Piezoresistor blank, preparation method thereof, piezoresistor and preparation method thereof

A technology of varistor and green body, which is applied in the field of varistor manufacturing to achieve the effects of high density, high mechanical strength and uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a piezoresistor green body, in one embodiment, comprising the following steps:

[0033] (1) Mix 70%~95% varistor powder and 5%~30% binder into pellets, after cooling to room temperature, crush them into Ф3mm~8mm pellets for molding ; Wherein, the varistor powder includes the following components by weight percentage: 85% to 95% of zinc oxide, 5% to 15% of additives; the additives include the following components by weight percentage: manganese carbonate 5%-8%, Bismuth oxide 35%-50%, tin dioxide 2%-4%, dicobalt oxide 15%-25%, titanium dioxide 5%-10%, barium carbonate 1%-3%, strontium carbonate 0.1%-1%, Boric acid 5%-20%, nickel oxide 2%-10%, aluminum nitrate 0.1%-1%; the binder includes the following components in weight percentage: paraffin wax 30%-88%, polymethyl methacrylate 5 %-30%, ethylene-vinyl acetate copolymer 5%-30%, stearic acid 2%-10%;

[0034] (2) Heat and melt the pellets in the barrel of the injection molding...

Embodiment 1

[0051] Granules for injection molding are composed of the following components by weight percentage:

[0052] Powder 70%

[0053] Binder 30%;

[0054] Described powder is made up of the component of following percentage by weight:

[0056] Additive 5%;

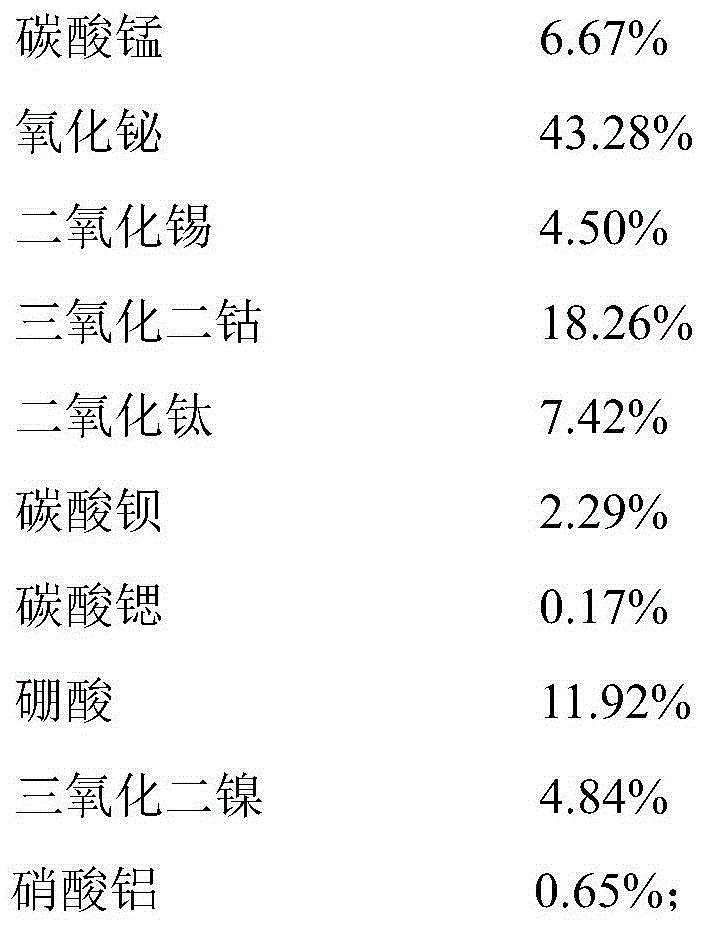

[0057] Additive is made up of the following components by weight percentage:

[0058]

[0059] The binder is composed of the following components in weight percentage:

[0060]

[0061] The preparation method of injection molding the varistor body and the varistor with the above pellets includes:

[0062] 1) Preparation of binder

[0063] First, heat the paraffin to 120°C. After the paraffin is completely melted, add polymethyl methacrylate and ethylene-vinyl acetate copolymer, and stir continuously with a stirring rod. After they are completely dissolved, add stearic acid to obtain a binder.

[0064] 2) Preparation of powder

[0065] Zinc oxide and additives are uniformly mixed through a ...

Embodiment 2

[0081] Granules for injection molding are composed of the following components by weight percentage:

[0082] Powder 75%

[0083] Binder 25%;

[0084] Described powder is made up of the component of following percentage by weight:

[0086] Additive 12%;

[0087] Described additive is made up of the component of following percentage by weight:

[0088]

[0089]

[0090] Described binding agent is made up of the component of following percentage by weight:

[0091]

[0092] The preparation method of injection molding the varistor body and the varistor with the above pellets includes:

[0093] 1) Preparation of binder

[0094] First heat the paraffin to 160°C. After the paraffin is completely melted, add polymethyl methacrylate and ethylene-vinyl acetate copolymer, and stir continuously with a stirring rod. After all the paraffin is dissolved, add stearic acid to obtain a binder.

[0095] 2) Preparation of powder

[0096] Mix zinc oxide an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com