Method for reducing surface ice adhesion strength of silicon wafer

A technology of adhesion strength and silicon wafer surface, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., to improve power generation efficiency and prevent the accumulation of ice and snow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

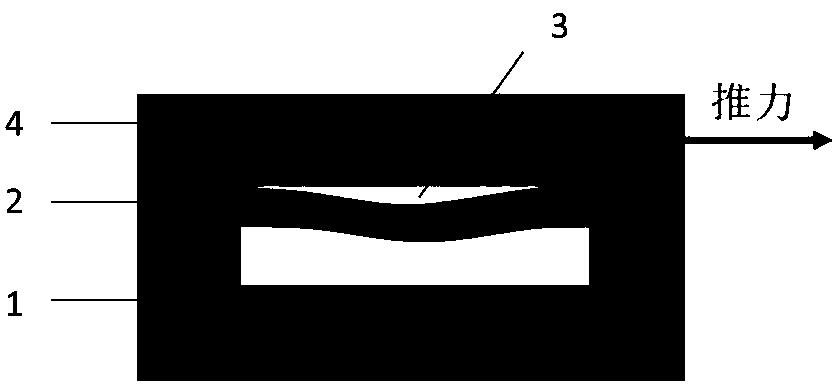

[0037] Such as figure 1 As shown, when the PDMS membrane 2 is subjected to the shear force (that is, thrust) of the ice accumulation 4, the PDMS membrane 2 between the ice accumulation 4 and the micron hole will generate cracks 3 induction points, which is conducive to the reduction of ice adhesion strength .

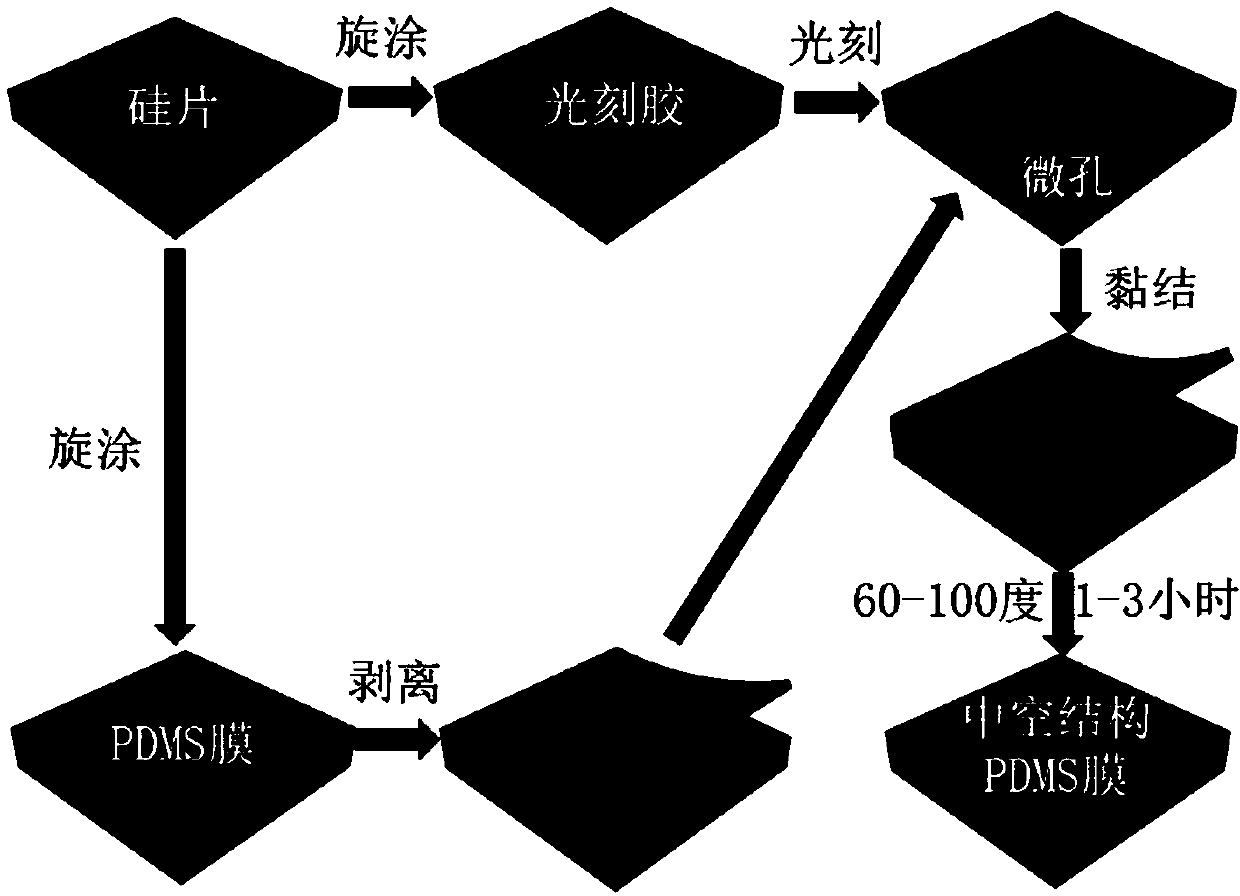

[0038] Such as figure 2 As shown, a method for reducing the ice adhesion strength on the surface of a silicon wafer comprises the following steps:

[0039] Step S10, preparing micron holes on the surface of the silicon wafer 1;

[0040] Step S20, covering the surface of the silicon wafer 1 with micron holes with a PDMS film;

[0041] Step S30, curing the PDMS film 2 on the surface of the silicon wafer 1 .

[0042] The micron hole has a height below 1.1 micron. Micro-holes with a height of less than 1.1 microns have a greater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com