Rinsing device used in plastic film cleaning and recycling production line

A plastic film and production line technology, which is applied in the field of polymer material recycling and processing, can solve the problems of affecting the working efficiency of the production line, the large area occupied by the rinsing device, and the increase in the use cost of the enterprise, so as to reduce the use cost, improve the cleaning effect, and improve the work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

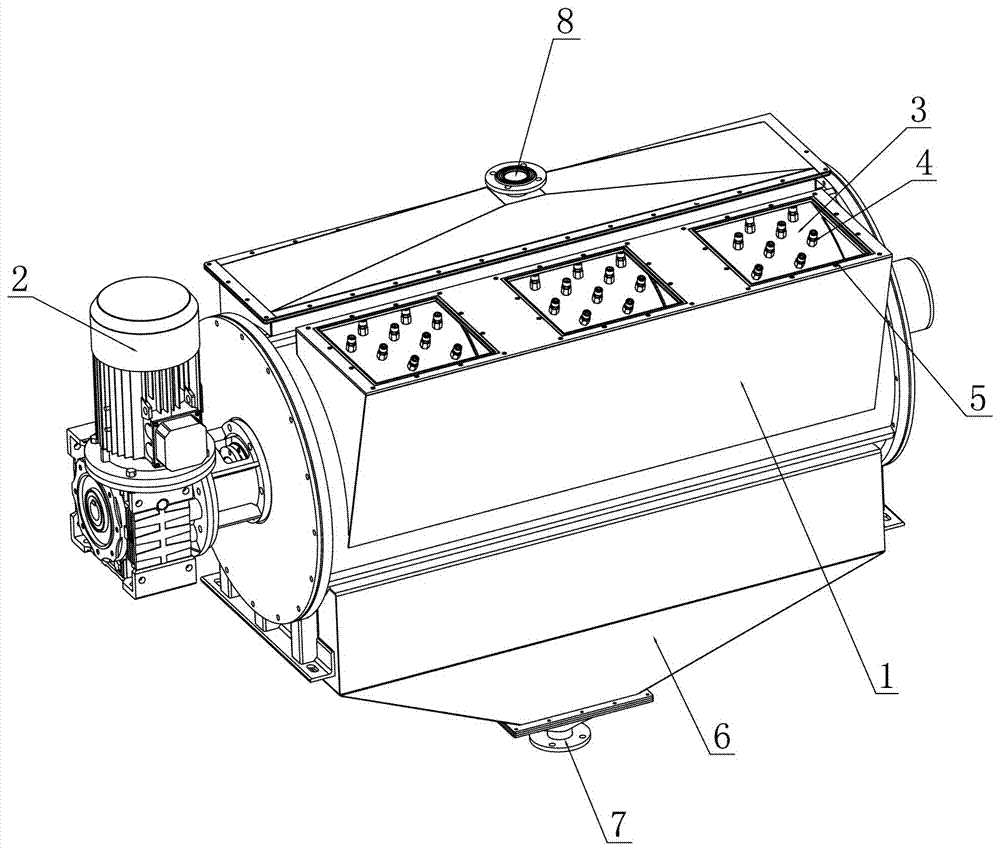

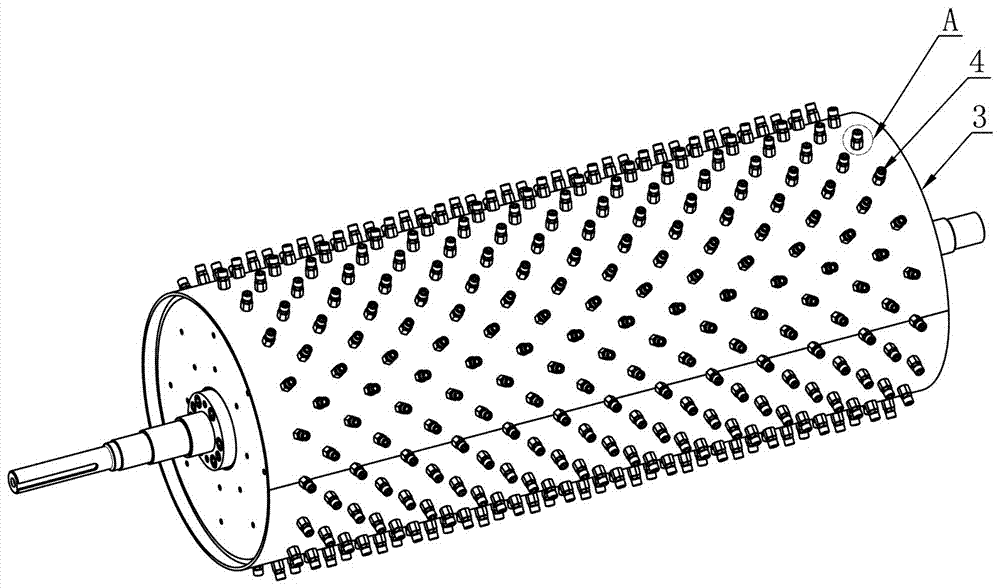

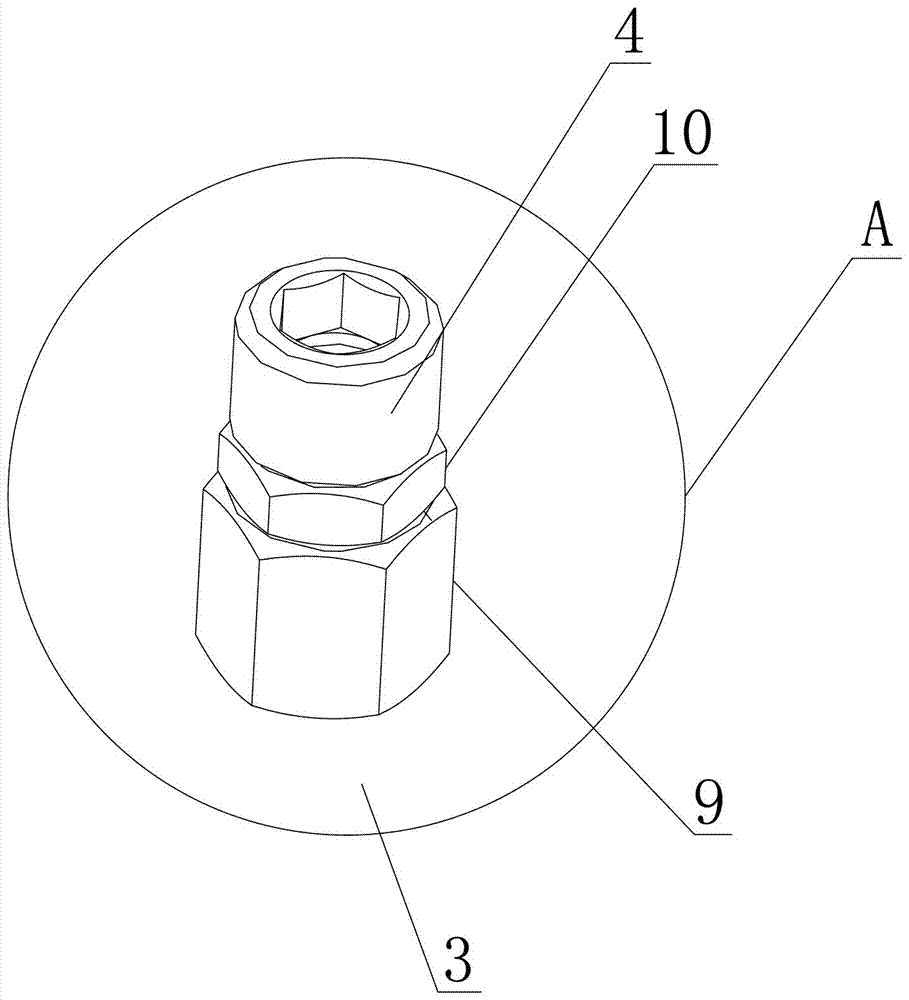

[0016] like figure 1 , figure 2 , image 3 As shown, the rinsing device in the plastic film cleaning and recycling production line includes a casing 1. Between the front and rear side plates of the casing 1, a pair of bearings and a bearing seat are movably supported by a geared motor 2 to rotate. The drum 3 is provided with a number of studs 4 on the outer circumferential wall of the drum 3 at intervals along the axial direction. The top of the shell 1 is provided with a feed port 5, the rear end is provided with a discharge port, and the bottom is provided with a water outlet. A discharge control valve is set at the discharge port of the shell 1, a perforated plate is covered at the water outlet of the shell 1, and a top feed port is set under the shell 1, which is opposite to the water outlet of the shell 1. Connected to the impurity stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com