Microwave sample pretreatment method applied to organic carbon detection

A treatment method, organic carbon technology, applied in the field of microwave chemistry, to achieve the effects of easy operation, sufficient reaction, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

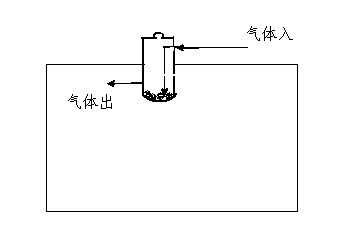

[0031] according to figure 1 As shown, put a 10-gram, 40-mesh carbon-free nickel oxide absorbing material into a 20-ml quartz or ceramic crucible, and then put 0.2 grams of the soil sample to be tested into the crucible. The crucible is put into the bottom of a sealed suitable quartz container permeable to microwave radiation, the upper part of the container is connected with the carrier gas inlet, and the lower part is connected with the carrier gas outlet. The carrier gas is a mixed gas of high-purity nitrogen with a flow rate of 100 ml / min and pure oxygen at 20 ml / min. When a microwave oven radiation device with a power of 800W is used, the temperature of the absorbing material rises to 1100°C in 2 minutes, and the organic carbon in the soil sample is oxidized to carbon dioxide and then carried by the carrier gas into the non-dispersive infrared spectrometer for measurement. The measurement results are consistent with those of commercial products. The results of the resist...

Embodiment 2

[0033] according to figure 1 As shown, a 15-gram, 60-mesh carbon-free cobalt trioxide absorbing material is put into a 30-milliliter quartz colorimetric tube, and then 0.2 g of the soil sample to be tested is also put into the colorimetric tube. The upper part of the colorimetric tube is tightly plugged with a stopper, which is provided with a carrier gas inlet and a carrier gas outlet, and the carrier gas inlet pipe extends into the depth of the colorimetric tube and is close to the position of the wave-absorbing material. The carrier gas is a mixed gas of high-purity nitrogen and 10 ml / min of pure oxygen at a flow rate of 50 ml / min. The colorimetric tube is inserted into the microwave oven at the upper middle part of the microwave oven and the part of the colorimetric tube containing the absorbing material is completely exposed to the interior of the microwave oven. When a microwave radiation device with a power of 800W is used, the temperature of the absorbing material ris...

Embodiment 3

[0035] according to figure 2 As shown, the ferrosilicon absorbing material with a weight of 20 grams and a particle size of 50 mesh is made into a molding device with a groove in the center. The groove is just enough to insert the quartz tube (1 cm in diameter) containing the sample, and the depth of the groove is 2 cm so that all the samples at the bottom of the tube can be fully heated by the wave-absorbing material. The quartz or ceramic tube containing the sample has a carrier gas inlet and a carrier gas outlet. The carrier gas is a mixed gas of high-purity nitrogen and 10 ml / min of pure oxygen at a flow rate of 30 ml / min. When using a microwave radiation device with a power of 800W, the temperature of the absorbing material rises to 120°C in 2 minutes, and the organic carbon in the water sample in the quartz tube is oxidized to carbon dioxide and then loaded into the non-dispersive infrared spectrometer by the carrier gas for measurement. The results are consistent wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com