High-strength and light refractory aggregate

A refractory aggregate and high-strength technology, applied in the field of refractory materials, can solve the problems of low strength and water resistance, and achieve the effect of high strength, good water resistance and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

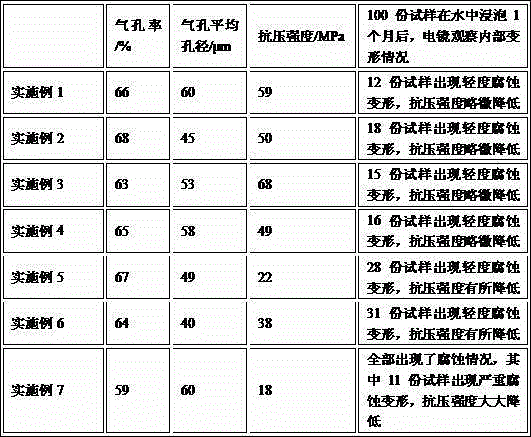

Examples

Embodiment 1

[0022] Production process of high-strength lightweight refractory aggregate:

[0023] (1) Preparation of mud:

[0024] According to parts by weight, 60 parts of alumina (particle size 3 μm), 18 parts of fused magnesia (particle size 9 μm), 0.5 parts of α-Al with a mass fraction of 99.9% 2 o 3 Nano powder (250nm in particle size), 0.5 part of perlite powder (20 μm in particle size), 0.9 part of sapphire powder (15 μm in particle size), 0.2 part of sericite (2 μm in particle size) as the main raw materials, after uniform ball milling, keep the temperature At 15°C, continue to add 25 parts of Suzhou clay, 1.1 parts of SDBS foaming agent, 0.5 parts of sodium tripolyphosphate, and 6 parts of dextrin and continue to stir to make a mixed mud;

[0025] (2) Sintering molding

[0026] The prepared mud is poured into a mold of 20mm×20mm×20mm, and the mold is demoulded after natural drying. The dried wet billet is fired in an electric furnace. The firing is divided into 3 steps:

[00...

Embodiment 2

[0031] Production process of high-strength lightweight refractory aggregate:

[0032] (1) Preparation of mud:

[0033] According to parts by weight, 62 parts of alumina (particle size 2 μm), 20 parts of fused magnesia (particle size 5 μm), 0.8 parts of α-Al with a mass fraction of 99.9% 2 o 3 Nano powder (200nm in particle size), 0.5 part of perlite powder (25 μm in particle size), 0.6 part of perlite powder (20 μm in particle size), 0.2 part of sericite (2 μm in particle size) as the main raw materials, after uniform ball milling, keep the temperature At 15°C, continue to add 25 parts of Suzhou clay, 0.8 parts of SDBS foaming agent, 0.5 parts of sodium tripolyphosphate, and 6.5 parts of dextrin and continue to stir evenly to obtain a mixed mud;

[0034] (2) Sintering molding

[0035] The prepared mud is poured into a mold of 20mm×20mm×20mm, and the mold is demoulded after natural drying. The dried wet billet is fired in an electric furnace. The firing is divided into 3 ste...

Embodiment 3

[0040] Production process of high-strength lightweight refractory aggregate:

[0041] (1) Preparation of mud:

[0042] According to parts by weight, 61 parts of alumina (particle size 3 μm), 19 parts of fused magnesia (particle size 8 μm), 0.6 parts of α-Al with a mass fraction of 99.9% 2 o 3 Nano-powder (particle size 240nm), 0.5 part of perlite powder (particle size 21 μm), 0.8 part of perlite powder (particle size 16 μm), 0.2 part of sericite (particle size 2 μm) as the main raw materials, after uniform ball milling, keep the temperature At 15°C, continue to add 25 parts of Suzhou clay, 1.0 parts of SDBS foaming agent, 0.5 parts of sodium tripolyphosphate, and 6.1 parts of dextrin and continue to stir evenly to obtain a mixed mud;

[0043] (2) Sintering molding

[0044] The prepared mud is poured into a mold of 20mm×20mm×20mm, and the mold is demoulded after natural drying. The dried wet billet is fired in an electric furnace. The firing is divided into 3 steps:

[0045...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com