A kind of bidirectional light emitting diode and its preparation method

A technology of light-emitting diodes and diodes, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of increasing electron recombination rate, increasing luminescence, and failing to solve the problem of device heating, so as to increase electron injection efficiency, improve stability, and improve The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The first step: ZnO powder and carbon powder with a purity of 99.99wt% are mixed and ground according to the mass ratio of 1:1, and the mixture is filled into a ceramic boat; a silicon wafer with a size close to the opening area of the ceramic boat is taken, and the acetone , anhydrous ethanol and deionized water, followed by ultrasonic cleaning and nitrogen flushing, the silicon wafer was covered with the polished side down and above the ceramic boat; then the ceramic boat was pushed into a tube furnace with a temperature of 1050 ° C; after 60 minutes of reaction , to form larger ZnO microrod arrays grown on the surface of the silicon wafer;

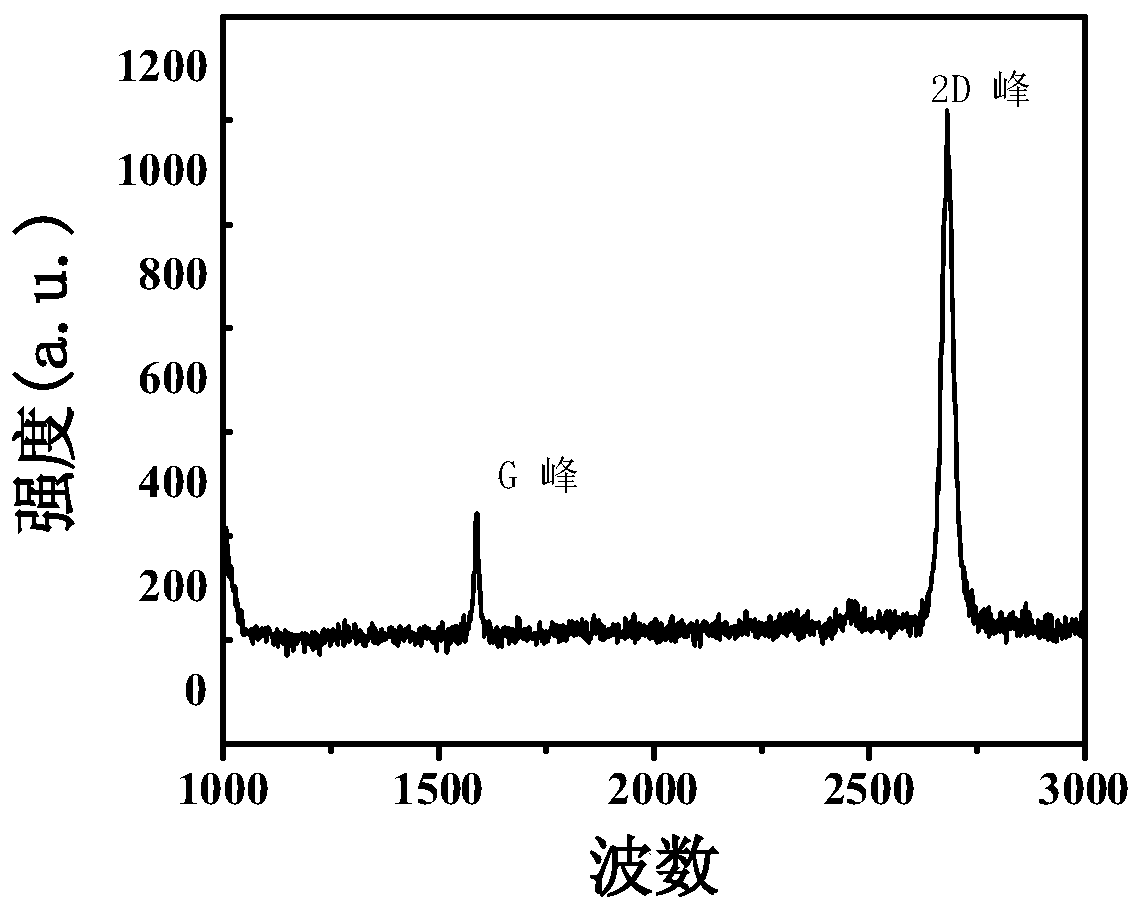

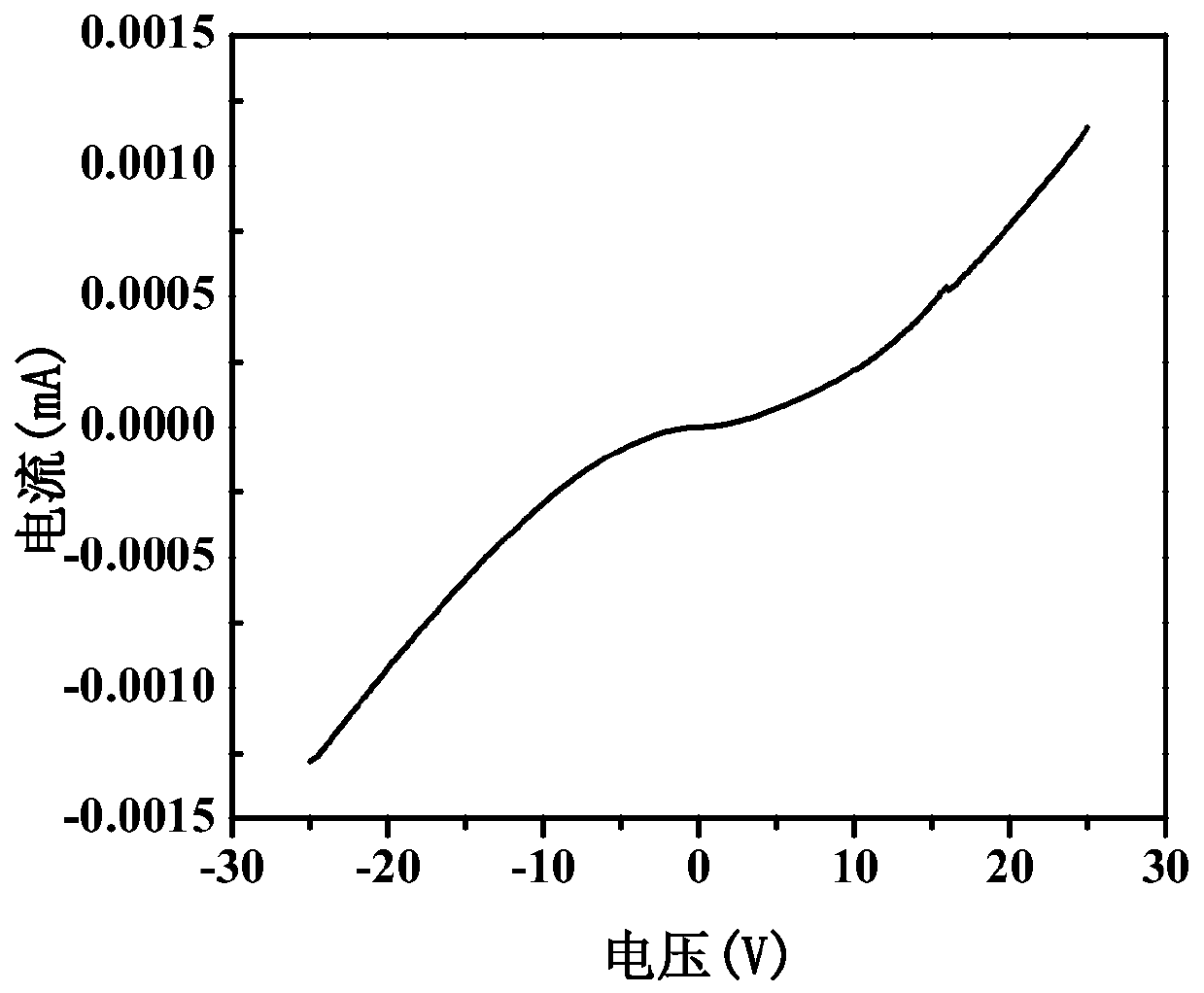

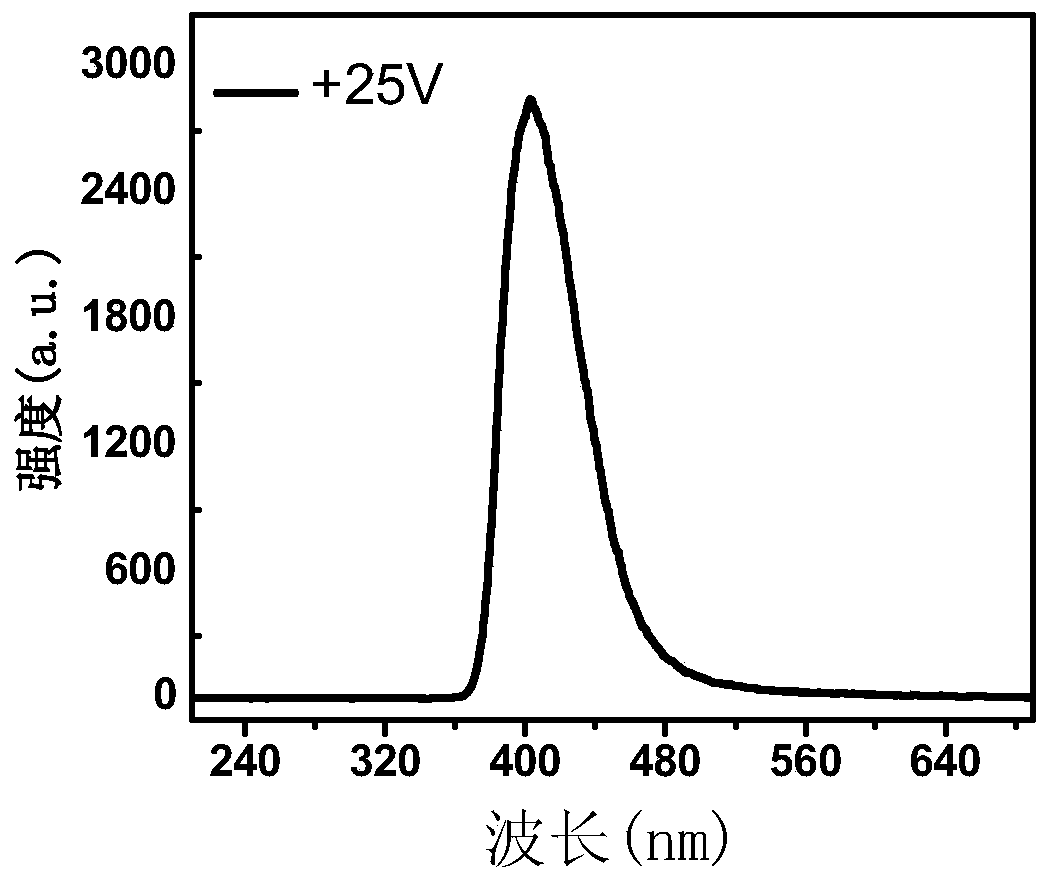

[0038] The second step: using 50g / L FeCl 3 Solution processing copper-based graphene, the specific method is to cut the PMMA spin-coated copper-based graphene into 0.5*0.5mm squares, and then place it on FeCl 3 Soak in the solution for 1 hour, then use a glass slide to resuspend the FeCl 3 The graphene in the solution was tra...

Embodiment 2

[0044] The first step: ZnO powder and carbon powder with a purity of 99wt% are mixed and ground according to a mass ratio of 1:3, and the mixture is filled into a ceramic boat; After ultrasonic cleaning with water ethanol and deionized water in sequence, after drying with nitrogen gas, place the polished side of the silicon wafer down and cover the top of the ceramic boat; then push the ceramic boat into a tube furnace with a temperature of 1050°C; after 80 minutes of reaction , to form larger ZnO microrod arrays grown on the surface of the silicon wafer;

[0045] The second step: using 20g / L FeCl 3 Solution processing copper-based graphene, the specific method is to cut the PMMA spin-coated copper-based graphene into 0.5*0.5mm squares, and then place it on FeCl 3 Soak in the solution for 2 hours, then use a glass slide to resuspend the FeCl 3 Transfer the graphene in the solution to clean water and clean it, then transfer it to a p-GaN substrate, then dry it in a drying ove...

Embodiment 3

[0051] The first step: ZnO powder and carbon powder with a purity of 99wt% are mixed and ground according to a mass ratio of 1:3, and the mixture is filled into a ceramic boat; After ultrasonic cleaning with water ethanol and deionized water in sequence, after drying with nitrogen gas, place the polished side of the silicon wafer down and cover the top of the ceramic boat; then push the ceramic boat into a tube furnace at a temperature of 950 °C; after 150 minutes of reaction , to form larger ZnO microrod arrays grown on the surface of the silicon wafer;

[0052] The second step: using 40g / L FeCl 3 Solution processing copper-based graphene, the specific method is to cut the PMMA spin-coated copper-based graphene into 0.5*0.5mm squares, and then place it on FeCl 3 Soak in the solution for 1.5 hours, then slide the suspension in FeCl 3 The graphene in the solution was transferred to clean water and cleaned, then transferred to the p-GaN layer, and then dried in a drying oven a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com