Method of using variably sized coating particles in mono component developing system

A developing system, a single-component technology, applied in the direction of equipment, developer, electrorecording process applying charge pattern, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The non-contact single component development system of the present invention tends to facilitate efficient development of electrostatic images and consistently produce high quality output images. More specifically, the system of the present invention tends to reduce the adhesion force that keeps toner particles on the toner support member, allowing toner particles to jump more easily and efficiently from the toner support member to, for example, on an image bearing member such as a photoreceptor.

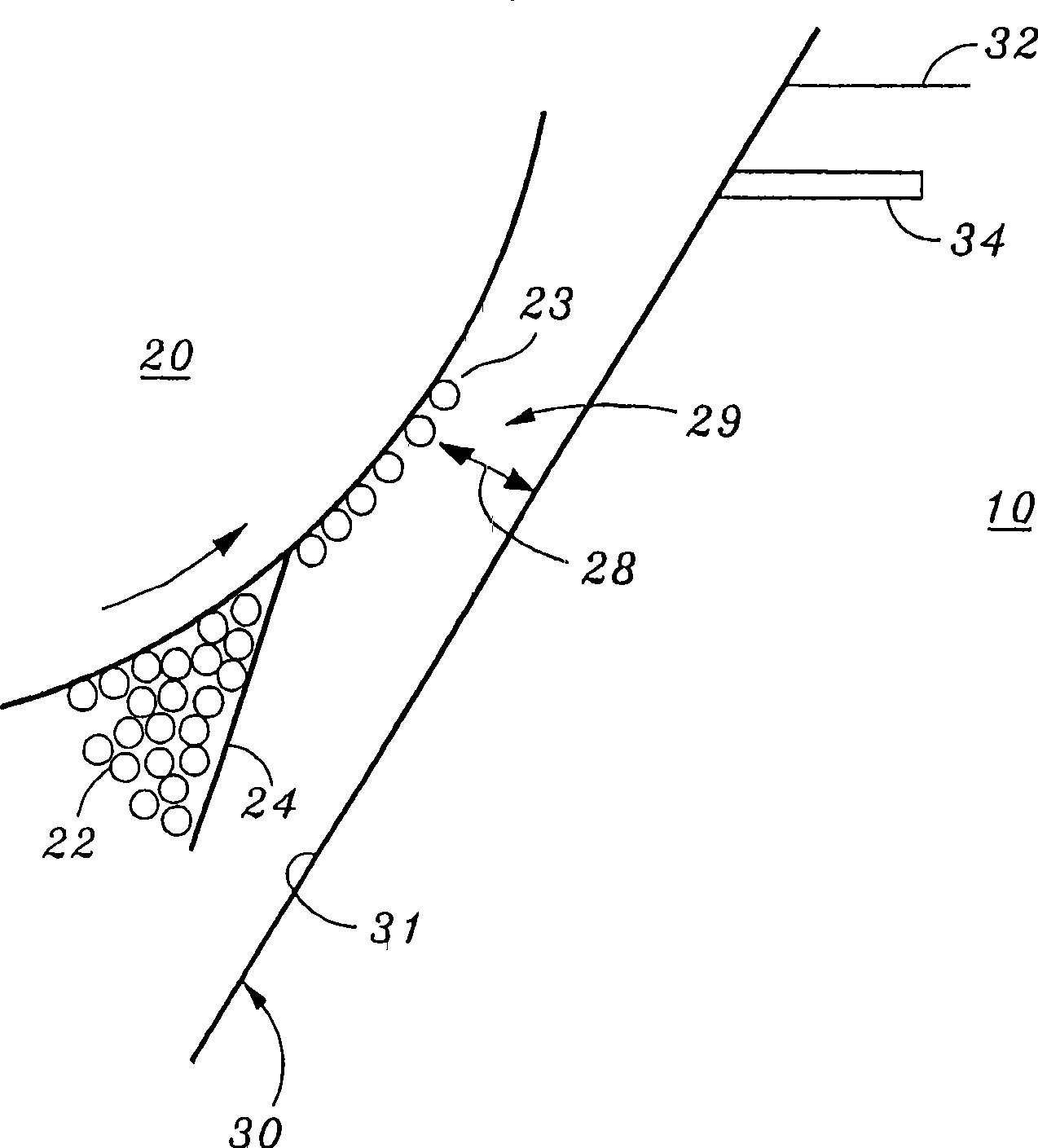

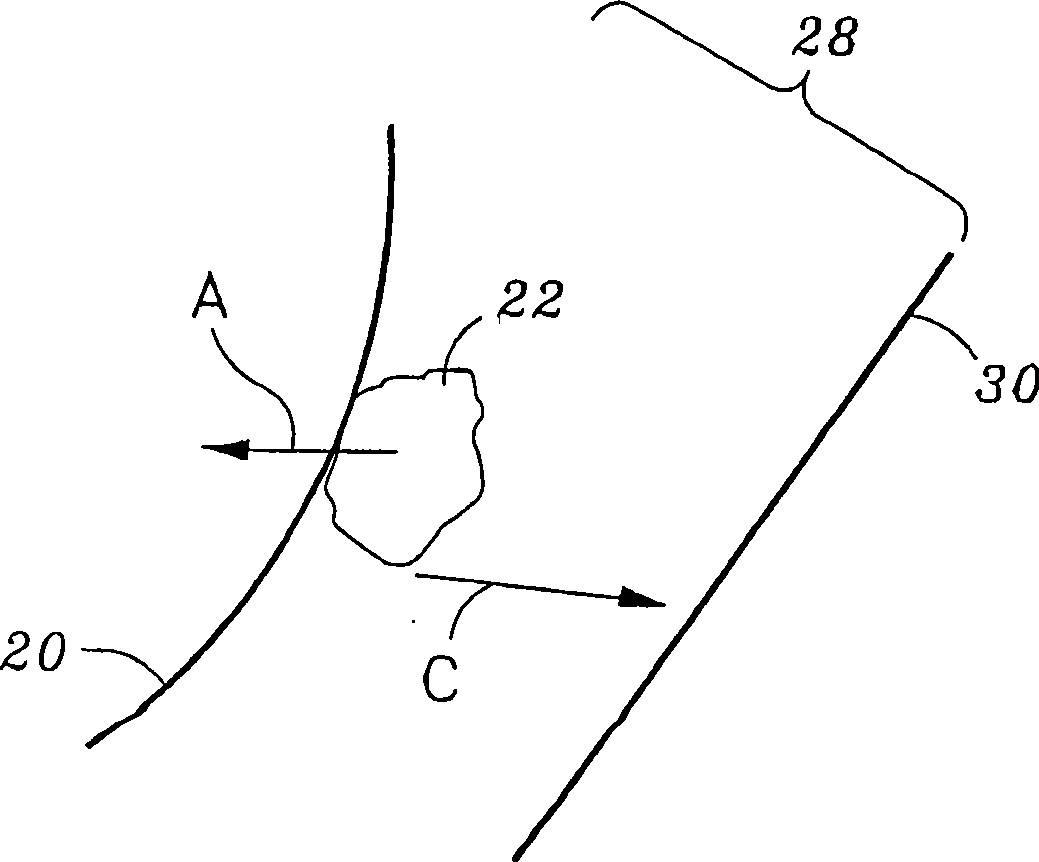

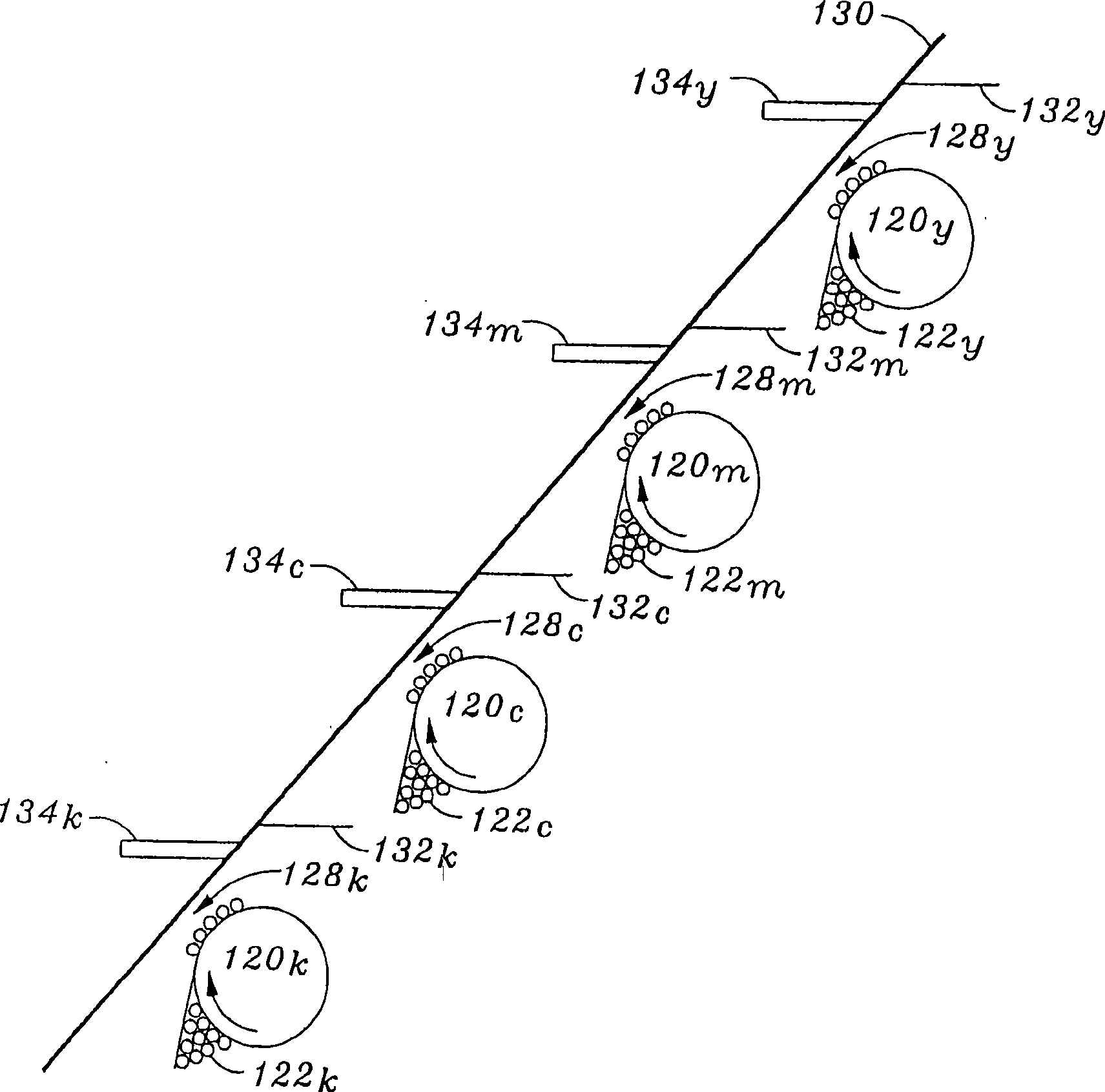

[0029] Refer to the accompanying drawings for details, figure 1 Shown is a non-contact or pop-up development system 10 for use with monocomponent toners in accordance with the present invention. The developing system 10 preferably includes a toner supporting member 20 such as a roller and a photosensitive body 30 such as a photosensitive drum or belt. Toner roll 20 and photoreceptor 30 are aligned in a spaced relationship to form a gap 28 at a “developing zone” 29 . Gap 28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com