Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49 results about "Xerography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Xerography or electrophotography is a dry photocopying technique. Its fundamental principle was invented by American physicist Chester Carlson and based on Hungarian physicist Pál Selényi's publications. Chester Carlson applied for and was awarded U.S. Patent 2,297,691 on October 6, 1942. The technique was originally called electrophotography. It was later renamed xerography—from the Greek roots ξηρός xeros, "dry" and -γραφία -graphia, "writing"—to emphasize that, unlike reproduction techniques then in use such as cyanotype, this process used no liquid chemicals.

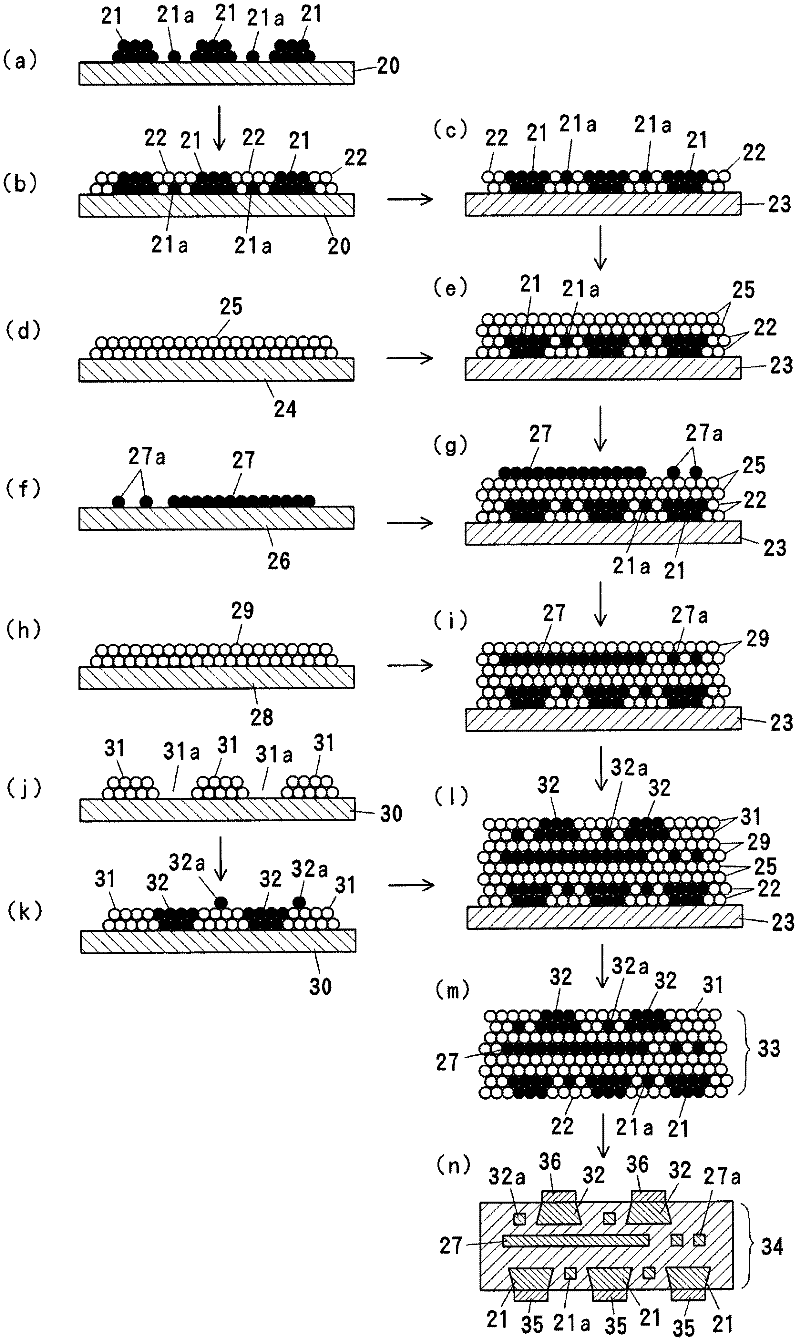

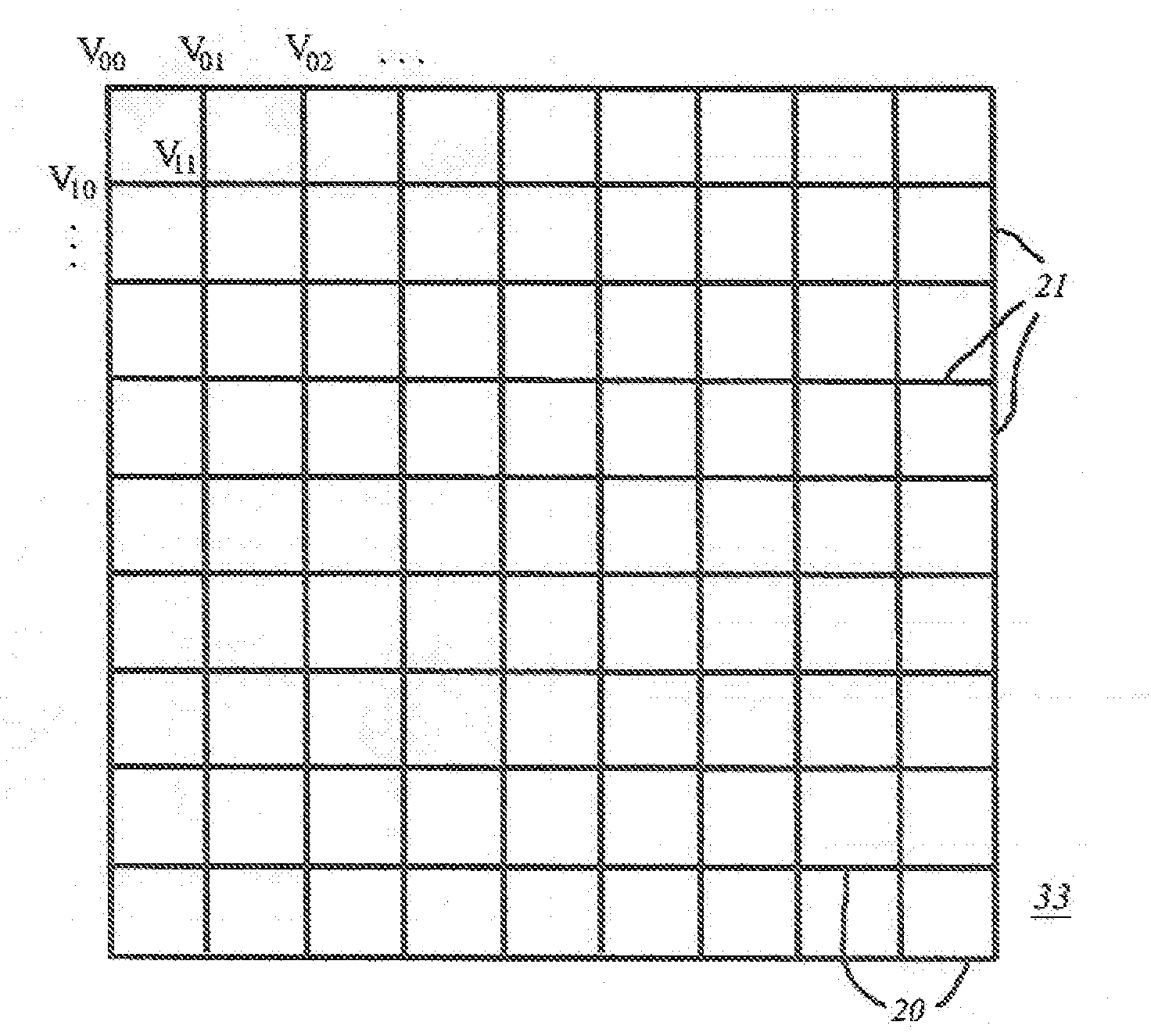

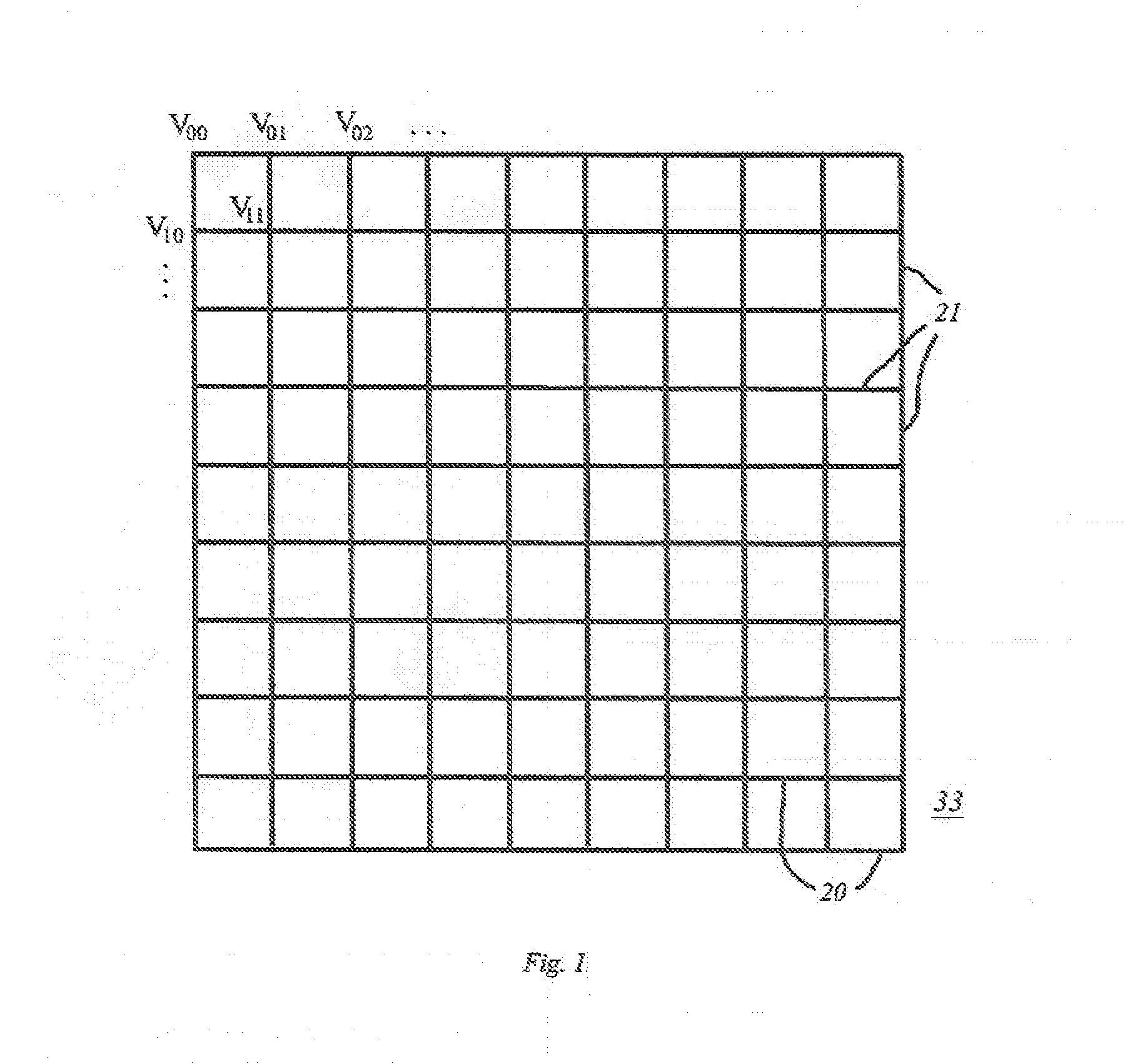

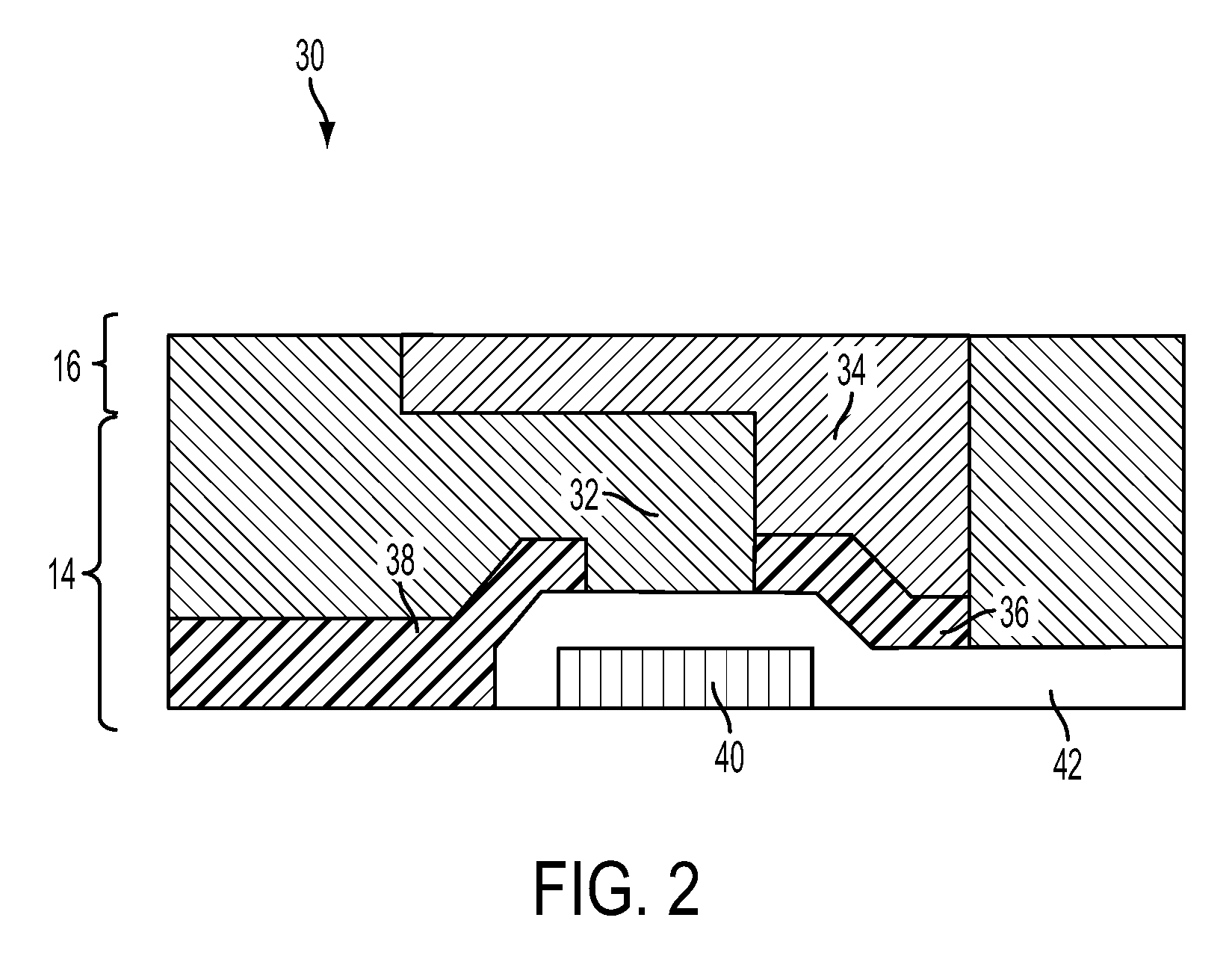

Xerographic micro-assembler

ActiveUS7332361B2Semiconductor/solid-state device testing/measurementSolid-state devicesObject basedImage transfer

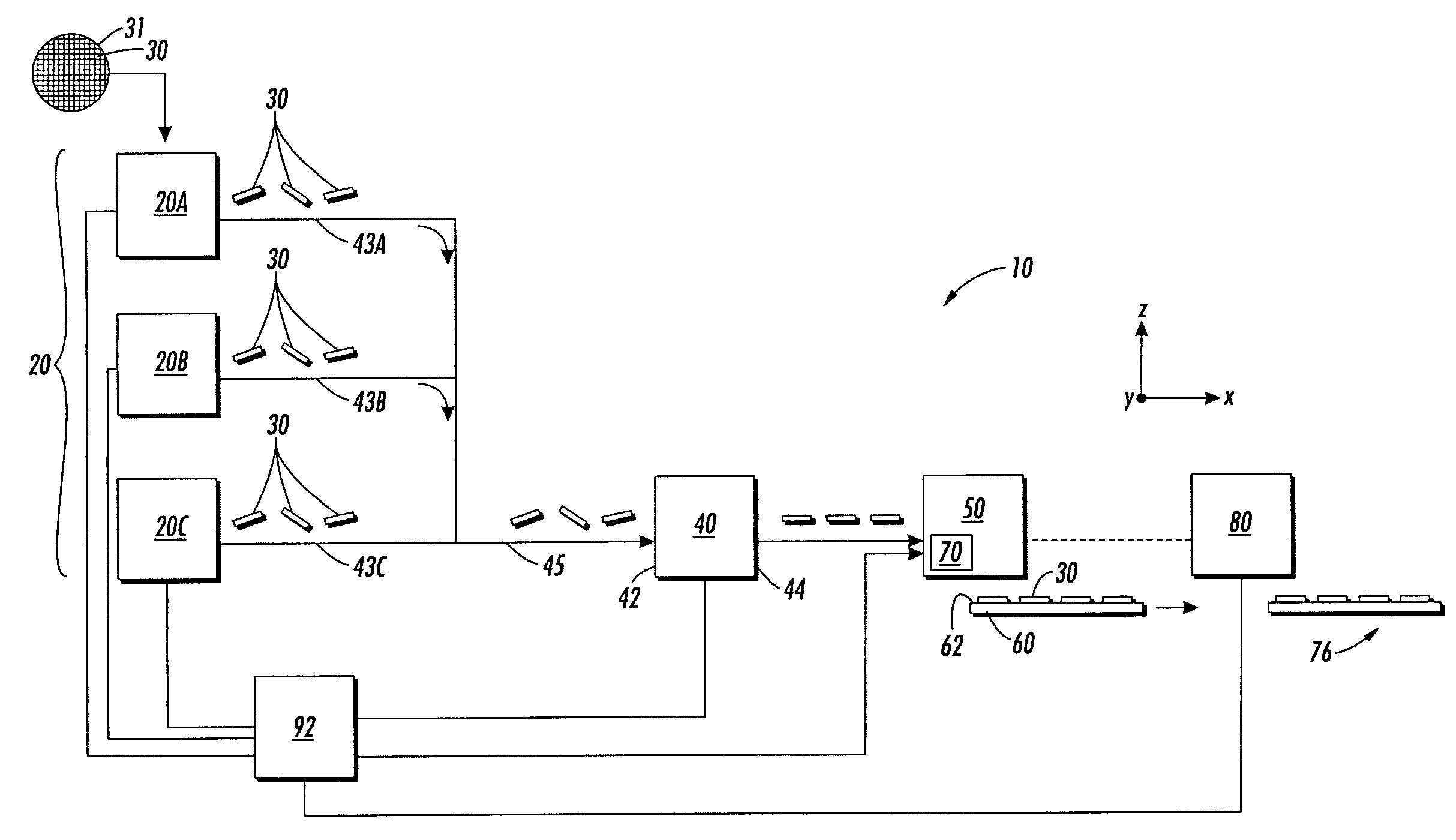

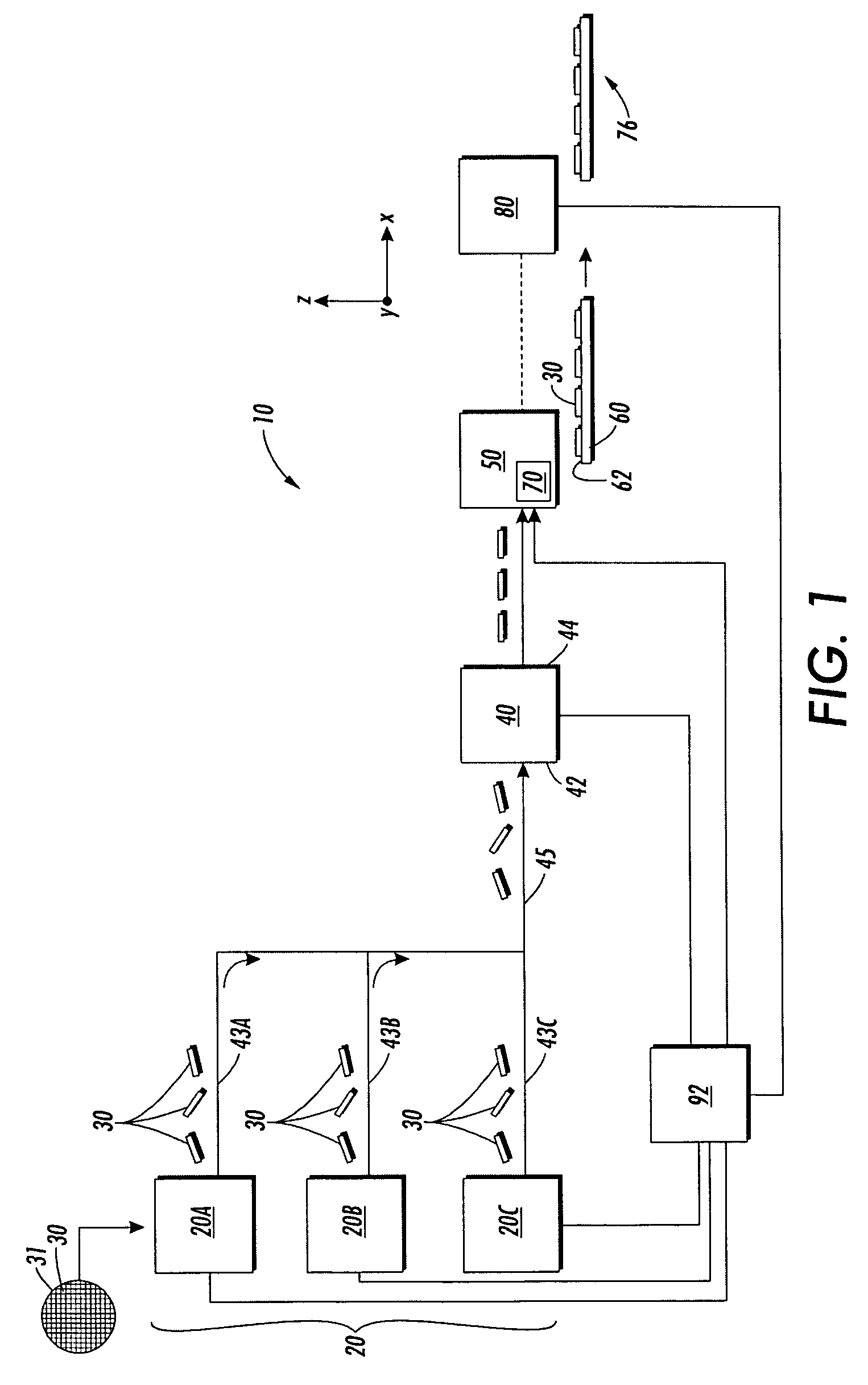

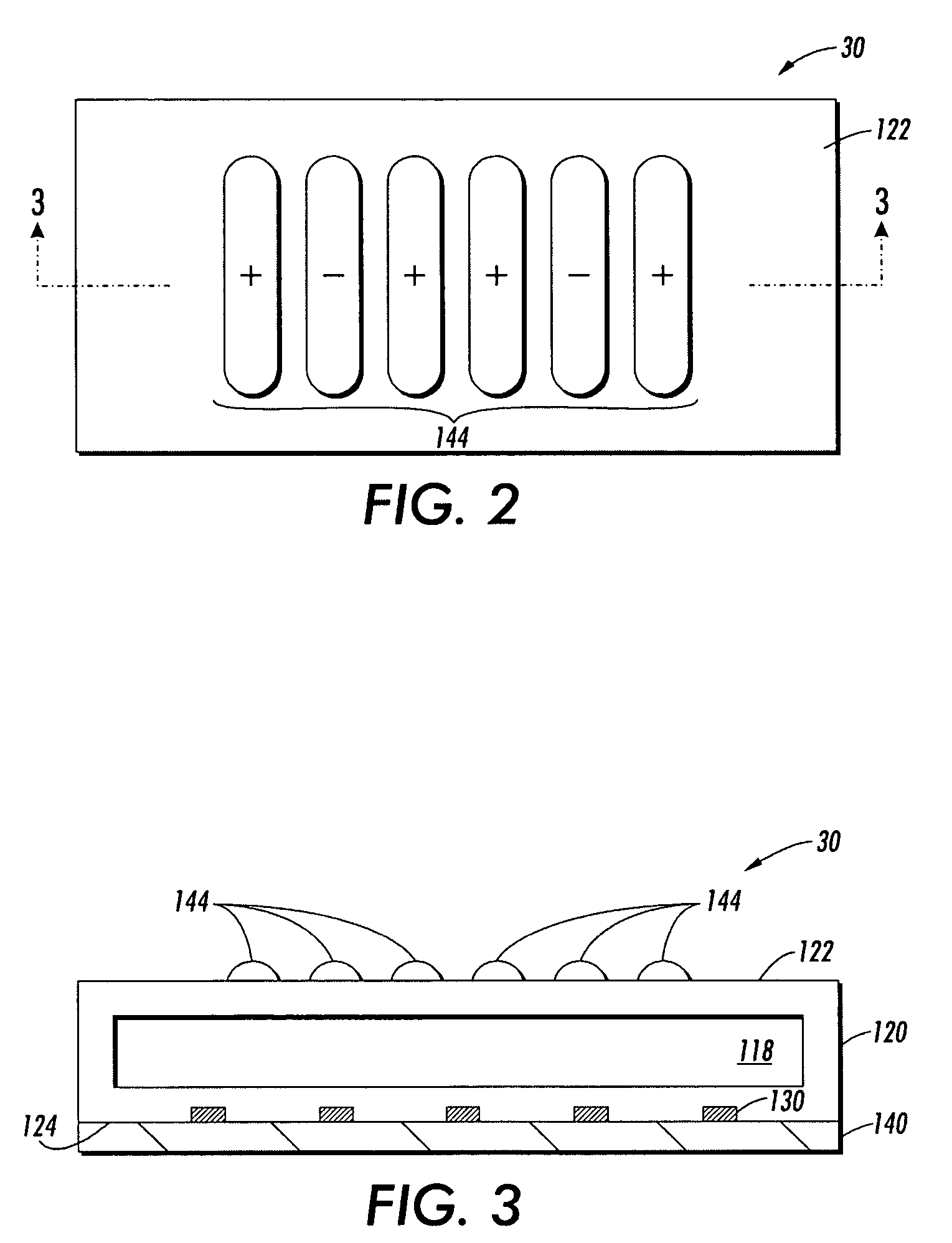

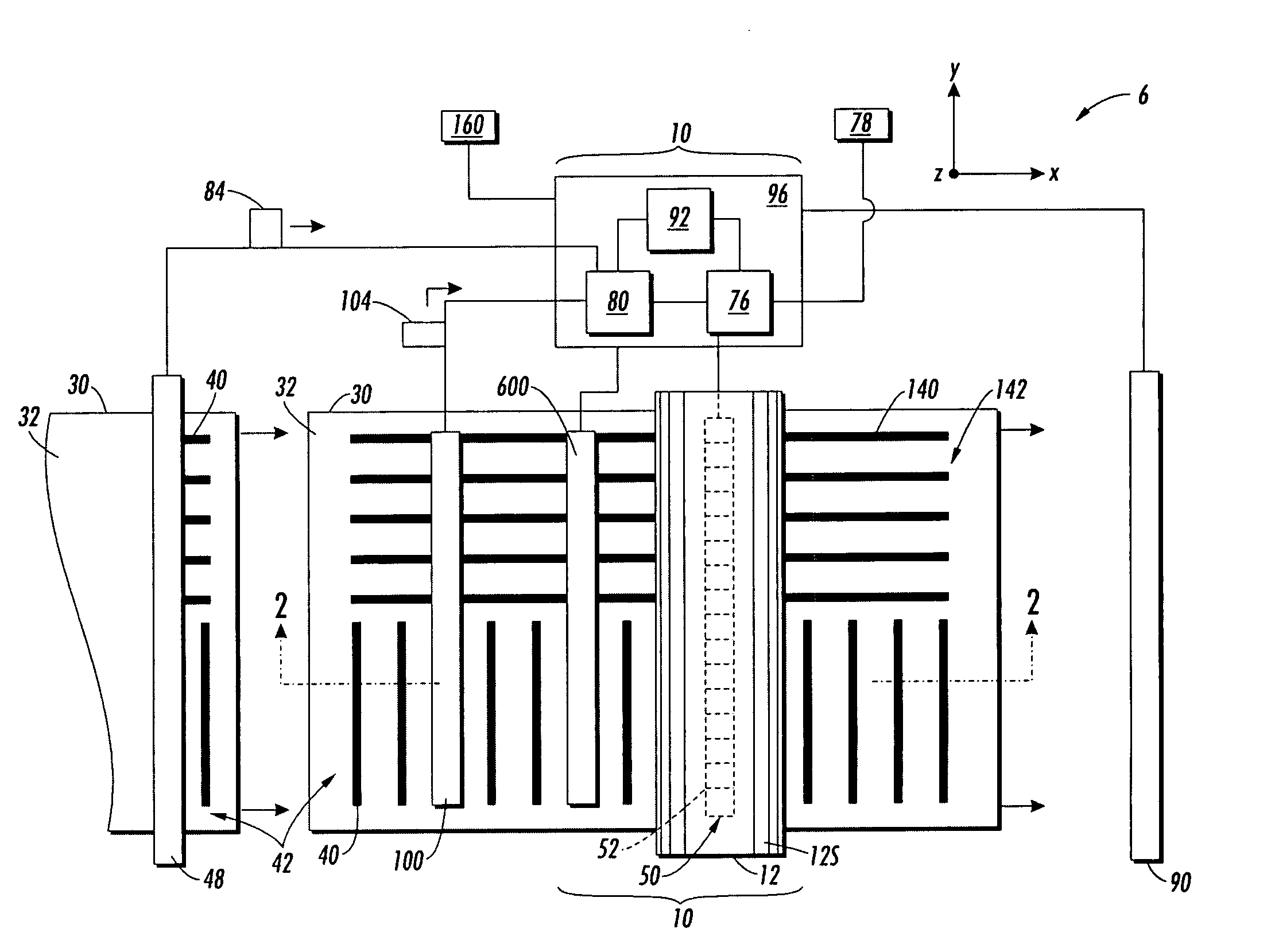

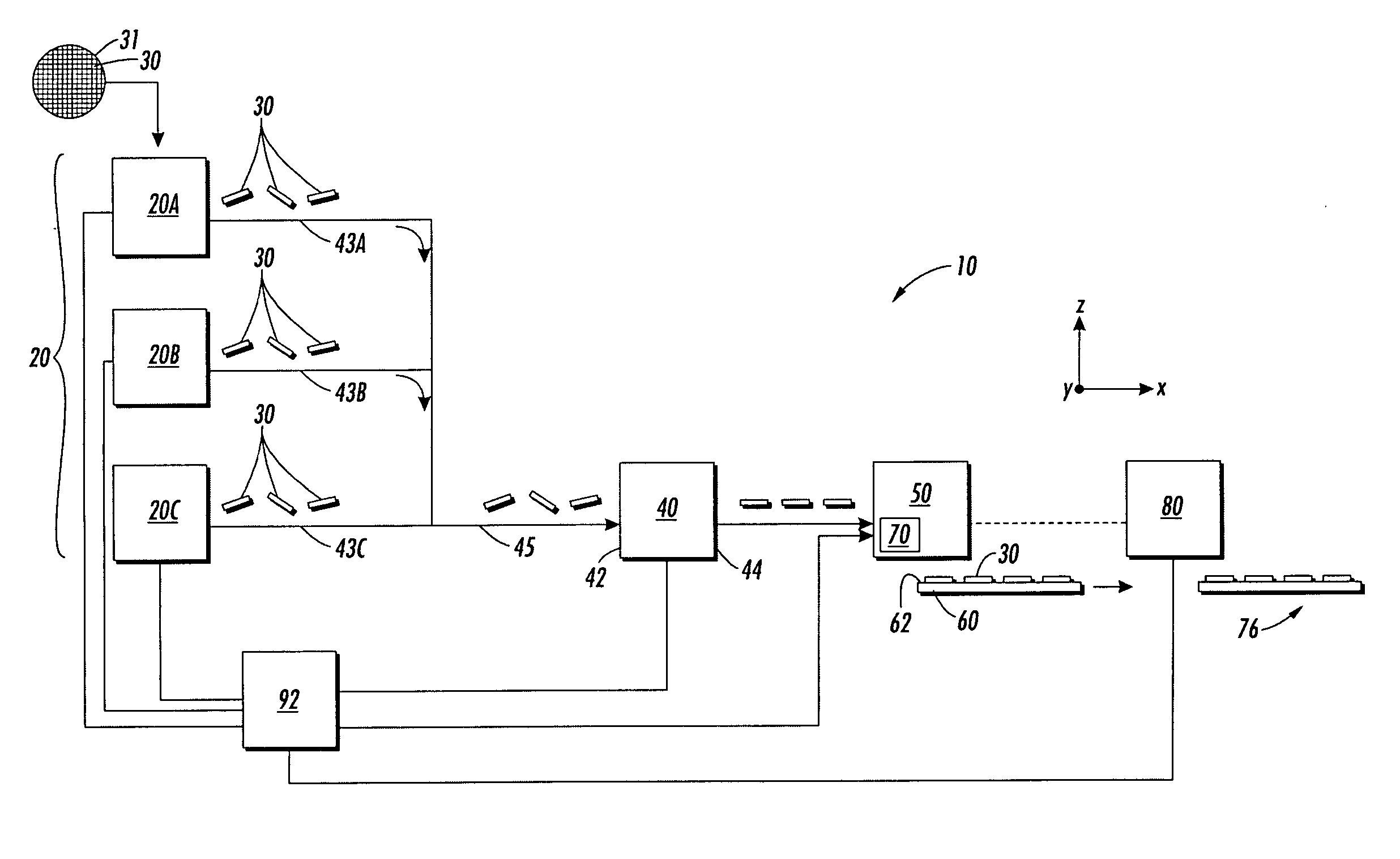

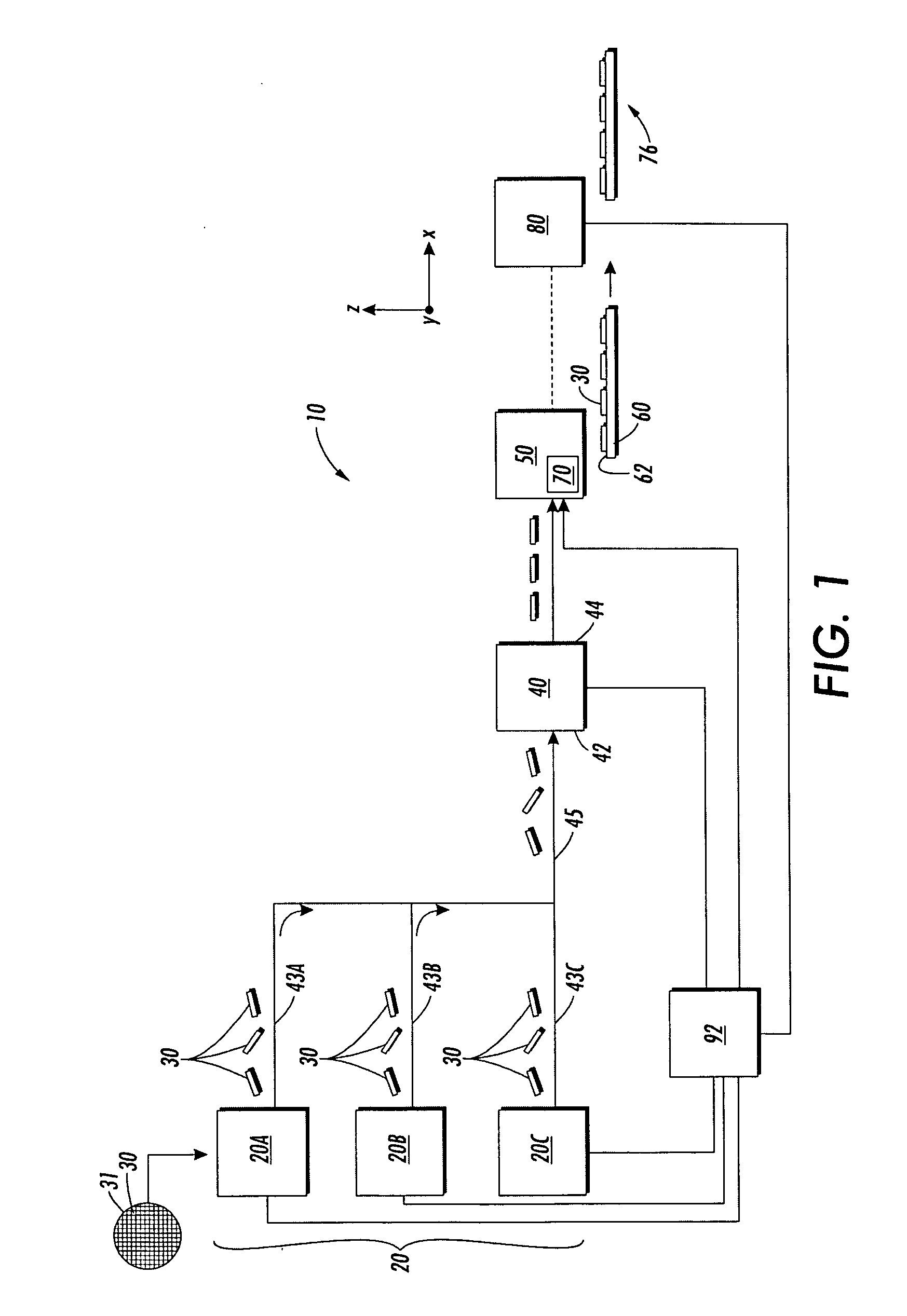

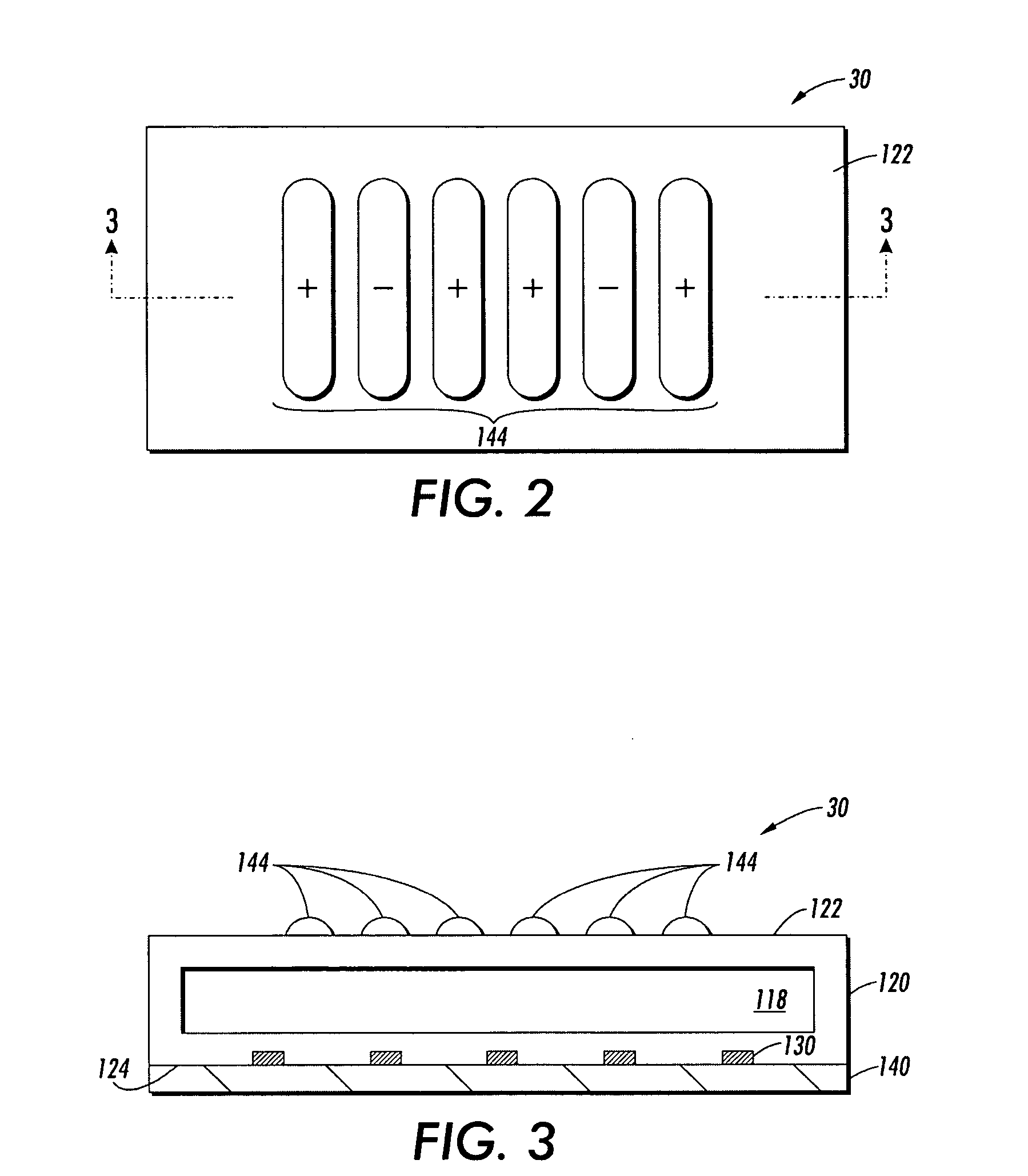

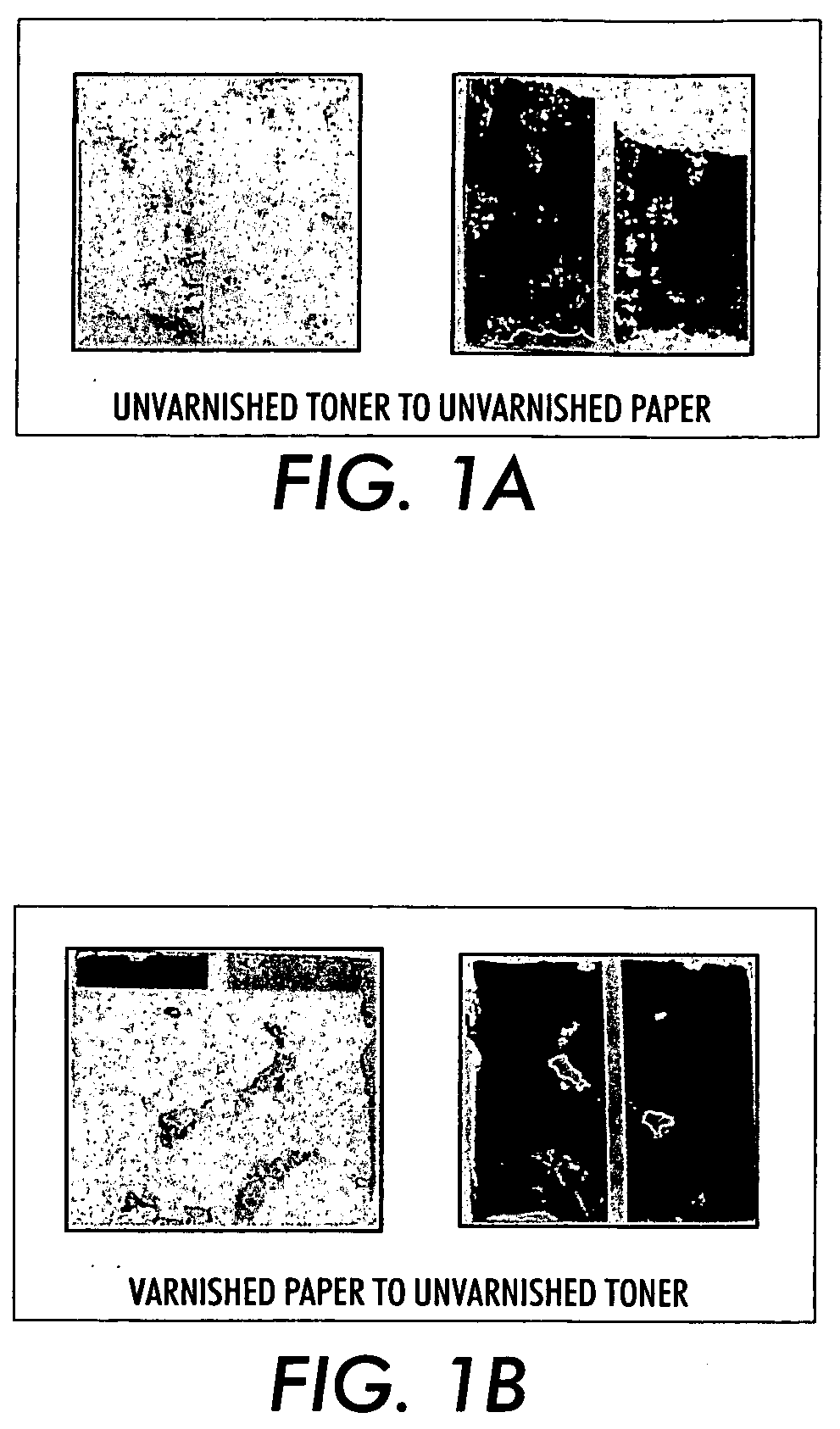

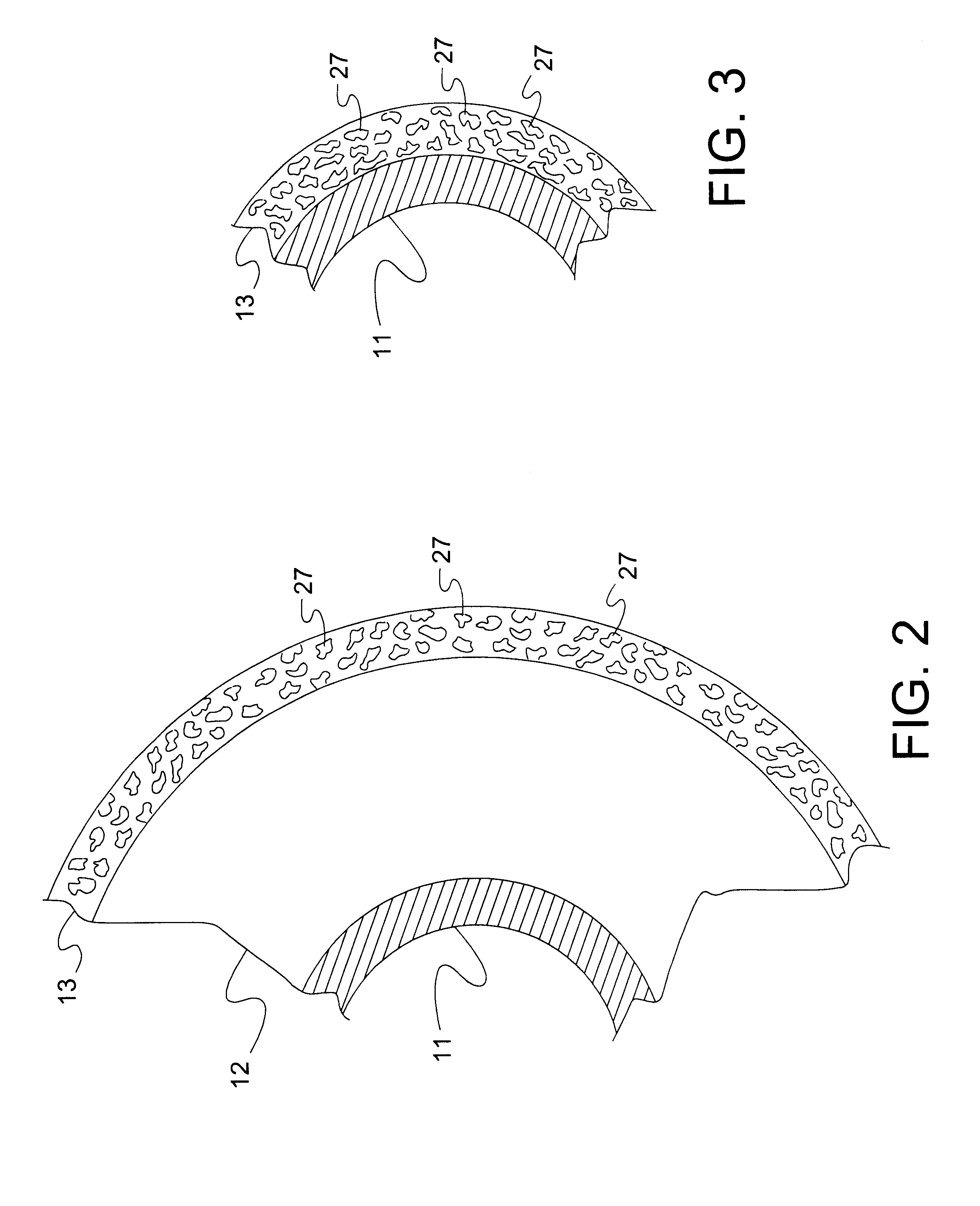

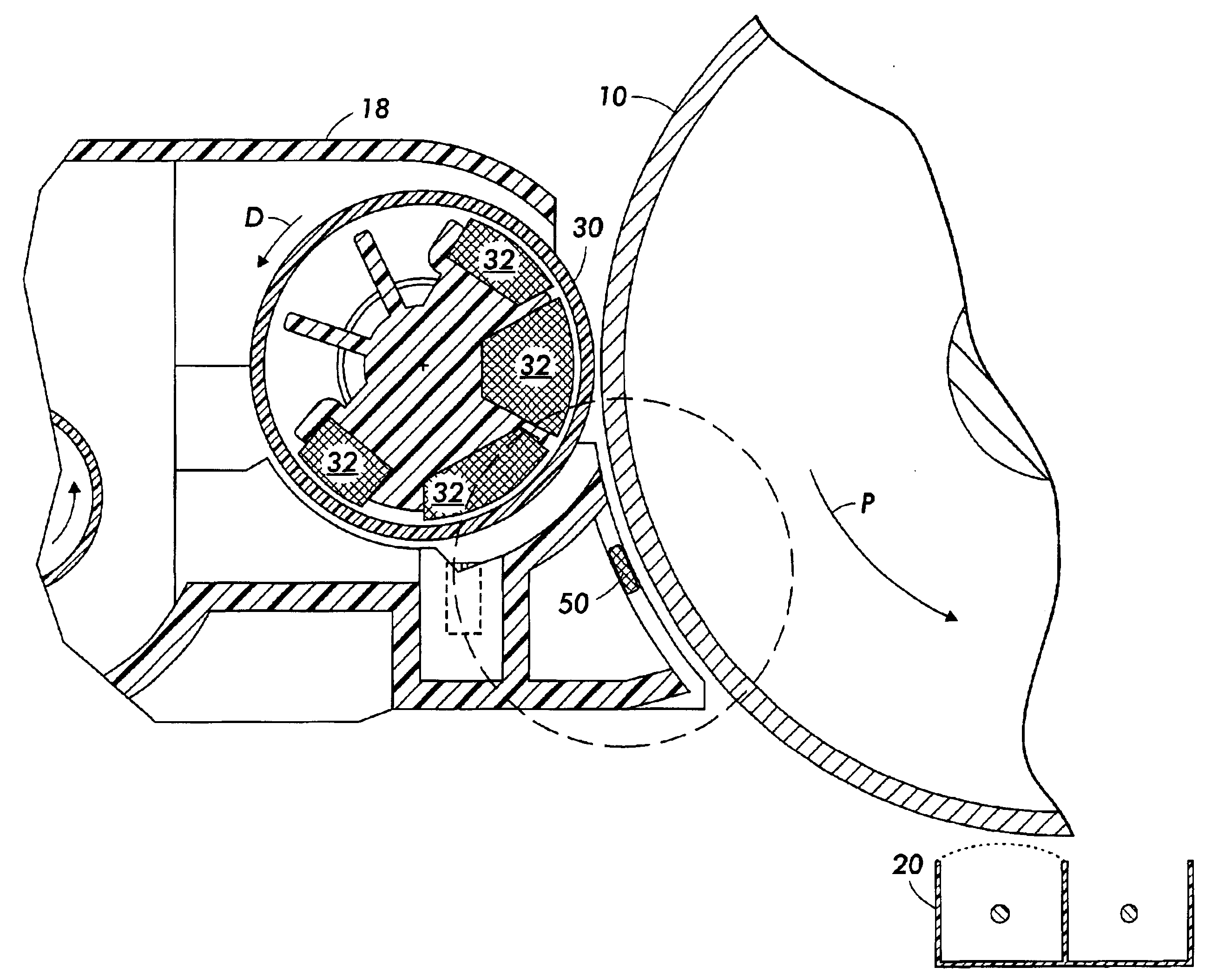

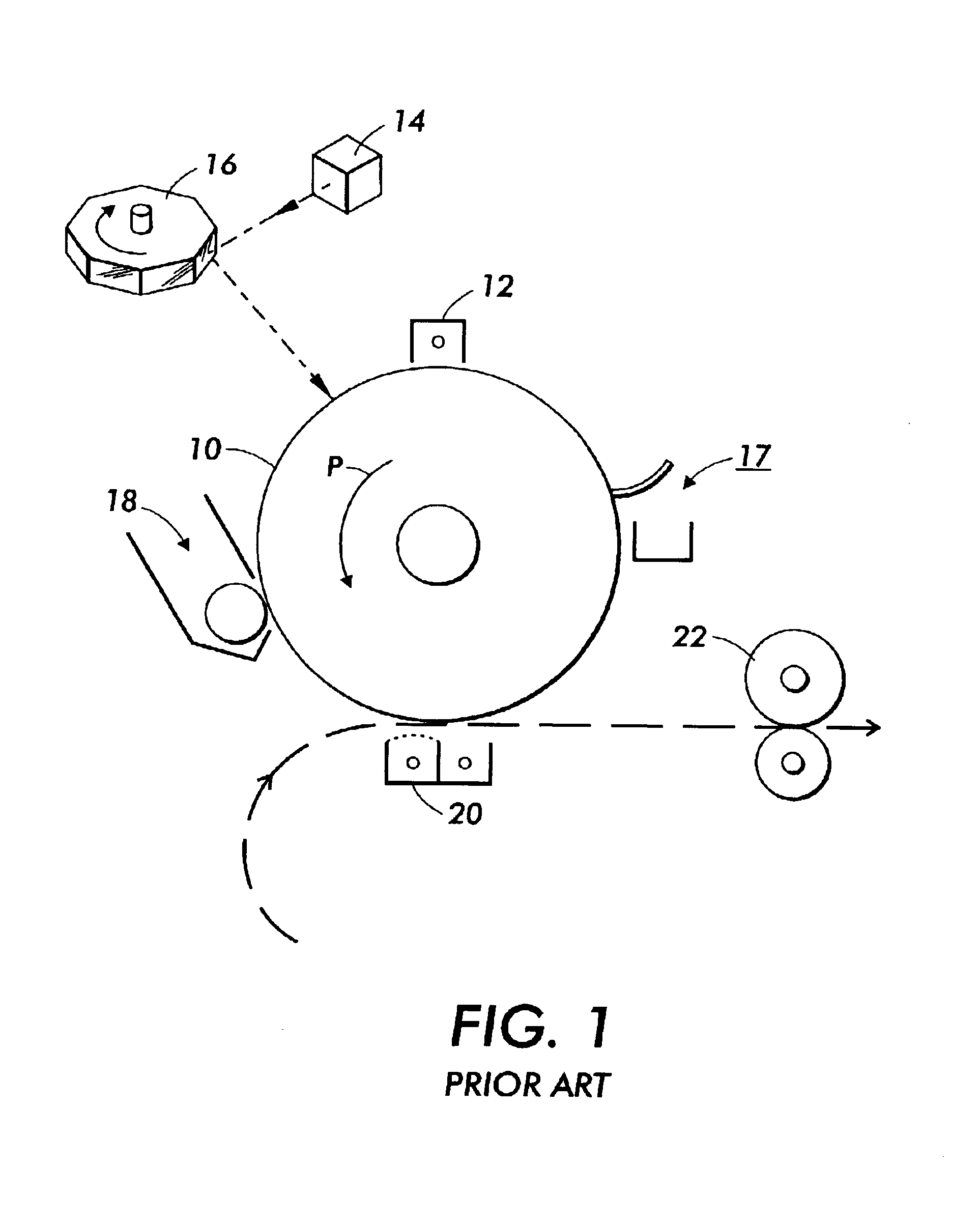

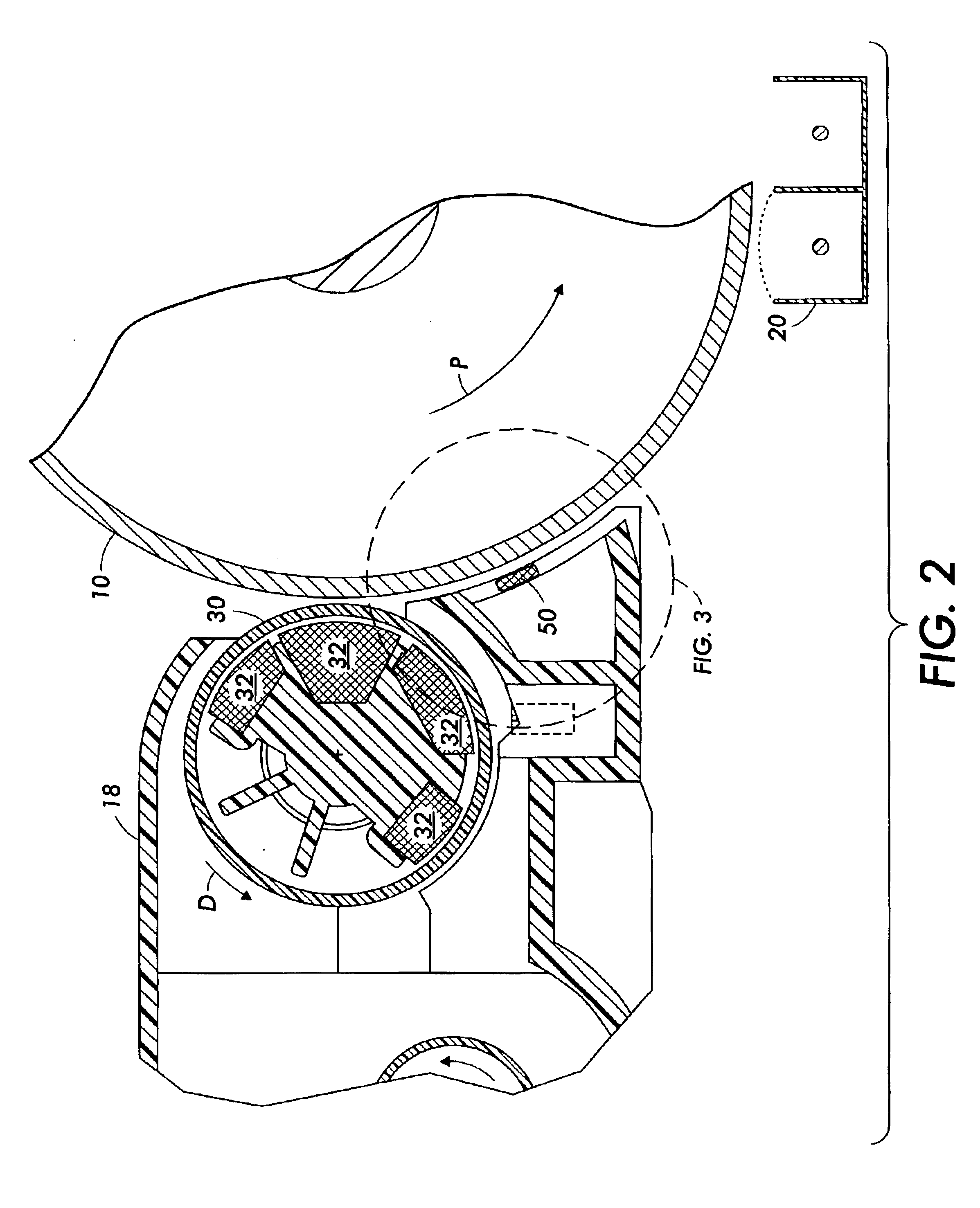

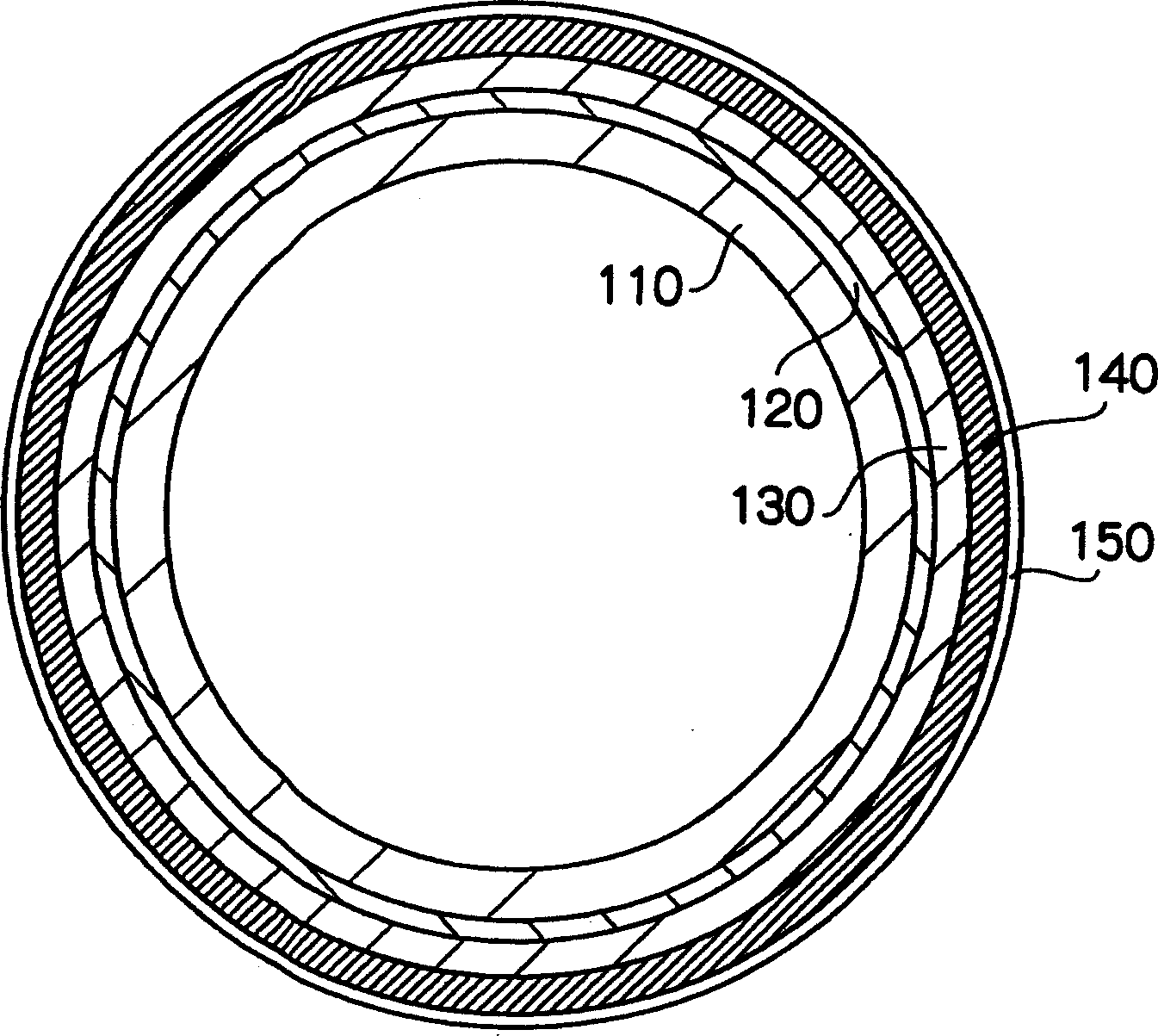

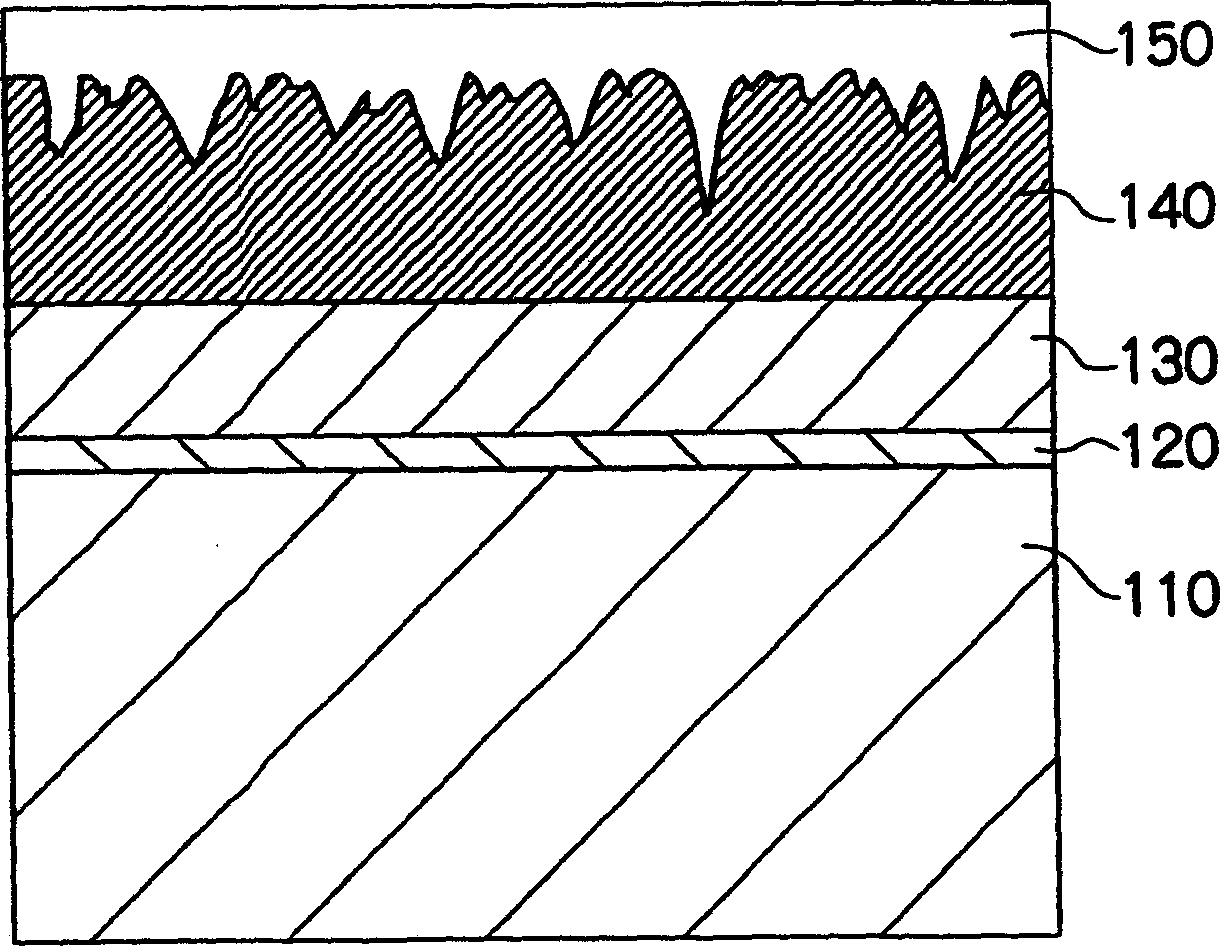

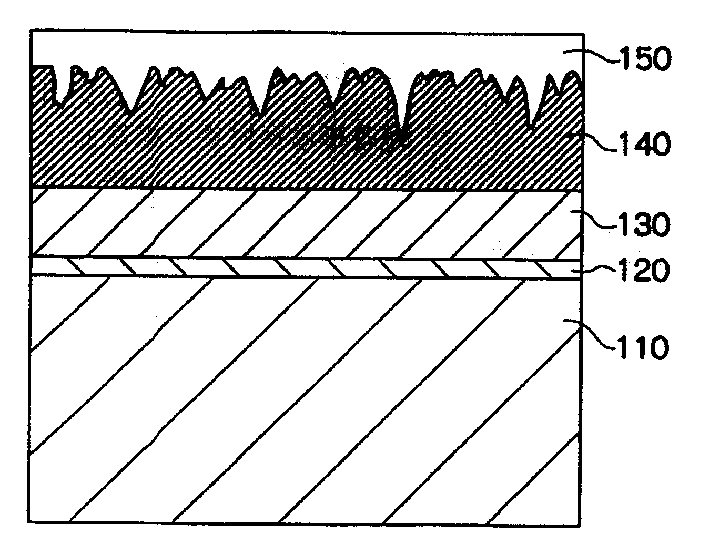

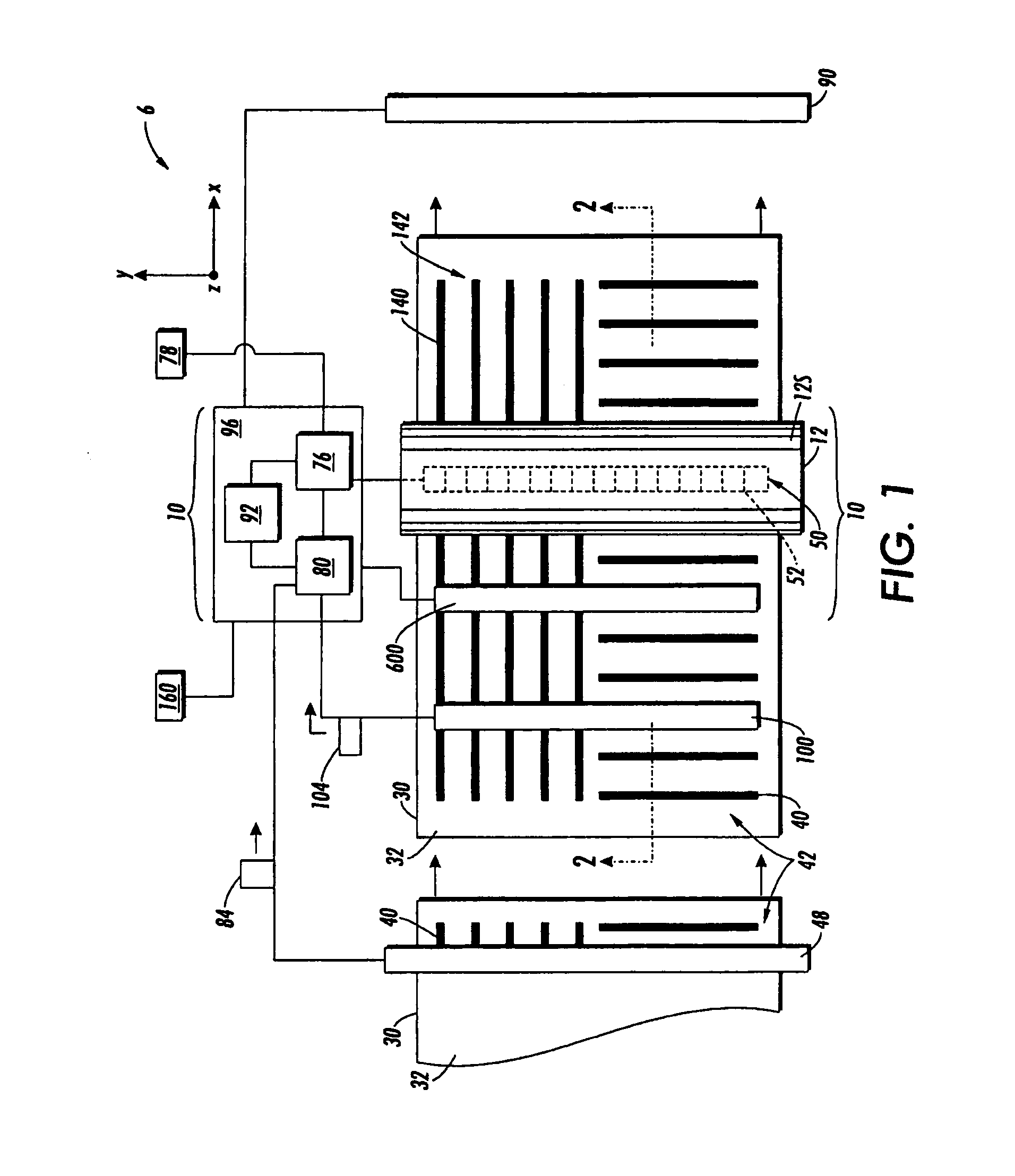

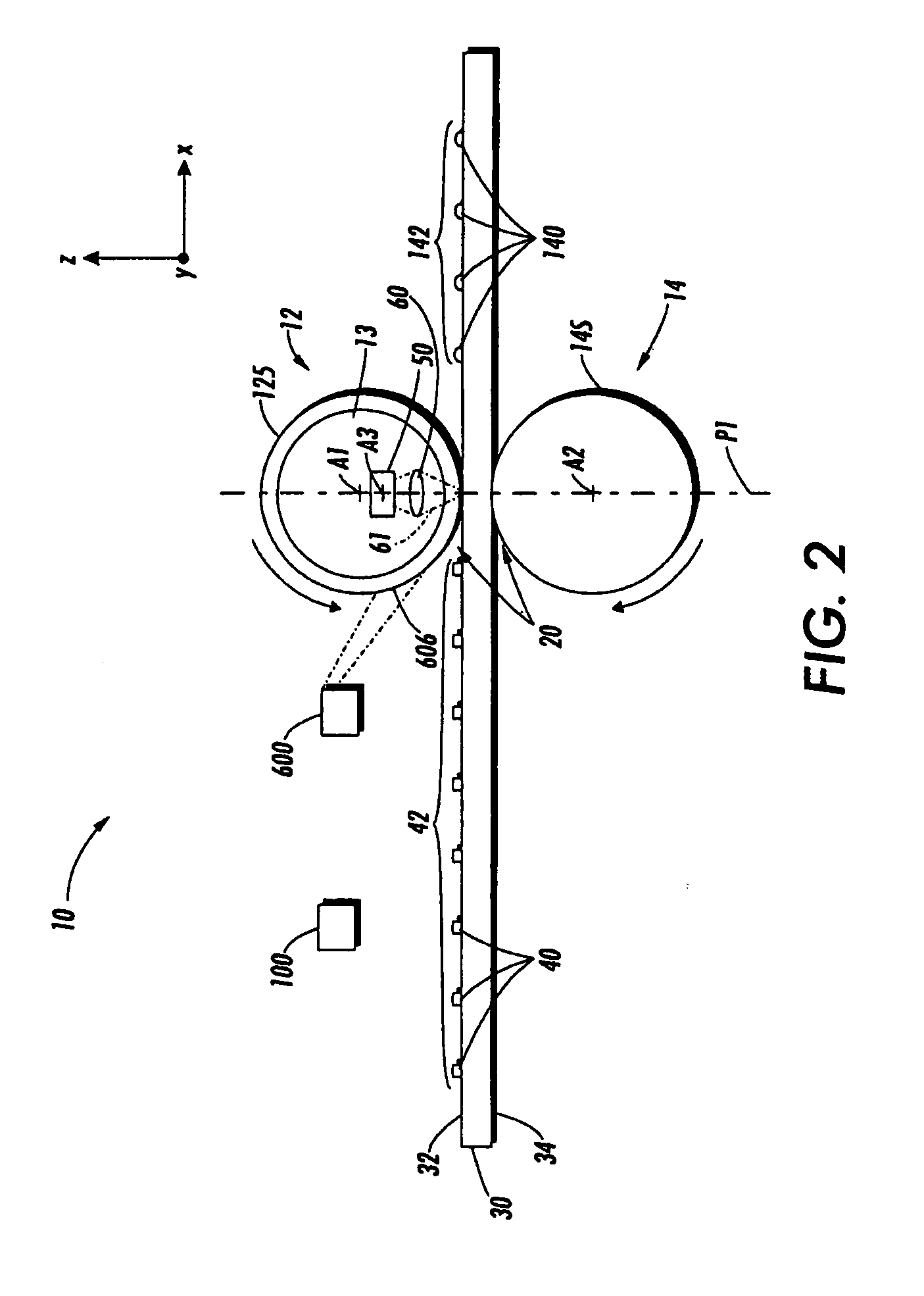

Xerographic micro-assembler systems and methods are disclosed. The systems and methods involve manipulating charge-encoded micro-objects. The charge encoding identifies each micro-object and specifies its orientation for sorting. The micro-objects are sorted in a sorting unit so that they have defined positions and orientations. The sorting unit has the capability of electrostatically and magnetically manipulating the micro-objects based on their select charge encoding. The sorted micro-objects are provided to an image transfer unit. The image transfer unit is adapted to receive the sorted micro-objects, maintain them in their sorted order and orientation, and deliver them to a substrate. Maintaining the sorted order as the micro-objects are delivered to the substrate may be accomplished through the use of an electrostatic image, as is done in xerography. The substrate with the micro-objects is further processed to interconnect the micro-objects—through electrical wiring, for example—to form the final micro-assembly.

Owner:XEROX CORP

Improved xerography methods and systems

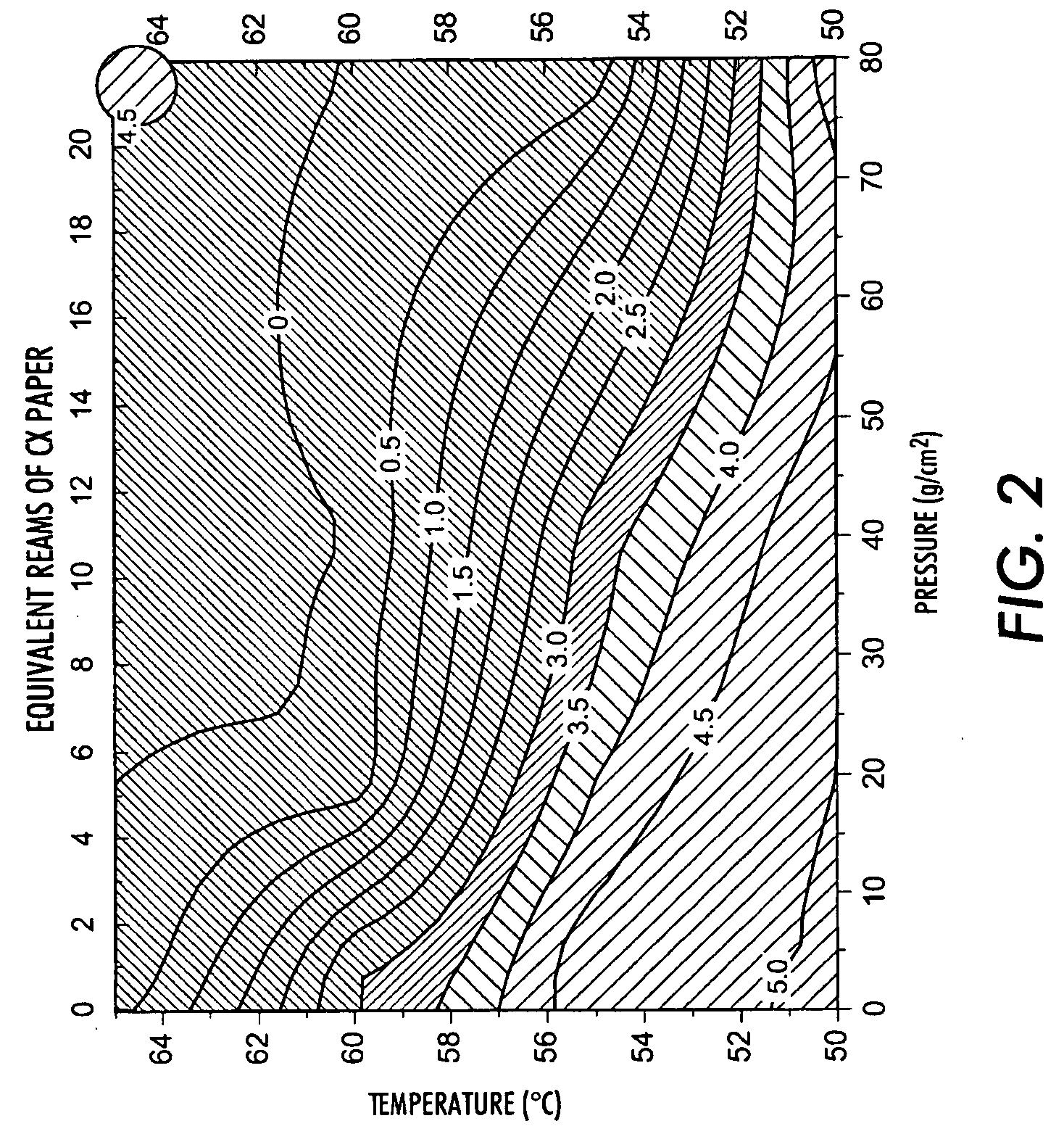

ActiveUS20060115305A1Ohmic-resistance heatingElectrographic process apparatusSurface finishXerography

Methods and apparatus for performing addressable fusing and / or heating of a substrate undergoing xerographic processing are disclosed. The apparatus includes a fuser having an array of addressable heating elements in radiative communication with a substrate through a fuser roll or fuser belt. The array of addressable heating elements is operated to selectively heat portions of the substrate to achieve a desired effect on the substrate, such as changing its surface finish, or fusing unfused toner to the substrate. In the case of toner fusing, the array is operated such that substantially only an area covered by the unfused toner is heated. This eliminates the need for blanket fusing, and generally provides for greater flexibility in xerographically processing substrates. Apparatus and methods for performing two-sided selective fusing and / or heating are also disclosed.

Owner:XEROX CORP

Xerographic micro-assembler

Xerographic micro-assembler systems and methods are disclosed. The systems and methods involve manipulating charge-encoded micro-objects. The charge encoding identifies each micro-object and specifies its orientation for sorting. The micro-objects are sorted in a sorting unit so that they have defined positions and orientations. The sorting unit has the capability of electrostatically and magnetically manipulating the micro-objects based on their select charge encoding. The sorted micro-objects are provided to an image transfer unit. The image transfer unit is adapted to receive the sorted micro-objects, maintain them in their sorted order and orientation, and deliver them to a substrate. Maintaining the sorted order as the micro-objects are delivered to the substrate may be accomplished through the use of an electrostatic image, as is done in xerography. The substrate with the micro-objects is further processed to interconnect the micro-objects—through electrical wiring, for example—to form the final micro-assembly.

Owner:XEROX CORP

Special pigment finishing offset paper and producing method thereof

InactiveCN1584205AReduce particle contentIncrease bulkNon-fibrous pulp additionCoatings with pigmentsGreen environmentXerography

This invention discovers a special pigment groom hectograph paper and its preparation. It utilizes the advantages of high yields machine pulp (PRC-APMP) and deink pulp (DIP) which is well thickness and green environment. That is optimizing pigment spreading formulation, optimizing pulp to materials ratio and its wet end chemical and copy making technique to reach the white value of all bleaching chemical pulp proportioning copy paper. The advantages of the products are: better printing adaptability, better relaxation thickness, better printing effect features compared with all chemical pulp hectograph paper. It's capable of producing top grade office and printing culture special pigment groom hectograph paper which is made according to different clients' requirement and selecting different optimized features' technique for different application such as laser printing, xerography and hectograph etc. So, it's capable of decreasing all chemical pulp quantity, saving wood, protecting forest, protecting environment from pollution.

Owner:YUEYANG FOREST & PAPER CO LTD

Overprint compositions for xerographic prinits

InactiveUS20050250039A1Reduce document offsetReduce and prevent thermal crackingOptical articlesElectrographic process apparatusOligomerMedicine

Radiation curable overprint compositions containing a radiation curable oligomer / monomer, at least one photoinitiator, and at least one surfactant are disclosed. The overprint compositions are particularly well-suited for reducing or preventing document offset and for protecting xerographic images on substrates subjected to abrasives, heat, and / or sunlight since the compositions protect such images from cracking, fading, and smearing.

Owner:XEROX CORP

UV Red Fluorescent EA Toner

ActiveUS20140197364A1High fluorescence pigment loadingNarrow size distributionInksDevelopersLanthanideRed fluorescence

The present disclosure relates to a toner design for a clear UV red fluorescence toner having a high lanthanide complex pigment loading, including methods of making the fluorescence toner using a saccharide or a sugar acid to avoid complexation of lanthanide ions from the pigment, with lower aggregation and coalescence temperatures in the preparation of toner particles, where the particles exhibit a narrow size distribution and good xerographic performance.

Owner:XEROX CORP

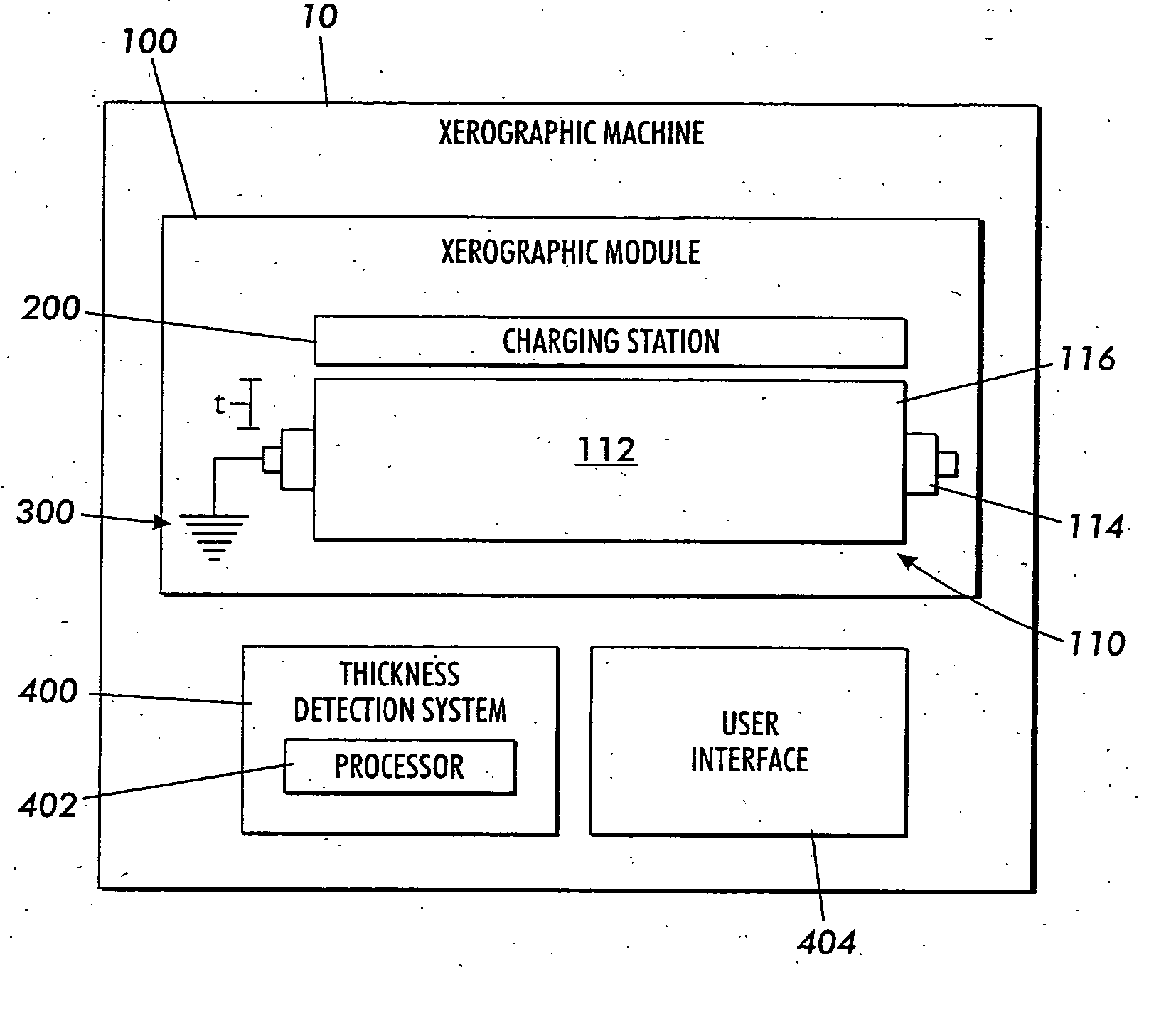

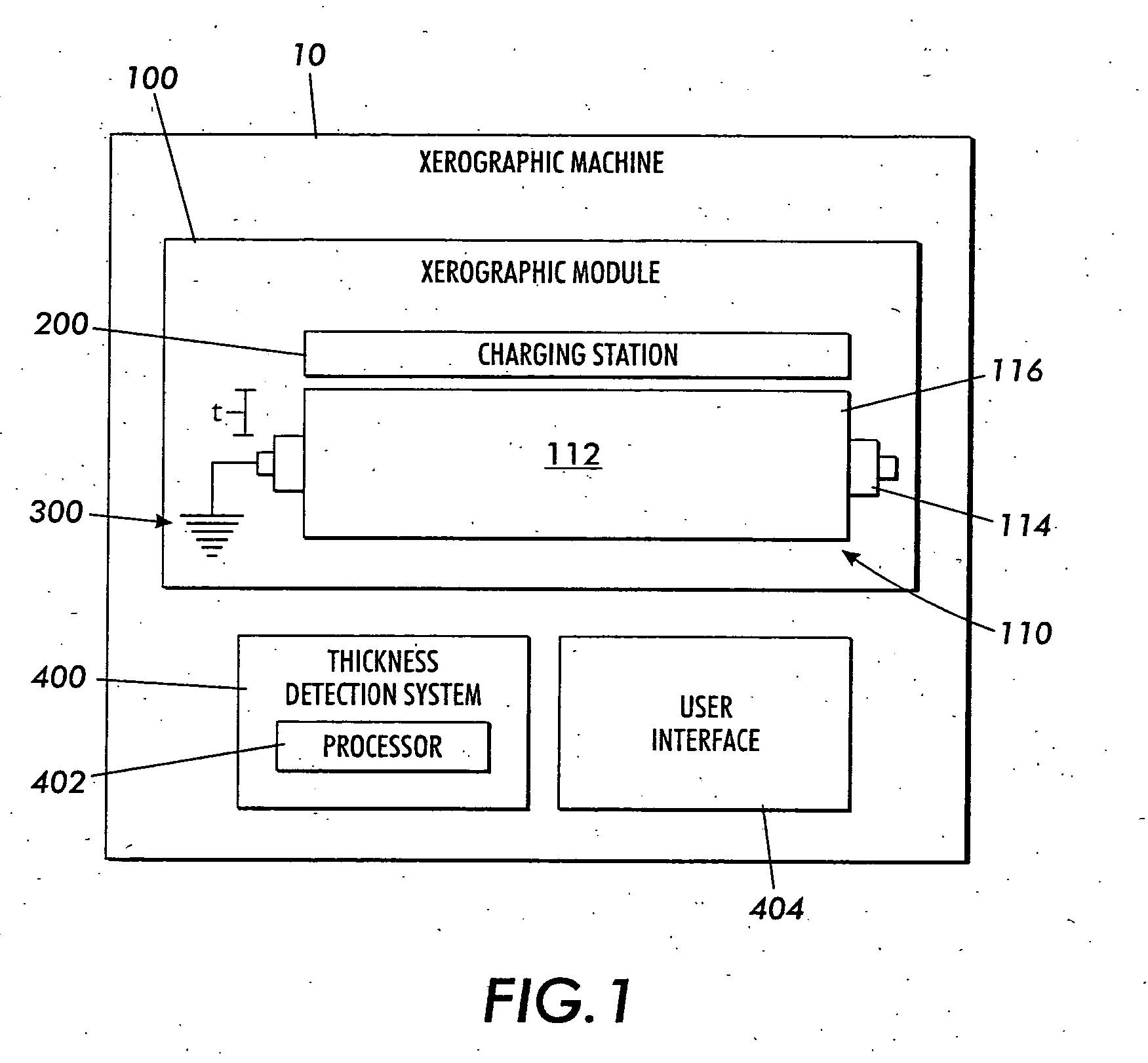

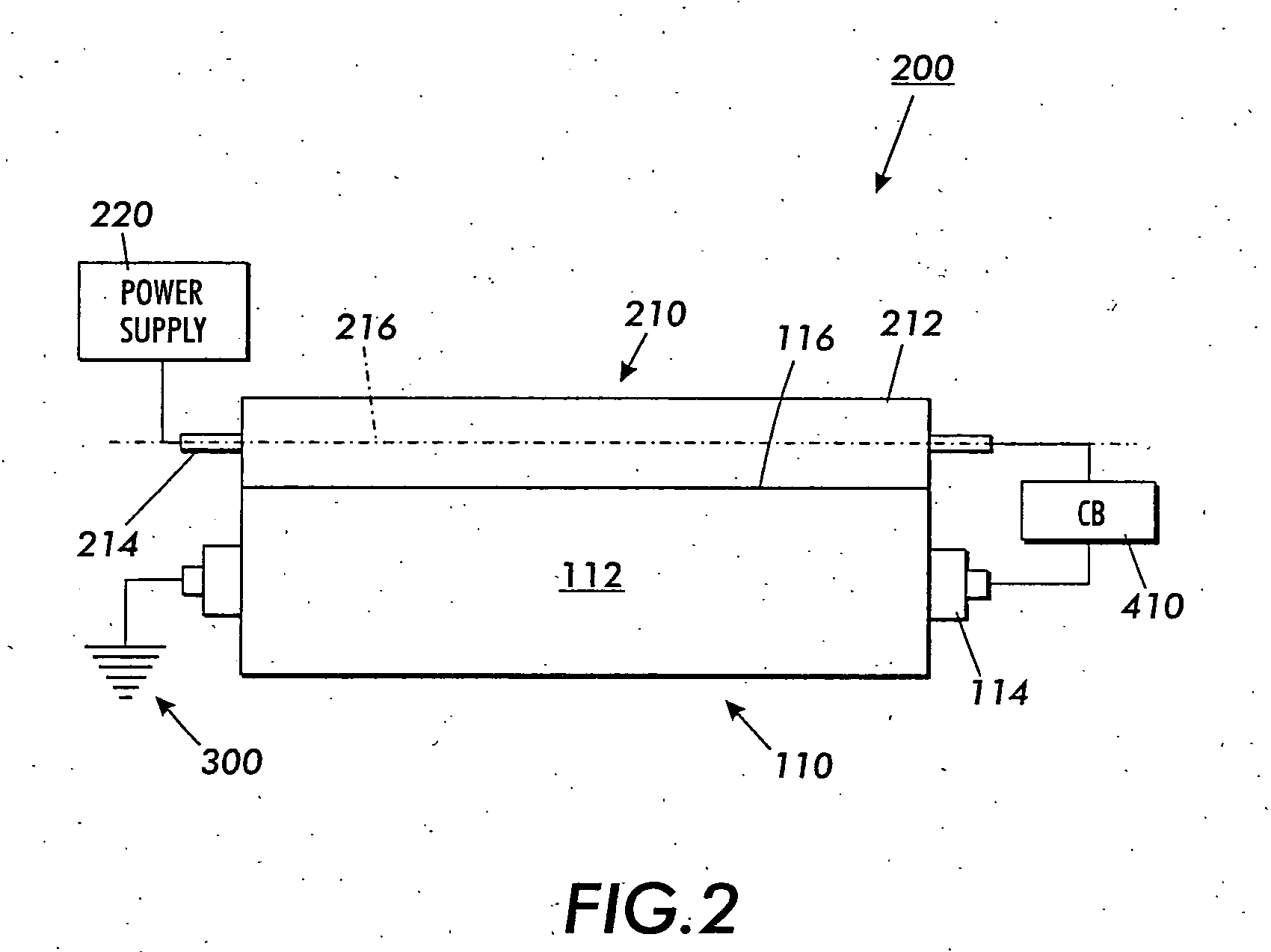

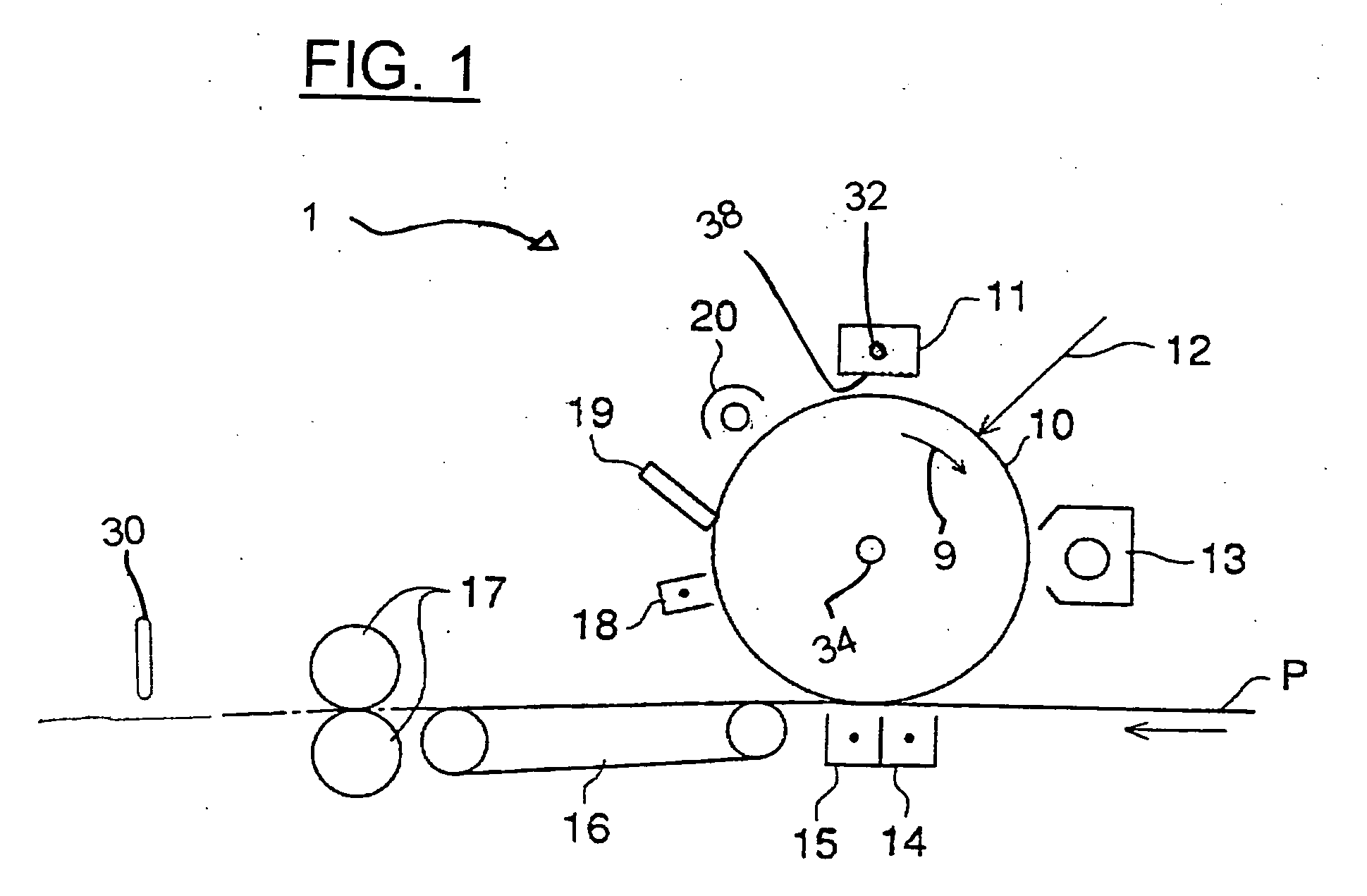

Xerographic photoreceptor thickness measuring method and apparatus

In a xerographic machine (10) having, a photoreceptor (110) including a photoconductive layer (112) arranged over an electrically conductive substrate (114), and a charging station (200) for applying a substantially uniform electrostatic charge to a surface (116) of the photoconductive layer (112), a method for detecting a thickness (t) of the photoconductive layer (112) is provided. The method includes: measuring an electrical property of the charging station (200); and, determining the thickness (t) of the photoconductive layer (112) from the measured electrical property.

Owner:XEROX CORP

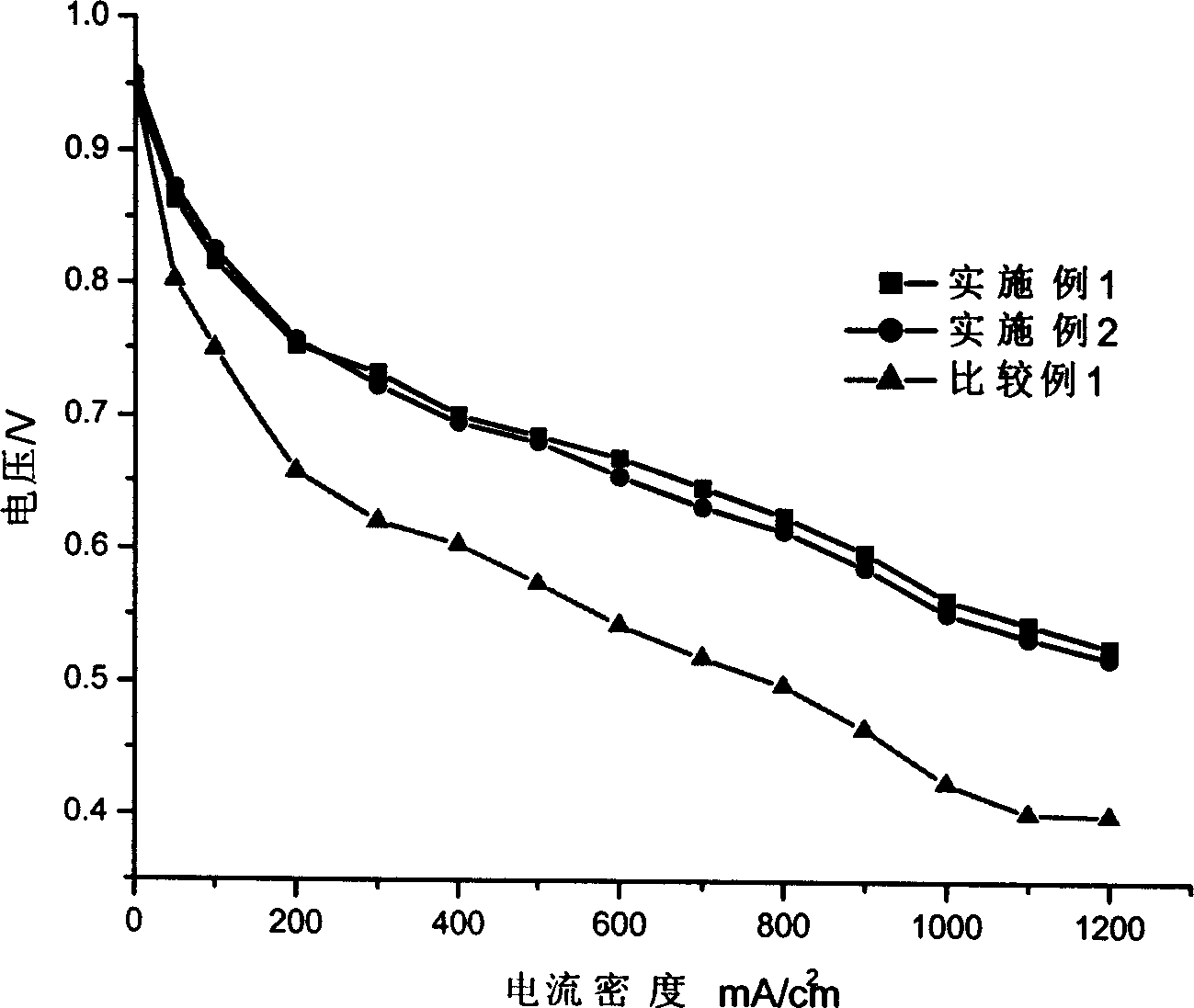

Ultrathin core assembly for synthetising catalyst coated membrane fuel cell by direct method

InactiveCN1560950ASimple processReduce manufacturing costCell electrodesCell component detailsCoated membraneXerography

A preparation method for catalyst coated membranes is to turn a slurry containing catalyst, proton exchange resin, hydrophone, solvent and SAA to powders then to transfer the powders onto the proton exchange membrane to prepare CCM by laser printing technology or xerography. The mass fractional relations of the components are: catalyst: proton exchange resin: hydrophone: solvent: SAA=10:2-5:50-1000:2-5:1-5, its size is smaller than 20mum, no swelling or deformation appear, thickness of CCM is 30-35 mum, the error is less than 10%, the thickness of the layer is less than 10mum and less than 5mum for single.

Owner:WUHAN UNIV OF TECH

Overprint compositions for xerographic prints

InactiveUS20070021522A1Good lookingReduce document offsetImpression capsDentistry preparationsOligomerMedicine

Xerographic prints with a toner-based image and an overprint, said overprint based on radiation curable compositions containing a radiation curable oligomer / monomer, at least one photoinitiator and at least one surfactant, are disclosed. The overprints are particularly well-suited for wetting over substrates containing residual fuser oil and reducing or preventing document offset and for protecting xerographic images on substrates subjected to abrasives, heat, and / or sunlight since the compositions protect such images from cracking, fading, and smearing.

Owner:XEROX CORP

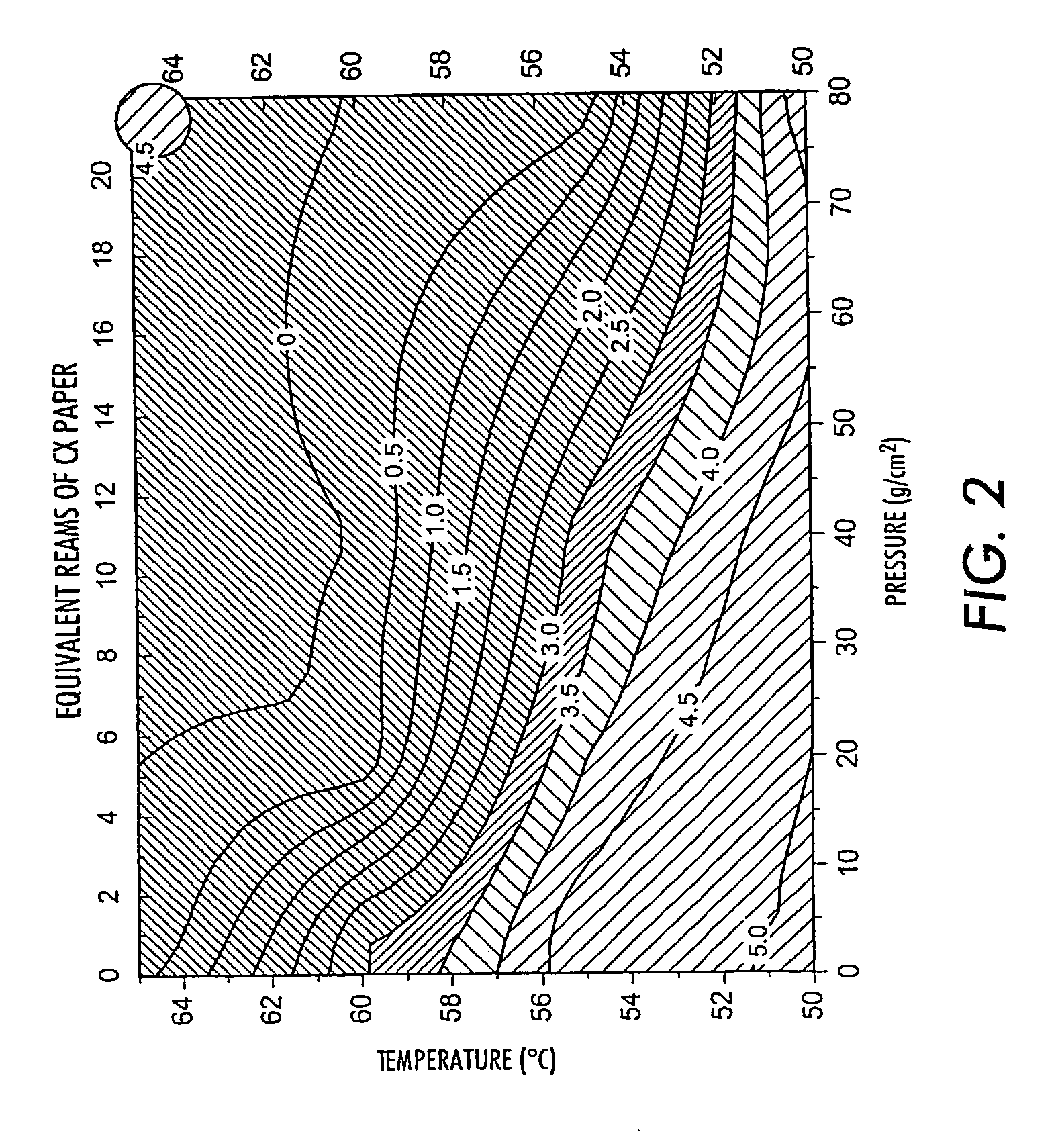

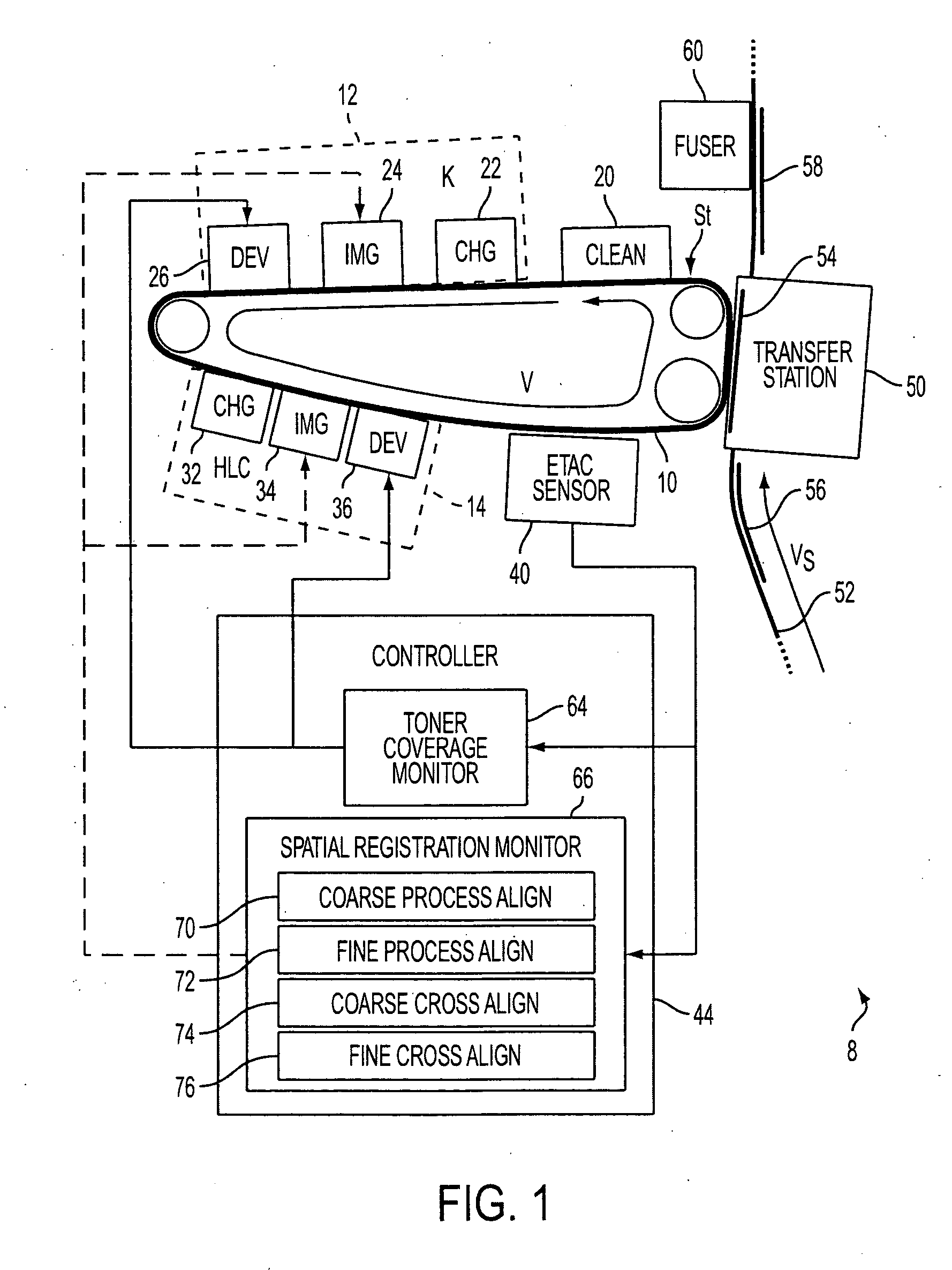

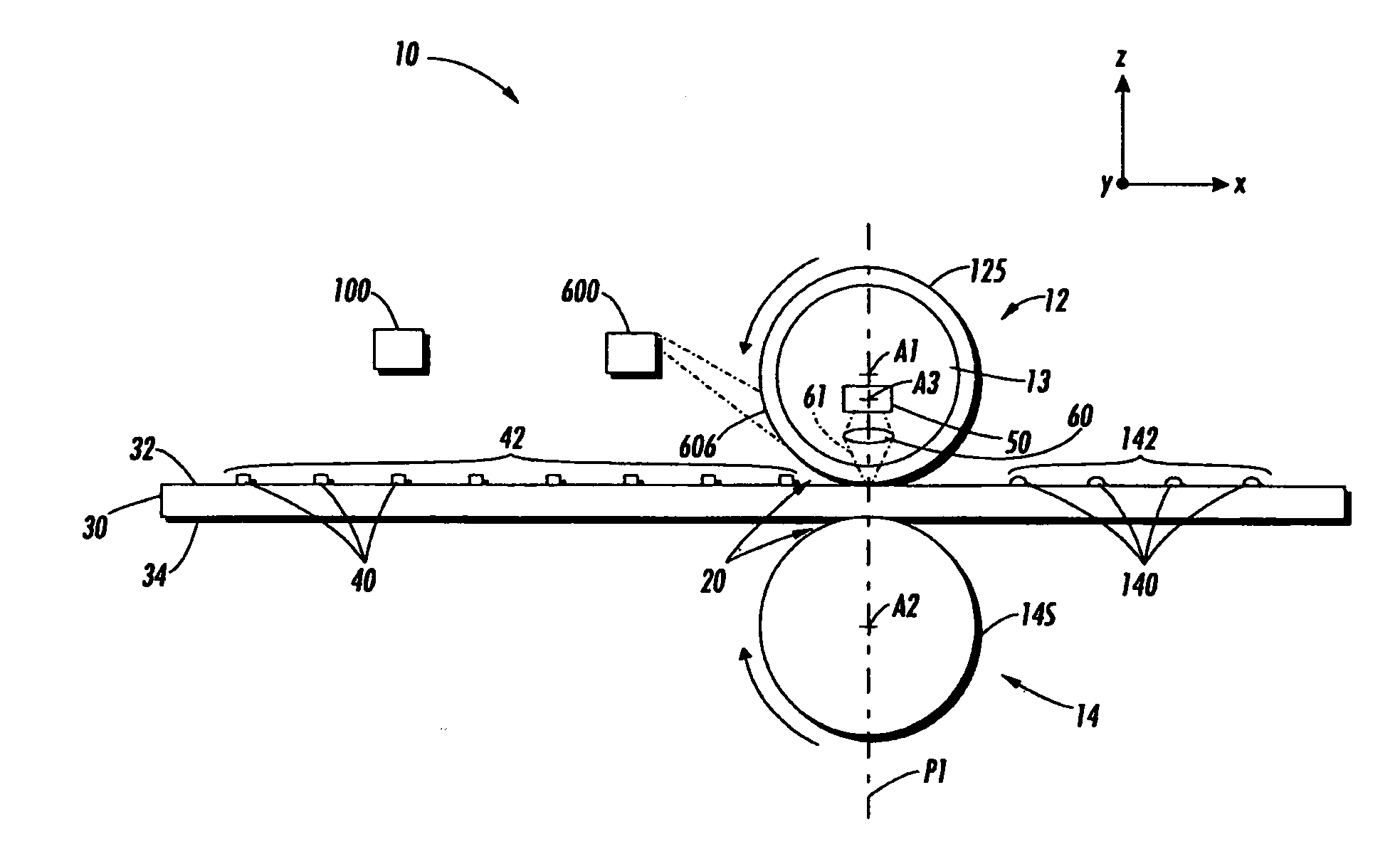

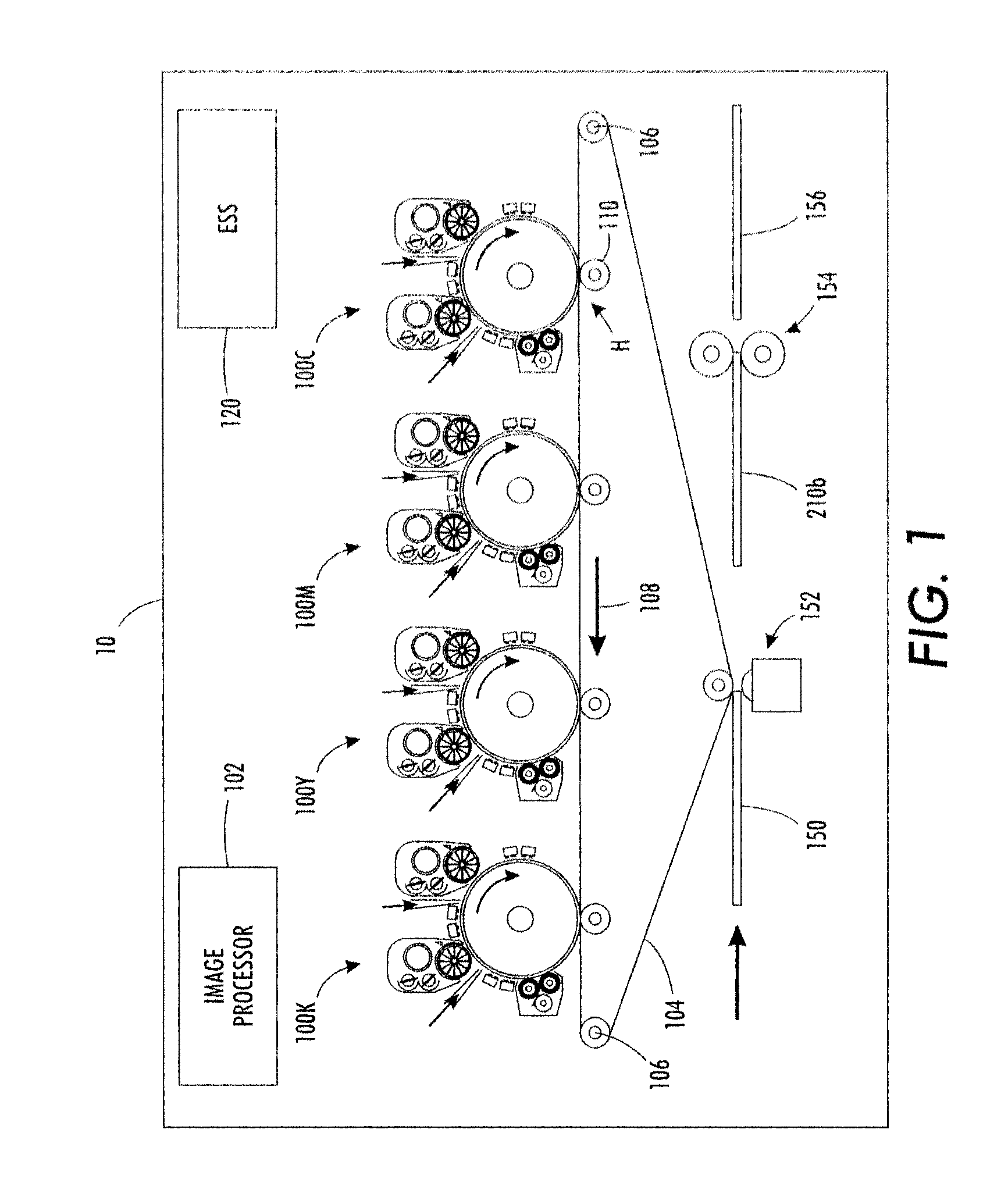

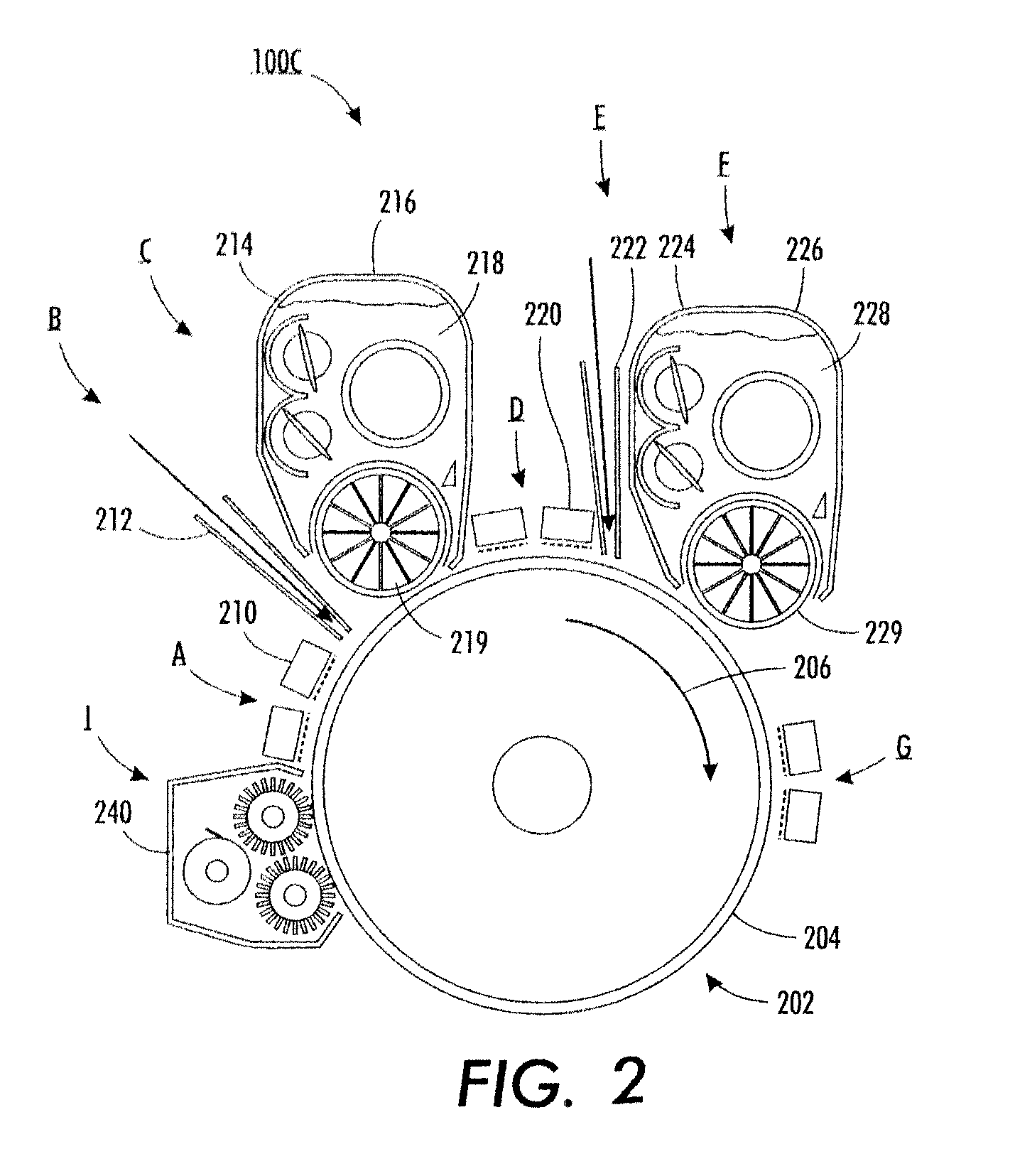

Color mis-registration measurement using an infra-red color density sensor

A xerographic system (8) includes a moving photoreceptor (10) and multiple toner development systems (12, 14) arranged to selectively dispose regions of toner on the moving photoreceptor. A toner density sensor (40) is arranged to measure toner density on the moving photoreceptor over a sensor area (A). A toner coverage monitor (64) operatively connected with the toner density sensor (40) monitors toner coverage based on measurements by the toner density sensor of toner coverage calibration regions disposed on the moving photoreceptor by the multiple toner development systems. A spatial registration monitor (66) also operatively connected with the toner density sensor (40) monitors spatial registration of the multiple toner development systems based on measurements by the toner density sensor of spatial registration calibration regions disposed on the moving photoreceptor by the multiple toner development systems.

Owner:XEROX CORP

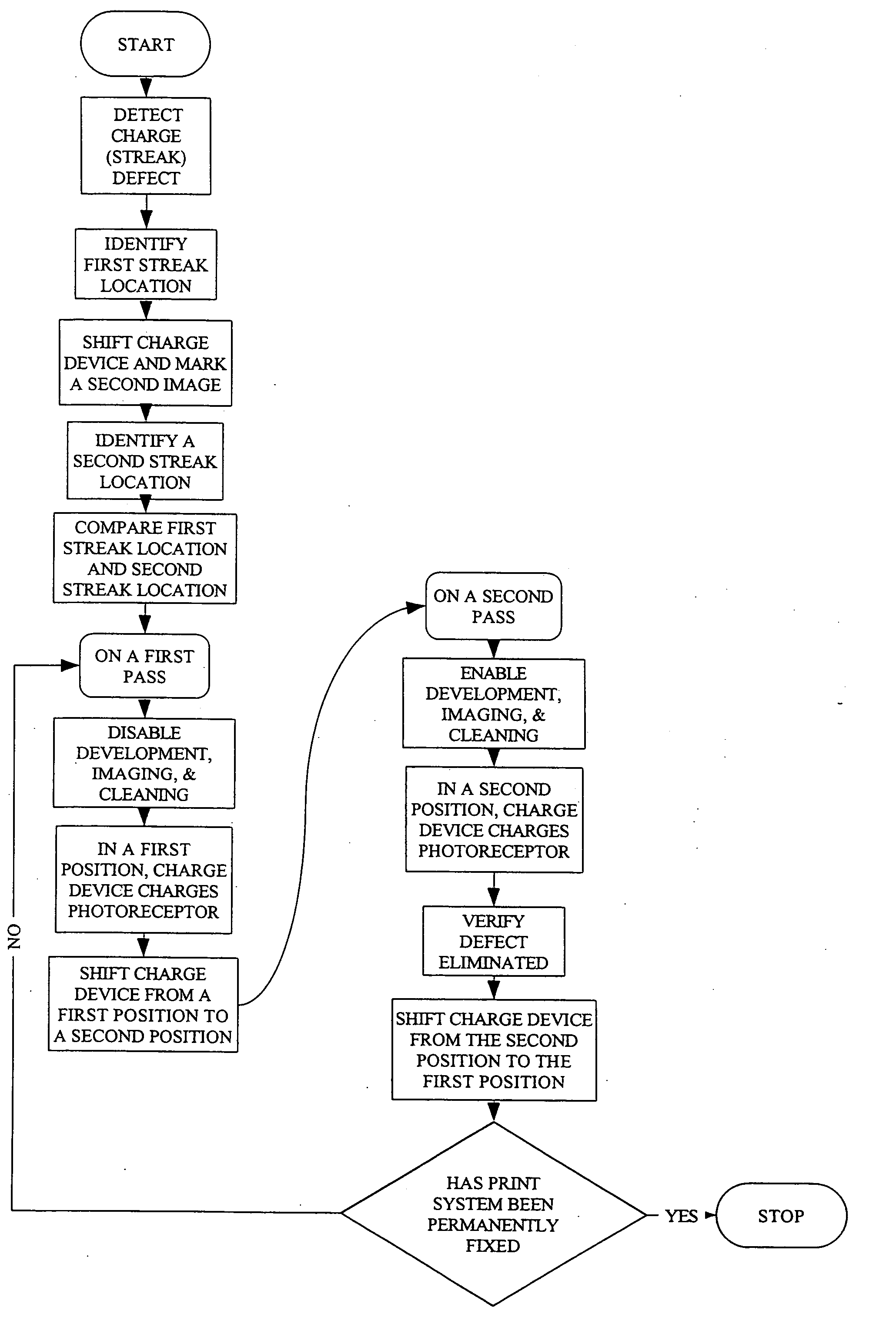

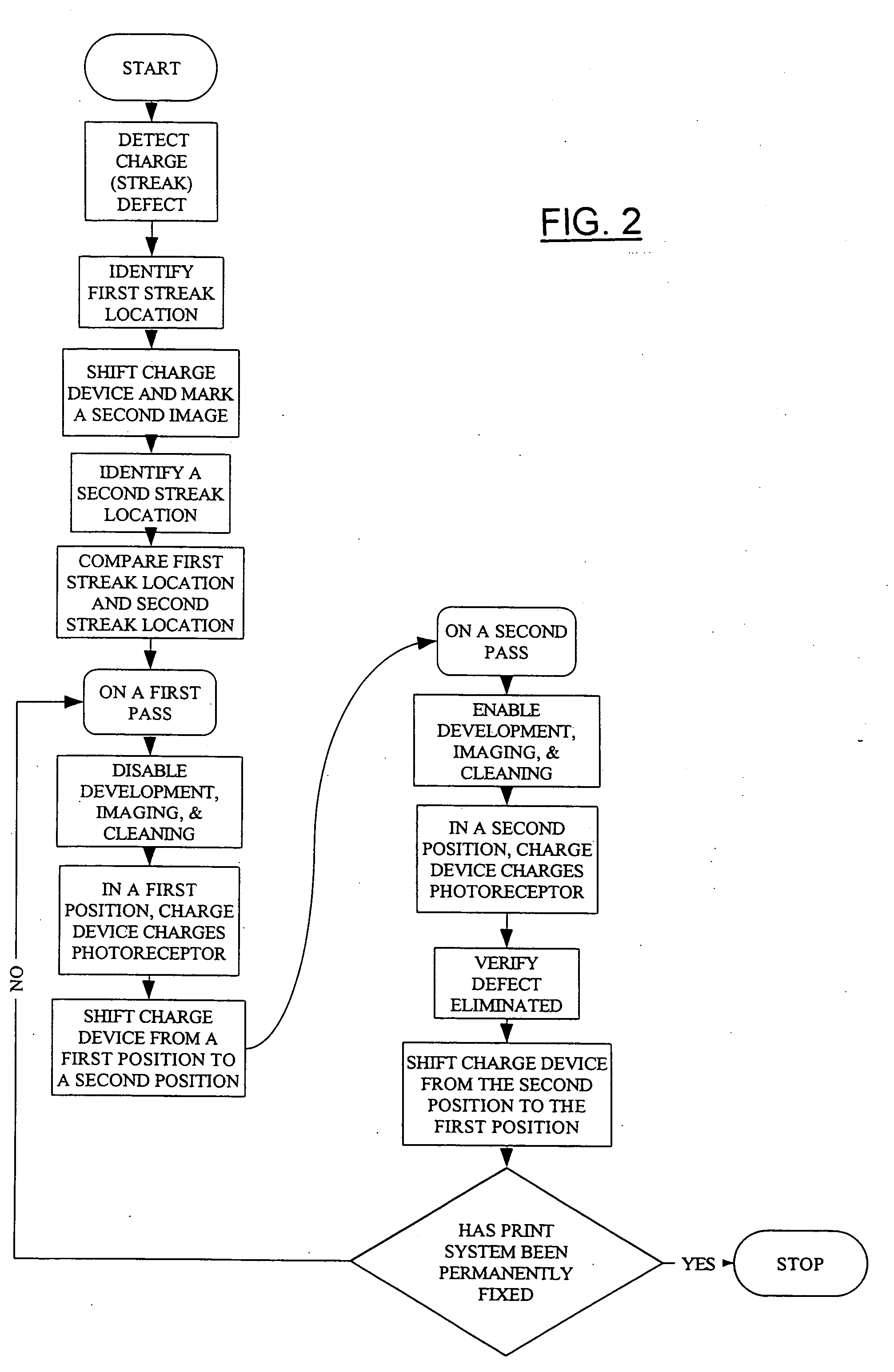

Xerographic device streak failure recovery

InactiveUS20060115285A1Avoid arcingElectrographic process apparatusCorona dischargeXerographyEngineering

Disclosed is an image forming method for an electrophotographic photoreceptor, comprising: detecting a first streak in a first image; identifying the first streak location; shifting a charge device and marking a second image; identifying a second streak location; comparing the first streak location with the second streak location and determining a distance therebetween; on a first pass, charging a photoreceptor with the charge device; shifting the charge device from a first position to a second position along the photoreceptor corresponding to the distance; and, on a second pass, charging the photoreceptor with the charge device.

Owner:XEROX CORP

Self-regenerative xerographic coatings

InactiveUS7050743B2Increasing life and effectivenessRadiation applicationsMaterial analysis by optical meansXerographyNitrogen oxide

Owner:XEROX CORP

Toner fusing system and process for electrostatographic reproduction, fuser member for toner fusing system and process, and composition for fuser member surface layer

InactiveUS6582871B2Synthetic resin layered productsElectrographic process apparatusElastomerSurface layer

A process for fusing toner to paper. This process employs a release fluid containing an aminofunctional polyorganosiloxane, and a fuser member having a fluoro-elastomer fusing surface layer that contains Fe2O3 filler.

Owner:HEIDELBERGER DRUCKMASCHINEN AG +1

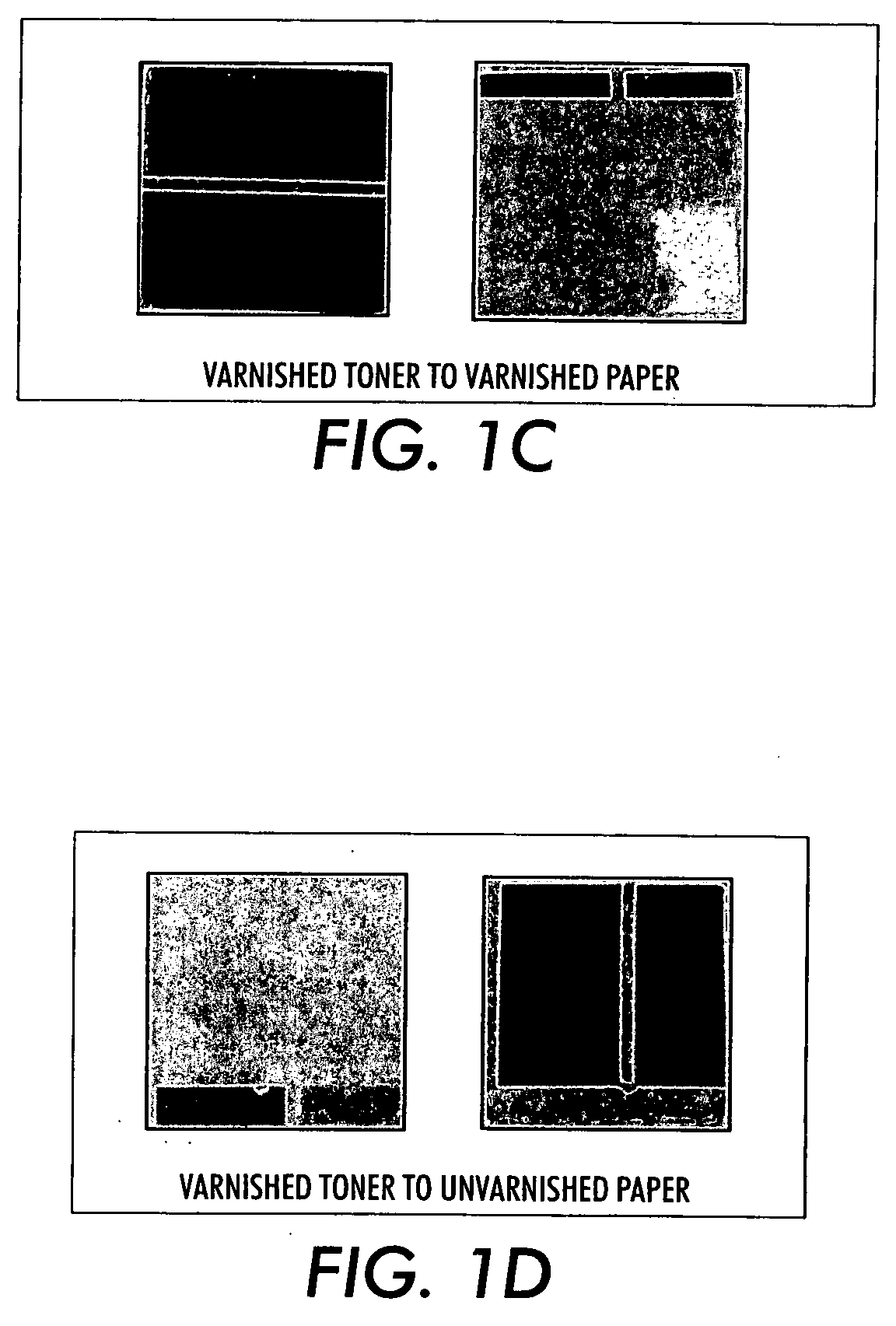

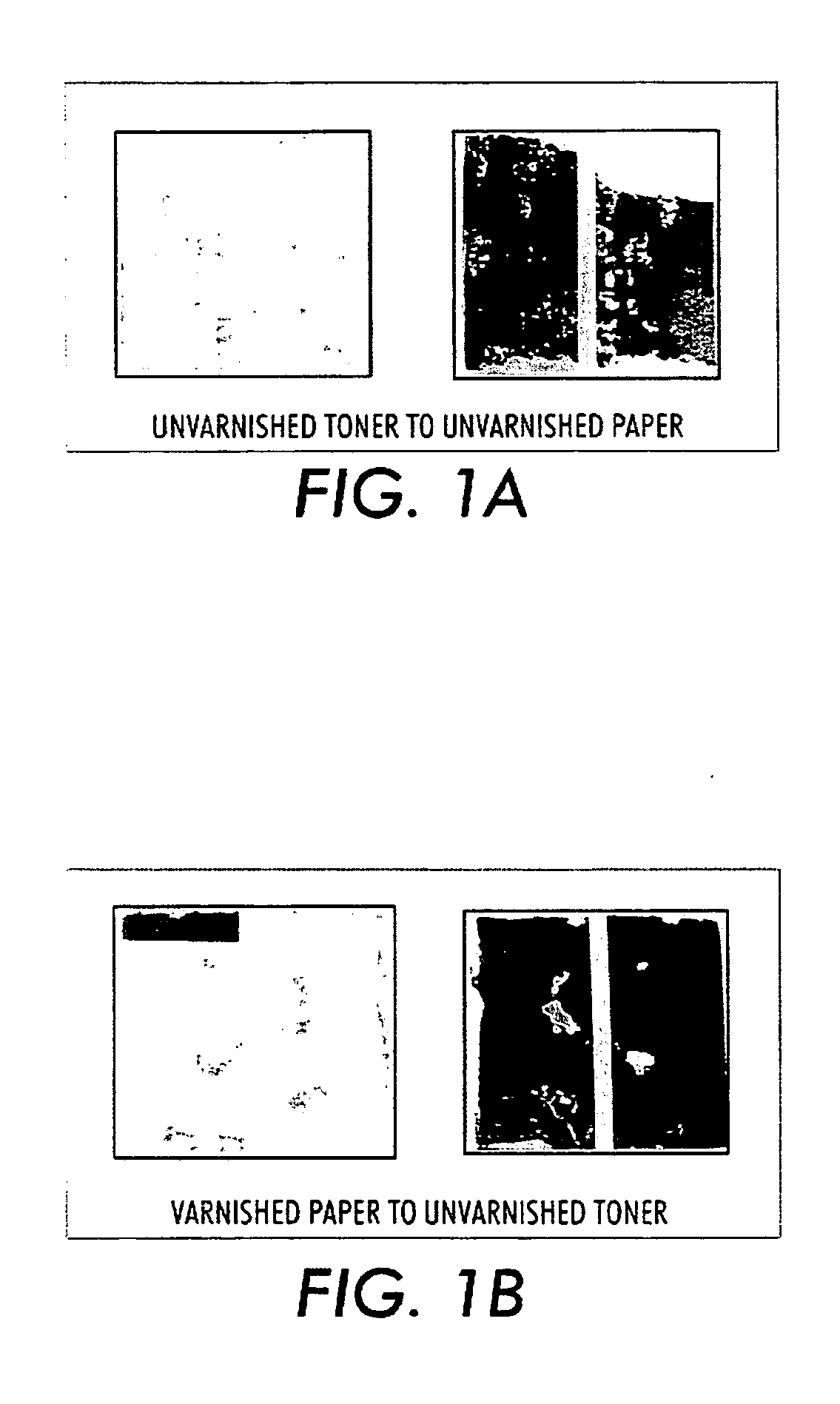

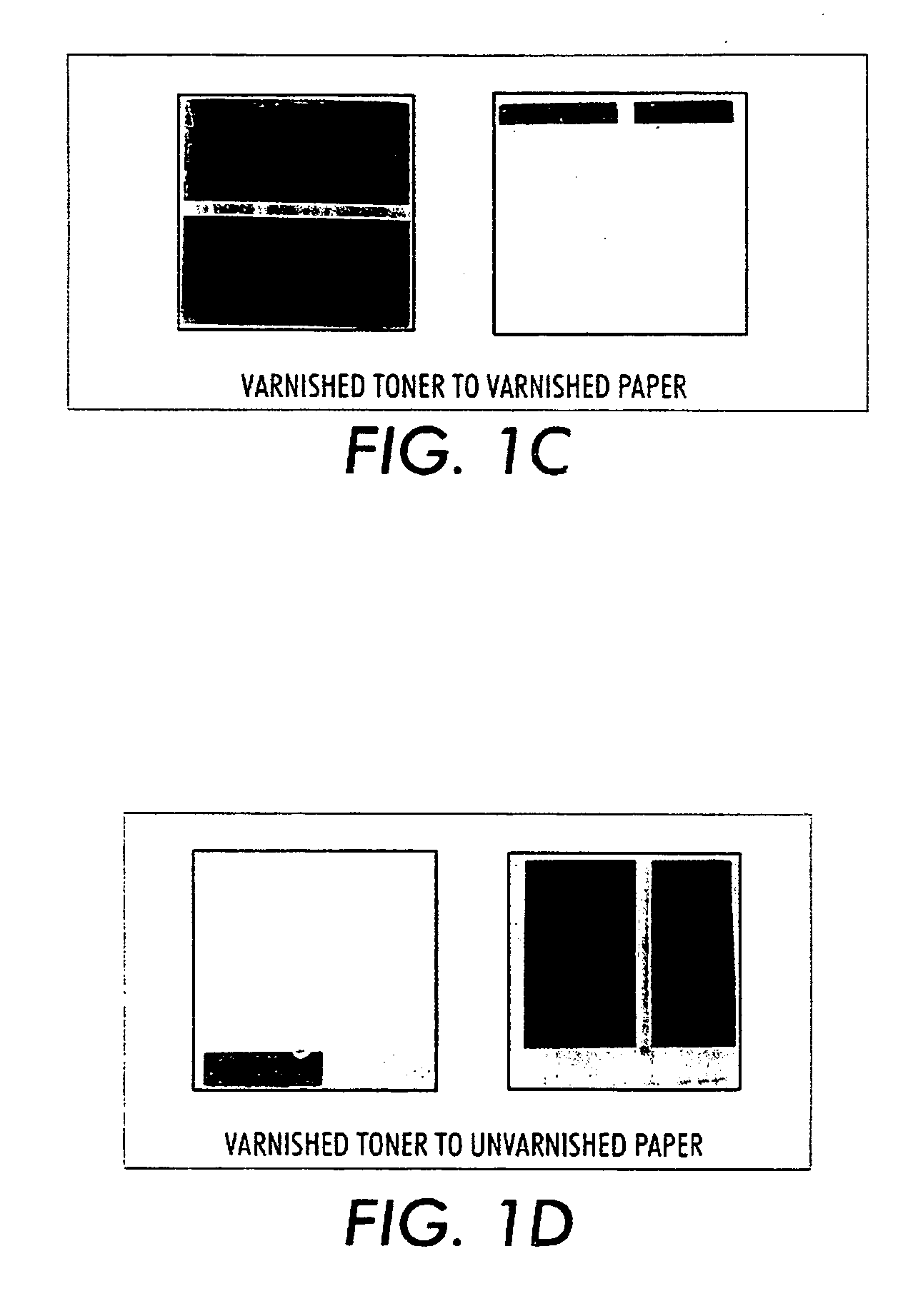

Method of applying spot varnish to xerographic image and emulsion aggregation toners for use therein

ActiveUS20060046180A1Electrographic processes using photoelectrophoresisDevelopersEmulsionXerography

A method of forming a xerographic image having at least one portion with a gloss different from a gloss of another portion of the xerographic image includes xerographically forming a toner image on a surface of a substrate and forming a finish over the toner image at the at least on portion, the finish being made of a differential gloss finish coating material that has a gloss different from that of the toner image. The differential gloss finish coating material is preferably an emulsion aggregation toner that is substantially free of pigments that adversely affect the transparency of the toner following fusing, the toner having gloss tunability through control of the amount of crosslinked portions included in the toner.

Owner:XEROX CORP

Xerographic printing system with magnetic seal between development and transfer

In a xerographic development apparatus using a magnetic brush formed from magnetic carrier particles, a magnetic strip disposed downstream of the development zone along the direction of motion of the photoreceptor retains a separate, small brush of carrier particles near the photoreceptor. The brush acts as a barrier separating a flow of “dirty” air (laden with airborne toner particles) upstream of the strip, and a flow of clean air downstream of the strip.

Owner:XEROX CORP

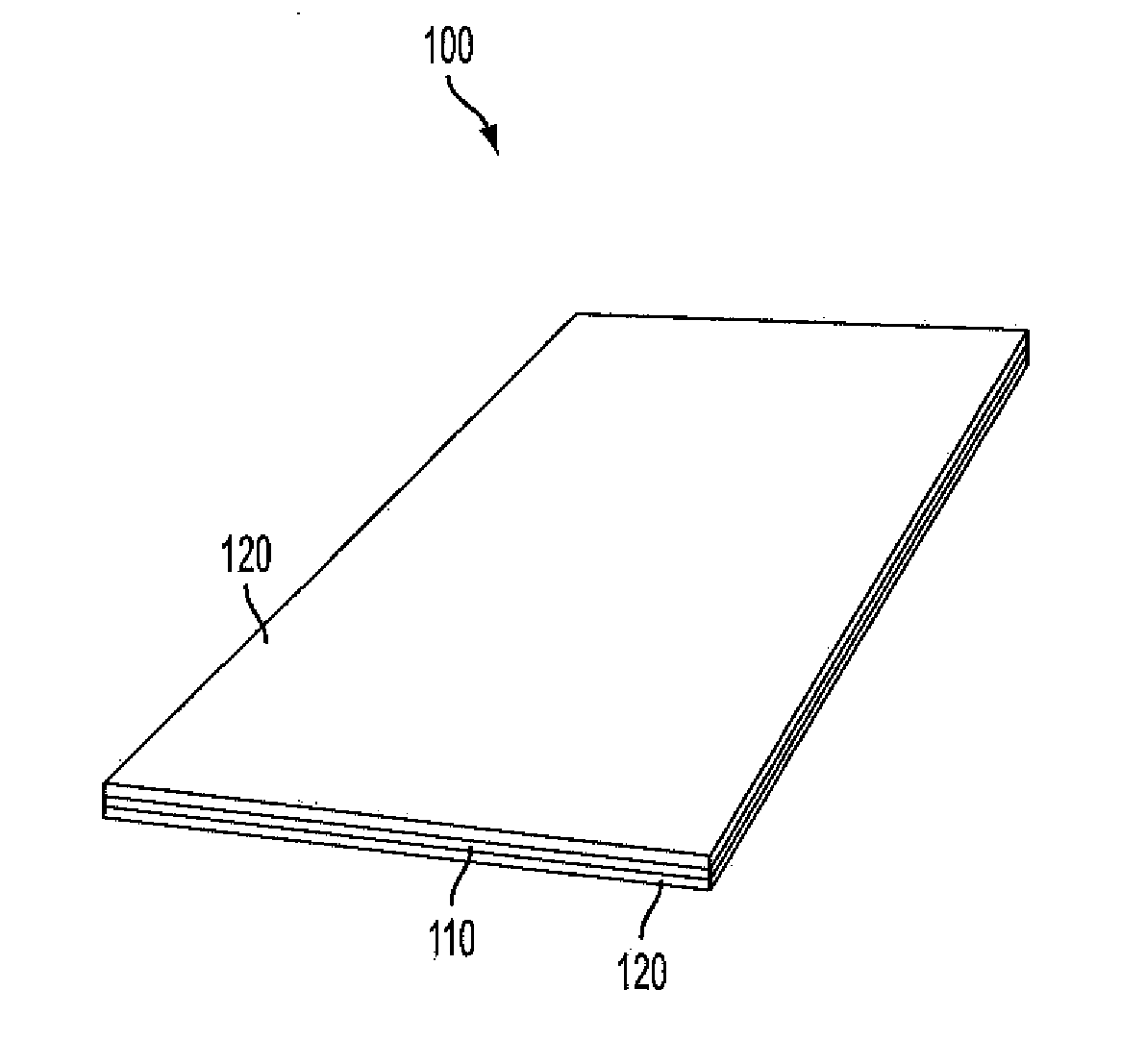

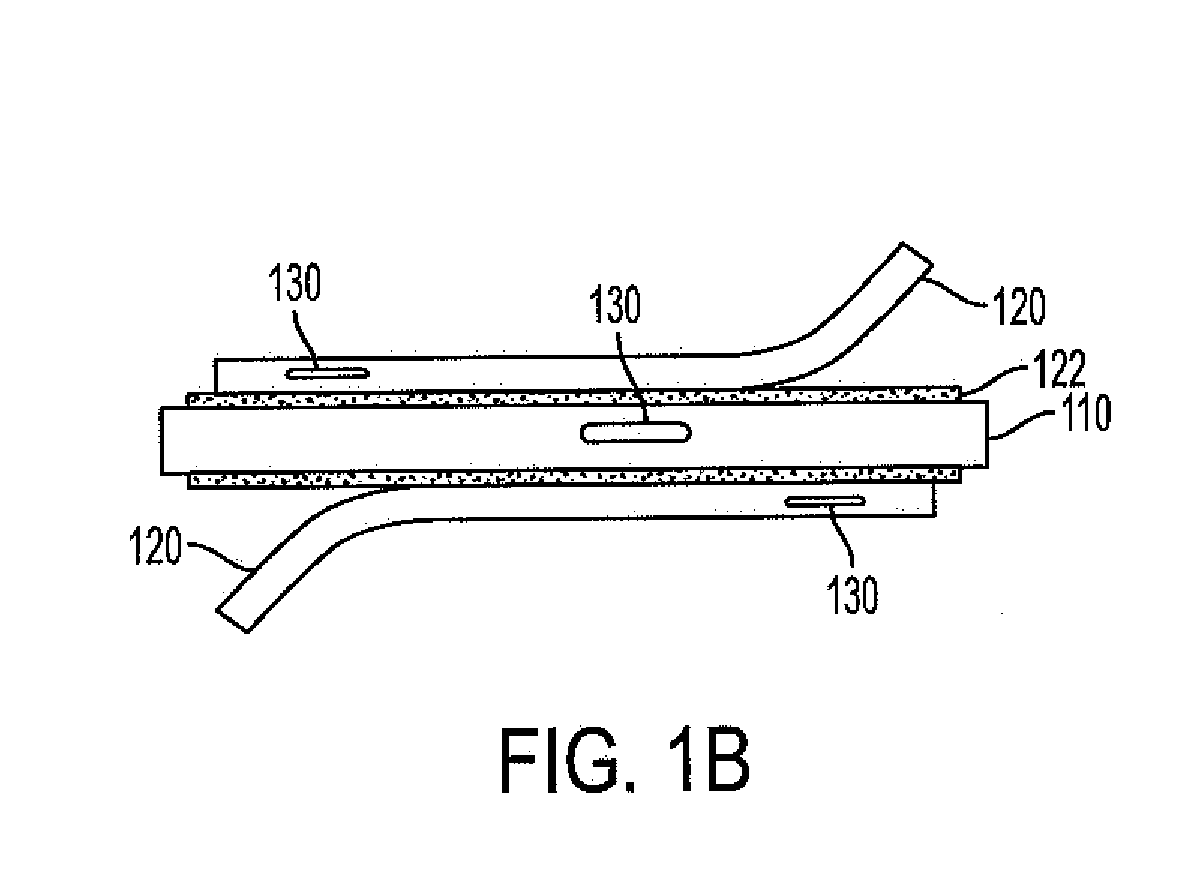

Laminated paper for xerography to reduce cost and recycling waste

InactiveUS20110155311A1Lamination ancillary operationsSynthetic resin layered productsSurface layerXerography

An imageable medium includes a reusable substrate and a removable surface layer semi-permanently bonded to a major surface of the substrate, the reusable substrate comprising an opaque backing to the removable surface layer and the removable surface layer comprising an imageable surface. A use indicator can be incorporated into the imageable medium, and correspond to at least one of the reusable substrate and removable surface layer. The use indicator can be an RFID chip. A method of imaging includes preparing an imageable medium by semi-permanently bonding an imageable layer to a reusable substrate, the reusable substrate providing an opaque backing to the imageable layer; imaging the imageable layer of the imageable medium; removing an imaged layer upon completion of use of the imaged medium; and repeatedly imaging a revealed imageable layer and removing the imaged layer.

Owner:PALO ALTO RES CENT INC

Control grid for solar energy concentrators and similar equipment

InactiveUS7967457B2Increased longevityImprove performanceSolar heating energyMirrorsCost effectivenessIndium tin oxide

Owner:RABINOWITZ MARIO

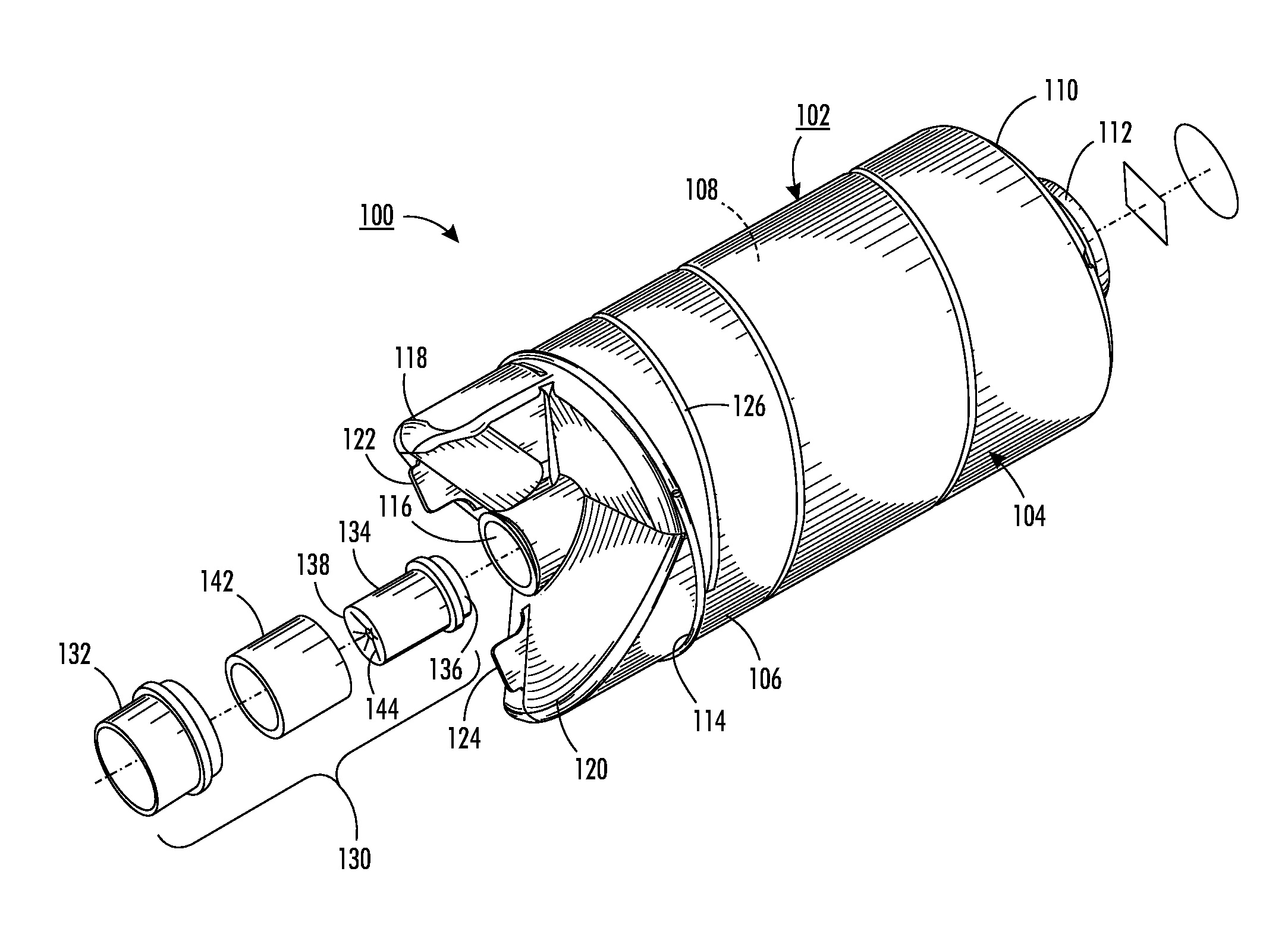

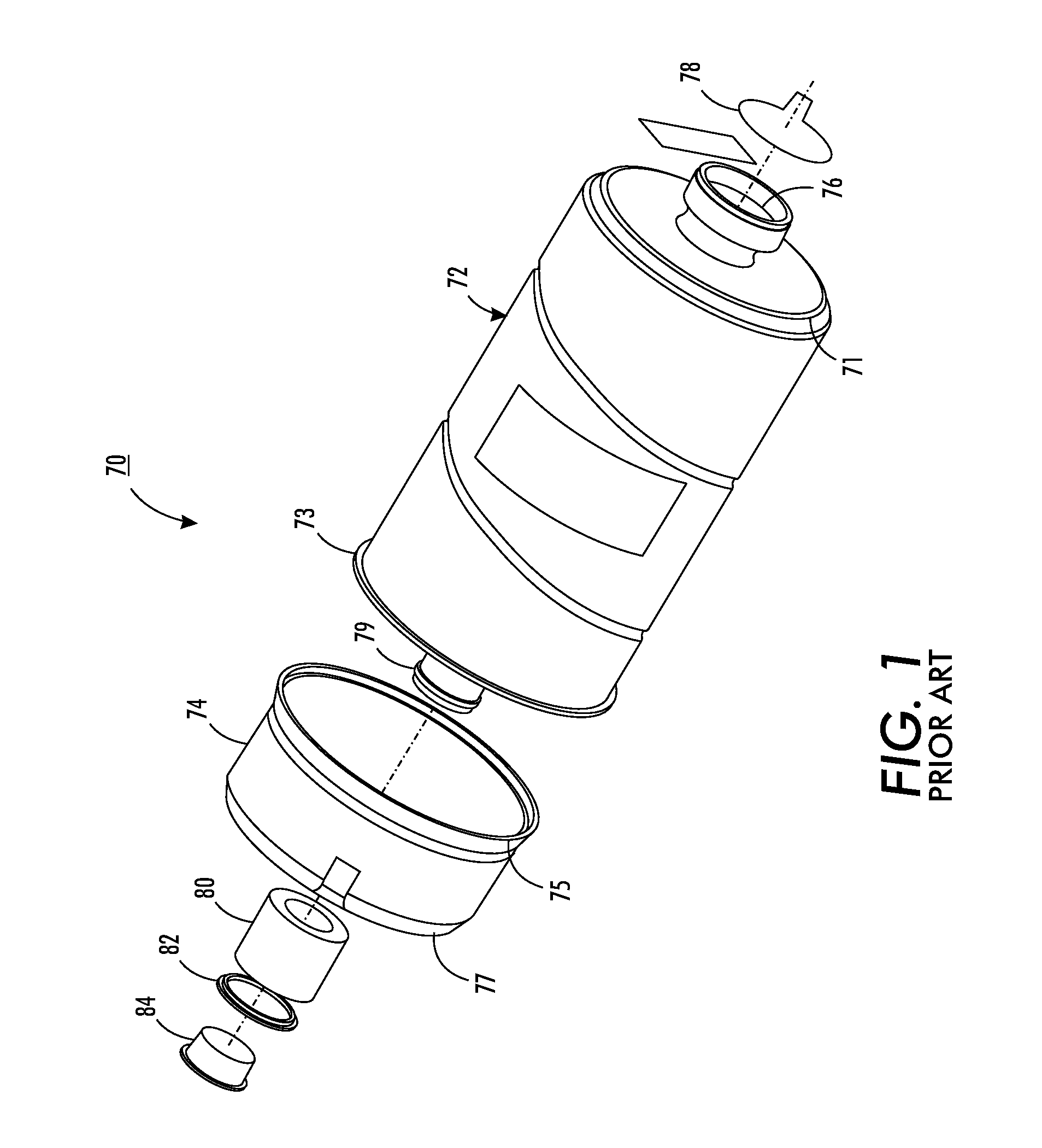

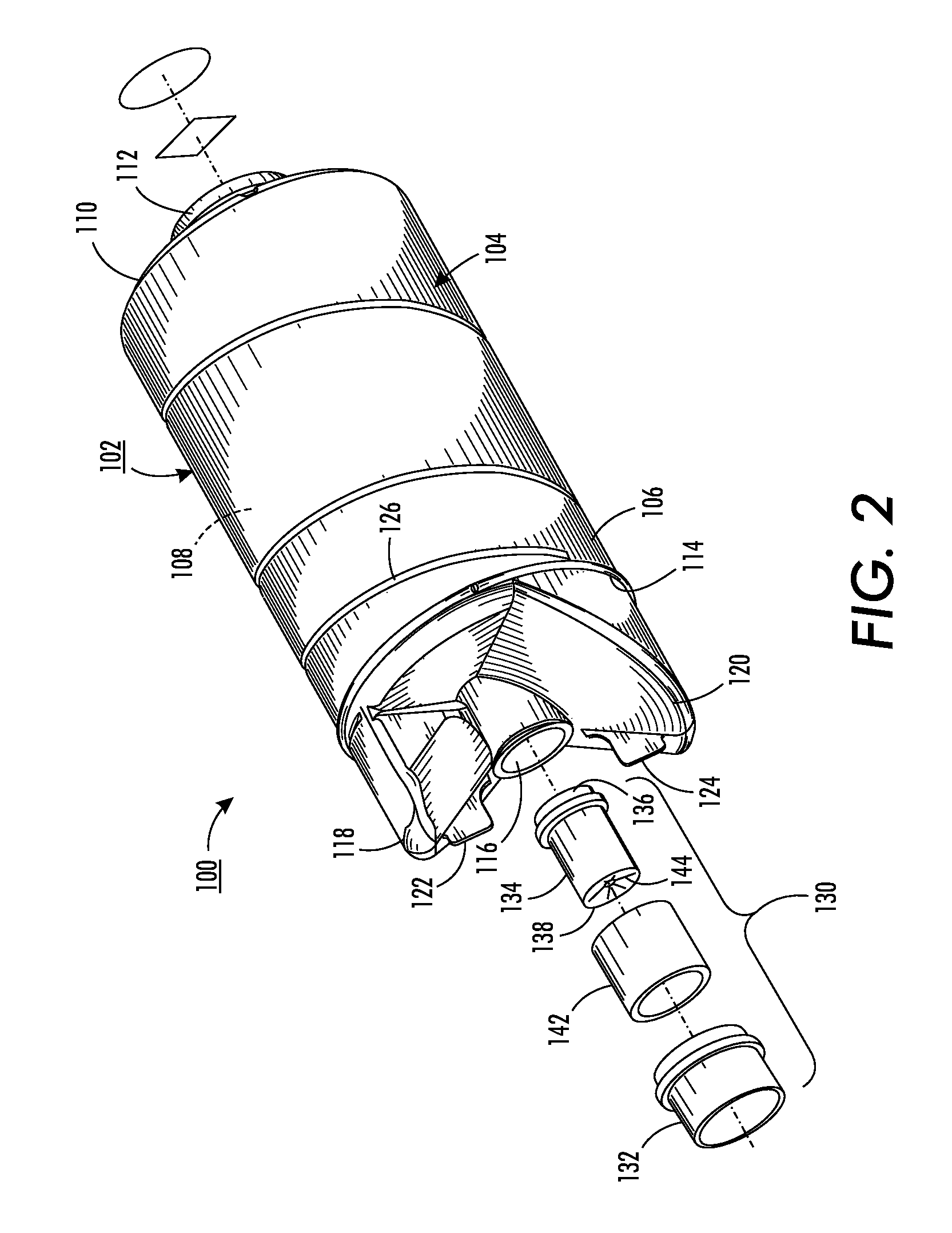

Replenisher toner container

InactiveUS20110142498A1Low costLow cost, robust and efficient replenisherElectrographic process apparatusEngineeringMechanical engineering

A low cost, robust and efficient replenisher toner container is provided and includes (a) a one-piece blow-molded container body having a wall defining an exterior surface of the body and an interior cavity within the body; (b) a first end, of the one-piece blow-molded container body, having a handle member; (c) a second end, of the one-piece blow-molded container body opposite the first end, including a single fill / dispense opening for filling the interior cavity with replenisher toner and for dispensing replenisher toner from the interior cavity; and (d) at least a one molded scoop member formed at the second end for efficiently delivering the replenisher toner being dispensed from the interior cavity into receiving components in the xerographic machine.

Owner:XEROX CORP

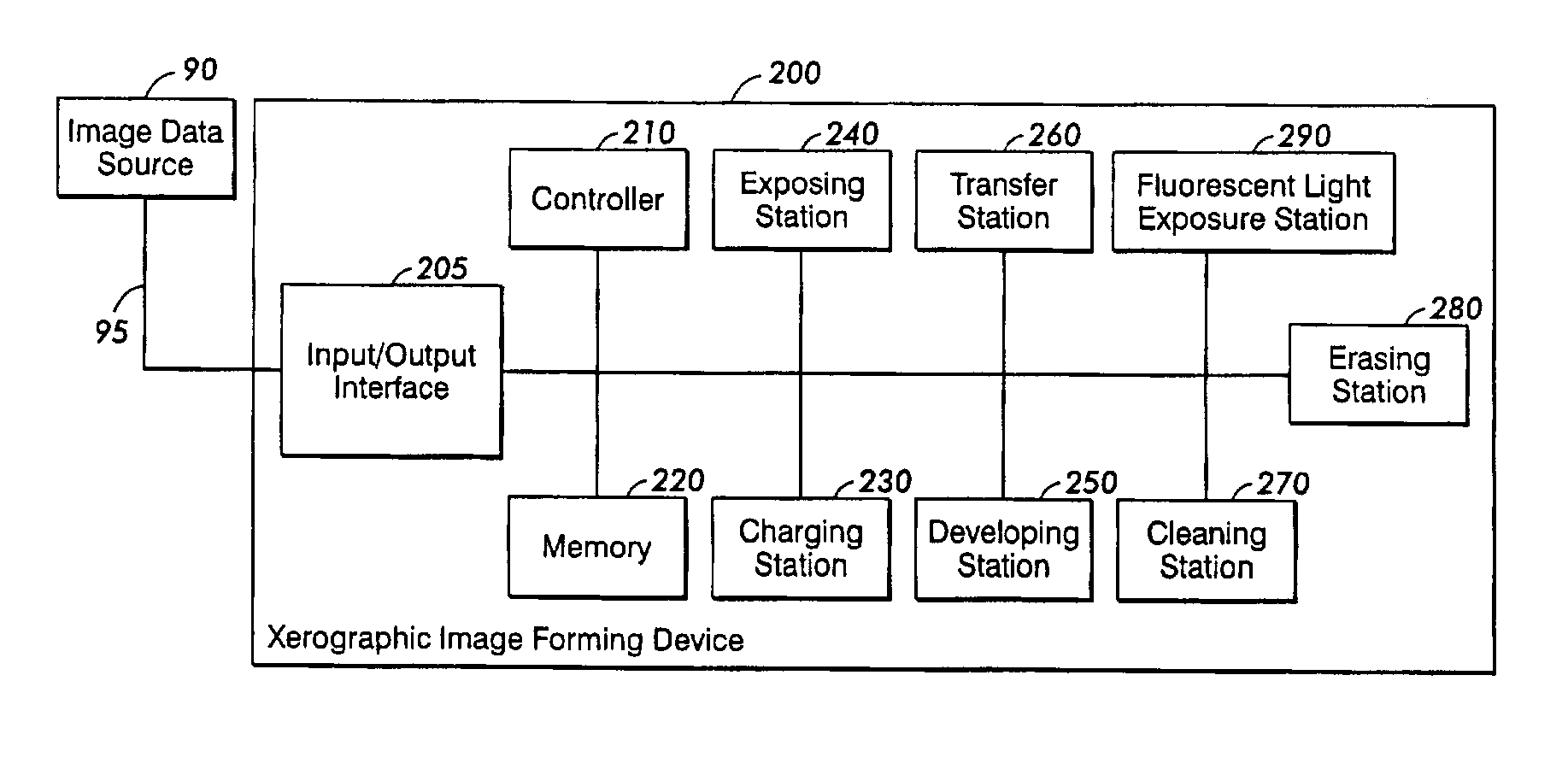

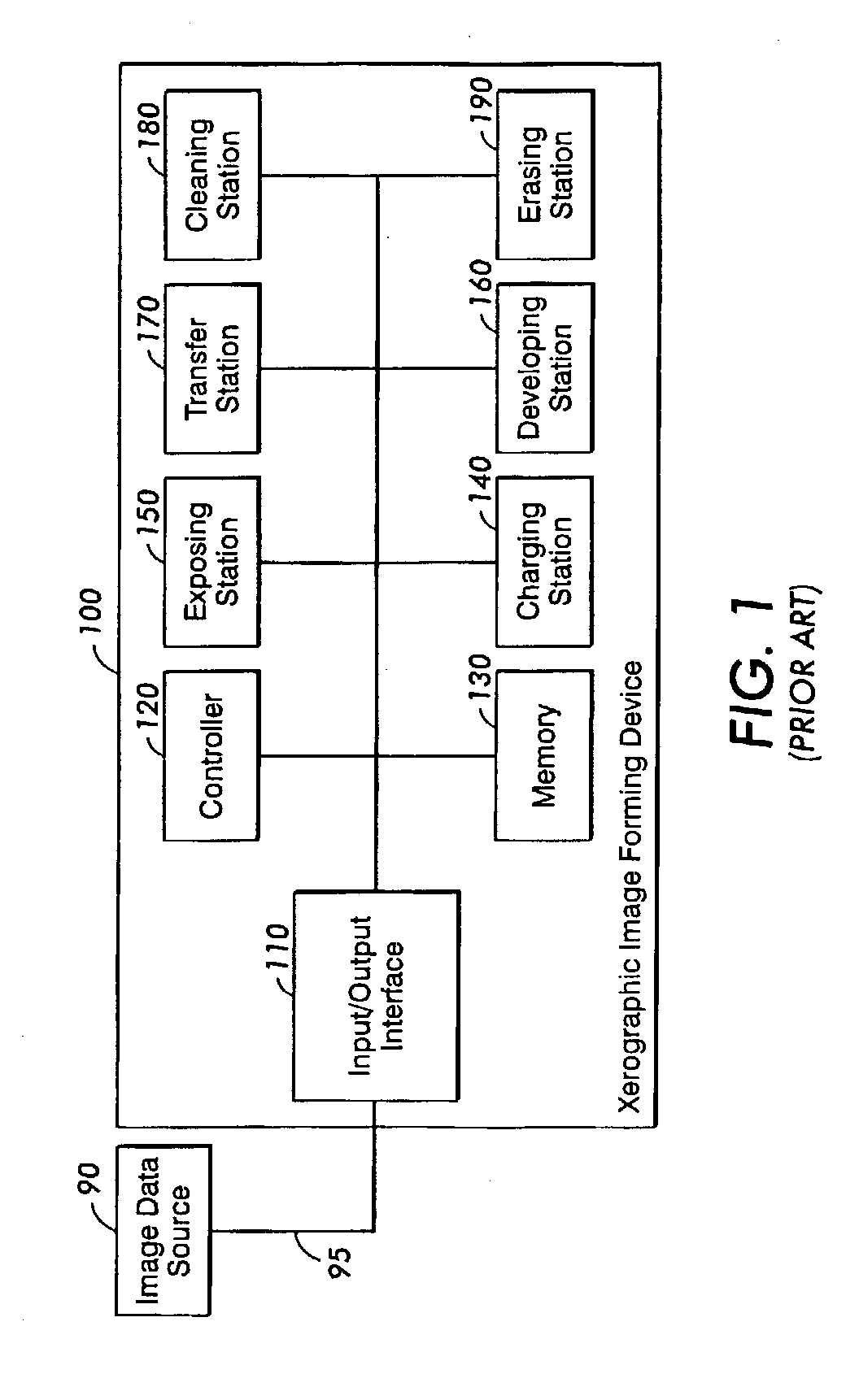

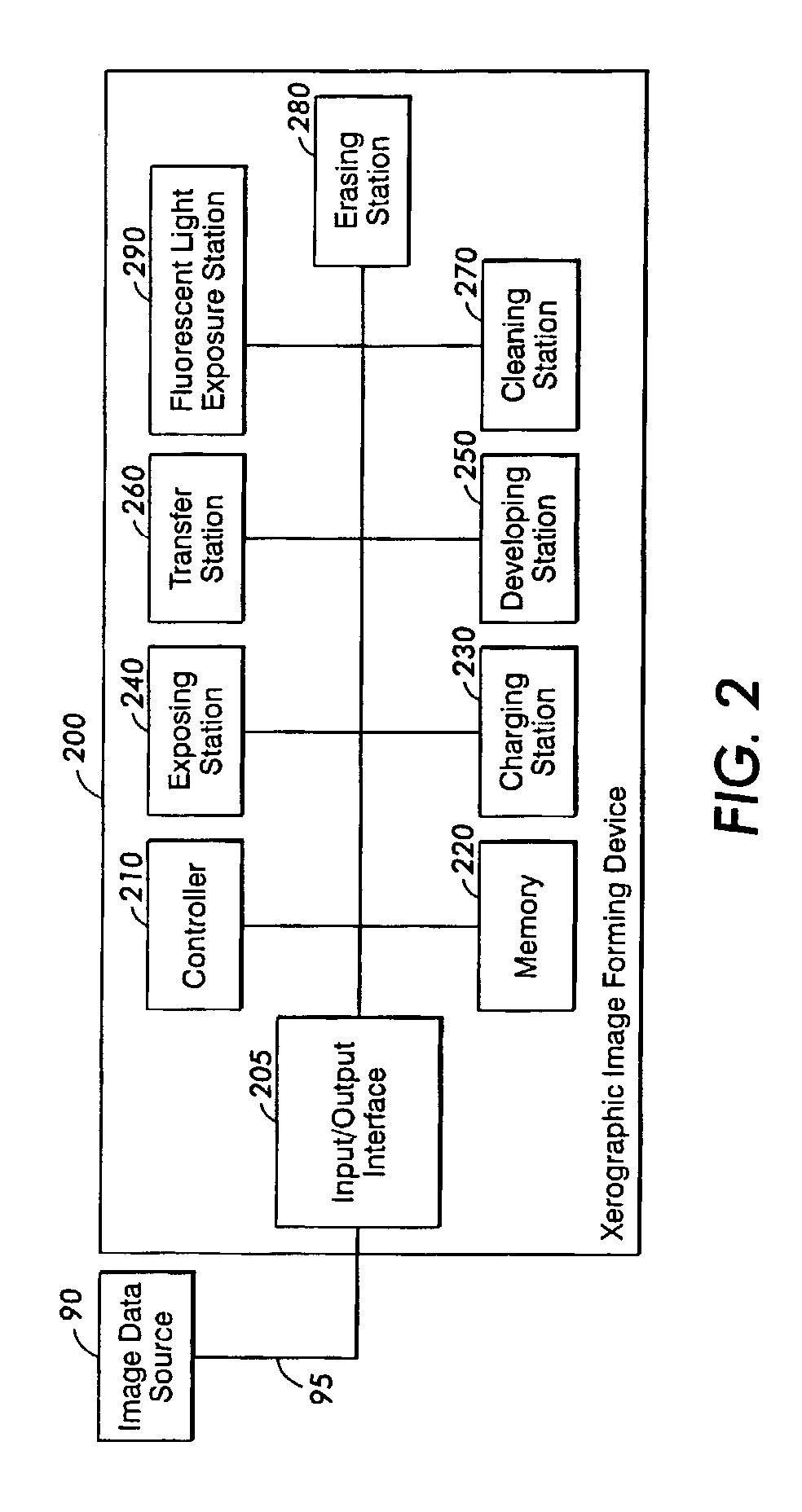

Method and apparatus for attenuating effects of positive over-spray on photoreceptor

Image quality of an image generated by a xerographic or equivalent image generating process may develop non-uniform charge characteristics, in addition to other negative effects, as a result of positive over-spray, but these negative effects can be at least attenuated by exposure of the photoreceptor to fluorescent light.

Owner:XEROX CORP

Electrophotographic photoreceptor, electrophotographic member, process cartridge and image forming apparatus

Owner:FUJIFILM BUSINESS INNOVATION CORP

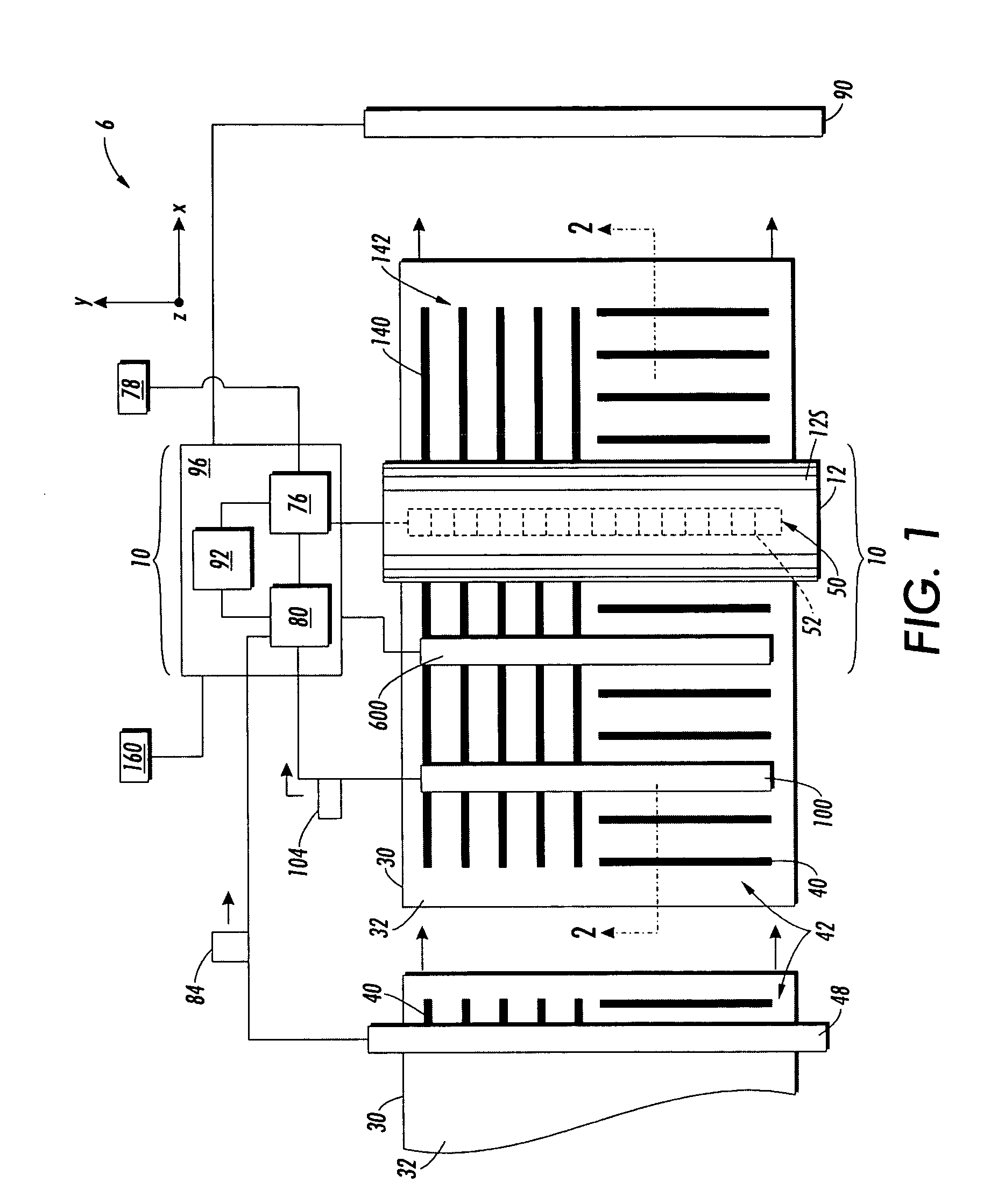

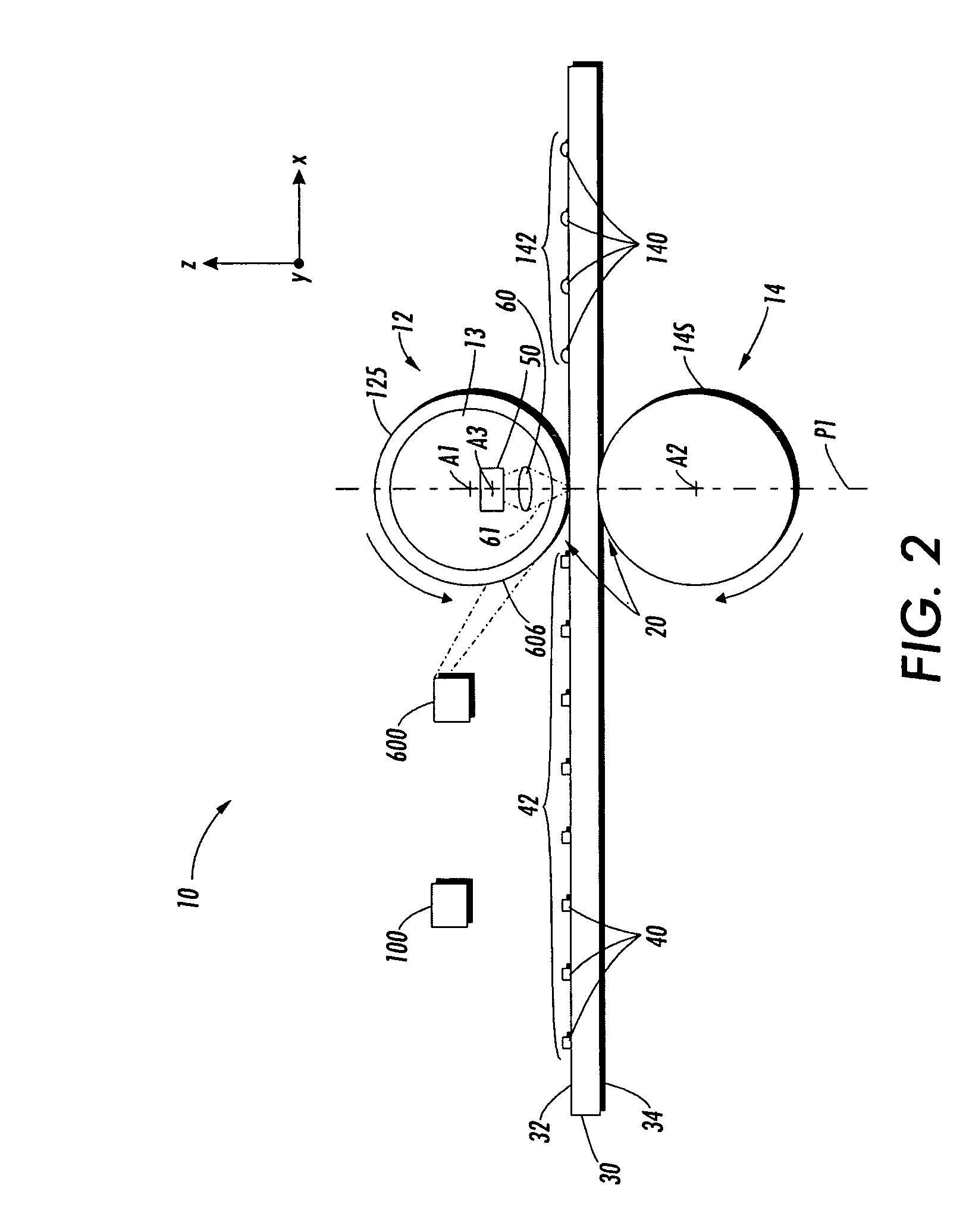

Xerography methods and systems employing addressable fusing of unfused toner image

Methods and apparatus for performing addressable fusing and / or heating of a substrate undergoing xerographic processing are disclosed. The apparatus includes a fuser having an array of addressable heating elements in radiative communication with a substrate through a fuser roll or fuser belt. The array of addressable heating elements is operated to selectively heat portions of the substrate to achieve a desired effect on the substrate, such as changing its surface finish, or fusing unfused toner to the substrate. In the case of toner fusing, the array is operated such that substantially only an area covered by the unfused toner is heated. This eliminates the need for blanket fusing, and generally provides for greater flexibility in xerographically processing substrates. Apparatus and methods for performing two-sided selective fusing and / or heating are also disclosed.

Owner:PALO ALTO RES CENT INC +1

Method for preparing colored toner used for laser printing and electrostatic copying

InactiveCN101526765ANarrow particle size distributionSimple processDevelopersXerographyPolymer chemistry

The invention discloses a method for preparing colored toner used for laser printing and electrostatic copying. The invention combines with bulk polymerization, phase inversion polymerization, suspension polymerization technology and emulsion polymerization technology, and comprises the following steps: firstly, colorant and other additives are mixed with trace macromolecule, monomer and initiator completely for bulk polymerization for several hours, and aqueous phase solution which is dissolved with surfactant and dispersant is added to carry out the phase inversion and then polymerization is continuously carried out to obtain the product. The method obtains red, yellow and blue tricolor toner by polyreaction directly; the method has simple technology, less investment on equipment, energy saving and the uniform coloring of the product; and resin molecular weight shows bimodal distribution, thereby being good for fixation performance. The method overcomes the problem that unimodal distribution of the resin molecular weight causes poor fixation effect, uneasy even distribution of the colorant in the colored toner and over-wide particle size distribution during preparing the colored toner by the polymerization process.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Xerographic insulating dry single-component electropositive developer

InactiveCN102063030AExcellent performance indexImprove performance indicatorsDevelopersHigh concentrationXerography

The invention relates to a xerographic insulating dry single-component electropositive developer for an electrostatic xerographic printer, which comprises the following components in percentage by weight: 40 to 80 percent of adhesive resin, 20 to 60 percent of magnetic material, 1 to 8 percent of charge controlling agent, 0.1 to 0.8 percent of internal additive and 0.1 to 0.8 percent of external additive, wherein the adhesive resin adopts a styrene-acrylic acid copolymer with the polymerization rate of 70:25:5, the average molecular weight of 0.1 to 0.2 million and the melt index MI of 1.5 to 5.5; the magnetic material adopts ferroferric oxide, and has the average particle size of 0.1 to 2.0 mu m, and magnetic characteristics such as the saturation magnetization of 60 to 100 emv / g and the coercive force of 90 to 1400 e in the magnetic field of 10 Koe; and the charge controlling agent adopts an aniline black dye. The developer simplifies processing technique and reduces the production cost, and can xerox images which have high concentration and high resolution with less bottom ash.

Owner:TIANJIN ZHONGHUAN TIANJIA ELECTRONICS

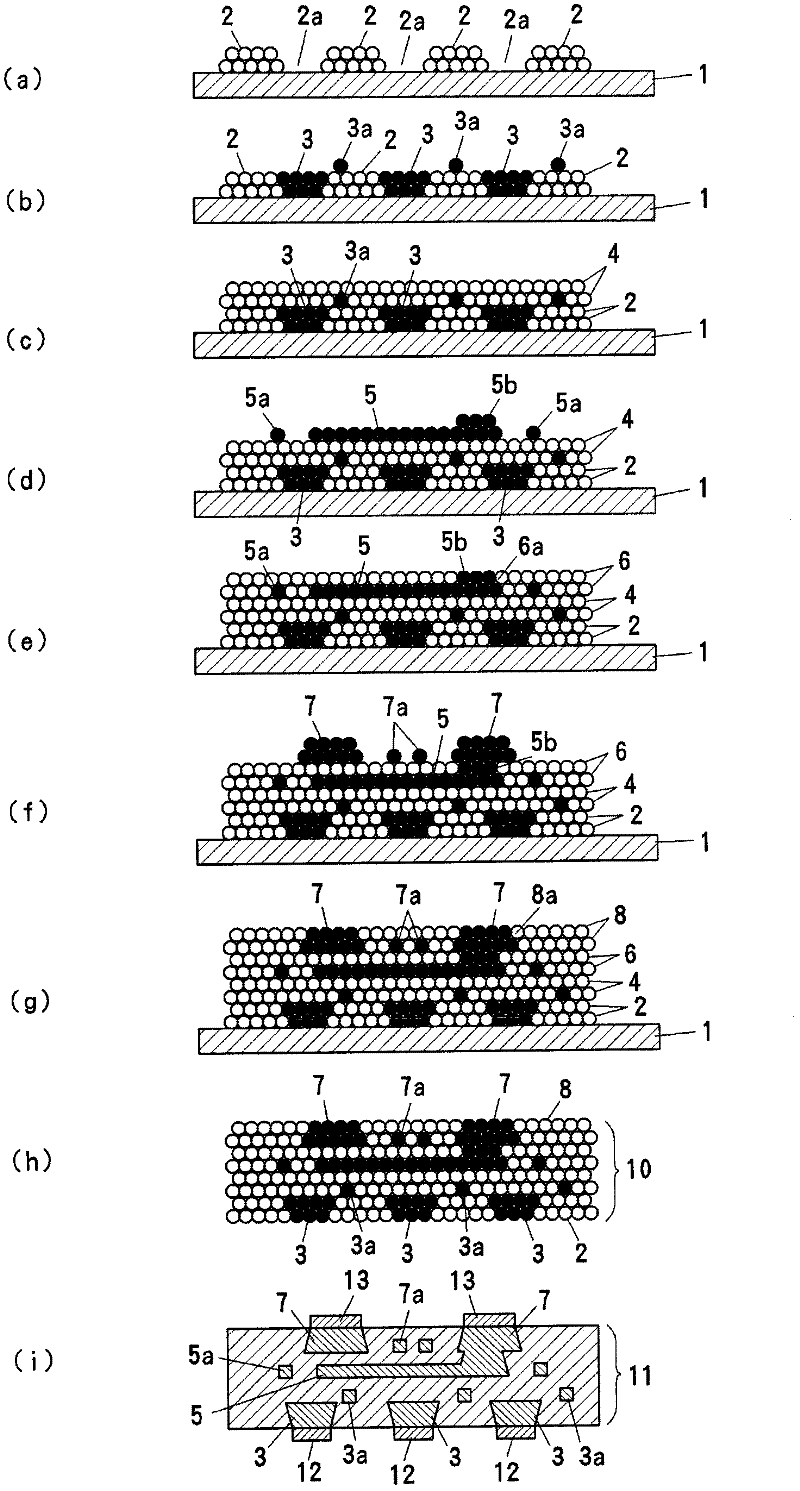

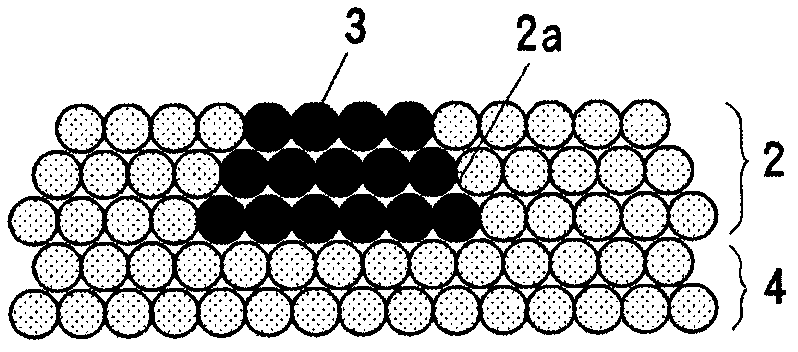

Ceramic multilayer substrate producing method

InactiveCN102415227AAvoid short circuitPrevents IR from deterioratingAdditive manufacturing apparatusPrinted circuit aspectsXerographyMaterials science

When electrodes are formed on the front and back main surfaces of a ceramic multilayer substrate by xerography, faults generated by fog toner are improved. A first outer layer ceramic layer which has openings at locations in which surface electrodes should be formed is formed on a carrier member, and surface electrodes are formed in the openings of the outer layer ceramic layer by xerography, using electrode toner. Further, after a laminated body is obtained by alternately forming inner layer ceramic layers and inner electrode patterns on the first outer layer ceramic layer and the surface electrodes, back surface electrodes are formed on the laminated body by xerography, using the electrode toner. After that, a second outer layer ceramic layer is formed so as to bridge the area other than the back surface electrodes, and the laminated body is removed from the carrier member, and is sintered to obtain a ceramic multilayer substrate. Thus, the fog toner generated when the front and back surface electrodes are formed is covered by the outer layer ceramic layer. Accordingly, the short circuit between the electrodes or the deterioration of IR can be resolved.

Owner:MURATA MFG CO LTD

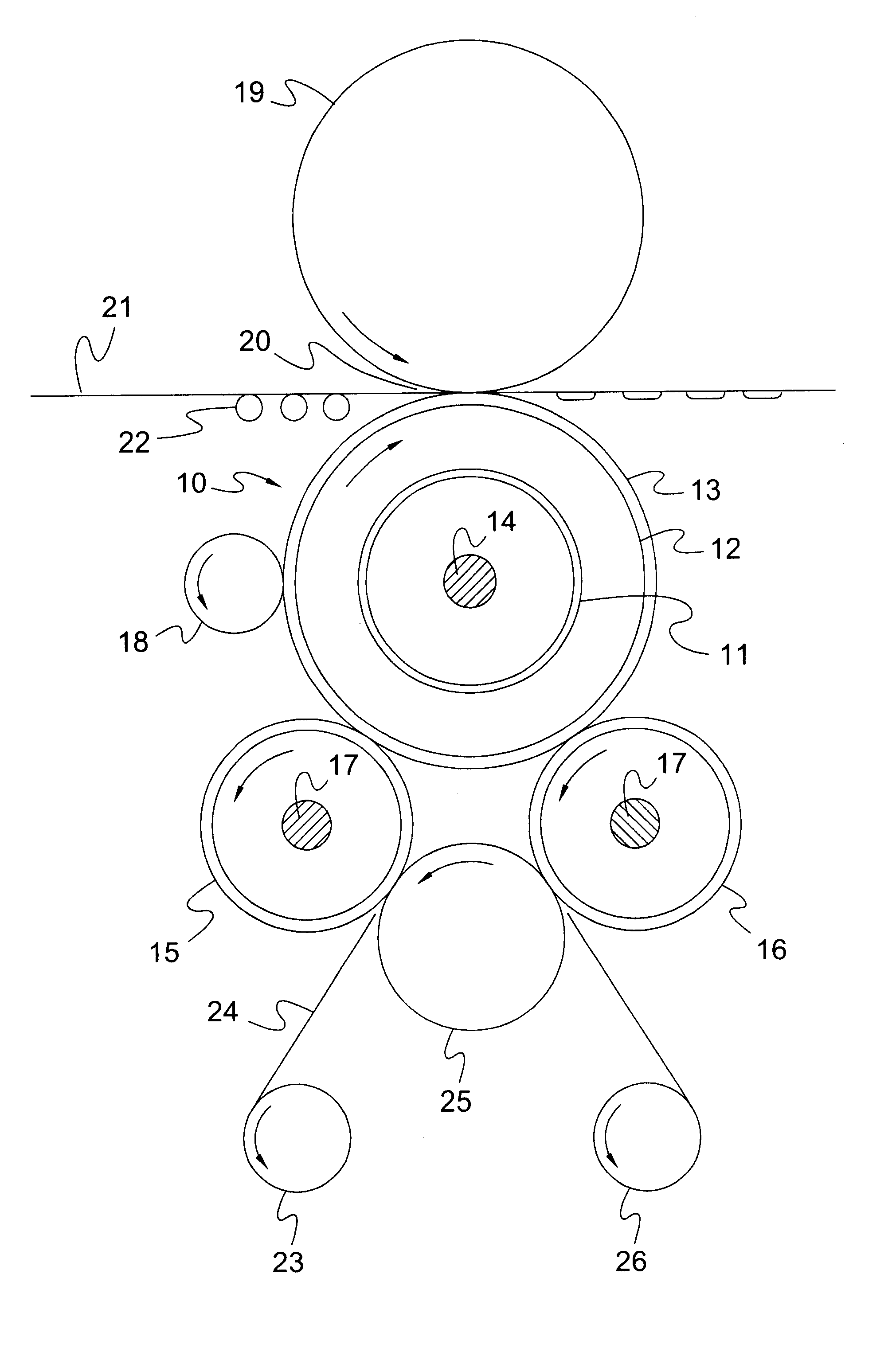

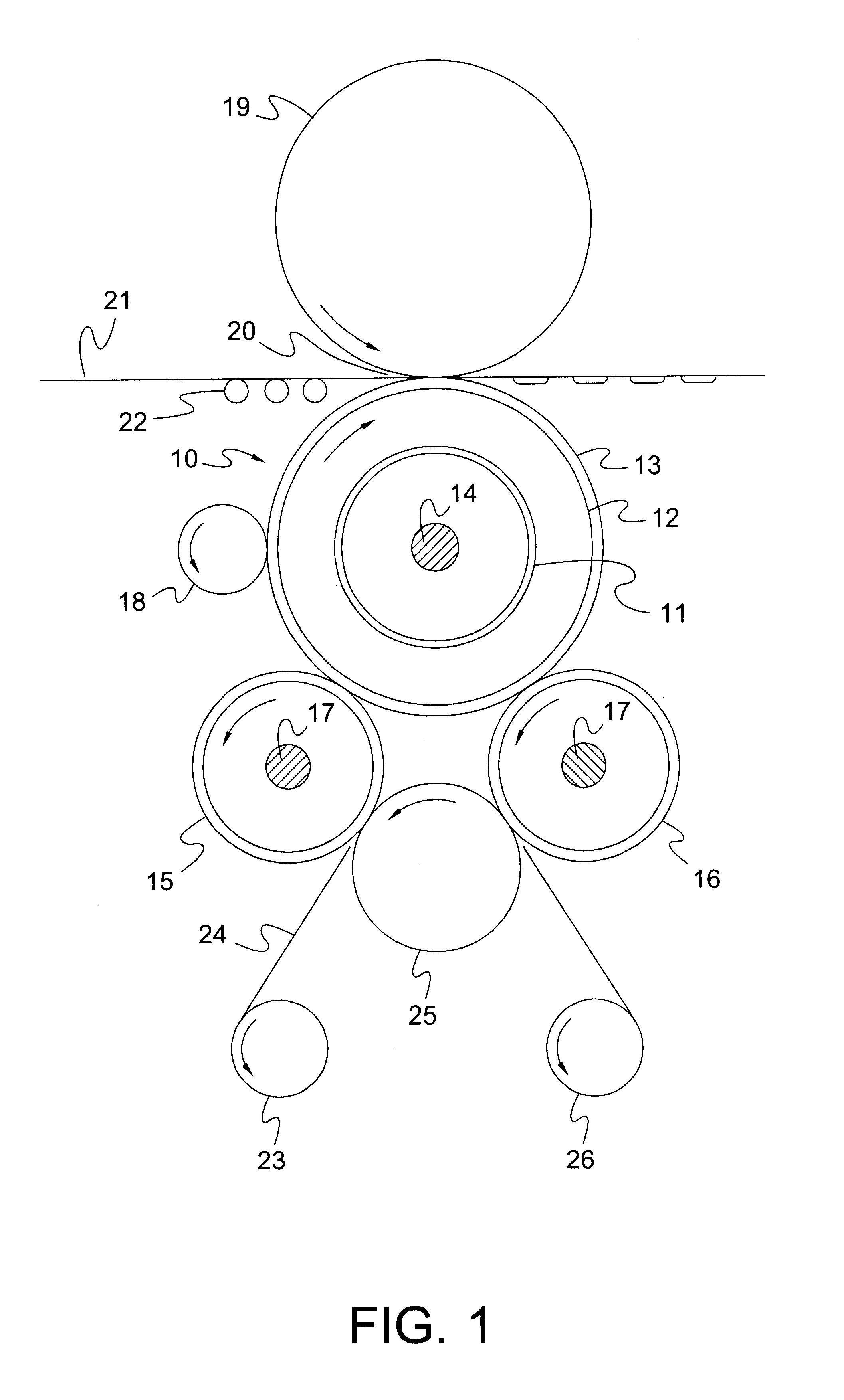

Method of applying spot varnish to xerographic image and emulsion aggregation toners for use therein

ActiveUS7288347B2Electrographic processes using photoelectrophoresisElectrographic process apparatusEmulsionXerography

A method of forming a xerographic image having at least one portion with a gloss different from a gloss of another portion of the xerographic image includes xerographically forming a toner image on a surface of a substrate and forming a finish over the toner image at the at least one portion, the finish being made of a differential gloss finish coating material that has a gloss different from that of the toner image. The differential gloss finish coating material is preferably an emulsion aggregation toner that is substantially free of pigments that adversely affect the transparency of the toner following fusing, the toner having gloss tunability through control of the amount of crosslinked portions included in the toner.

Owner:XEROX CORP

Control Grid for Solar Energy Concentrators and Similar Equipment

InactiveUS20090038827A1Lower costLow atomic weightSolar heating energySolar heat collector controllersOptical switchMesh grid

This invention provides a better means to achieve affordable solar energy, as well as other technologies. It does so by improving control grids (for addressing and alignment) in solar concentrators and optical equipment in general. Thus troublesome and expensive grid material like Indium Tin Oxide (ITO) can be replaced by more manageable, hardier, and in the long run relatively less expensive nanotubes; or a carbon grid simply laid down by ordinary photocopy (Xerographic) reduction techniques. The instant invention relates to improvements in the control (addressing and alignment) grid for Solar Energy Concentrators; and similar equipment such as Optical Switches [e.g. cf. M. Rabinowitz U.S. Pat. No. 6,976,445]; and Display devices such as Dynamic Reflection, Illumination, and Projection equipment [e.g. cf. M. Rabinowitz U.S. Pat. No. 7,130,102]; as well as display equipment in general. The control grid acts to address and align active optical elements such as mirrored balls, multipainted balls, electrophoretic, and magnetophoretic cells in solar concentrators [e.g. cf. M. Rabinowitz U.S. Pat. Nos. 7,133,183 and 6,843,573]; and in other equipment. Methods of fabricating the grids are also described.

Owner:RABINOWITZ MARIO

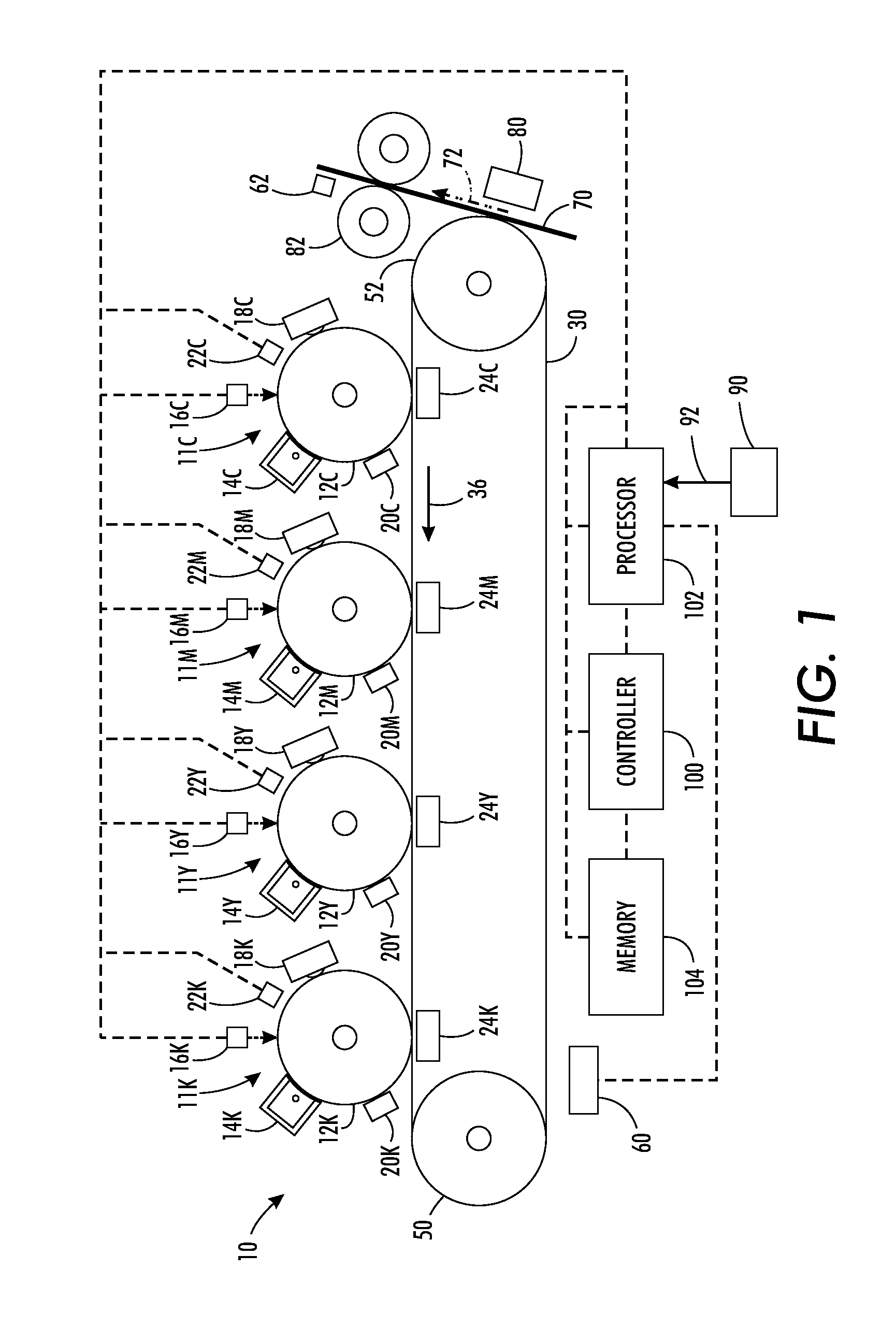

Xerographic color image forming machine having marking engines with both low gloss and high gloss developers

A color image forming machine is provided having a plurality of xerographic marking engines, each forming associated color separations that are combined to produce a color print image. Each marking engine includes two independently controlled developers using toners of the same color and strength of color but with different fused gloss characteristics, in that one of the toners will produce a print with a comparatively lower gloss and the other will produce a print with a comparatively higher gloss, thereby providing a greater control over the range of the gloss of the output print.

Owner:XEROX CORP

Additional composite function material for electrostatic developer

ActiveCN102636969APrevent sticking to photosensitive drumSolve printing problemsDevelopersElectricityComposite function

The invention discloses an additional composite function material for an electrostatic developer. The additional composite function material is prepared by raw materials including, by weight, from 50 to 70 parts of magnetic powder, from 8 to 15 parts of silicon oil, from 1 to 5 parts of zinc stearate and from 10 to 15 parts of fumed silica, and the materials are sequentially fed into a high-speed mixer to be mixed according to the proportions, so that the additional composite function material is obtained. The additional composite function material is used for the electrostatic photocopying technology, can be used with single-component silica, effectively prevents a tone agent from being adhered with a photosensitive drum during usage, and solves the problem of hollow printed or photocopied images and texts. In addition, the problem of image rippling due to over thick tone agent accumulated on a magnetic roller can be accessorily solved when the additional composite function material is used in a magnetic single-component system, and the quantity of electricity of the tone agent can also be regulated.

Owner:NANJING TESHINE IMAGING TECH

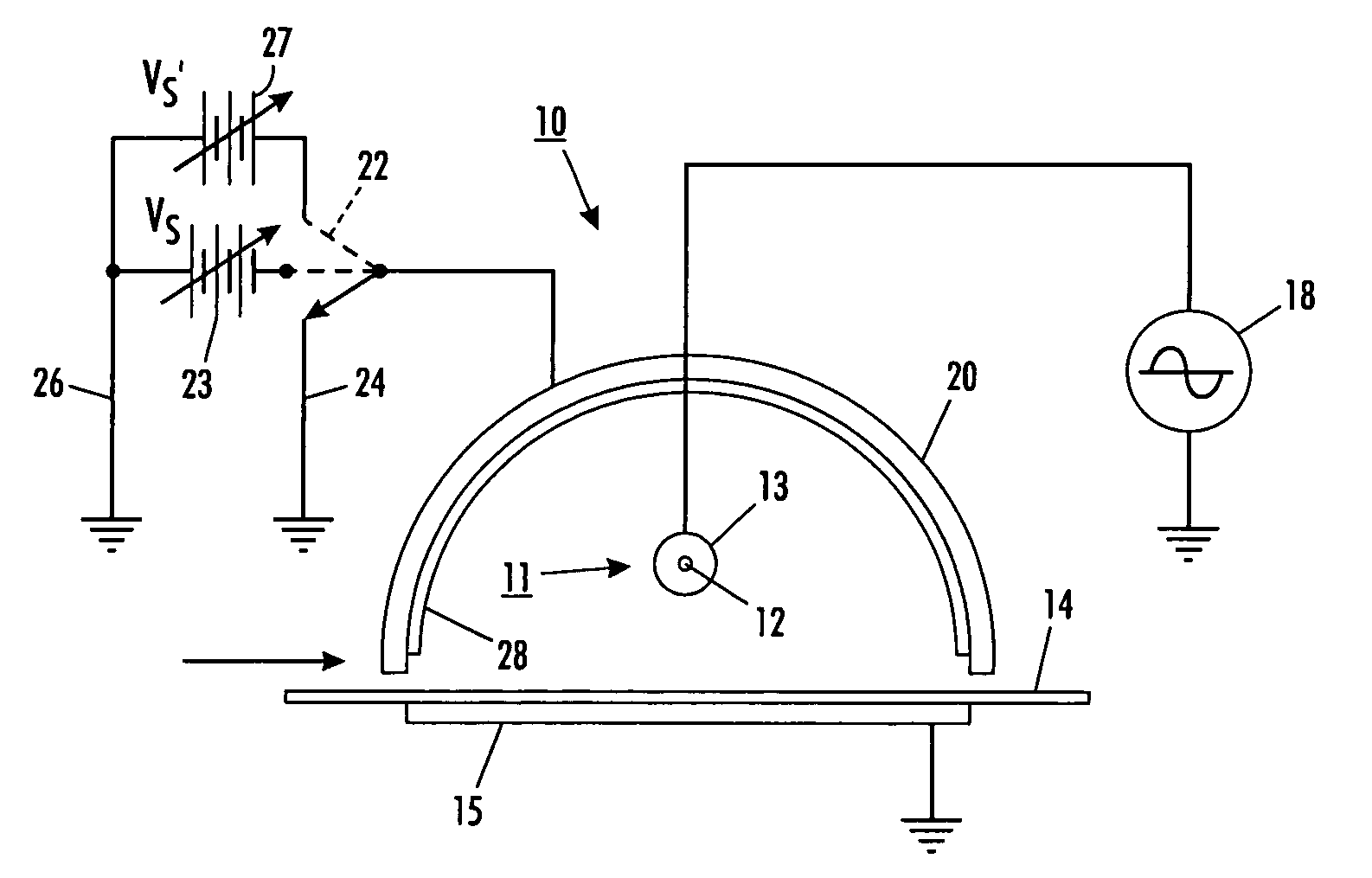

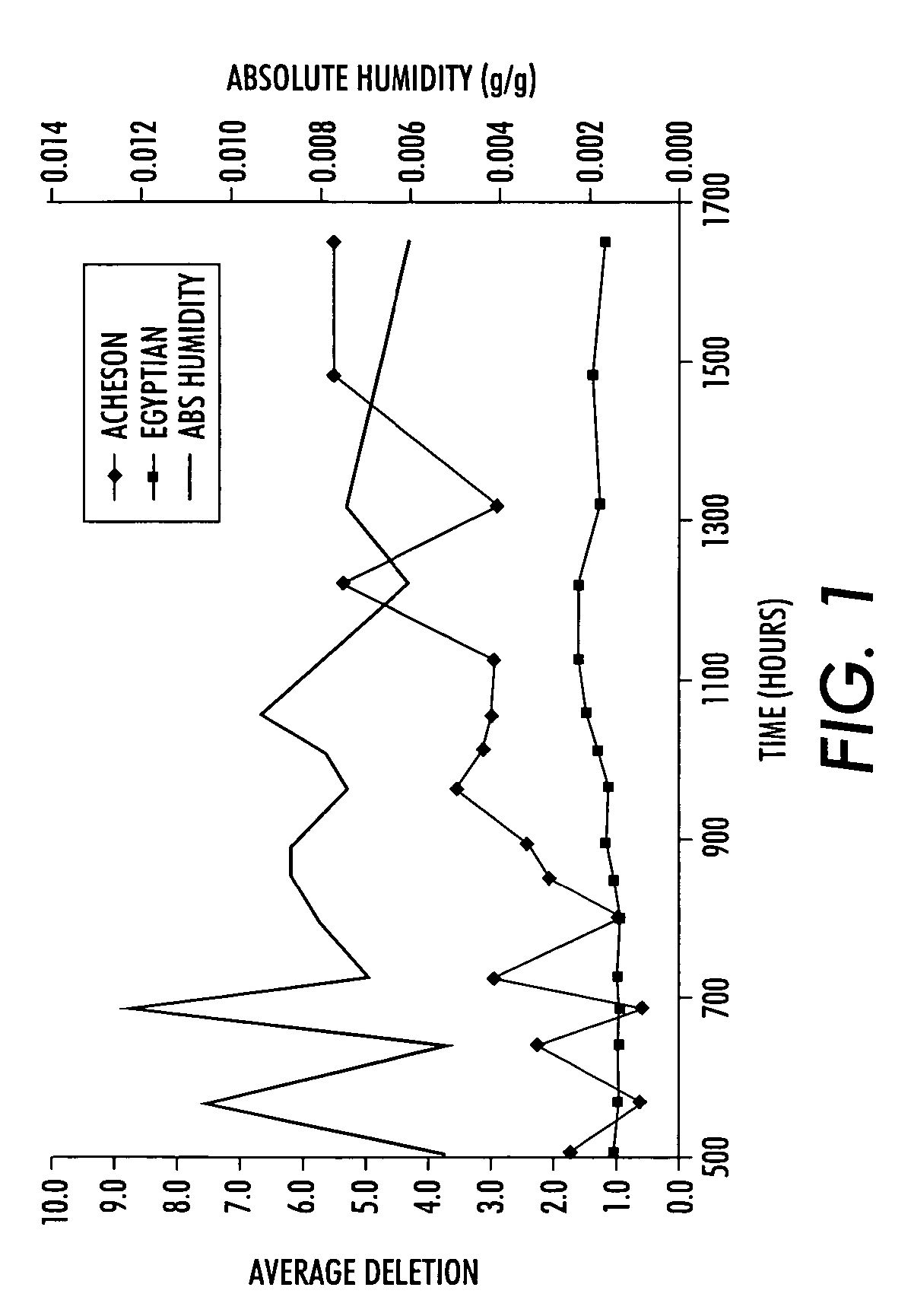

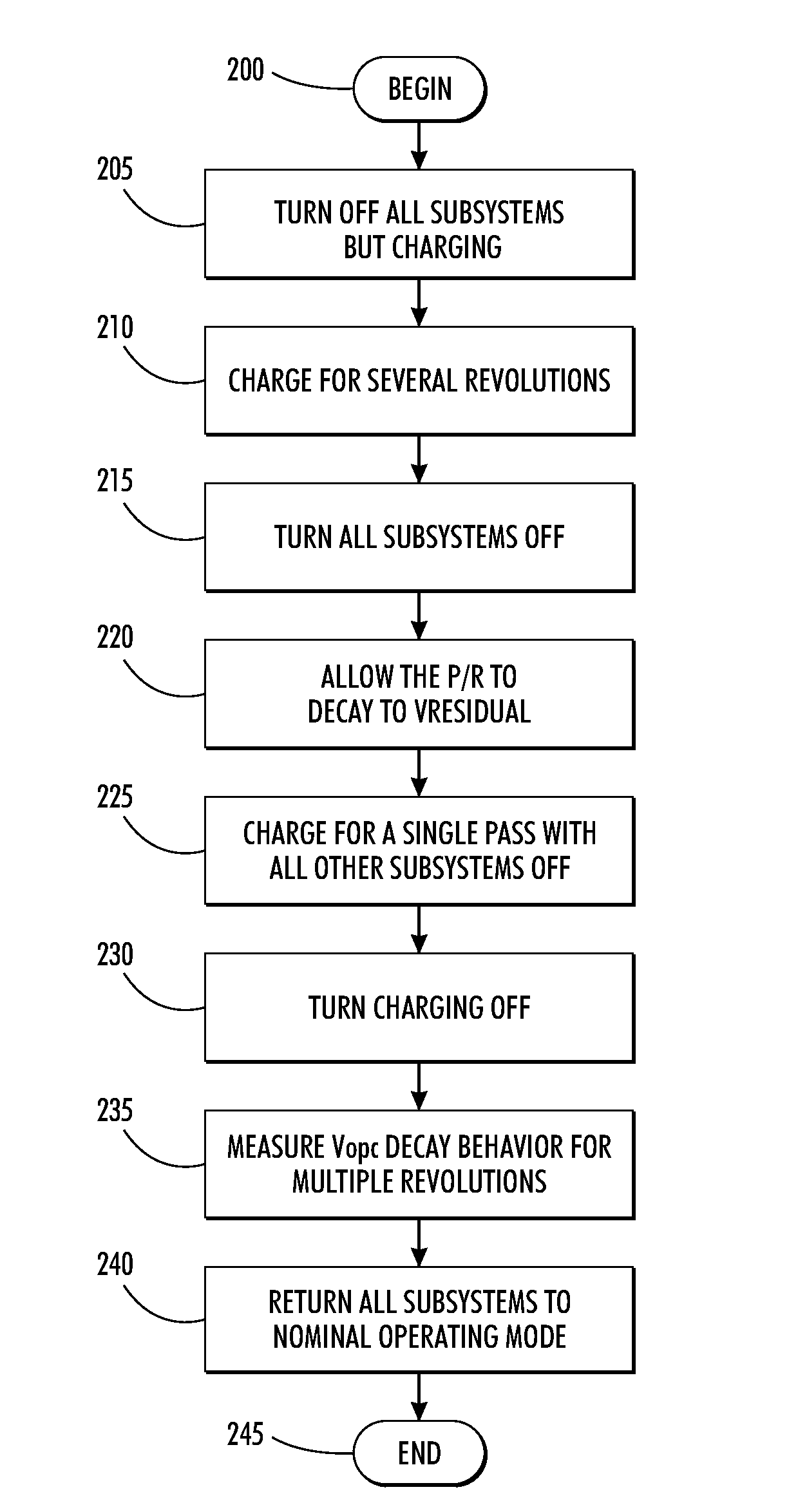

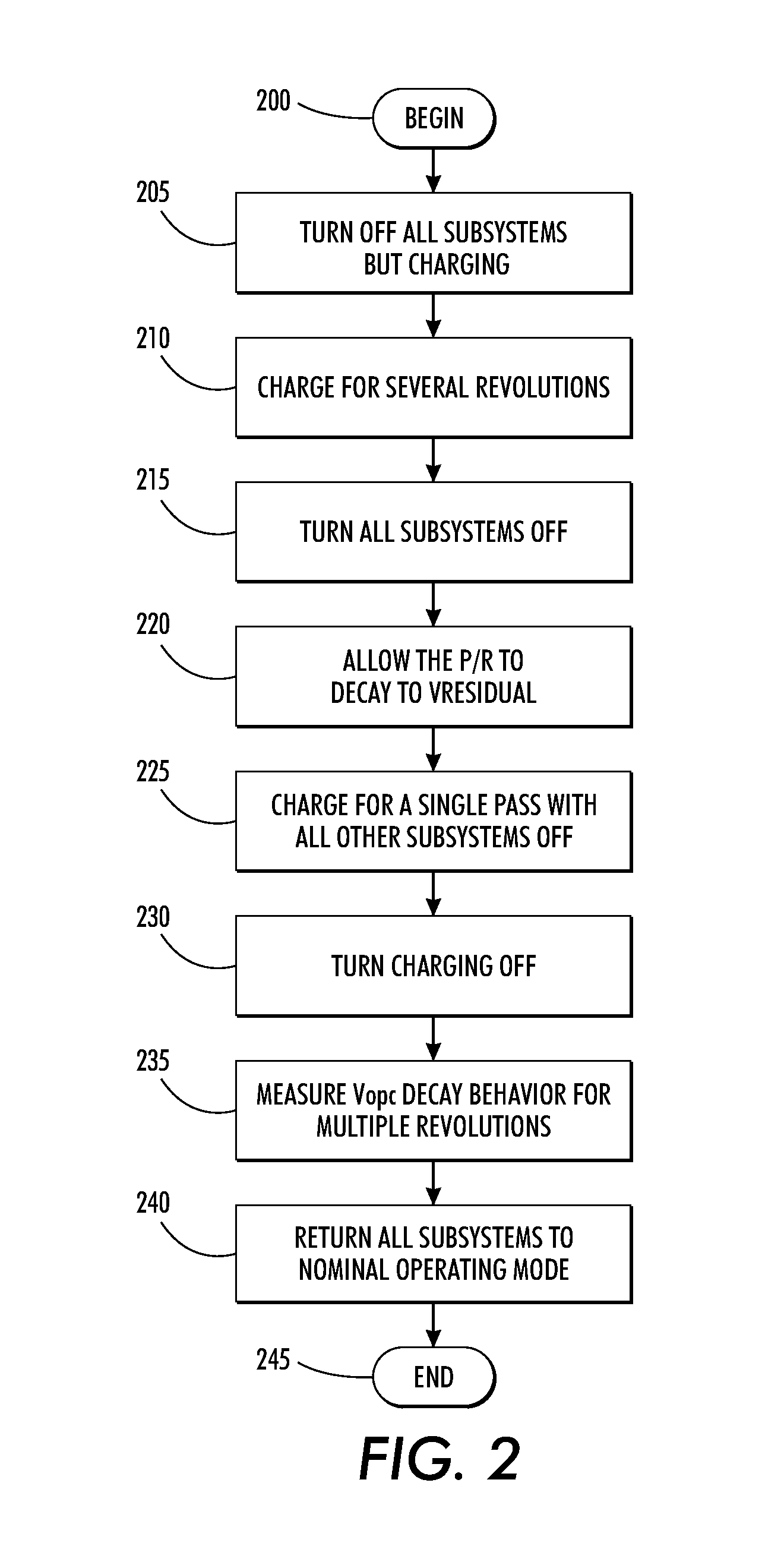

Method and system for troubleshooting charging and photoreceptor failure modes associated with a xerographic process

InactiveUS20130129365A1Electrographic process apparatusCorona dischargeCharging stationReliability engineering

This disclosure provides methods and systems for troubleshooting charging and photoreceptor failure modes associated with a xerographic process. Specifically, according to an exemplary method the photoreceptor decay behavior, with and without the effects of depletion, are quantified and used to determine a performance state of one or more of the charging stations and the photoreceptor surface.

Owner:XEROX CORP

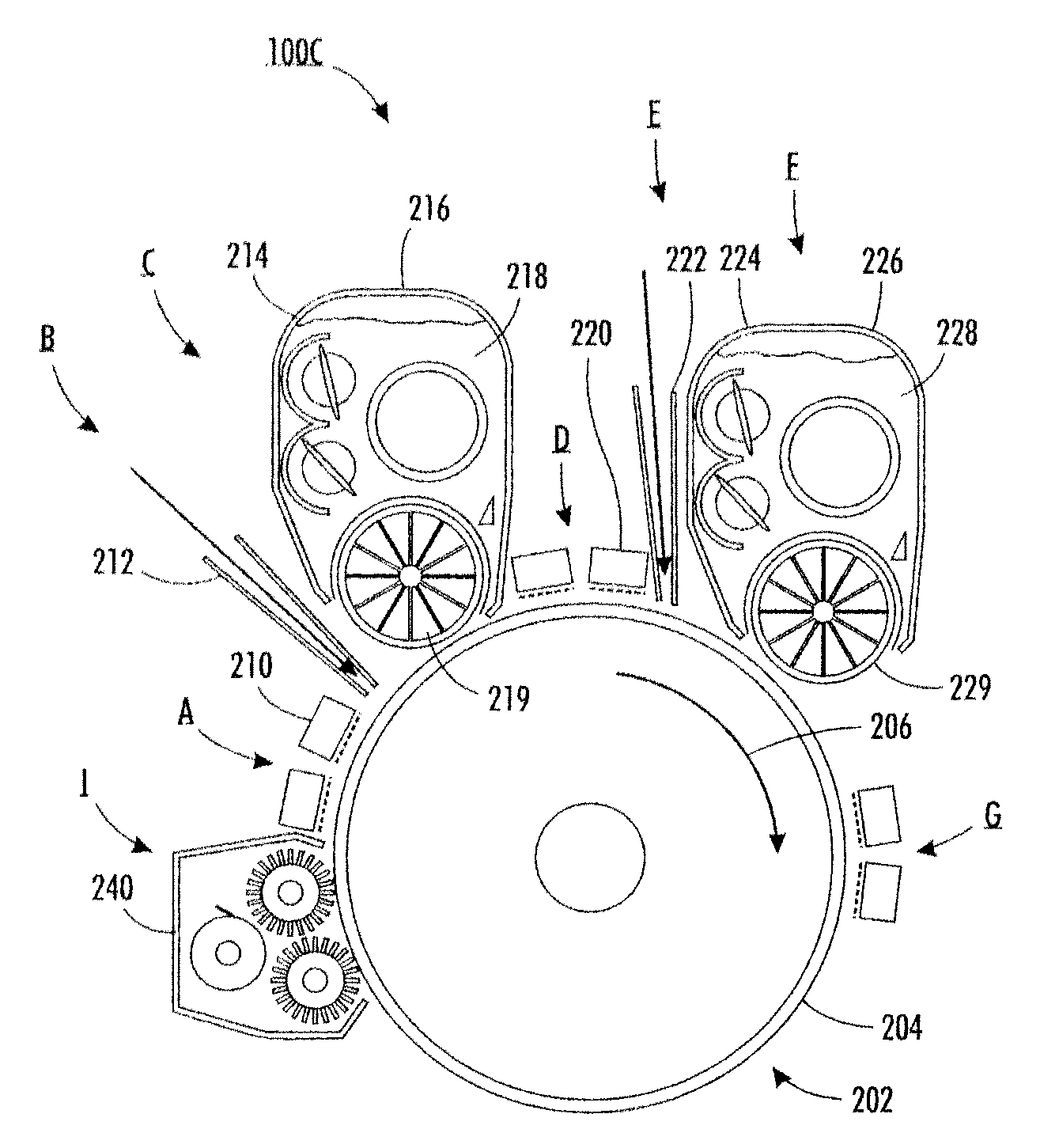

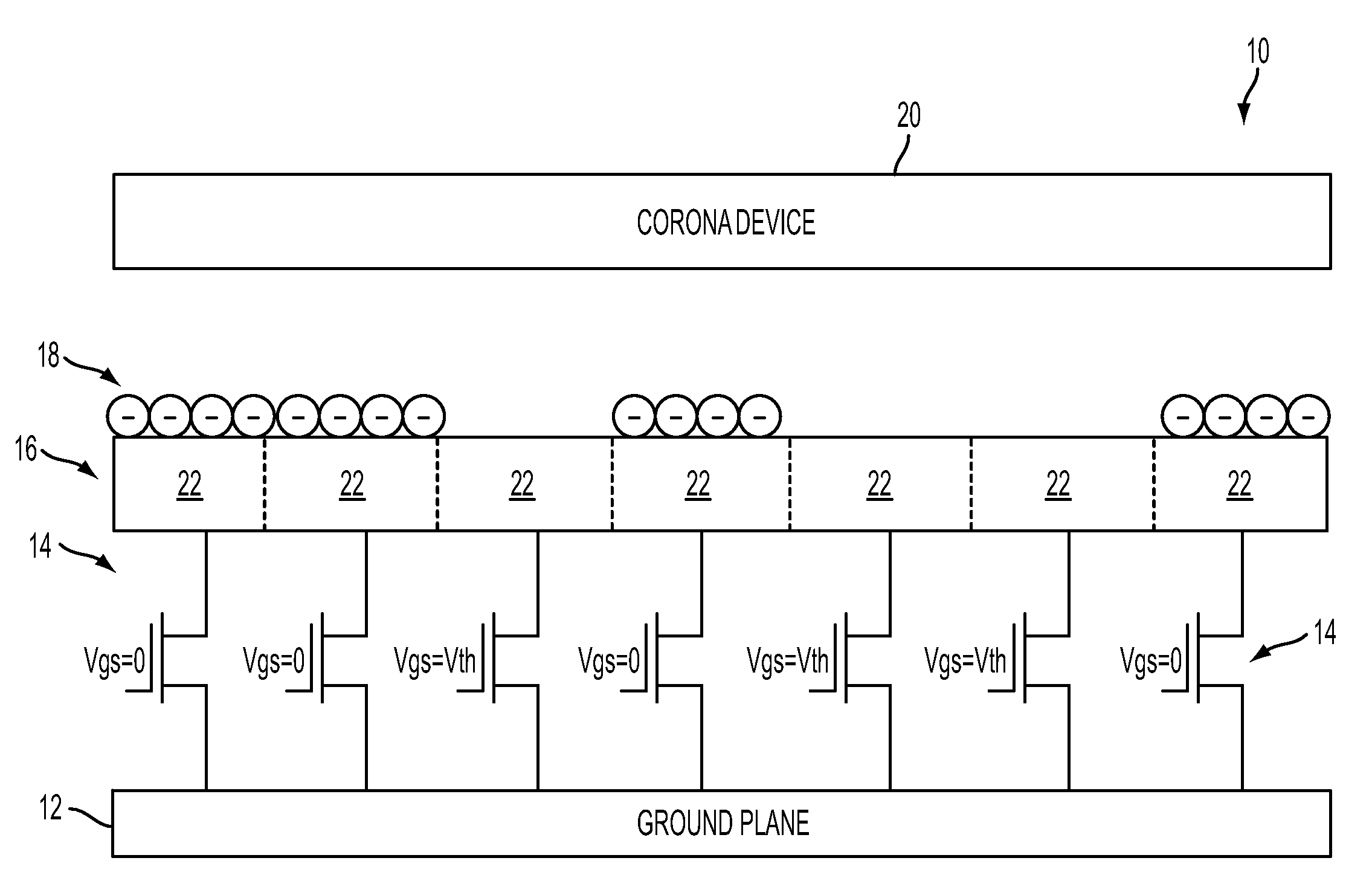

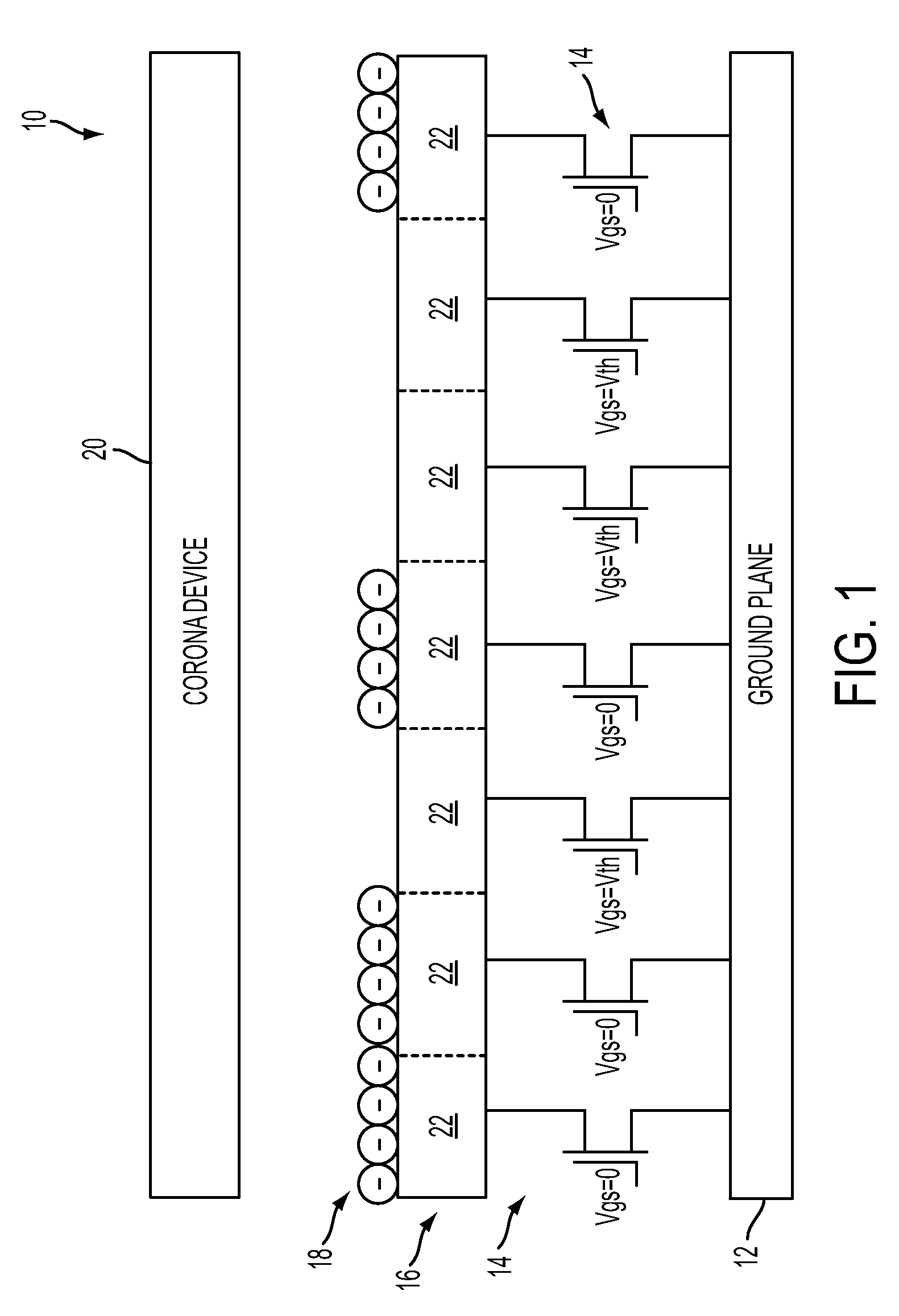

Image forming apparatus with a TFT backplane for xerography without a light source

ActiveUS20100201777A1Facilitate using TFT controlEasy to useRecording apparatusElectrographic process apparatusCharge carrierLatent image

Systems and methods are described that facilitate using TFT control of electronic discharge for surface potential reduction and latent image formation on an imaging member. Corona charging is performed to first create a background surface potential, followed by selective discharge of individual pixels using an array of TFTs to supply free charge carriers to reduce the electrostatic surface potential to nearly zero. This is followed by discharged area development (DAD) to develop the latent image on a print medium (e.g., paper). The described systems and methods do not require a HVPS to drive the backplane; therefore, the TFT matrix is electrostatically decoupled from the developer and other system components in direct contact with the imaging member. Accordingly, known addressing systems may be used to address the TFT array.

Owner:XEROX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com