Aeolian sand cement stabilized graded broken stone

A technology for grading crushed stone and cement stabilization, applied in the field of building materials, can solve the problems of unsatisfactory flexural tensile strength and crack resistance of crushed stone, short service life of roads, lack of road construction stone resources, etc., to reduce road construction. The effect of cost, low cost and short transportation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

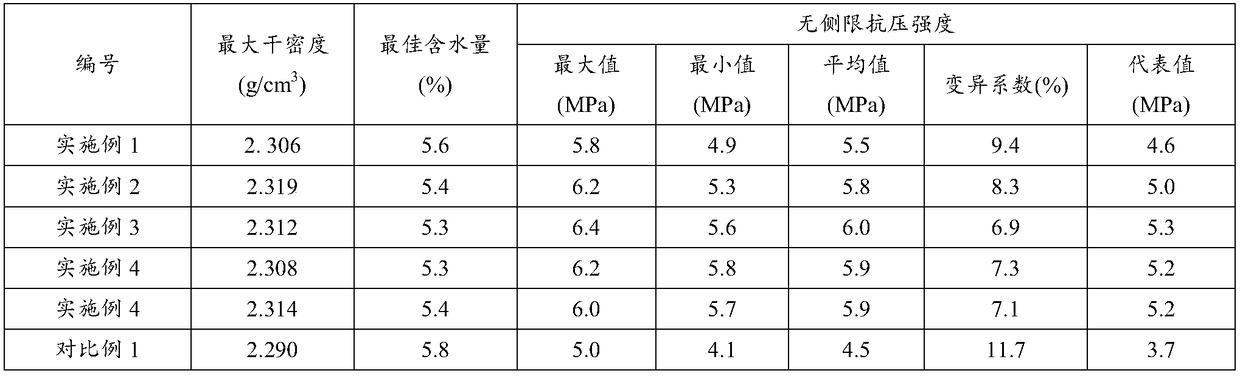

Examples

Embodiment 1

[0028] An aeolian sand cement stabilized graded crushed stone is composed of P.F32.5 cement, water, and aeolian sand graded crushed stone. Its mass percentage ratio is: cement: 4.2%, water: 5.6%, wind Sand graded gravel: 90.2%.

[0029] Among them, the aeolian sand graded crushed stone is composed of raw materials with the following mass ratios: aeolian sand: stone chips: crushed stone = 8:26:66.

[0030] The mass ratio of the particle size distribution of aeolian sand is:

[0031] (0~0.075)mm:(0.075~0.25)mm:(0.25~3)mm=2:87:11.

[0032] The mass ratio of the particle size distribution of the crushed stone is:

[0033] (4.75~9.5)mm: (9.5~19.0)mm: (19.0~26.5)mm=18:43:39.

Embodiment 2

[0035] A kind of aeolian sand cement stabilized graded crushed stone is composed of P.F32.5 cement, water and aeolian sand graded crushed stone. Its mass percentage ratio is: cement: 4.7%, water: 5.4%, wind Sand graded gravel: 89.9%.

[0036] Aeolian sand graded gravel is composed of raw materials with the following mass ratios: aeolian sand: stone chips: gravel = 13:17:70.

[0037] The mass ratio of the particle size distribution of aeolian sand is:

[0038] (0~0.075)mm:(0.075~0.25)mm:(0.25~3)mm=1:75:24.

[0039] The mass ratio of the particle size distribution of the crushed stone is:

[0040] (4.75~9.5)mm: (9.5~19.0)mm: (19.0~26.5)mm=22:39:39.

Embodiment 3

[0042] A kind of aeolian sand cement stabilized graded crushed stone is composed of P.F32.5 cement, water and aeolian sand graded crushed stone. Its mass percentage is: cement 4.7%, water: 5.2%, aeolian sand Sand graded gravel: 90.1%.

[0043] Among them, the aeolian sand graded crushed stone is composed of raw materials with the following mass ratios: aeolian sand: stone chips: crushed stone = 12:20:68.

[0044] The mass ratio of the particle size distribution of aeolian sand is:

[0045] (0~0.075)mm:(0.075~0.25)mm:(0.25~3)mm=1:79:20.

[0046] The mass ratio of the particle size distribution of the crushed stone is:

[0047] (4.75~9.5)mm: (9.5~19.0)mm: (19.0~26.5)mm=21:41:38.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com