Low-grade gold ore heap leaching method based on high voltage electropulse crushing

A high-voltage electric pulse, low-grade technology, applied in the field of metallurgy, can solve the problems of reducing the permeability of the solution, the mechanical crushing is not very good, and the gap of the ore heap can be reduced, so as to shorten the heap leaching period and solve the long heap leaching time. , Improve the effect of gold leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

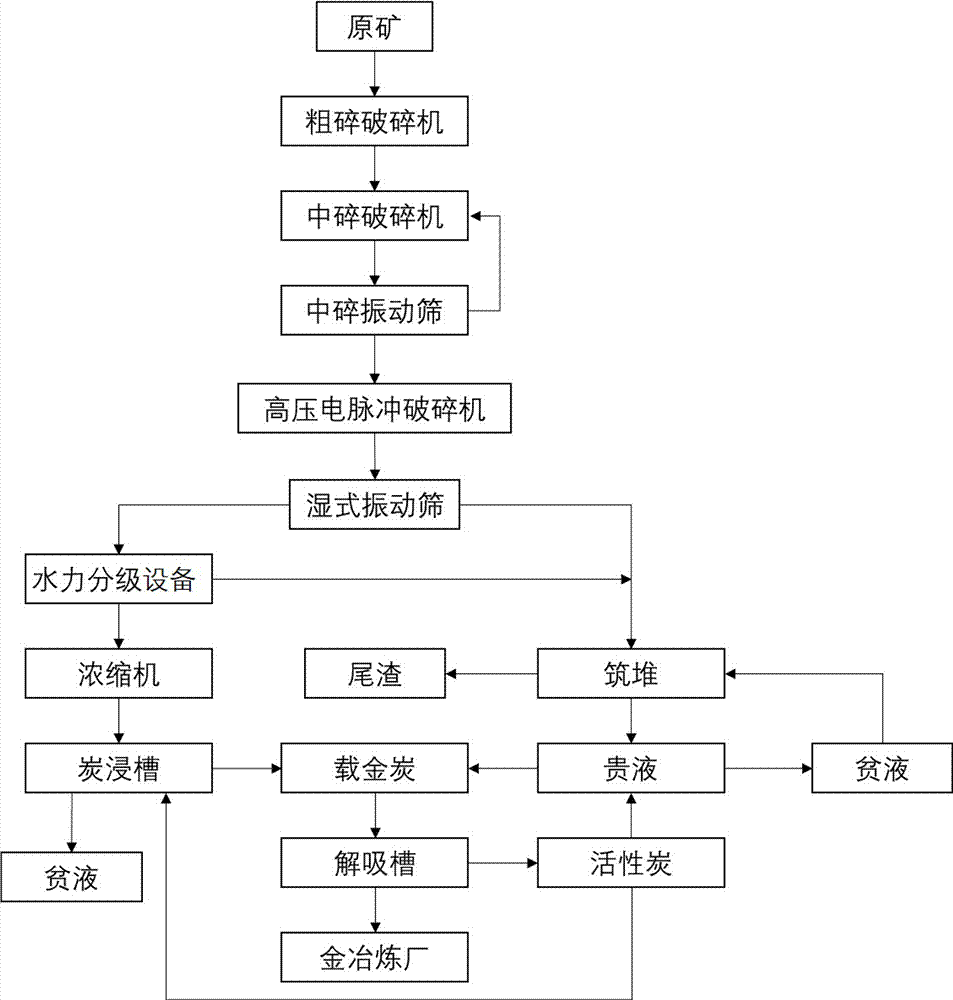

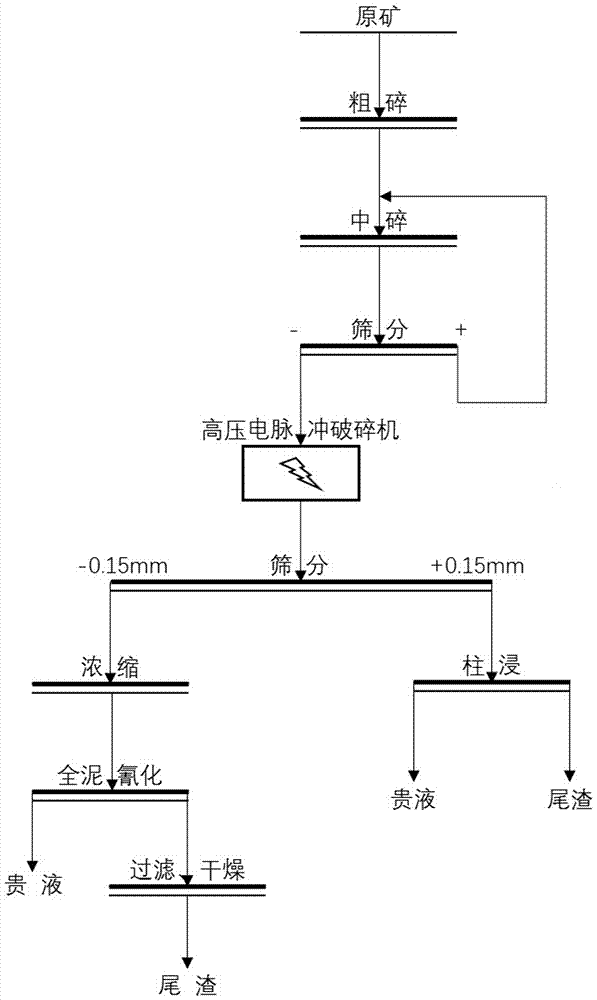

[0035] Such as figure 1 As shown, a low-grade gold ore heap leaching method based on high-voltage electric pulse crushing comprises the following steps:

[0036] (1) The raw ore undergoes open-circuit coarse crushing and closed-circuit intermediate crushing in sequence to obtain closed-circuit intermediate crushing products.

[0037] Open-circuit coarse crushing adopts a coarse crusher, the upper limit of the particle size of which is 150-250mm, and the coarse crusher is one of the conventional crushers such as cone crusher, jaw crusher or impact crusher;

[0038] Closed-circuit secondary crushing adopts secondary crushing crusher and secondary crushing vibrating screen, and the open-loop coarse crushing products of suitable size obtained by open-circuit primary crushing are all fed into the secondary crushing crusher, and the primary second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com