Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Magnesium Oxide / Zinc Oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of ultravioresistant PVC composite material suitable for plateau environment

InactiveCN104497435AImproves UV resistanceImprove flame retardant performanceChemical solutionPolyvinyl chloride

The invention belongs to the technical field of new material, and concretely relates to an improved preparation technology for enhancing the functionality of a polyvinyl chloride (PVC) material. The preparation technology of the present invention comprises the following steps: 1)preparing a nano reinforcement; and 2)preparing the hybrid PVC functional composite material by a chemical solution method to prepare the hybrid PVC functional composite material. According to the invention, zinc oxide and titanium dioxide are composited for usage, anti ultraviolet performance of the composite material can be greatly increased; nano-sized magnesium hydroxide, zinc oxide and titanium dioxide particles are organically combined to prepare the PVC functional composite material, PVC anti ultraviolet capability can be optimized, aging rate can be reduced, service life is prolonged, flame retardation performance is enhanced, fire hazard generation is reduced, and the external environment adaptation capability of the PVC material at Qinghai-Tibet plateau can be finally increased.

Owner:QINGHAI UNIVERSITY

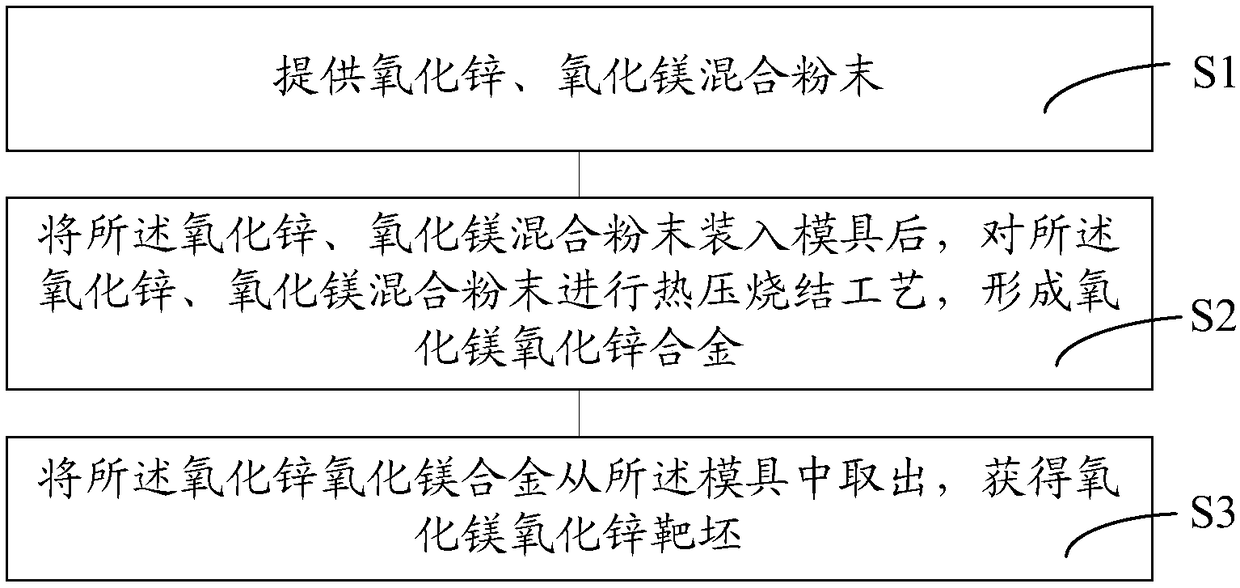

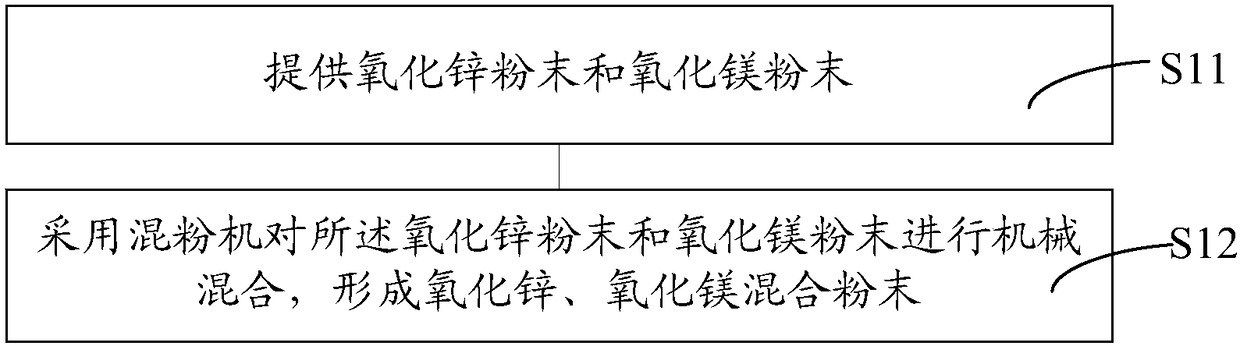

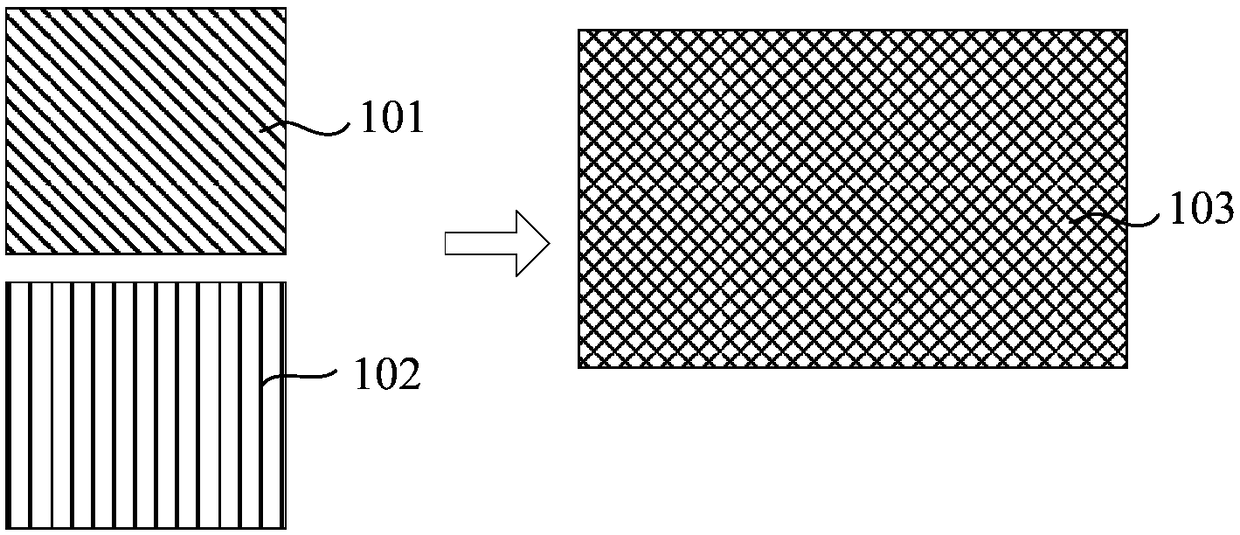

Method for manufacturing magnesium oxide and zinc oxide target billet

InactiveCN108249911AImprove compactnessImprove uniformityVacuum evaporation coatingSputtering coatingMagnesium Oxide / Zinc OxideAlloy

The invention provides a method for manufacturing a magnesium oxide and zinc oxide target billet. The method comprises the following steps: providing zinc oxide and magnesium oxide mixed powder; adding the zinc oxide and magnesium oxide mixed powder into a die, and performing a hot-pressing sintering technology on the zinc oxide and magnesium oxide mixed powder to form a magnesium oxide and zinc oxide alloy; and taking out the magnesium oxide and zinc oxide alloy from the die to obtain the magnesium oxide and zinc oxide target billet. Compared with a normal-pressure sintering or cold-pressingmolding technology, the method in the invention can improve the density and the microhomogeneity of the formed magnesium oxide and zinc oxide target billet and reduce the probability of cracks in themagnesium oxide and zinc oxide target billet to make the density of the magnesium oxide and zinc oxide target billet reach 98% or more and the magnesium oxide and zinc oxide target billet have a uniform color, so the performances of the formed magnesium oxide and zinc oxide target billet are improved, and the magnesium oxide and zinc oxide target billet has stable physical properties and can meetperformance requirements of a sputtering target.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Formula and production process of oil-water type anti-slip material

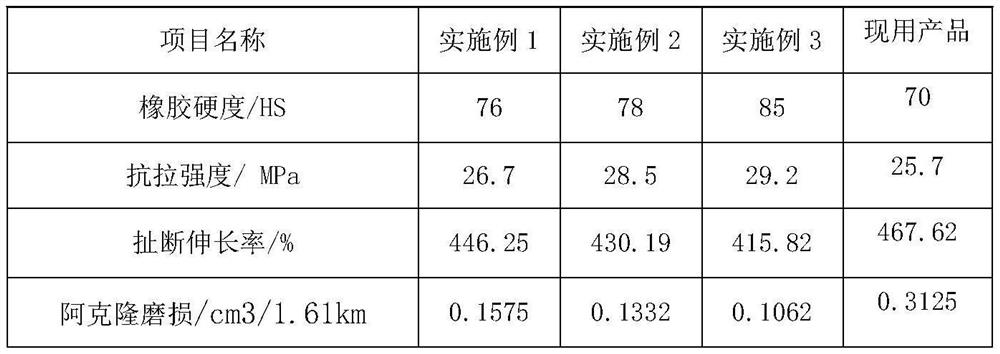

The invention relates to the technical field of shoe sole anti-slip technology, in particular to a formula of an oil-water type skid-resistant material. The antiskid material is prepared from the following raw materials in parts by weight: N230S (JSR) nitrile butadiene rubber, 7030 (LG) nitrile butadiene rubber, brominated butyl rubber, carbon black, acetyl tributyl citrate, magnesium oxide, 997#zinc oxide, stearic acid, C9 resin and a lubricant. Nitrile butadiene rubber is selected as main rubber, so that on one hand, the oil resistance of the rubber material is improved; on the other hand,brominated butyl rubber is added to interfere in the normal crosslinking of the rubber and improve the hysteresis of the rubber. The surfaces of the carbon black and the brominated butyl rubber have polar groups, so that the antiskid performance of the natural rubber sole can be further improved. The C9 resin is added into the rubber, so that the free volume of a molecular chain in the vulcanizedrubber is reduced, the friction among chain segments, between fillers and between the chain segments and the carbon black is increased, and the lag is enhanced; therefore, the wet skid resistance of the nitrile rubber can be further enhanced.

Owner:ZHEJIANG AOKANG SHOES

Antibacterial negative potential component, as well as preparation method and application thereof

InactiveCN102491482AAvoid breedingSolve unsolvable problemsWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by substance additionSilicon oxideBiological activation

The invention discloses an antibacterial negative potential component, as well as a preparation method and application thereof. The component comprises the following components in percentage by weight: 10-25% of tourmaline, 5-15% of nephrite, 5-15% of zeolite, 5-20% of limonite, 5-20% of medical stone, 5-20% of serpentine, 3-5% of magnesium oxide, 3-5% of zinc oxide and 3-5% of silicon oxide. The preparation method is as follows: weighing the components in proportion, mixing, heating, cooling, crushing, and performing ball milling to get micron-size powder; and further adding deionized water, stirring, uniformly mixing and performing heat treatment, thus obtaining the antibacterial negative potential component. The antibacterial negative potential component disclosed by the invention can play a comprehensive role of the antibacterial negative potential component disclosed by the invention with maximum effectiveness by virtue of further optimal combination of functional materials, can be used for inhibiting the breeding of bacteria while performing activation, mineralization and negative potentialization on the water, further always controlling the pH value of the water within a range which is most suitable for a health standard of human bodies and enabling the water after the treatment through the antibacterial negative potential component to become the high-quality good water which is really suitable for being drunk by people.

Owner:水经(上海)生物科技有限公司

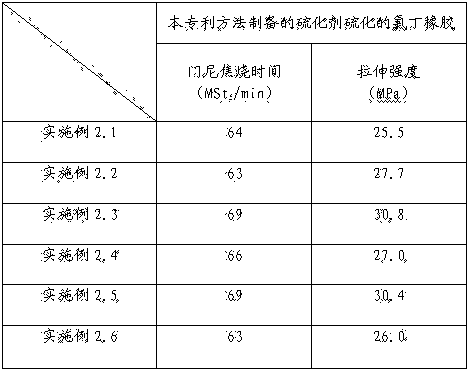

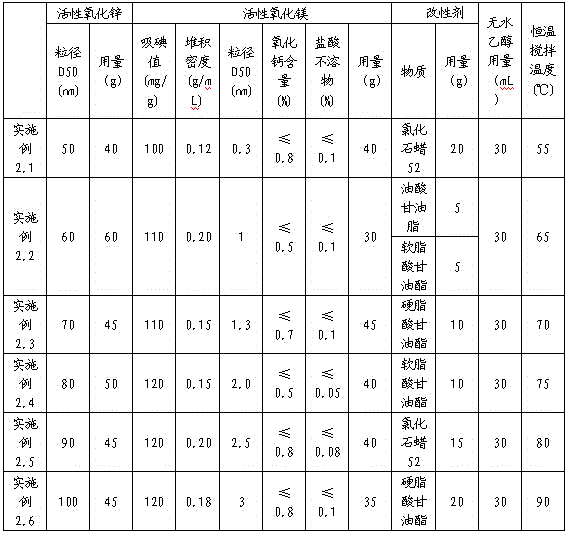

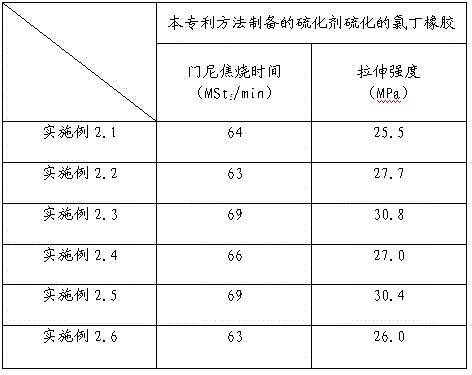

Magnesium oxide and zinc oxide blended vulcanizing agent for neoprene vulcanization and preparation method thereof

The invention relates to a magnesium oxide and zinc oxide blended vulcanizing agent for neoprene vulcanization and a preparation method thereof. The vulcanizing agent is prepared from the following components, by weight, 80.0%-90.0% of a mixture of active magnesium oxide and active zinc oxide and 10.0%-20.0% of a dispersant, wherein the weight ratio of active magnesium oxide to active zinc oxide is 1:0.2-3.0. The preparation method comprises the following steps: a, mixing active magnesium oxide and active zinc oxide to obtain a substance A, and dissolving the dispersant in anhydrous ethanol to obtain a substance B; b, carrying out surface-coating modification on the substance A with the substance B to obtain a blend; and c, heating and stirring the blend to obtain an ointment-like or sticky magnesium oxide and zinc oxide blended vulcanizing agent. The vulcanizing agent provided by the invention has the following advantages: the problem that a traditional powdery vulcanizing agent is not uniformly dispersed and activity of magnesium oxide is easy to fail when the powder is added into neoprene is solved; dispersibility of zinc oxide and activity permanence of magnesium oxide are enhanced; and scorching dangerousness of a rubber compound with high mooney viscosity is reduced.

Owner:河北镁神科技股份有限公司 +1

Low-heat-generation rubber material and rubber track

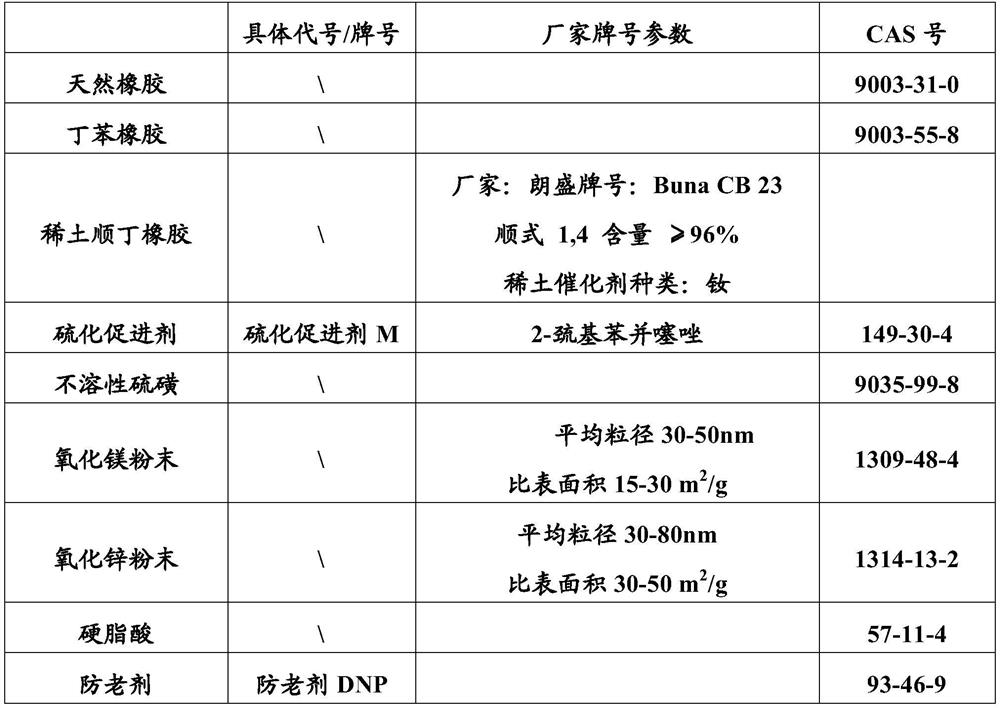

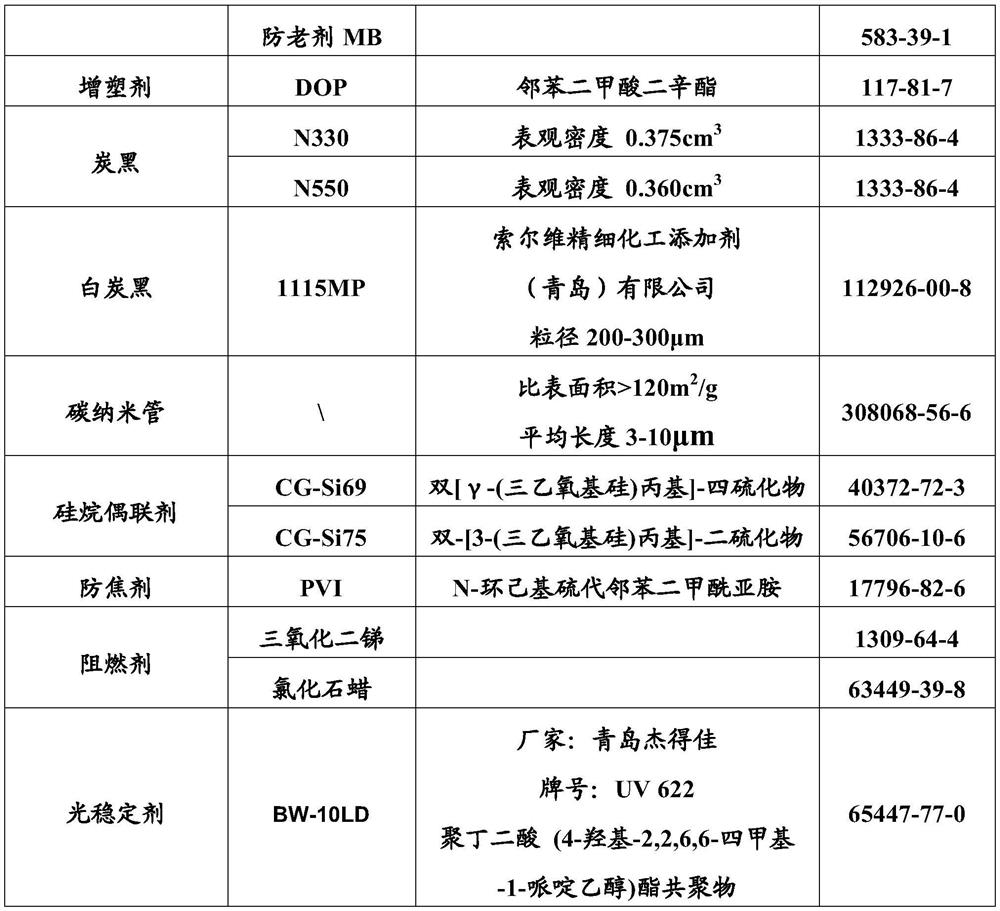

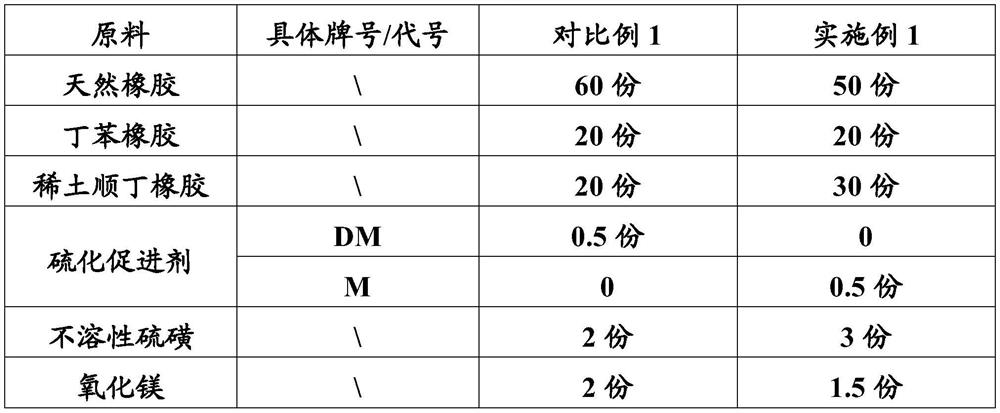

PendingCN111718522AImprove performanceHigh tensile strength valueEndless track vehiclesRubber materialPolymer science

The invention relates to a low-heat-generation rubber material. The material is obtained by refining a raw material composition containing the following components: natural rubber, butadiene styrene rubber, rare earth butadiene rubber, a vulcanization accelerator, insoluble sulfur, magnesium oxide, zinc oxide, stearic acid, an anti-aging agent, carbon black, white carbon black, carbon nanotubes, asilane coupling agent, an anti-scorching agent, a plasticizer, a flame retardant and a light stabilizer.

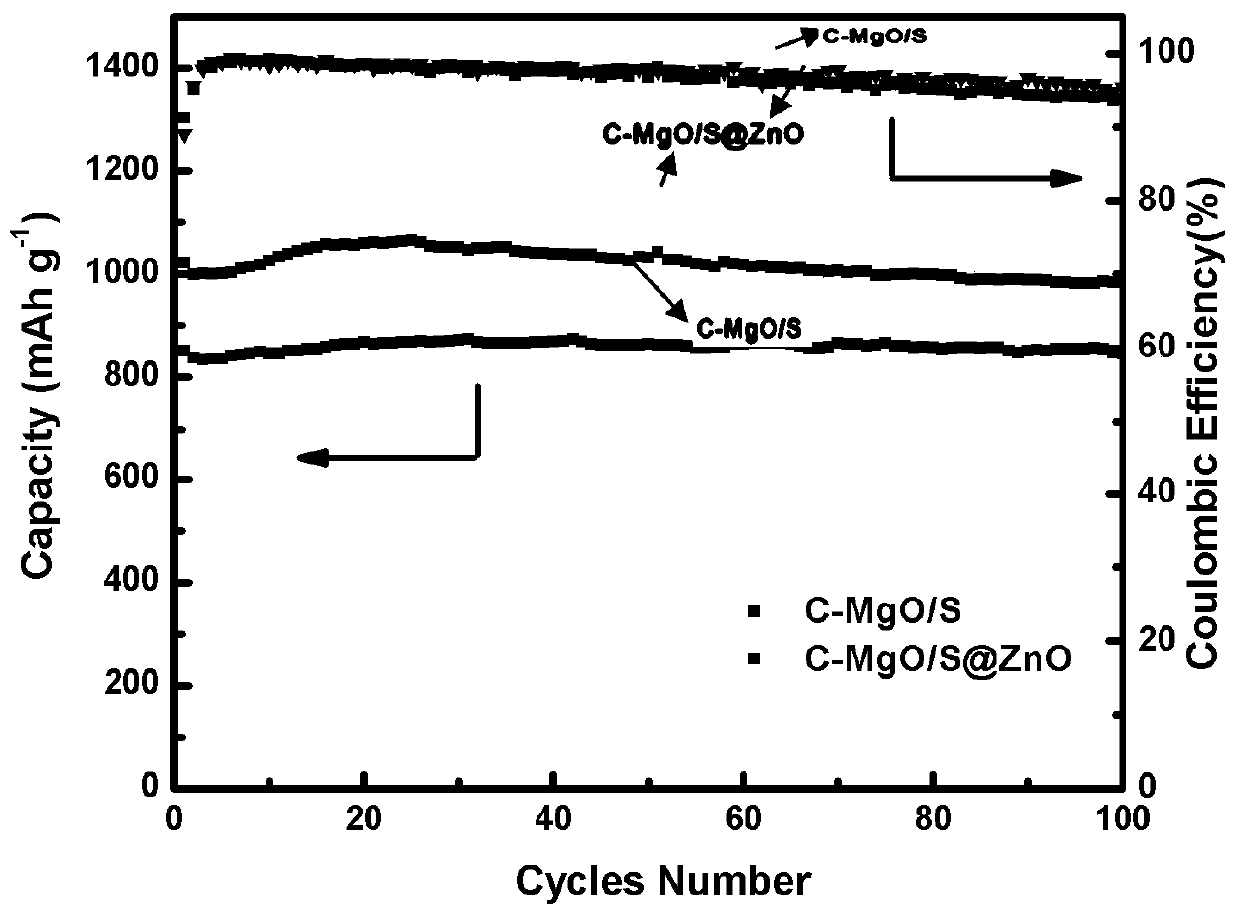

Method for preparing sulfur/carbon@metal oxide nanotube lithium-sulfur battery positive electrode material by using atomic layer deposition technology

ActiveCN110676442ALimit volume expansionImprove adsorption capacityPositive electrodesLi-accumulatorsCarbon fibersLithium sulfur

The invention provides a method for preparing a sulfur / carbon@metal oxide nanotube lithium-sulfur battery positive electrode material by using an atomic layer deposition technology. The method is characterized by comprising the steps of adding magnesium acetate into a polyacrylonitrile spinning solution, carrying out electrostatic spinning to obtain a polyacrylonitrile film containing magnesium oxide, obtaining carbon fibers doped with magnesium oxide through carbonization, depositing zinc oxide on the surfaces of the fibers through atomic layer deposition to obtain a carbon / magnesium oxide@zinc oxide composite material, and obtaining the carbon / magnesium oxide@zinc oxide sulfur-loaded material through hot melting sulfur loading, and applying the material to a lithium-sulfur battery positive electrode material. According to the invention, the atomic layer deposition method is utilized in the process of preparing the lithium-sulfur battery positive electrode material, thereby being conducive to controlling the thickness and the uniformity of a wrapping layer, and achieving one-step doping of the positive electrode material. The preparation method provided by the invention of the composite material is simple in process, and the lithium-sulfur battery positive electrode material with good cycling stability and high specific capacity is obtained.

Owner:ZHEJIANG SCI-TECH UNIV

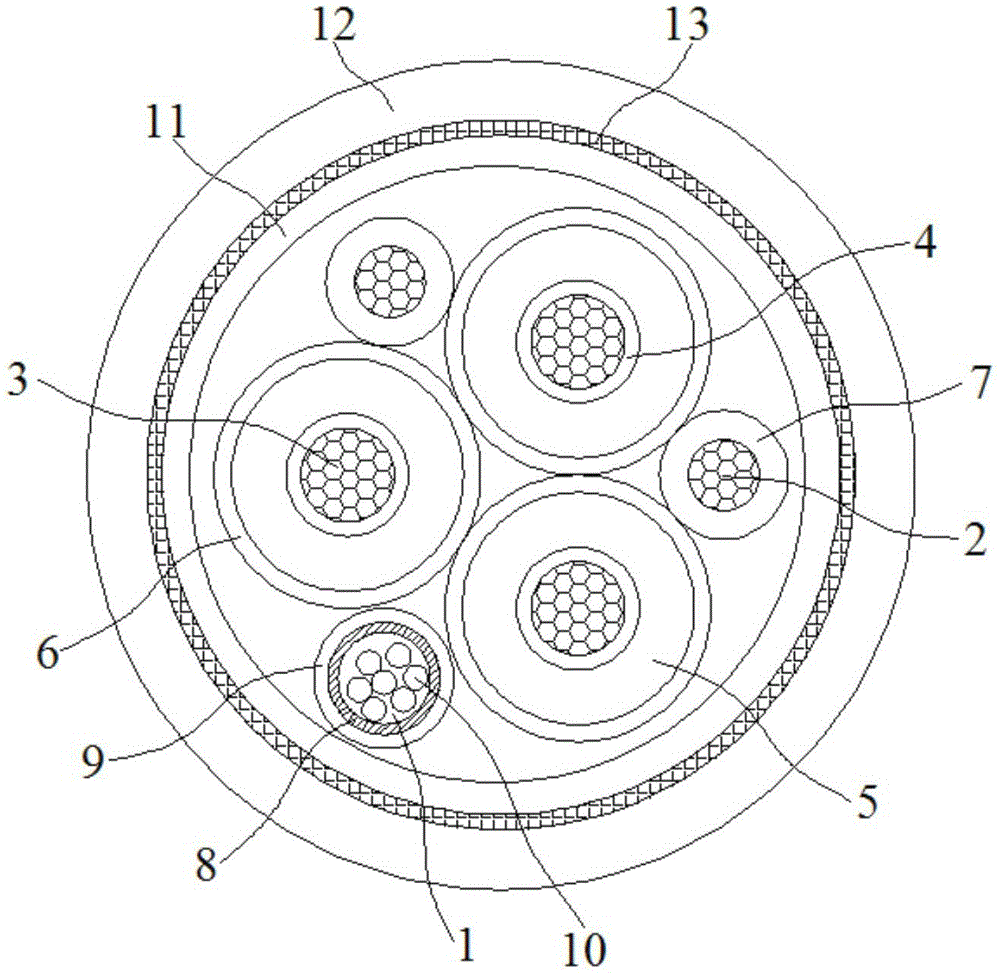

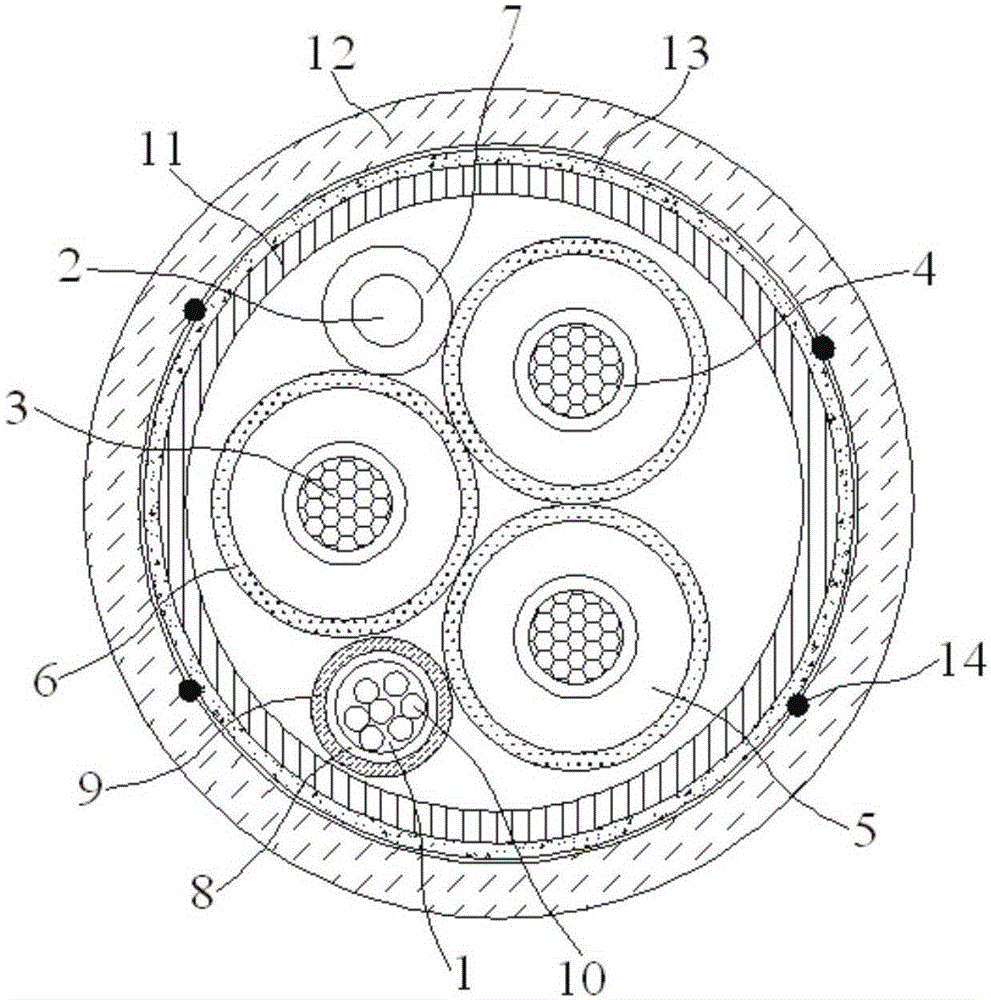

Novel opto-electronic combined medium-voltage trailing cable for port machinery and manufacturing process thereof

InactiveCN105070367AHigh tensile strengthHigh elongation at breakPower cables with screens/conductive layersInsulated cablesDimethylaniline N-oxideWear resistant

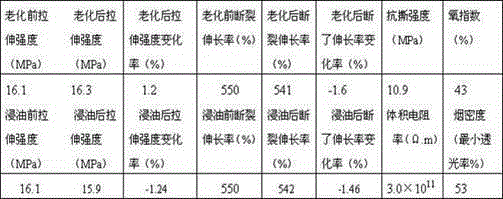

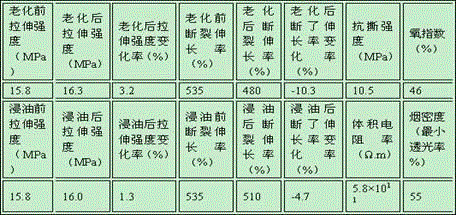

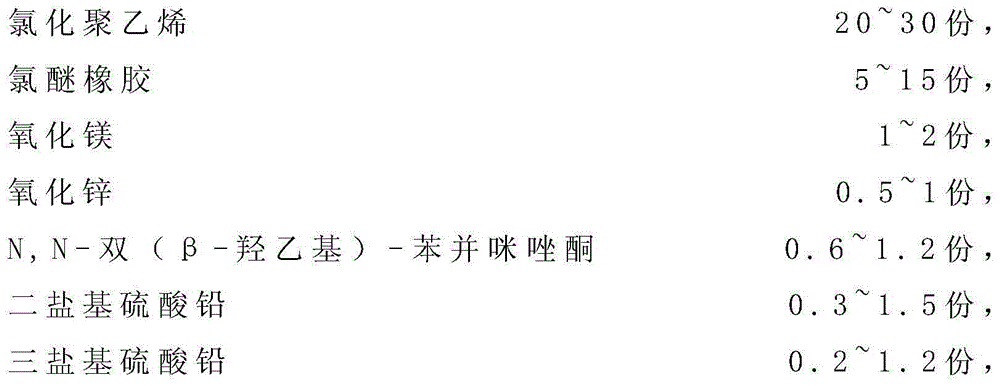

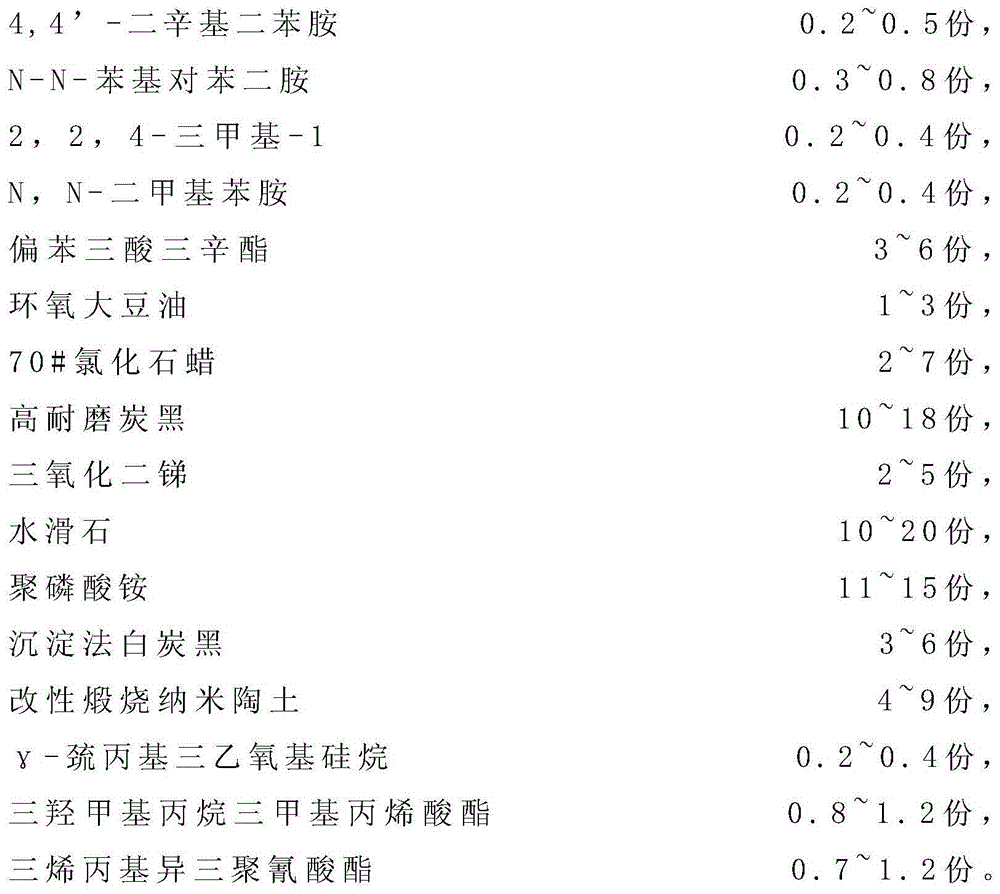

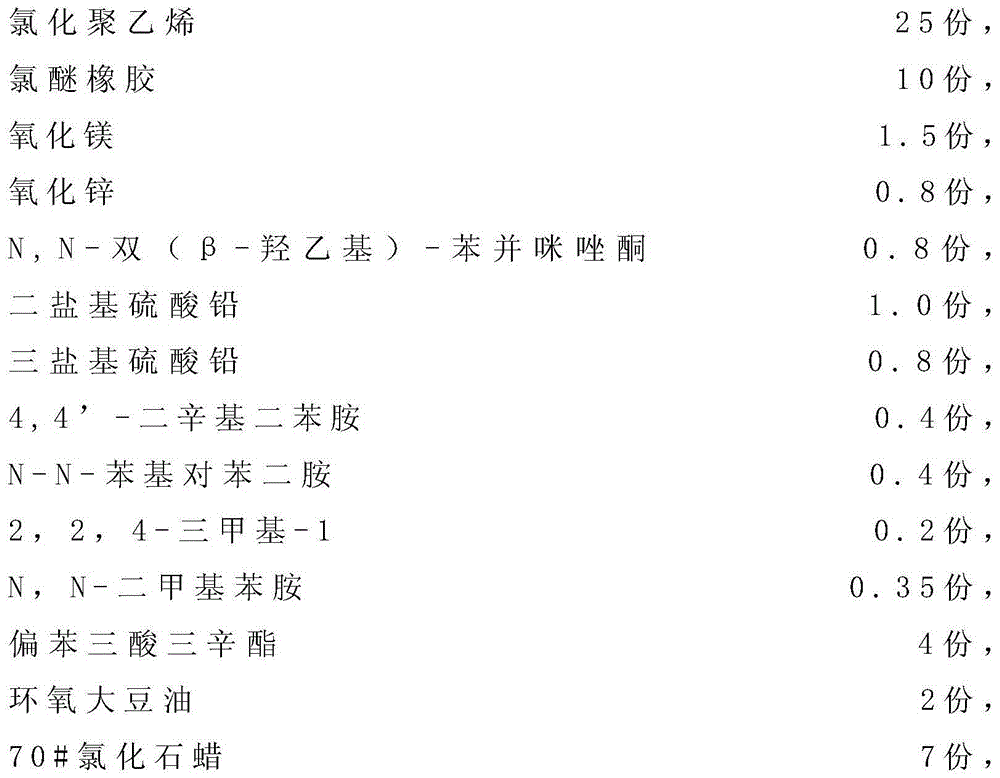

The present invention discloses a novel opto-electronic combined medium-voltage trailing cable for port machinery and a manufacturing process thereof. An opto-electronic unit of the trailing cable comprises a loose tube and a tensile insulating layer, wherein the loose tube is internally filled with a plurality of optical fibers, and the tensile insulating layer comprises the following components of CPE Chlorinated polyethylene, an epichloro-hydrin rubber, magnesium oxide, N,N-bi(beta- ethoxyl)-benzimidazolone, dibasic lead sulfate, lead sulfate tribasic, bis(4-octylphenyl)amine, N-N- phenyl p-phenylenediamine, 2,2,4-trimethyl-1, N,N-dimethylaniline, trioctyl trimellitate, an epoxidized soybean oil, a 70# chlorinated paraffin, high wear-resistant carbon black, antimonous oxide, hydrotalcite, ammonium polyphosphate, a precipitated white carbon and an modified roasted nano clay. A tensile strength of the trailing cable provided by the present invention is larger than 12 Mpa, elongation at break of the cable is larger than 350%, aging characteristics and wear-resisting properties of a protecting bush are improved, and an aging temperature can reach 135 DEG C.

Owner:JIANGSU HENGTONG POWER CABLE

Components of anti-tensile insulated cable sheath and preparation process thereof

InactiveCN104910534AHigh tensile strengthHigh elongation at breakPlastic/resin/waxes insulatorsInsulated cablesPolymer scienceDimethylaniline N-oxide

The invention discloses components of an anti-tensile insulated cable sheath. The components comprise chlorinated polyethylene, epichloro-hydrin rubber, magnesium oxide, zinc oxide, N,N-bis(beta-hydroxyethyl)-benzimidazolone, dibasic lead sulphate, tribasic lead sulphate, 4,4'-dioctyldiphenylamine, N-N-phenyl p-phenylenediamine, 2,2,4-trimethyl-1, N-N-dimethylaniline, trioctyl trimellitate, epoxidized soybean oil, 70# chlorinated paraffin, high abrasion furnace carbon black, antimonous oxide, gamma-mercaptopropyltriethoxysilane, trimethylol propane trimethacrylate, triallyl tricarbimide ester, triallyl cyanurate and the like. The invention further discloses a preparation process for preparing a cable sheath by virtue of the formula. The cable sheath prepared by the components and the preparation process provided by the invention has a tensile strength of greater than 12Mpa and an elongation at break of greater than 350%, the ageing performance and the wear resistance of the sheath are improved, a good weather resistance is achieved, and the volume resistivity of the material is also improved.

Owner:WUXI INST OF ARTS & TECH

Chloroprene rubber spray glue with long high temperature-resistant operation time, and preparation method thereof

ActiveCN109971393AHigh acceptabilityImprove receptivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolymer science

The invention discloses a chloroprene rubber spray glue with a long high temperature-resistant operation time, and a preparation method thereof. The chloroprene rubber spray glue comprises chloroprenerubber, solvents and assistants; the chloroprene rubber is formed by mixing carboxyl-modified chloroprene rubber with a high-crystallinity rubber sheet or a medium-crystallinity rubber sheet; the solvents comprise cyclohexane, 120# solvent oil, ethyl acetate and n-hexane; and the assistants comprise magnesium oxide, zinc oxide, fumed silica, chlorination polypropylene, an antioxidant 1010, terpene phenolic resin, alkyl phenolic resin, epoxy phenolic resin, a coupling agent A1100 and methyltrimethoxysilane. The chloroprene rubber adopts the carboxyl-modified chloroprene rubber mixed high-crystallinity rubber sheet or medium-crystallinity rubber sheet to effectively improve the heat resistance, and the epoxy resin is introduced to prolong the tack time and improve the operability. The improvement of the solvents minimizes the smell, and cooperates with many operations to greatly improve the user's satisfaction and achieve high adaptability.

Owner:福建南宾树脂有限公司

BMT-BZT composite novel microwave dielectric ceramic material and preparation method thereof

ActiveCN111675531AExcellent microwave dielectric propertiesExcellent dielectric propertiesPolyvinyl alcoholSlurry

The invention relates to a BMT-BZT composite novel microwave dielectric ceramic material and a preparation method thereof, and belongs to the technical field of microwave dielectric ceramics. Tantalumpentoxide, barium carbonate, magnesium oxide, zinc oxide, manganese carbonate, lanthanum oxide, boric acid and polyvinyl alcohol are used as raw materials. The preparation method comprises the following steps: preparing the raw materials to obtain powder A, ball-milled slurry B, pre-sintered powder C, ball-milled slurry D, sintering aid powder E, mixed powder F and a green body G; and putting theobtained green body G into a sintering furnace, sintering, carrying out heat preservation, and then cooling along with the furnace to obtain the BMT-BZT composite novel microwave dielectric ceramic material. The BMT material and the BZT material are compounded in two phases, and manganese carbonate is introduced to modify the composite material, so that the microwave dielectric property of the composite material is improved; and a glass sintering aid is introduced to solve the problem of difficult sintering, and the sintering temperature of the composite material is reduced, so that the BMT-BZT composite novel microwave dielectric ceramic material has extremely high value in the aspect of 5G filters.

Owner:山西省玻璃陶瓷科学研究所(有限公司)

Preparation method of propylene carbonate

InactiveCN104961720ASimple processEase of industrial productionOrganic chemistryHeterogenous catalyst chemical elementsReaction temperatureRare earth

The invention discloses a preparation method of propylene carbonate. The preparation method is characterized by comprising the following steps: adding urea and 1,2-propylene glycol at a molar ratio of 1:(1-6) into a high-pressure kettle, and conducting a reaction on a magnesium oxide-zinc oxide composite rare earth oxide catalyst, wherein the catalyst dosage is 1-3wt% of the urea; stirring for heating, wherein the reaction temperature is 120-180 DEG C, and the reaction time is 0.5-4h; after the reaction, stopping stirring, and cooling to room temperature; and distilling the kettle liquid and separating to obtain the product propylene carbonate. The preparation method disclosed by the invention has the following advantages: the technology of directly generating propylene carbonate from urea and propylene glycol is simple, and industrial production is easy to realize; the preparation process has high reaction speed and high conversion rate and product yield; the adopted raw materials are cheap, the operation is simple and safe, and thus the preparation method has a remarkable value in industrial application; and the prepared propylene carbonate is nontoxic and biodegradable and has good usability and wide application range.

Owner:何肖凤

Transparent electromagnetic shielding film

PendingCN113068391AGood resistance to salt sprayGood ring test resistanceMagnetic/electric field screeningIridiumNichrome

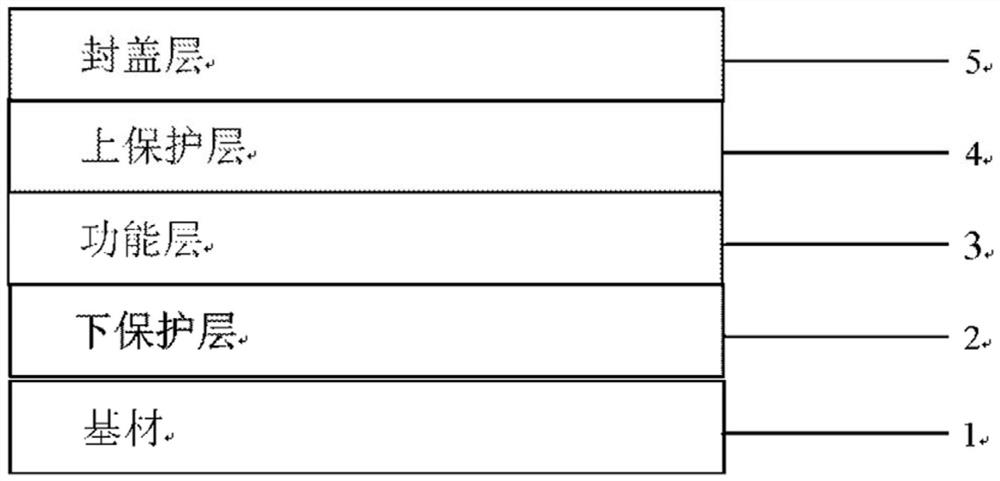

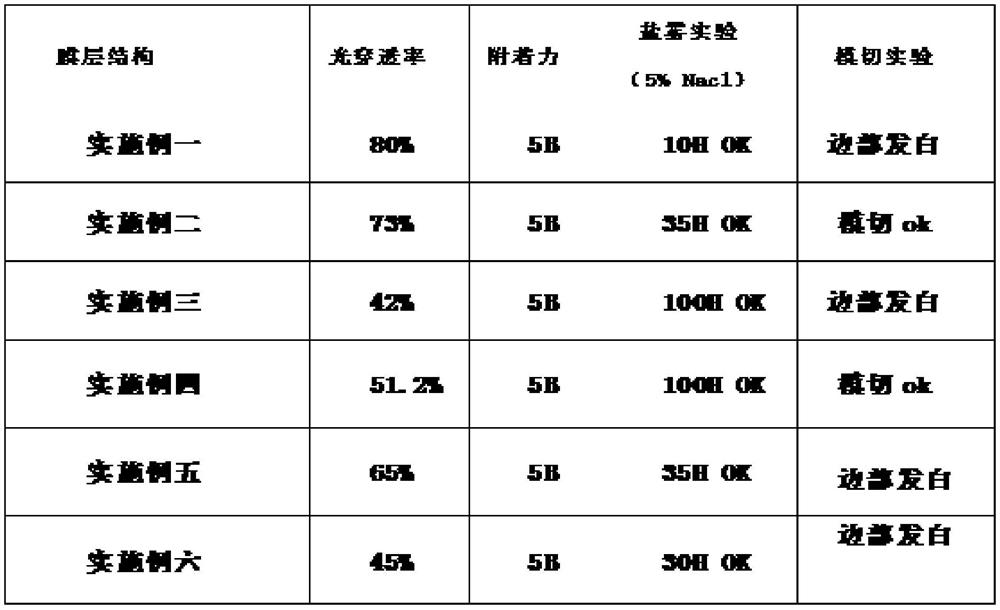

A transparent electromagnetic shielding film comprises a base material layer, a lower protective layer, a metal functional layer, an upper protective layer for preventing oxidation and a sealing cover layer for retaining water and isolating air, wherein the lower protective layer is titanium oxide, zinc oxide, nickel-chromium alloy, silicon dioxide, niobium pentoxide, aluminum oxide, magnesium oxide-doped zinc oxide or an aluminum oxide-doped zinc oxide layer, the metal functional layer is a copper, silver, titanium, gold, aluminum, rhenium, palladium, ruthenium, rhodium, platinum, iridium or osmium layer or an alloy layer of the above metals, and the upper protective layer is a silicon dioxide, zinc oxide, nickel, chromium, nickel-chromium alloy, aluminum oxide-doped zinc oxide or silicon oxide-doped aluminum layer. Through film layer structure matching, the shielding film has good salt mist resistance and environmental measurement resistance, also has excellent optical performance, high light transmittance and a better laser die cutting effect, is convenient for laser large-scale cutting and processing, and can be used for manufacturing fine parts; the shielding film has a nano-level size and is thinner and lighter; the film layer is compact and has no pinhole points; the sheet resistance uniformity is good; the adhesive force of the film layer is good; and good gluing is realized.

Owner:JIANGSU RIJIU OPTOELECTRONICS LTD

High-strength towing-used photoelectric composite cable and manufacture method thereof

InactiveCN105161186AEasy to operateImprove thermal stabilityPower cables with screens/conductive layersInsulated cablesDimethylaniline N-oxideWear resistant

The present invention discloses a high-strength towing-used photoelectric composite cable and a manufacture method thereof. The high-strength towing-used photoelectric composite cable comprises a photoelectric unit, ground wire core conductors and power wire core conductors; wherein the photoelectric unit comprises a loose tube and a tensile insulating layer; and the tensile insulating layer comprises the following parts by weight of components: chlorinated polyethylene, epichlorohydrin rubber, magnesium oxide, zinc oxide, N, N-bis(beta-hydroxyethyl)-benzimidazolone, dibasic lead sulphate, tribasic lead sulphate, 4, 4'-dioctyldiphenylamine, N-N-phenyl-p-phenylenediamine, 2, 2, 4-trimethyl-1, N, N-dimethylaniline, tricapryl trimellitate, epoxidized soybean oil, 70# chlorinated paraffin, high wear-resistant carbon black, antimony oxide, hydrotalcite, ammonium polyphosphate, precipitated white carbon, modified calcined nano clay, gamma-mercaptopropyl triethoxysilane, trimethylol-propane trimethacrylate, triallyl isocyanurate and triallyl cyanurate calcium. The high-strength towing-used photoelectric composite cable of the present invention has tensile strength greater than 12Mpa and elongation at break greater than 350%, aging performance and wear-resistant performance of a sheath can be improved, the aging temperature can achieve 135 DEG C, thus good weather resistance is achieved.

Owner:JIANGSU HENGTONG POWER CABLE

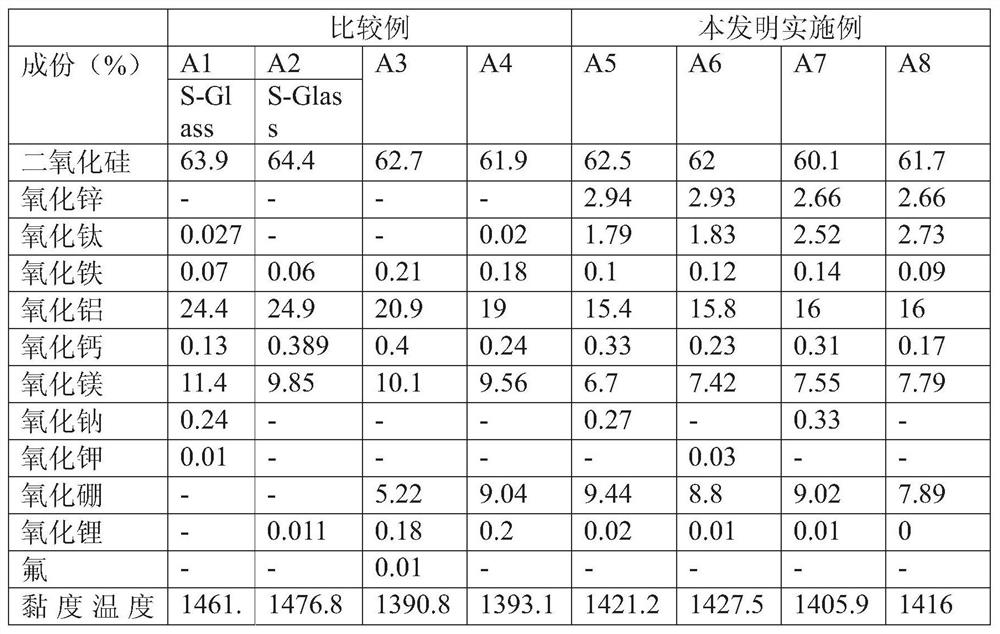

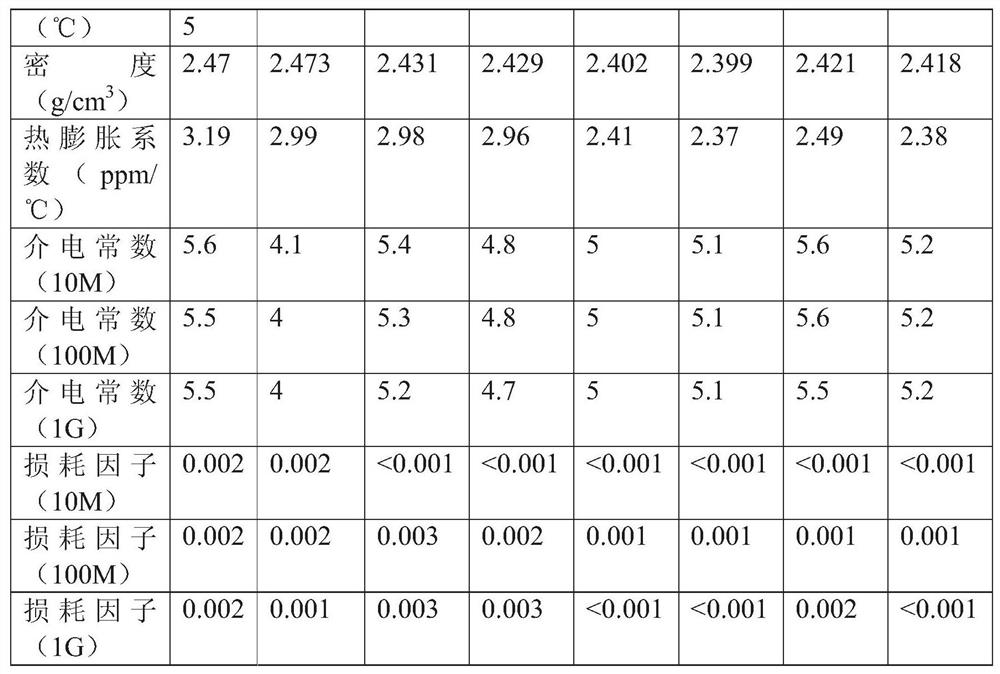

Glass composition with low thermal expansion coefficient, and glass fiber manufactured therefrom

PendingCN113105118AImproved coefficient of thermal expansionOptimum viscosity temperatureThermal dilatationGlass fiber

The invention discloses a glass composition with a low thermal expansion coefficient. The glass composition is characterized in that the glass composition comprises a main body material, a reinforcing material and a fluxing material; the main body material comprises silicon oxide, and the weight percentage of the silicon oxide is 55-66% of that of the glass composition; the reinforcing material comprises aluminum oxide, and the weight percentage of the aluminum oxide is 10-20% of that of the glass composition; the fluxing material comprises magnesium oxide, zinc oxide and titanium dioxide; and the weight of the magnesium oxide is 3-12% of that of the glass composition, the weight percentage of the zinc oxide is 0.01-7% of that of the glass composition, and the weight percentage of the titanium dioxide is 0.01-6% of that of the glass composition. The glass composition disclosed by the invention can have a lower thermal expansion coefficient and better mass production performance, and meets the strict requirements of future high-end electronic products.

Owner:台嘉蚌埠玻璃纤维有限公司

Boron phosphate ceramic material and preparation method thereof

The invention relates to a boron phosphate ceramic material and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps: mixing ammonium dihydrogen phosphate and boric oxide to obtain a mixture I; and carrying out ball milling, drying and mechanical pressing on the mixture I, keeping the temperature at 350-750 DEG C, and conducting crushing to obtain a boron phosphate powder; mixing magnesium oxide, zinc oxide, bismuth oxide and gadolinium oxide to obtain a mixture II; mixing ammonium dihydrogen phosphate and boron oxide according to different mass ratios to obtain a mixture III; mixing the mixture II and the mixture III, conducting mixing with boron phosphate powder, and carrying out ball milling and drying to obtain a zirconium phosphate ceramic powder; and carrying out mechanical pressing on the zirconium phosphate ceramic powder, carrying out cold isostatic pressing treatment, and carrying out heat preservation for 2-5 hours under the conditions of air atmosphere, normal pressure and 900-1200 DEG C to prepare the boron phosphate ceramic material. The preparation method is simple in process, short in production cycle and environment-friendly, and the prepared boron phosphate ceramic material is high in pressure / bending strength, good in thermal expansion performance and excellent in neutron shielding performance.

Owner:WUHAN UNIV OF SCI & TECH

Acid/alkali-resistant insulating rubber material and preparation method for same

ActiveCN105086041AGood acid and alkali resistanceImprove insulation performanceCalcium silicateRubber material

The invention discloses an acid / alkali-resistant insulating rubber material, which comprises 65 to 80 parts by weight of reclaimed rubber, 20 to 50 parts by weight of fluororubber, 4 to 9 parts by weight of magnesium oxide, 2 to 6 parts by weight of zinc oxide, 25 to 40 parts by weight of nanometer calcium silicate, 0.2 to 0.8 part by weight of an accelerator, 8 to 15 parts by weight of 2-dibenzofuranol, 4 to 12 parts by weight of 4-bromo-2-furanpentanal, 18 to 30 parts by weight of furfuryl alcohol resin and 8 to 15 parts by weight of polyimide fibers. A preparation process comprises the following steps of adding the reclaimed rubber and the fluororubber into an internal mixer for internal mixing; loading the magnesium oxide, the zinc oxide, the nanometer calcium silicate, the accelerator, the 2-dibenzofuranol, the 4-bromo-2-furanpentanal, the furfuryl alcohol resin and the polyimide fibers into a reaction kettle at temperature of 120 to 170 DEG C for mechanical stirring; mixing mixture A and mixture B to obtain mixture C; performing extrusion treatment and natural cooling on mixture C to obtain the rubber material with high acid / alkali resistance and insulating property.

Owner:三丰盈新材料(江苏)有限公司

Hnbr elastomeric compositions

An elastomeric composition comprising hydrogentated nitrile butadiene rubber (HNBR), maleinized polybutadiene, and metal oxide. In addition, they optionally comprise a cure system, fillers, and other additives. In some embodiments, the metal oxide comprises one or more compounds selected from magnesium oxide, zinc oxide, and hydrotalcite. The elastomeric composition has improved swell resistance when exposed to water.

Owner:ZEON CHEMICALS LP

Super wear-resistant rubber, preparation method and crawler belt

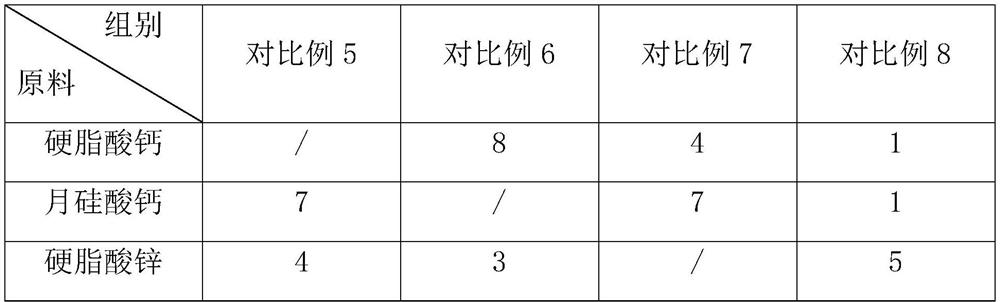

PendingCN112980059AImprove wear resistanceExtended service lifeMagnesium Oxide / Zinc OxideStearic acid

The invention discloses super wear-resistant rubber, a preparation method and a crawler belt. The super wear-resistant rubber is prepared from the following basic materials in parts by weight: 100 parts of raw rubber, 2-5 parts of a vulcanization accelerator, 2-4 parts of magnesium oxide, 2-4 parts of zinc oxide, 1-2 parts of stearic acid, 3-6 parts of an anti-aging agent, 30-60 parts of carbon black, 10-30 parts of surface modified nano-diamond, 0.5-4 parts of graphene, 0.5-2 parts of a scorch retarder CTP, 0.5-2 parts of a light stabilizer, and 1-3 parts of a flame retardant. Through different raw rubber components and addition of the anti-aging agent, the scorch retarder, the flame retardant, the carbon black, the surface modified diamond, the graphene, the light stabilizer and the like, the wear resistance of the rubber is improved, and the service life of the rubber is prolonged; during actual use, the components and the proportion of the raw rubber and the proportion of the compounding agent can be adjusted according to actual requirements, so that the use requirements of different public products are met; the vulcanization accelerator, the magnesium oxide, the zinc oxide, the stearic acid and the like promote the vulcanization process of the rubber, so that the vulcanization of the rubber is more sufficient, different production methods are adopted for raw rubber with different components, and the requirement for wear resistance of the rubber is met.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Method for preparing acid by catalytic dehydrogenation of alcohol under solvent-free conditions

ActiveCN109627155BAvoid the problem of aggregation inactivationLow costOrganic compound preparationCarboxylic compound preparationPtru catalystDehydrogenation

The invention discloses a method for preparing an acid by catalytic dehydrogenation of alcohol under the condition of no solvent, which comprises the following steps: under a protective atmosphere, adding a supported metal catalyst and a basic additive to the alcohol, performing catalytic dehydrogenation reaction, and obtaining the acid; The supported metal catalyst is based on at least one of magnesium oxide, zinc oxide, zirconium dioxide, ceria, lanthanum trioxide, hydroxyapatite, activated carbon, carbon nanofibers, and carbon nanotubes as a carrier, with Cu, At least one of Ni is an active component. The invention carries out the reaction of alcohol catalytic dehydrogenation to prepare acid under solvent-free conditions, avoids the problem of catalyst aggregation and deactivation, and has the advantages of low reaction temperature, short reaction time, low catalyst cost, high catalyst activity and good stability.

Owner:珠海市格特生物科技有限公司

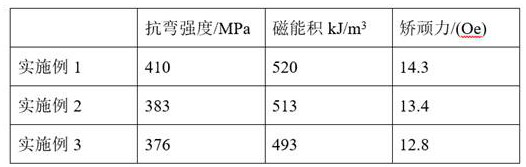

A kind of preparation method of thin sheet type rare earth permanent magnet material

ActiveCN110473704BInductances/transformers/magnets manufactureMagnetic materialsTemperingMagnesium Oxide / Zinc Oxide

The invention improves a preparation method of a thin sheet type rare earth permanent magnet material, and relates to the technical field of magnetic materials. A method for preparing a thin sheet-type rare earth permanent magnet material, comprising the following steps: (1) Preparation of a main phase alloy, mixing materials containing neodymium, dysprosium, iron, and boron respectively to prepare a main phase alloy, and then pulverizing , grinding, and sieving to obtain the main phase alloy powder; (2) preparation of the grain boundary phase alloy, mixing materials containing neodymium, Co, Mo, boron, and iron respectively, and then performing rapid solidification, and the quenching rate is 27-35m / s, prepare a grain boundary alloy, and then pulverize it to obtain a grain boundary phase alloy powder; (3) Mix the main phase alloy powder, grain boundary phase alloy powder, magnesium oxide, and zinc oxide evenly, then perform molding, press into a sheet-shaped green embryo, and then Sintering, cooling after tempering to obtain thin sheet type rare earth permanent magnet material. According to the preparation method of the thin sheet type rare earth permanent magnet material of the present invention, the prepared rare earth permanent magnet material has excellent magnetic properties, high bending strength and strong corrosion resistance.

Owner:安吉县宏铭磁性器材有限公司

A kind of acid and alkali resistant insulating rubber material and preparation method thereof

ActiveCN105086041BGood acid and alkali resistanceImprove insulation performanceCalcium silicateRubber material

The invention discloses an acid and alkali resistant insulating rubber material, which comprises 65-80 parts of reclaimed rubber, 20-50 parts of fluorine rubber, 4-9 parts of magnesium oxide, 2-6 parts of zinc oxide, and 25-40 parts of nano-calcium silicate , 0.2-0.8 parts of accelerator, 8-15 parts of 2-dibenzofuran alcohol, 4-12 parts of 4-bromo-2-furan valeraldehyde, 18-30 parts of furfuryl alcohol resin, 8-15 parts of polyimide fiber . The preparation process is: adding reclaimed rubber and fluorine rubber into the internal mixer for mastication; adding magnesium oxide, zinc oxide, nano-calcium silicate, accelerator, 2-dibenzofuran alcohol, 4-bromo-2-furalvaleraldehyde , furfuryl alcohol resin and polyimide fibers are placed in a reaction kettle with a temperature of 120-170°C and mechanically stirred; mixture A and mixture B are mixed to obtain mixture C; mixture C can be obtained after extrusion treatment and natural cooling The above-mentioned rubber material has strong acid and alkali resistance and good insulation performance.

Owner:三丰盈新材料(江苏)有限公司

Environment-friendly adhesive for artificial board and preparation method of environment-friendly adhesive

InactiveCN104387992AEnvironmentally friendlySafeNon-macromolecular adhesive additivesMacromolecular adhesive additivesSodium phosphatesOperability

The invention discloses an environment-friendly adhesive for an artificial board and a preparation method of the environment-friendly adhesive. The adhesive comprises the following components: water-soluble sodium silicate, sodium phosphate, nano silicon dioxide, spinel particles, glass fibers, tourmaline powder, magnesium oxide, zinc oxide, octyl phenol polyethylene ether, guanylurea phosphate, diammonium hydrogen phosphate, boric acid, an inorganic antibacterial agent and deionized water. The environment-friendly adhesive disclosed by the invention has the advantages that (1) aldehyde materials are not contained in raw materials, and free formaldehyde and any other harmful gases cannot be generated, so that the adhesive has the performance characteristics of environmental protection and safety; (2) the adhesive has high adhesive performance and internal bonding strength, is high in self-strength after molding, and can be used for improving the whole strength of the artificial board; (3) the adhesive has excellent properties such as flame resistance, bacterium inhibition, air purification and the like, the comprehensive performance and use safety of the artificial board, particularly the adhered artificial board, can be effectively improved, and the service life can be prolonged; and (4) the adhesive is simple in preparation process, strong in operability, good in quality stability and easy in sizing.

Owner:SUZHOU YIAIFU CHEM MATERIAL TECH

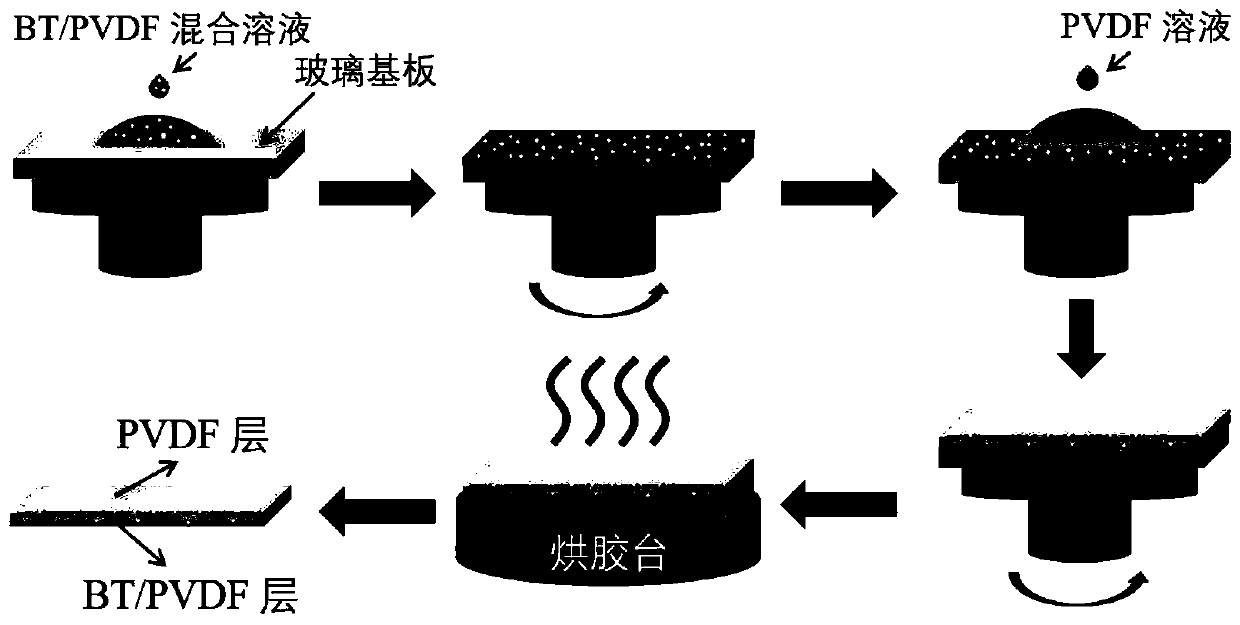

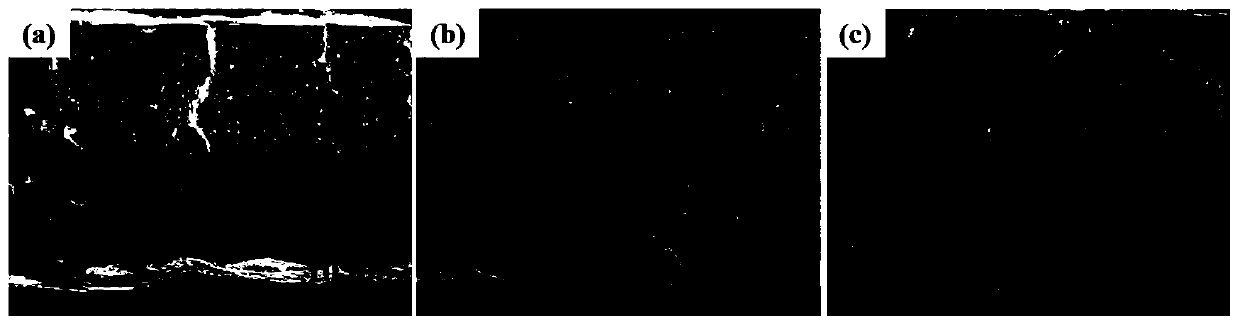

Double-layer structure flexible piezoelectric film with high output and method for its preparation and application

ActiveCN108530806BHigh dielectric constantHigh strengthPiezoelectric/electrostrictive device material selectionLead zirconate titanateStrontium titanate

A double-layer structure flexible piezoelectric film with high output and its preparation and application method belong to the field of electronic composite materials and nano functional materials. The solution layer-by-layer spin coating-heat treatment process is adopted, and inorganic piezoelectric materials are used as fillers to improve the piezoelectric output of the composite film, and the double-layer structure is used to obtain higher output and better mechanical properties at the same time. The inorganic fillers are nanoparticles or nanofibers of piezoelectric ceramics such as barium titanate, barium strontium titanate, and lead zirconate titanate, or metal oxide nanoparticles or nanofibers such as magnesium oxide and zinc oxide, or multi-walled carbon nanometers. Tube. The polymer matrix can be materials such as polyvinylidene fluoride, polyvinylidene fluoride-trifluoroethylene, polyvinylidene fluoride-trifluoroethylene-hexafluoropropylene and the like. The efficiency of the filler can be improved by adjusting the filler content and its distribution in the bilayer. The composite material has the characteristics of good flexibility, high piezoelectric output, high sensitivity, and light weight. It can be used as a power source for wearable devices, and as a flexible sensor to detect human activities.

Owner:UNIV OF SCI & TECH BEIJING

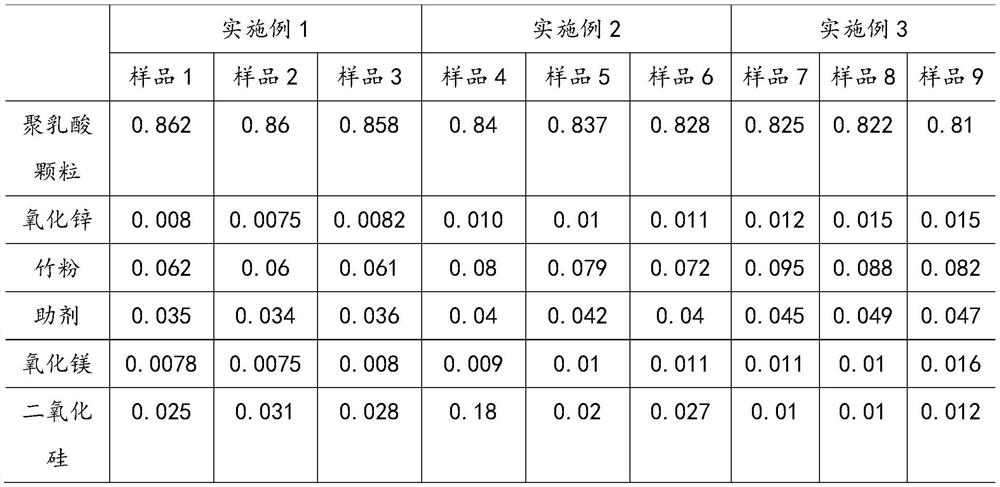

Environment-friendly toy material and preparation method thereof

PendingCN112961478AMeet environmental protection requirementsImprove performanceMagnesium Oxide / Zinc OxideSilicon dioxide

The invention discloses an environment-friendly toy material which comprises the following components in parts by mass: 70-85 parts of micro-foaming polylactic acid particles, 4-6 parts of bamboo powder, 2-4 parts of a combination of bamboo powder, magnesium oxide and silicon dioxide, 2-4 parts of a combination of bamboo powder, zinc oxide and silicon dioxide and 3-5 parts of auxiliaries. The toy material takes polylactic acid as a main material, the bamboo powder, magnesium oxide, zinc oxide and the like are introduced to enhance the performance, the environment-friendly requirement is met, meanwhile, a single-material mixing mode is abandoned, the bamboo powder and various materials are mixed in a mode of forming a combination, and the environment-friendly toy material has the advantages that the material mixing uniformity is greatly improved, and the performance of a material product is obviously improved. A preparation method of the environment-friendly toy material is disclosed.

Owner:晋江力奇模具有限公司

Oxide material with plasmon resonance performance and antibacterial packaging application

PendingCN114277614ALow costHazard reductionFlexible coversCoatings with pigmentsAluminum doped zinc oxideAntimony doping

The invention discloses an oxide material with plasmon resonance performance and antibacterial packaging application, belongs to the technical field of fruit and vegetable storage and packaging, solves the problems that most of existing preservatives are chemical preservatives, harm human health and cause environmental pollution, and has the technical key points that the oxide material comprises indium-doped cadmium oxide (ICO), indium-doped cadmium oxide (ICO), antimony-doped tin oxide (ATO), indium-doped tin oxide (ITO), aluminum-doped zinc oxide (AZO), indium-doped molybdenum oxide (IMO), small-particle-size magnesium oxide (MgO), zinc oxide (ZnO), tin oxide (SnO2), molybdenum oxide (MoO3) and tungsten oxide (WO3) nanoparticles are prepared into long-acting, non-toxic and reusable packaging paper or film through molecular modification or non-modification and synthesis. The material with the packaging paper or film has the advantages of antibacterial and anticorrosive functions, long acting, no toxicity and reusability.

Owner:JILIN UNIV

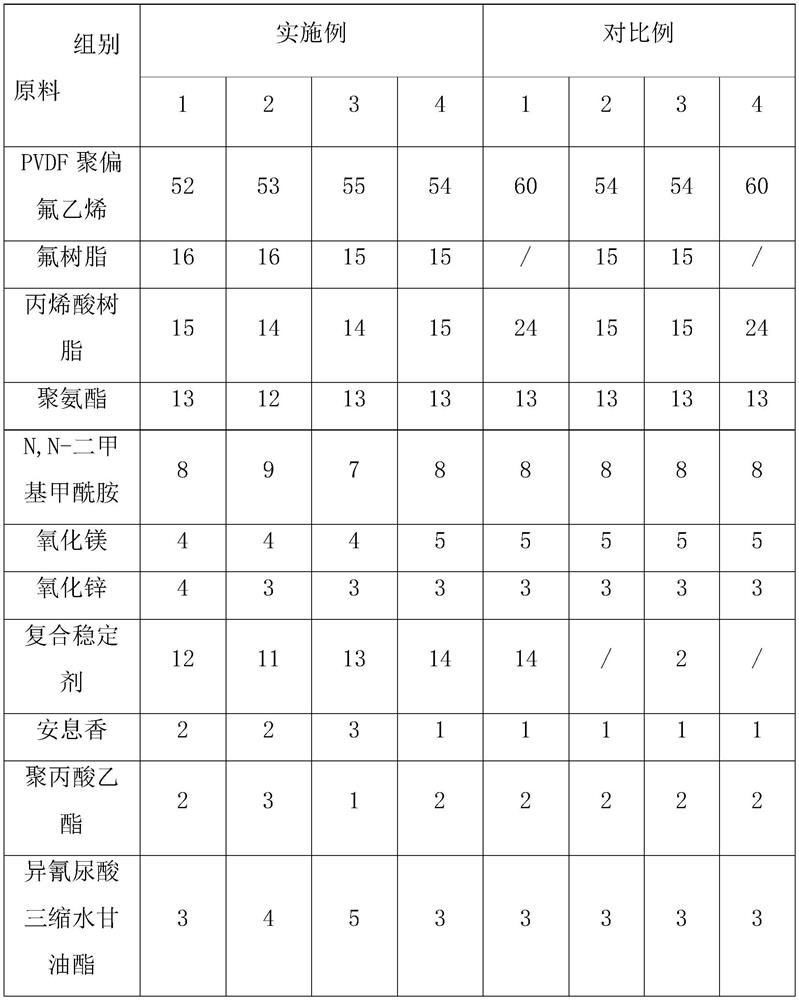

PVDF (Polyvinylidene Fluoride) solid fluorocarbon coating and preparation method thereof

PendingCN114479569AImprove mechanical propertiesImprove stain resistanceCoatingsPolymer scienceAcrylic resin

Owner:广东依斯特新材料有限公司

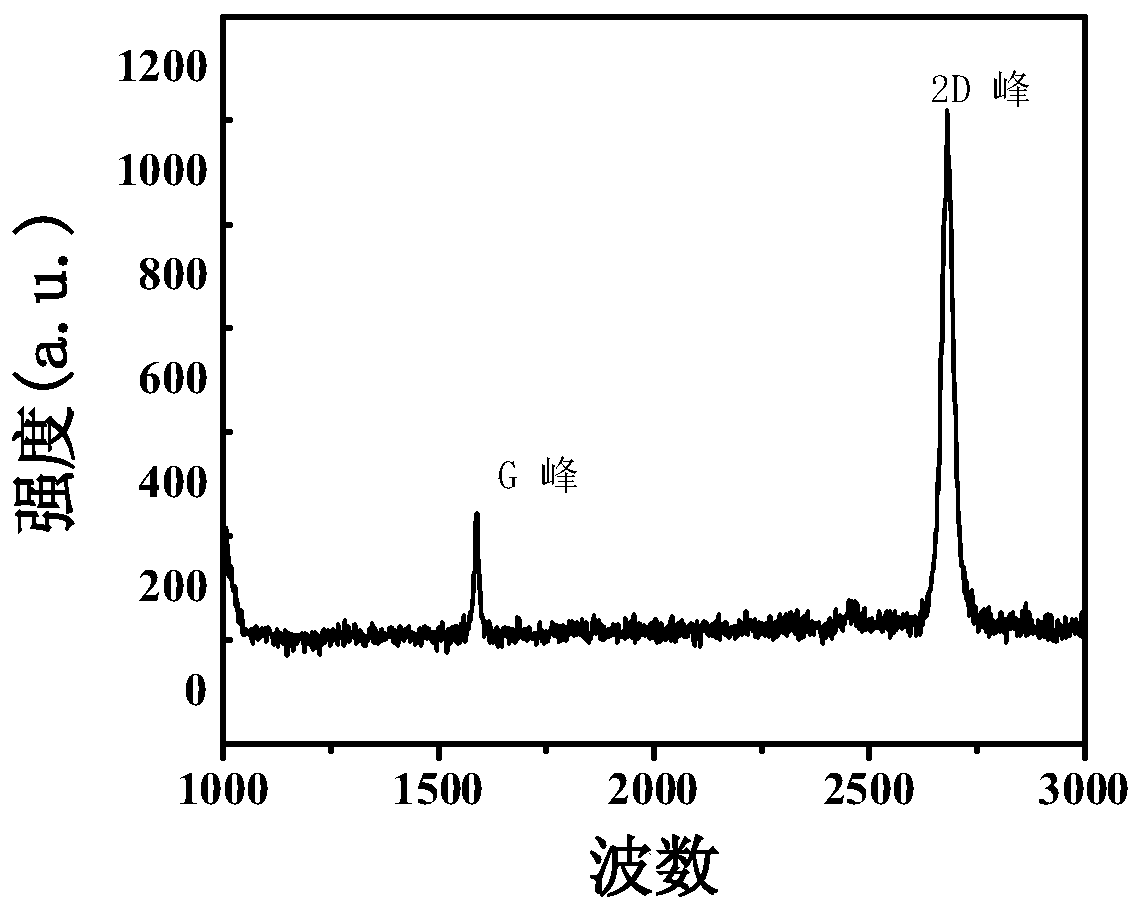

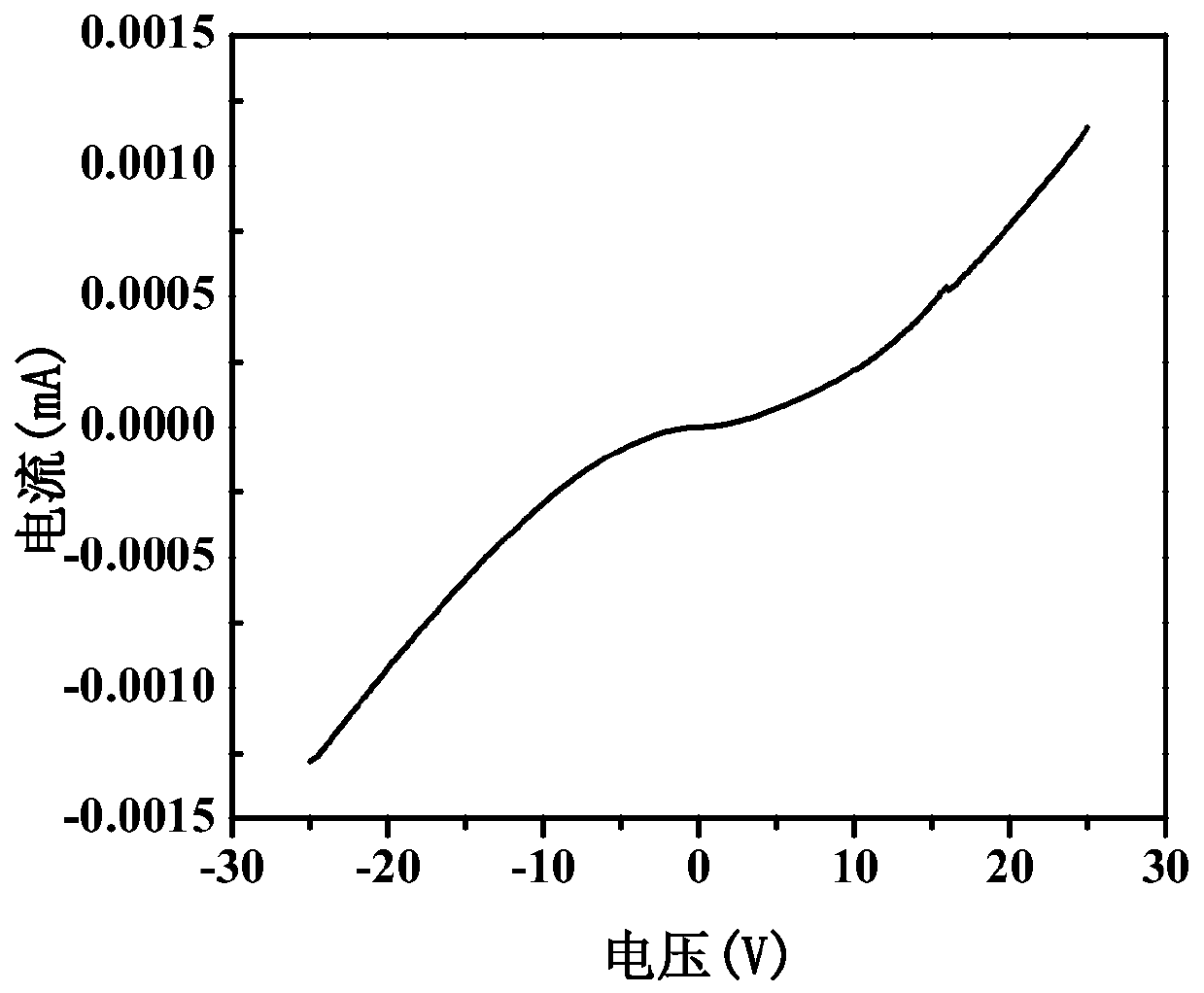

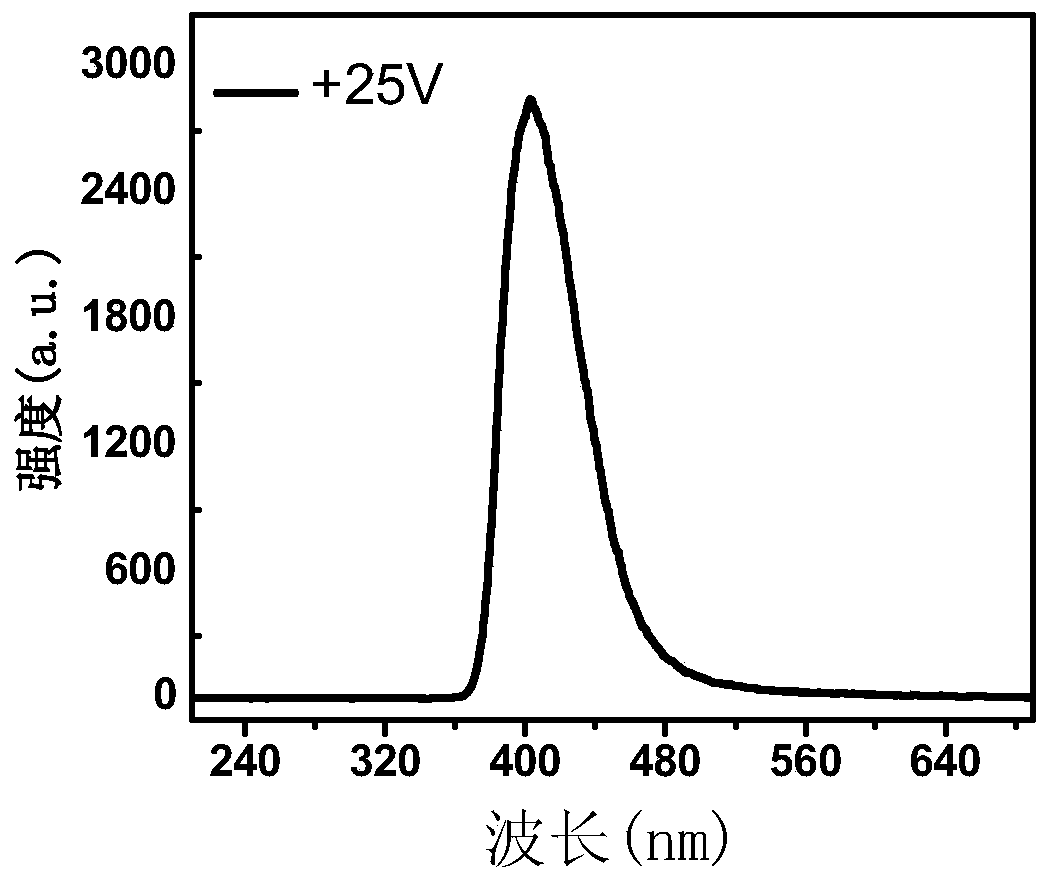

A kind of bidirectional light emitting diode and its preparation method

ActiveCN107634125BImprove compound efficiencyImprove Blu-ray characteristicsSemiconductor devicesHeterojunctionGallium nitride

The invention discloses a bidirectional light emitting diode and a manufacturing method thereof. The diode is a GaN-graphene-MgO-ZnO micro-rod bidirectional light emitting diode and sequentially comprises a p-type GaN layer, a graphene layer, a MaO layer and a ZnO micro-rod from down to up, a side electrode is arranged on the gallium nitride layer, and a right side electrode is arranged on the zinc oxide layer. The method comprises steps that the graphene layer is added on the GaN layer; 2), the MgO layer is plated on an upper surface of the graphene layer; 3), a ZnO micro-rod array is manufactured on a silicon chip to form a GaN-graphene-MgO-ZnO heterojunction; and 5), the side electrode is arranged on the surface of the GaN layer, and the right side electrode covers the zinc micro-rod surface. The bidirectional light emitting diode is advantaged in that current injection of a graphene enhancement junction is utilized, luminescence can be realized under positive and negative biases, high brightness is realized, the manufacturing process is simple, and cost is low.

Owner:SOUTHEAST UNIV

Magnesium oxide zinc oxide compound vulcanizing agent for chloroprene rubber vulcanization and preparation method thereof

ActiveCN104163960BGood dispersionImprove activity retentionVulcanizationMagnesium Oxide / Zinc Oxide

The invention relates to a magnesium oxide zinc oxide compound vulcanizing agent for chloroprene rubber vulcanization and a preparation method thereof. The vulcanizing agent is made of the following components: active magnesium oxide and active zinc oxide mixture 80.0%-90.0%; dispersion agent 10.0%-20.0%; the weight ratio of active magnesium oxide to active zinc oxide is 1:0.2-3.0. The preparation method is as follows: a, mixing active magnesium oxide and active zinc oxide to obtain substance A, dissolving the dispersant in absolute ethanol to obtain substance B; b, performing surface coating modification on substance A by substance B to obtain a compound; c 1. Heat and stir the compound to obtain a paste-like or viscous magnesium oxide zinc oxide compound vulcanizing agent. This vulcanizing agent solves the problems that the traditional vulcanizing agent is added into chloroprene rubber in powder form, which causes uneven dispersion of powder and easy failure of magnesium oxide activity, and improves the dispersion of zinc oxide and the activity retention of magnesium oxide. Reduced scorch hazard for high Mooney viscosity compounds.

Owner:河北镁神科技股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com