Porous material substrate used in GaN film grown by HVPE method and method thereof

A porous material and substrate technology, which is applied in the field of silicon-based composite nanoporous material substrate and its preparation, can solve the problems of difficult nano-GaN voids and sapphire substrate peeling difficulties, so as to reduce the dislocation density and improve the available Sexuality, the effect of improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

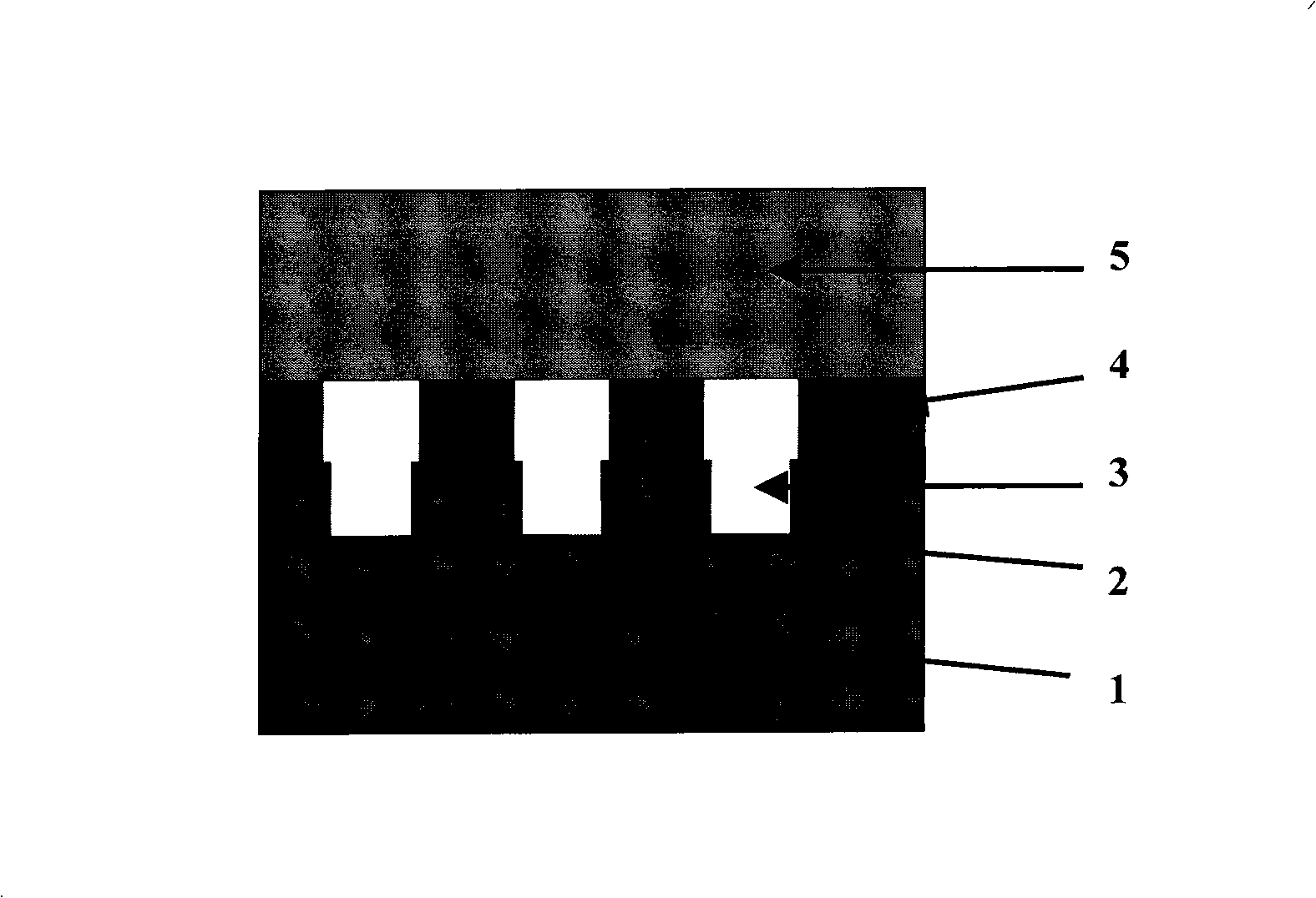

[0019] First grow a layer of GaN film on the Si substrate as a template, and then deposit a thin layer of metal Al with a thickness of about 1 μm on the template by electron beam evaporation, and then put the template with the thin layer of metal Al into the oxalic acid solution ( 0.3mol / L), at room temperature using a voltage of 40 volts for anodization for 40 minutes, and then soak the template in phosphoric acid solution (5wt%) for 30 minutes to remove the part of the aluminum oxide at the bottom of the hole that is in contact with the lower layer of GaN, and then use ICP etc. Dry etching technology, etch to obtain porous GaN material, so that the bottom of the hole is exposed to the surface of the Si substrate; on this basis, use corrosion or electrochemical methods to achieve corrosion of Si and obtain a composite nanoporous structure; then through Surface treatment such that the surface of Si is covered with SiN x or SiO 2 layer to meet the subsequent epitaxial growth r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com