Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Surface capping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Capping Surface. A capping surface enables you to make an intersecting cut and view results on remaining exterior surfaces. You must select the portion of the model to display, which can be either above or below the capping surface.

Method for chemical vapor deposition of silicon on to substrates for use in corrosive and vacuum environments

InactiveUS7070833B2Improve propertiesReduce outgassingPretreated surfacesSolid state diffusion coatingRoom temperatureSurface conditions

A method of passivating the surface of a substrate to protect the surface against corrosion, the surface effects on a vacuum environment, or both. The substrate surface is placed in a treatment environment and is first dehydrated and then the environment is evacuated. A silicon hydride gas is introduced into the treatment environment, which may be heated prior to the introduction of the gas. The substrate and silicon hydride gas contained therein are heated, if the treatment environment was not already heated prior to the introduction of the gas and pressurized to decompose the gas. A layer of silicon is deposited on the substrate surface. The duration of the silicon depositing step is controlled to prevent the formation of silicon dust in the treatment environment. The substrate is then cooled and held at a cooled temperature to optimize surface conditions for subsequent depositions, and the treatment environment is purged with an inert gas to remove the silicon hydride gas. The substrate is cycled through the silicon depositing step until the surface of the substrate is covered with a layer of silicon. The treatment environment is then evacuated and the substrate cooled to room temperature.

Owner:SILCOTEK CORP

Nanosized particles of molybdenum sulfide and derivatives, method for its preparation and uses thereof as lubricant additive

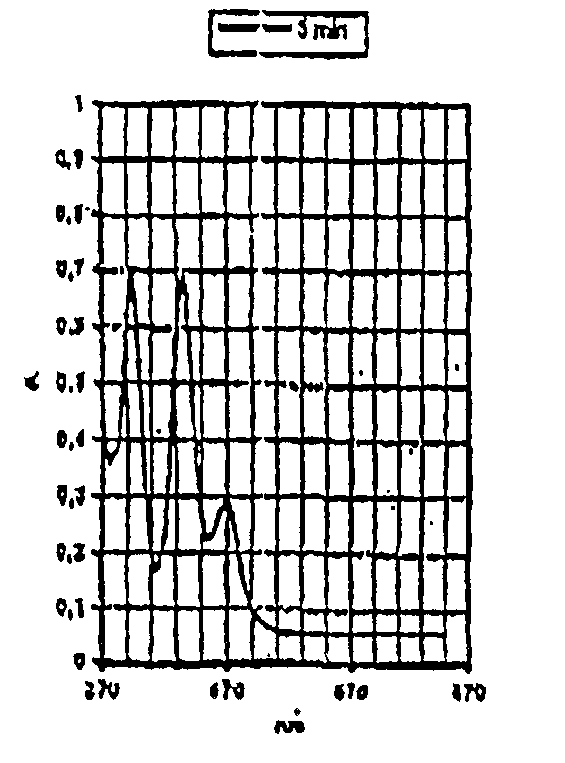

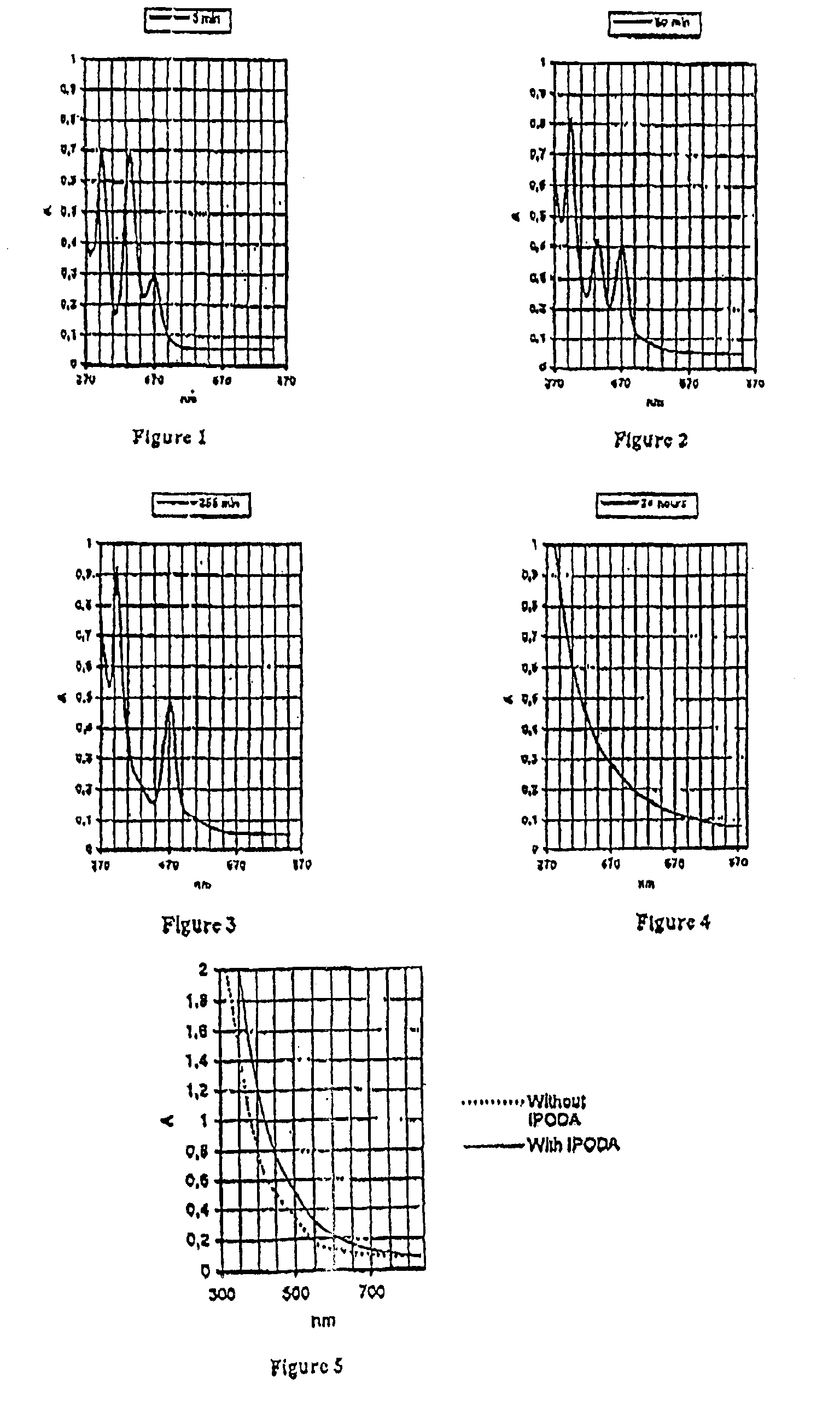

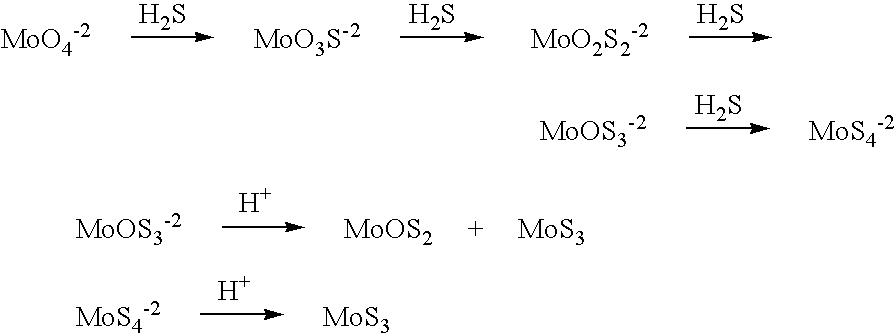

InactiveUS6878676B1Prevent coagulationProvide solubility and stabilityGroup 1/11 element organic compoundsAdditivesNano sizeSulfur

A lubricant composition is disclosed that comprises: (a) a lubricant and (b) at least one molybdenum-containing compound in the form of surface-capped nanosized particles of the general formula: (Z)n(X—R)m wherein Z is an inorganic moiety comprising molybdenum and sulfur in the form of particles having dimensions in the range of from about 1 to about 100 nm; (X—R) is a surface-capping reagent wherein R is a C4 to C20 straight or branched-chain alkyl or alkylated cycloalkyl radical or radicals and X is a functional group capable of specific sorption and / or chemical interaction with molybdenum / sulfur moiety; n is the number of molecules of Z in the particles; m is an integer representing the amount of surface-capping reagents relative to a single particle; and the ratio of m to n is in the range of from about 1:1 to about 10:1.

Owner:CROMPTON CORP

Metal surface coating method and application thereof

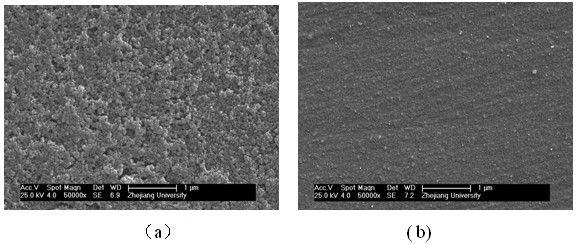

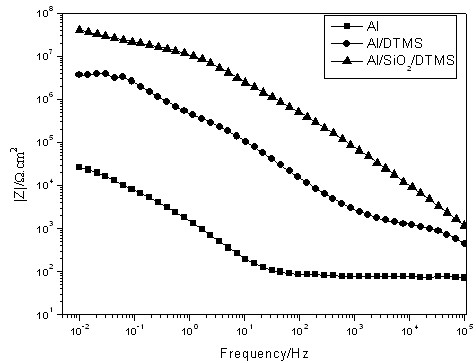

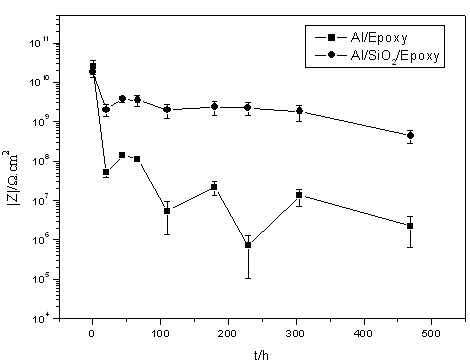

ActiveCN102321900AImprove the protective effectZero pollutionElectrolytic inorganic material coatingSilanesHigh surface

The invention discloses a metal surface coating method and an application thereof. An inert, porous nano-oxide film is deposited firstly on a metal substrate by an electrodeposition method, and then a protective layer is covered on the surface. The nano-oxide film is prepared on a metal surface by precursor aqueous solutions of SiO2, TiO2 or ZrO2 through an electrodeposition method. The protective layer used for covering is a commonly-used organosilane film, inorganic / organic hybridized silane film or common organic coating. The metal surface coating and protecting technology provided by the invention has a simple process, low cost, is especially green and environment-friendly, has wide adaptability, and almost has no selectivity for the types of the metal substrate or subsequent protective layers. The nano-oxide film pretreatment layer prepared by electrodeposition has good bonding force with the metal substrate, high surface energy, a rough and porous surface, and large specific surface area, and thus can tightly bond with the subsequent covering layer, which greatly improves the corrosion resistance of the whole protective layer.

Owner:ZHEJIANG UNIV

Method for measuring non-uniform conductive material surface coating thickness according to eddy currents

ActiveCN103344174AAvoid measurement effectsHigh precisionElectrical/magnetic thickness measurementsConductive materialsEddy-current testing

The invention discloses a method for measuring non-uniform conductive material surface coating thickness according to eddy currents. Based on the frequency sweep eddy current testing technology, continuous frequency within a certain range is used for stimulating one test point of a tested non-uniform conductive material provided with a coating and a substrate standard test block without the coating; the optimal measuring frequency at the test point is found, therefore, the effect of the nonuniformity of the conductivity of a substrate on the measurement of the surface coating thickness can be effectively avoided, and the accuracy of the measurement of the surface coating thickness is effectively improved.

Owner:EDDYSUN (XIAMEN) ELECTRONICS CO LTD

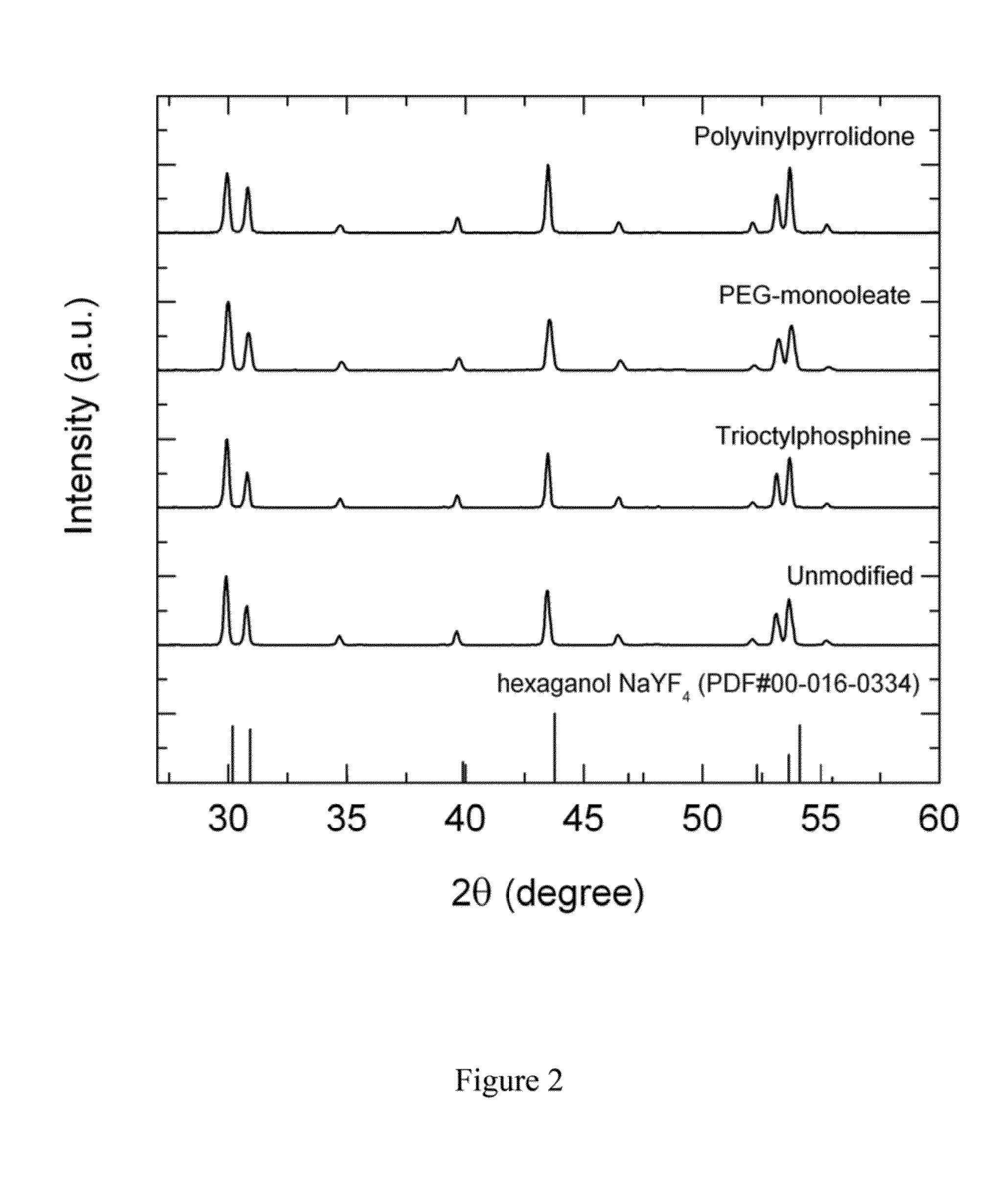

Surfactant effects on efficiency enhancement of luminescent particles

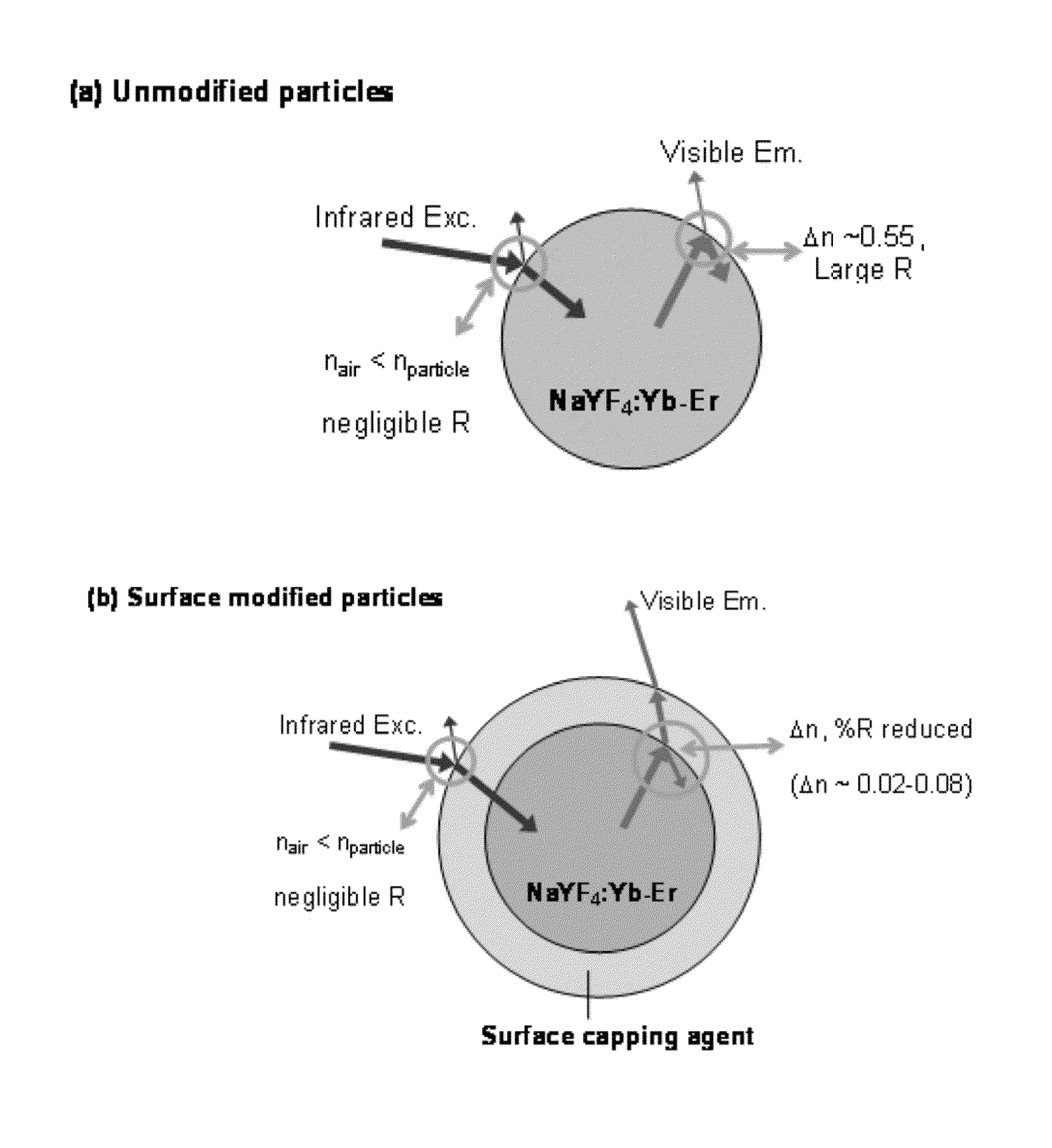

InactiveUS20130320263A1Reduce refractive index mismatchLower refractive indexLuminescent compositionsDisease monitoringDopant

Disclosed are luminescent compositions having luminescent particles coated by a surface capping agent. Luminescent particles include rare earth doped phosphors, semiconductor quantum dots, and organic phosphors. Surfactants include macromolecules, polypeptides, polysaccharides, and polymers. Rare earth doped phosphors have host compositions and rare earth dopants, wherein the host compositions include NaYF4, LaF3, YF3, CeF3, CaF2, CsCdBr3, and Y2O3, and wherein the rare earth dopants include Cs, Pr, Nd, Sm, Er, Gs, Tb, Dy, Ho, Er, Tim, Yb, and combinations of two or more of these. The refractive index mismatch of the luminescent compositions and surrounding medium is less than about 0.1. Also disclosed are methods of making the luminescent compositions, luminescent devices and displays containing the luminescent compositions, uses of the luminescent compositions in particle imaging velocimetry, and uses of the luminescent compositions as contrast agents for disease monitoring.

Owner:RUTGERS THE STATE UNIV

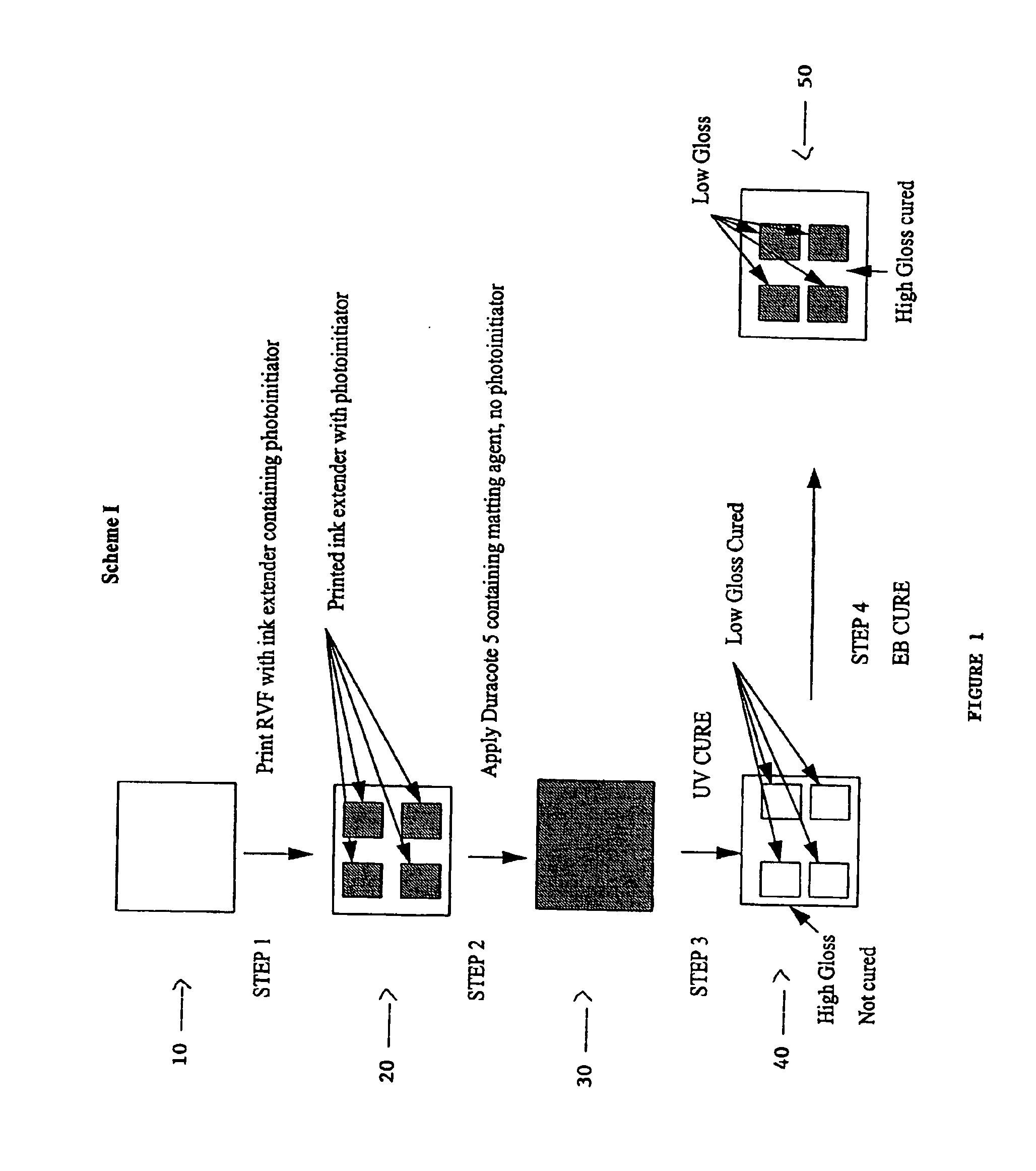

Surface covering having gloss in-register and method of making

InactiveUS6890625B2High glossReduce glossLayered productsDecorative surface effectsLength wavePhotoinitiator

Surface covering components that include a topcoat layer with different gloss levels in various regions on the top coat layer, and methods of manufacturing such surface covering components, are disclosed. The surface covering components include a coating layer that includes regions that have a relatively higher gloss, and regions with a relatively lower gloss. The differential gloss is provided by coating a substrate with a UV-curable coating composition, subjecting a first region of the surface coating to polymerization under a first set of conditions, and subjecting a second region of the surface coating to polymerization under a second set of conditions. The UV-curable coating compositions include UV-curable components and one or more flatting agents. The different polymerization conditions involve applying various photoinitiators, thermal initiators and / or cure altering agents to some regions of the coated substrate, and not applying these components to other regions of the substrate. The components are applied in the form of a pattern. Regions in contact with these components are cured at different rates in one step or in different steps, for example, sequential UV and EB irradiation or UV irradiation at different wavelengths and / or exposure times. The resulting surface coverings and surface covering substrates have differential gloss in register with the printed and / or sprayed patterns.

Owner:AFI LICENSING

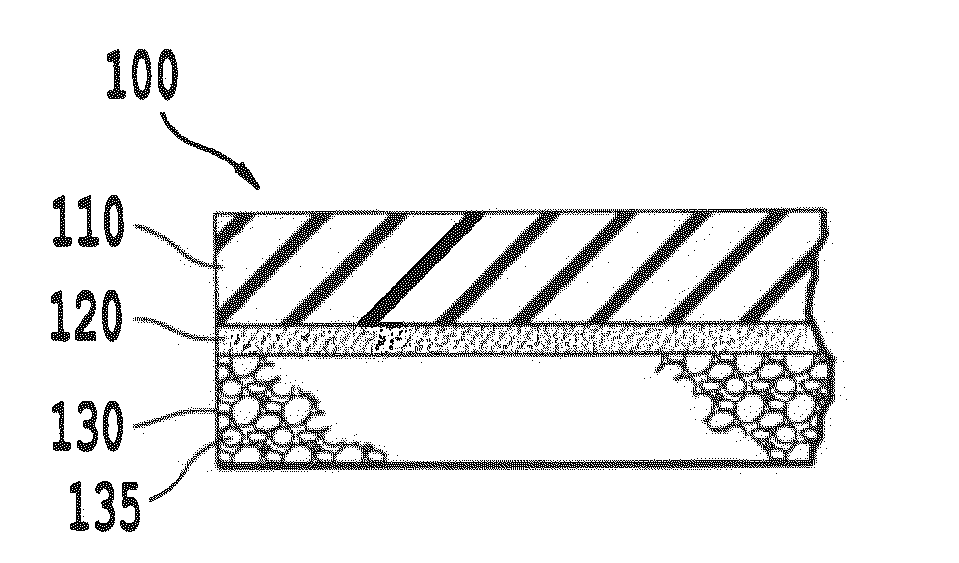

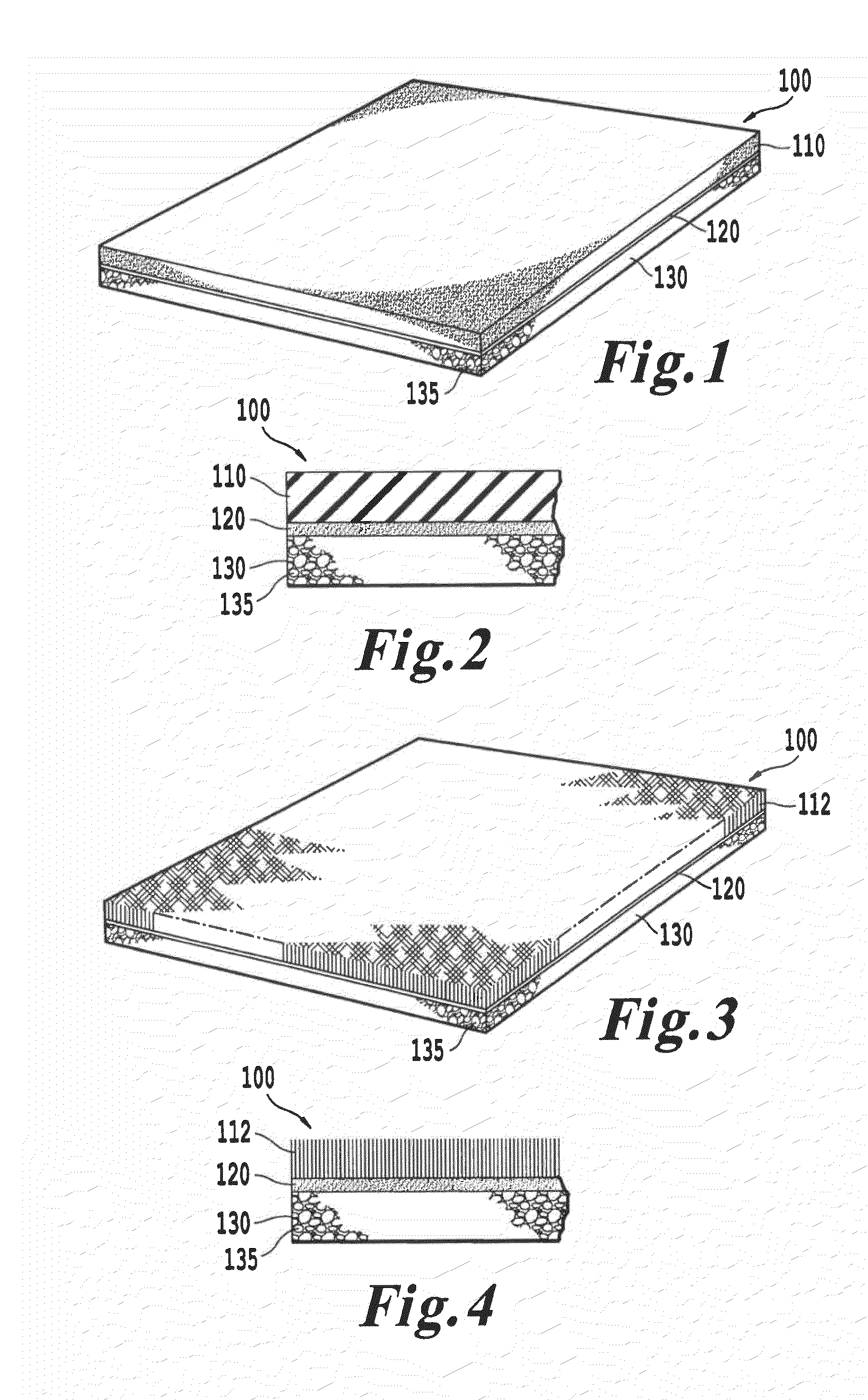

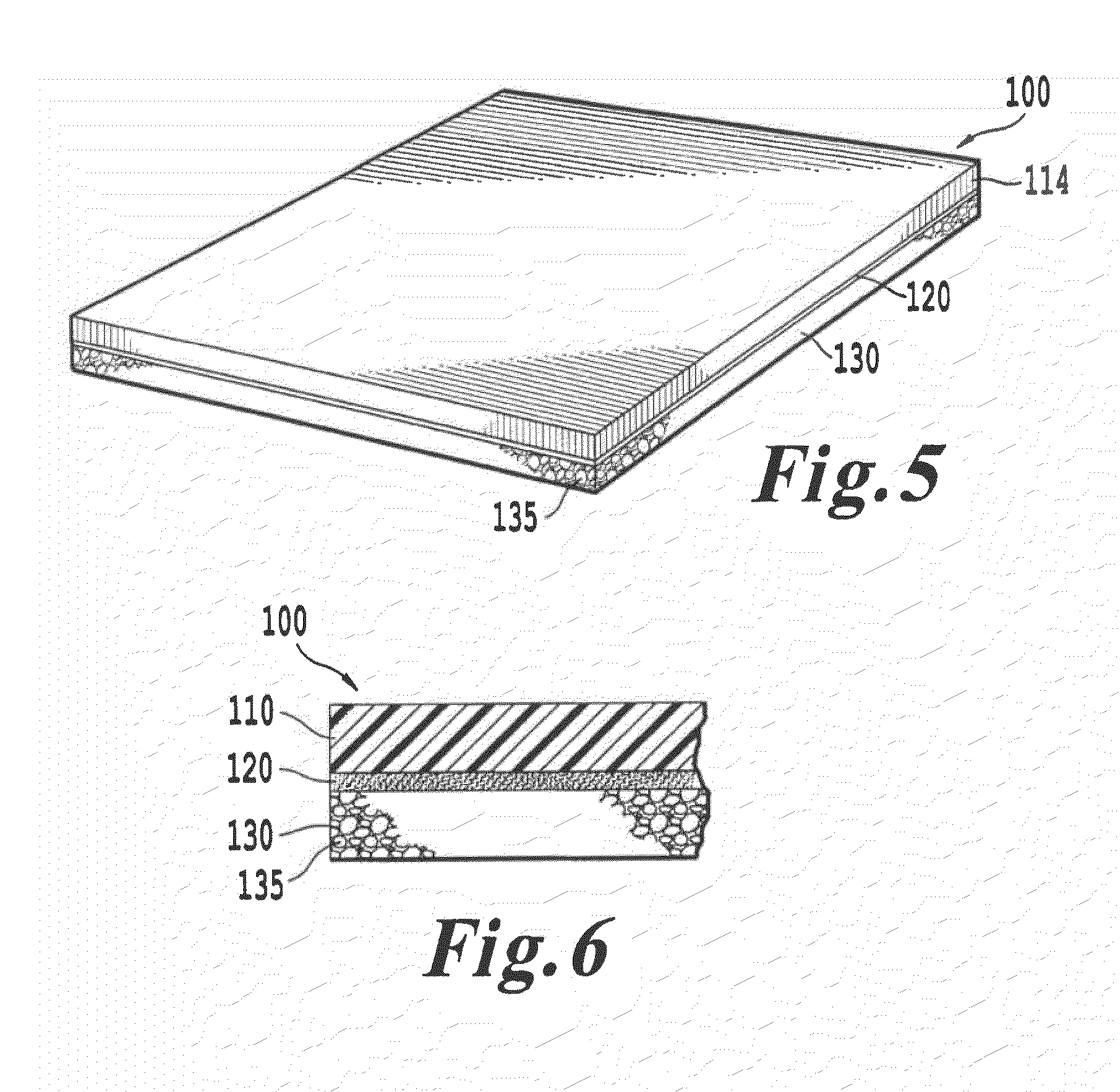

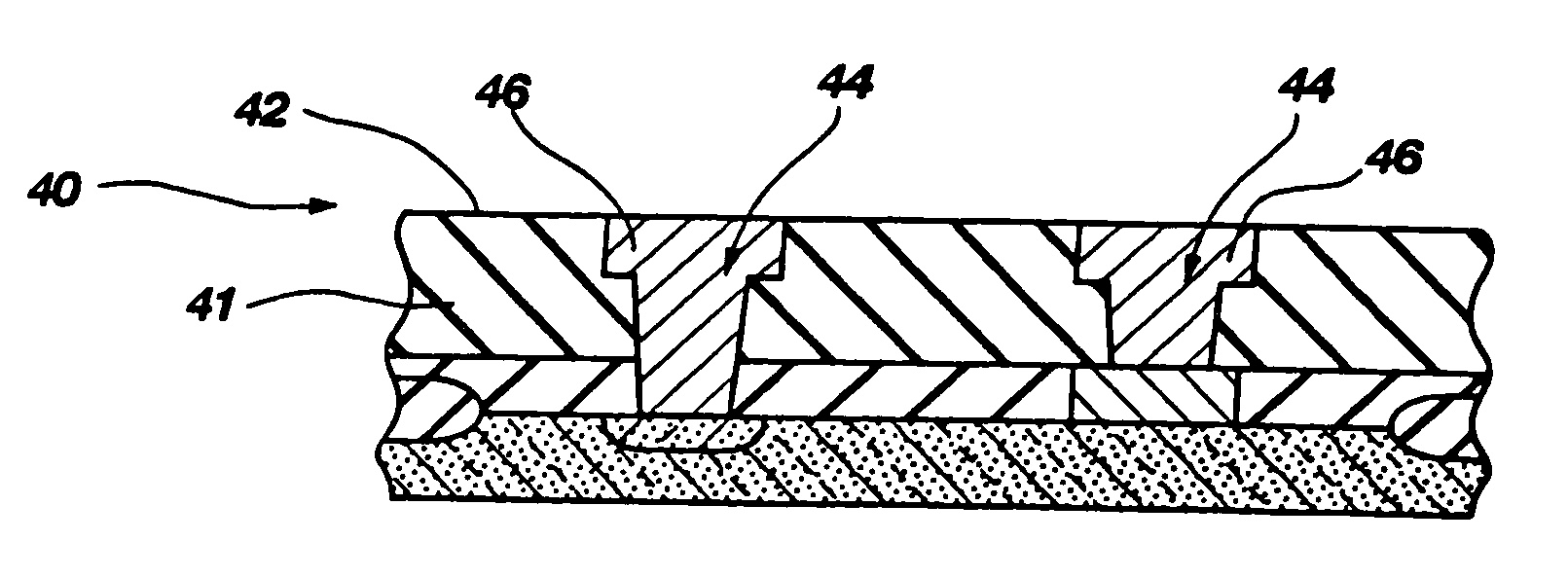

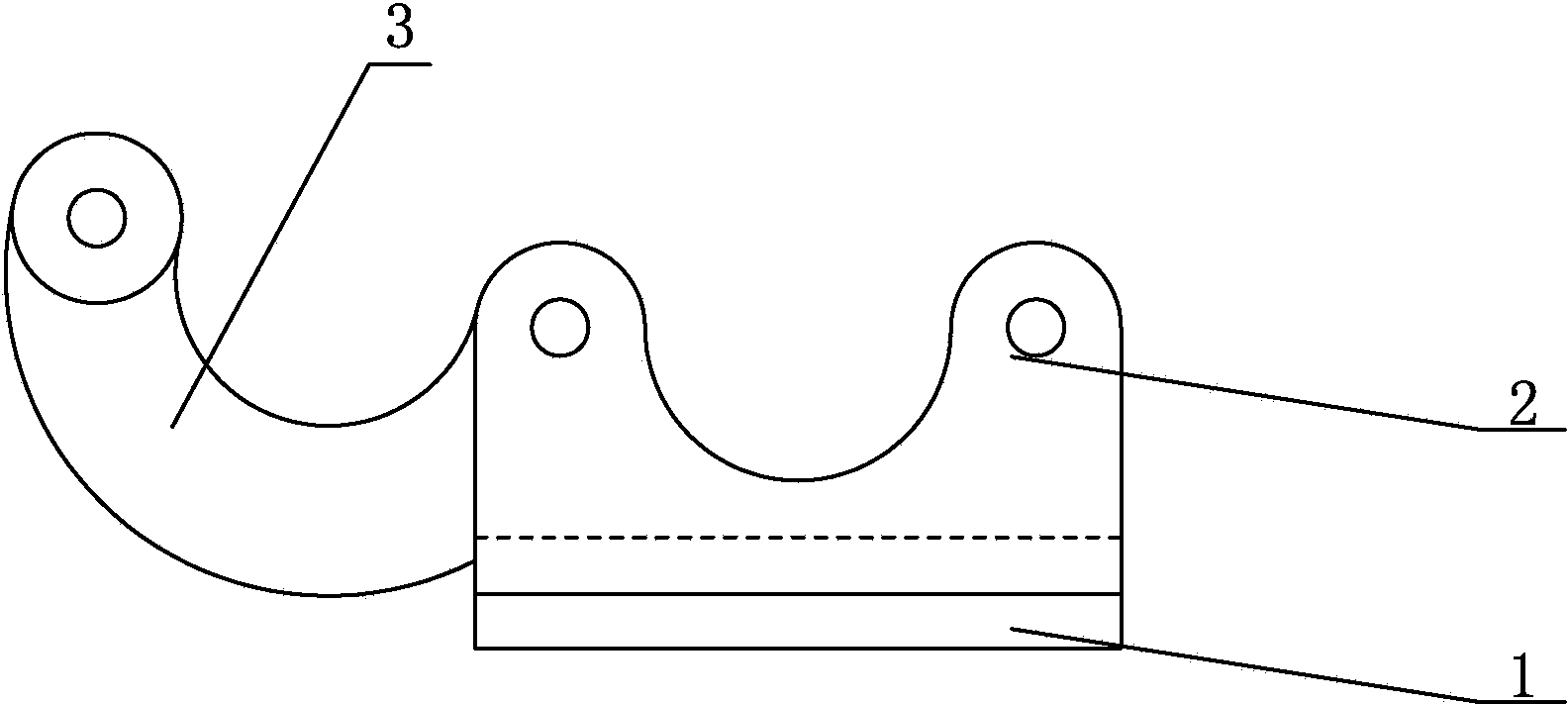

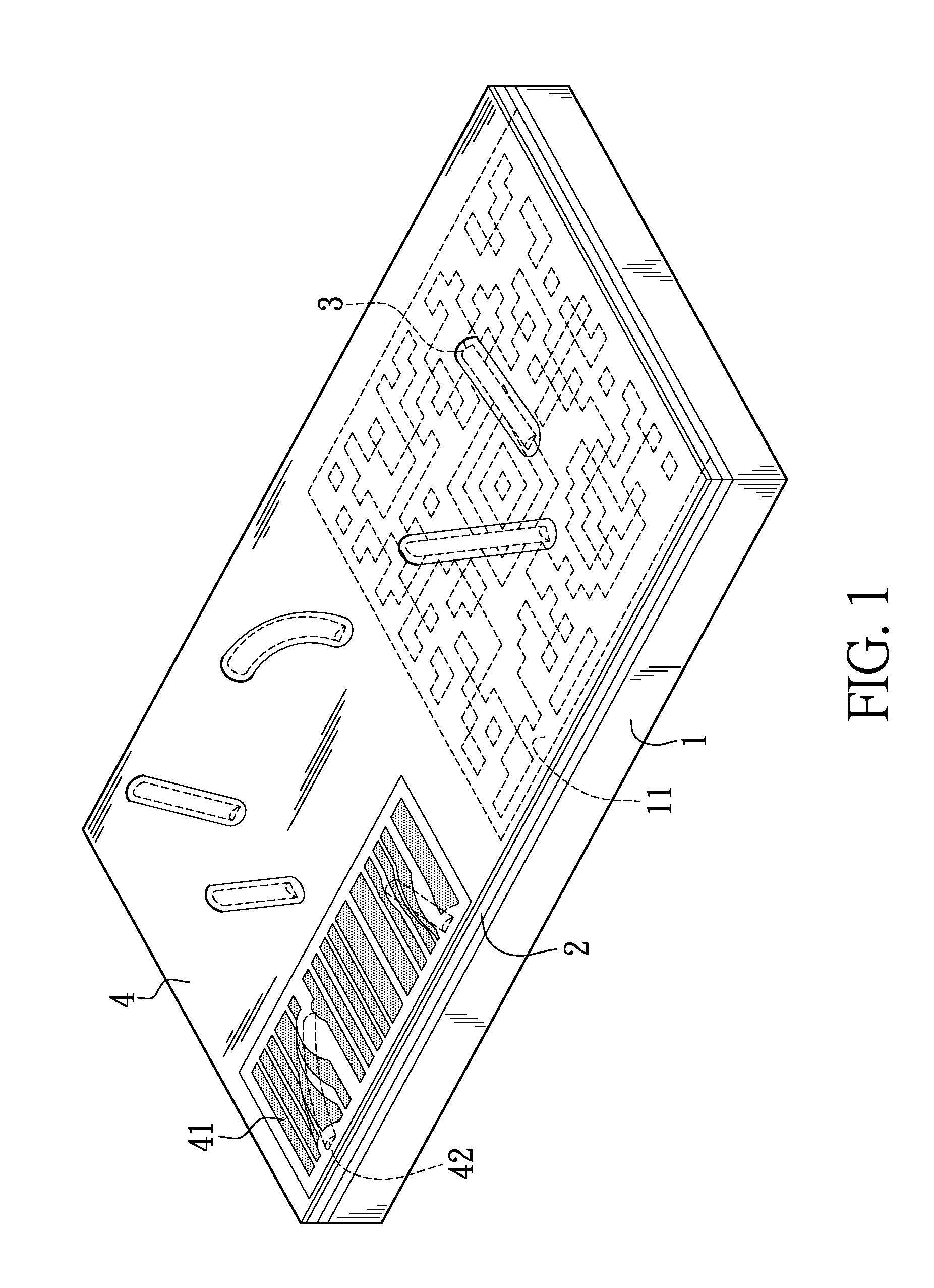

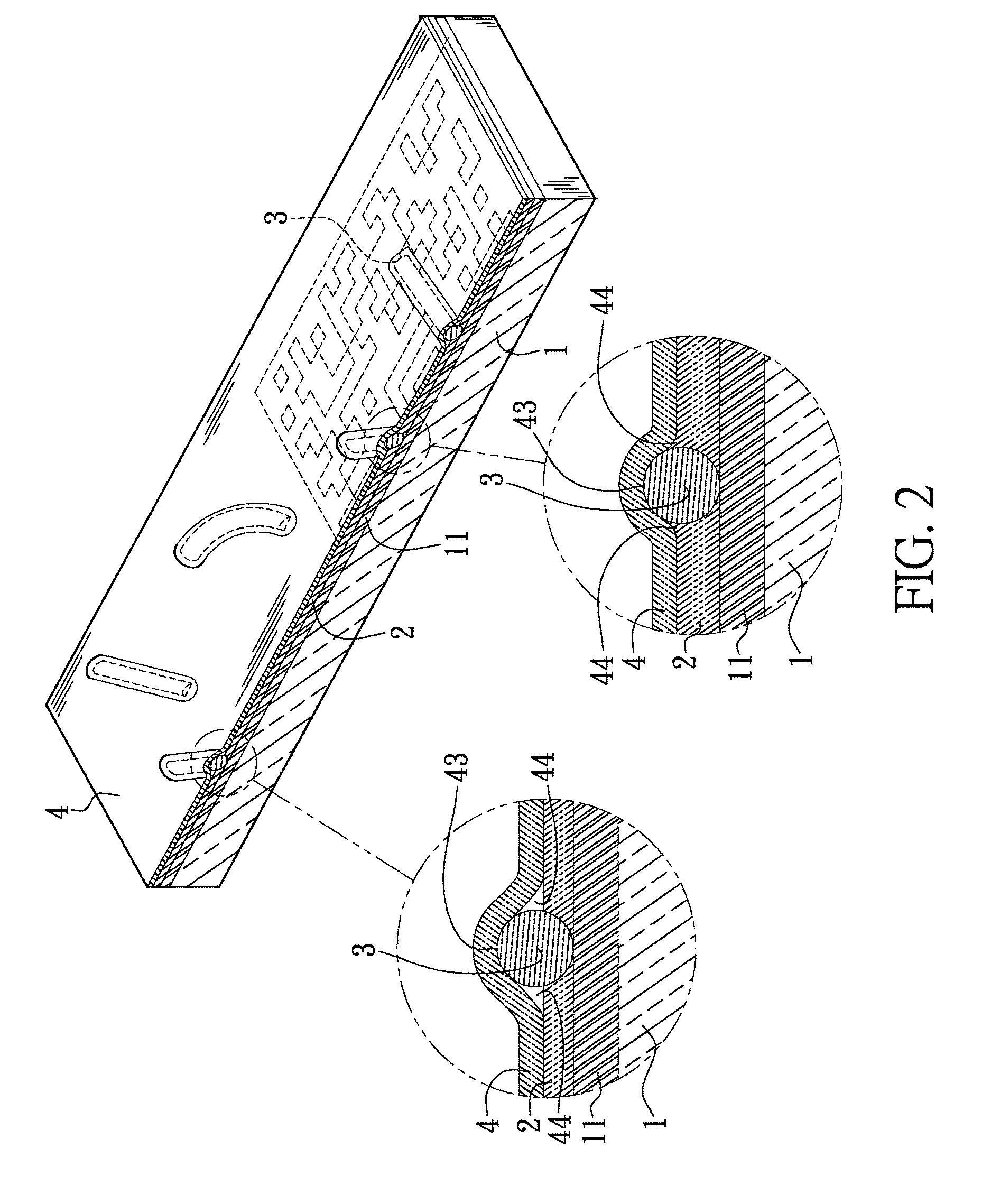

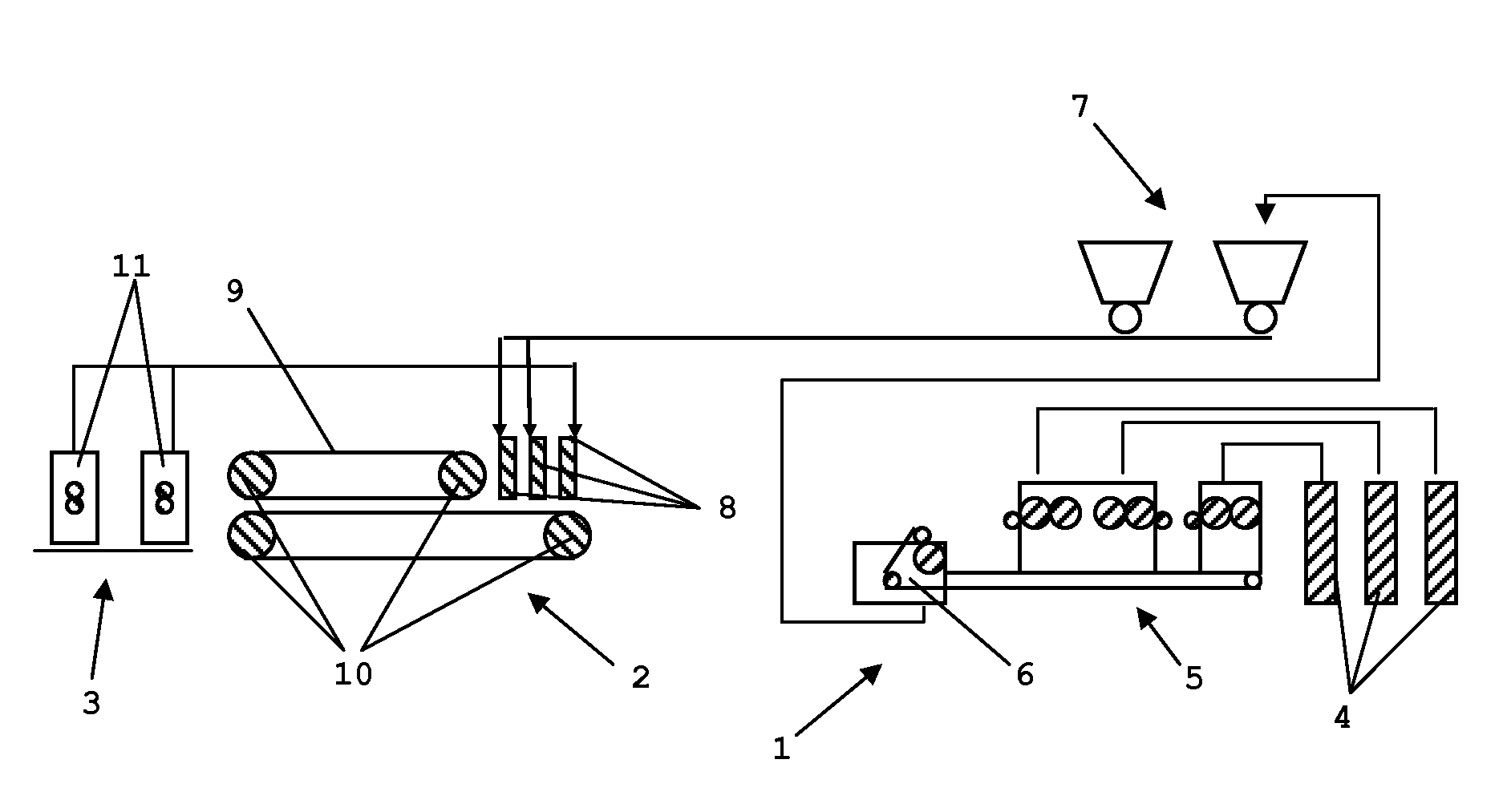

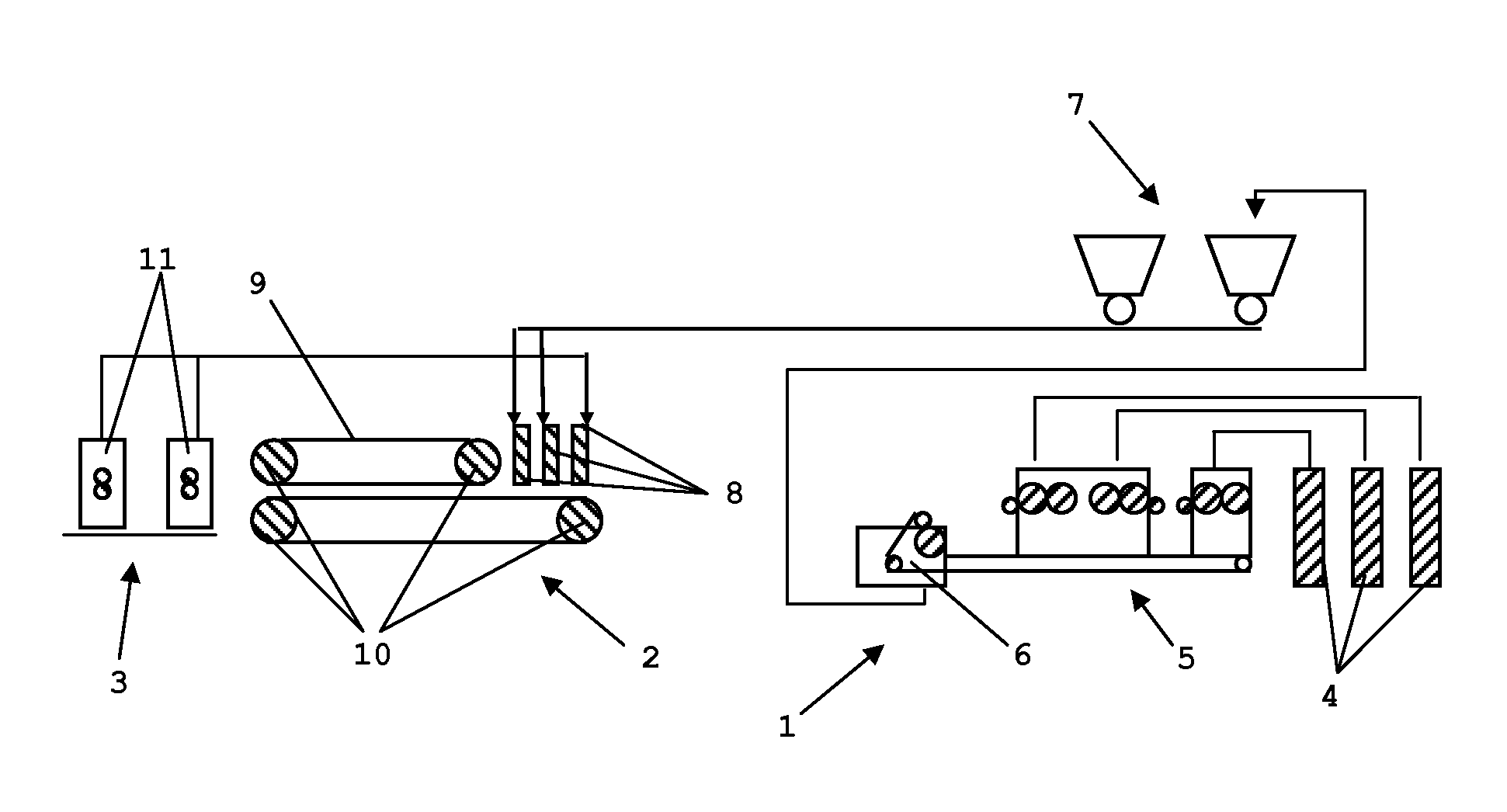

Recyclable surface covering and method and system for manufacturing a recyclable surface covering

ActiveUS20110189410A1Mechanical working/deformationFriction grip releasable fasteningsEngineeringSurface cover

A process and system for making a laminated surface covering and the surface covering itself are described. The covering includes several layers bonded to each other. The system performs the process. One example of the process includes passing a first material across a first conveyor, passing a second material across a second conveyor, passing a bonding material across a third conveyor, contacting the first material and the second material to the bonding material, and heating at least one of the first material and the second material. The process also includes introducing the first material, the second material, and the bonding material into a pressure zone such that the bonding material is introduced between a bottom surface of the first material and a top surface of the second material. The process applies pressure to bond the first material and second material together via the bonding material to produce a laminated material.

Owner:ECORE INT

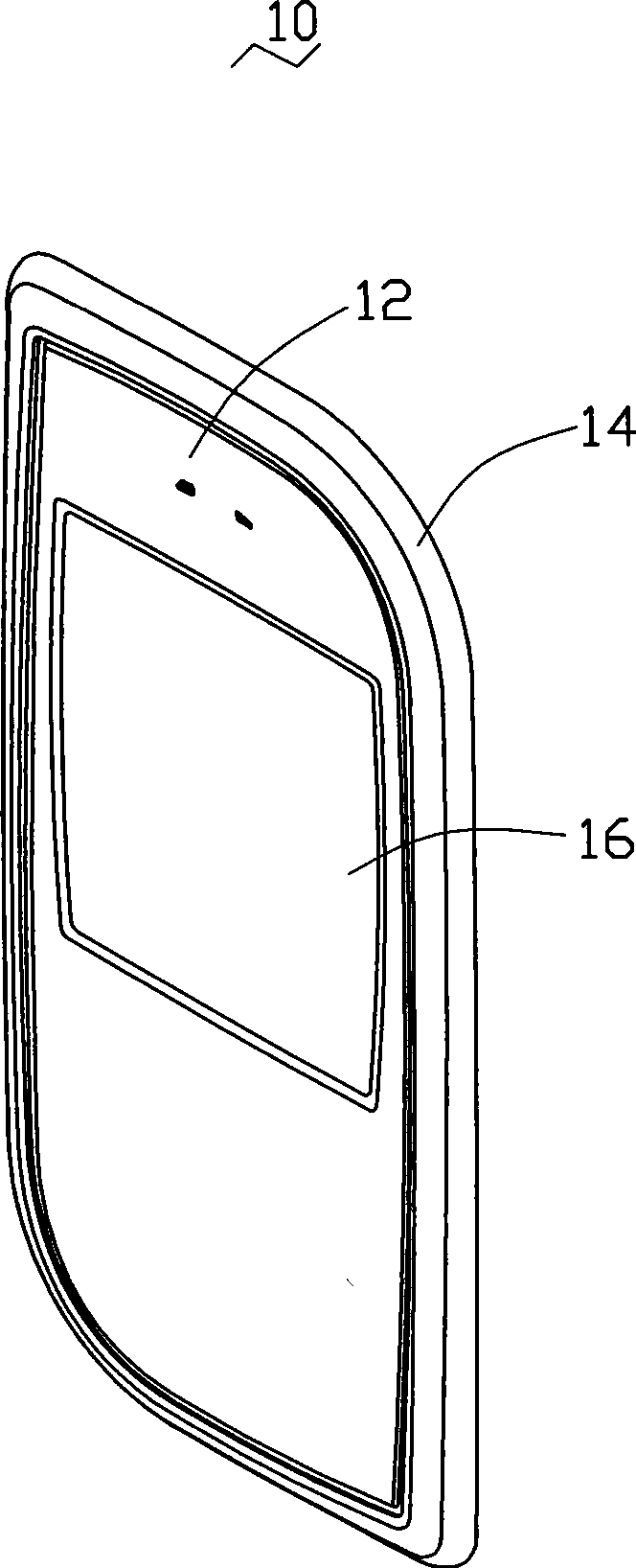

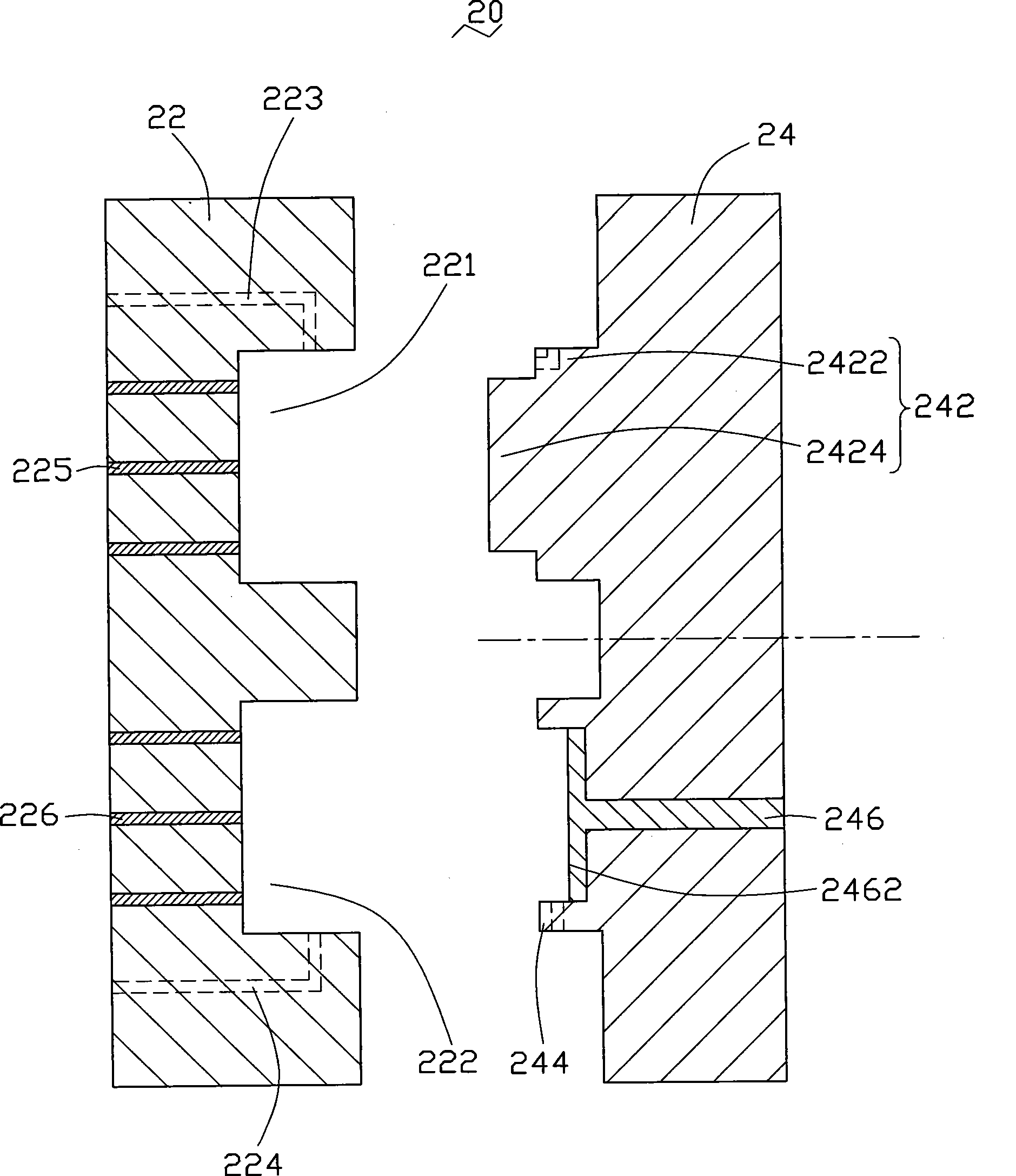

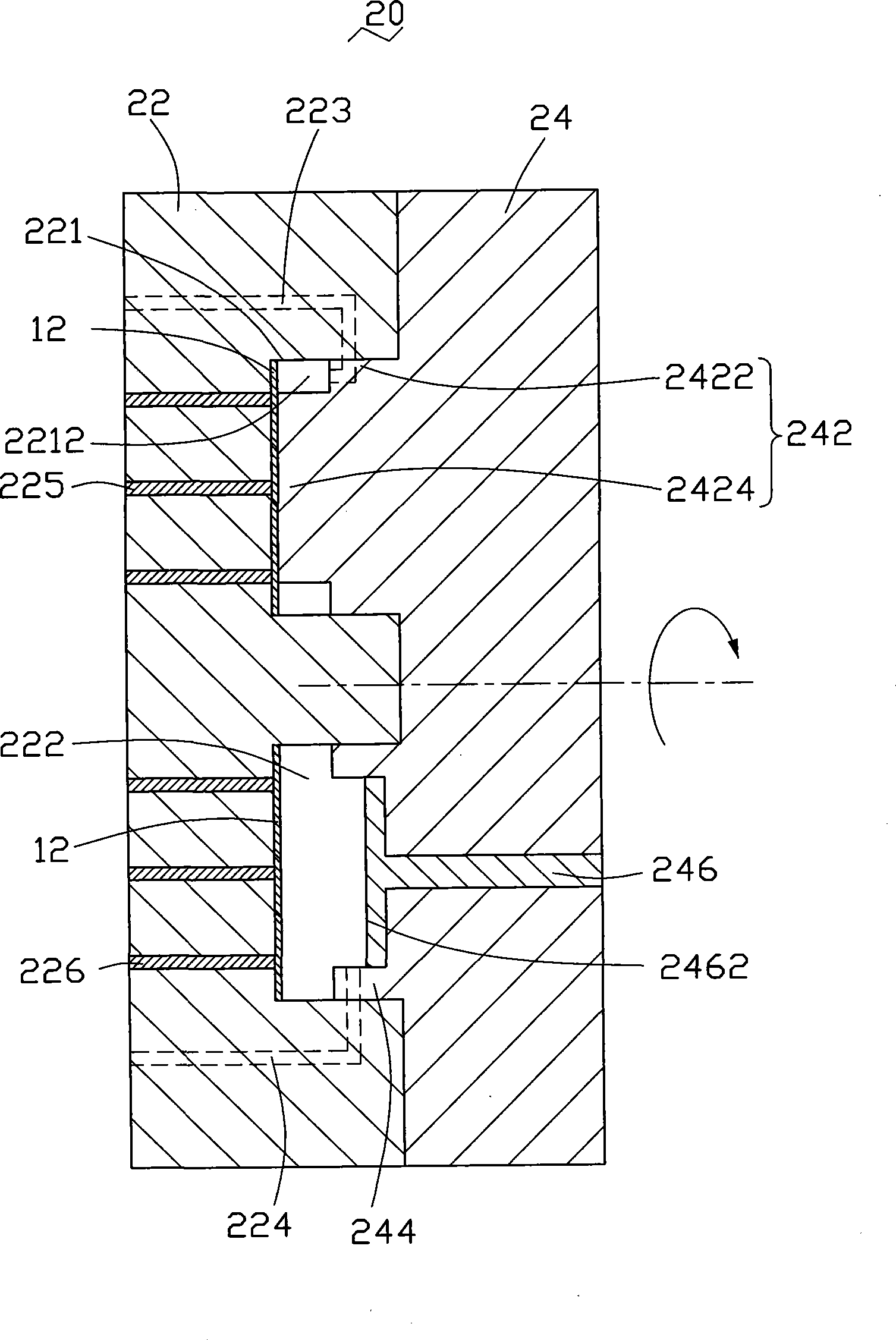

Casing, method and mold for fabricating the same

InactiveCN101370362AEliminate wrinklesQuality improvementOptical articlesDomestic articlesSurface coverMaterials science

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

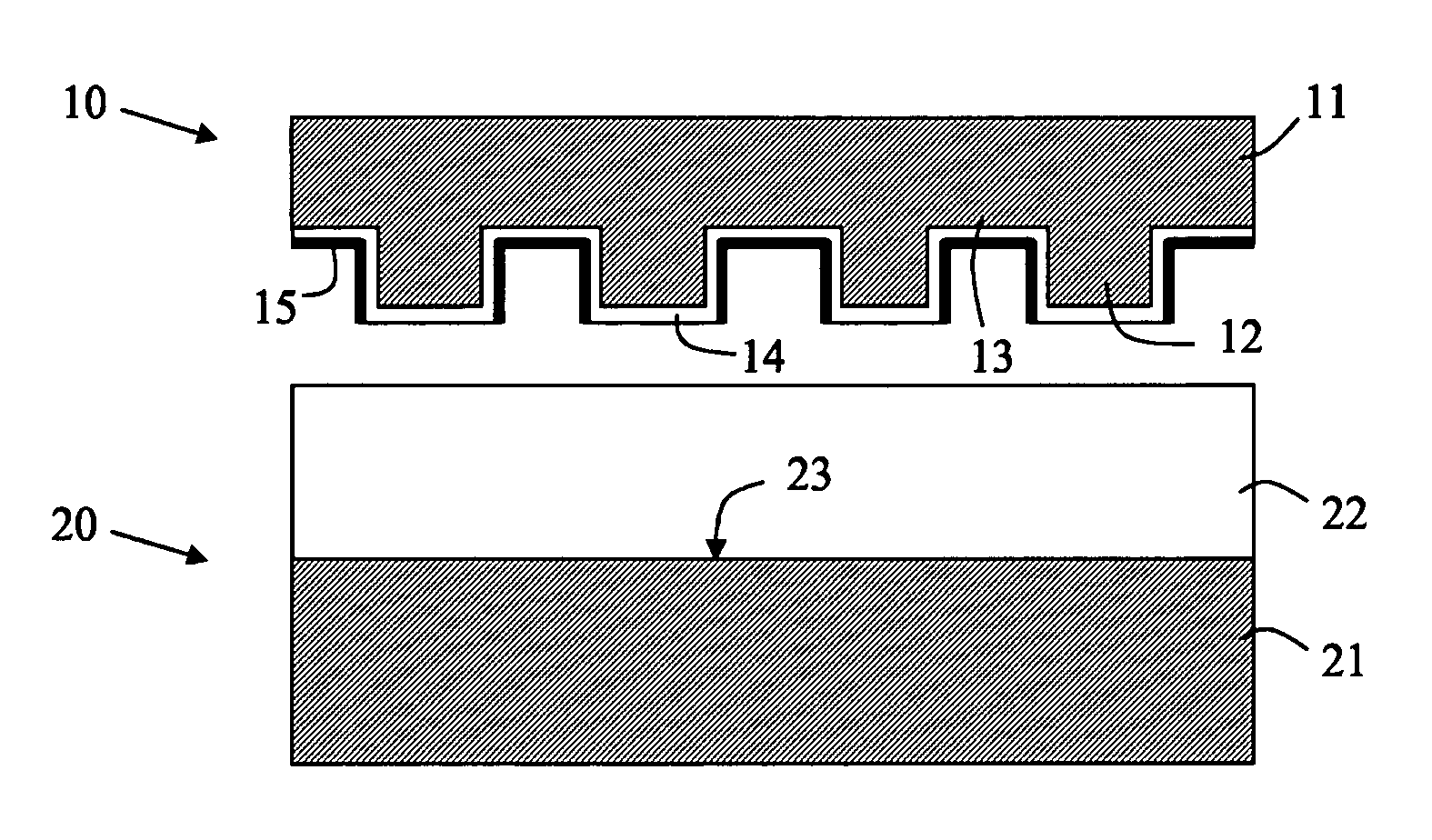

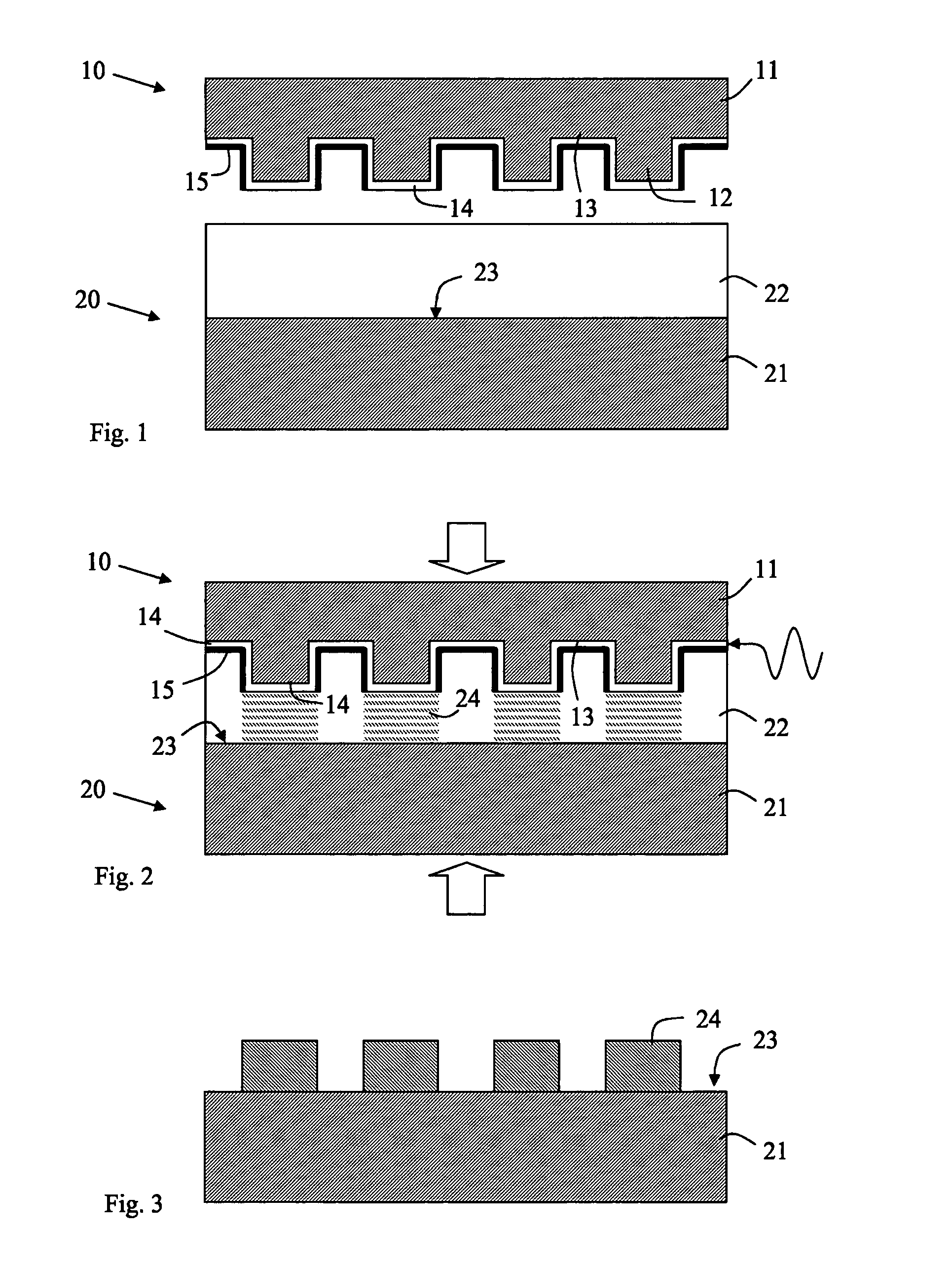

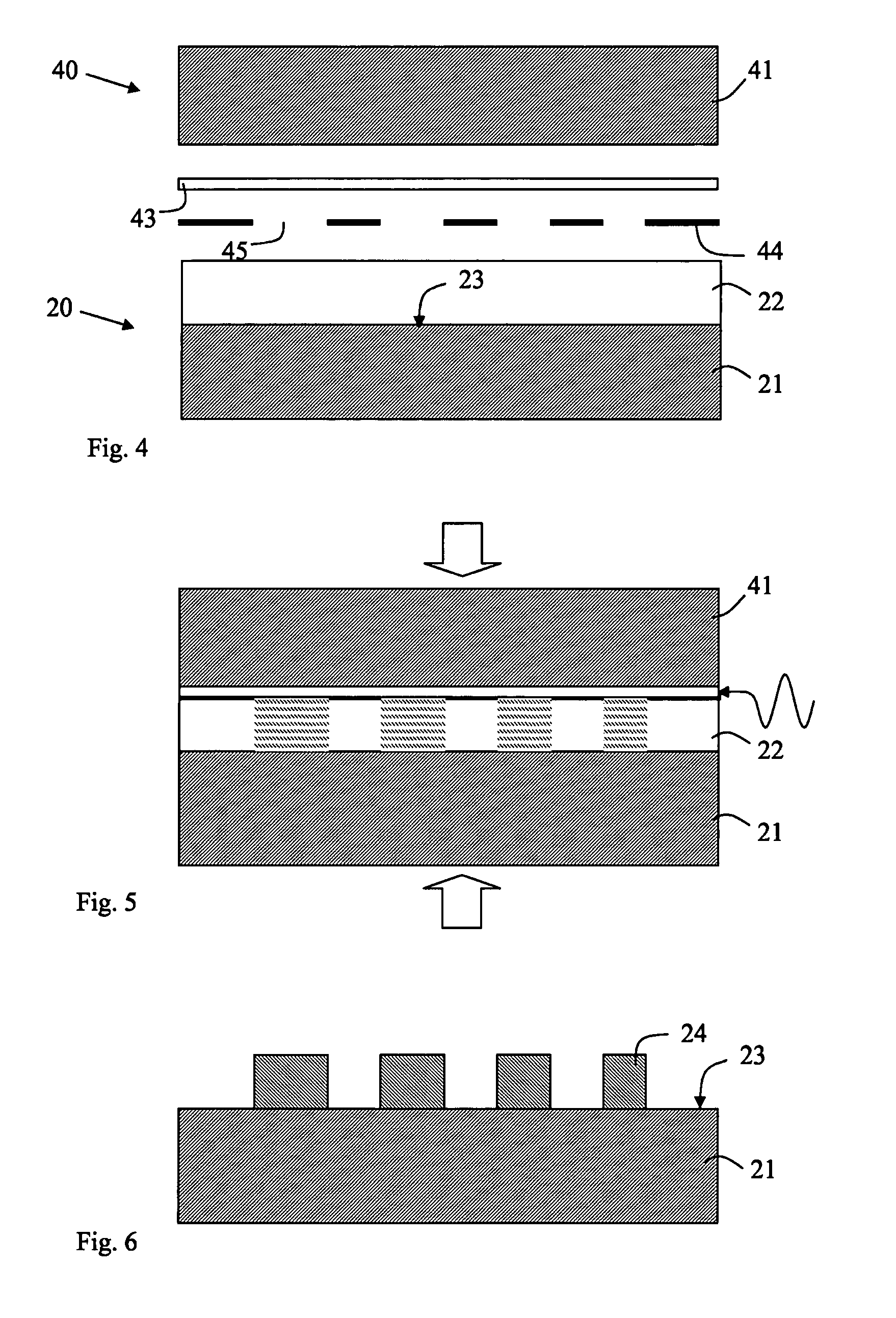

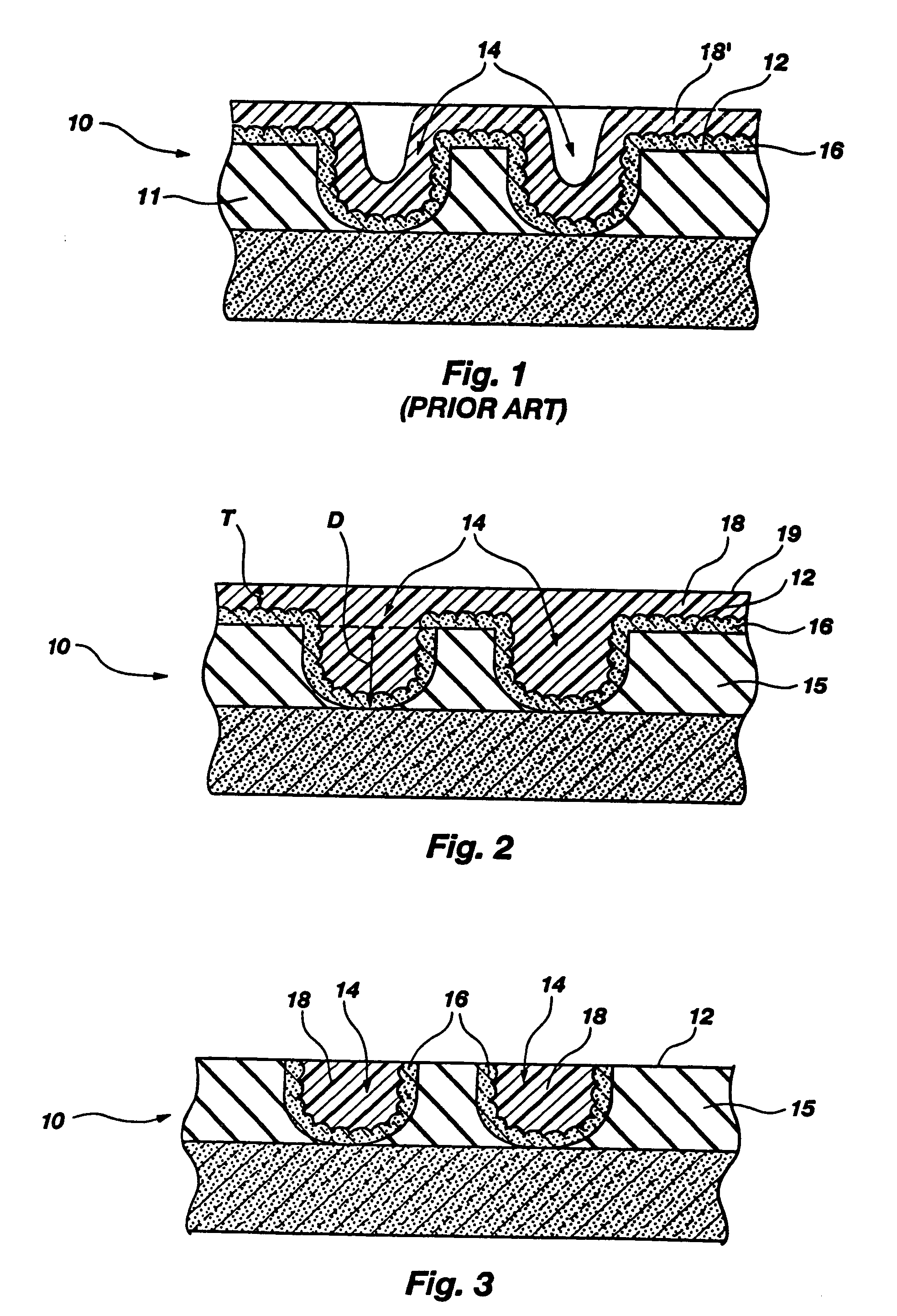

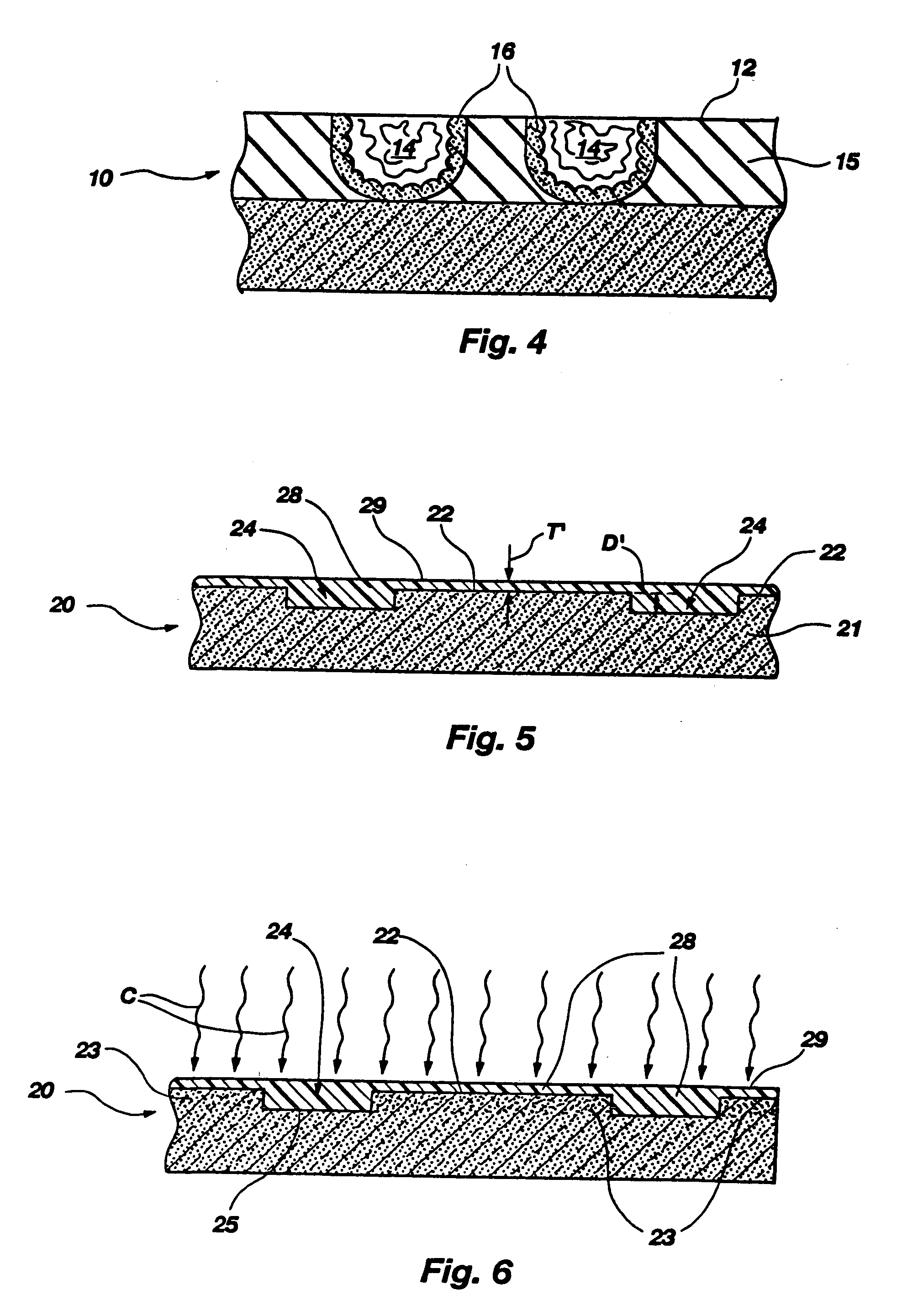

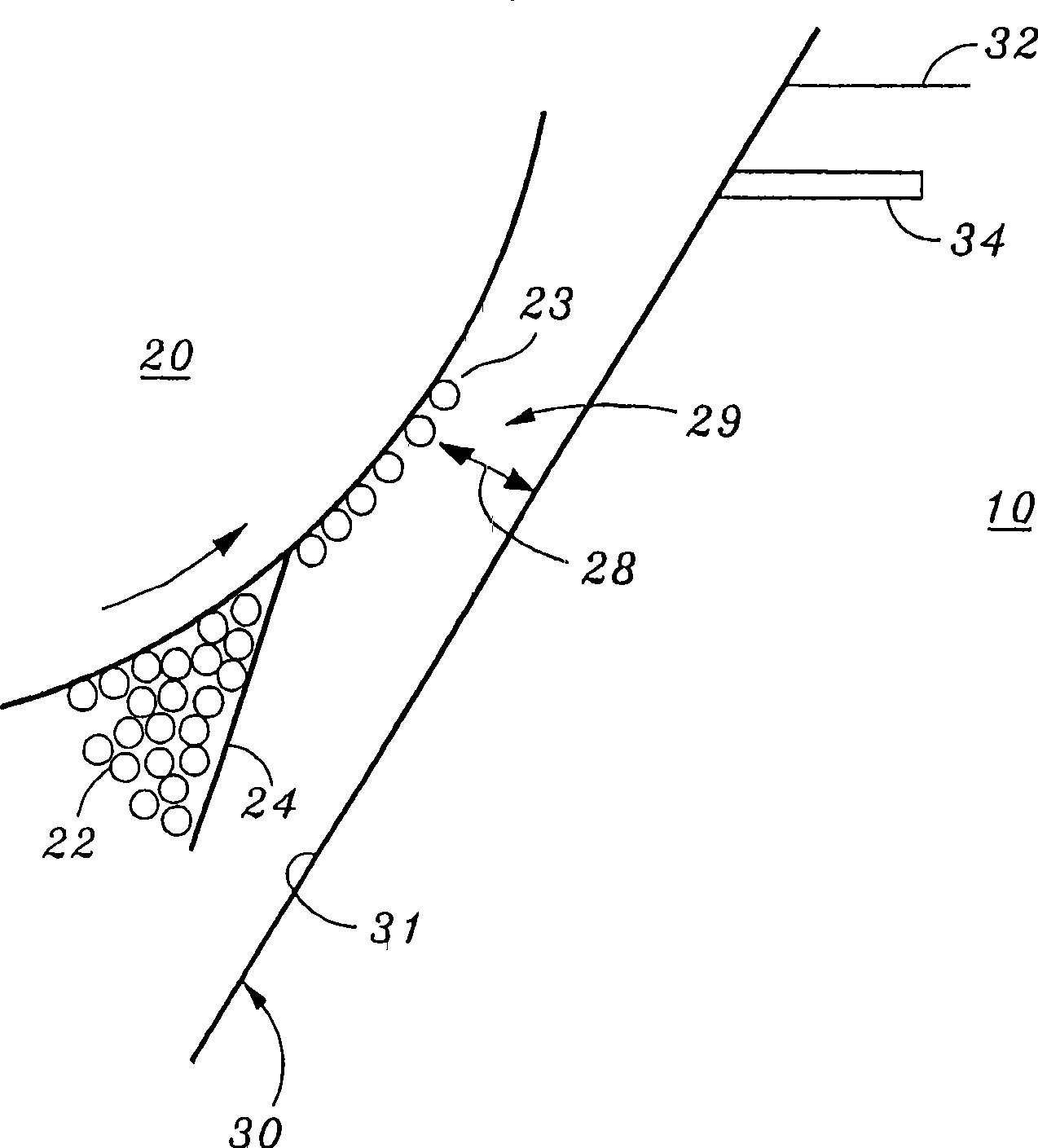

Means for transferring a pattern to an object

A template (10) having a first surface (13, 14), usable for transferring a pattern of the first surface to an object (20) having a second surface (23) covered by a light-sensitive coating (22), by contacting the patterned first surface with the coating, wherein the template comprises a carrier base (11) of e.g. nickel, and a waveguide (14) is disposed on the carrier base at the first surface. The waveguide is devised to lead light therein, introduced at a radiation input, and to leak evanescent waves to portions (24) of the coating corresponding to said pattern. The template may also be devised with an opaque shield (15), disposed at the first surface over selected portions of the waveguide, which serves to define where the evanescent waves can leak to the coating. The invention also relates to a method and an apparatus for using the template, and a method for manufacturing it.

Owner:OBDUCAT AB SE

Method for preparing two-sided silicon nano-wire array

InactiveCN102556953AImprove efficiencyEasy to operateDecorative surface effectsChemical vapor deposition coatingChemical platingSilicon nanowires

The invention relates to a silicon nano-wire, in particular to a method for preparing a two-sided silicon nano-wire array. According to the method, a silicon surface is etched by combining the corrosivity of a solution and the catalysis of metal ions at low temperature to form the silicon nano-wire array. The method comprises the following steps of: cleaning the silicon surface; passivating the surface of a silicon wafer by using hydrogen; covering a uniform layer of silver nanoparticle network on each of two surfaces of the silicon wafer by using a chemical plating method; preparing the two-sided silicon nano-wire array; and removing excessive silver nanoparticles. The method has the advantages that: expensive equipment and high-temperature environment are avoided in the preparation process, and the method is easy to operate and control, low in cost and high in efficiency, and can be applied to large-scale industrial production.

Owner:JIANGSU UNIV

Externally glazed article

The invention describes an article and method comprising a refractory article having an outer surface covered by an insulating coating over which a protective glaze is applied. The method includes applying a suspension of an insulating coating to a refractory piece, drying the suspension, applying a glaze slip over the coating, and drying the slip to form a protective glaze. In one embodiment, the article comprises a carbon-bonded alumina-graphite nozzle, an insulating coating containing hollow microspheres, and a protective glaze formed from a fusible frit. The invention is described as improving wetting to the refractory piece, reducing delamination of the glaze and insulating coating from the piece, and reducing oxidation of the piece.

Owner:VESUVIUS CRUCIBLE CO

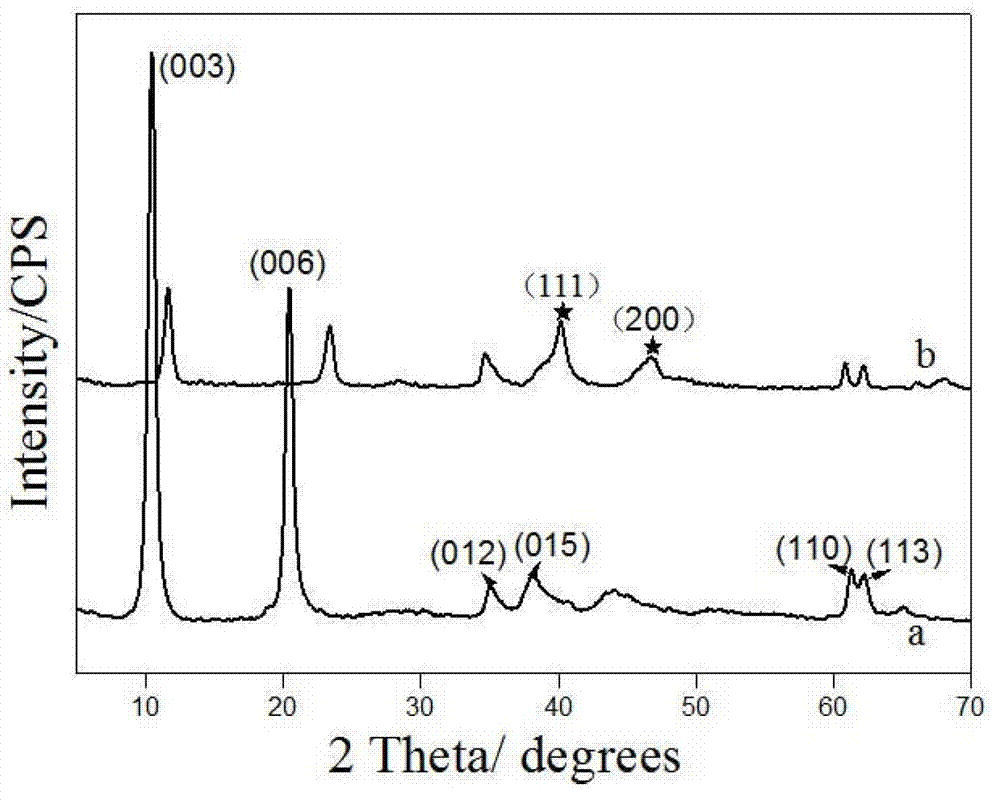

In situ controllable synthesis method for hydrotalcite-supported Pd nano crystal catalysts with different morphologies and application of hydrotalcite-supported Pd nano crystal catalysts in catalysis of Heck reaction

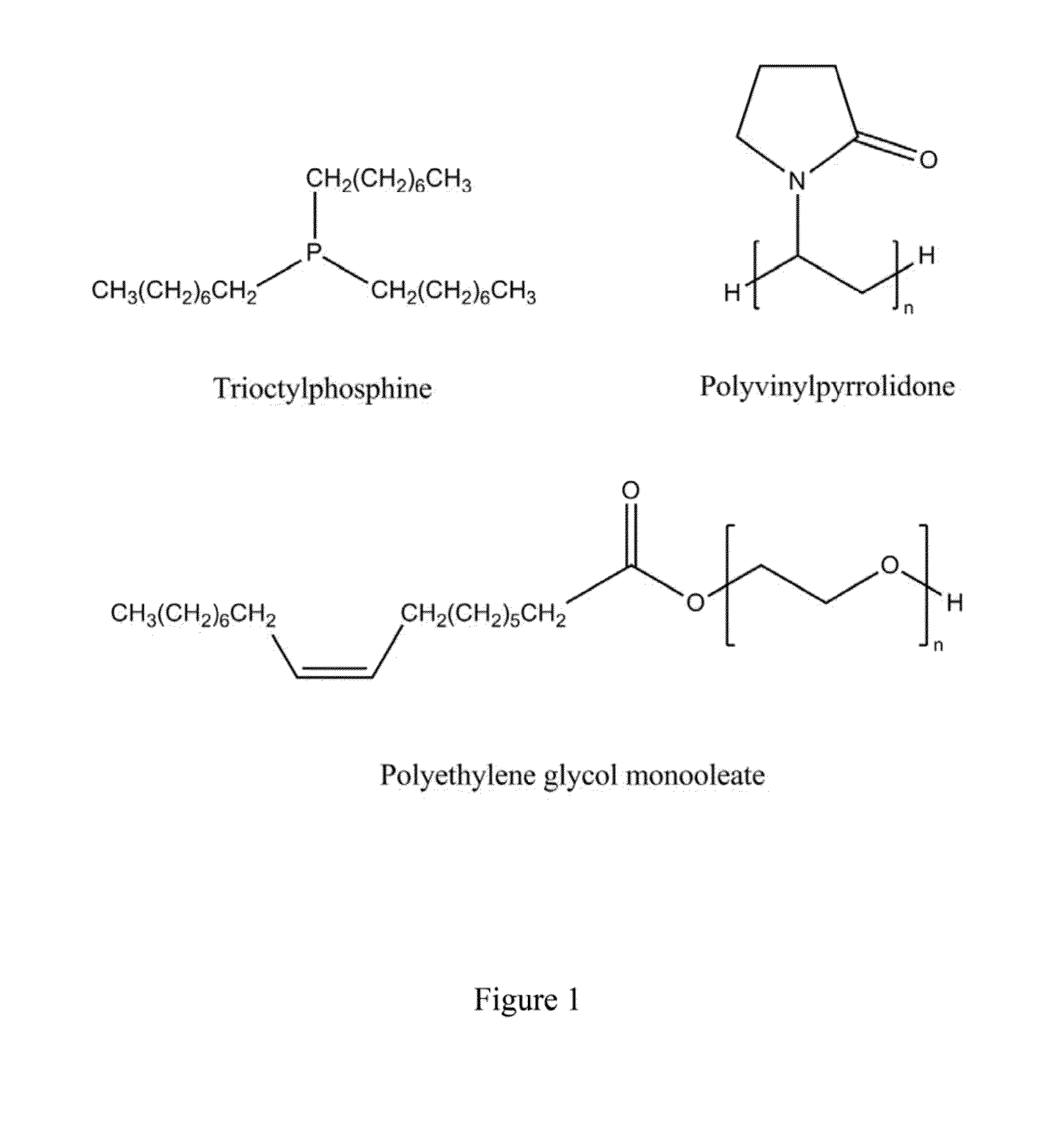

ActiveCN103203231AHigh densityNot fullHydrocarbon by hydrocarbon and non-hydrocarbon condensationMetal/metal-oxides/metal-hydroxide catalystsSynthesis methodsTruncated octahedron

The invention belongs to the technical field of preparation of supported nano crystal catalysts and in particular relates to in situ controllable equipment for hydrotalcite-supported Pd nano crystal catalysts with different morphologies and research on activity of the hydrotalcite-supported Pd nano crystal catalysts in catalysis of a Heck coupled reaction. The synthesis process of the hydrotalcite-supported Pd nano crystal catalyst comprises the following step of: growing Pd nano crystals with different morphologies (cube, truncated octahedron and triangle) and different exposed crystal faces ({111} and {100}) in situ on the surface of hydrotalcite by adopting a one-pot synthesis method under the conditions of different reducing agents (polyvinylpyrrolidone and ethylene glycol) and surface capping agents (I<->, Cl<-> and polyvinylpyrrolidone) with a mixed solution composed of Na2PdCl4 and nitrate intercalation hydrotalcite. Besides, the synthesized hydrotalcite-supported Pd nano crystal catalysts with different morphologies are used for evaluating the Heck coupled reaction and researching a catalytic activity sequence of different exposed Pd crystal faces of the hydrotalcite-supported Pd nano crystal catalysts, and a foundation is laid for further reasonably designing an efficient supported nano crystal catalyst.

Owner:BEIJING UNIV OF CHEM TECH

Fluorinated silica microchannel surfaces

InactiveUS6865939B2Reduce resistancePrecise and rapid protocolVolume/mass flow measurementPretreated surfacesAlkanePolymer science

A method for surface modification of microchannels and capillaries. The method produces a chemically inert surface having a lowered surface free energy and improved frictional properties by attaching a fluorinated alkane group to the surface. The coating is produced by hydrolysis of a silane agent that is functionalized with either alkoxy or chloro ligands and an uncharged C3-C10 fluorinated alkane chain. It has been found that the extent of surface coverage can be controlled by controlling the contact time from a minimum of about 2 minutes to a maximum of 120 minutes for complete surface coverage.

Owner:SANDIA NAT LAB

Method for reducing diameter of self-crimping micron tube by virtue of metal nanoparticles

ActiveCN104555899ASmall diameterEasy to manufactureDecorative surface effectsChemical vapor deposition coatingPhotoresistNanotube

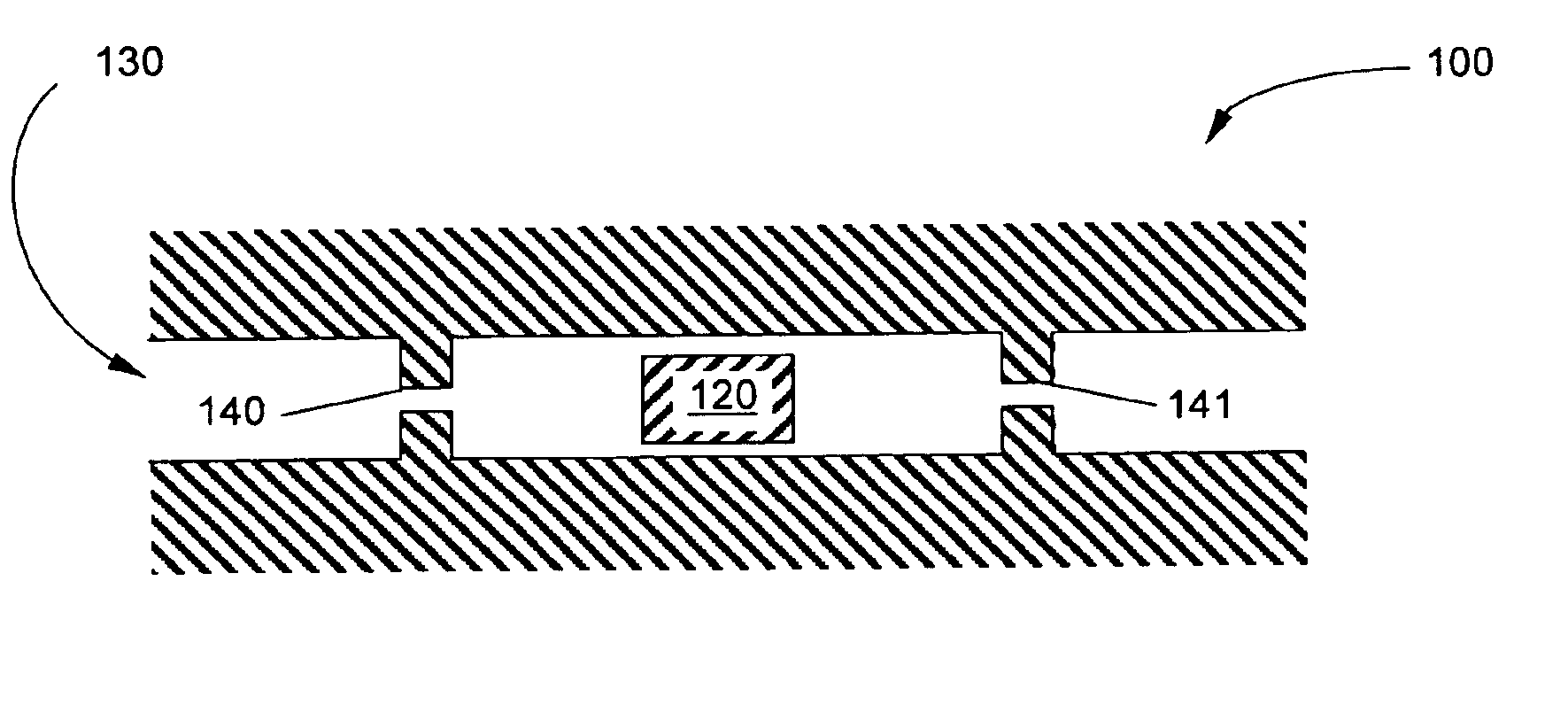

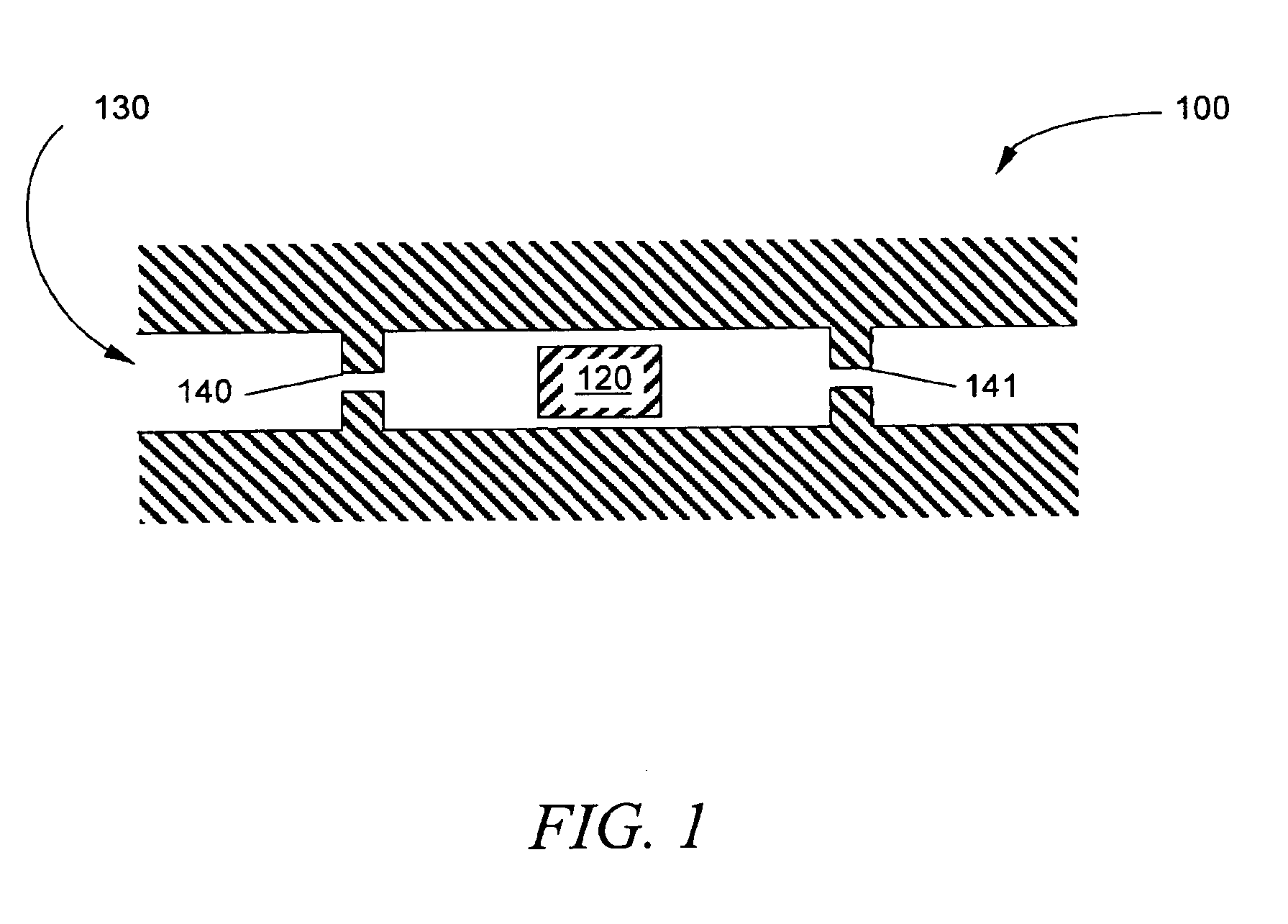

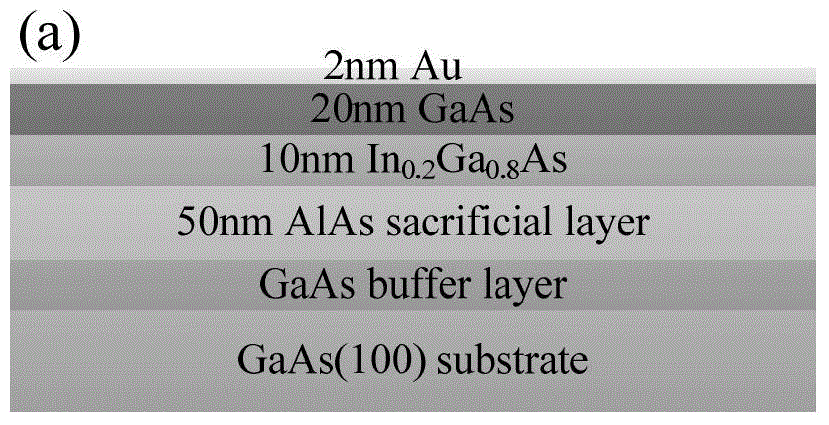

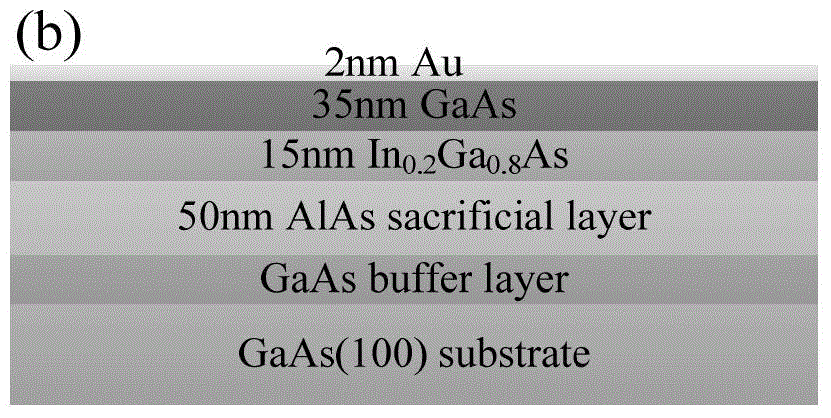

The invention provides a method for reducing the diameter of a self-crimping micron tube by virtue of metal nanoparticles. The method comprises the following steps: depositing a buffer layer on a substrate or a virtual substrate; depositing a sacrificial layer on the buffer layer; depositing a strain thin film on the sacrificial layer; carrying out primary photoetching and corrosion, wherein the strain thin film forms a table-board, so that the sacrificial layer is exposed; carrying out secondary photoetching and forming a pattern window by using photoresist; depositing a metal thin film, and annealing at a high temperature, wherein the metal thin film forms the metal nanoparticles; and laterally corroding the sacrificial layer, wherein the strain thin film covering the metal nanoparticles on the surface is self-crimped to form the tube. On the premise of not changing the thickness of the thin film and strain, the diameter of the self-crimping micron tube can be remarkably reduced just by virtue of the metal nanoparticles and the self-crimping micron tube with the diameter which is near to 1 micron can be easily prepared, and even the nanotube with the diameter which is lower to several hundred nanometers and a regular array can be easily prepared. Meanwhile, the method can ensure that the micron tube or the nanotube has excellent mechanical and structural characteristics.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Porous material substrate used in GaN film grown by HVPE method and method thereof

InactiveCN101514484ARelease internal stressQuality improvementPolycrystalline material growthFrom chemically reactive gasesGallium nitridePlasma etching

The invention relates to a nano-porous material substrate used in hydride vapor phase epitaxy (HVPE) gallium nitride (GaN) film and a preparation method thereof. The invention is characterized in that composite nano-porous material is taken as a substrate for epitaxially growth of a thick film GaN, and the quality of crystalloid can be improved, meanwhile, the substrate can be conveniently stripped. A metal Al thin layer is firstly sedimentated on a GaN template taking Si as the substrate, even porous meshed anodic aluminum oxide (AAO) is formed by an electrochemic method, porous GaN material is obtained by erosion of technologies such as induced coupling plasma etching (ICP) and the like, and the bottom of the holes are exposed outside the surface of the Si substrate; on this basis, a corrosion method is adopted to realize the corrosion for Si and obtain the composite nano-porous structure; by the superficial treatment, the Si is covered with a SiNx layer or SiO2 layer, so as to meet the requirements of subsequent epitaxial growth. After being washed, the product is put into an HVPE system, and the thick film GaN layer grows. The invention greatly simplifies the technique for manufacturing a mask film by photoetching, and is suitable for scientific experiments and batch production.

Owner:DAHOM FUJIAN ILLUMINATION TECH

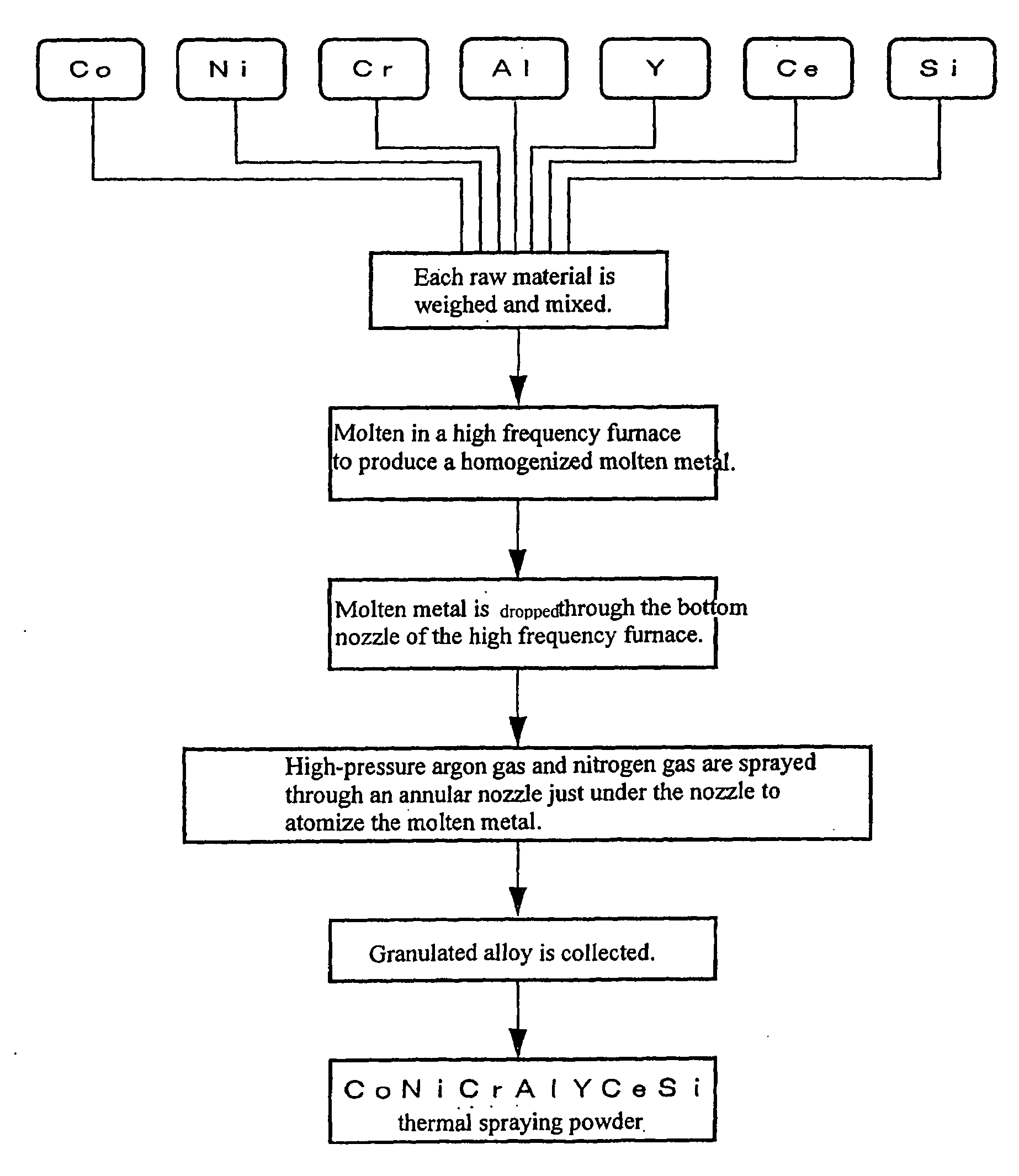

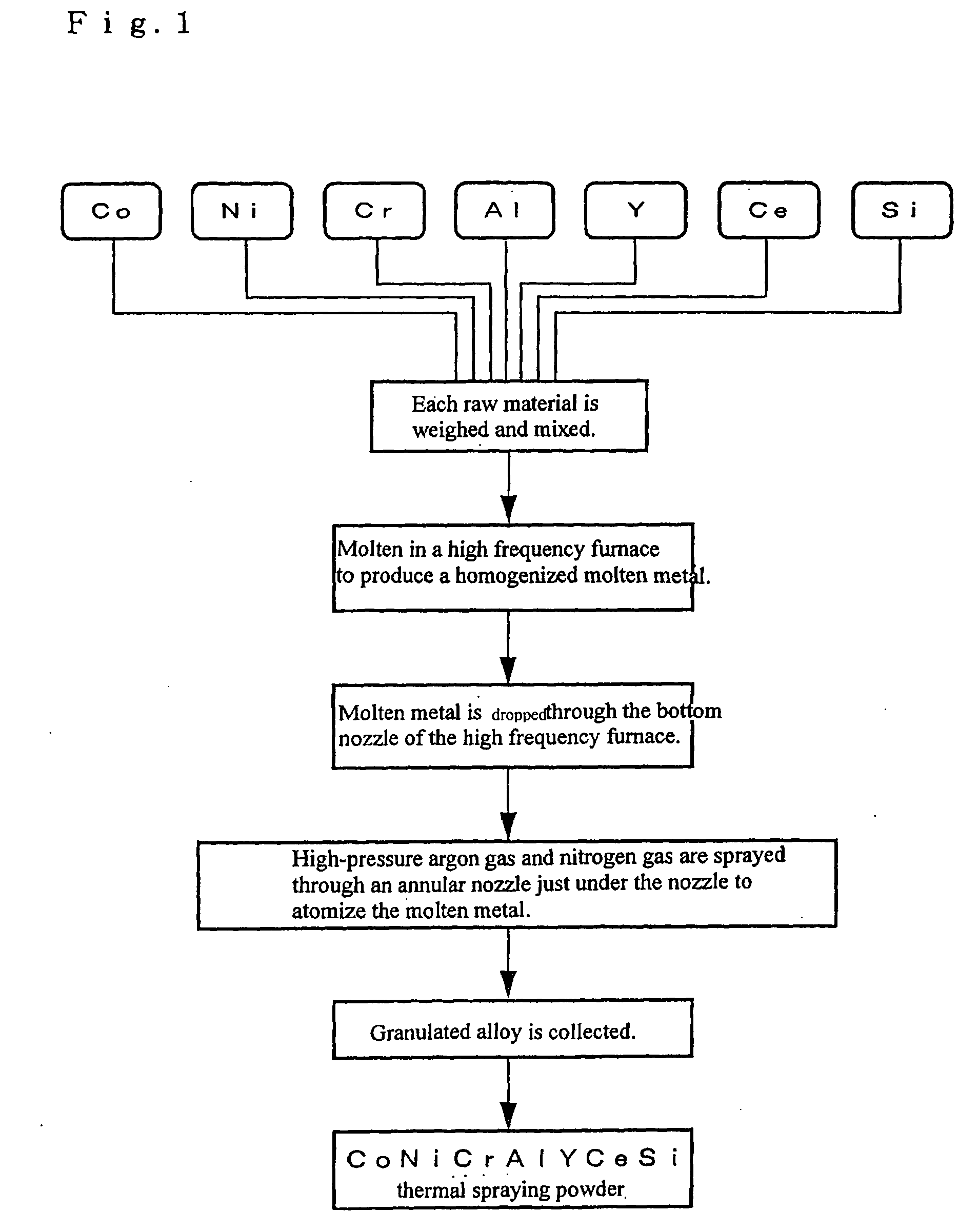

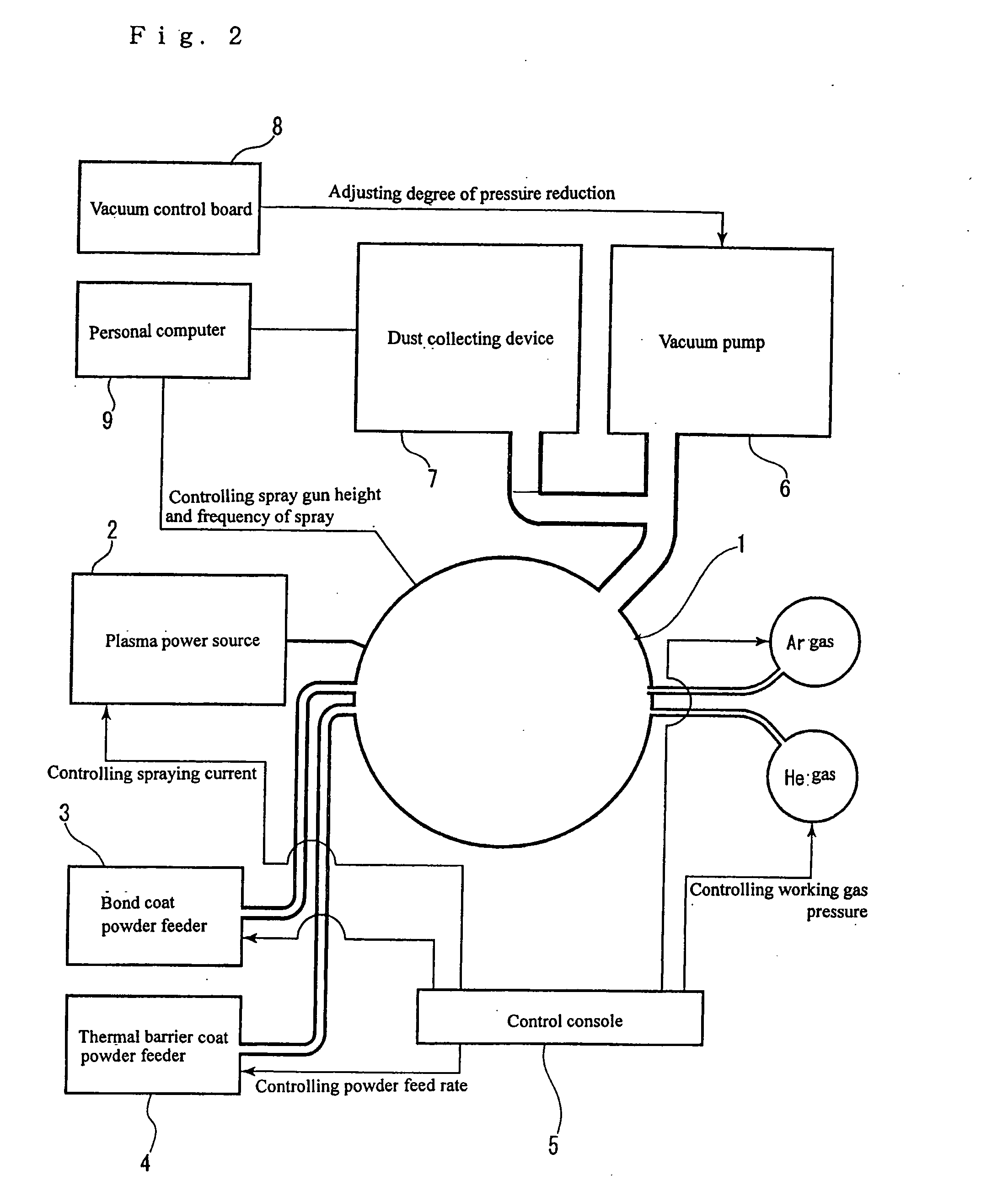

Member coated with thermal barrier coating film and thermal spraying powder

InactiveUS20060240273A1Growth inhibitionLow costLiquid surface applicatorsMolten spray coatingThermal sprayingAlloy

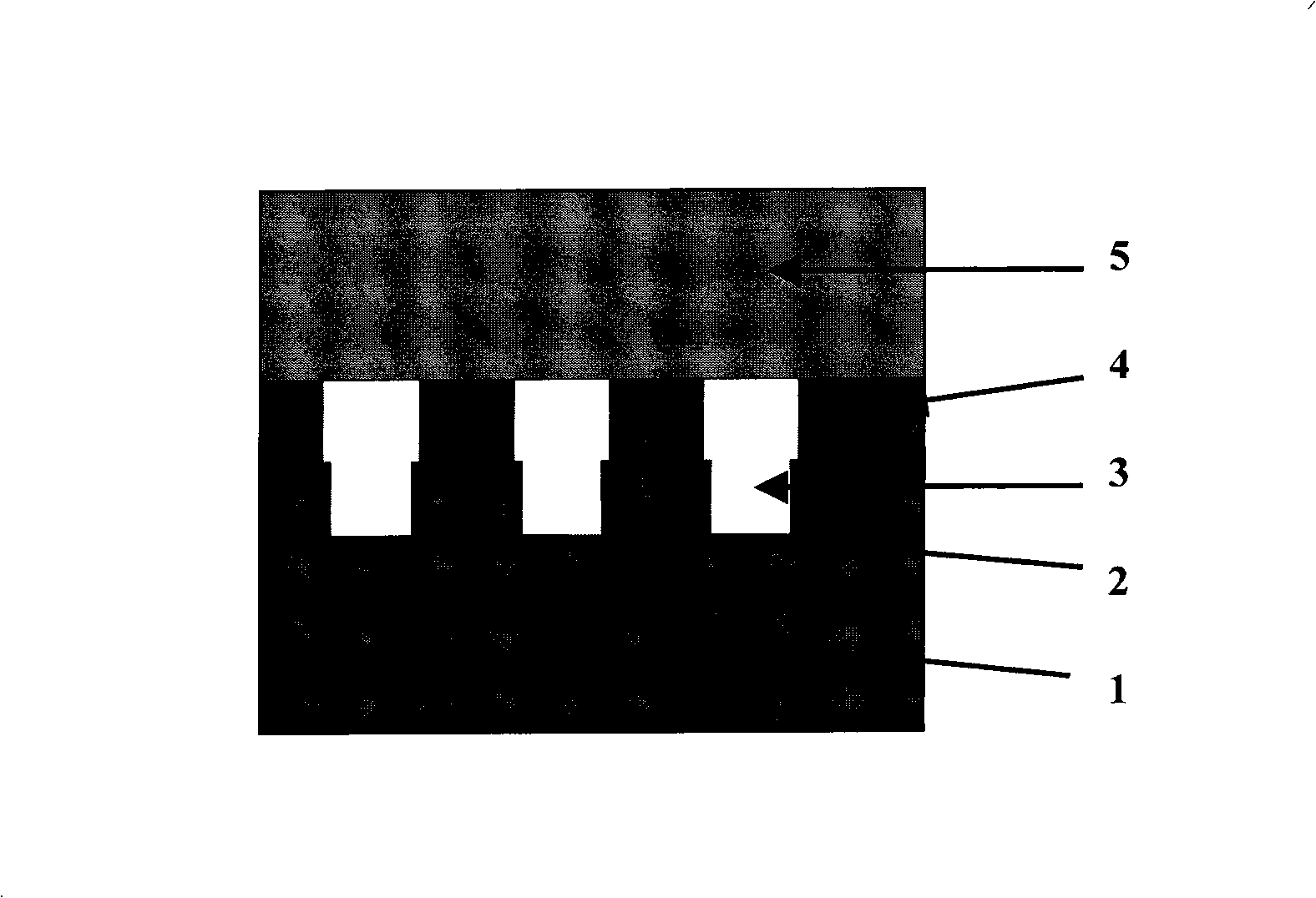

The present invention provides a member coated with thermal barrier coating film having a metal substrate, the surface of which is covered with an adhesive layer (bond coat layer) composed of a heat resisting alloy and a thermal barrier film layer (thermal barrier coating layer) composed of a heat resisting ceramic formed on the adhesive layer, and a thermal spraying powder used for the formation of the adhesive layer, characterized in that the adhesive layer is a MCrAlX alloy (wherein M is at least one metal selected from among Fe, Ni and Co, and X is at least one metal selected from among Y, Hf, Ta, Cs, Pt Zr, La and Th), and an element capable of inhibiting the growth of an oxide layer (TGO) which is grown between the adhesive layer and the thermal barrier film layer by the exposure to a high temperature is added to the adhesive layer.

Owner:TOHOKU TECHNO ARCH CO LTD

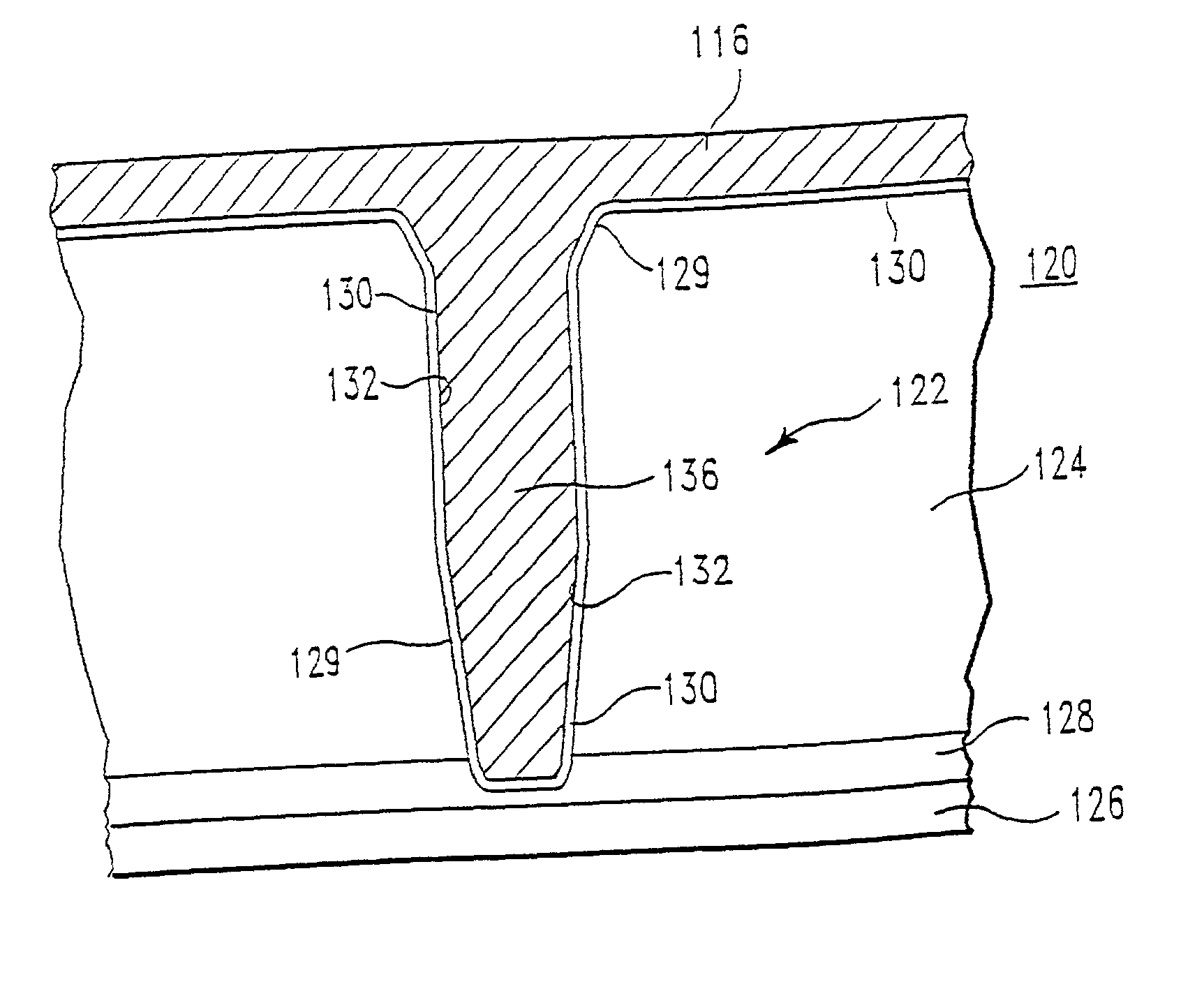

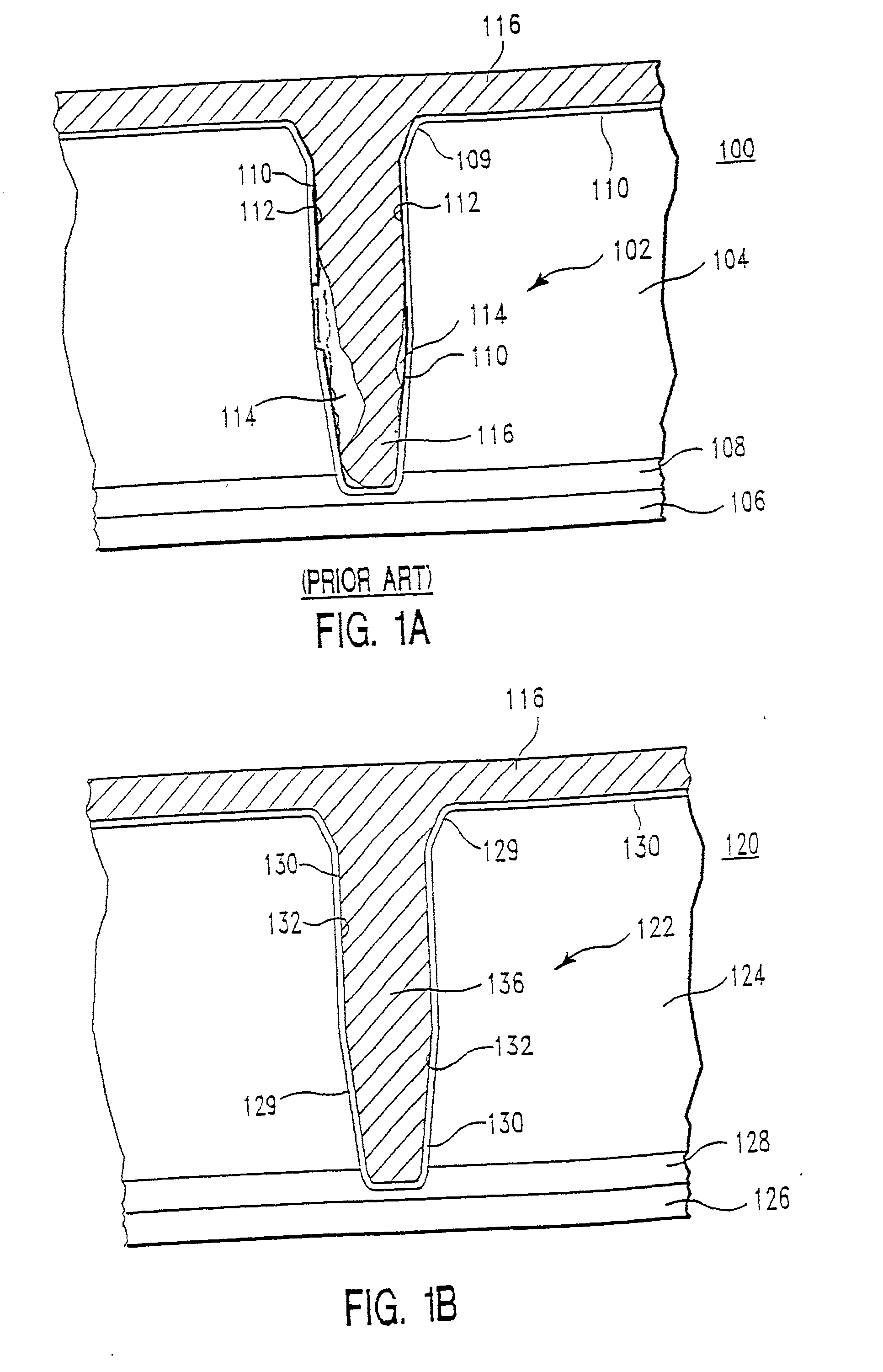

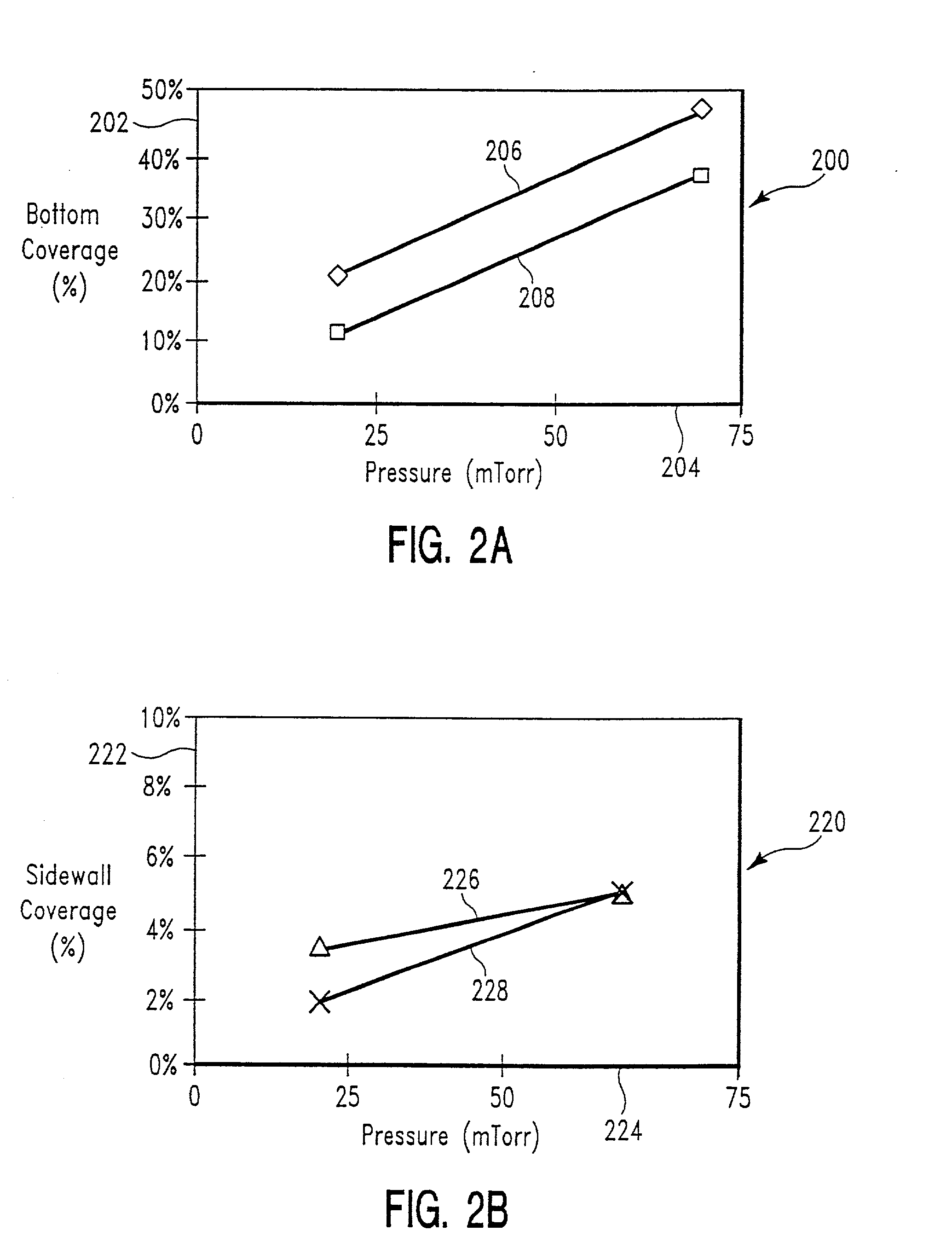

Method of depositing a copper seed layer which promotes improved feature surface coverage

InactiveUS20020068449A1Semiconductor/solid-state device detailsVacuum evaporation coatingInductively coupled plasmaMaterials science

Owner:APPLIED MATERIALS INC

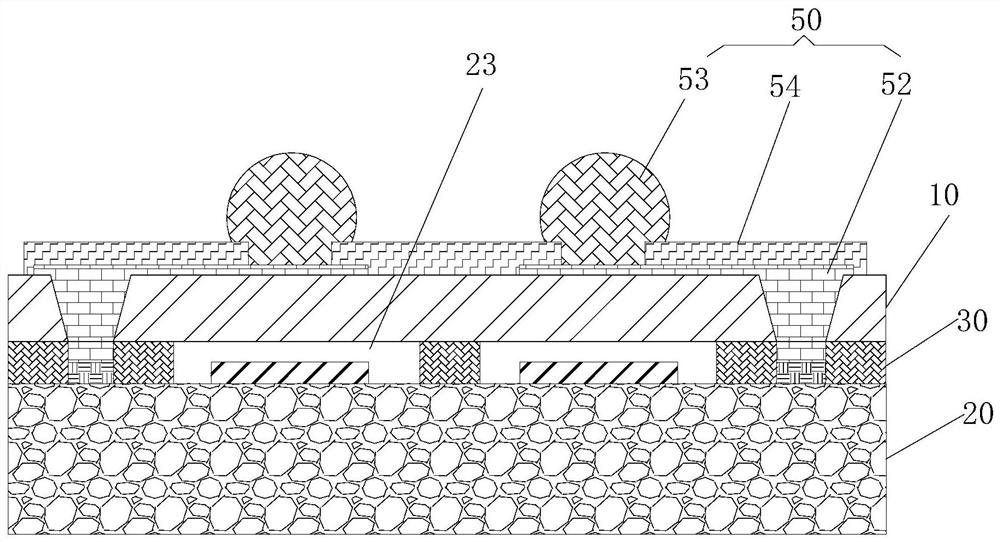

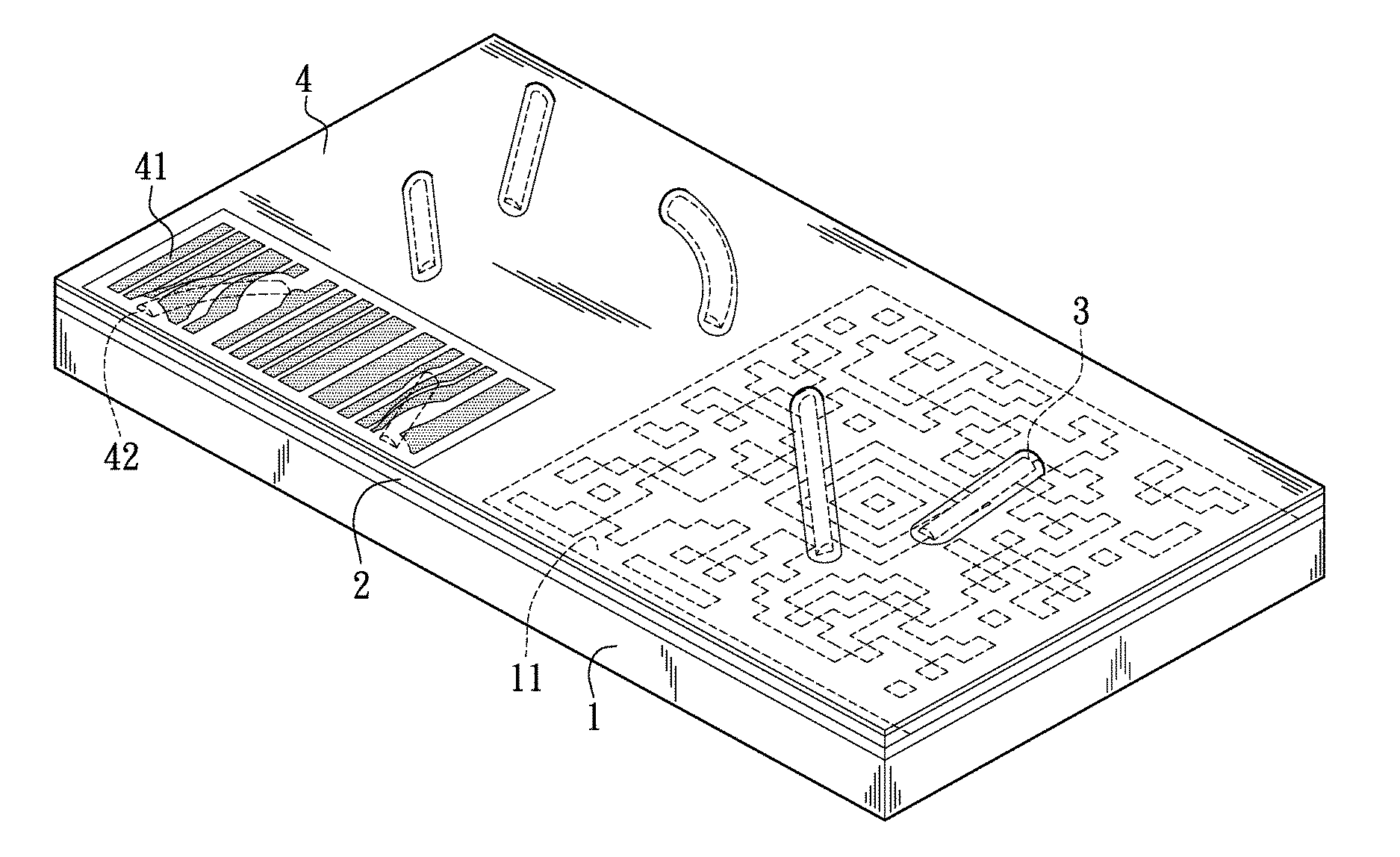

Surface acoustic wave filter packaging method and structure based on glass cover plate

The invention discloses a surface acoustic wave filter packaging method and structure based on a glass cover plate, and the method comprises the steps: 1), providing the glass cover plate and a chip wafer, wherein a first surface of the chip wafer is provided with a bonding pad and an IDT functional region; (2) making a blind hole in the glass cover plate, temporarily bonding a glass carrier plateto the first surface of the opening side of the blind hole, grinding the other surface of the glass cover plate to get through the blind hole to form a through hole, wherein the inner diameter of thethrough hole is gradually decreased from the first surface to the other surface; (3) covering the first surface of the chip wafer with an insulating layer, and making openings in the positions, opposite to the bonding pad and the IDT functional region, of the insulating layer; 4) bonding the glass cover plate with the chip wafer, enabling the through hole to be opposite to the opening at the bonding pad of the insulating layer, and forming a cavity by the insulating layer and the glass cover plate in the IDT functional region; and 5) removing the glass carrier plate, and manufacturing a metalconnecting piece on the glass cover plate to be electrically connected with the bonding pad. The IDT functional region is prevented from being corroded by external moisture, corrosive liquid and thelike, the device packaging reliability is improved, one-time packaging is achieved, and batch production can be achieved.

Owner:XIAMEN SKY SEMICON TECH CO LTD

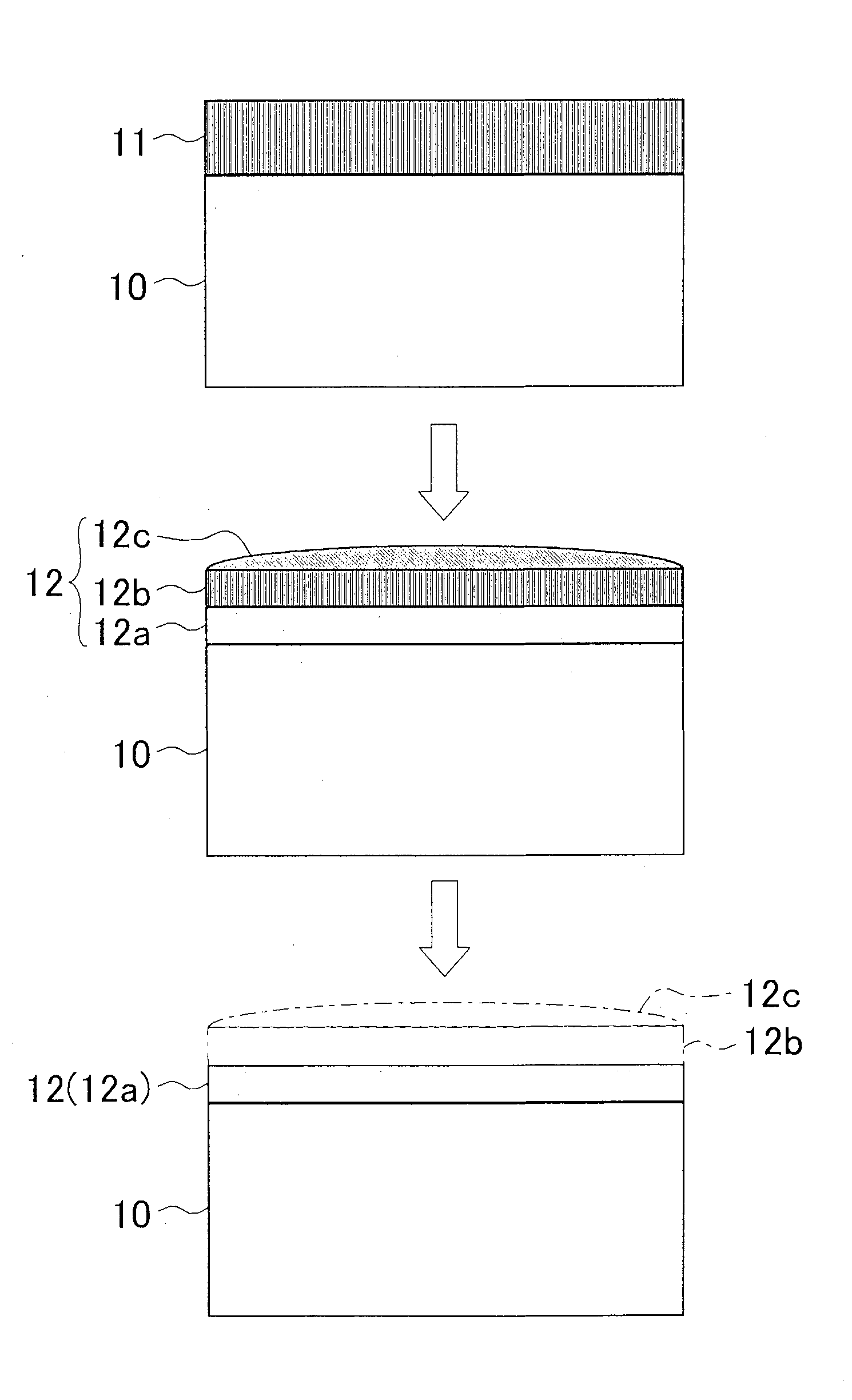

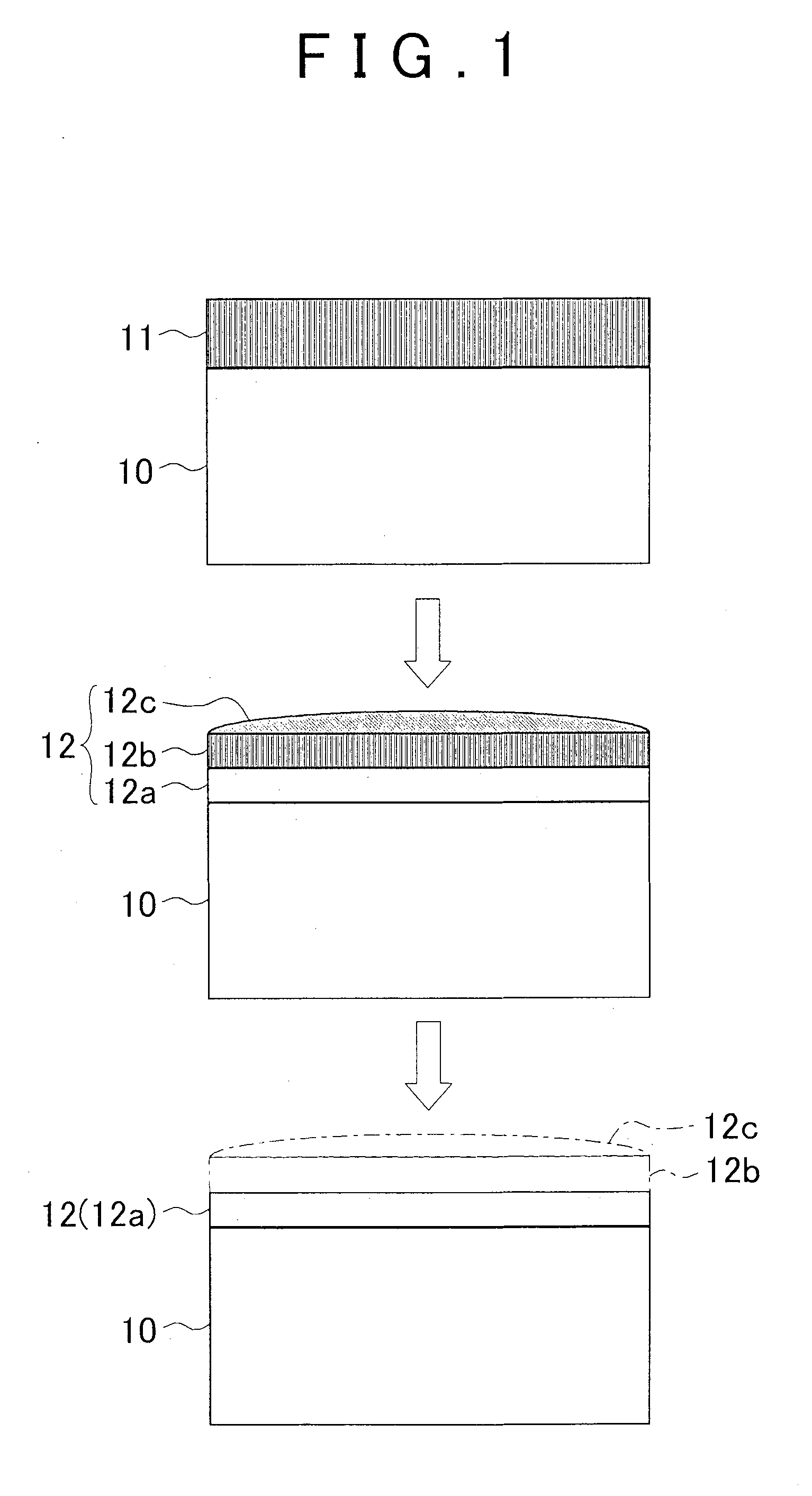

Semiconductor device fabrication methods employing substantially planar buffer material layers to improve the planarity of subsequent planarazation processes

InactiveUS20070004219A1Semiconductor/solid-state device manufacturingCapacitorsDevice materialSemiconductor

A method for fabricating a semiconductor device structure includes applying a stress buffer material onto a semiconductor device structure and spreading the stress buffer material. When the stress buffer material is spread, it substantially fills recesses formed in a surface of the semiconductor device structure and imparts the stress buffer material with a substantially planar surface. The thickness of the stress buffer material covering the surface of the semiconductor device structure may be less than the depths of the recesses. The surface may remain substantially uncovered by the material.

Owner:WHITMAN JOHN +1

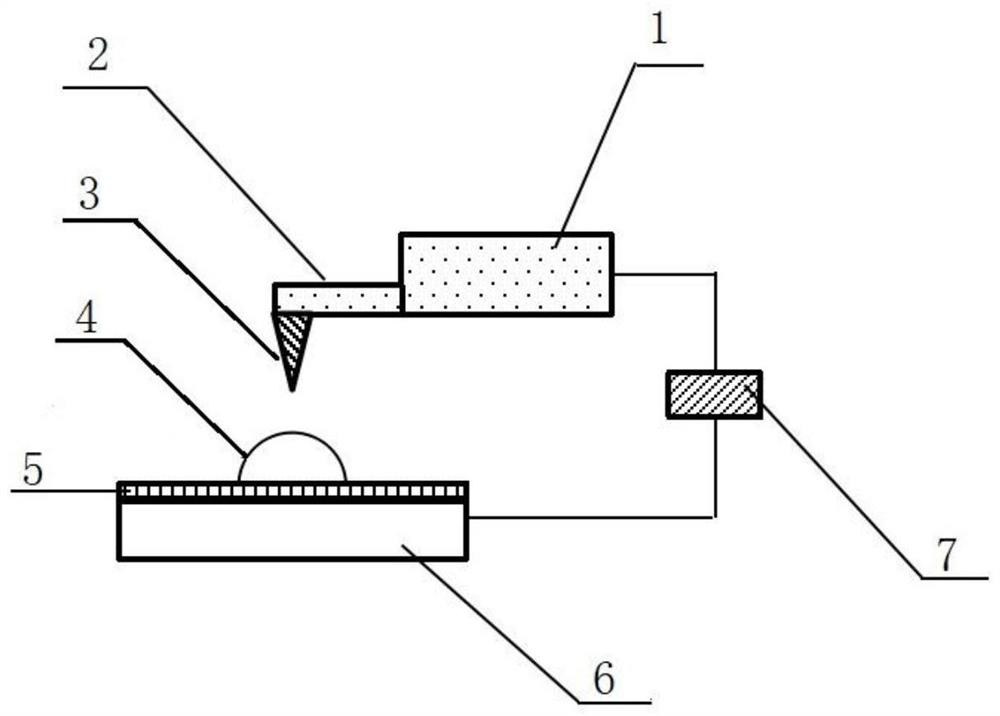

Manufacturing method of nanofiber probe tip for measuring surface topography of sample

The invention relates to a method for preparing a nanofiber probe tip. The method comprises the following specific steps of preparing a substrate, covering a surface of a conductive flat plate with adielectric layer; probe surface treatment, covering a surface of a probe with a conductive layer; preparing solution, namely preparing turbid liquid from nanofibers and the distilled water according to a certain proportion; bonding fibers, controlling the probe to slowly approach the liquid drops till the probe is in contact with the liquid drops. The method is advantaged in that the surface tension of liquid is adjusted by utilizing an electric field, the shape and the height of a liquid bridge between the probe and a substrate are controlled, so fibers are absorbed on the surface of the probe. The prepared nanofiber probe tip can improve sensitivity of an atomic force microscope to surface topography characteristics of a material and measurement precision of mechanical properties, the method has the capability of controlling the fiber orientation at the same time, so the nanofiber prepared by the method can be applied to special tests, and the preparation method is simple to operate,relatively low in cost and high in robustness.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Construction method for arched framework revetment

InactiveCN108643205AAvoid churnPromote recoveryHops/wine cultivationTurf growingSurface finishEngineering

The invention discloses a construction method for an arched framework revetment. The construction method includes the following steps of (1) slope surface finishing; (2) measurement and laying-off, specifically, roadbed side lines and roadbed revetment foundation side lines are laid out according to an arched framework and with the control of the revetment central line, control pillars are arranged, and the outline of the multi-layer framework are drawn; (3) roadbed slope brushing, specifically, a side slope is finished according to gradient hanging lines, the slope surface capping mass and loss stones need to be cleared at the roadbed; (4) digging, specifically, an arched framework foundation groove is dug, and an arched framework formwork is installed and fixed in the dug foundation groove; (5) pouring, specifically, concrete is poured from a banket of the arched framework from bottom to top, and after pouring, surface finishing and flattening are carried out; (6) jointing, specifically, the two sides and bottom of a slope surface draining groove of the arched framework revetment are subjected to mortar sealing treatment; and (7) planting, specifically, grass is planed in the arched framework in a spray-seeding mode, and membrane curing is also conducted. The construction method for the arched framework revetment lowers the engineering coast and prevents water and soil loss while the slope surface protecting function is achieved.

Owner:CHENGDU MUNICIPAL ENG GRP

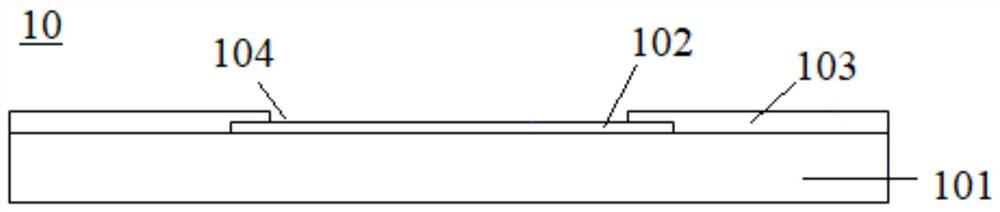

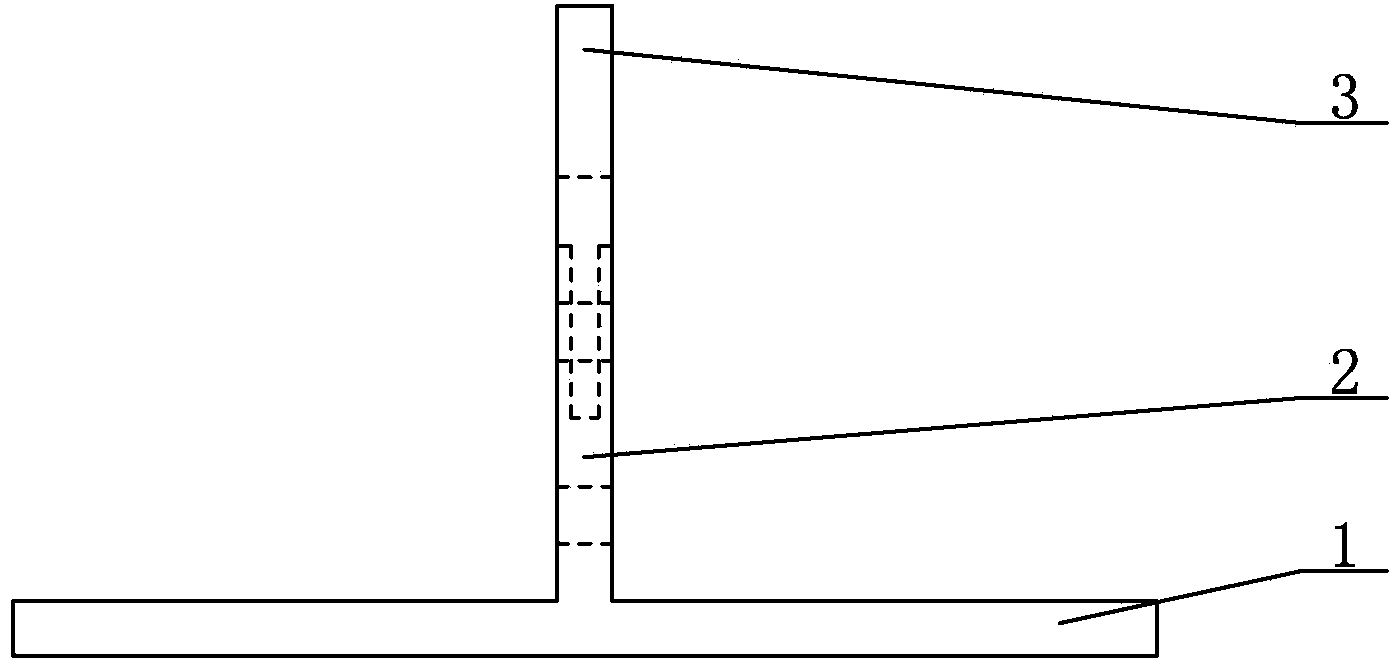

Preparation method of metal bump structure

PendingCN113471159AAvoid shortingSemiconductor/solid-state device detailsSolid-state devicesStructural engineeringBlock structure

The invention discloses a preparation method of a metal bump structure. The preparation method comprises the steps of providing a substrate; forming an insulating block-up layer on the upper surface of the passivation layer of the substrate and the upper surface of part of the bonding pad; removing the insulating block-up layer at the preset position to enable the remaining insulating block-up layer to form an insulating block-up block, and covering the upper surfaces of the passivation layer, the insulating block-up block and part of the bonding pad with a seed layer; and forming a photoresist layer on the seed layer, then removing the photoresist layer at a preset position to form a photoresist layer pane which exposes the bonding pad outwards, forming a metal convex block in the photoresist layer pane in an electroplating mode, wherein part of the metal convex block is formed on the insulation block-up block, and the top of the metal convex block is provided with a concave part and a protruding part oppositely formed on the edge of the concave part. According to the preparation method of the metal bump structure disclosed by the embodiment of the invention, the opposite concave part is formed in the upper part of the metal bump through the arrangement of the insulating block-up block, so that the problem of short circuit between adjacent welding spots caused by pin fusion and overflow is effectively avoided.

Owner:CHIPMORE TECH CORP LTD +1

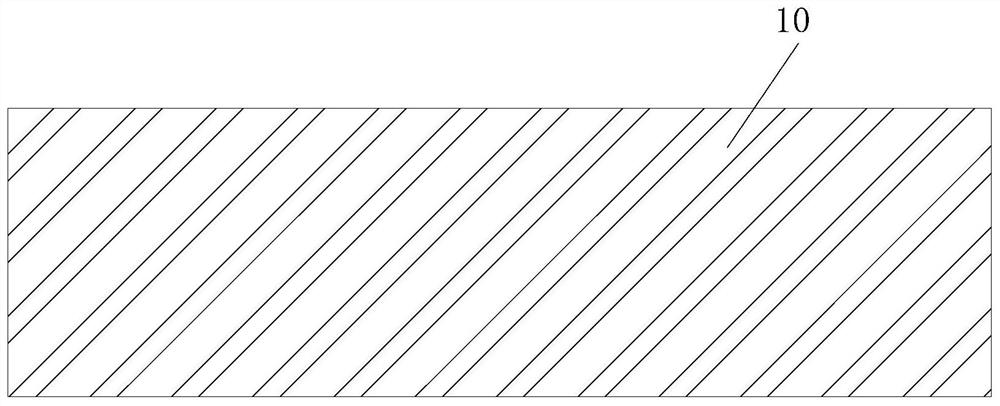

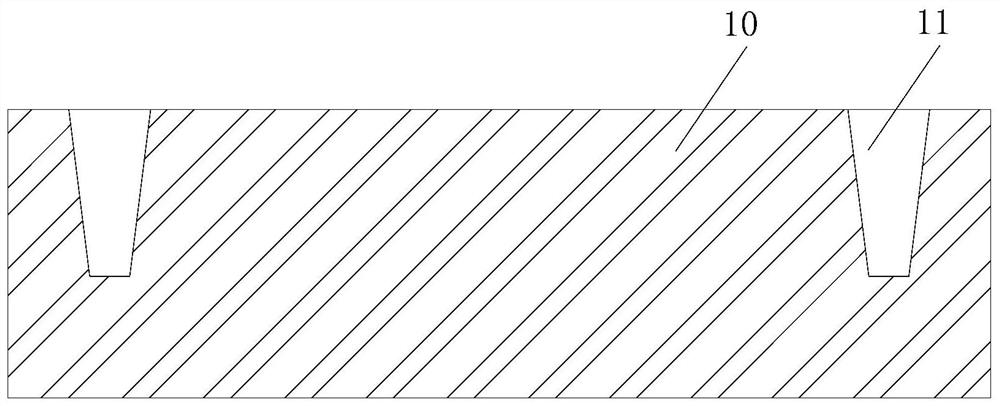

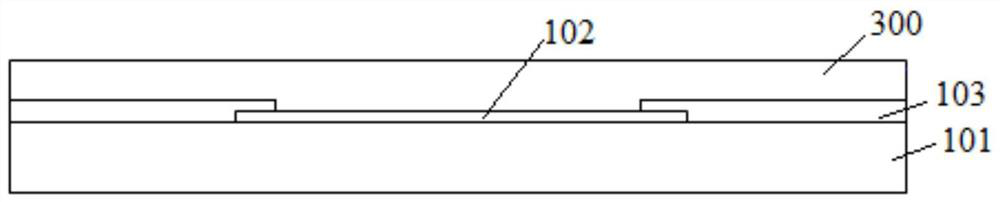

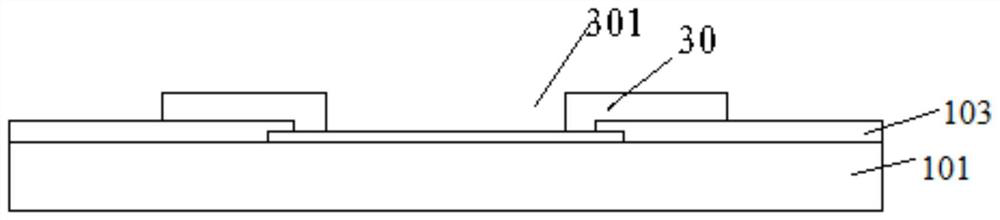

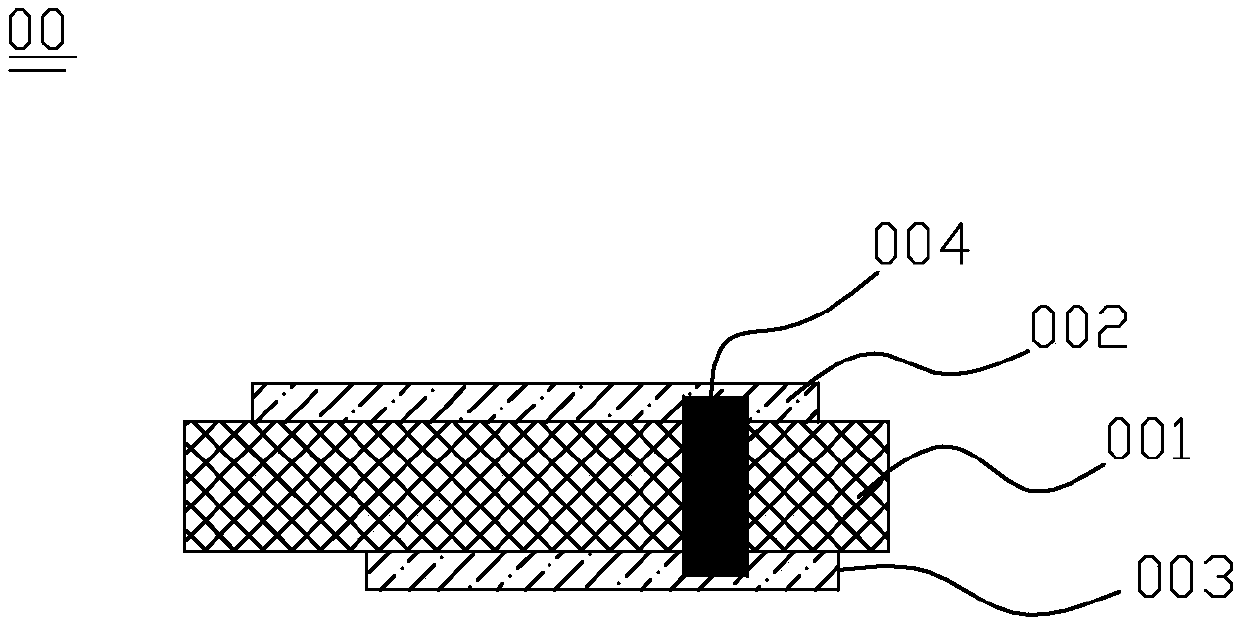

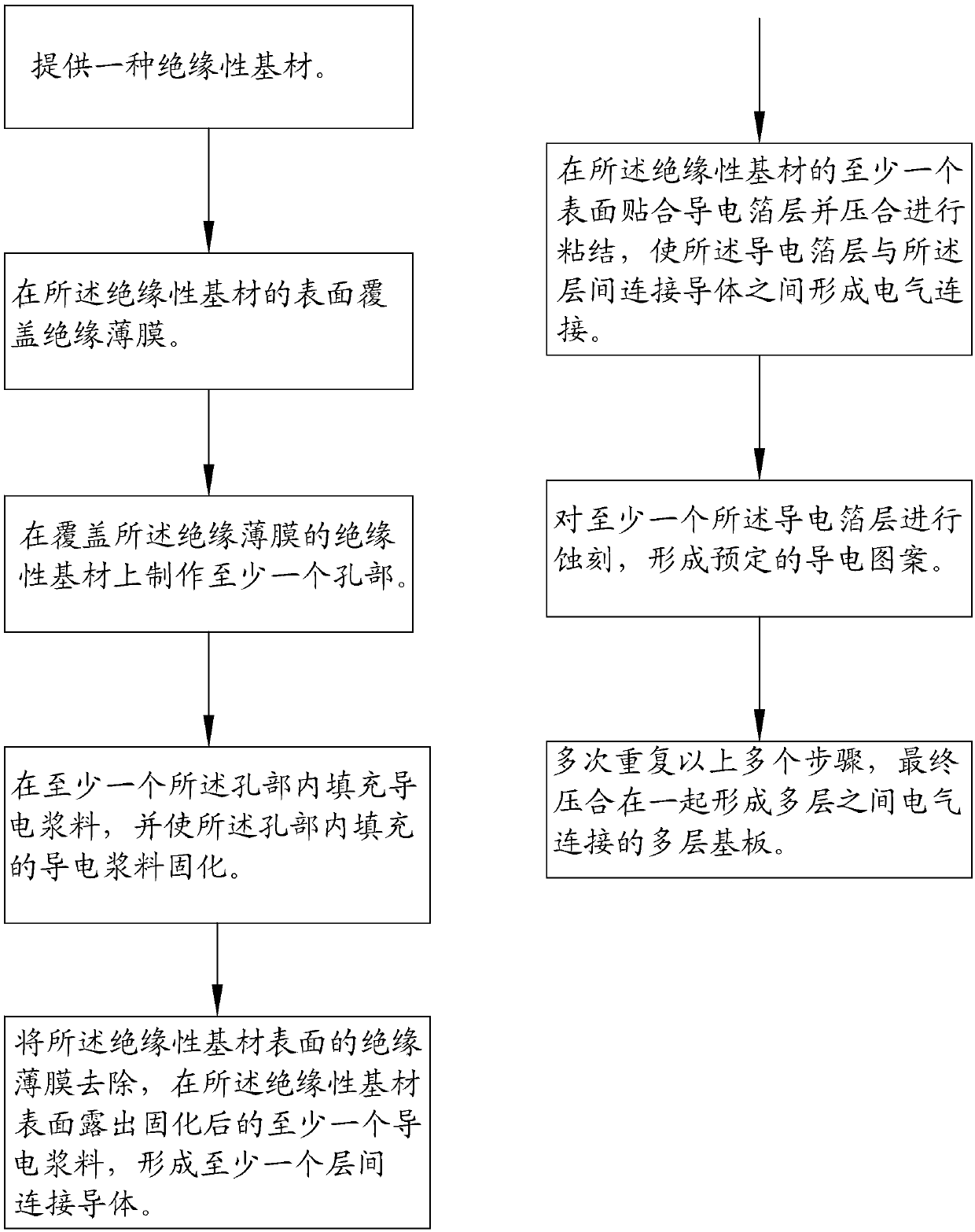

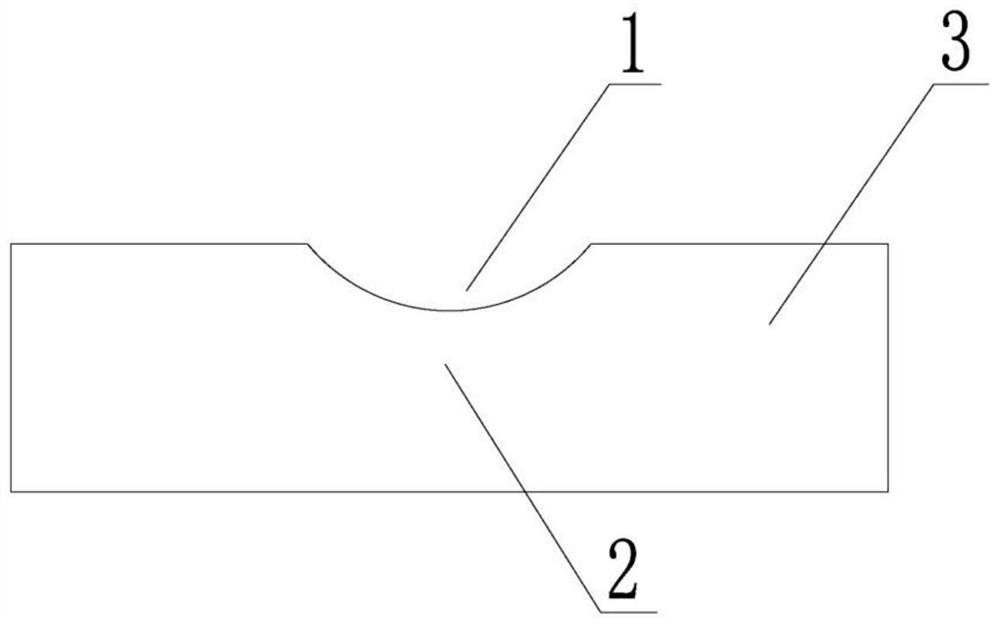

Manufacturing method of multilayer substrate and multilayer substrate

InactiveCN110366329AEasy to manufactureImprove efficiencyMultilayer circuit manufacturePrinted element electric connection formationEtchingElectrical conductor

The invention discloses a manufacturing method of a multilayer substrate. The method comprises the following steps of: the step 1, providing an insulating substrate; the step 2, covering an insulatingfilm on the surface of the insulating substrate; the step 3, manufacturing at least one hole part on the basis; the step 4, filling conductive slurry in at least one hole part, and solidifying the conductive slurry filled in the at least one hole part; the step 5, removing the insulating film, and exposing the cured at least one conductive slurry on the surface of the insulating substrate to format least one interlayer connection conductor; the step 6, attaching a conductive foil layer on the at least one surface of the insulating substrate, and performing laminating for bonding; the step 7,etching at least one of the conductive foil layers to form a predetermined conductive pattern; and the step 8, repeating the above steps 1-7 for many times, and finally performing laminating to forma multi-layer substrate. The invention provides a multilayer substrate manufactured by the method.

Owner:ELECTRIC CONNECTOR TECH

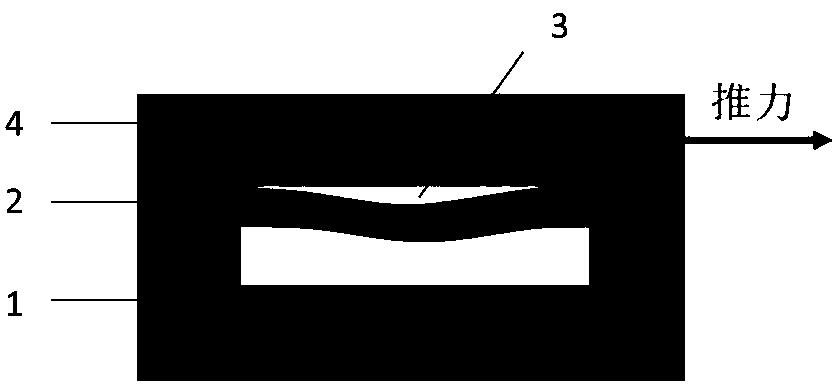

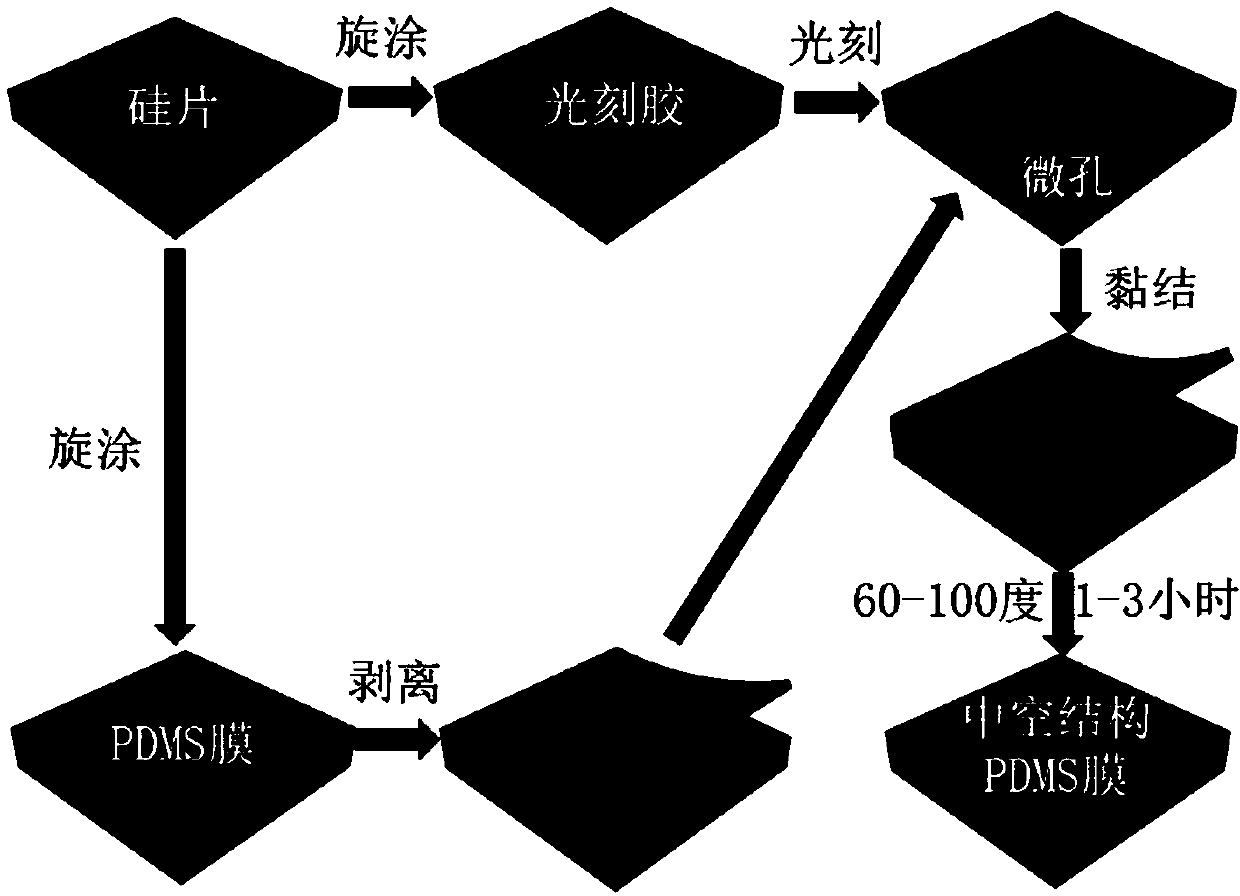

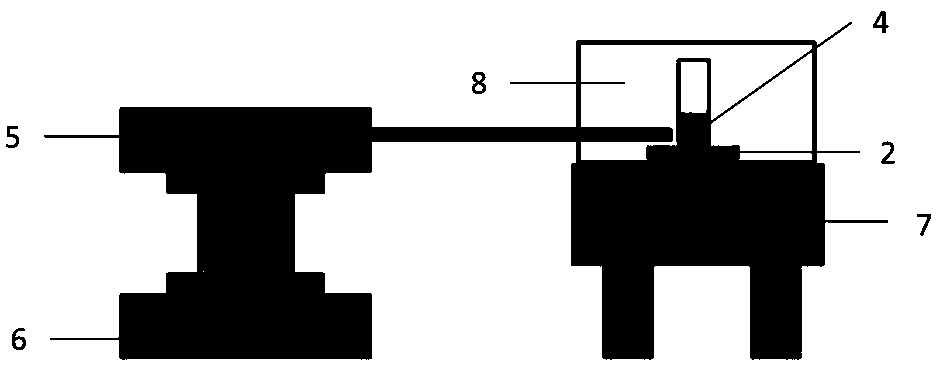

Method for reducing surface ice adhesion strength of silicon wafer

ActiveCN111181485AAvoid accumulationGood removal effectPhotovoltaicsCoatingsOxygen plasmaSilicon chip

The invention discloses a method for reducing surface ice adhesion strength of a silicon wafer, which comprises the following steps of: S10, preparing micropores with the height of 1.1 microns on thesurface of a silicon material, S20, covering the surface of the silicon material with the micropores with a PDMS film, and cleaning the surface of the silicon material with the micropores by using oxygen plasma before the PDMS film is adhered to the surface of the silicon material with the micropores, and S30, curing the PDMS film on the surface of the silicon material. The method S10 for preparing the micropores in the surface of the silicon material comprises the following substeps of: S101, spin-coating photoresist on the surface of the silicon material, S102, exposing the photoresist in amicropore region to be prepared, and S103, etching the exposure area.

Owner:HANGZHOU DIANZI UNIV

Transverse earth borrowing method applied to roadbed by Luoyang shovel

The invention relates to a transverse earth borrowing method applied to a roadbed by a Luoyang shovel, belonging to the technical field of roadway maintenance. The method solves the problems of existing earth borrowing devices and methods applied to the roadbed that the social work function and service life of the road are affected, personal security of workers is hard to ensure, and the earth borrowing efficiency is low. The method specifically comprises the following steps: ensuring that the roadbed at an earth borrowing opening is 1m higher than the highest earth borrowing opening; cleaning weed and surface capping mass away from a side slope by a shovel, and the distributing points; digging a platform at each earth borrowing opening, pouring a cement concrete horizontal table which is 50cm long, 15cm wide and 5cm high outside each earth borrowing opening, measuring by adopting a leveling instrument, and burying a snap joint at each of the front and rear ends of the horizontal table; preserving the poured concrete horizontal table for at least 7 days; starting borrowing earth when the Luoyang shovel reaches a specified earth borrowing opening; and filling earth blocks in a prepared aluminum box from at the middle part of the head of the Luoyang shovel and finally sealing the aluminum box. The method provided by the invention is used for transversely borrowing earth for the roadbed.

Owner:HARBIN INST OF TECH

A chemical tempering method for ultrathin unequal-thickness glass

InactiveCN113336429AUniform stressGood bending propertiesGlass tempering apparatusVitrificationIon exchange

A chemical tempering method for ultrathin unequal-thickness glass belongs to the technical field of chemical tempering methods for ultrathin glass, and comprises the following steps: 1) covering the surface of an equal-thickness area of the unequal-thickness glass with a PET film for protection, and then coating the upper surface of the unequal-thickness area of the unequal-thickness glass with a film for protection; 2) putting the coated unequal-thickness glass into a tempering liquid for tempering treatment, so that the stress layer thickness of a tempered unequal-thickness area is 6-8 microns, the stress value is 500-600MPa, the stress layer thickness of a tempered uniform-thickness area is 10-12 microns, and the stress value is 650-750MPa; and (3) carrying out film stripping, cleaning, drying, inspection, packaging and delivery on the tempered unequal-thickness glass cooled to normal temperature. The method has the beneficial effects that the non-uniform-thickness area of the unequal-thickness glass is subjected to film coating protection, so that an effect of blocking part of ion exchange in the chemical tempering process is achieved, so that the ultra-thin glass has excellent bending performance, high impact resistance and scratch resistance.

Owner:芜湖东信光电科技有限公司

Anti-forgery label using random protruding elements and method for manufaturing the same

InactiveUS20170032709A1Different tactile sensationStampsAdhesivesVisual identificationElectrical and Electronics engineering

An anti-forgery label using random protruding elements and a method for manufacturing the same. A substrate with a printed layer thereon is provided. An adhesive layer is coated on the printed layer, and a plurality of protruding elements are randomly distributed and adhered on the printed layer the adhesive layer. The surfaces of the printed layer and the protruding elements are covered with a light-permeable overcoat layer. A corresponding engaging region is formed in each of the protruding elements where it touches the overcoat layer, and a gap region is formed between the overcoat layer and the adhesive layer in proximity to each of the protruding elements. As such, randomly distributed tactile and visual identification features and irregular deformed identification regions are formed.

Owner:SENSE DIGITAL

Surface treatment method and coating agent

ActiveUS20150218385A1InhibitionImprove liquidityFoundry mouldsSemiconductor/solid-state device manufacturingCarbon filmTitanium zirconium

A surface treatment method on a base material coated a surface with a carbon film includes: supplying at least any one of titanium, zirconium, niobium, vanadium, hafnium, tantalum, and tungsten to the carbon film; and heating the carbon film to 400° C. or more under an inert atmosphere, thereby forming a coating film on the base material.

Owner:TOYOTA JIDOSHA KK

Method to produce a surface covering

The present invention relates to a method to produce a polymeric sheet comprising the steps of providing an acid-based polymer, providing a neutralizing agent, the neutralizing agent being selected from the group consisting of an organic metallic compound, a metallic salt of a fatty acid, and an ionomer, or a mixture thereof, providing a processing oil, mixing said acid-based polymer, said neutralizing agent, said processing oil, to obtain a polymeric composition, and processing said polymeric composition to form a polymeric sheet. The polymeric sheet may be used as a component, or as a substrate, of a surface covering. The polymeric sheet may also be used to form polymeric particles which are component of so-called “homogenous”, or substrate-free, surface covering.

Owner:TARKETT INC

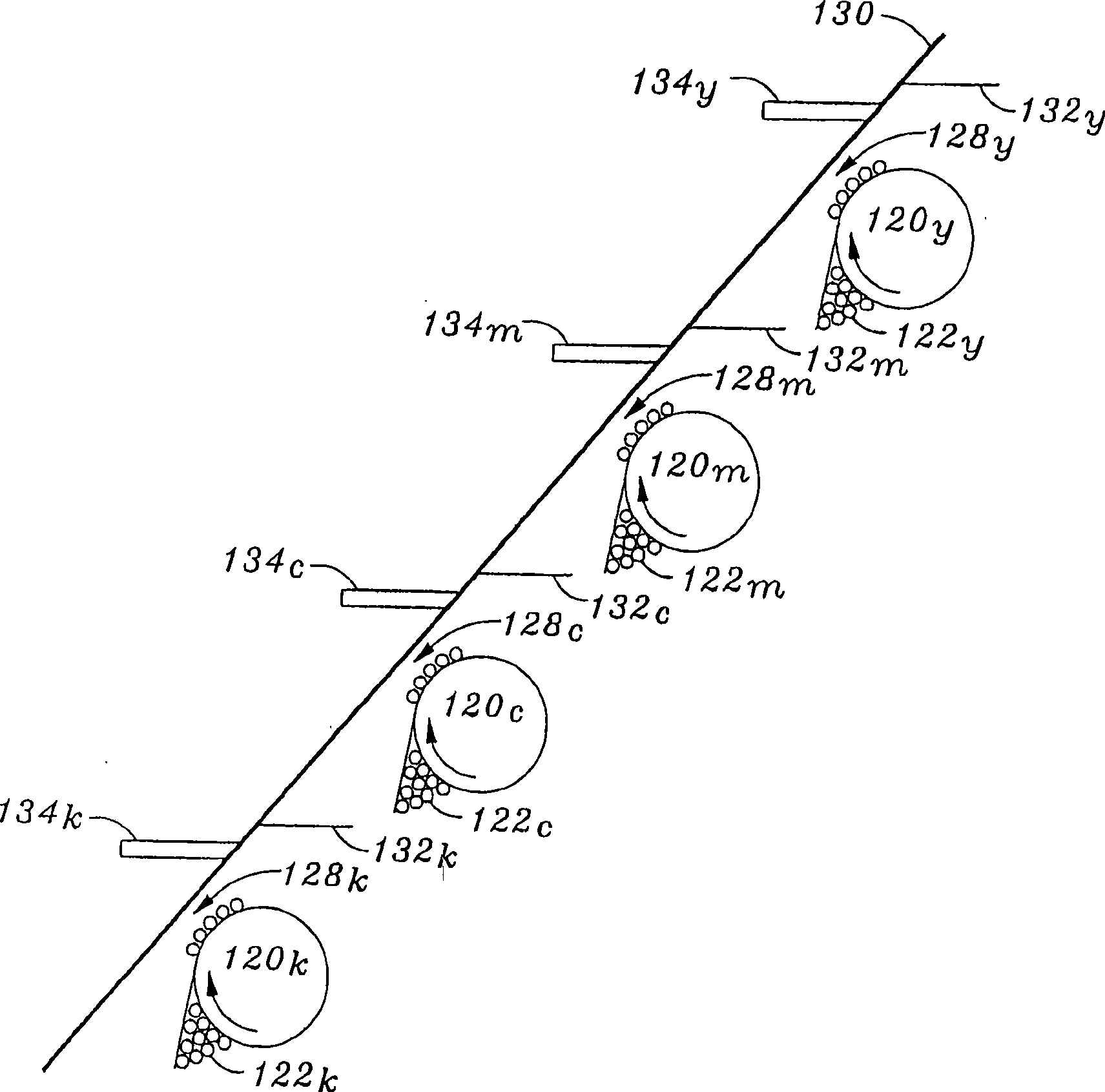

Method of using variably sized coating particles in mono component developing system

The present invention is directed to a non-contact, single-component developing system for electrophotographic machines that effectively reduces the impact of adhesion forces on the development process. The developing system of the present invention utilizes a single-component toner that tends to reduce the adhesion forces that hold the toner particles on a toner support member. Preferably, the toner is combined with large and small silica particles having a concentration by weight that results in an optimum surface coverage of toner particles by large and small silica particles that facilitates a reduction in the adhesion forces holding the toner particles on the toner support member.

Owner:AETAS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com