Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Reduce particle content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special pigment finishing offset paper and producing method thereof

InactiveCN1584205AReduce particle contentIncrease bulkNon-fibrous pulp additionCoatings with pigmentsGreen environmentXerography

This invention discovers a special pigment groom hectograph paper and its preparation. It utilizes the advantages of high yields machine pulp (PRC-APMP) and deink pulp (DIP) which is well thickness and green environment. That is optimizing pigment spreading formulation, optimizing pulp to materials ratio and its wet end chemical and copy making technique to reach the white value of all bleaching chemical pulp proportioning copy paper. The advantages of the products are: better printing adaptability, better relaxation thickness, better printing effect features compared with all chemical pulp hectograph paper. It's capable of producing top grade office and printing culture special pigment groom hectograph paper which is made according to different clients' requirement and selecting different optimized features' technique for different application such as laser printing, xerography and hectograph etc. So, it's capable of decreasing all chemical pulp quantity, saving wood, protecting forest, protecting environment from pollution.

Owner:YUEYANG FOREST & PAPER CO LTD

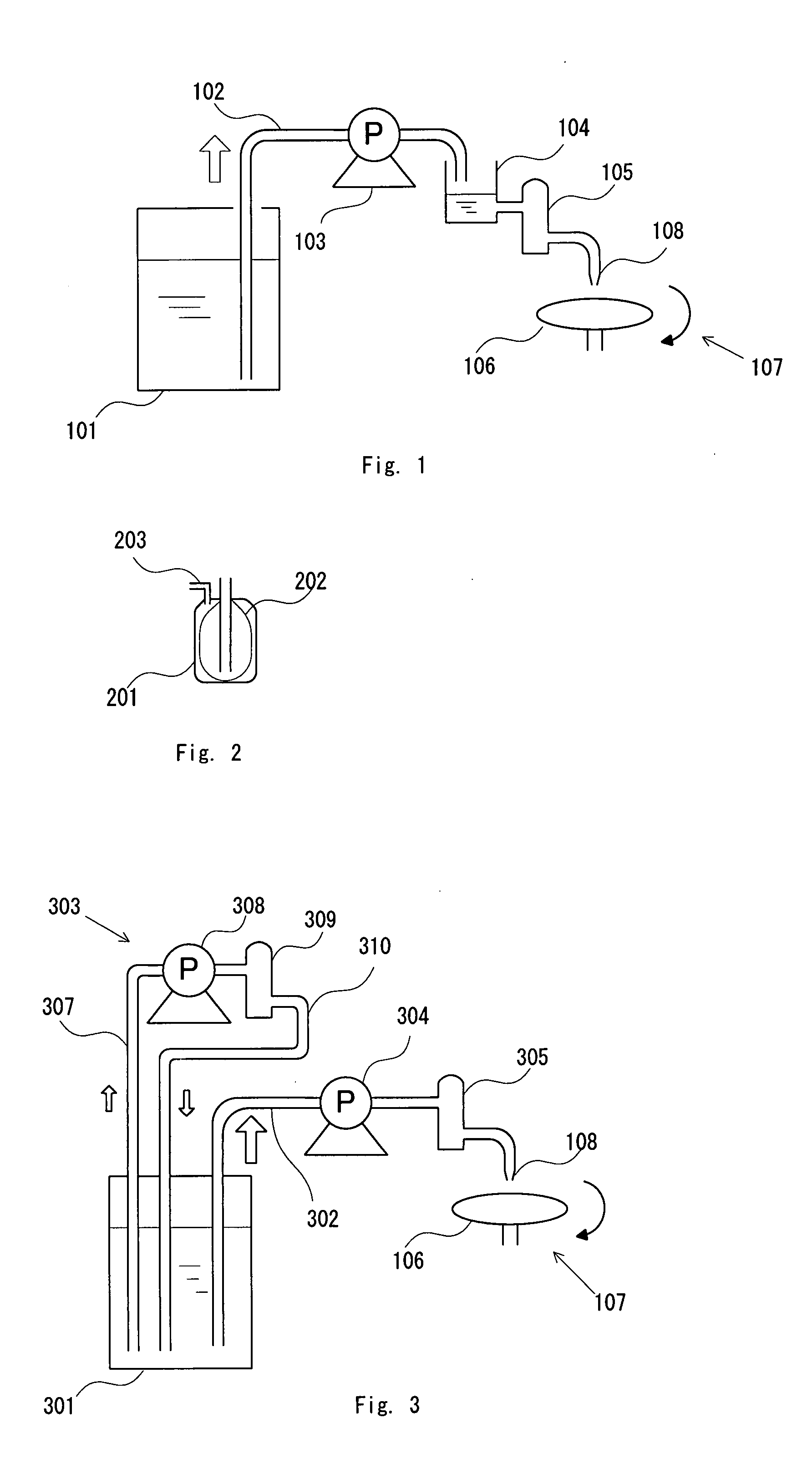

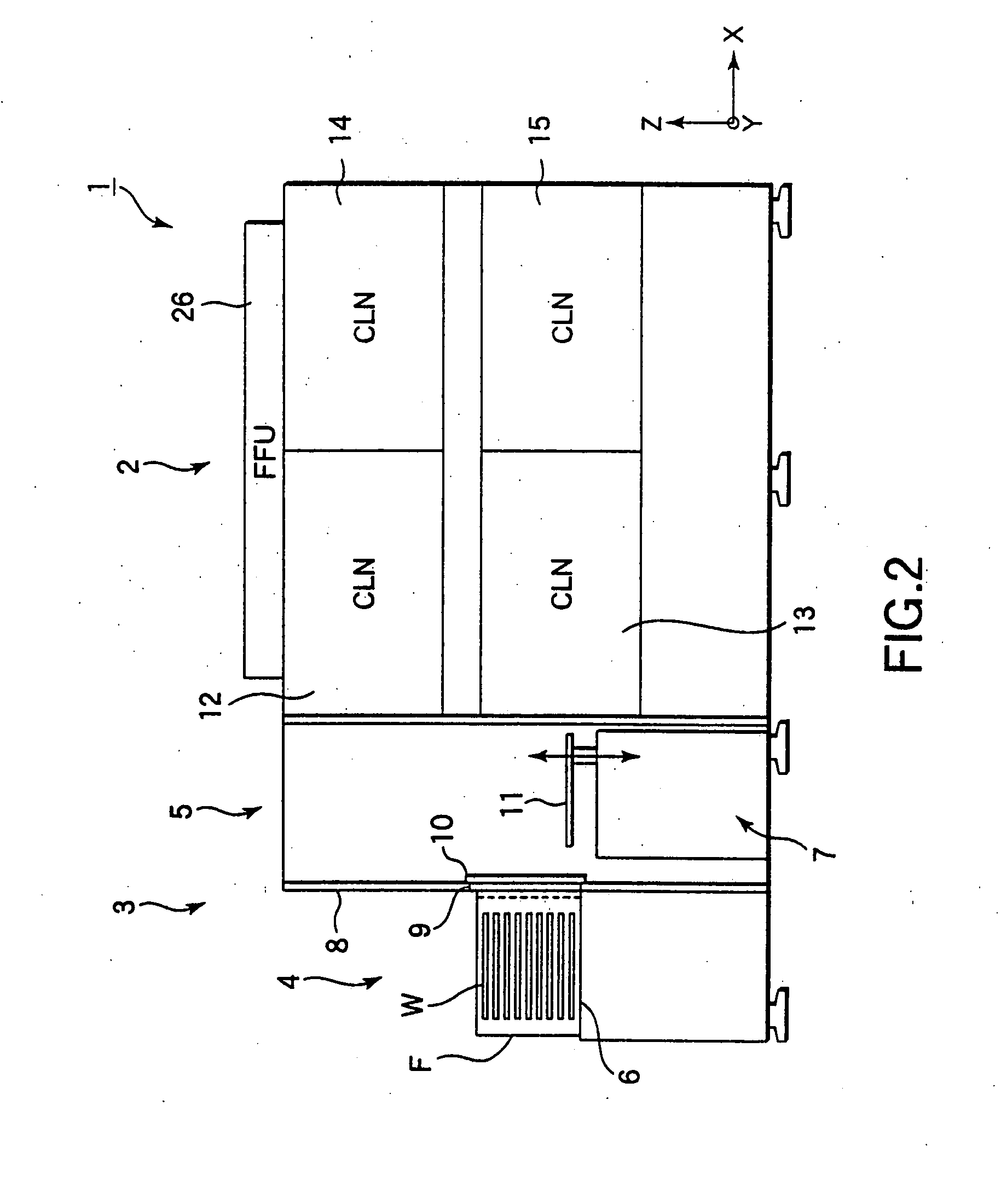

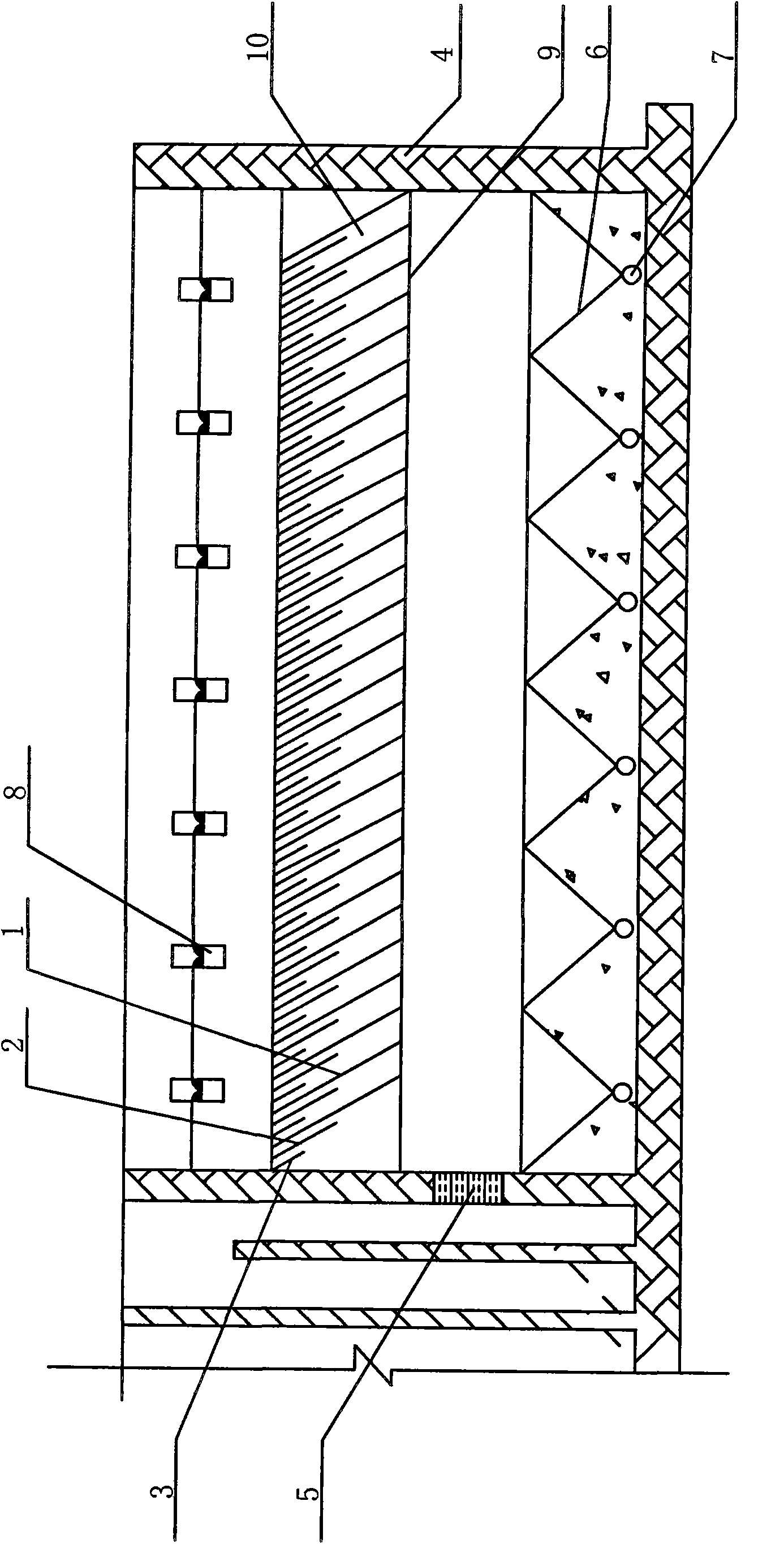

Liquid processing apparatus and liquid processing method

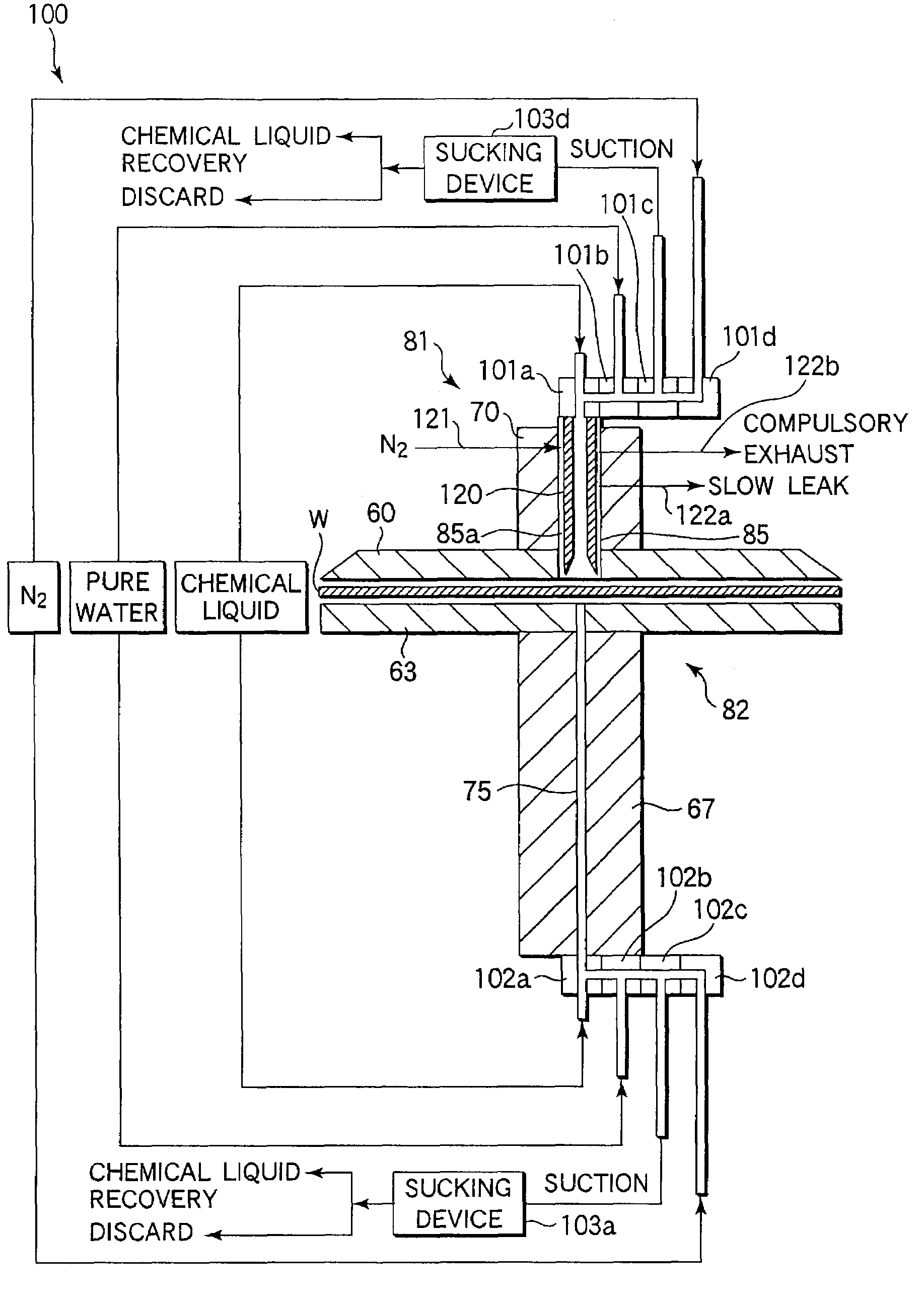

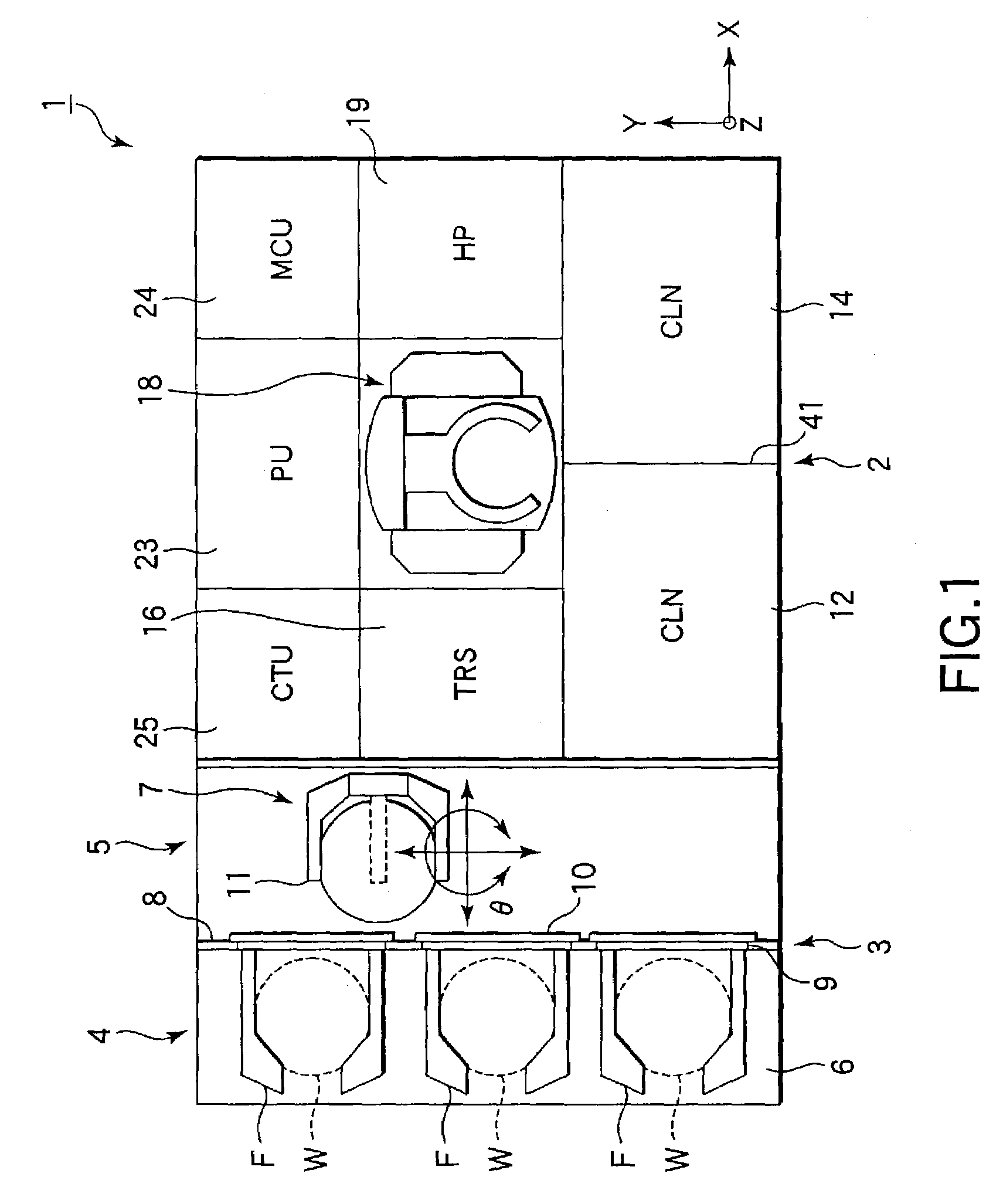

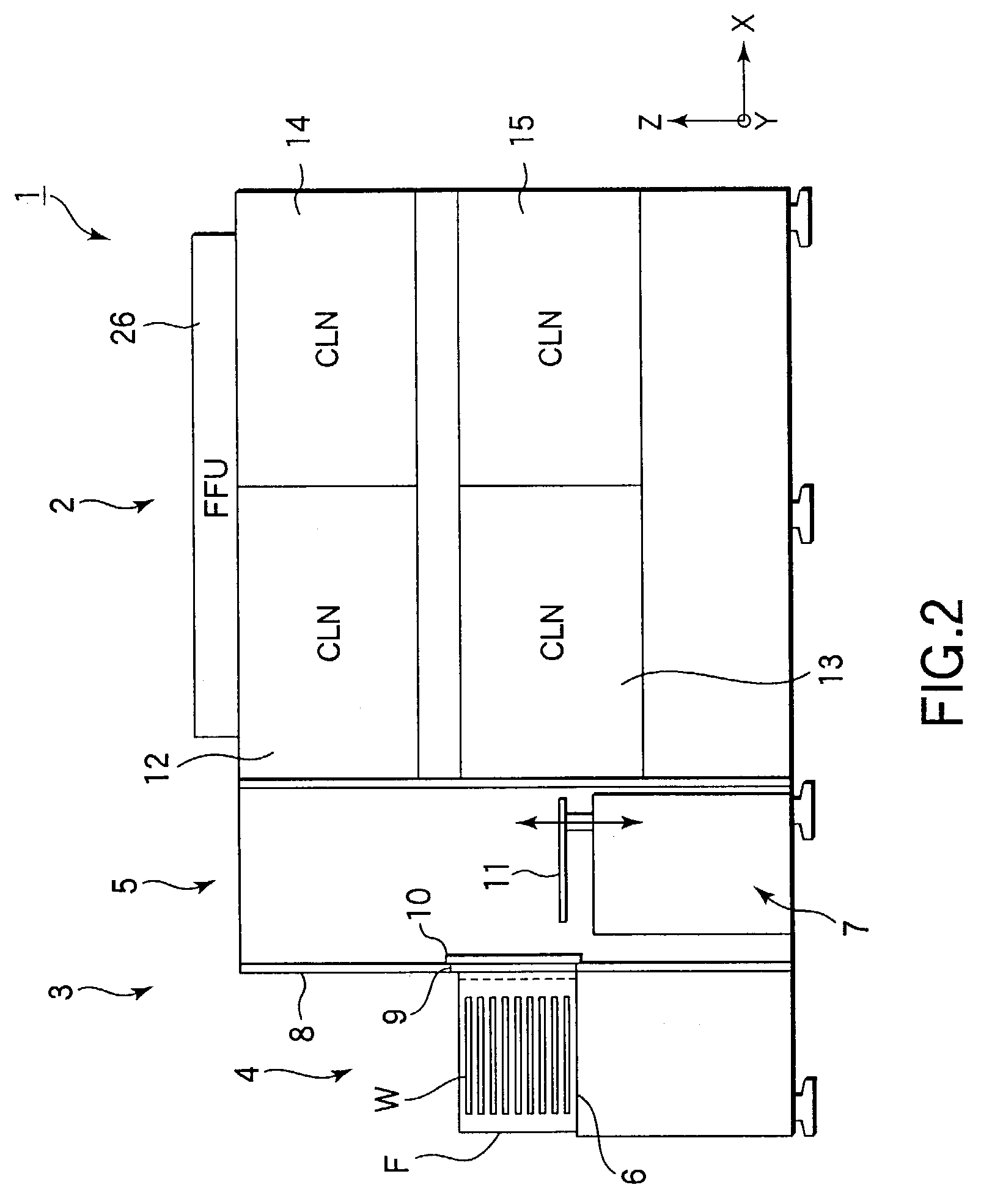

InactiveUS7275553B2Effective recoverySuppress generationElectrostatic cleaningSemiconductor/solid-state device manufacturingEngineeringNozzle

A cleaning processing apparatus comprises a spin chuck for holding a wafer W, an under plate being positioned to face the back surface of the wafer W with a prescribed gap provided therebetween, a support member for supporting the under plate, and a nozzle hole formed to extended through the plate member and the support member. A chemical liquid, a pure water and a gas can be supplied into a nozzle hole through opening-closing valves, and the chemical liquid and the pure water remaining inside the nozzle hole can be sucked by a sucking device. A pure water remaining inside the nozzle hole is sucked and removed by using the sucking device after the processing of the wafer W with a pure water and, then, a gas is spurted onto the back surface of the wafer W.

Owner:TOKYO ELECTRON LTD

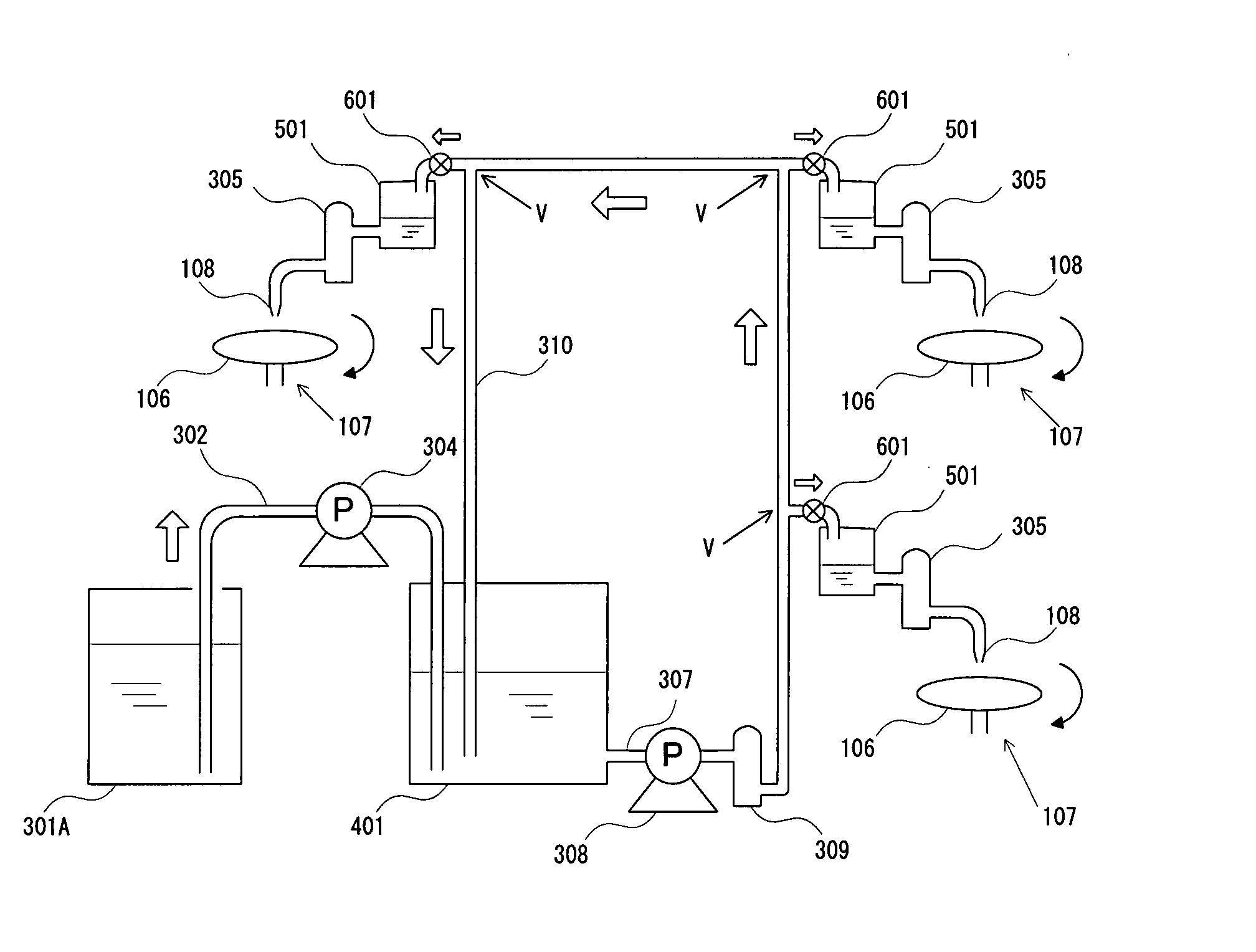

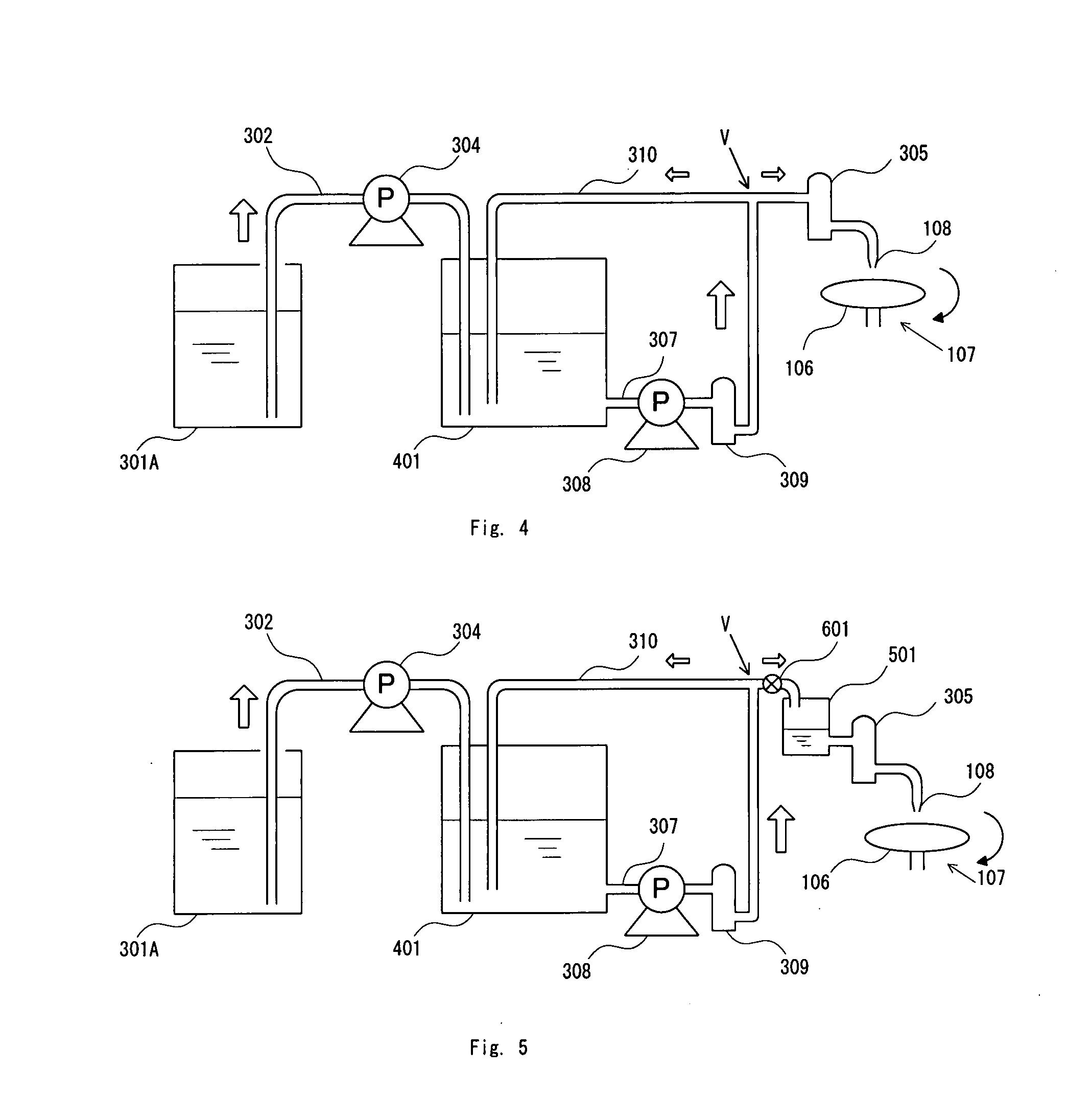

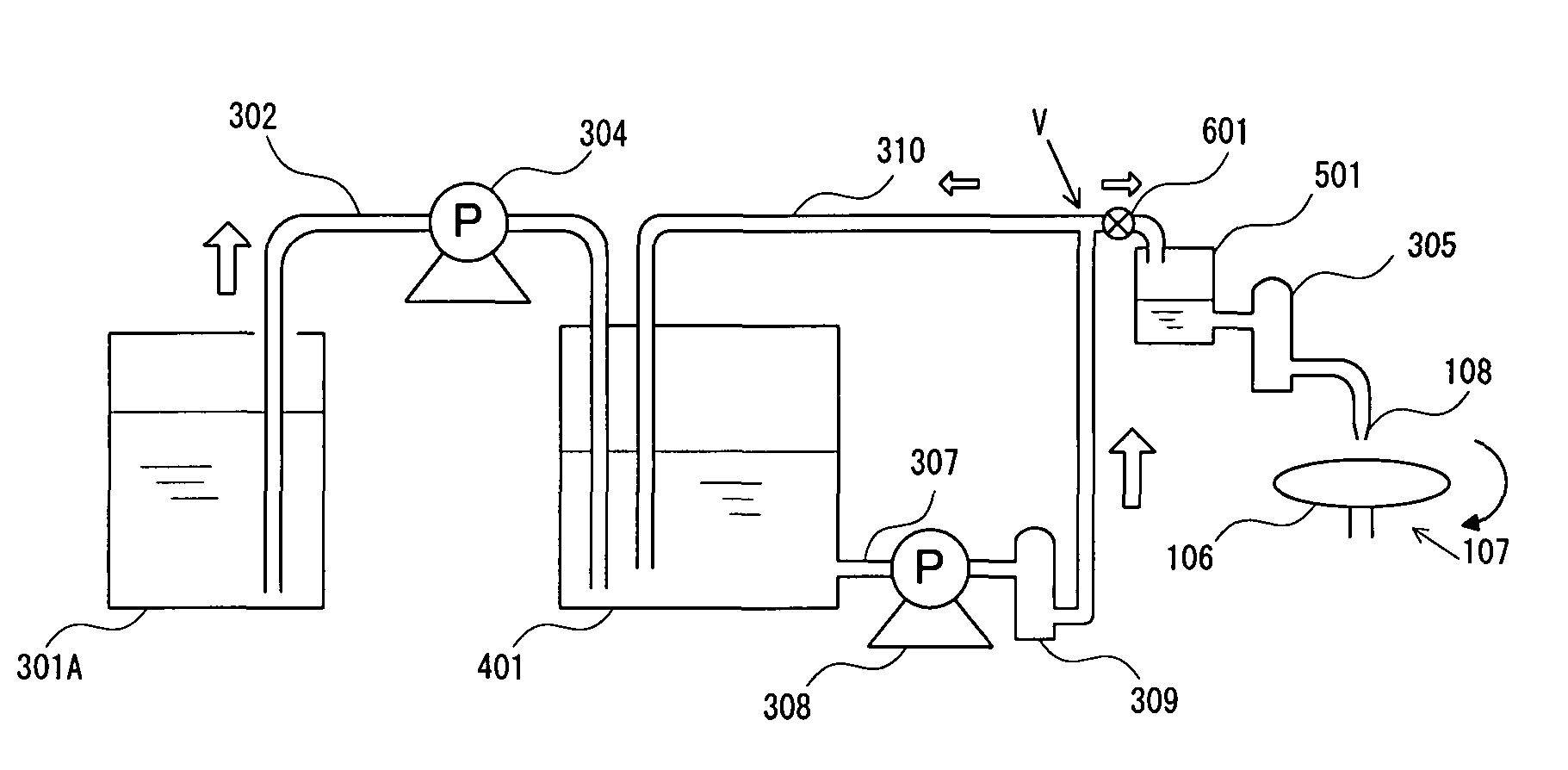

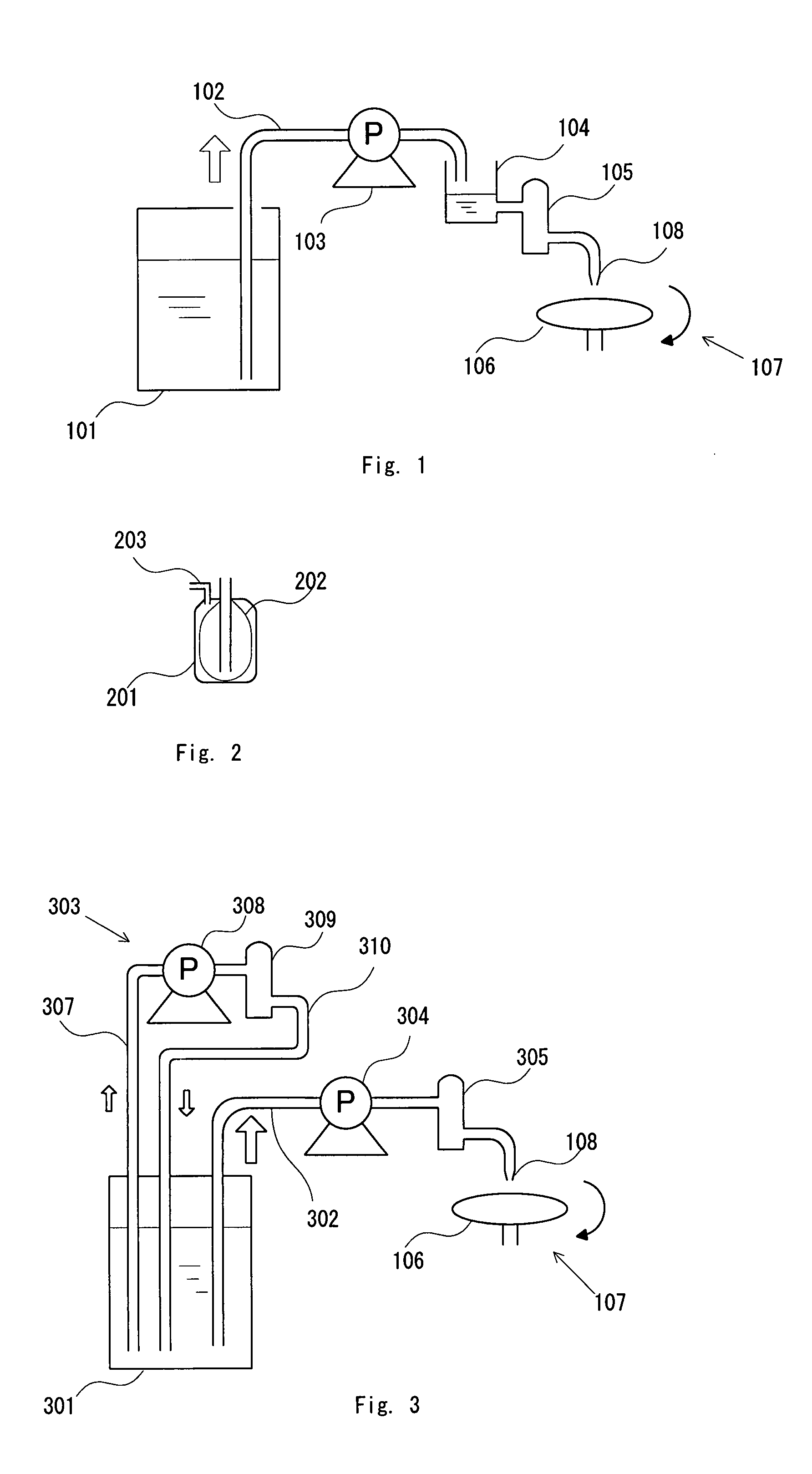

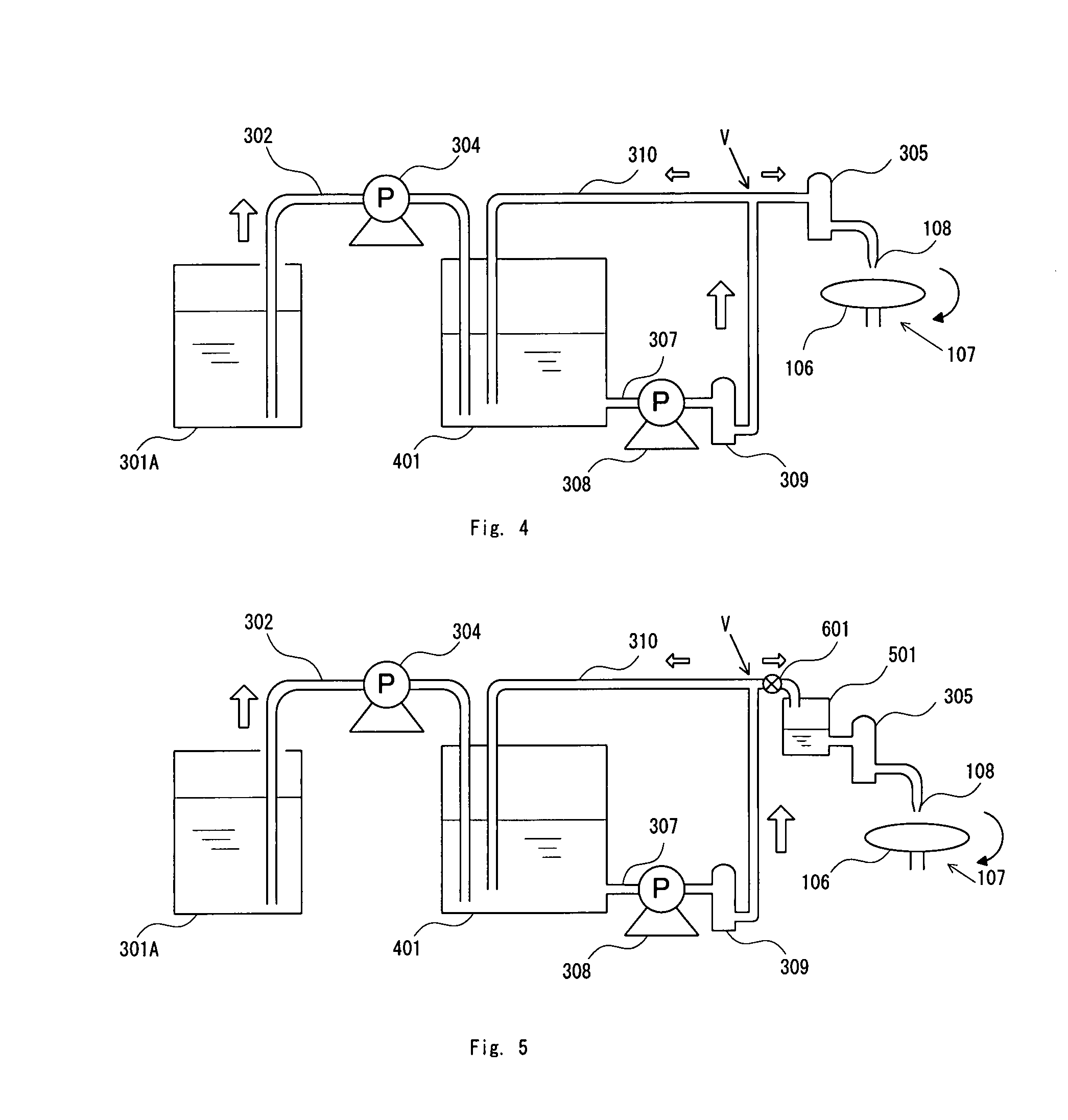

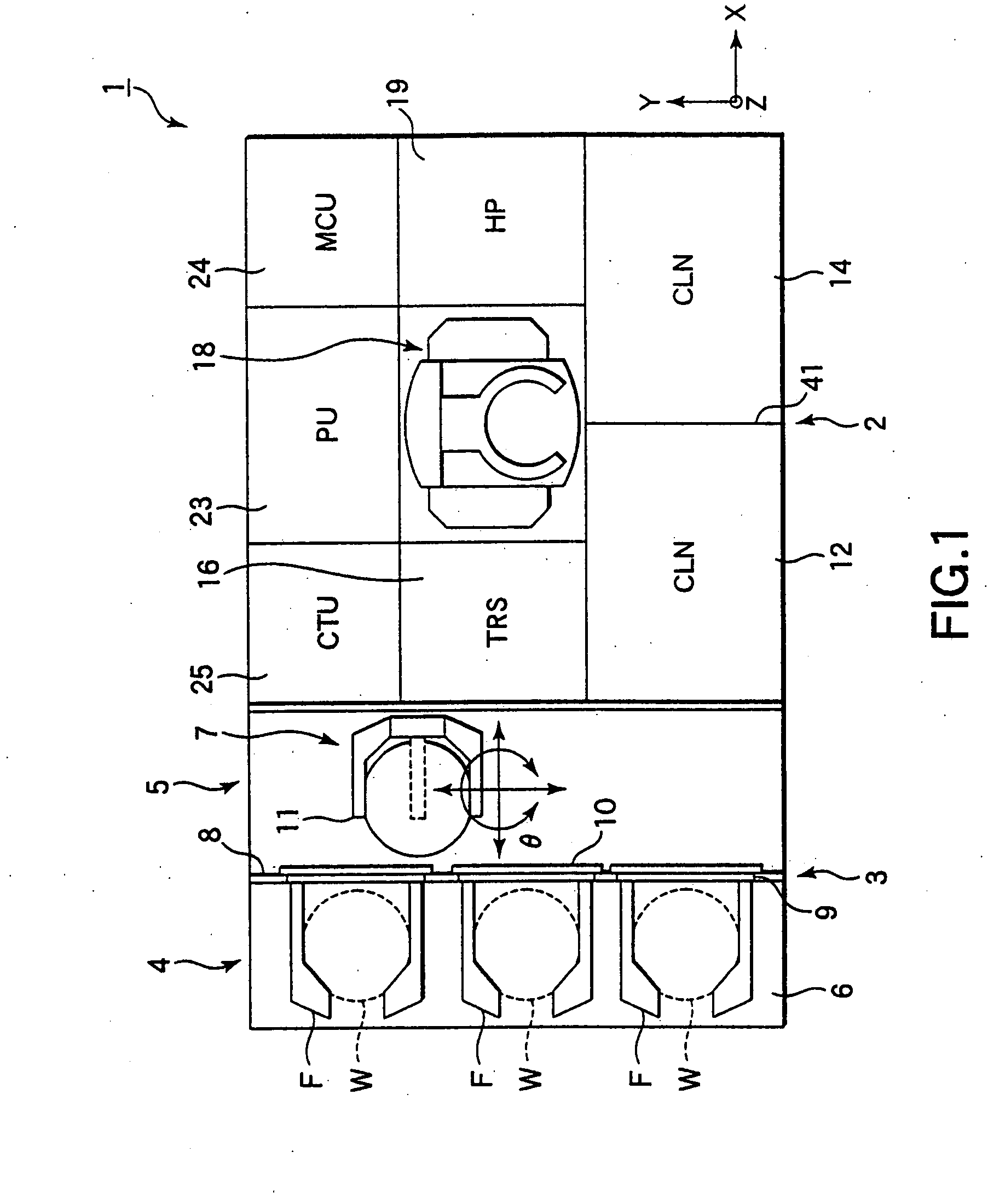

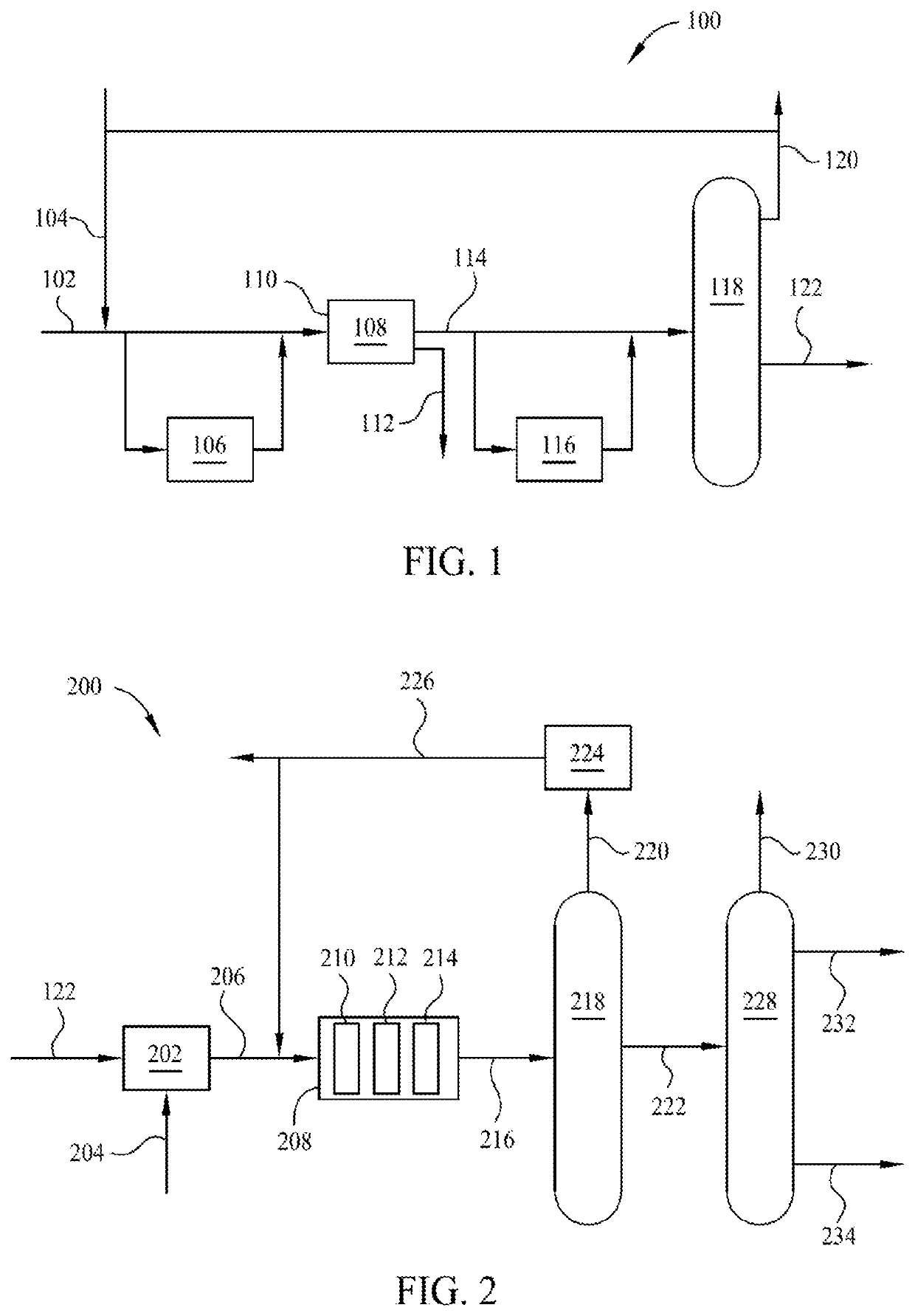

Photoresist Coating Liquid Supplying Apparatus, And Photoresist Coating Liquid Supplying Method And Photoresist Coating Apparatus Using Such Photoresist Coating Liquid Supplying Apparatus

InactiveUS20080087615A1Reduce defectsIncrease productionLiquid separation auxillary apparatusPhotomechanical apparatusResistMaterial defect

This invention provides a photoresist coating liquid supplying apparatus and a photoresist coating liquid supplying method, for supplying a photoresist coating liquid having a low particle content to a photoresist coating apparatus, and a photoresist coating apparatus using such a photoresist coating liquid supplying apparatus, which can realize coating without causing significant defects in a cost-effective manner. The photoresist coating liquid supplying apparatus comprises a buffer vessel for a photoresist coating liquid, a circulation filtering apparatus for drawing a part of the coating liquid from the buffer vessel, filtering the coating liquid, and then returning the filtered coating liquid to the buffer vessel, and a pipe for supplying the coating liquid from the buffer vessel or the circulation apparatus to a coating apparatus. The photoresist coating liquid supplying method uses the photoresist coating liquid supplying apparatus. The photoresist coating apparatus comprises a combination of the coating liquid supplying apparatus with a slit coating apparatus.

Owner:MERCK PATENT GMBH

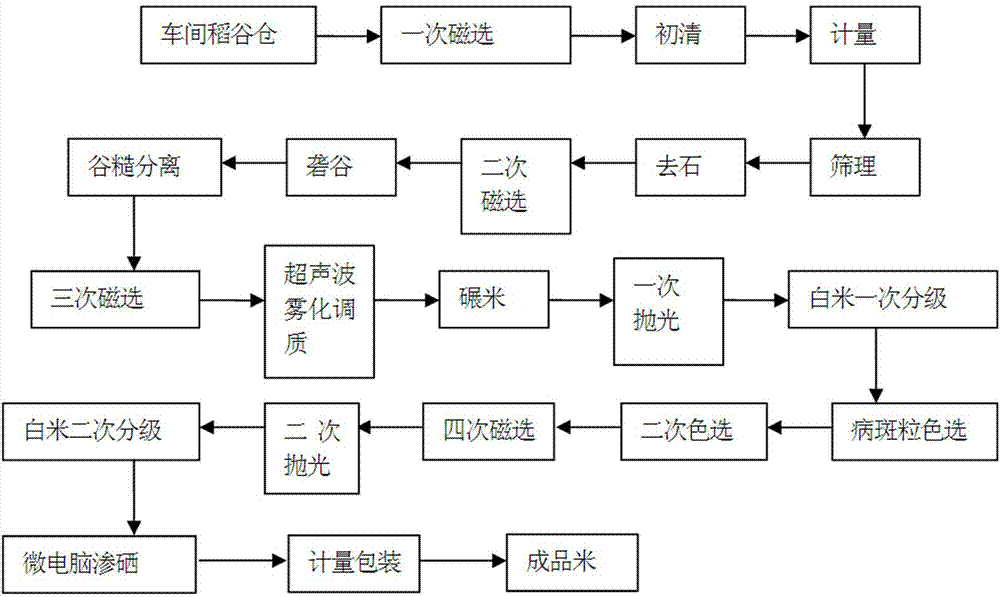

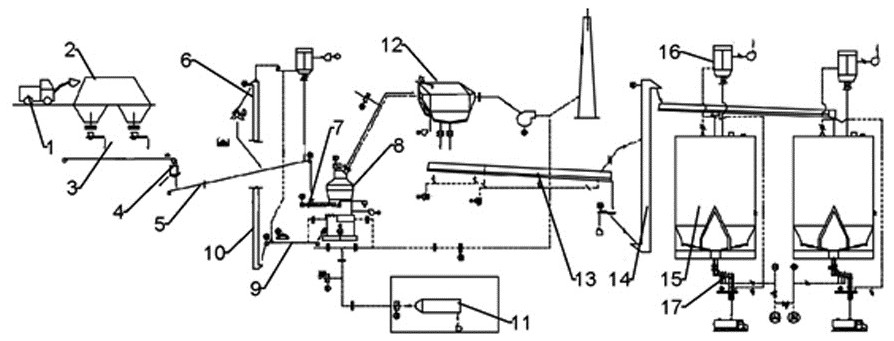

High-quality rice fine processing process

ActiveCN104772178AImprove Sorting Efficiency and PurityImprove the quality of finished riceSortingGrain millingSecondary colorChemistry

The invention provides a high-quality rice fine processing process, which comprises the processing flow processes of primary magnetic separation, primary cleaning, metering, sieving, stone removing, secondary magnetic separation, husking, husked rice separation, tertiary magnetic separation, ultrasonic atomization tempering, rice milling, primary polishing, polished rice primary grading, spotted rice color separation, secondary color separation, fourth magnetic separation, secondary polishing, polished rice secondary grading and metering and packaging. According to the ultrasonic atomization tempering, an ultrasonic atomization humidification mode is used for humidifying the rice, the tempering time is 10 to 20 minutes, the tempering temperature is controlled to be between 30 DEG C and 40 DEG C, the unit humidification quantity is 0.5 to 5 percent, the actual seeping quantity is 2 to 3 percent, and the moisture content of the polished rice finally obtained through processing is not greater than 14 percent; tempering agents adopt ultrasonic atomization water; during the spotted rice color section, a photoelectric color separation device is used for automatically picking out different-color rice, the full-process temperature reduction is carried out in the whole processing flow process, and the temperature rice in the processing process is controlled not to exceed 5 DEG C. The high-quality rice fine processing process has the advantages that the high-quality rice can be subjected to integrated utilization and deep processing, and the final product quality is improved.

Owner:YUNNAN HONGHE WOLONG RICE IND CO LTD

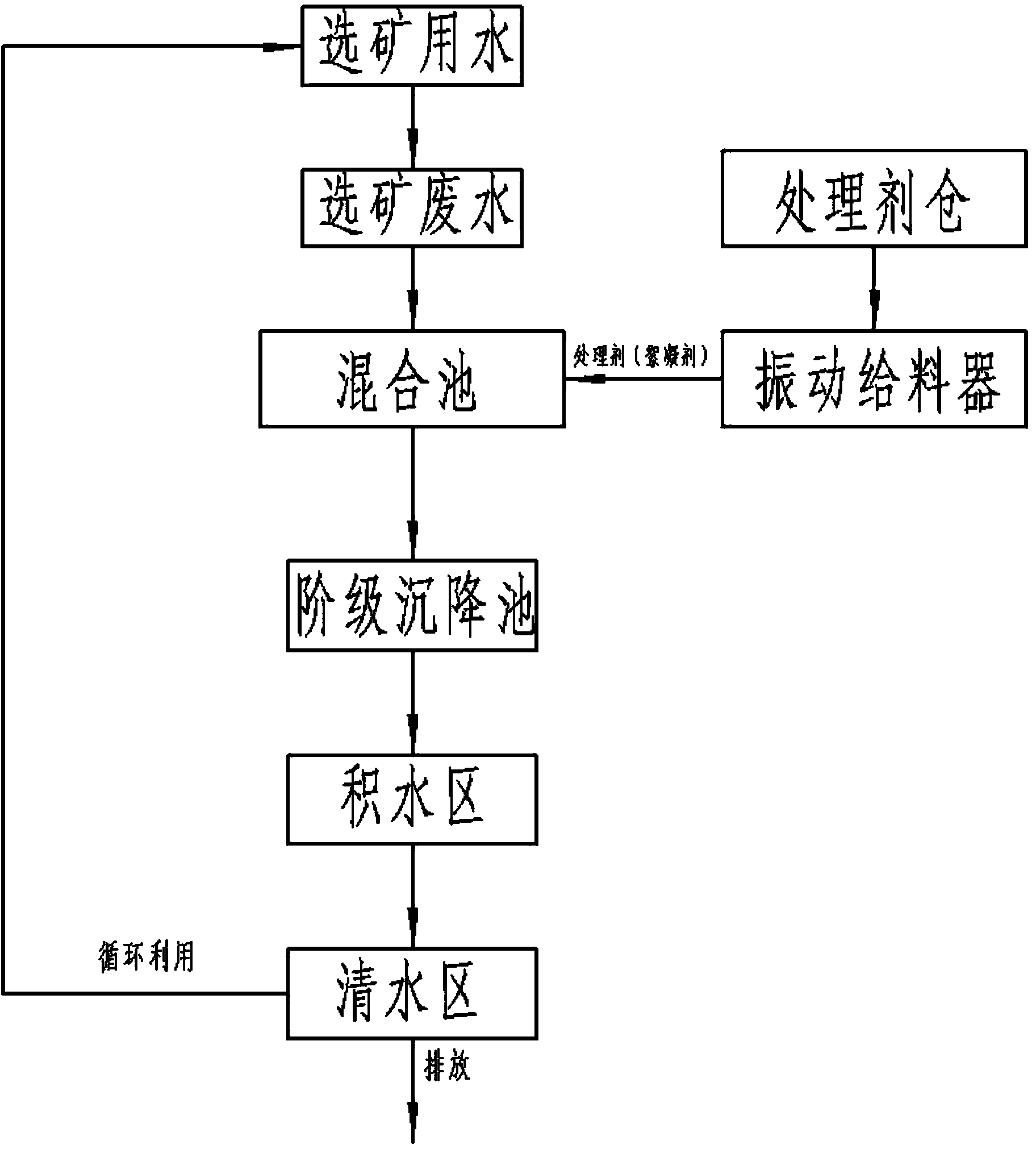

Polymetallic ore beneficiation wastewater recycling method

InactiveCN103708591AReduce productionIncrease the amount of purificationWater/sewage treatment by flocculation/precipitationSlagWater circulation

The invention provides a polymetallic ore beneficiation wastewater recycling method. The polymetallic ore beneficiation wastewater recycling method is characterized by comprising two steps of physical treatment and biological treatment. According to the polymetallic ore beneficiation wastewater recycling method, the existing beneficiation wastewater output equipment and tailings ponds of aluminium and zinc beneficiation industries are used, wastewater treating agents such as calcium hydroxide, saponification slag and calcium carbide are added to wastewater in a mixing tank so as to ensure that suspended matters in the wastewater settle, the wastewater is purified so as to meet the technical requirements that obtained clear water is continuously used for beneficiation, the content of suspended matters in the treated water is less than 100mg / L, the pH value of the treated water is 8, and the cyclic utilization of the beneficiation wastewater is realized. The polymetallic ore beneficiation wastewater recycling method has the characteristics of low investment, low running cost, energy conservation, emission reduction and cyclic economy and is suitable for the cyclic utilization of the polymetallic ore beneficiation wastewater.

Owner:GUANGXI KESHENGDA MACHINERY MFG

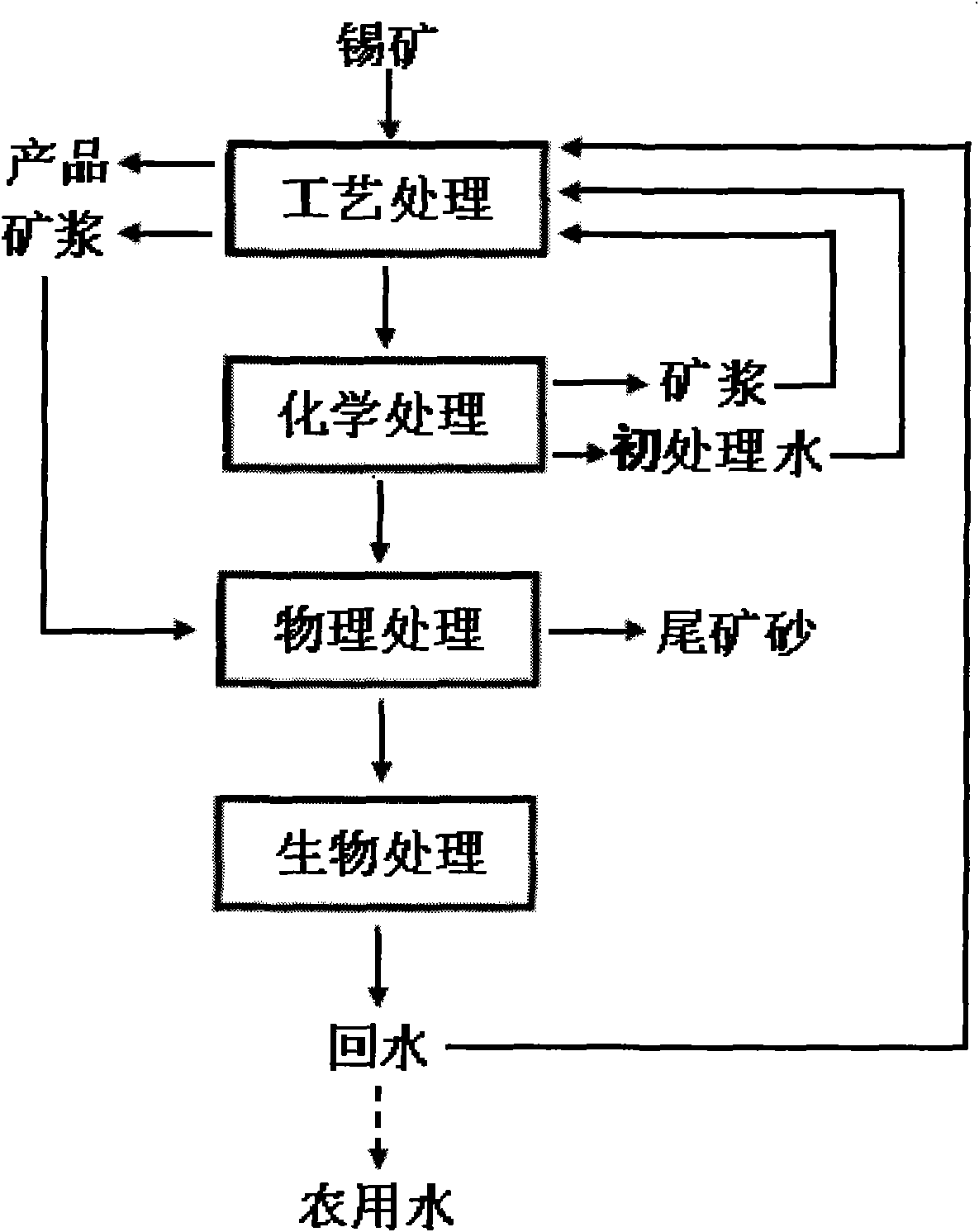

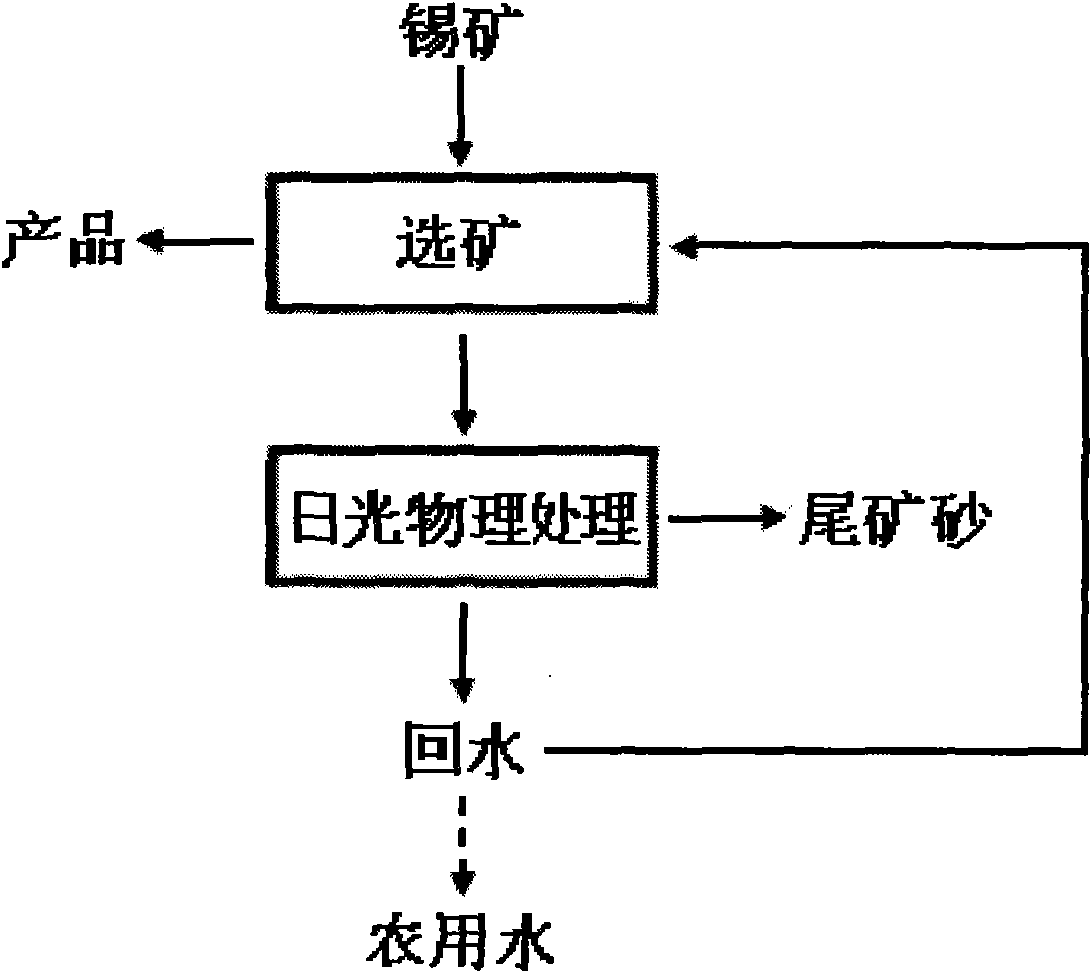

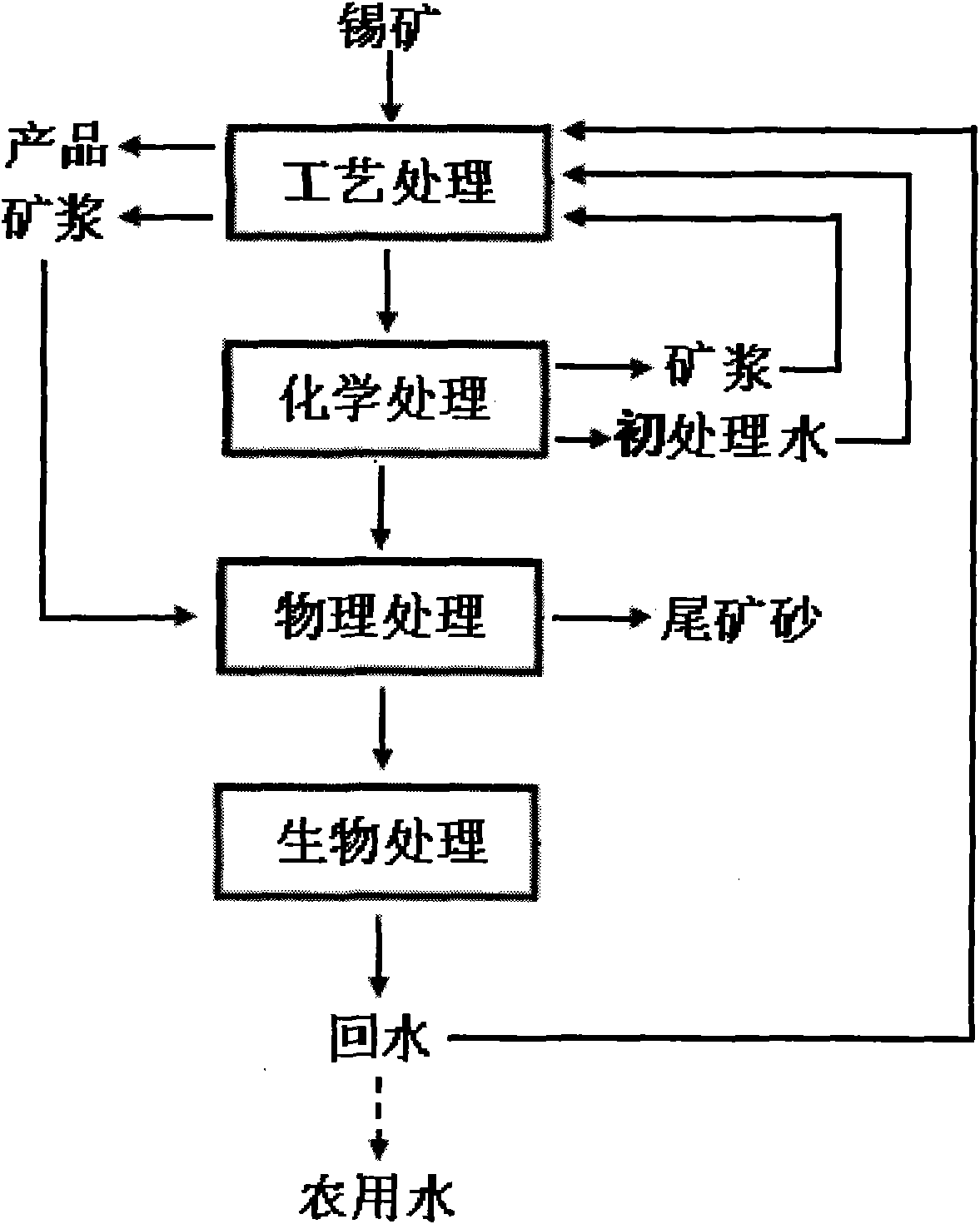

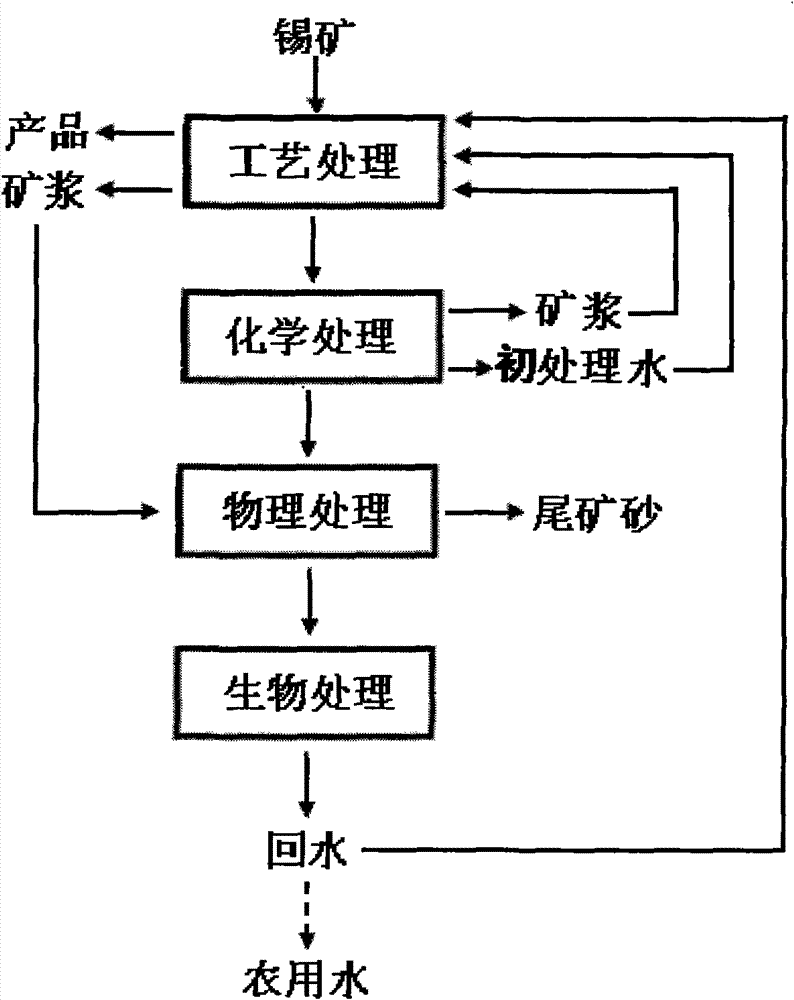

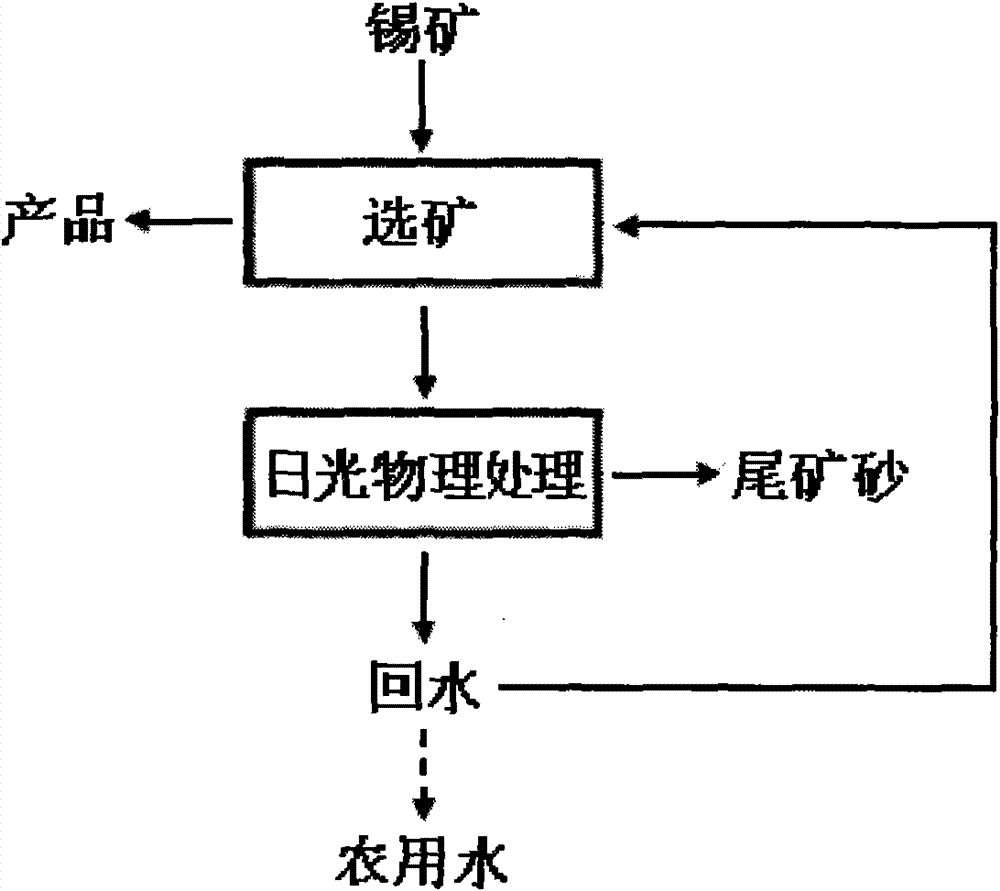

Four-step method for processing and recycling tin ore floatation wastewater

ActiveCN102030445AIncrease dosageImprove sedimentation rateMultistage water/sewage treatmentEnergy based wastewater treatmentChemical treatmentAgricultural irrigation

The invention discloses a four-step method for processing and recycling tin ore floatation wastewater, which comprises a new floatation technique, chemical treatment, physical treatment and biological treatment. The four-step method is characterized in that the principle of putting prevention first and providing prevention and control is adopted. The method is as follows: the new floatation technique and process are utilized to reduce the floatation wastewater and the microgranular particles from the headstream and reduce the usage amount of floatation reagents; because the chemical treatment method is used, the concentration of polyacrylamide in the tin ore floatation wastewater is increased from 0.5 percent to 0.9-1.1 percent, and the settling rate of part of the wastewater is improved; the physical treatment method is adopted to increase the settling distance and the settling time, the settling distance is extended for another 600 to 800m on the basis of 200m, and the settling time is increased for another 25 to 27 hours on the basis of 10 hours; aquatic organisms or plants, such as fish, frogs, aquatic weeds and the like are adopted to process the wastewater, the ecological reconstruction is realized, the agricultural irrigation standards are met, the utilization ratio of floatation return water is improved from 86 percent to above 97 percent, and peaceful and friendly coexistence of human and environment is realized.

Owner:广西华锡矿业有限公司铜坑矿业分公司

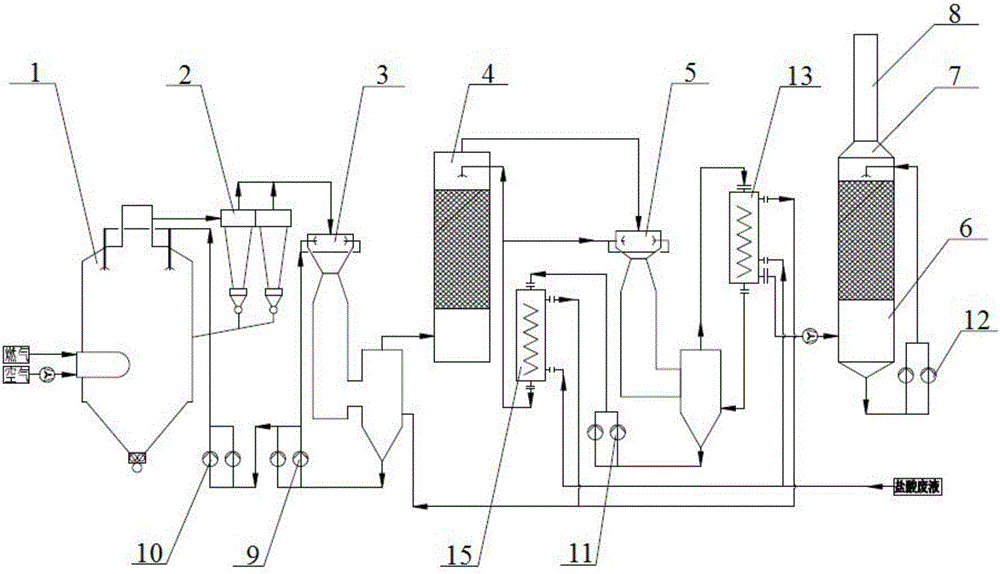

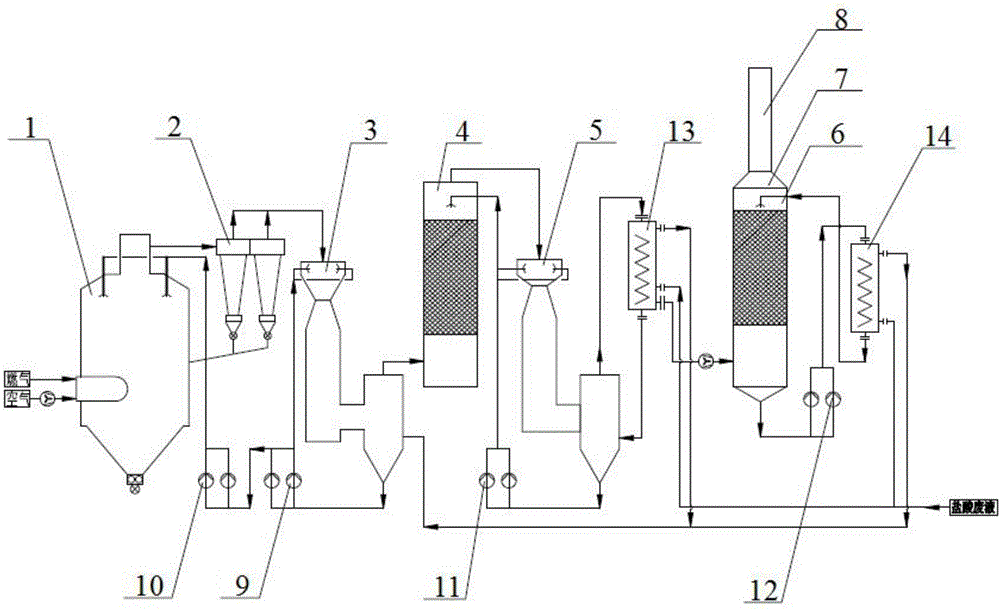

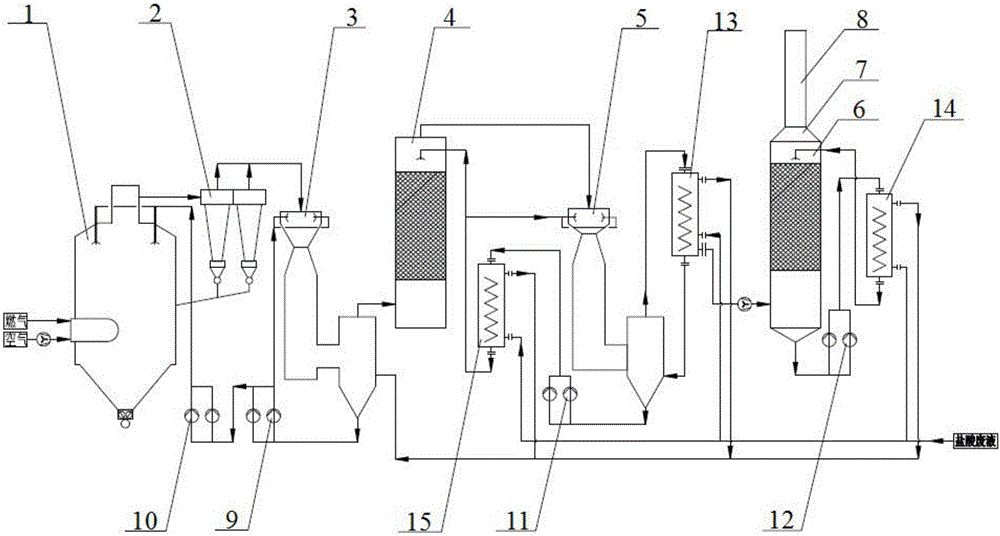

Hydrochloric acid waste liquid regenerating method and system

ActiveCN105887108AReduce wasteImprove recycling efficiencyUsing liquid separation agentWater/sewage treatment by heatingLiquid wasteFlue gas

The invention relates to a hydrochloric acid waste liquid regenerating method. The method adopts a spray roasting method, and comprises the following steps that part of waste heat of circulating liquid in a first-stage washing mechanism is recycled to be used for preheating at least one part of hydrochloric acid waste liquid entering a venturi preconcentrator. The invention further relates to a hydrochloric acid waste liquid regenerating system. The hydrochloric acid waste liquid regenerating system comprises a roasting furnace, the venturi preconcentrator, an absorption tower and one or more stage washing mechanisms, which are sequentially connected through a flue gas pipeline; a heat exchanging mechanism is arranged on a circulating liquid pipeline of the first-stage washing mechanism; a refrigerant inlet of the heat exchanging mechanism is connected with a hydrochloric acid waste liquid storing tank; a refrigerant outlet is connected with the venturi preconcentrator. The hydrochloric acid waste liquid is preheated by the circulating liquid in the first-stage washing mechanism, so that the energy is saved, the consumption is reduced, and the efficiency of regenerating and recycling hydrochloric acid can be improved; besides, the circulating liquid in the first-stage washing mechanism is cooled, and the heat exchanging capacity between the low-temperature circulating liquid and flue gas is large, so that the washing effect of the first-stage washing mechanism and the absorbing effect of the absorption tower can be improved.

Owner:WISDRI ENG & RES INC LTD

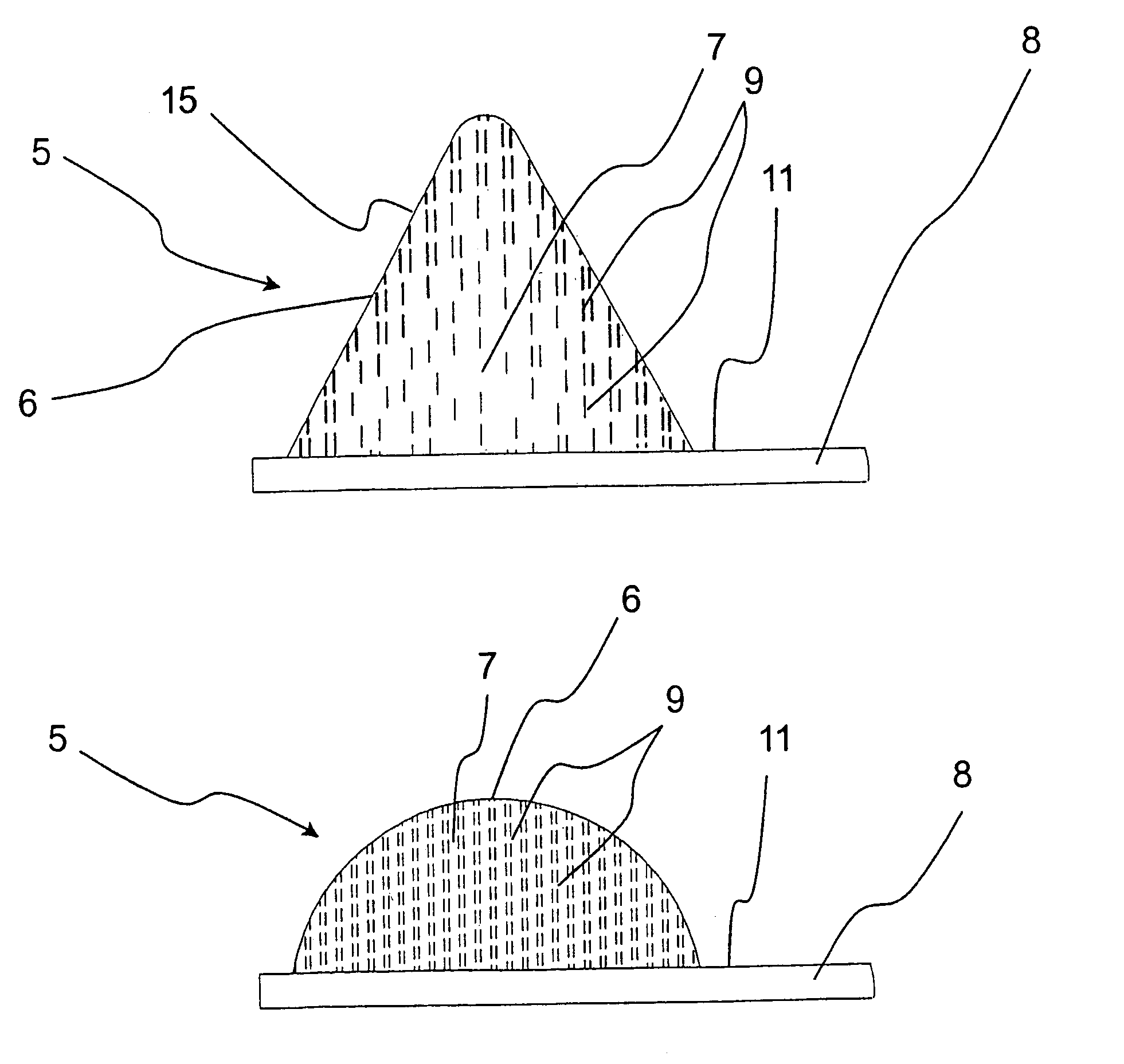

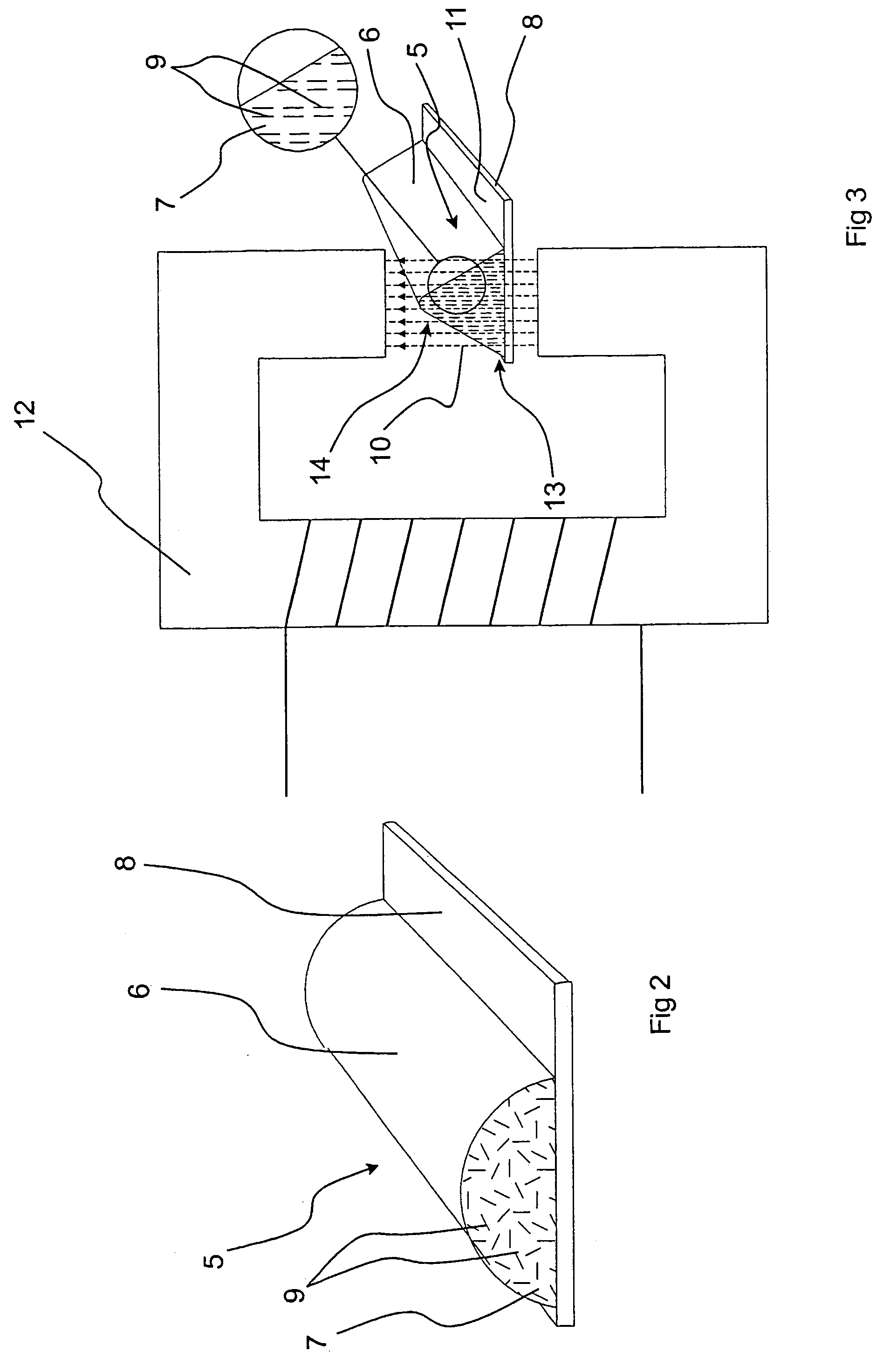

Element for electromagnetic shielding and method for manufacturing thereof

InactiveUS7161090B2Reduce the amount requiredImprove conductivityScreening gaskets/sealsCross-talk/noise/interference reductionElectromagnetic shieldingEngineering

A method for manufacturing an element for electromagnetic shielding. The method is characterized by the steps of arranging, along a curve corresponding to the extension of the completed element, a viscous material in the form of a bead, and orienting the particles in the material by applying a magnetic field across the bead. The material carries particles with substantial electrical conductivity and also ferromagnetic and / or ferrimagnetic properties. Also disclosed are a corresponding element for electromagnetic shielding, a device for electromagnetic shielding including such an element, use of such an element in a mobile phone and at a base station, and also a mobile phone and a base station including such an element.

Owner:NOLATO SILIKONTEKNIK

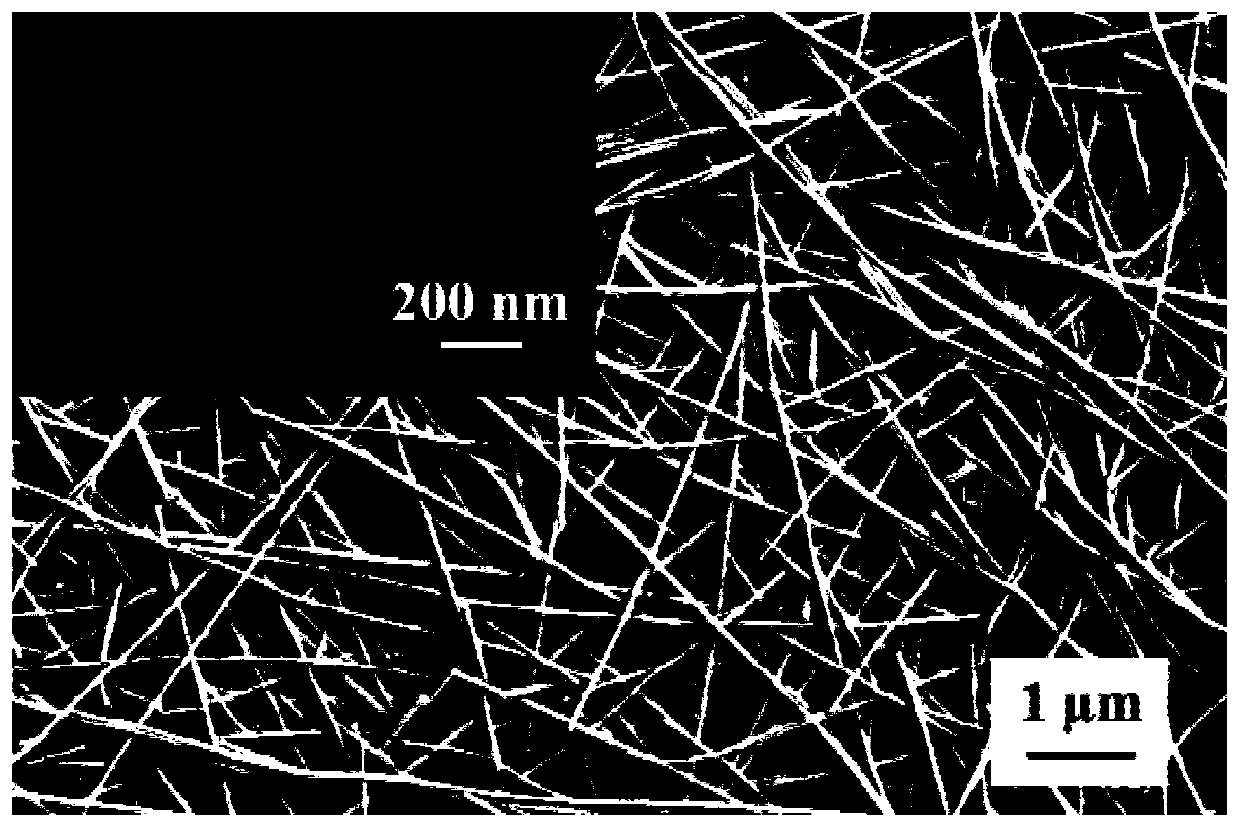

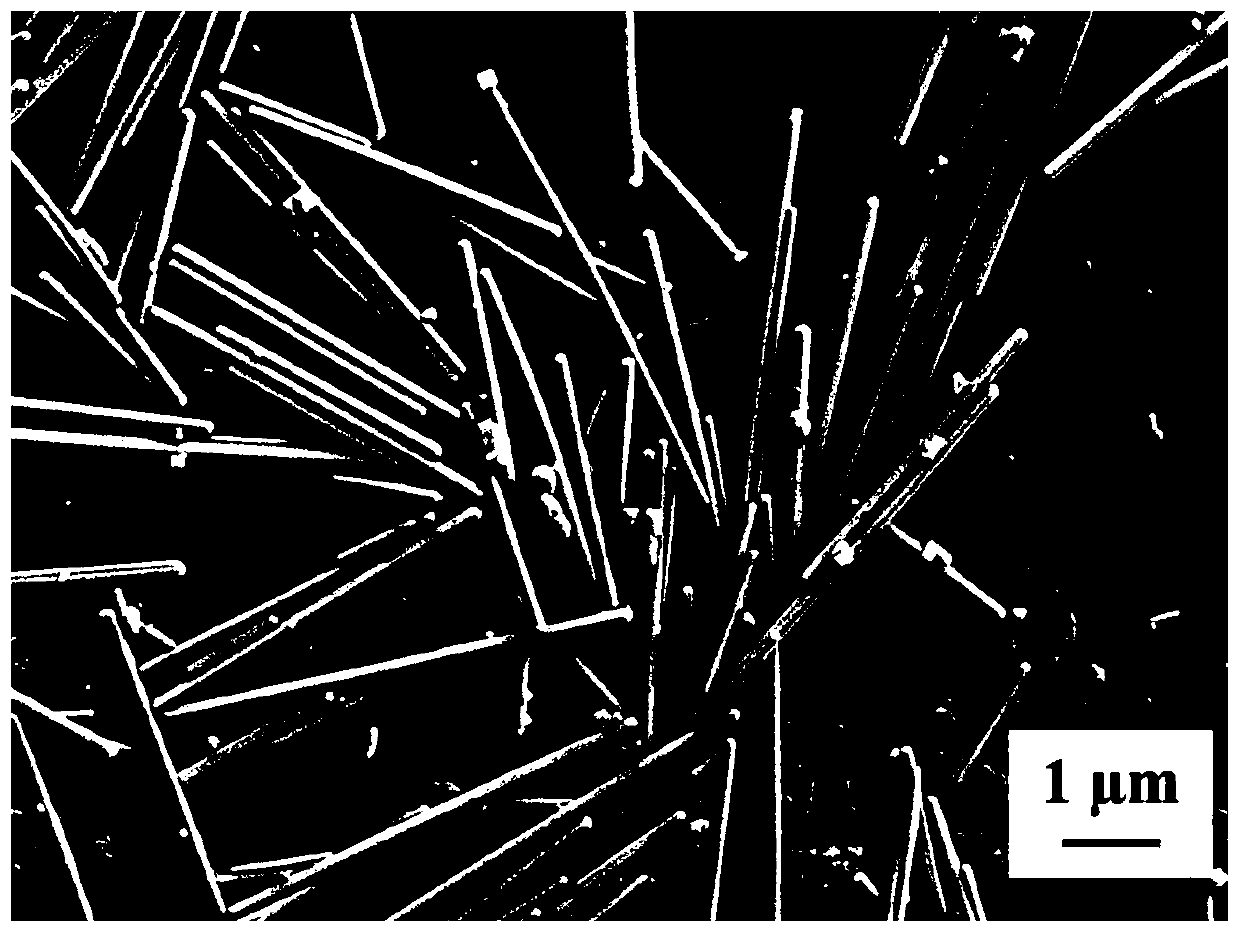

Large-length-diameter ratio silver nanowire based on one-pot polyol method and preparation method and application thereof

InactiveCN110586928AReduce particle contentEasy to manufactureMaterial nanotechnologyTransportation and packagingOrganic solar cellMetal chloride

The invention belongs to the technical field of synthesis of metal nanowires, and particularly relates to a large-length-diameter ratio silver nanowire based on a one-pot polyol method and a simple, efficient and rapid preparation method and application thereof. The preparation method comprises the steps that a PVP solution, a metal chloride solution and an AgNO3 solution are evenly mixed and react for 1-2 hours at a constant temperature of 120-160 DEG C through a one-pot method, and then cooling and centrifugation are conducted to obtain a dispersion solution of the large-length-diameter ratio silver nanowire. According to the preparation method, the one-pot synthesis method is adopted, and the controllability of a polyol synthesis method and the uniformity of a hydrothermal method are effectively combined to realize simple, efficient and rapid preparation of the large-length-diameter ratio silver nanowire. After centrifugal cleaning, the silver nanowire dispersion solution with an extremely low particle content is obtained. The silver nanowire has a diameter of 30-50nm, a length of 30-40 [mu]m and a length-diameter ratio of 1000 and has a broad application prospect in the fieldsof touch screen panel, organic solar cells, organic light-emitting diodes, and the like.

Owner:SOUTH CHINA UNIV OF TECH

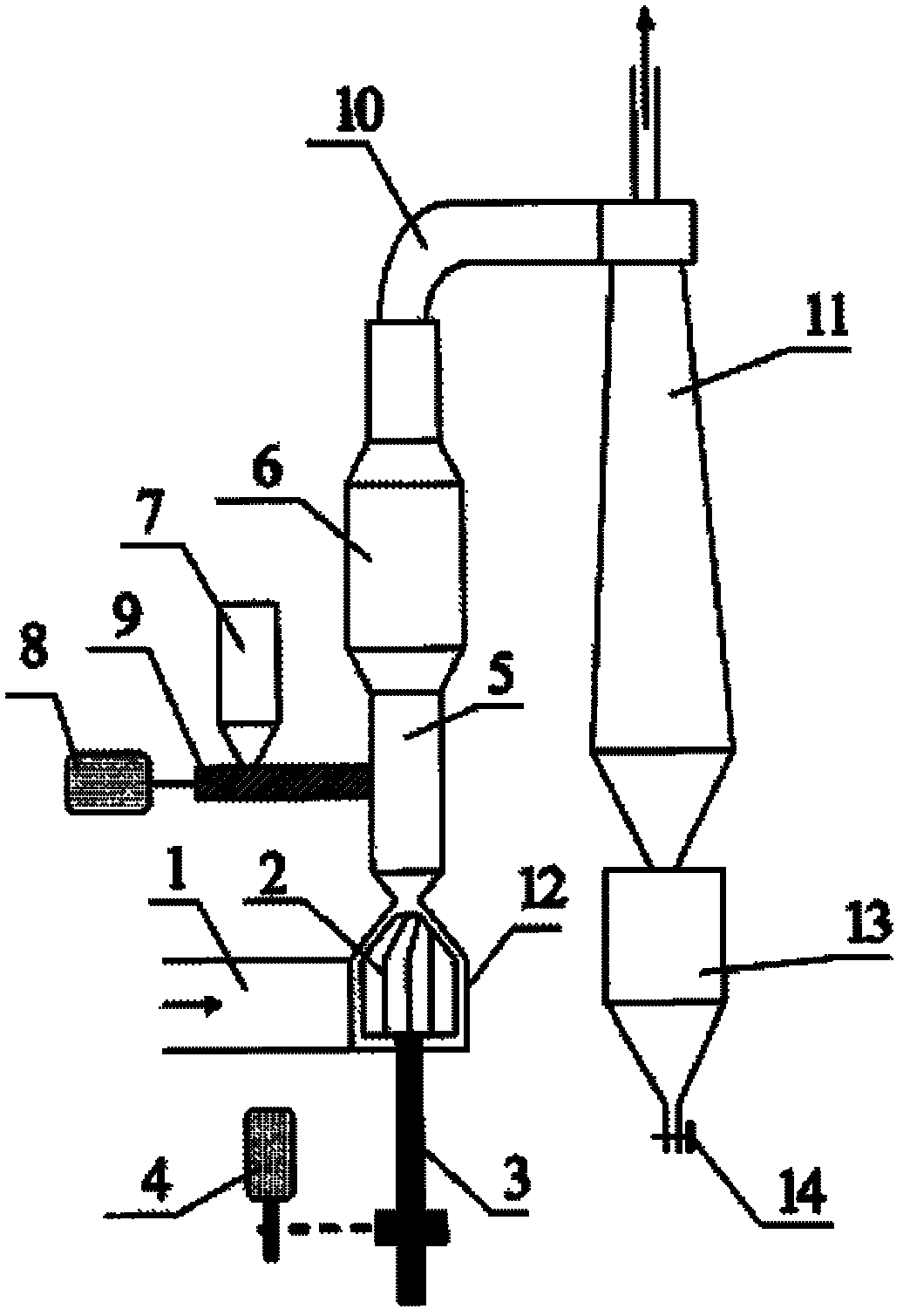

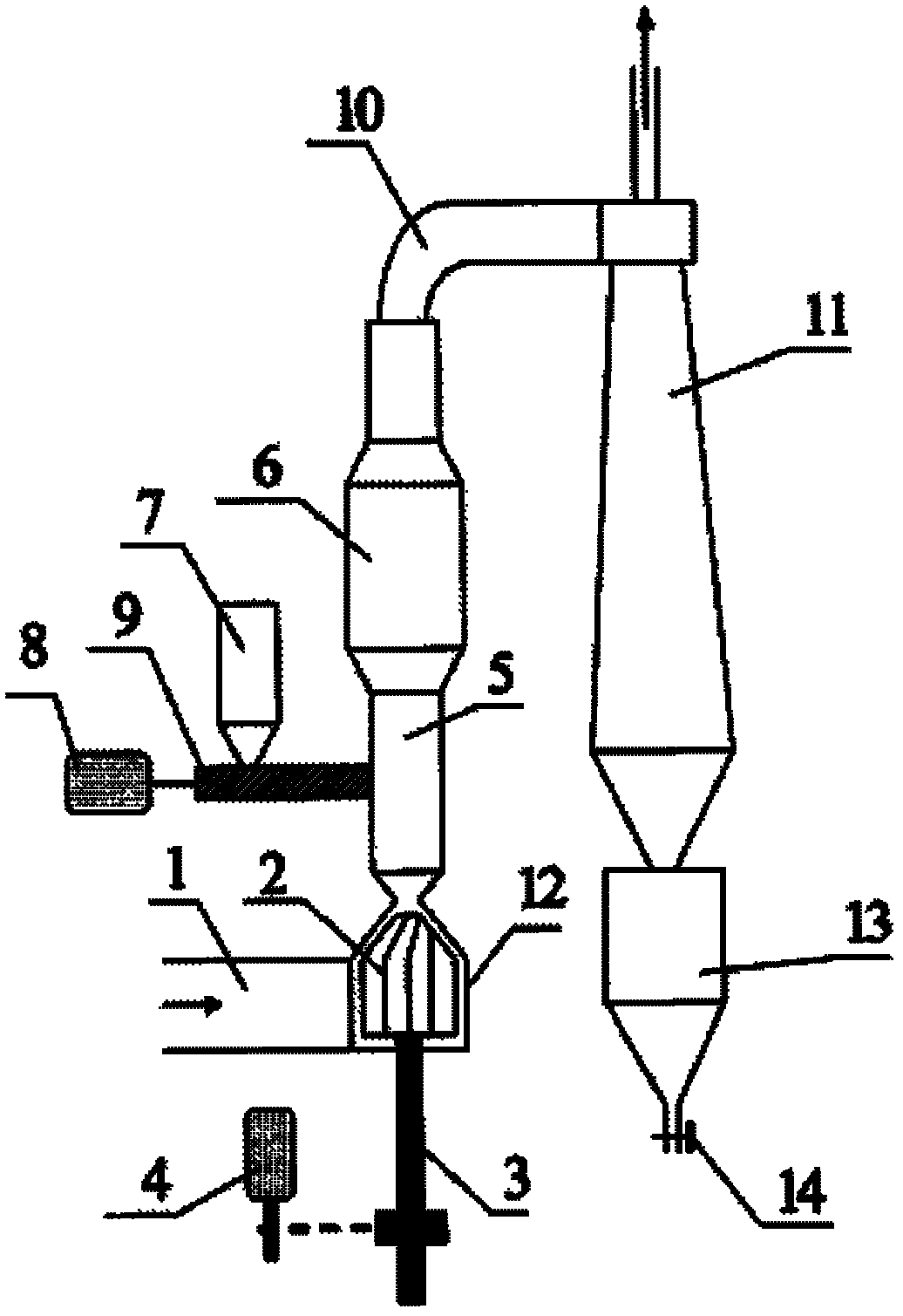

Dry-type desulphurization device

InactiveCN102500227ASmall pressure lossReduce particle contentDispersed particle separationFlue gasNuclear engineering

The invention relates to a dry-type desulphurization device which comprises a primary desulphurization reactor, a flue gas feeding device and a desulfurizer supplying device which are communicated with the primary desulphurization reactor, a cyclone secondary desulphurization reactor, and a dust collector mounted below the reactor; the flue gas feeding device adopts a wind chamber which is provided with an internal cyclone vane and has a contractible nozzle used as an outlet, and is disposed below the primary desulphurization reactor; the primary desulphurization reactor adopts a cylinder structure with an expansion section at the central part; an outlet of the primary desulphurization reactor is connected with an inlet of the secondary desulphurization reactor through a pipe; and the invention is characterized in that the diameter of the central expansion section of the primary desulphurization reactor is 1.2-1.5 times as large as the diameters of the upper and lower sections of the reactor.

Owner:XIAN RUIJINYUAN ENERGY TECH

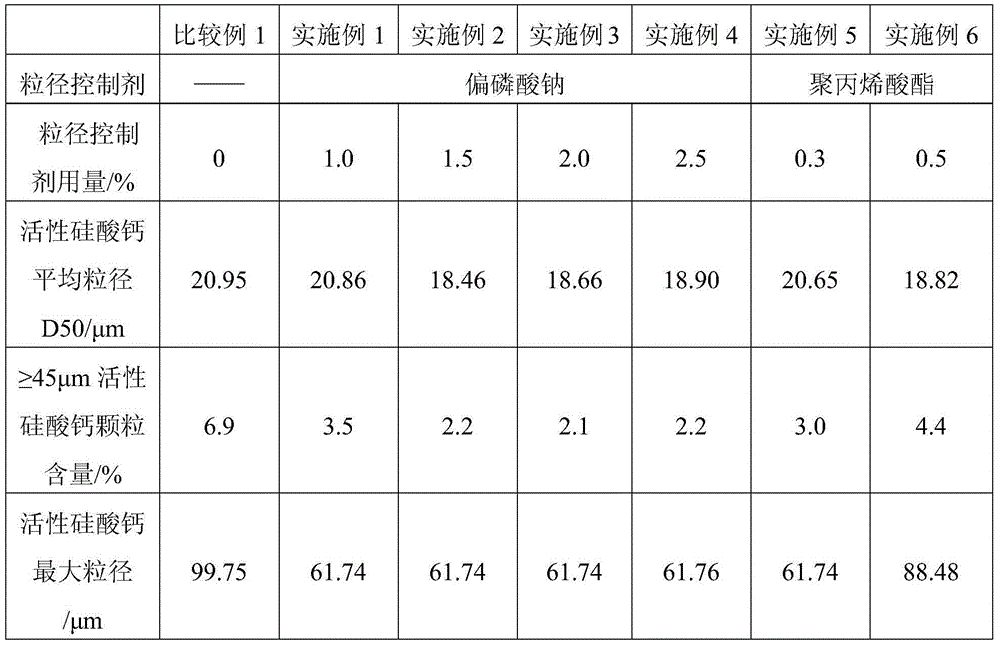

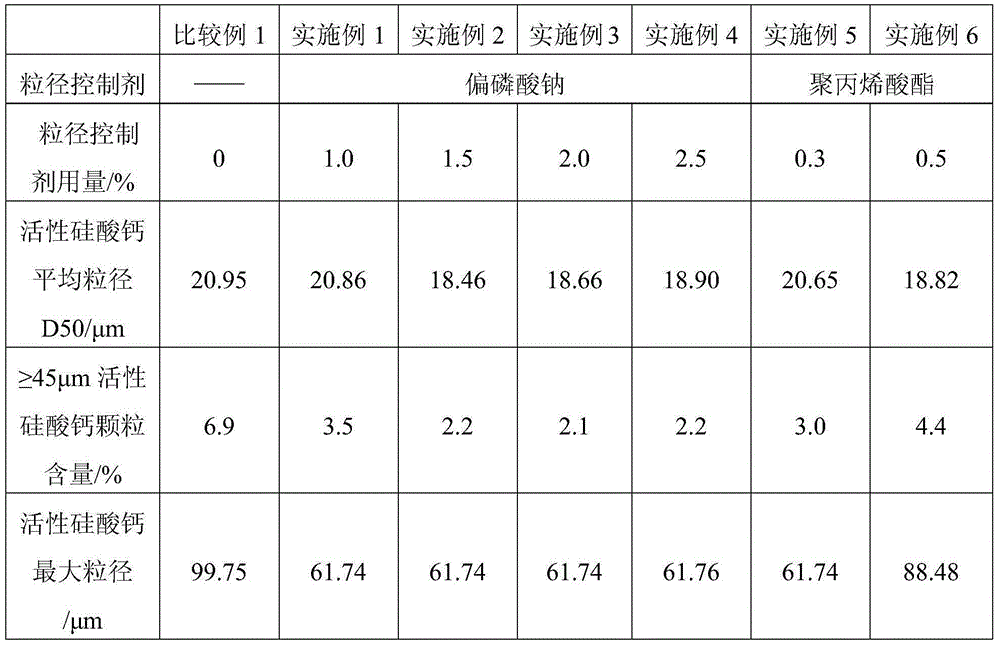

Preparation method of activated calcium silicate

ActiveCN104085896ASolve the problem of high content of large particlesImprove product qualitySolid waste managementAlkaline-earth metal silicatesCalcium silicatePolyphosphate

The invention provides a preparation method of activated calcium silicate. The method comprises the following steps: mixing lime milk, pulverized ash desilliconization liquid and a particle size control agent for reaction to obtain activated calcium silicate slurry, wherein the particle size control agent is one of pyrophosphate, metaphosphate, polyphosphate, polyacrylic ester and polyacrylate, the addition amount of pyrophosphate, metaphosphate or polyphosphate is 0.2-2.5% of dry weight of the pulverized ash desilliconization liquid and lime milk, and the addition amount of polyacrylic ester or polyacrylate is 0.05-0.5% of dry weight of the pulverized ash desilliconization liquid and lime milk. According to the preparation method, large particles in the activated calcium silicate can be effectively reduced, and the influence on the papermaking process and the quality of paper products can be reduced.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

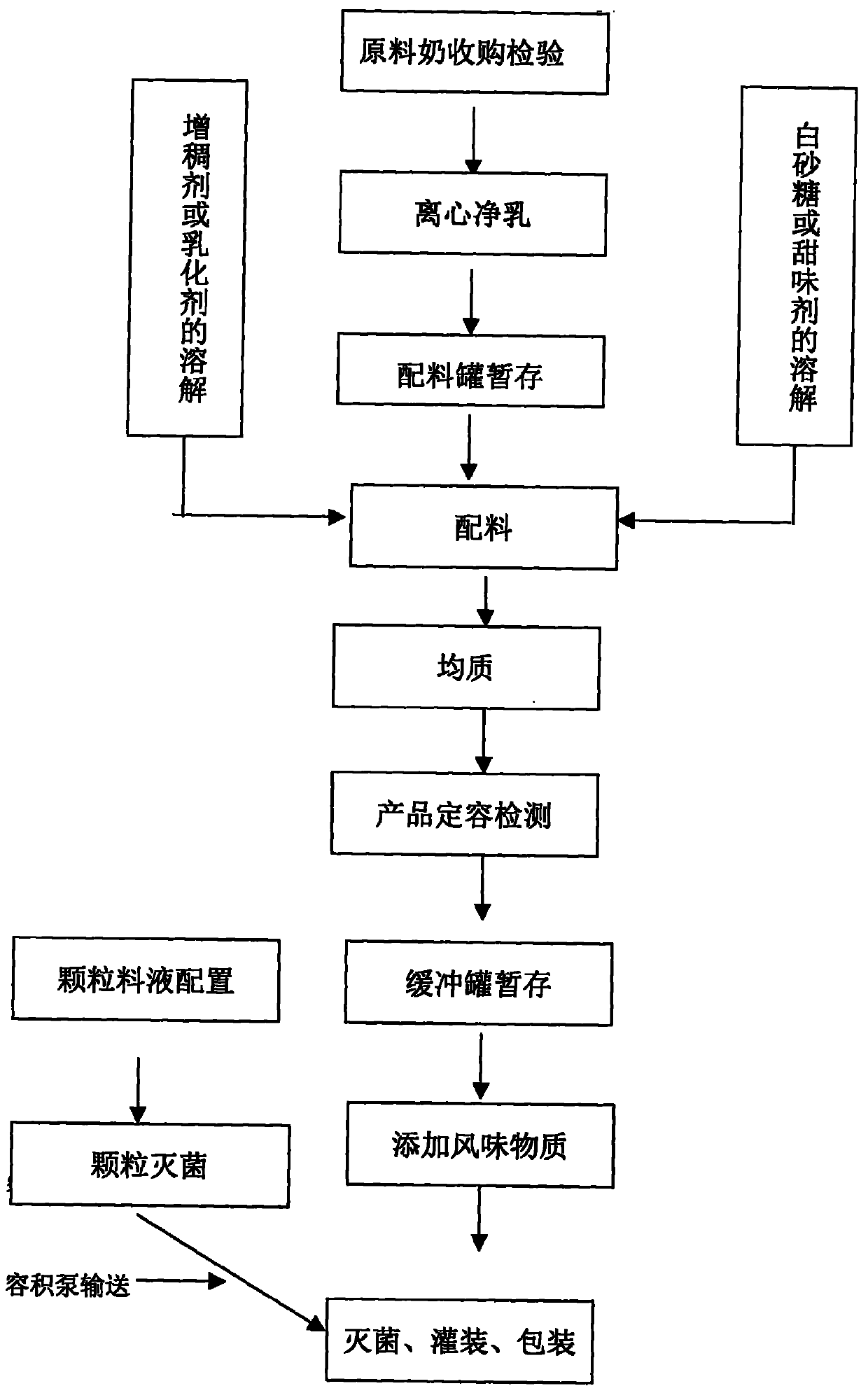

Method for producing liquid milk product containing grains

InactiveCN101715829AIncrease the amount of controlReduce mistakesMilk preparationLiquid milkAcidity regulator

The invention relates to the field of production methods of liquid milk, in particular to a method for producing liquid milk product containing grains, comprising the following steps of: (1) preparing grain solution, adding grains into a grain dosing tank, adding water, preparing the required concentration and then slowly stirring to evenly distributing the grains in the solution; (2) preparing a base material: mixing a stabilizing agent and / or an acidity regulating agent with milk, evenly stirring and homogenizing; (3) sterilizing grain liquid and the prepared grain liquid by using a tubular sterilizing machine; (4) filling: filling the sterilized grain liquid to a packaging unit and then filling the sterilized base material; and (5) overturning the packaging unit to evenly mixing the grains and the base material. By the method, dependent preparation, dependent sterilization and dependent filling of the base material and the grain liquid can be realized and the addition of the grains can be better controlled in the production process, thereby reducing the inevitable waste caused by errors in the production process.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

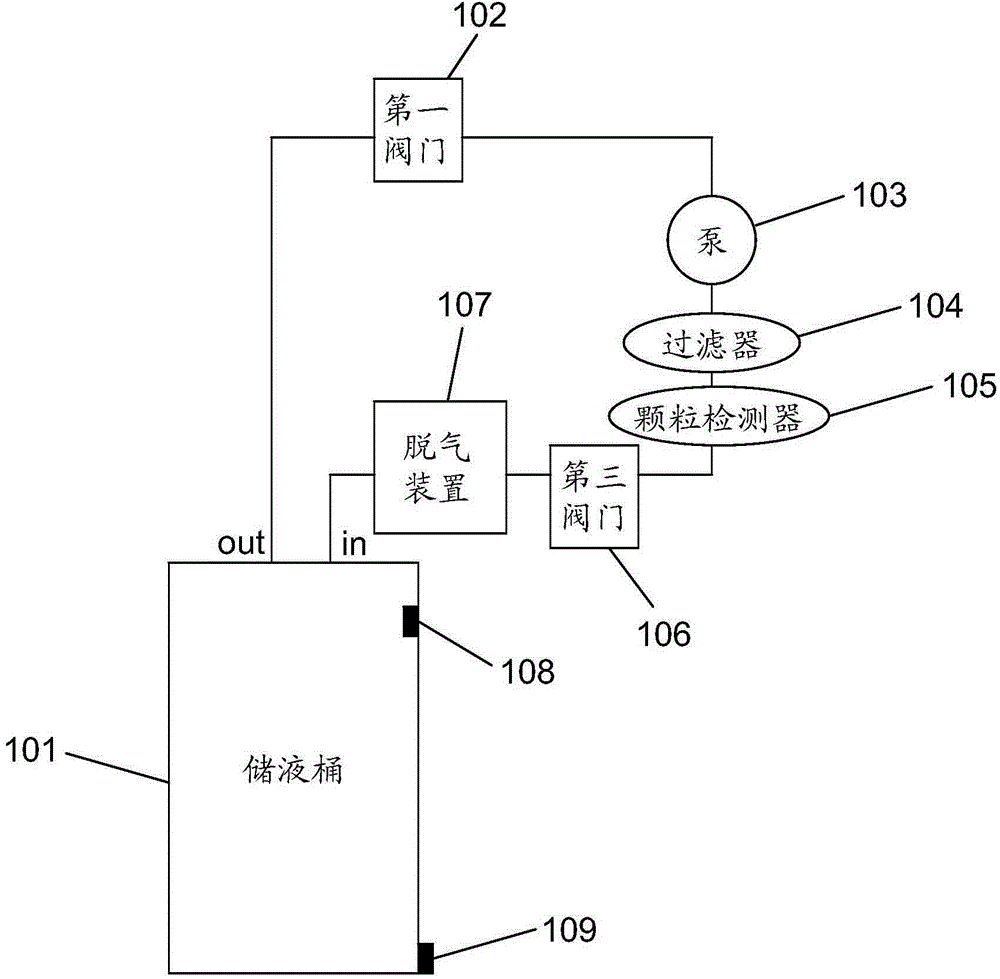

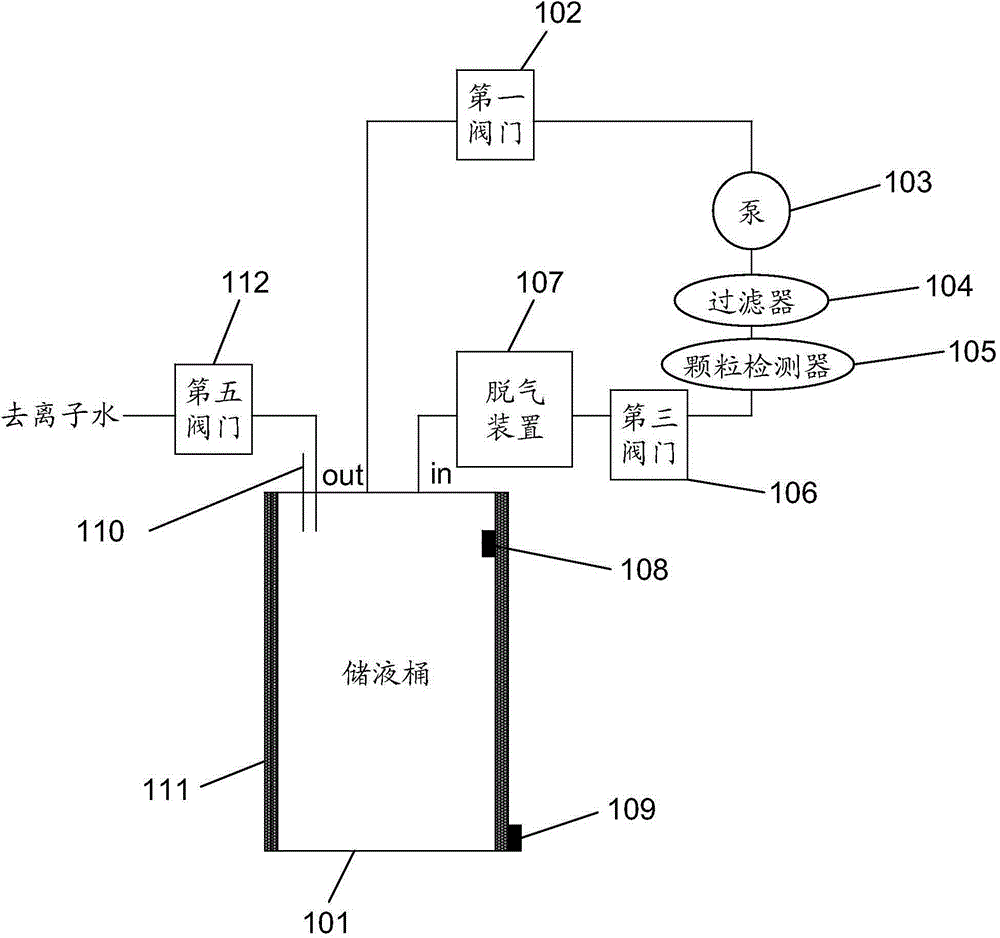

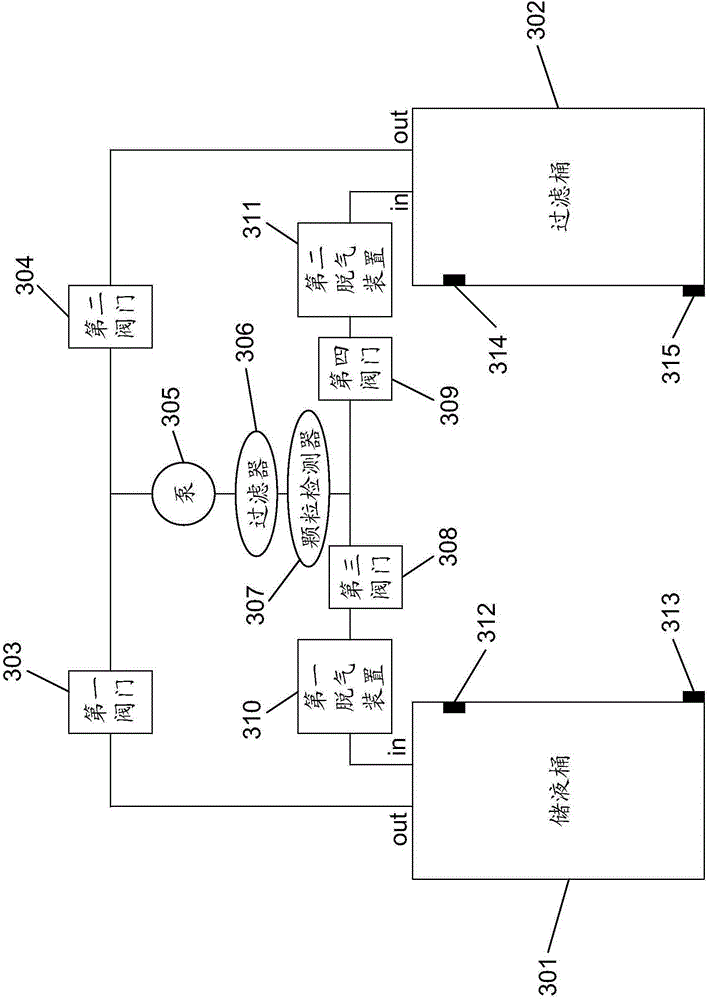

Polishing slurry filtering device

ActiveCN105313015AReduce particle contentGrinding/polishing apparatusPulp and paper industryEngineering

The invention discloses a polishing slurry filtering device. The polishing slurry filtering device comprises a slurry storage barrel, a first valve, a pump, a filter, a particle detector and a third valve, wherein the slurry storage barrel is used for storing original polishing slurry or recovered polishing slurry; a slurry inlet end of the first valve is connected with the slurry storage barrel; a slurry inlet end of the pump is connected with a slurry outlet end of the first valve; a slurry inlet end of the filter is connected with a slurry outlet end of the pump; a slurry inlet end of the particle detector is connected with a slurry outlet end of the filter; a slurry inlet end of the third valve is connected with a slurry outlet end of the particle detector, and a slurry outlet end of the third valve is connected with the slurry storage barrel. Polishing slurry is filtered repeatedly by the device, the content of particles in the polishing slurry filtered by the filter is detected by the particle detector, and the content of the particles in the polishing slurry can be guaranteed to be smaller than or equal to a preset value.

Owner:ACM RES SHANGHAI

Photoresist coating liquid supplying apparatus, and photoresist coating liquid supplying method and photoresist coating apparatus using such photoresist coating liquid supplying apparatus

InactiveUS7867559B2Reduce defectsImprove the display effectPhotomechanical apparatusPretreated surfacesResistPhotoresist

This invention provides a photoresist coating liquid supplying apparatus and a photoresist coating liquid supplying method, for supplying a photoresist coating liquid having a low particle content to a photoresist coating apparatus, and a photoresist coating apparatus using such a photoresist coating liquid supplying apparatus, which can realize coating without causing significant defects in a cost-effective manner.The photoresist coating liquid supplying apparatus comprises a buffer vessel for a photoresist coating liquid, a circulation filtering apparatus for drawing a part of the coating liquid from the buffer vessel, filtering the coating liquid, and then returning the filtered coating liquid to the buffer vessel, and a pipe for supplying the coating liquid from the buffer vessel or the circulation apparatus to a coating apparatus. The photoresist coating liquid supplying method uses the photoresist coating liquid supplying apparatus. The photoresist coating apparatus comprises a combination of the coating liquid supplying apparatus with a slit coating apparatus.

Owner:MERCK PATENT GMBH

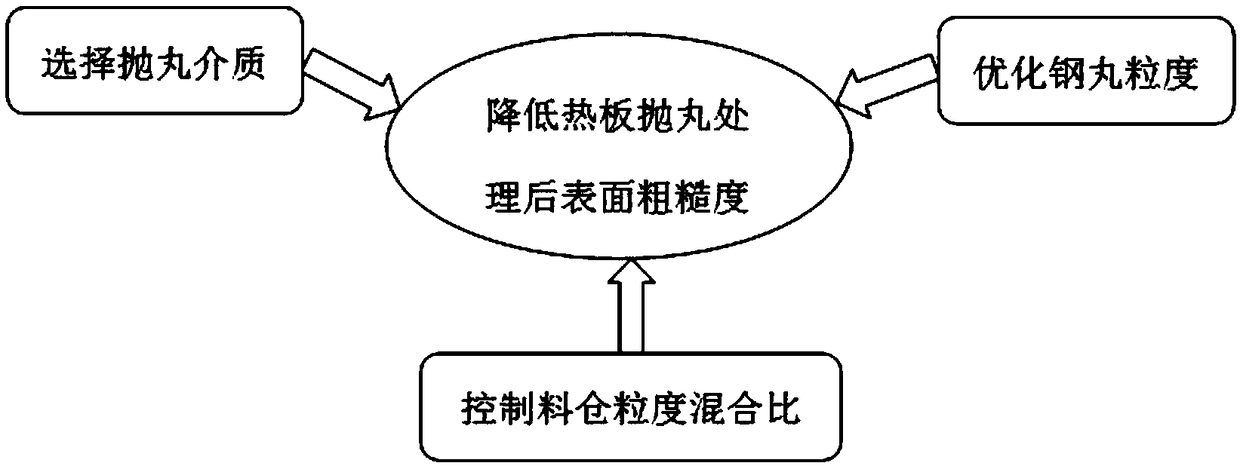

Method for reducing surface roughness of heating plate subjected to shot blasting

ActiveCN109333369AImprove cleaning efficiencyReduce surface roughnessAbrasive feedersAbrasive machine appurtenancesMetallurgyMixing ratio

The invention provides a method for reducing surface roughness of a heating plate subjected to shot blasting. The method comprises the steps of selecting a shot blasting medium, specifically, steel shots are selected as the shot blasting medium; optimizing the granularity of the steel shots, specifically, the total quantity of the steel shots with the granularity being 0.5 mm or above is smaller than 2%, and the total quantity of the steel shots with the granularity being 0.3-0.425 mm is about 90%; and controlling the stock bin granularity mixing ratio of the steel shots in the stock bin of ashot blaster, specifically, the steel shots with the granularity being 0.3 mm-0.355 mm account for 50% or above, and the steel shots with the granularity being 0.5 mm or above account for less than 5%. By means of the method for reducing surface roughness of the heating plate subjected to shot blasting, the problems that the surface of the heating plate is deeply polished, not ideal in shape, highin roughness and the like can be effectively solved, the maximum cleaning efficiency can be obtained, and the surface roughness of a cooling plate subjected to shot blasting can also be remarkably reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

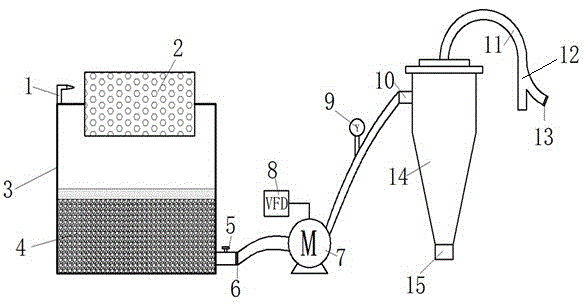

Sorting method and device for contaminated soil particles with different particle sizes

ActiveCN105618281ARealize sortingControl pressureVortex flow apparatusContaminated soil reclamationSoil scienceEnvironmental engineering

The invention discloses a sorting method and device for contaminated soil particles with different particle sizes. The sorting device comprises a water spraying pipe 1, a drum screen 2, a mud tank 3, a filter screen 6, a mud pump 7, a hydrocyclone feed port 10, an overflow pipe 11, a filter screen 13, a hydrocyclone 14 and a desilting port 15, wherein the water spraying pipe 1 and the drum screen 2 are both fixedly installed on the mud tank 3; the mud pump 7 is connected with the mud tank 3 and the hydrocyclone feed port 10 through mud pipelines correspondingly, and the filter screen 6 is arranged in the mud pipeline between the mud pump 7 and the mud tank 3; the overflow pipe 11 is installed on the hydrocyclone 14, and the filter screen 13 is installed at the end of the overflow pipe 11; the desilting port 15 is formed in the bottom of the hydrocyclone 14. The sorting method and device have the advantages that the technique is simple, the sorting effect is good, the device is suitable for various weather environments, the application range is wide, and subsequent drip washing cost can be reduced; the method and device have extremely good application prospects.

Owner:SUN YAT SEN UNIV

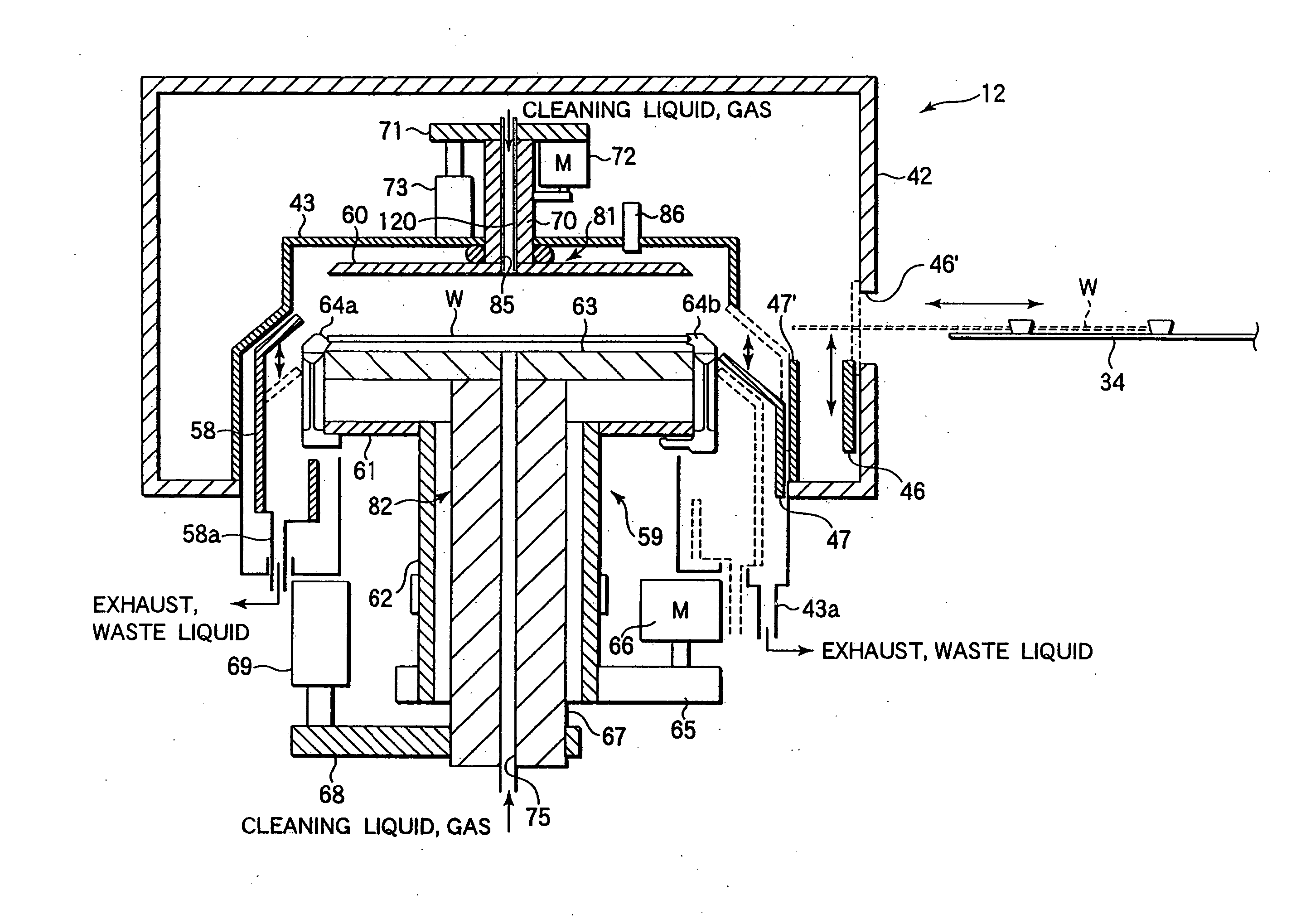

Liquid processing apparatus and liquid processing method

InactiveUS20080006299A1Effective recoverySuppress generationSemiconductor/solid-state device manufacturingCleaning using gasesCompound (substance)Engineering

A cleaning processing apparatus comprises a spin chuck for holding a wafer W, an under plate being positioned to face the back surface of the wafer W with a prescribed gap provided therebetween, a support member for supporting the under plate, and a nozzle hole formed to extended through the plate member and the support member. A chemical liquid, a pure water and a gas can be supplied into a nozzle hole through opening-closing valves, and the chemical liquid and the pure water remaining inside the nozzle hole can be sucked by a sucking device. A pure water remaining inside the nozzle hole is sucked and removed by using the sucking device after the processing of the wafer W with a pure water and, then, a gas is spurted onto the back surface of the wafer W.

Owner:TOKYO ELECTRON LTD

Forming equipment of wavy noodles and process using same to manufacture noodles

ActiveCN104542785ACreate pollutionAvoid damageDough shaping and cutting apparatusDough processingManufactured formEngineering

The invention relates to forming equipment of wavy noodles and a process using the same to manufacture the noodles. The forming equipment comprises a shredding knife, a wave-manufacturing forming device and a steaming box, wherein the wave-manufacturing forming device comprises an air-blowing rod and a wavy adjusting rod; the outer wall surface of the air-blowing rod is provided with small holes facing to the wavy adjusting rod; the air-blowing rod is connected with an air-blowing pipeline, and air is provided for an inner cavity of the air-blowing rod and is blown out through the small holes; the downstream of the wave-manufacturing forming device is also provided with the steaming box which is connected with the wave-manufacturing forming device by a flour-conveying mesh belt; and the steaming box is connected with the wave-manufacturing forming device by the flour-conveying mesh belt, and the wavy noodles formed by the wave-manufacturing forming device fall onto the flour-conveying mesh belt and are conveyed into the steaming box for steaming by the flour-conveying mesh belt. The forming equipment and the manufacturing process have the advantages that the manufactured noodles are uniform-scattered-irregular wavy noodles, and the phenomenon of noodle sticking can be effectively reduced.

Owner:TINGYI (CAYMAN ISLANDS) HOLDING CORPORATION

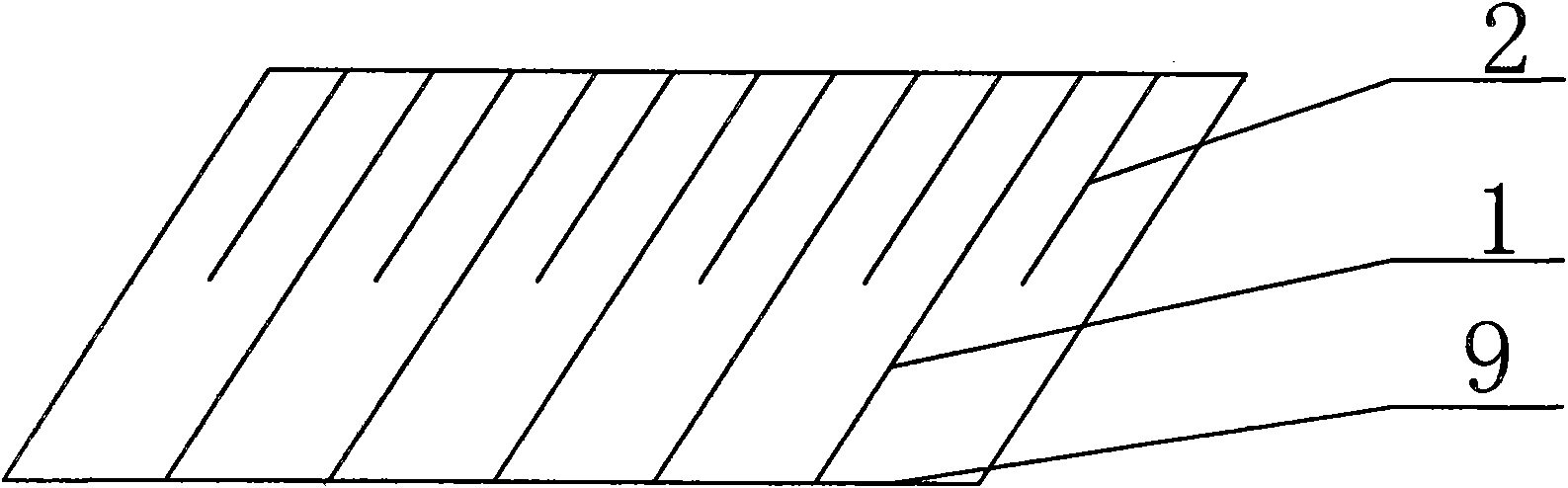

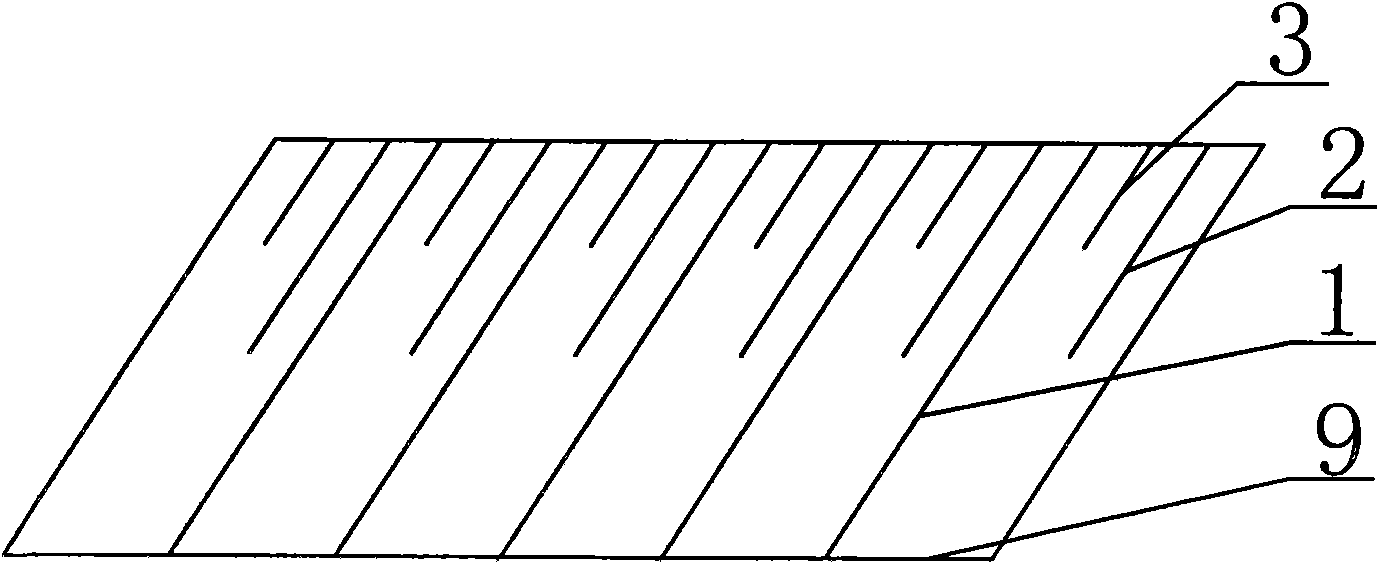

Multistage sloping plate water treatment device

InactiveCN101830576AImprove the water effectReduce particle contentMultistage water/sewage treatmentSteel barTherapeutic effect

The invention relates to a multistage sloping plate water treatment device which comprises a precipitating pool, a sloping plate group, a mud precipitating hopper, a mud discharge pipe, a water distributing device and a plurality of water collecting grooves, wherein the sloping plate group is arranged on the mud precipitating hopper of the precipitating pool; the water collecting grooves are arranged on the sloping plate group; the mud discharge pipe is arranged at the bottom of the mud precipitating hopper; the water distributing device is arranged on the side wall of the precipitating pool below the sloping plate group; and the sloping plate group comprises a plurality of sloping plates and a steel bar for fixing the sloping plates and is fixed between the left side wall and the right side wall of the precipitating pool by the steel bar. The multistage sloping plate water treatment device is characterized in that the sloping plates for forming the sloping plate group are one or more of long sloping plates, middle-length sloping plates and short sloping plates. The invention has the advantages of good discharge water effect and obvious reduction of particle content of discharge clear liquid; aiming at raw water of surface water, the treatment effect can reach 1NTU; and the surface load is about two times of that of conventional equipment and reaches more than 15m<3> / m<2>.

Owner:郭振岳 +1

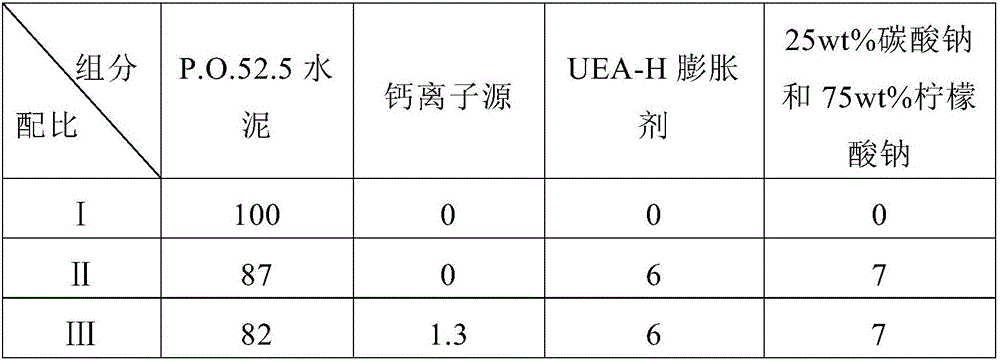

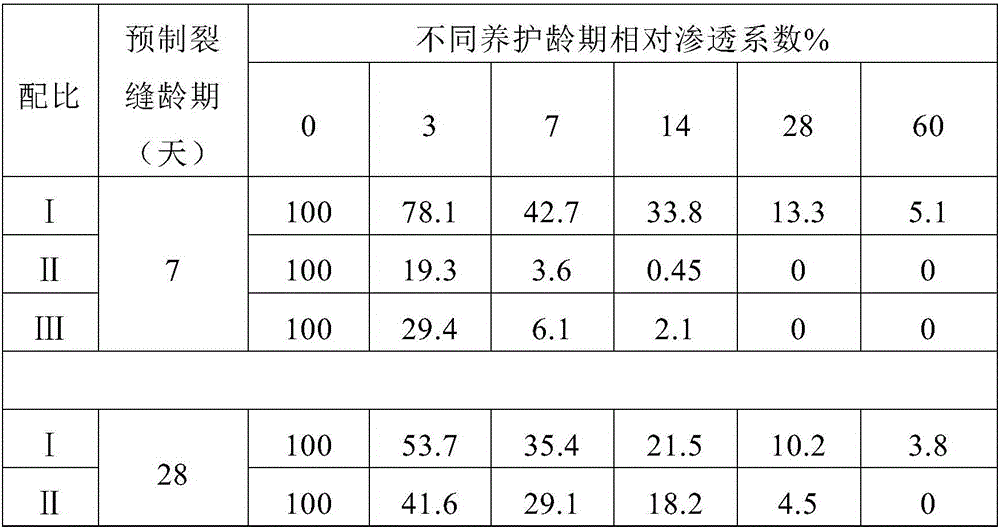

Mineral admixture for crack self-healing of steam-cured cement-based material and preparation of mineral admixture

ActiveCN106007442AGenerated in large quantities and stableImprove self-healing abilitySelf-healingMaterials science

The invention relates to a mineral admixture for crack self-healing of a steam-cured cement-based material and preparation of the mineral admixture. The mineral admixture is prepared from the following components in percentage by weight: 35%-50% of an expanding mineral component, 40%-55% of a crystalline mineral component and 5%-10% of a calcium ion source mineral component. The mineral components are weighed in proportion and uniformly mixed, and the mineral admixture is prepared. The mineral admixture has the advantages that the self-healing effect is remarkable, the cost is low, the durability of the steam-cured cement-based material is effectively improved and the like.

Owner:TONGJI UNIV

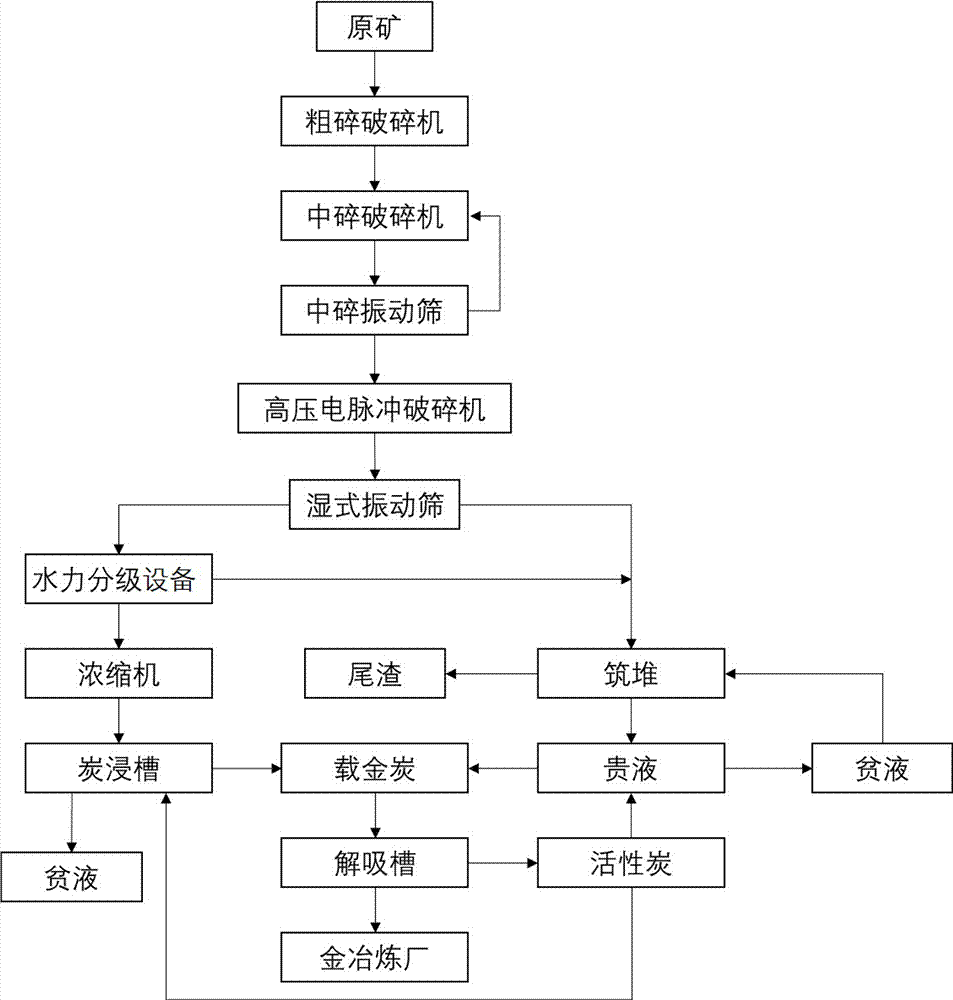

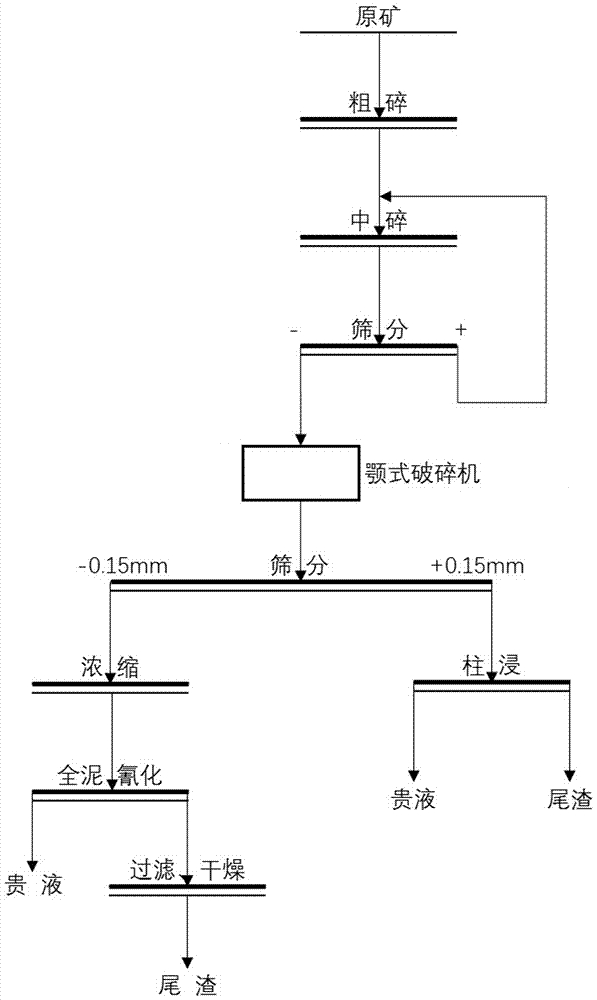

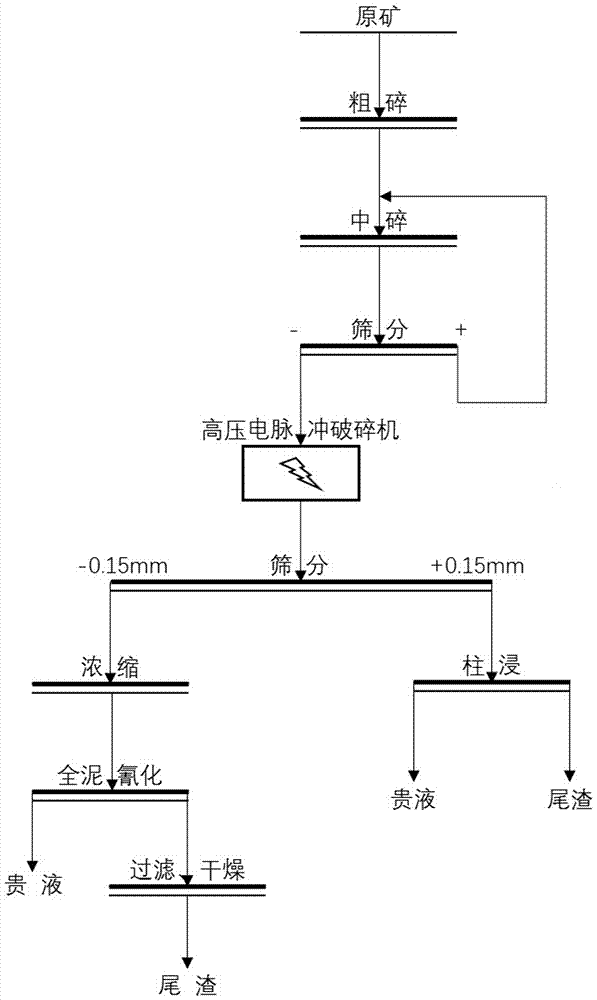

Low-grade gold ore heap leaching method based on high voltage electropulse crushing

ActiveCN107297264AIncrease exposureMeet the exposure rateProcess efficiency improvementGrain treatmentsPrillLower grade

The invention relates to a low-grade gold ore heap leaching method based on high voltage electropulse crushing. The method comprises the following steps: firstly, carrying out open circuit coarse crushing and closed circuit intermediate crushing on raw ores until appropriate particle size is reached, and then feeding the raw ores into a high voltage electropulse crushing machine to be treated; secondly, carrying out open circuit fine crushing on the raw ores by adopting the high voltage electropulse crushing machine, and carrying out combined classification on a product by adopting a wet type vibrating screen and classifying equipment; thirdly, feeding a finer overflow product into an all-slime cyanidation leaching system, mixing settled sand, coarse grain materials and appropriate amount of soda lime, then forming an ore heap, and carrying out heap leaching; and fourthly, obtaining golden liquid and tailings after leaching is finished, and adsorbing, desorbing and smelting the golden liquid, so that a gold product is obtained. Compared with the prior art, the method provided by the invention has the advantages that the high voltage electropulse crushing is adopted for treating low-grade gold ores, gold exposure rate of the product is high, fine particle content is low, heap leaching period can be obviously shortened, consumption of a leaching agent is reduced, and gold leaching rate is improved; and a fine-fraction graded product is also recycled while the heap leaching is carried out.

Owner:FUZHOU UNIV

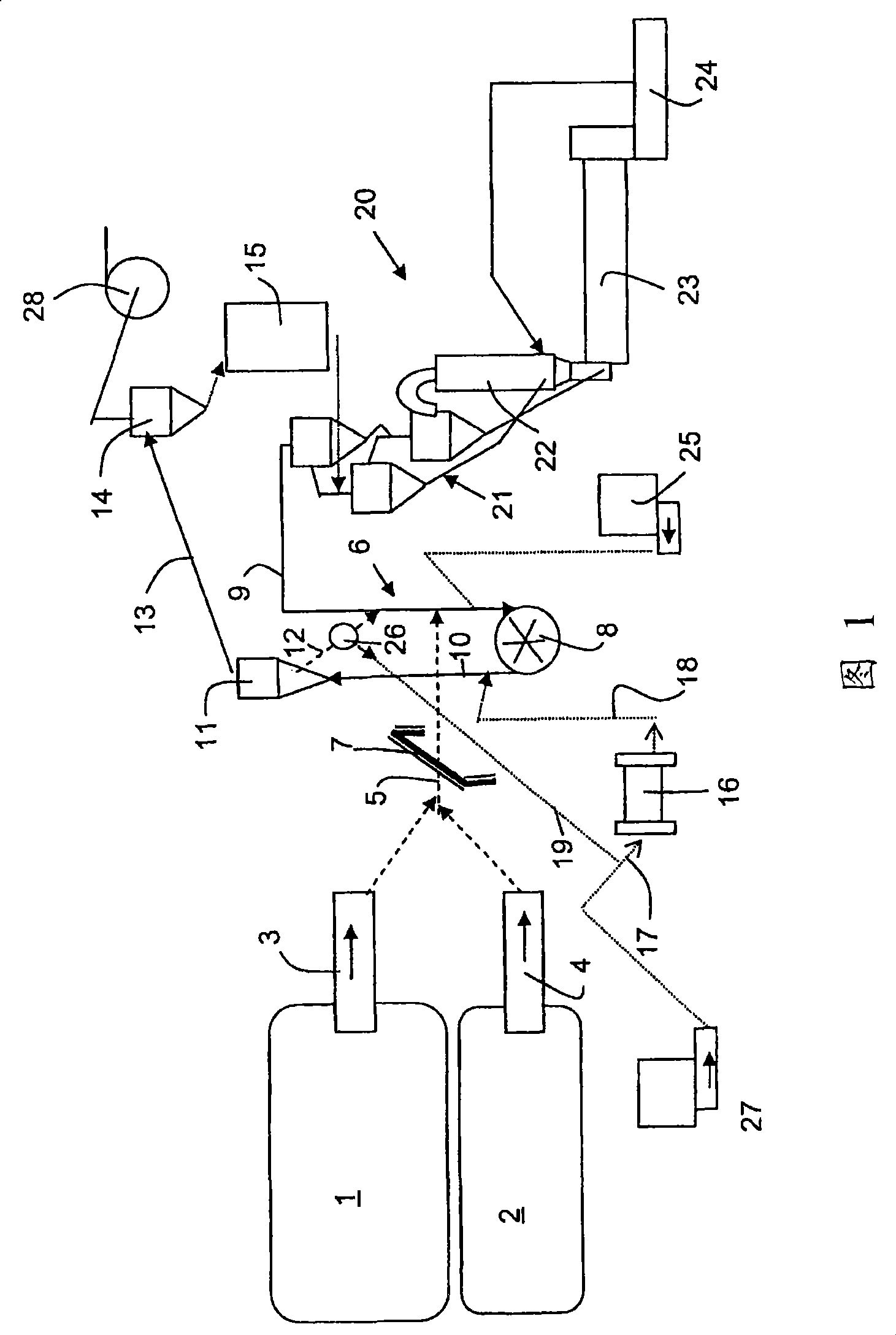

Method and plant for drying and comminution of moist, mineral raw materials

ActiveCN101384518AAchieving wear rateReduce energy consumptionRotary drum furnacesClinker productionSilica particleEngineering

Described is a method as well as a plant for drying and comminution of moist, mineral raw materials, such as chalk, marl and clay, by which method the raw materials are dried and comminuted subject to simultaneous supply of hot gases in a drier crusher (8) from which the material is subsequently directed in suspended form to a separator (11) in which it is separated into a coarse fraction which is returned to the drier crusher (8) for further drying and comminution and into a fine fraction which is directed to the next stage of the process and where any hard material components such as flint, sand and marble are subjected to grinding in a separate grinding unit (16). The method and plant is peculiar in that a part quantity of the coarse fraction from the separator (11) is proportionately fed to the separate grinding unit (16) for the grinding of hard material components. Hence, it will be possible to substantially reduce the specific energy consumption and the CO2 emission from the kiln system due to the elimination of need prior to drying and comminution in the drier crusher to suspend the raw materials in water which must subsequently be removed. This is ascribable to the fact that the hard material components by the method according to this invention will be drained away from the circuit between the drier crusher and the separator. A further advantage of the method according to this invention is the significant reduction achieved in the wear rate of the drier crusher and its energy consumption. Furthermore, it will be possible to produce a raw meal with excellent burning characteristics due to the reduction in the content of coarse silica particles in the raw meal, which in turn will reduce the NOx emission from the kiln.

Owner:F L SMIDTH & CO AS

Solvent and temperature assisted dissolution of solids from steam cracked tar

ActiveUS11286428B2Reduce particle contentIncrease productionThermal non-catalytic crackingTreatment with plural serial cracking stages onlyPhysical chemistryLiquid hydrocarbons

Processes for preparing a low particulate liquid hydrocarbon product are provided and include blending a tar stream containing particles with a fluid and heating to a temperature of 250° C. or greater to produce a fluid-feed mixture that contains tar, the particles, and the fluid. The fluid-feed mixture contains about 20 wt % or greater of the fluid, based on a combined weight of the tar stream and the fluid. Also, about 25 wt % to about 99 wt % of the particles in the tar stream are dissolved or decomposed when producing the fluid-feed mixture.

Owner:EXXONMOBIL CHEM PAT INC

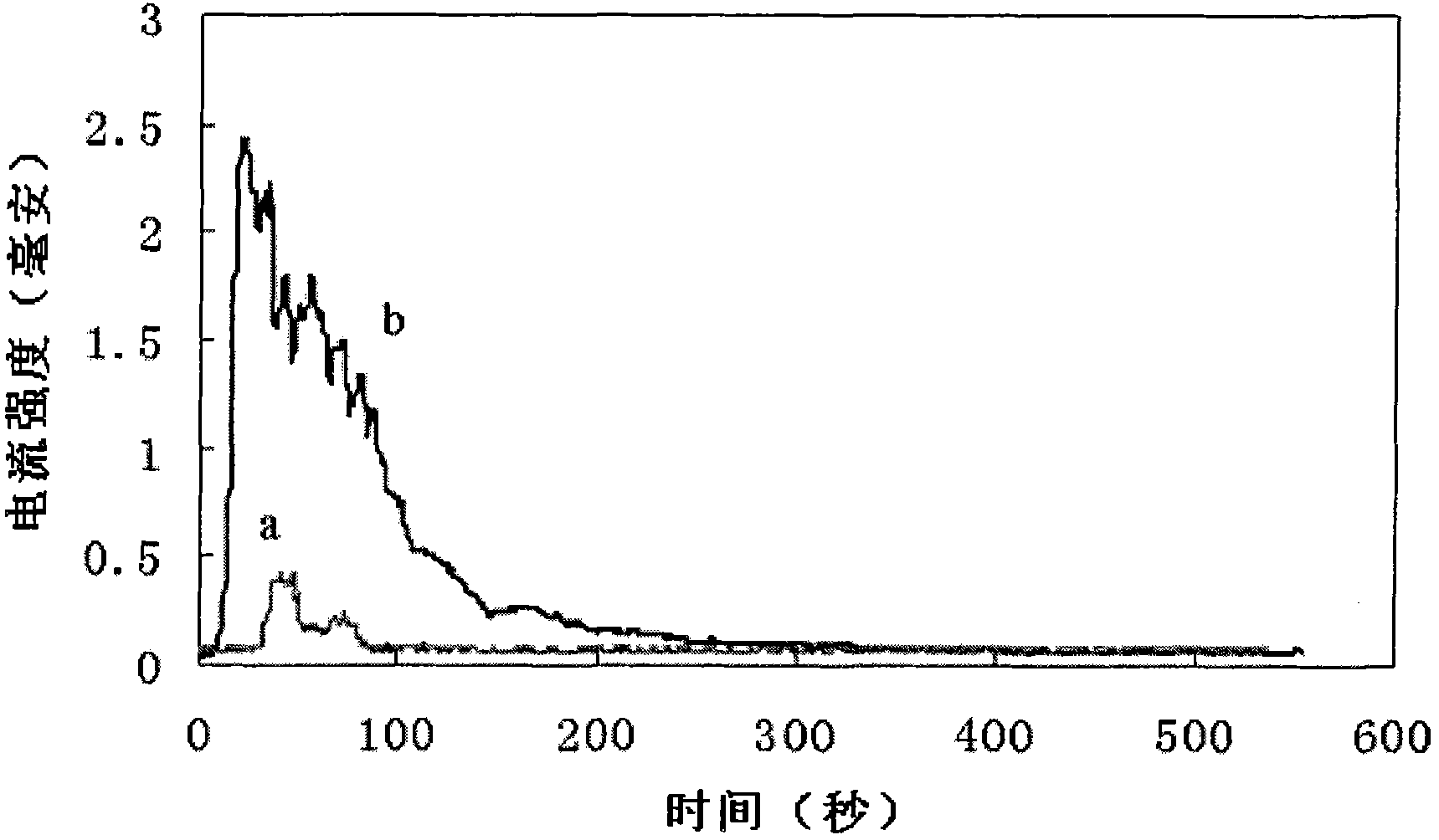

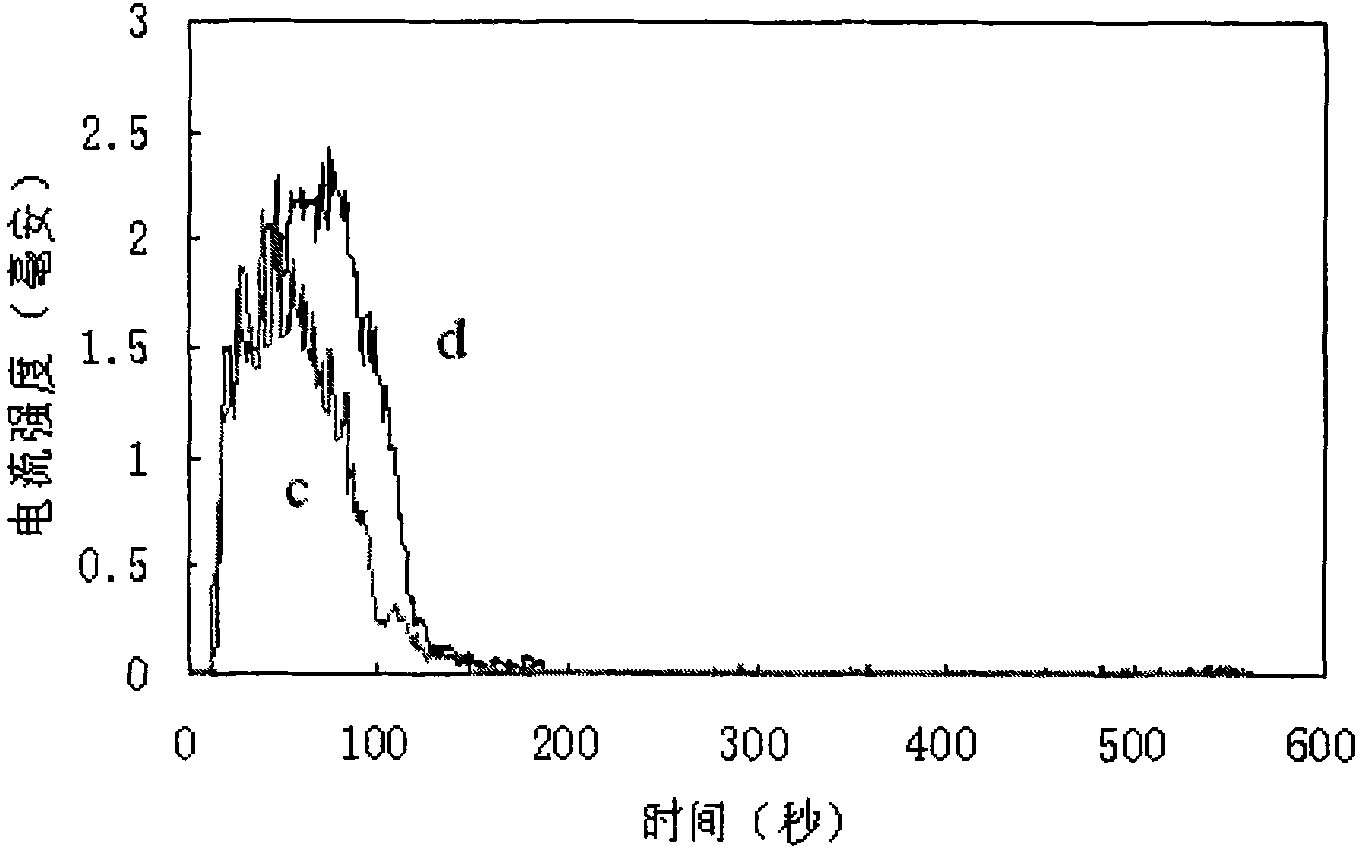

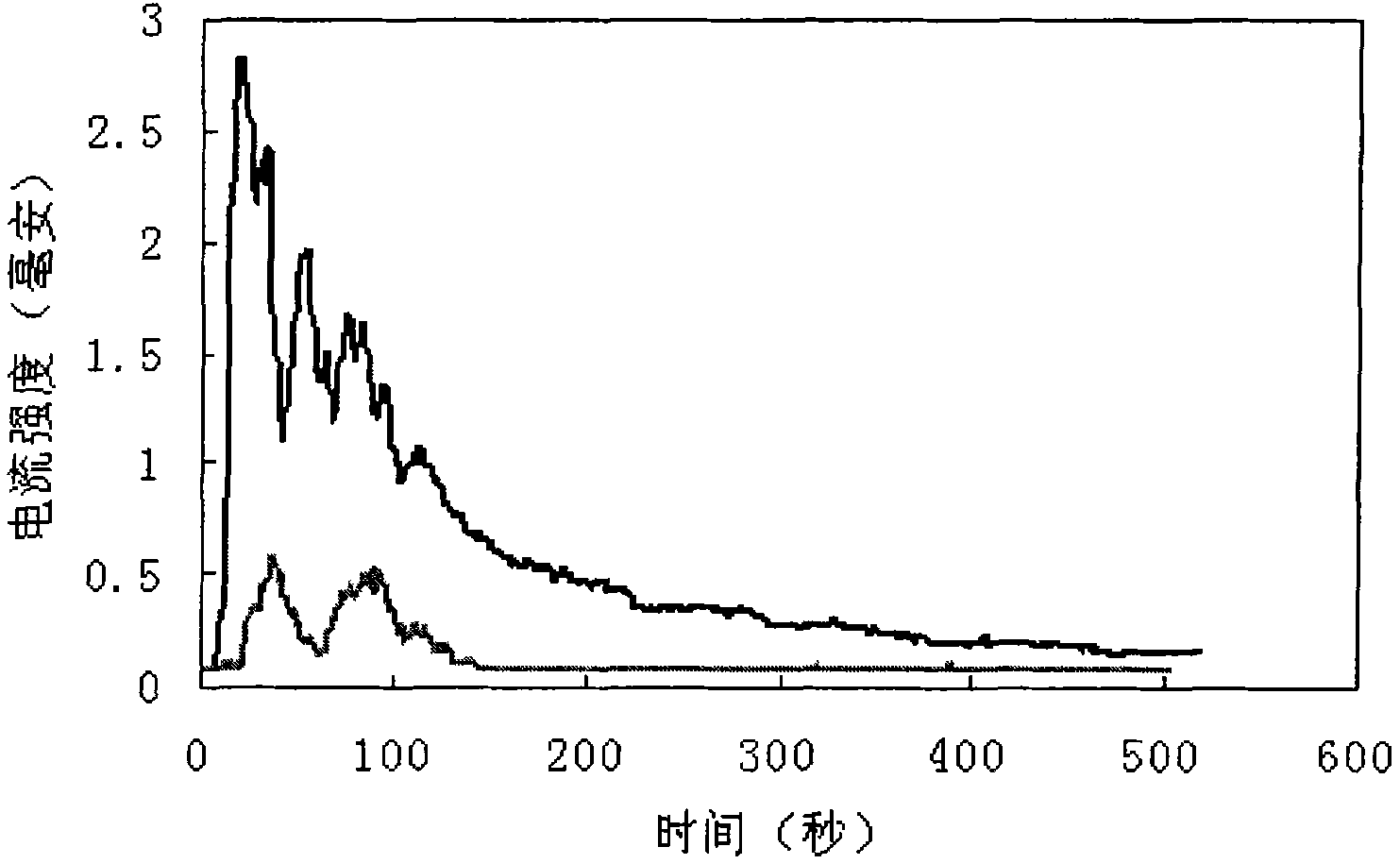

De-emulsifier and demulsification method for hydrocarbon oil

ActiveCN102453496BEfficient replacementEasy to replaceDewatering/demulsification with chemical meansSolid particleOil phase

The invention provides a de-emulsifier which comprises a polyoxyethylene nonionic surfactant, acid and fatty alcohol with a carbon atom number of 1 to 10. The invention also provides a demulsification method which comprises the following steps: mixing hydrocarbon oil and a de-emulsifier with water and allowing an obtained mixture to be separated into an oil phase and a water phase under the action of an electric field, wherein, the de-emulsifier used in the method is the de-emulsifier provided in the invention. By using the de-emulsifier and the demulsification method for hydrocarbon oil provided in the invention, an oil-water intermediate emulsification layer in hydrocarbon oil which has a high content of solid particles can be effectively eliminated, thereby avoiding too great current in the process of electric dehydration. In addition, the de-emulsifier has simple composition and is easy to popularize and apply.

Owner:CHINA PETROLEUM & CHEM CORP +1

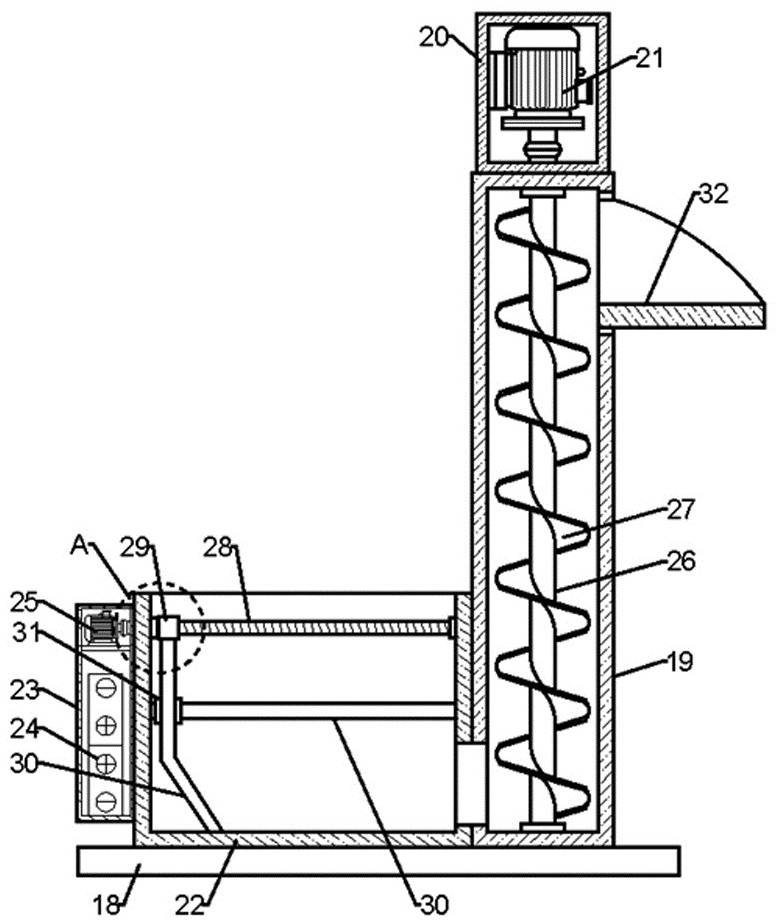

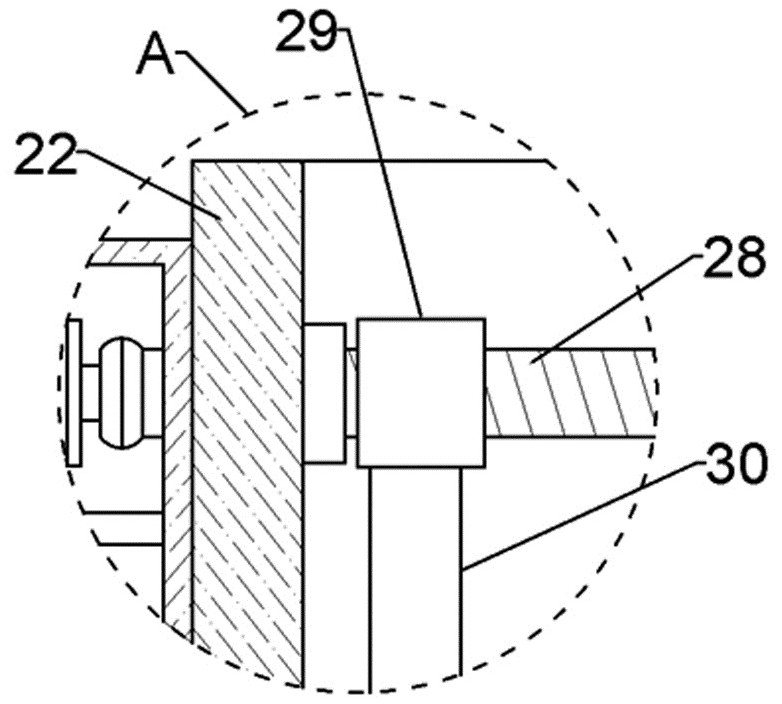

Production process convenient for manufacturing superfine slag powder

PendingCN112275434AReduce particle contentStrengthen high quality requirementsDispersed particle filtrationGrain treatmentsSlagMaterials science

The invention discloses a production process convenient for manufacturing superfine slag powder. The production process comprises the following steps: weighing and metering steel slag, conveying and filtering the steel slag, repeatedly grinding the steel slag, collecting and conveying finished steel slag powder, and lifting and storing mineral powder. A finished product lifter comprises a bottom plate, a lifting assembly and a scraping assembly. A material collecting box is fixedly arranged on one side of the top face of a base, a conveying cylinder with the two ends closed is vertically and fixedly connected to the middle of the other side of the top face of the base, and the lifting assembly is arranged in the conveying cylinder. The scraping assembly is arranged in the material collecting box. The production process is convenient to operate, and the problem that the content of the steel slag in the mineral powder is large due to the fact that an existing mineral powder manufacturingtechnological process does not have a steel slag repeated grinding function is solved.

Owner:稷山县华越建材有限公司

The preparation method of active calcium silicate

ActiveCN104085896BSolve the problem of high content of large particlesImprove product qualitySolid waste managementAlkaline-earth metal silicatesCalcium silicatePapermaking

The invention provides a preparation method of activated calcium silicate. The method comprises the following steps: mixing lime milk, pulverized ash desilliconization liquid and a particle size control agent for reaction to obtain activated calcium silicate slurry, wherein the particle size control agent is one of pyrophosphate, metaphosphate, polyphosphate, polyacrylic ester and polyacrylate, the addition amount of pyrophosphate, metaphosphate or polyphosphate is 0.2-2.5% of dry weight of the pulverized ash desilliconization liquid and lime milk, and the addition amount of polyacrylic ester or polyacrylate is 0.05-0.5% of dry weight of the pulverized ash desilliconization liquid and lime milk. According to the preparation method, large particles in the activated calcium silicate can be effectively reduced, and the influence on the papermaking process and the quality of paper products can be reduced.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

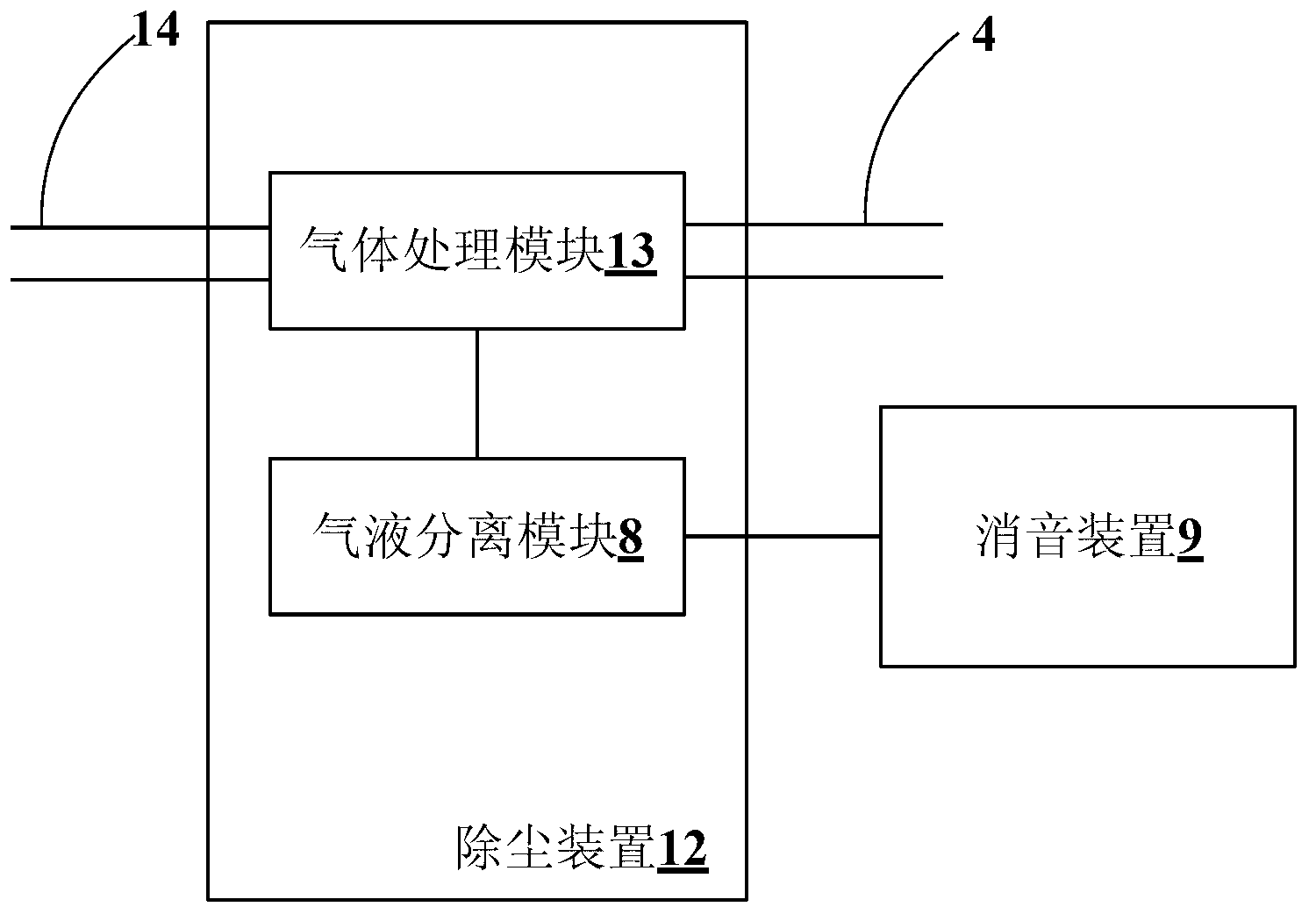

Waste gas treatment method for silencer, dust-extraction device and engineering machinery motor

InactiveCN102840010AImprove protectionReduce particle contentExhaust apparatusSilencing apparatusLiquid gasMuffler

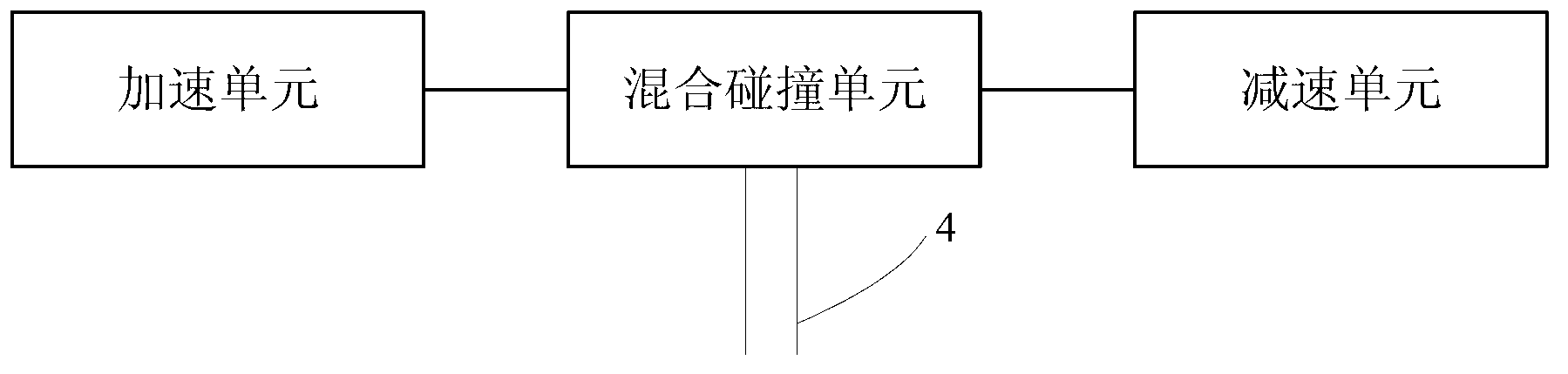

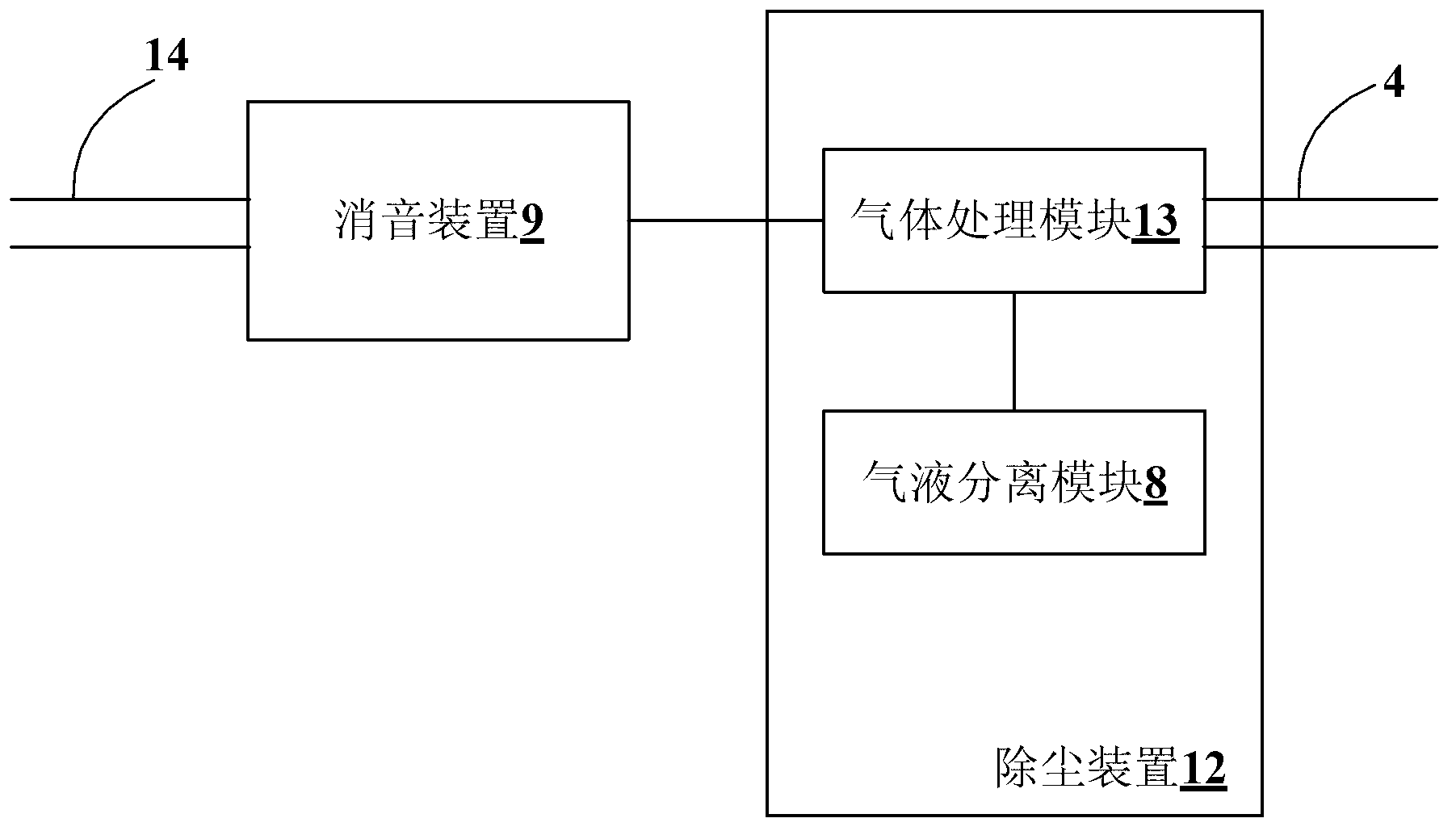

The invention discloses a waste gas treatment method for a silencer, a dust-extraction device and an engineering machinery motor, wherein the silencer comprises the dust-extraction device and a silencing device, the dust-extraction device comprises a gas treatment module and a liquid-gas separation module. The dust-extraction device and the silencing device are connected through one of the two modes which are that the gas treatment module, the liquid-gas separation module and the silencing device are connected sequentially and the silencing device, the gas treatment module and the liquid-gas separation module are connected sequentially. And the gas treatment module comprises an accelerating unit, a hybrid collision unit and a decelerating unit, the accelerating unit, the hybrid collision unit and the decelerating unit are connected sequentially, and a spray head is arranged at an inlet portion of the hybrid collision unit. Venturi tube effect is used in the dust-extraction device to remove dust and purify waste gas, and accordingly particle content in discharge is lowered, and environment protection is better achieved.

Owner:SANY HEAVY MACHINERY

Four-step method for processing and recycling tin ore floatation wastewater

ActiveCN102030445BReduce productionIncrease the amount of purificationEnergy based wastewater treatmentMultistage water/sewage treatmentChemical treatmentPolyacrylamide

The invention discloses a four-step method for processing and recycling tin ore floatation wastewater, which comprises a new floatation technique, chemical treatment, physical treatment and biological treatment. The four-step method is characterized in that the principle of putting prevention first and providing prevention and control is adopted. The method is as follows: the new floatation technique and process are utilized to reduce the floatation wastewater and the microgranular particles from the headstream and reduce the usage amount of floatation reagents; because the chemical treatmentmethod is used, the concentration of polyacrylamide in the tin ore floatation wastewater is increased from 0.5 percent to 0.9-1.1 percent, and the settling rate of part of the wastewater is improved;the physical treatment method is adopted to increase the settling distance and the settling time, the settling distance is extended for another 600 to 800m on the basis of 200m, and the settling timeis increased for another 25 to 27 hours on the basis of 10 hours; aquatic organisms or plants, such as fish, frogs, aquatic weeds and the like are adopted to process the wastewater, the ecological reconstruction is realized, the agricultural irrigation standards are met, the utilization ratio of floatation return water is improved from 86 percent to above 97 percent, and peaceful and friendly coexistence of human and environment is realized.

Owner:广西华锡矿业有限公司铜坑矿业分公司

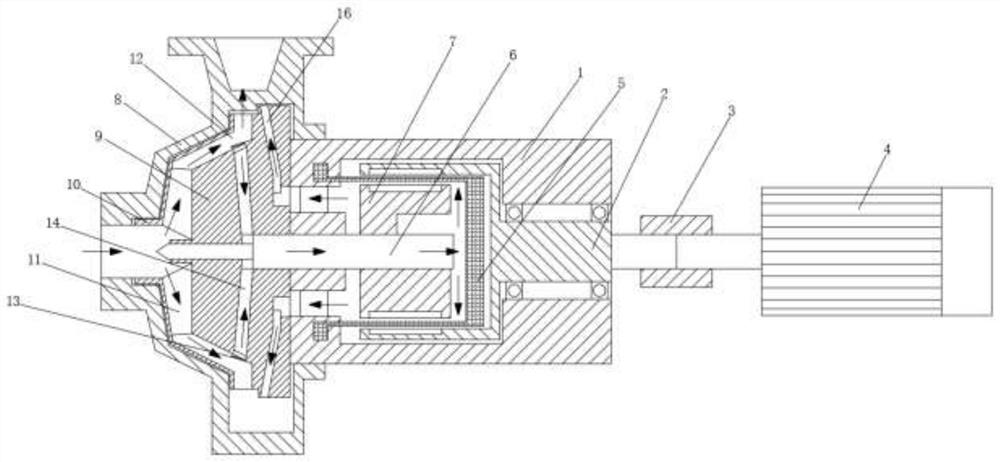

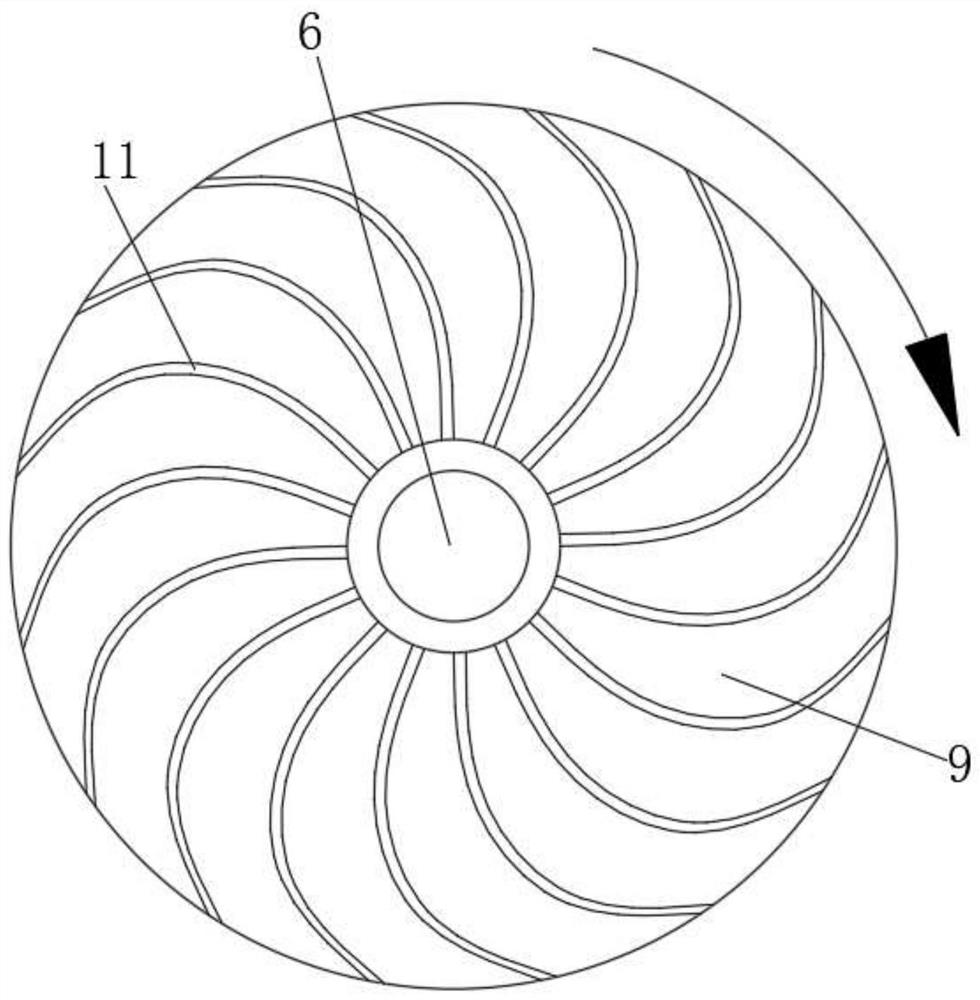

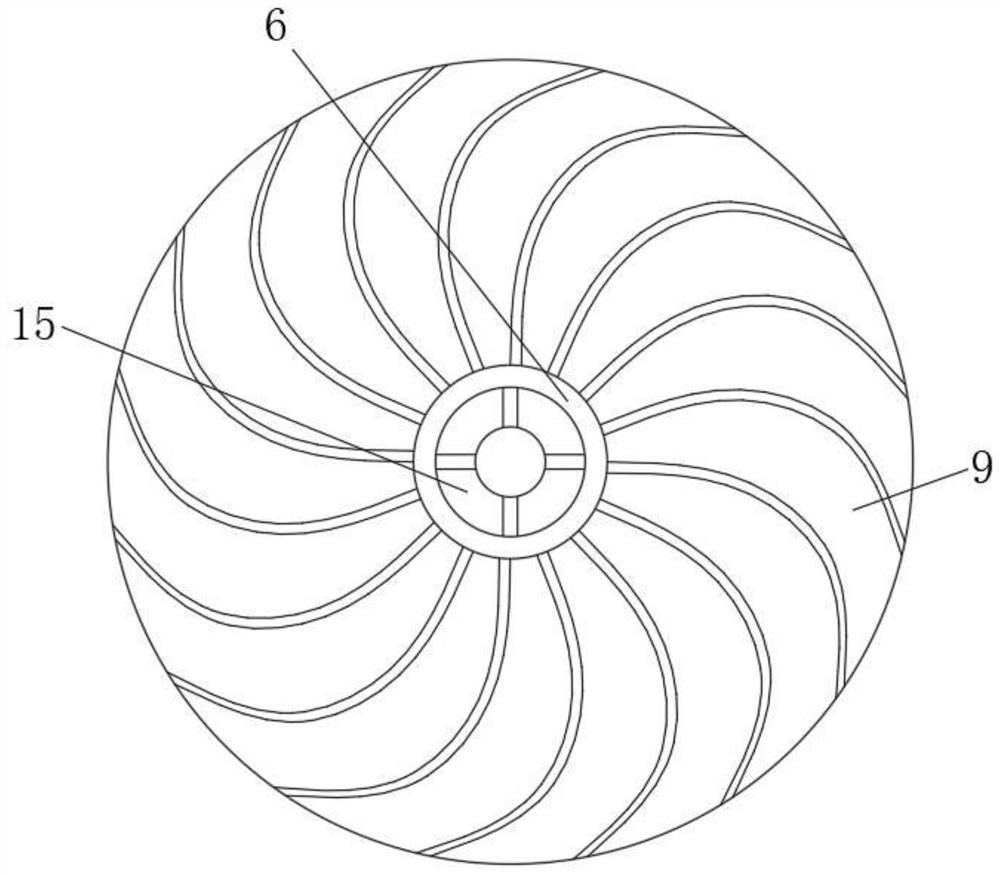

Stainless steel magnetic centrifugal pump

InactiveCN112664462AExtended service lifeGuaranteed service lifePump componentsPump installationsCentrifugationEngineering

The invention relates to the technical field of transportation pump equipment, and discloses a stainless steel magnetic centrifugal pump which comprises a support. According to the stainless steel magnetic centrifugal pump, a separation flow channel communicates with gaps of wheel blades and obliquely extends upwards, water under the action of rotary centrifugation passes through the separation flow channel, solid-liquid separation can be conducted, solid particles are layered to the outer ring, liquid and scraping blades are matched to scrape layers and the liquid enter a water inlet channel, and under the action of reverse rotation blades, the liquid can overcome centrifugal force to enter a pump shaft and be conveyed to an inner cavity of an isolation sleeve, an inner magnetic rotor is cooled, the particle content is reduced, the service life of the isolation sleeve is prolonged, rotation failure caused by blockage is prevented, meanwhile, the liquid is injected from the pump shaft, tooth holes are formed in the left side of the support in a axial direction, the liquid entering the isolation sleeve is discharged from the tooth holes arranged in the circumferential direction, so that the pressure of the liquid entering the isolation sleeve is uniform, and the problems that the pressure of the liquid entering an existing structure is not uniform easily, axial force and radial force are exerted on the pump shaft, and damage is caused easily are solved.

Owner:朱井美

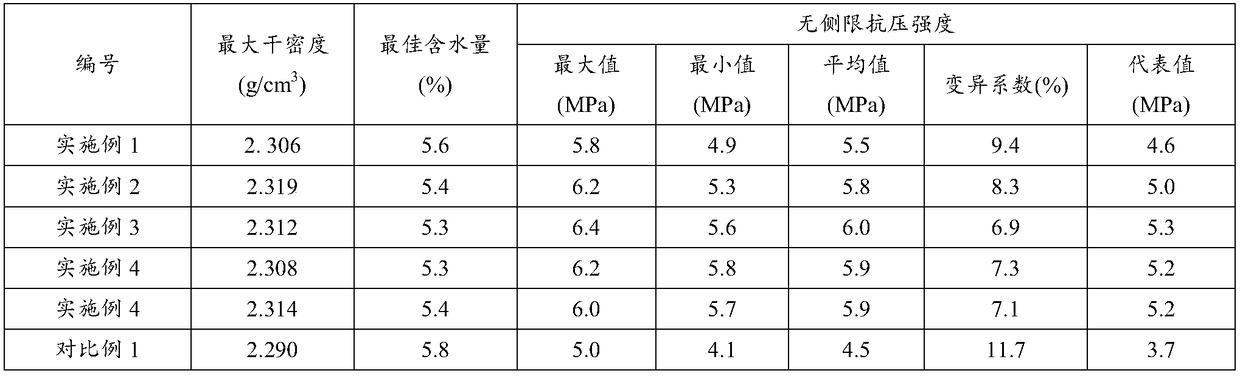

Aeolian sand cement stabilized graded broken stone

The invention discloses aeolian sand cement stabilized graded broken stone. The aeolian sand cement stabilized graded broken stone comprises the following raw materials by mass percent: 4.2-5.2% of cement, 4.6-6.6% of water, and the balance of aeolian sand graded broken stone; the aeolian sand graded broken stone comprises the following raw materials by mass ratio, and the ratio of the aeolian sand to the stone chips to the broken stone is equal to (8-13):(17-26):(66-70). According to the aeolian sand cement stabilized graded broken stone, the capital input of the highway projects is relatively low, the cost of the raw materials for building the road is low, and the flexural-tensile strength and the crack resistant property of the cement stabilized graded broken stone are improved.

Owner:CCCC SECOND HARBOR ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com