Manufacturing method of multilayer substrate and multilayer substrate

A technology of multi-layer substrate and manufacturing method, which is applied in the direction of multi-layer circuit manufacturing, printed circuit manufacturing, and electrical connection formation of printed components, etc., which can solve the problem of unsatisfactory interlayer conductivity and signal transmission, manufacturing process and equipment High requirements, complex manufacturing process and other issues, to achieve the effect of facilitating mass production, simple and convenient manufacturing methods, and improving product quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to fully understand the advantages of the present invention and the objects attained by the embodiments of the present invention, the structures of some embodiments are shown, however, the present invention can be implemented in many different forms and should not be construed as being limited by the implementations set forth herein. Example limitations. Rather, these embodiments are presented so that this will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art. In the drawings, the size and relative sizes of layers and regions may be exaggerated for clarity. Preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings.

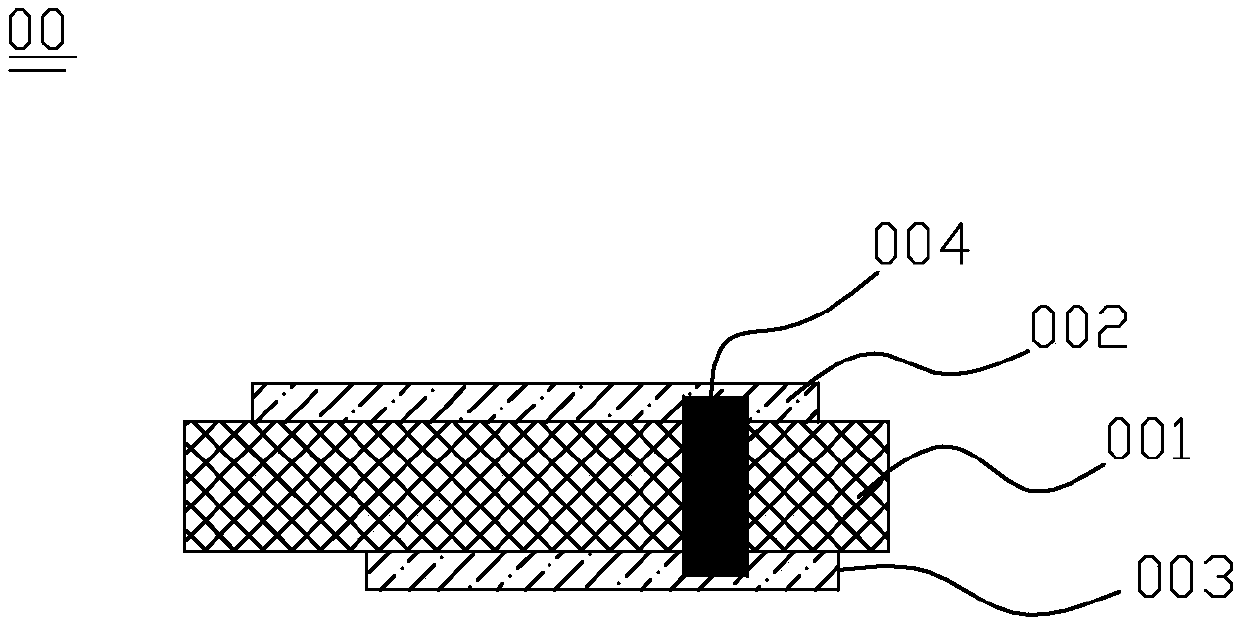

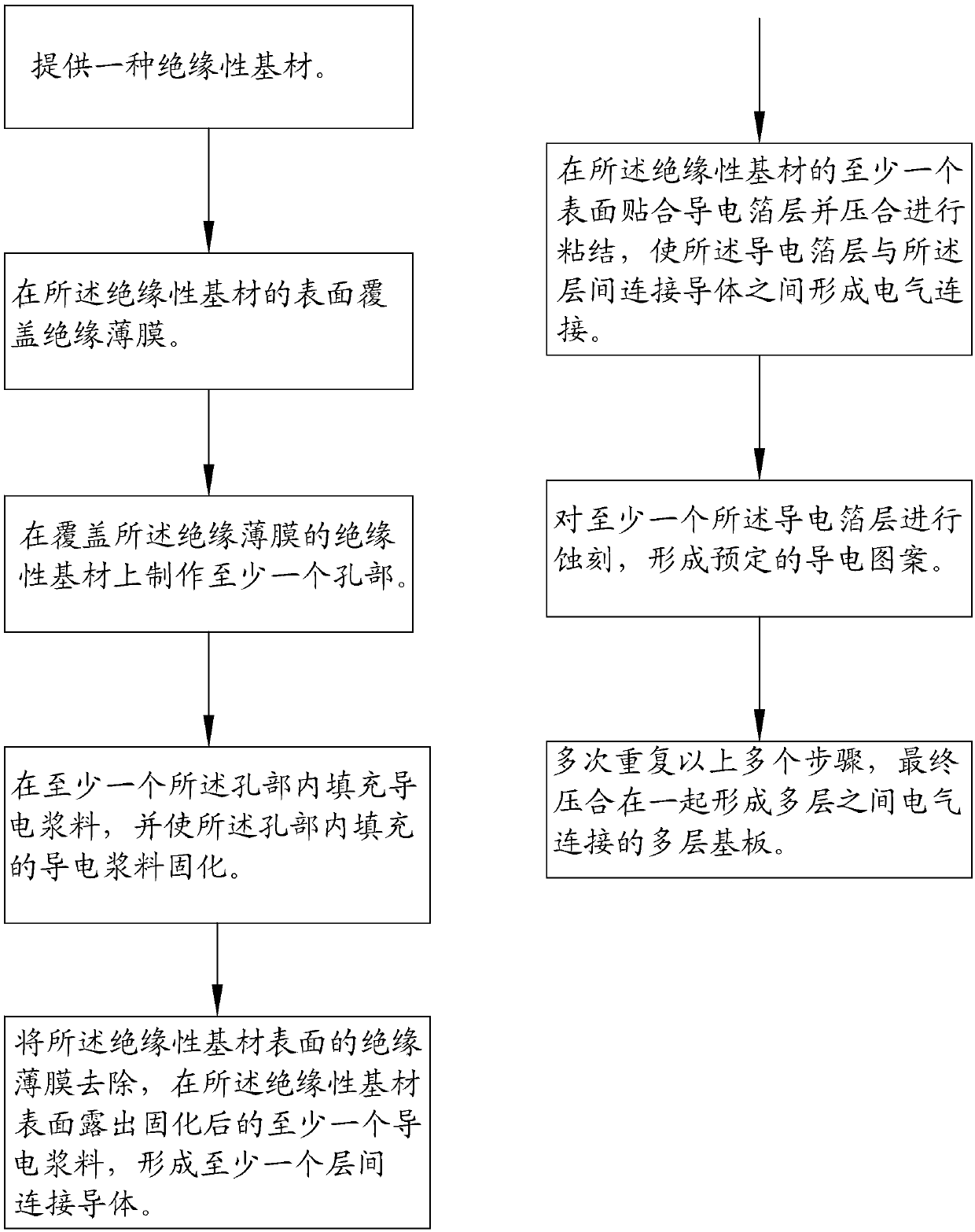

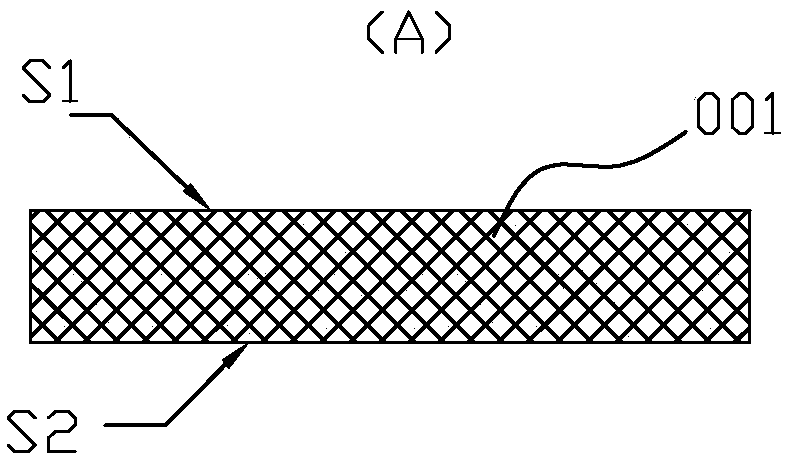

[0039] see figure 1 , combined with Figure 3A ~ Figure 3G As shown, generally, the multilayer substrate 00 includes an insulating base material 001 , a first conductive pattern layer 002 , a second conductive pattern l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com