the heat exchange is passed into the first reactor 3 through the first high-pressure air flow control valve 9, React with reduced oxygen carrier attached to a certain amount of inert monomer. The reduced oxygen carrier is Mn 3 o 4 , the inert monomer is Al 2 o 3 , the mass ratio of the two is Mn 3 o 4 :Al 2 o 3 =1.69:1. The oxidation reaction pressure is 15 atm, and the oxidation reaction temperature is 930°C. The reacted oxygen deficient air passes through the first oxygen deficient flow control valve 13, then passes through the gas turbine 17 to perform external work, and then is cooled and discharged by the heat exchanger 2 after heat exchange. Stop feeding the high-pressur...

Embodiment 2

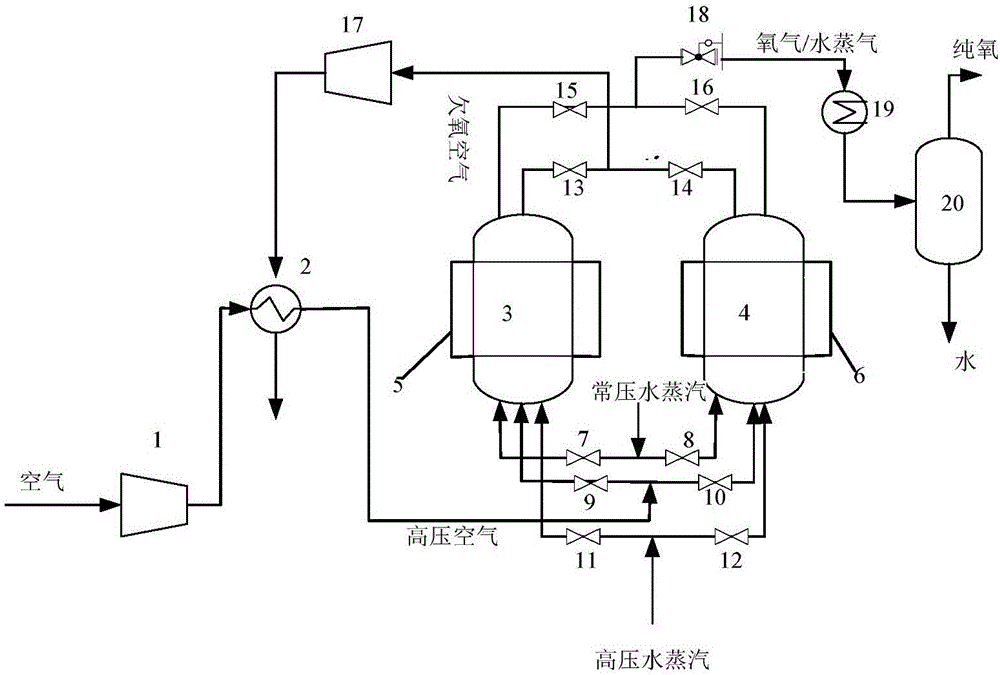

[0033] Such as figure 2 A kind of preparation method of pure oxygen shown, comprises the following steps:

[0034] Step 1: After the fresh air is pressurized by the air compressor 1, it exchanges heat with the oxygen-deficient air through the heat exchanger 2, and the high-pressure air after the heat exchange is passed into the first reactor 3 through the first high-pressure air flow control valve 9 , to react with the reduced oxygen carrier attached to a certain amount of inert monomer. The reduced oxygen carrier is Cu 2 O, the inert monomer is MgAl 2 o 4 , the mass ratio of the two is Cu 2 O: MgAl 2 o 4 =1:5.3. The oxidation reaction pressure is 10 atm, and the oxidation reaction temperature is 1070°C. The reacted oxygen deficient air passes through the first oxygen deficient flow control valve 13, then passes through the gas turbine 17 to perform external work, and then is cooled and discharged by the heat exchanger 2 after heat exchange. Stop feeding the high-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com