High-temperature-resistant ceramic powder coating material and preparation method thereof

A technology of high temperature resistant ceramics and coating materials, applied in the field of materials, can solve the problems of low through porosity, insufficient high temperature resistance and strength, and can not make up for the brittleness of ceramic materials, so as to improve high temperature tolerance, improve strength, optimize stability, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

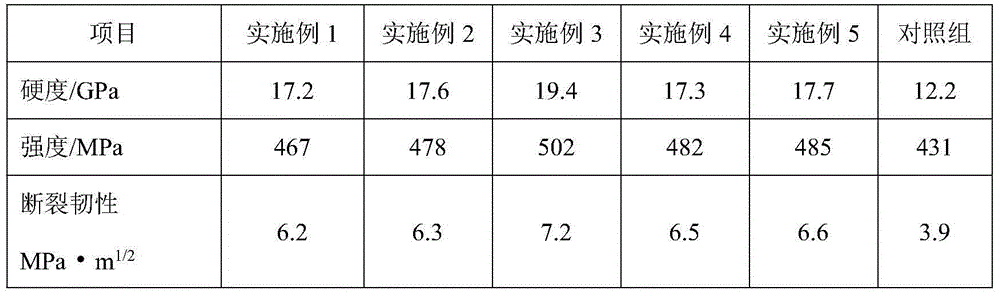

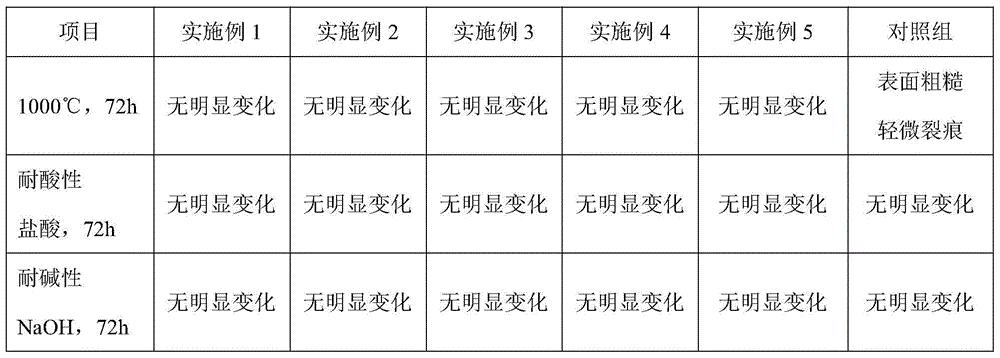

Examples

Embodiment 1

[0030] A high-temperature-resistant ceramic powder coating material is composed of the following components in parts by mass:

[0031] (1) 15 parts of silicon carbide; (2) 3 parts of nano-nickel oxide and 6 parts of nano-magnesium oxide; (3) nano-γ-Al 2 o 3 , 15 copies; (4) Ta 2 o 5 , 2.5 parts; (5) silicon dioxide, 25 parts; (6) titanium oxide, 4.5 parts; (7) nanometer thorium dioxide, 5 parts.

[0032] Wherein, the mass ratio of nano-nickel oxide to nano-magnesium oxide is 1:2.

[0033] According to the preparation method of the high-temperature-resistant ceramic powder coating material provided by the present invention, the above-mentioned high-temperature-resistant ceramic powder coating material is prepared, and the preparation steps are as follows:

[0034] (1) Weighing: Accurately weigh each component;

[0035] (2) Grinding: mix each component together, after stirring evenly, put into grinder and grind;

[0036] (3) Calcination: put the mixture obtained in step (3...

Embodiment 2

[0039] A high-temperature-resistant ceramic powder coating material is composed of the following components in parts by mass:

[0040] (1) silicon carbide, 30 parts; (2) 9 parts of nano-nickel oxide and 12 parts of nano-magnesium oxide; (3) nano-γ-Al 2 o 3 , 23 copies; (4) Ta 2 o 5 , 4 parts; (5) silicon dioxide, 45 parts; (6) titanium oxide, 7.5 parts; (7) nanometer thorium dioxide, 15 parts.

[0041] Wherein, the mass ratio of nano-nickel oxide to nano-magnesium oxide is 3:4.

[0042] According to the preparation method of the high-temperature-resistant ceramic powder coating material provided by the present invention, the above-mentioned high-temperature-resistant ceramic powder coating material is prepared, and the preparation steps are as follows:

[0043] (1) Weighing: Accurately weigh each component;

[0044] (2) Grinding: mix each component together, after stirring evenly, put into grinder and grind;

[0045] (3) Calcination: put the mixture obtained in step (3) ...

Embodiment 3

[0048] A high-temperature-resistant ceramic powder coating material is composed of the following components in parts by mass:

[0049](1) silicon carbide, 22 parts; (2) 6 parts of nano-nickel oxide and 9 parts of nano-magnesium oxide; (3) nano-γ-Al 2 o 3 , 18 copies; (4) Ta 2 o 5 , 3.5 parts; (5) silicon dioxide, 35 parts; (6) titanium oxide, 5.5 parts; (7) nanometer thorium dioxide, 10 parts.

[0050] Wherein, the mass ratio of nano-nickel oxide to nano-magnesium oxide is 2:3.

[0051] According to the preparation method of the high-temperature-resistant ceramic powder coating material provided by the present invention, the above-mentioned high-temperature-resistant ceramic powder coating material is prepared, and the preparation steps are as follows:

[0052] (1) Weighing: Accurately weigh each component;

[0053] (2) Grinding: mix each component together, after stirring evenly, put into grinder and grind;

[0054] (3) Calcination: put the mixture obtained in step (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com