Surface acoustic wave filter packaging method and structure based on glass cover plate

A surface acoustic filter, glass cover technology, applied in electrical components, impedance networks, etc., can solve the problems of strict flatness requirements of substrates and sealing covers, filter damage, easy to change device performance, etc., to avoid the risk of splitting , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

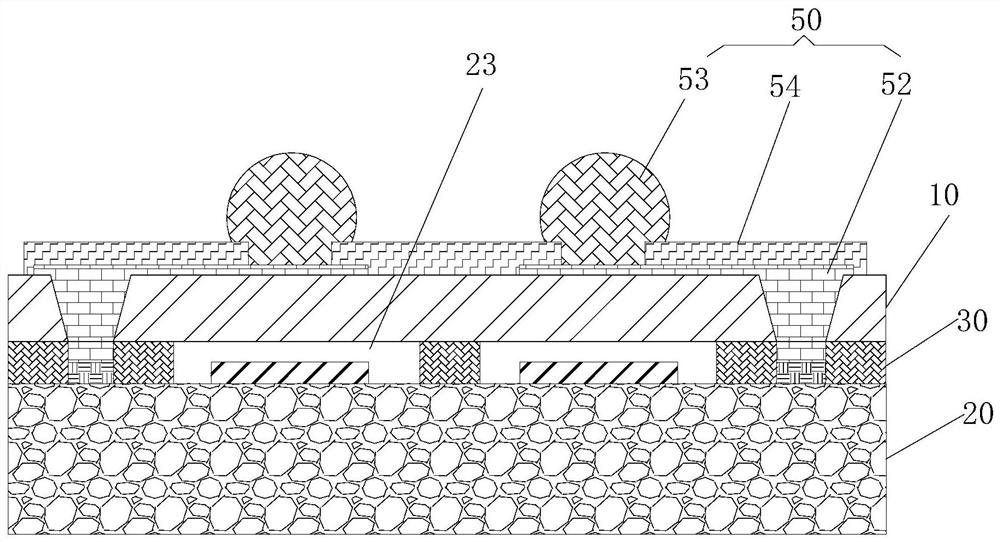

[0061] see Figure 11 to Figure 12 , a surface acoustic filter packaging method and structure based on a glass cover, its main features are the same as in Embodiment 1, the difference is:

[0062] In step 5), making the metal connector 50 is specifically: by depositing a seed layer at the pad 21, electroplating and filling the through hole 12 of the glass cover 10 to form the metal connection circuit 51, and making the metal connection circuit 51 in the external connection area of the metal connection circuit 51. The soldering portion 53 , the outer connection area of the metal circuit is located directly above the pad 21 . That is, the metal line and the soldering portion 53 constitute the metal connector 50 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com