Organic compound based on azabenzene and application thereof in OLED

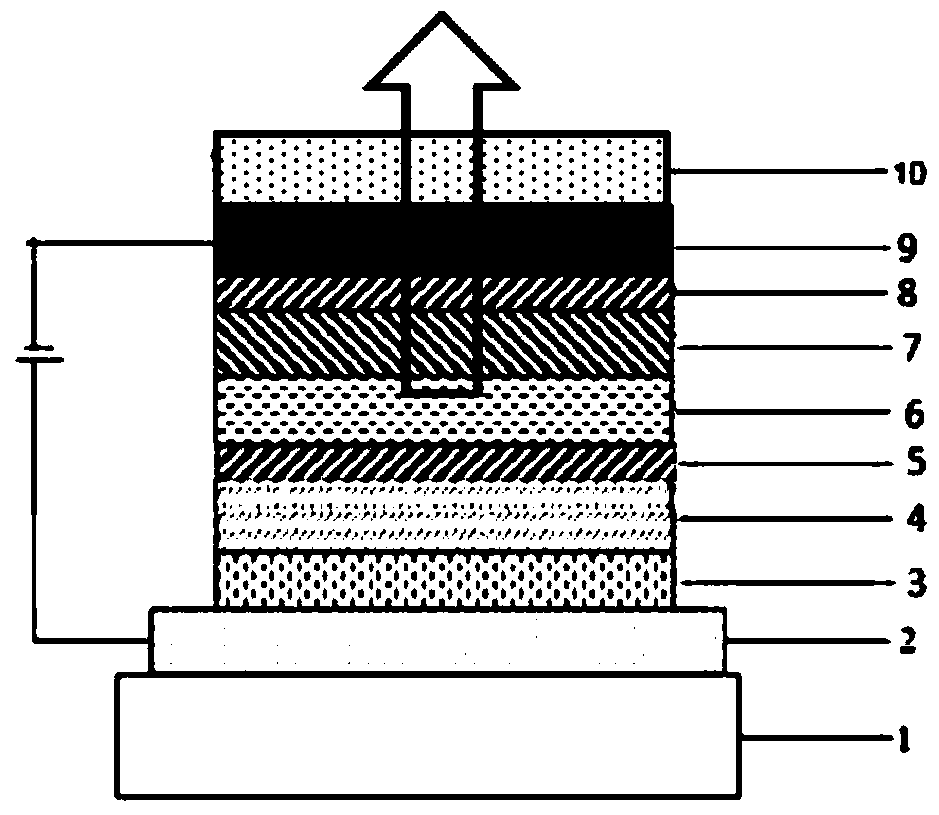

A technology for organic compounds and azepines, which is applied to organic compounds and their application on OLEDs, can solve the problems of affecting the angular distribution of OLED radiation spectrum, complicated manufacturing processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Embodiment 1: the synthesis of intermediate II

[0090] When Ar 1 and Ar 4 When linked with azabenzene by C-C bond,

[0091]

[0092] Under nitrogen atmosphere, weigh raw material A and dissolve it in DMF, then add and palladium acetate, stir the mixture, then add aqueous potassium phosphate solution, heat the mixed solution of the above reactants to reflux at 120-150°C for 5-15 hours; after the reaction is completed, add water after cooling, filter the mixture and store in a vacuum oven After drying, the obtained residue was purified by silica gel column to obtain compound intermediate I;

[0093] The raw material A and The molar ratio of palladium acetate and raw material A is 1:1.0~3, the mol ratio of palladium acetate and raw material A is 0.001~0.04:1, the molar ratio of potassium phosphate and raw material A is 1.0~4.0:1, and the consumption ratio of raw material A and DMF is 1g: 10-30ml;

[0094]

[0095] Under nitrogen atmosphere, weigh intermediat...

Embodiment 2

[0120] Embodiment 2: the synthesis of compound 1:

[0121]

[0122] In a 250mL three-neck flask, blow nitrogen, add 0.01mol intermediate A1, 150ml DMF, 0.03mol intermediate B1, 0.0002mol palladium acetate, stir, and then add 0.02mol K 3 PO 4 The aqueous solution was heated to 150°C, refluxed for 24 hours, sampled and plated, and the reaction was complete. Cool naturally, extract with 200ml of dichloromethane, separate layers, dry the extract with anhydrous sodium sulfate, filter, rotate the filtrate, and purify through a silica gel column to obtain the target product with a HPLC purity of 99.4% and a yield of 64.7%.

[0123] Elemental analysis structure (molecular formula C 37 h 23 N 3 o 2 ): theoretical value C, 82.05; H, 4.28; N, 7.76; 0, 5.91; test value: C, 82.06; ESI-MS(m / z)(M + ): The theoretical value is 541.18, and the measured value is 541.26.

Embodiment 3

[0124] Embodiment 3: the synthesis of compound 10:

[0125]

[0126] In a 250mL three-necked flask, nitrogen was introduced, 0.01mol of intermediate A2, 150ml of DMF, 0.03mol of intermediate B1, 0.0002mol of palladium acetate were added, stirred, and then 0.02mol of K 3 PO 4 The aqueous solution was heated to 150°C, refluxed for 24 hours, sampled and plated, and the reaction was complete. Cool naturally, extract with 200ml of dichloromethane, separate layers, dry the extract with anhydrous sodium sulfate, filter, rotate the filtrate, and purify through a silica gel column to obtain the target product with a HPLC purity of 99.1% and a yield of 67.2%.

[0127] Elemental analysis structure (molecular formula C 41 h 25 N 3 o 2 ): theoretical value C, 83.23; H, 4.26; N, 7.10; O, 5.41; test value: C, 83.26; H, 4.29; N, 7.15; ESI-MS(m / z)(M + ): The theoretical value is 591.19, and the measured value is 591.26.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com