Industrial waste heat type low-temperature multi-effect sea water desaltation system and sea water desaltation method thereof

A technology for industrial waste heat and seawater, applied in chemical instruments and methods, seawater treatment, water/sewage treatment, etc., can solve the problems of equipment service life, high cost of seawater desalination, cumbersome cleaning and maintenance, etc., to reduce emissions and realize resources. Comprehensive utilization and the effect of improving desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

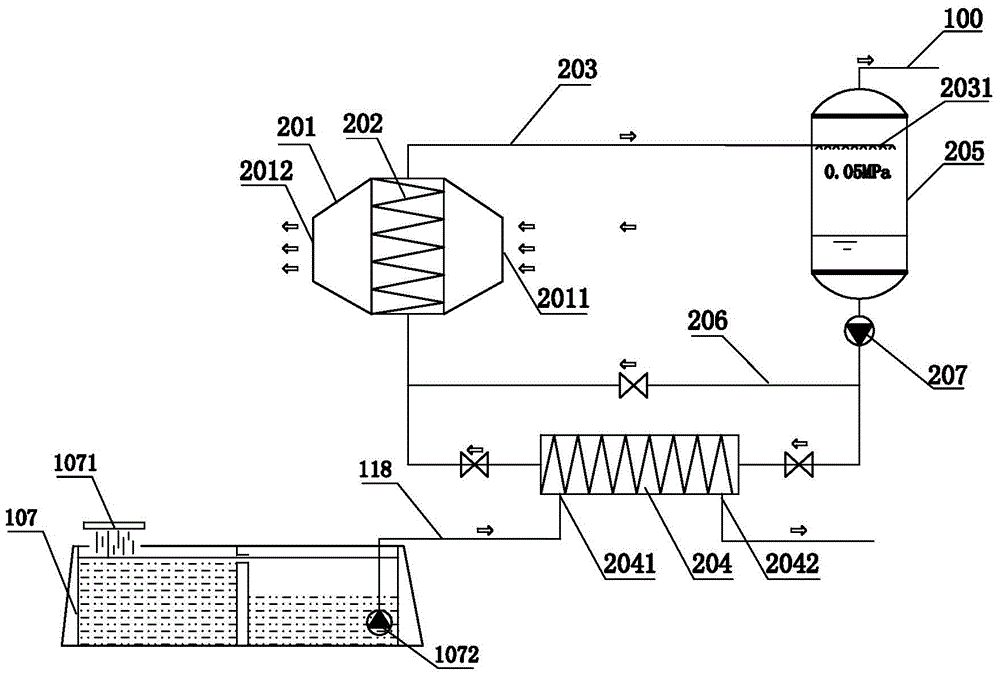

[0045] Such as figure 1 , figure 2 and image 3 As shown, the industrial waste heat type low-temperature multi-effect seawater desalination system of the present invention includes: image 3 The flue gas waste heat recovery device shown is used to produce heat source steam and preheat feed seawater, and uses the produced heat source steam as a driving heat source to desalinate seawater figure 1 The low-temperature multi-effect seawater desalination device shown.

[0046] Such as image 3 As shown, the flue gas waste heat recovery device includes: a casing 201, on which a high-temperature flue gas inlet 2011 and a low-temperature flue gas outlet 2012 are arranged, and a first heat exchange device 202 is arranged inside the casing 201, the The first heat exchange device 202 is provided with a return water inlet, a hot water outlet and a safety valve, wherein the hot water outlet is connected to one end of the hot water pipeline 203; a flash tank 205 is provided at the botto...

Embodiment 2

[0054] refer to figure 1 and image 3 , the method for desalinating seawater by using the industrial waste heat type low-temperature multi-effect seawater desalination system of the present invention includes: using a flue gas waste heat recovery device to produce heat source steam and preheating the seawater as feed material, and using the produced heat source steam to The step of seawater desalination treatment.

[0055] refer to image 3 , wherein the steps of using the flue gas waste heat recovery device to produce heat source steam and preheat the feed seawater are as follows:

[0056] A10. After calcining petroleum coke, the calcination furnace produces ultra-high temperature flue gas of about 1000°C. After the waste heat is recovered by the flue gas waste heat boiler, the temperature of the discharged flue gas is still as high as 200°C-220°C. The high-temperature flue gas of 200°C-220°C is automatically The high-temperature flue gas inlet 2011 enters the casing 201, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com