Efficient textile lint wetting box

A humidification box and textile technology, which is applied in the processing of textile material containers, spraying/spraying textile material processing, etc., can solve the problems of insufficient uniform and comprehensive humidification of lint cotton, increased cost of lint packaging, and increased difficulty of packaging, etc., to improve humidification efficiency, The effect of high degree of automation and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

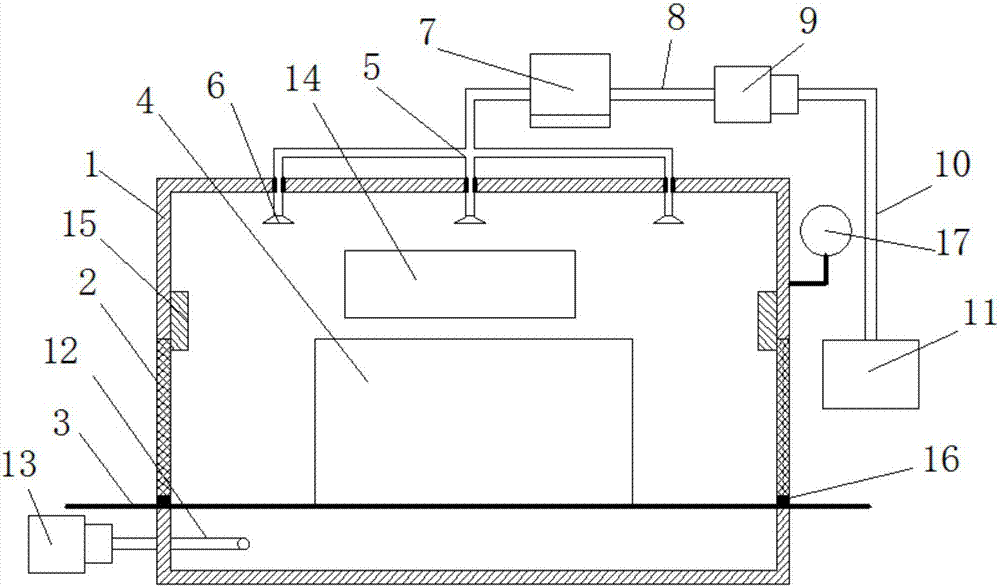

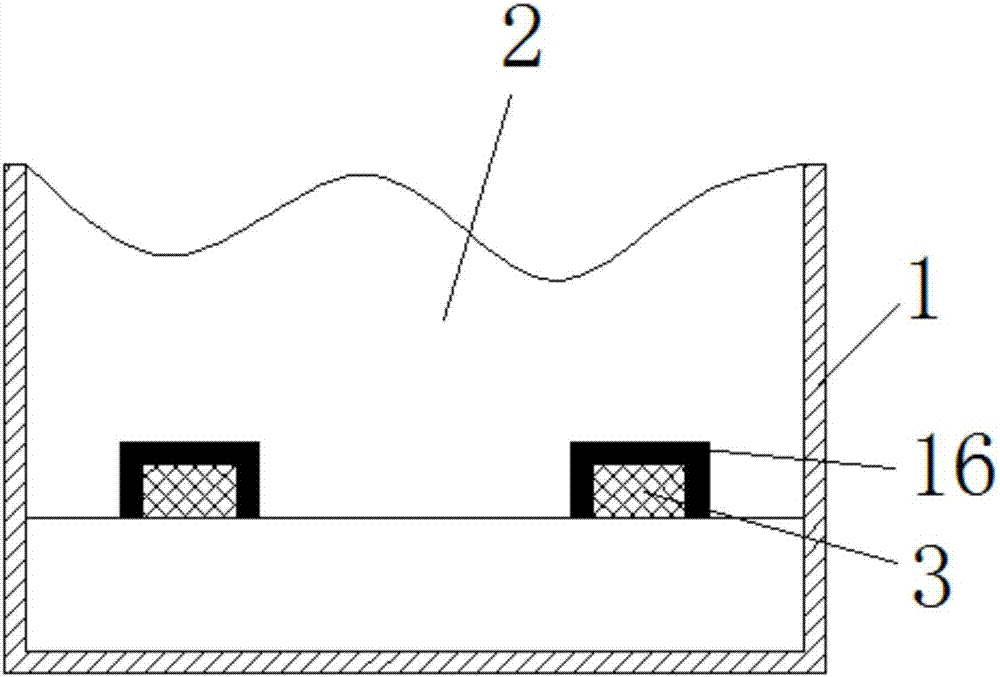

[0030] see Figure 1-2 , a high-efficiency textile lint humidification box, including a humidification box shell 1 and a water storage tank 11, a hydraulic booster 15 is connected to the humidification box shell 1, a working compartment door 2 is connected to the humidification box shell 1, and the hydraulic booster 15 It is located above the working compartment door 2; a sliding rail 3 is fixed on the casing 1 of the humidification box, and the sliding rail 3 is connected to a tray 4; a vacuum pump 13 is installed on the left side of the casing 1 of the humidification box, and the suction port of the vacuum pump 13 is connected to an exhaust pipe 12, and the suction pipe 12 The end away from the vacuum pump 13 is located in the casing 1 of the humidification box; the water storage tank 11 is connected with a suction pipe 10, and the end of the suction pipe 10 away from the water storage tank 11 is connected to the water inlet of the water pump 9, and the water outlet of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com