Manufacturing method of nanofiber probe tip for measuring surface topography of sample

A surface topography measurement and nanofiber technology, which is applied in measuring devices, scanning probe technology, scanning probe microscopy, etc., can solve problems such as low utilization rate, cumbersome process, and strict requirements for precision in nanostructure scanning. Achieve the effect of high utilization rate and strong robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

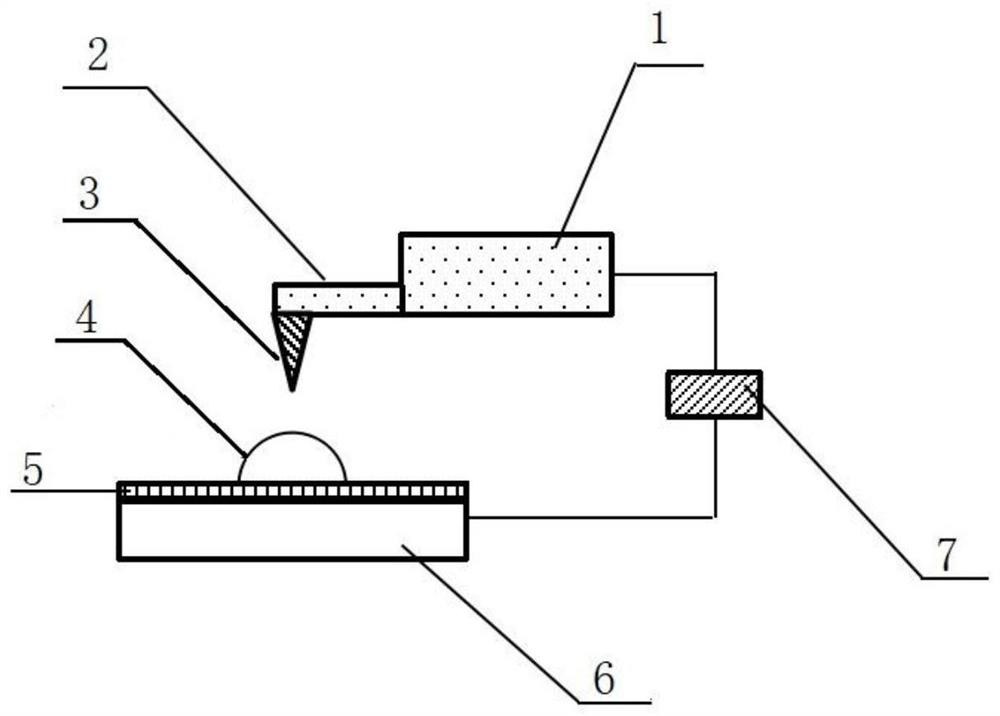

[0042] like figure 1 As shown, a nanofiber probe tip manufacturing equipment for sample surface topography measurement, specifically includes: probe, probe clamping mechanism, substrate support mechanism, power supply,

[0043] The probe includes a needle body and a conductive layer, and the conductive layer is coated on the surface of the needle body;

[0044] The probe clamping mechanism includes a probe clamping end and a probe cantilever beam installed at the end, and the probe is vertically suspended and installed on the probe cantilever beam;

[0045] The base support mechanism includes a conductive plate and a dielectric layer, and the dielectric layer is coated on the surface of the conductive plate;

[0046] Connect the probe and conductive plate to both ends of the power supply;

[0047]The suspended liquid drops are formed on the surface of the base support mechanism, the power is turned on, and the probe is controlled by the probe clamping mechanism to slowly app...

Embodiment 2

[0056] like Figure 4 Shown, a kind of nanofiber probe tip manufacturing method for sample surface topography measurement, the method comprises the following steps:

[0057] 1) Prepare the substrate: prepare a conductive flat plate, the roughness Ra of the conductive flat plate should be less than 0.1 micron, the material of the conductive flat plate can be any conductive solid, and the size of the flat plate is not strictly required. It is carried out under a microscope, so the recommended size is 10*10*0.5 mm, and the surface of the flat plate is covered with a non-conductive material as a dielectric layer. The thickness and covering method of the dielectric layer are related to the material selected, usually the thickness ranges from 100 to 60,000 nanometers, it is recommended to use the suspension coating method to attach polydimethylsiloxane PDMS (the mass ratio of PDMS and crosslinking agent is 10:1) to the surface of the conductive plate, the thickness of the suspension...

Embodiment 3

[0067] like Figure 4 Shown, a kind of nanofiber probe tip manufacturing method for sample surface topography measurement, the method comprises the following steps:

[0068] 1) Prepare the substrate: prepare a conductive flat plate, the roughness Ra of the conductive flat plate should be less than 0.1 micron, the material of the conductive flat plate can be any conductive solid, and the size of the flat plate is not strictly required. It is carried out under a microscope, so the recommended size is 10*10*0.5 mm, and the surface of the flat plate is covered with a non-conductive material as a dielectric layer. The thickness and covering method of the dielectric layer are related to the material selected, usually the thickness ranges from 100 to 60000 nanometers, it is recommended to use the method of suspension coating to attach polystyrene (the mass ratio of polystyrene and crosslinking agent is 10:1) to the surface of the conductive plate, the adhesion thickness is 50 microns...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com