Active one-bath dyeing process of wool-flax blended yarns

A technology for blending yarn and linen, which is applied in the field of reactive one-bath dyeing process of wool and linen blended yarn, can solve problems such as poor color fastness to perspiration, and achieve the effects of improving homochromaticity, reducing water and electricity consumption, and reducing water and electricity energy consumption costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

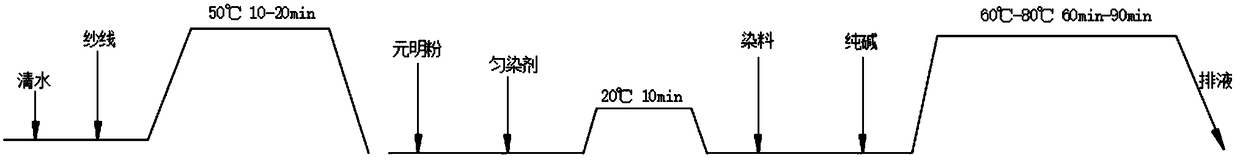

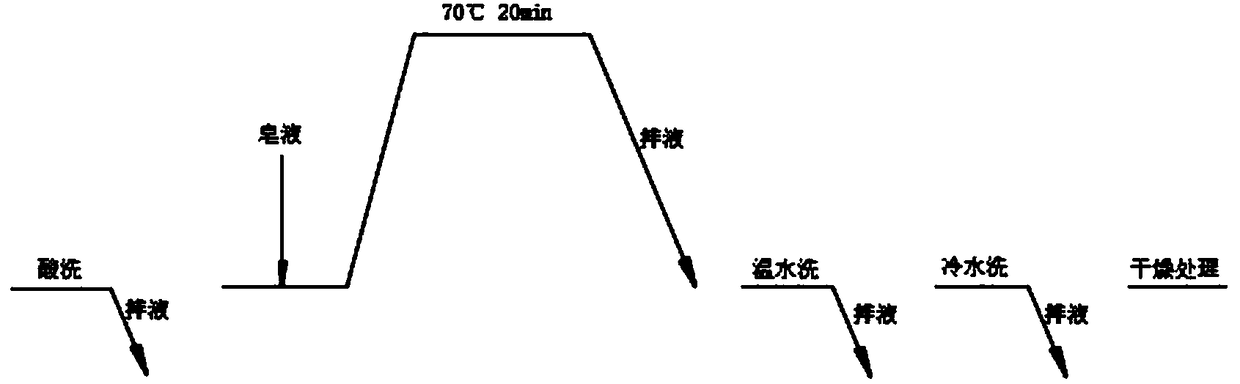

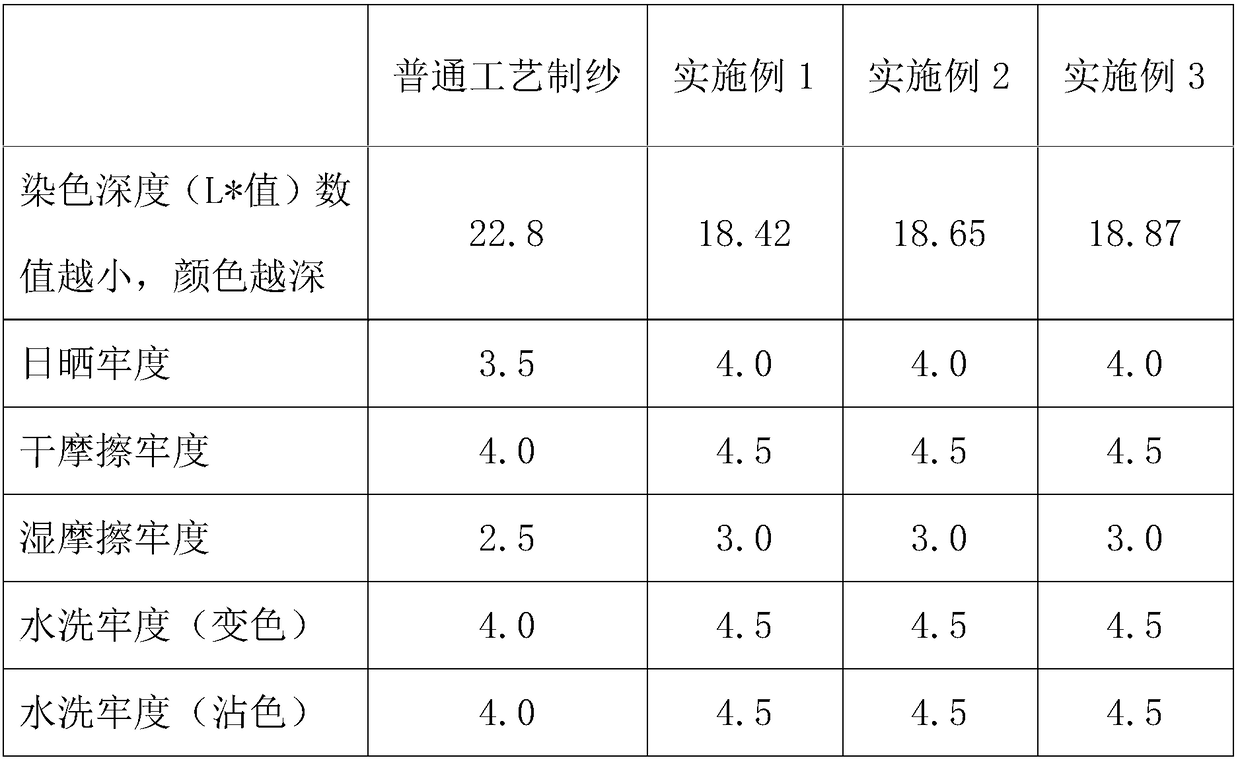

[0031] The active one-bath dyeing process of wool and flax blended yarn in this embodiment comprises the following steps (the process flow chart is as follows: Figure 1-2 shown):

[0032] Step 1: Yarn pretreatment, add water at room temperature, raise the temperature of the water to 50 degrees Celsius, soak the yarn in water for 10 minutes;

[0033] Step 2: Yarn dyeing, put sodium sulfate and leveling agent into the water in step 1, stir the solution evenly and run it for 10 minutes, raise the temperature to 60 degrees Celsius at a heating rate of 0.7℃ / min, and add Dye, soak in heat for 30 minutes, then add soda ash step by step to fix the color for 60 minutes, and discharge the waste liquid after fixing the color;

[0034] Wherein the leveling agent is Albegal B-LV, and its consumption is 2% of yarn weight, and the consumption of described sodium sulfate is 50g / L, and described dyestuff is cotton reactive dyestuff, and the consumption of described dyestuff is yarn weight. ...

Embodiment 2

[0041] The active one-bath dyeing process of wool and flax blended yarn in this embodiment comprises the following steps (the process flow chart is as follows: Figure 1-2 shown);

[0042] Step 1: Yarn pretreatment, add water at room temperature, raise the temperature of the water to 50 degrees Celsius, soak the yarn in water for 15 minutes;

[0043] Step 2: Yarn dyeing, put sodium sulfate and leveling agent into the water in step 1, stir the solution evenly and run it for 10 minutes, raise the temperature to 70 degrees Celsius at a heating rate of 0.7℃ / min, and add Dye, and keep warm for 30 minutes, then cool down to 60 degrees Celsius, then add soda ash step by step to fix the color for 70 minutes, and discharge the waste liquid after fixing the color;

[0044] Wherein the leveling agent is Albegal B-LV, and its consumption is 3% of yarn weight, and the consumption of described sodium sulfate is 70g / L, and described dyestuff is cotton active dyestuff, and the consumption of...

Embodiment 3

[0051] The active one-bath dyeing process of wool and flax blended yarn in this embodiment comprises the following steps (the process flow chart is as follows: Figure 1-2 shown):

[0052] Step 1: Yarn pretreatment, add water at room temperature, raise the temperature of the water to 50 degrees Celsius, soak the yarn in water for 20 minutes;

[0053] Step 2: Yarn dyeing, put sodium sulfate and leveling agent into the water in step 1, stir the solution evenly and run it for 10 minutes, raise the temperature to 80 degrees Celsius at a heating rate of 0.7℃ / min, and add Dye, and keep warm and soak for 30 minutes, then cool down to 60 degrees Celsius, then add soda ash step by step to fix the color for 90 minutes, and discharge the waste liquid after fixing the color;

[0054] Wherein the leveling agent is Albegal B-LV, and its consumption is 4% of yarn weight, and the consumption of described sodium sulfate is 100g / L, and described dyestuff is reactive dyestuff for cotton, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com