Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Improve electron injection efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

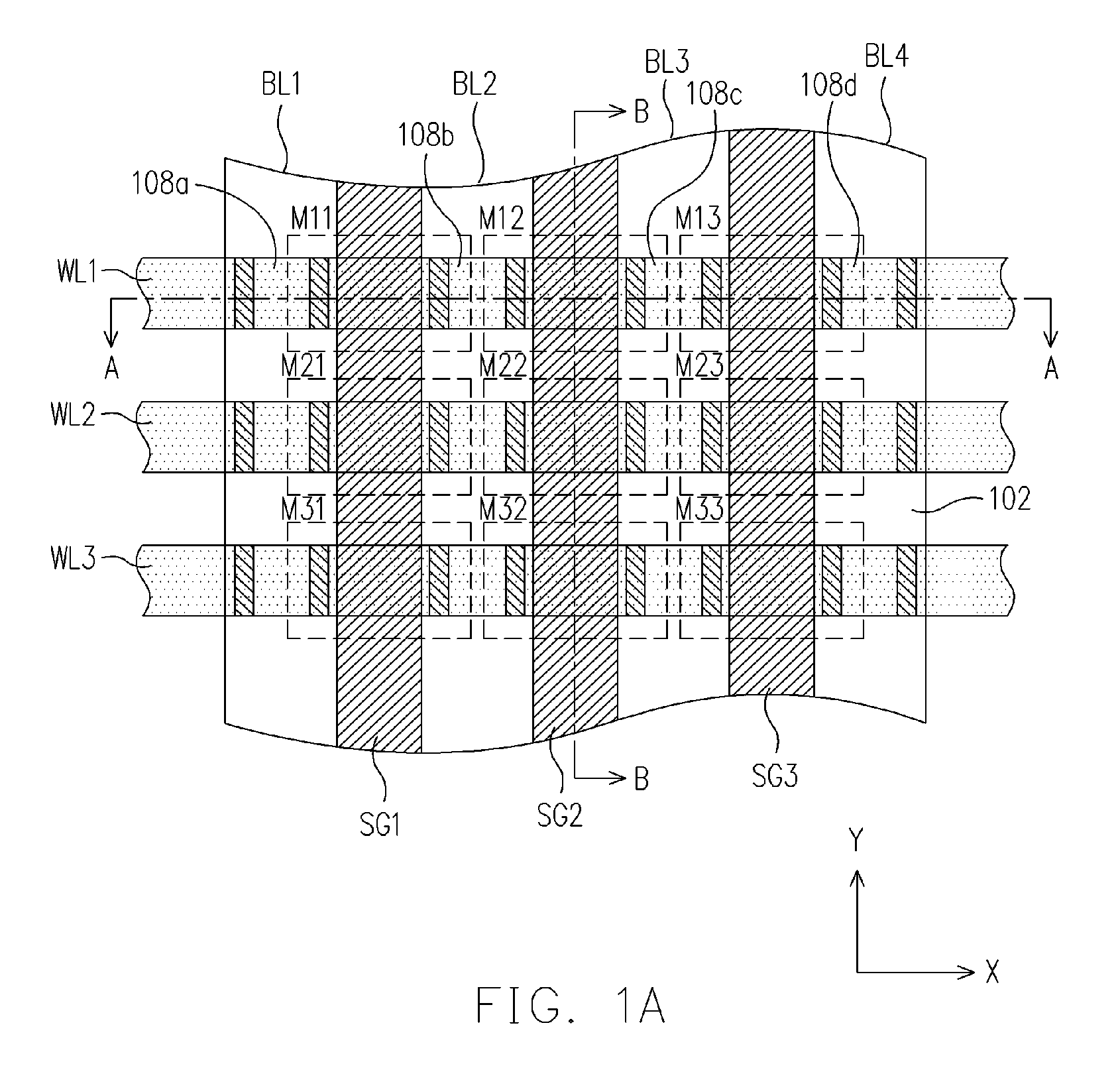

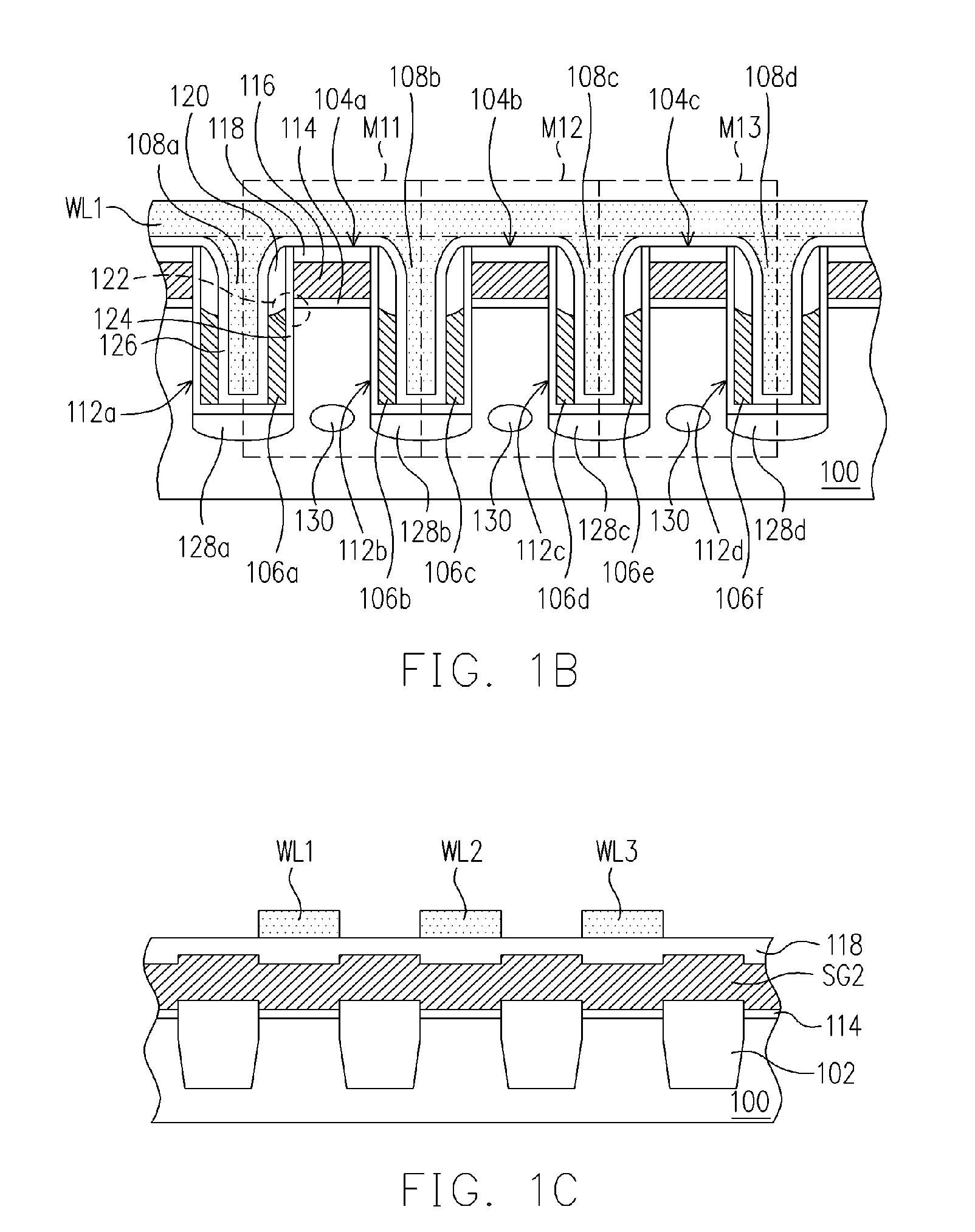

Non-volatile memory, manufacturing and operating method thereof

InactiveUS20060291281A1Total current dropHigh speedSolid-state devicesRead-only memoriesEngineeringNon-volatile memory

A non-volatile memory having a substrate, a select gate, a pair of charge storage layers, a pair of source / drain regions and a control gate is provided. At least a pair of trenches are formed in the substrate. The select gate is formed on the substrate between the pair of trenches. A pair of charge storage layers is formed on the sidewalls of the trenches next to the select gate. A pair of source / drain regions is formed in the substrate at the bottom of the trenches. The control gate is formed on the substrate to fill the trenches completely.

Owner:POWERCHIP SEMICON CORP

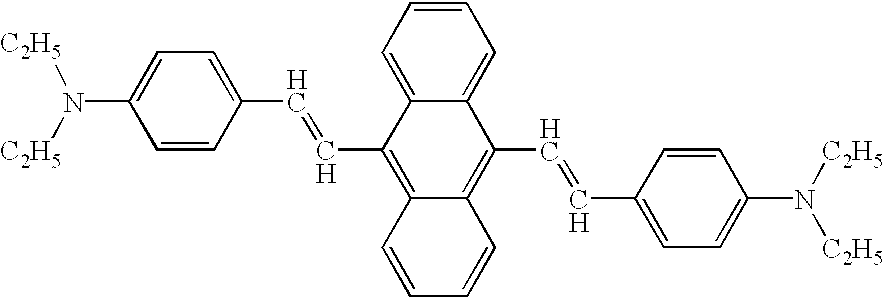

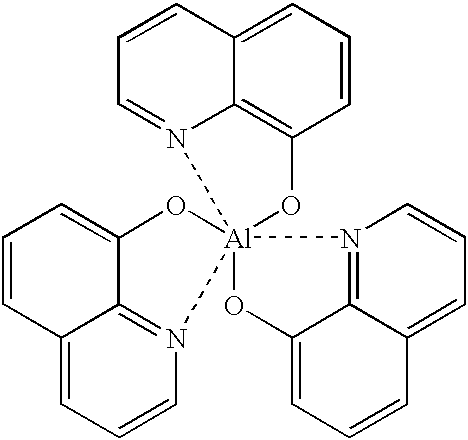

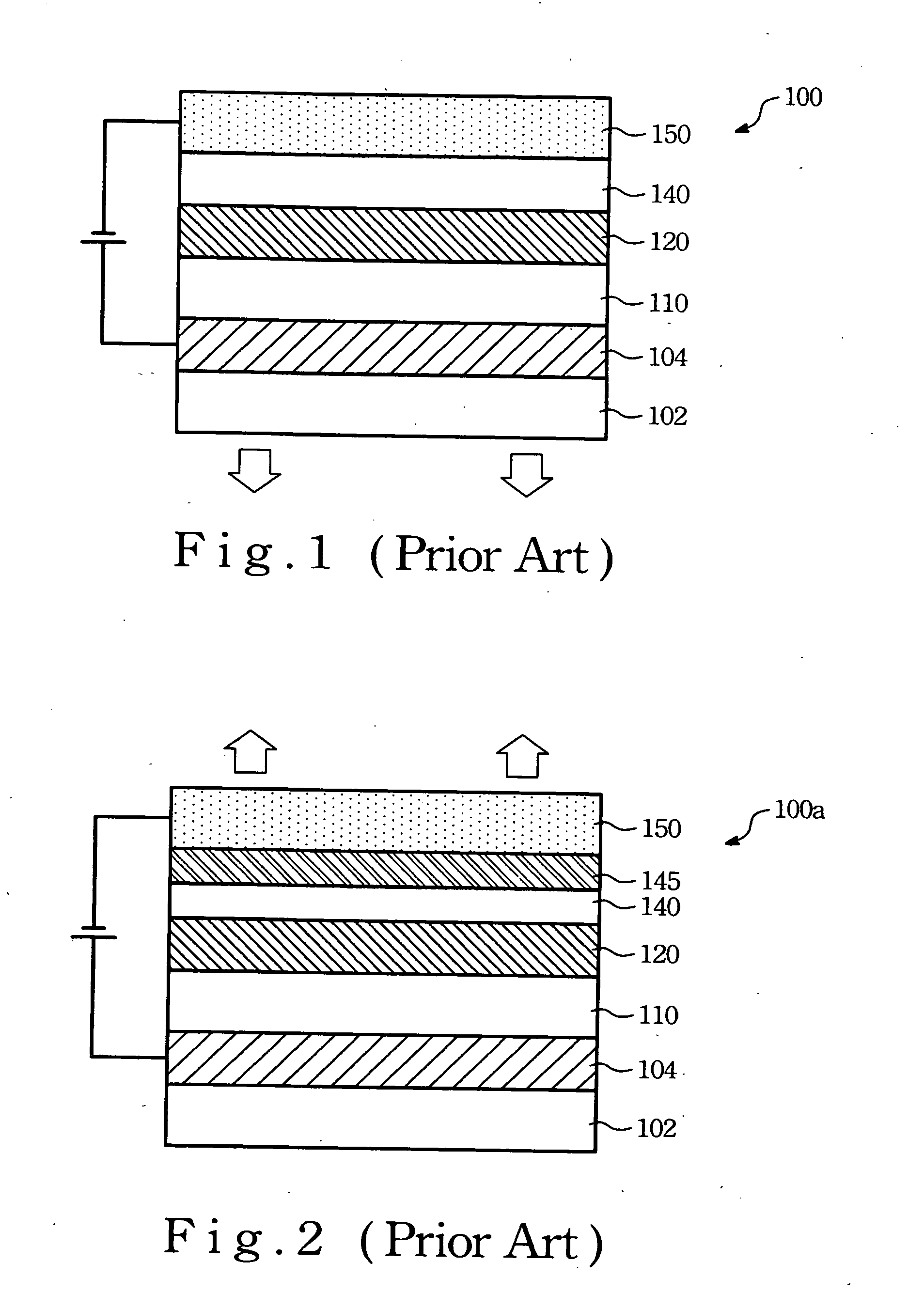

EL device with insulating layer of a bromide or iodide

InactiveUS6525465B1Improve electron injection efficiencyReduce voltageDischarge tube luminescnet screensElectroluminescent light sourcesIodideLuminescent material

An organic electroluminescent device having: a pair of an anode and cathode, a single-layered or multi-layered film therebetween containing an organic luminescent material and an insulating film of a chloride, a bromide or an iodide between the cathode and the single-layered or multi-layered film, the device being adapted to emit light by application of voltage or current across the pair of electrodes.

Owner:SHARP KK

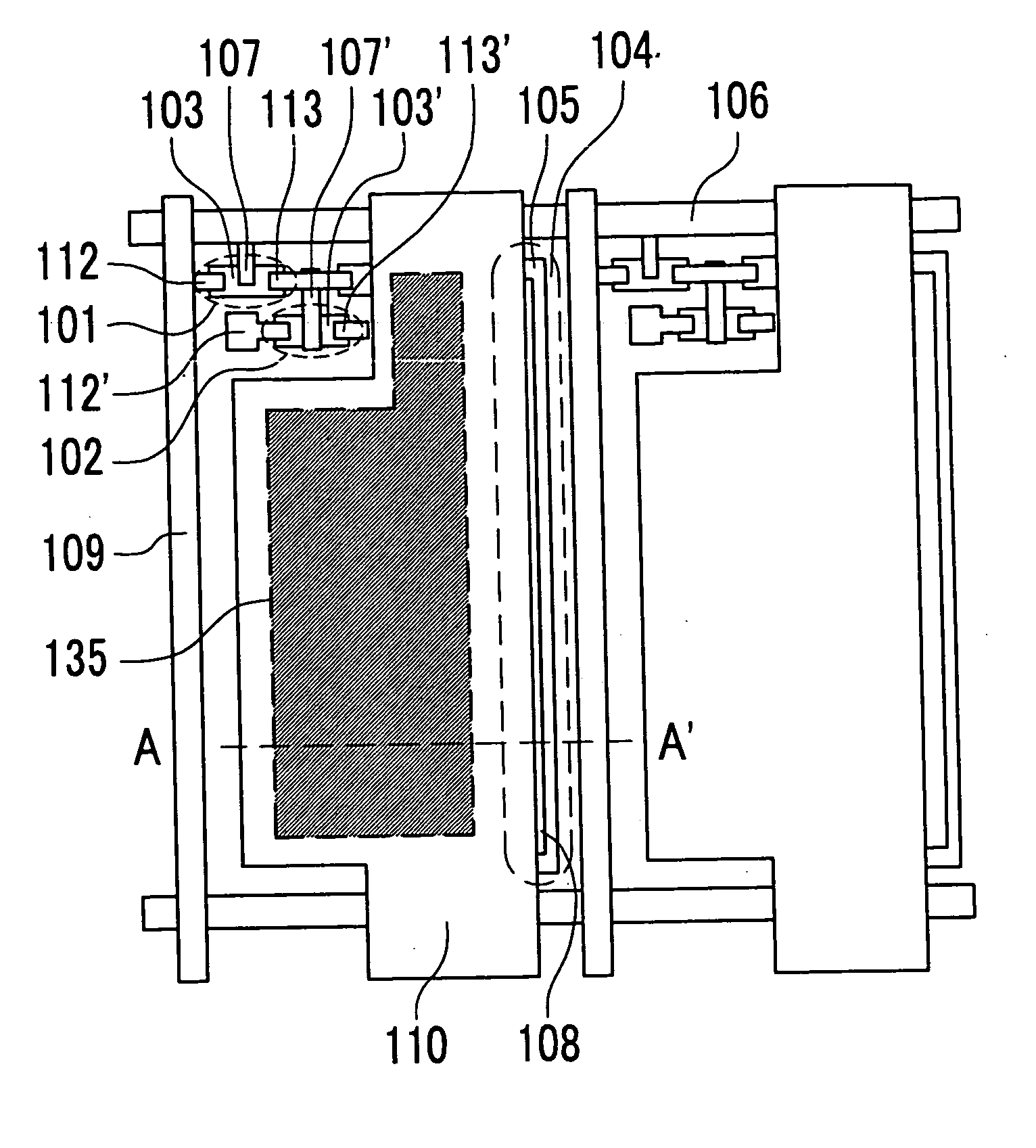

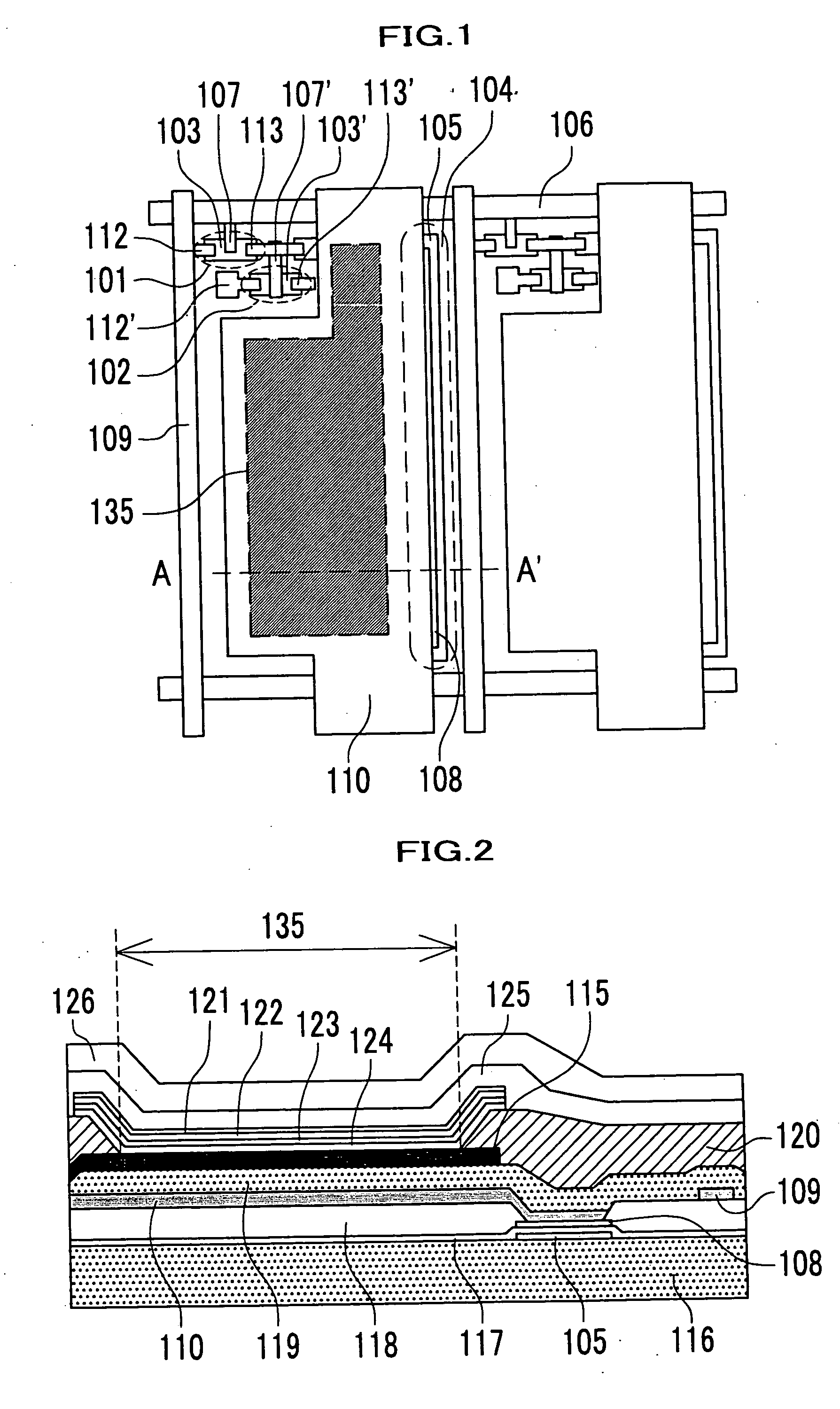

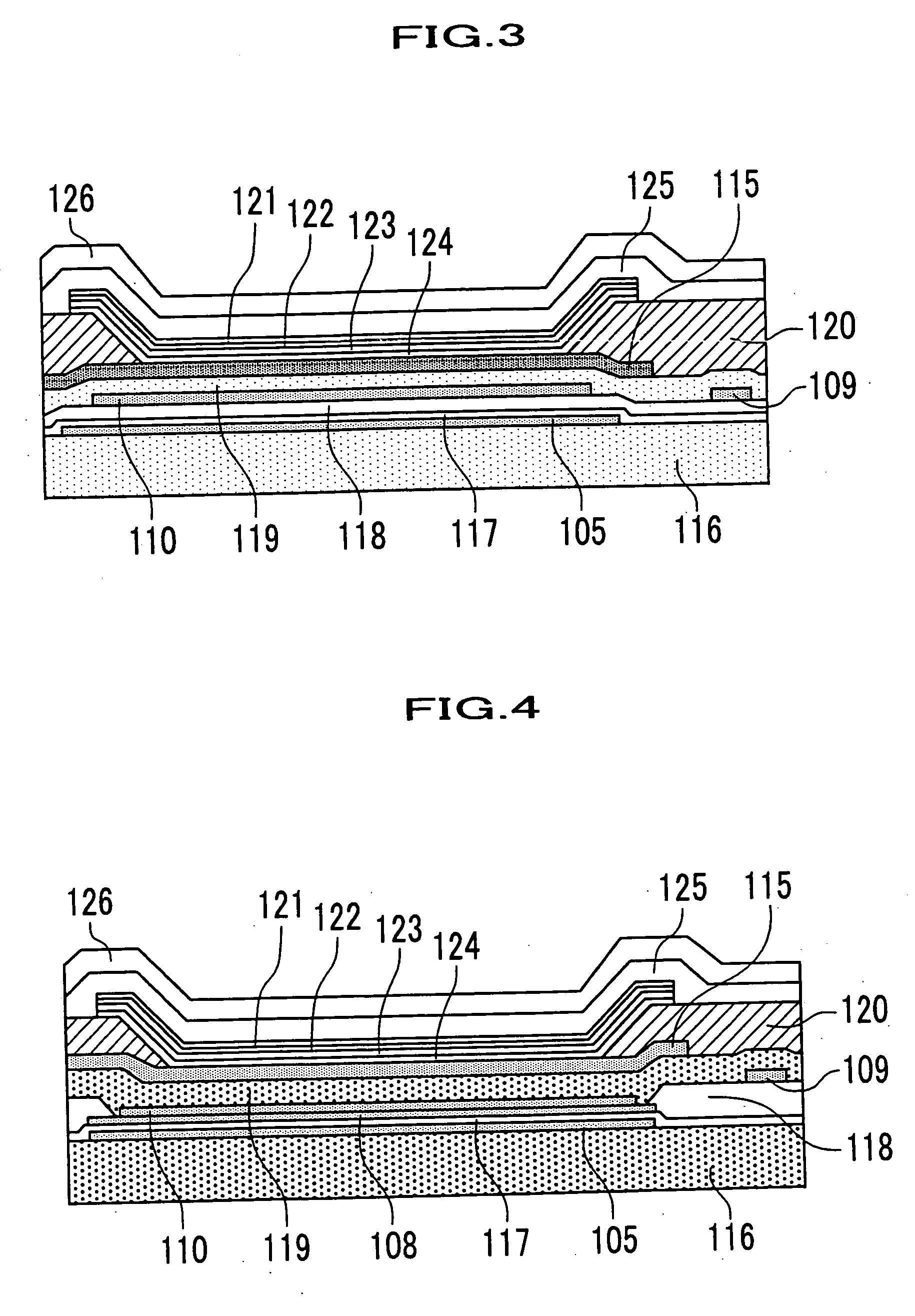

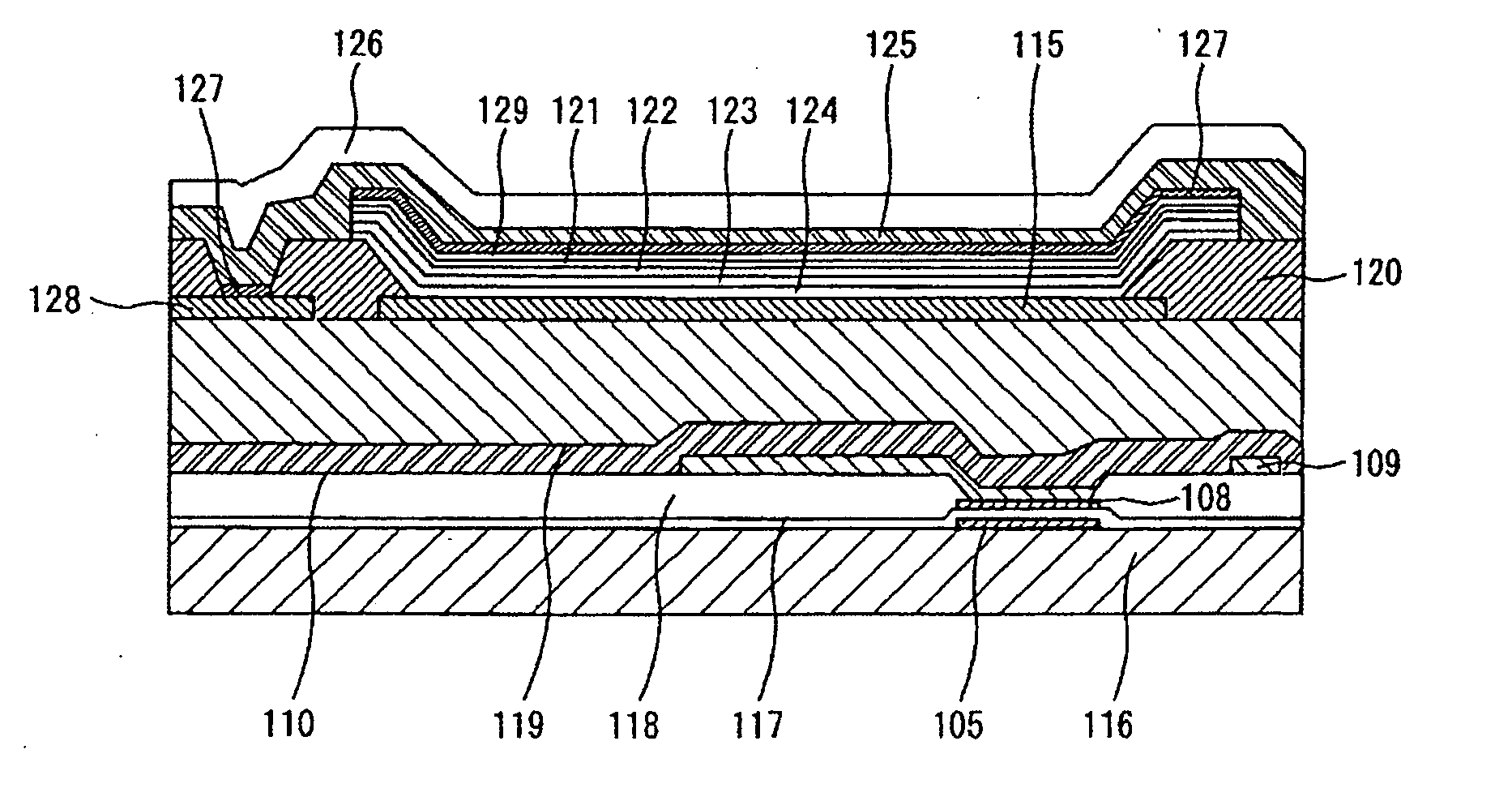

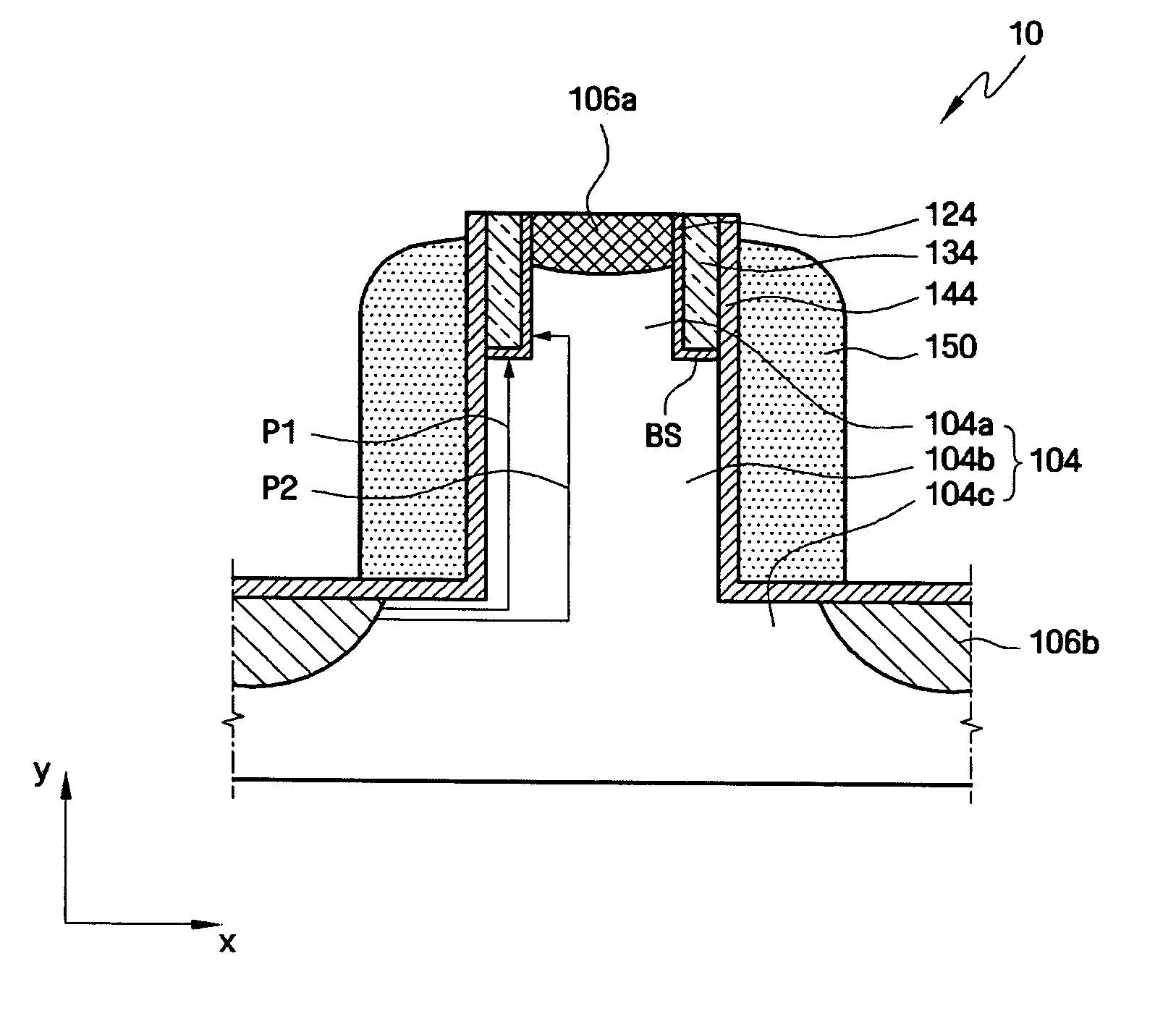

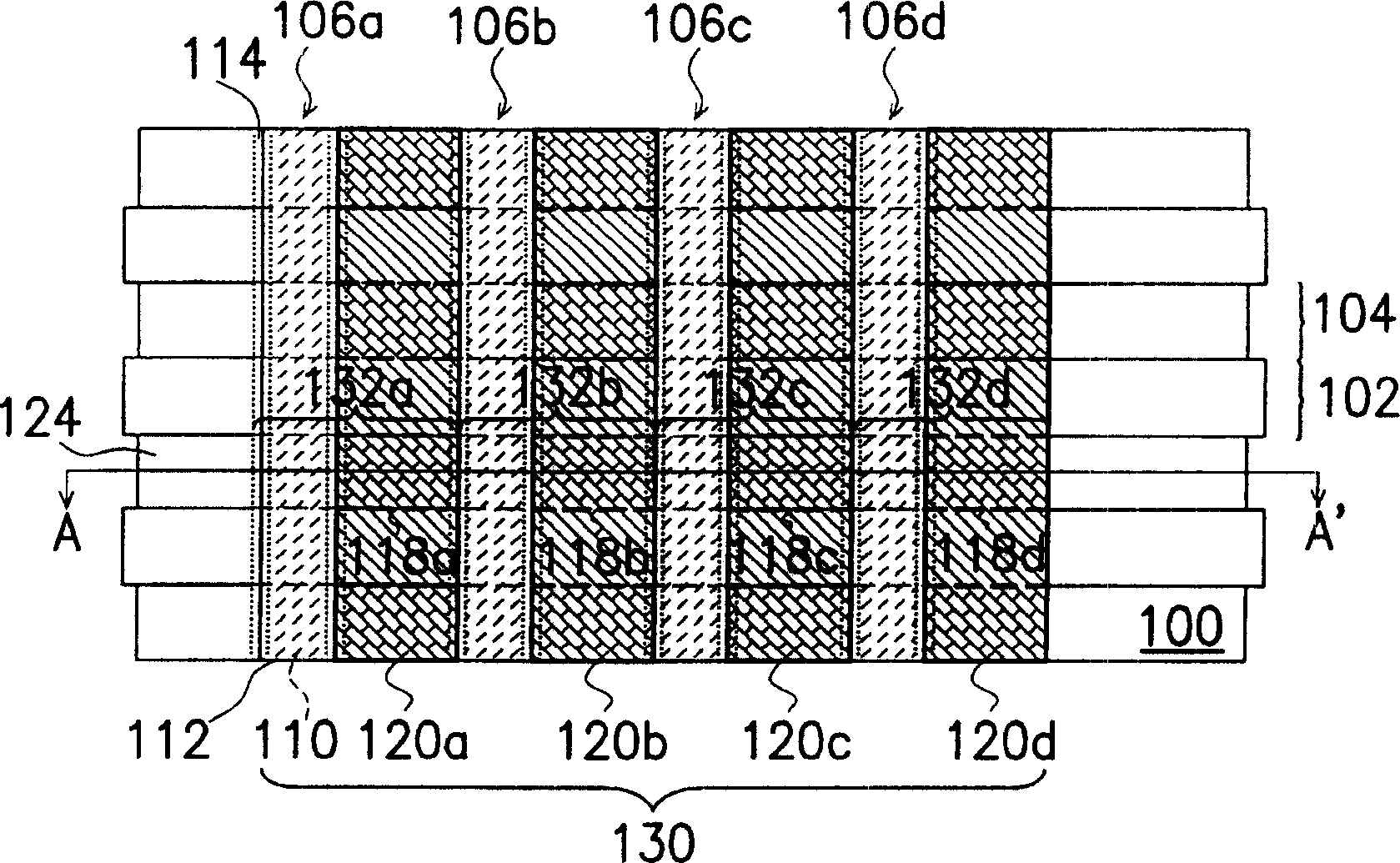

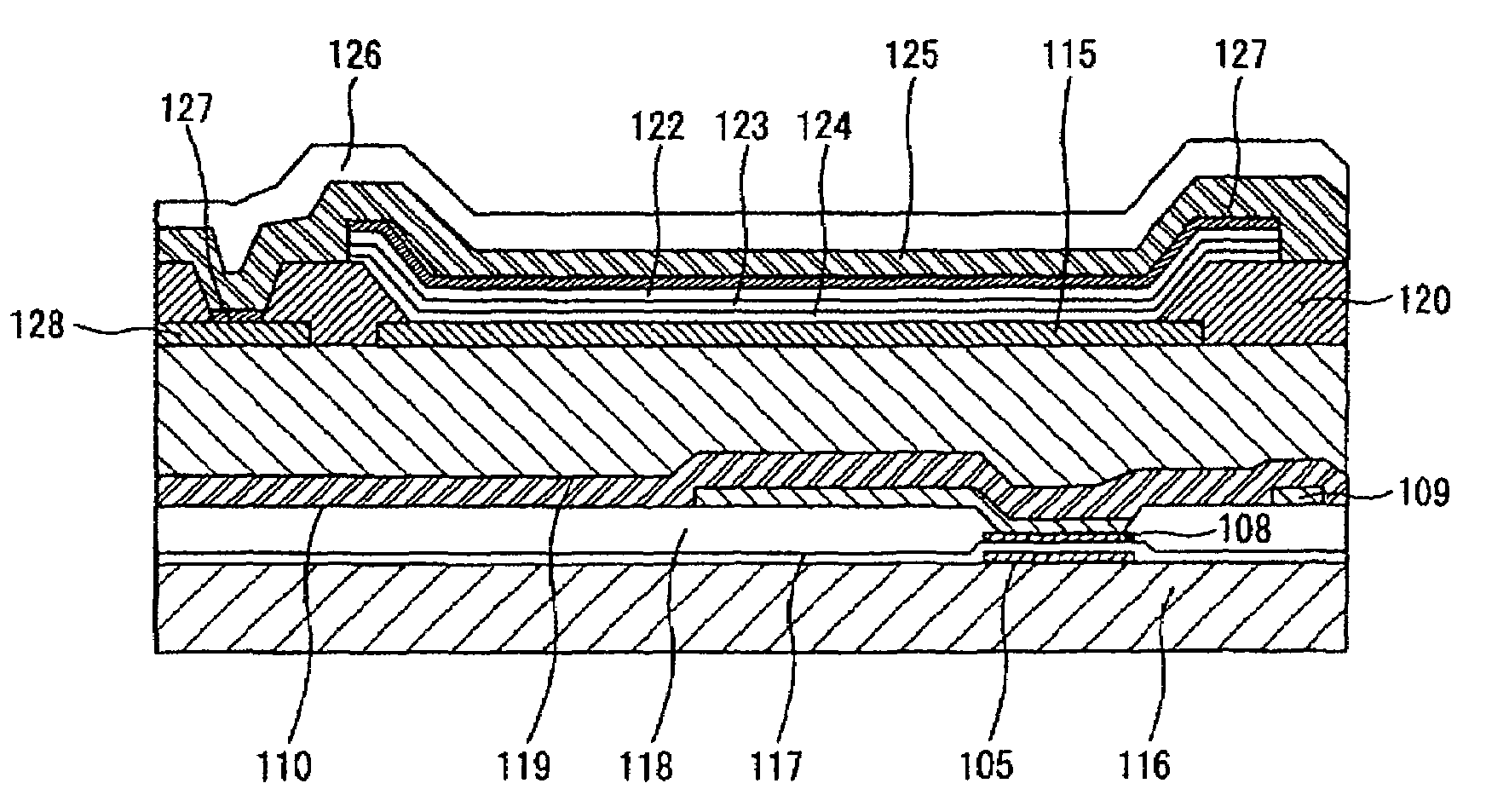

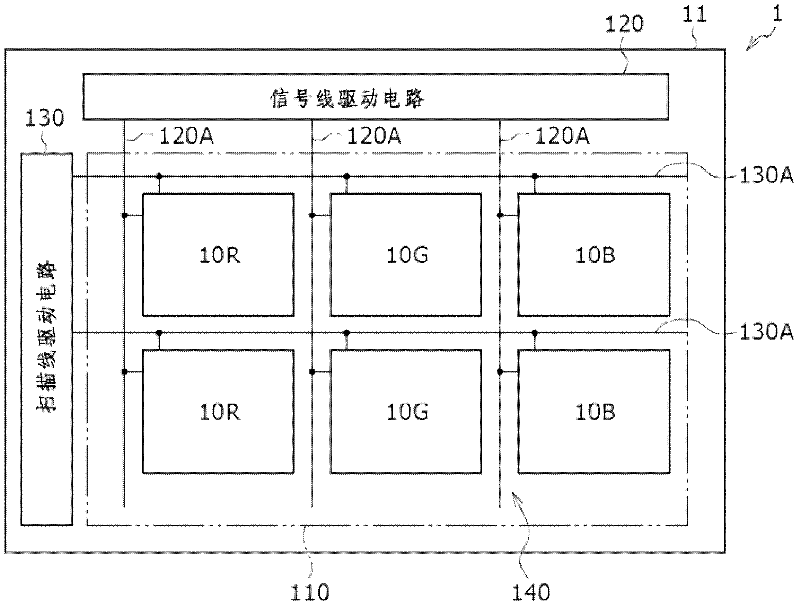

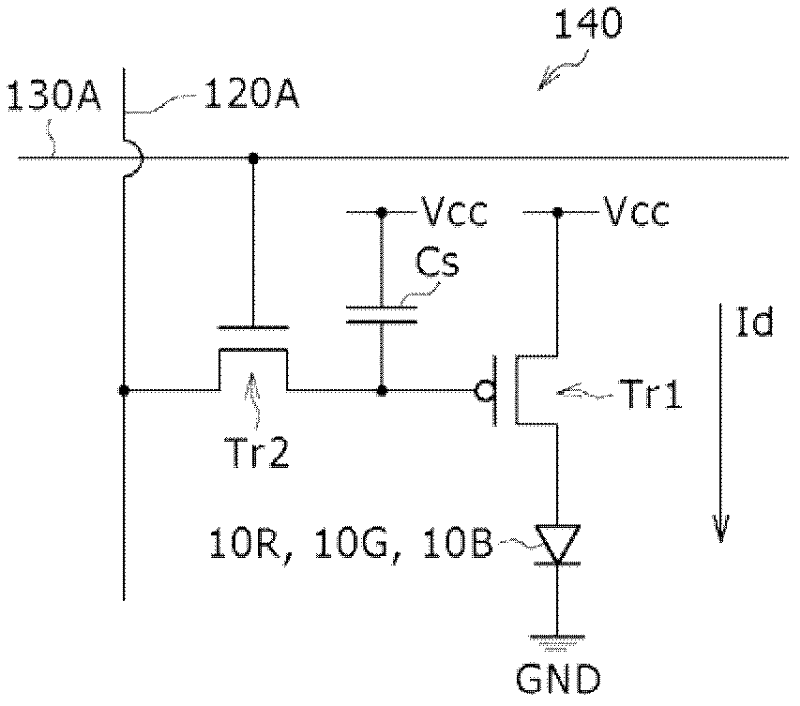

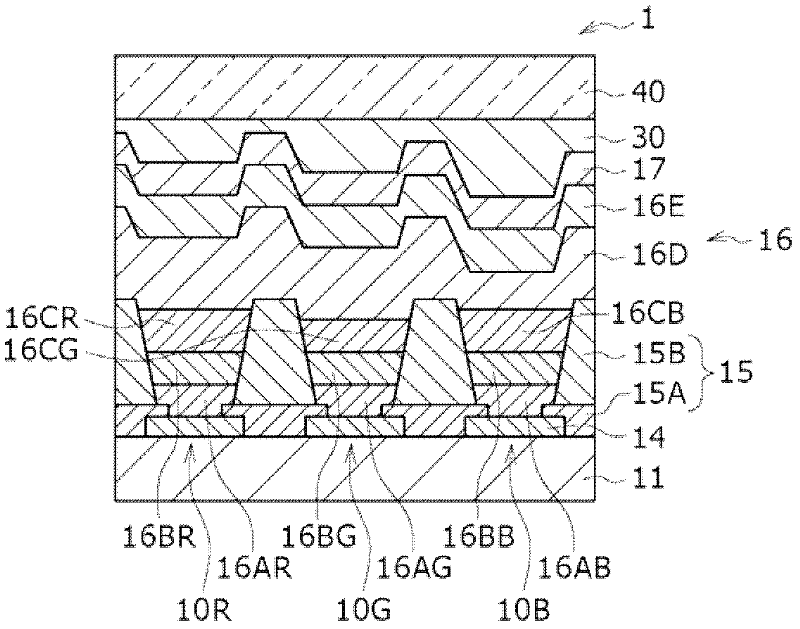

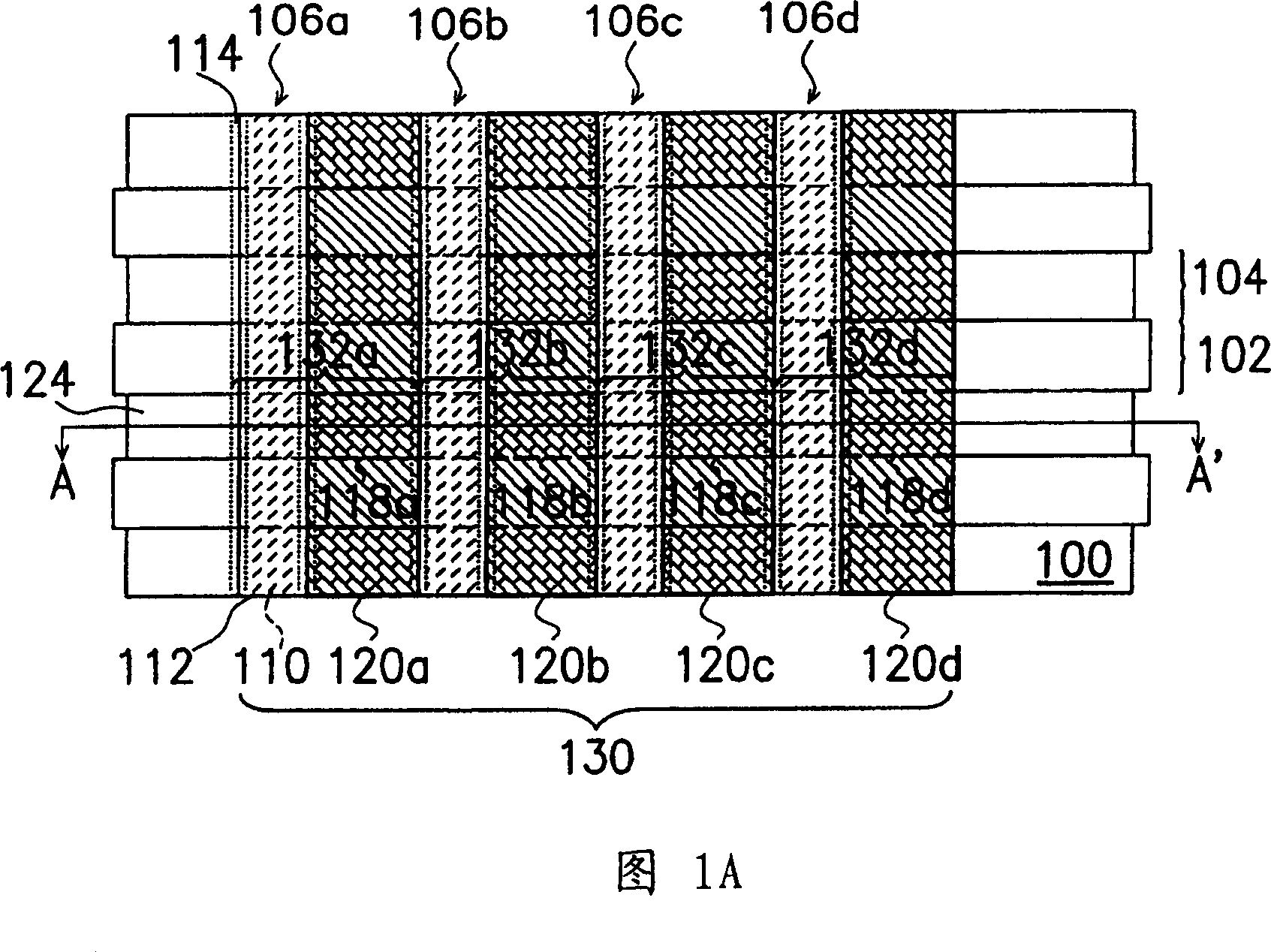

Organic light-emitting display device

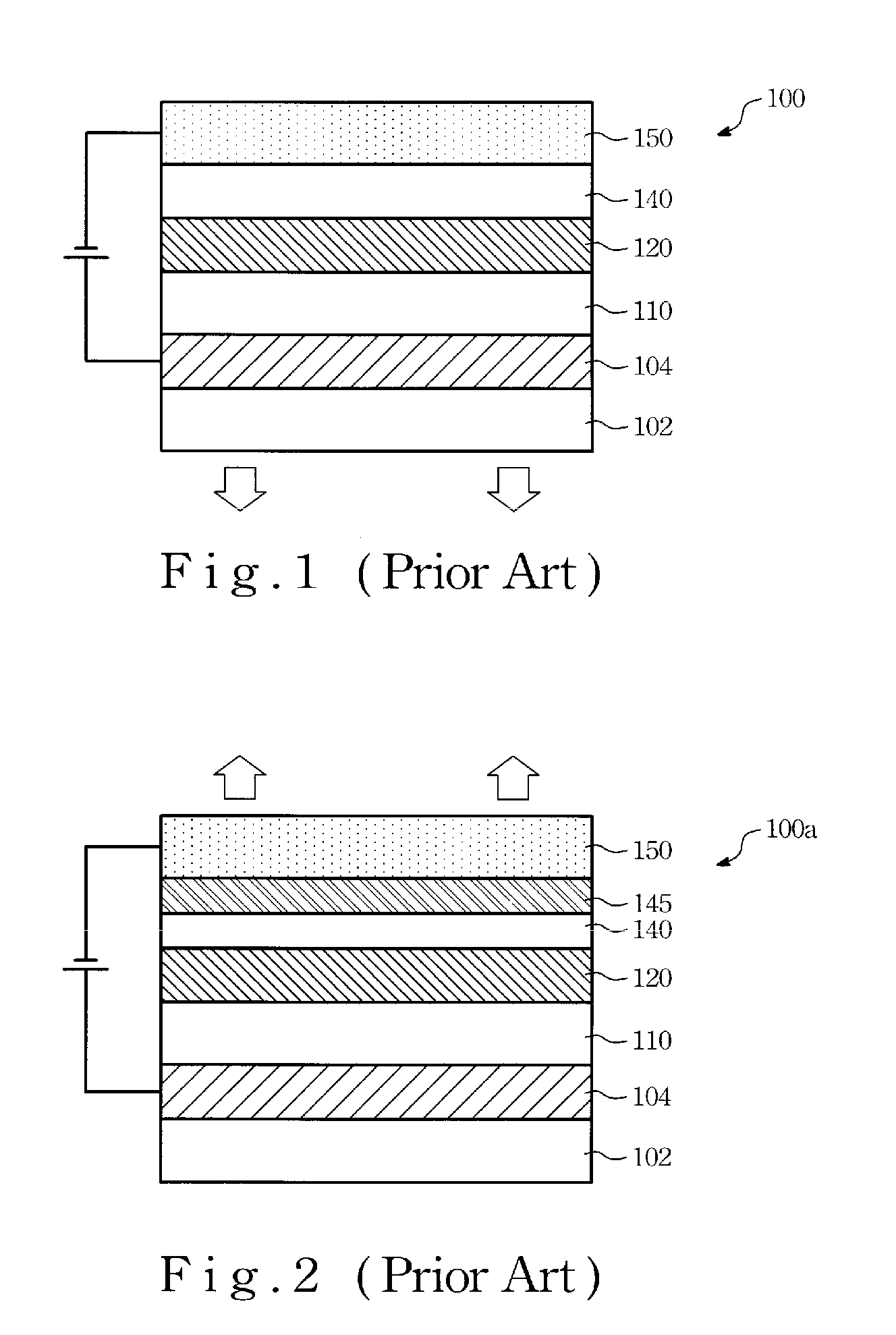

InactiveUS20050168142A1Improve electron injection efficiencyDischarge tube luminescnet screensStatic indicating devicesDisplay deviceEngineering

The present invention provides OLEDs of the top emission type comprising organic light-emitting (LE) elements by preventing the problems such as the widening of the power lines, the reduction in the aperture ratio caused by the widening of the upper and the lower capacitor electrodes and the short circuit between the upper and the lower electrodes caused by the roughness of the flattening layers. Two kinds of the OLEDs are provided. One is an OLED comprising a region of LE layer sandwiched between the upper and lower electrodes is formed on a power line of TFT for driving the pixel. Another comprises a region of the LE layer formed on an electrode of capacitor connected to the TFTs to control the light-emitting element. Accordingly, without forming a flattening layer on the light-emitting layer, there is no electric short circuit between the lower electrode and the upper electrode.

Owner:SAMSUNG DISPLAY CO LTD +1

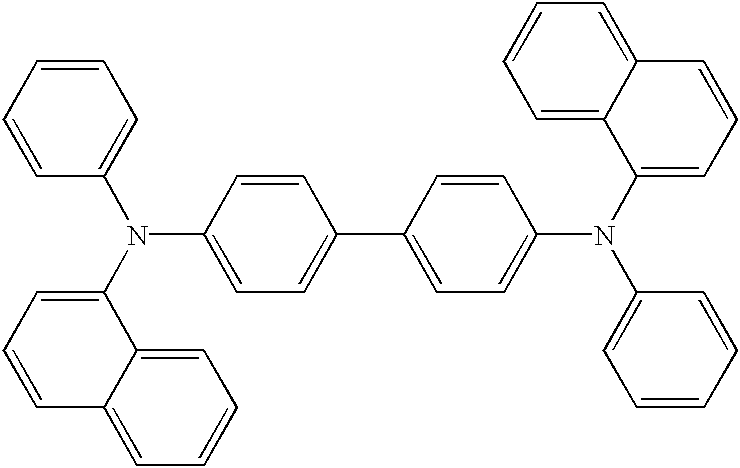

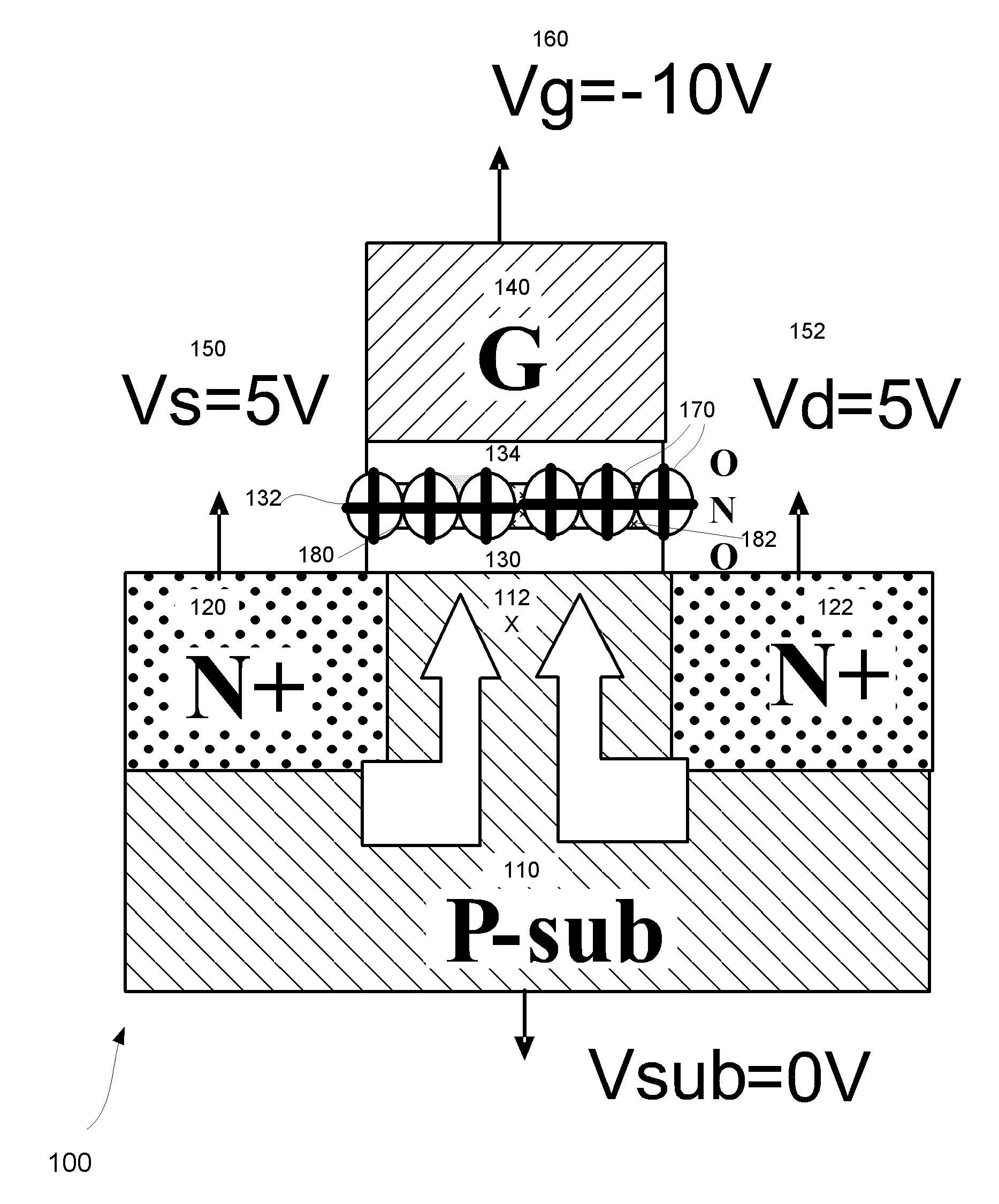

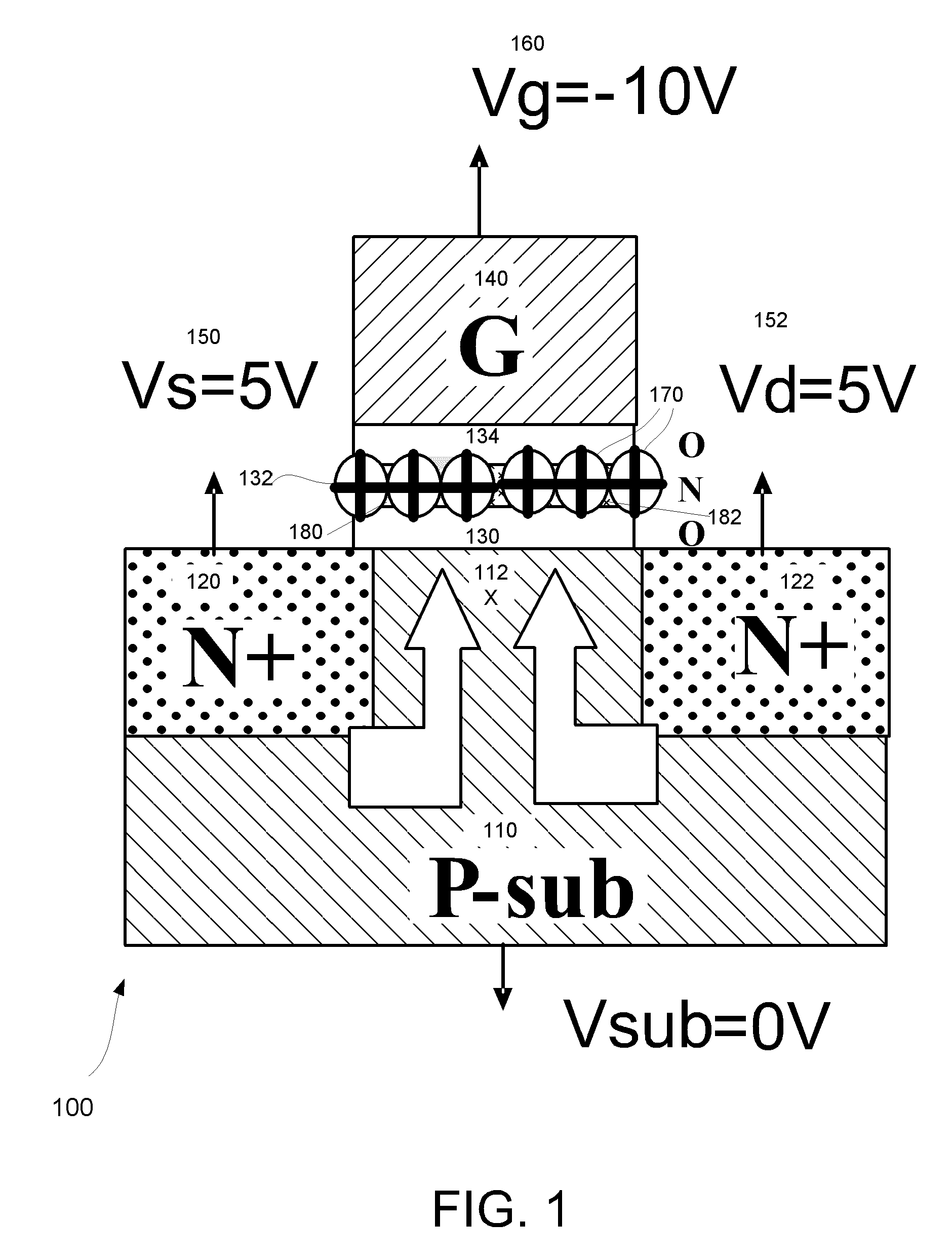

Field effect transistor, organic thin-film transistor and manufacturing method of organic transistor

InactiveUS20080012009A1Improve electron injection efficiencyHole injection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionOrganic field-effect transistor

A method for determining the combination of the electrode and organic semiconductor with improved electron injection efficiency and hole injection efficiency in an organic TFT is provided, two types of FETS, that is, an n channel FET and a p channel FET are realized, and further, a complementary TFT (CTFT) is provided. The method for obtaining the vacuum level shift at the electrode metal / organic semiconductor interface from physical constants of constituent elements of the electrode and the organic semiconductor is provided. By changing the electrode metal through an electrochemical method, the electrodes whose electron injection and hole injection can be controlled are formed. By using these electrodes, two types of FETs such as an n channel FET and a p channel FET are realized, thereby providing a complementary TFT (CTFT).

Owner:HITACHI LTD

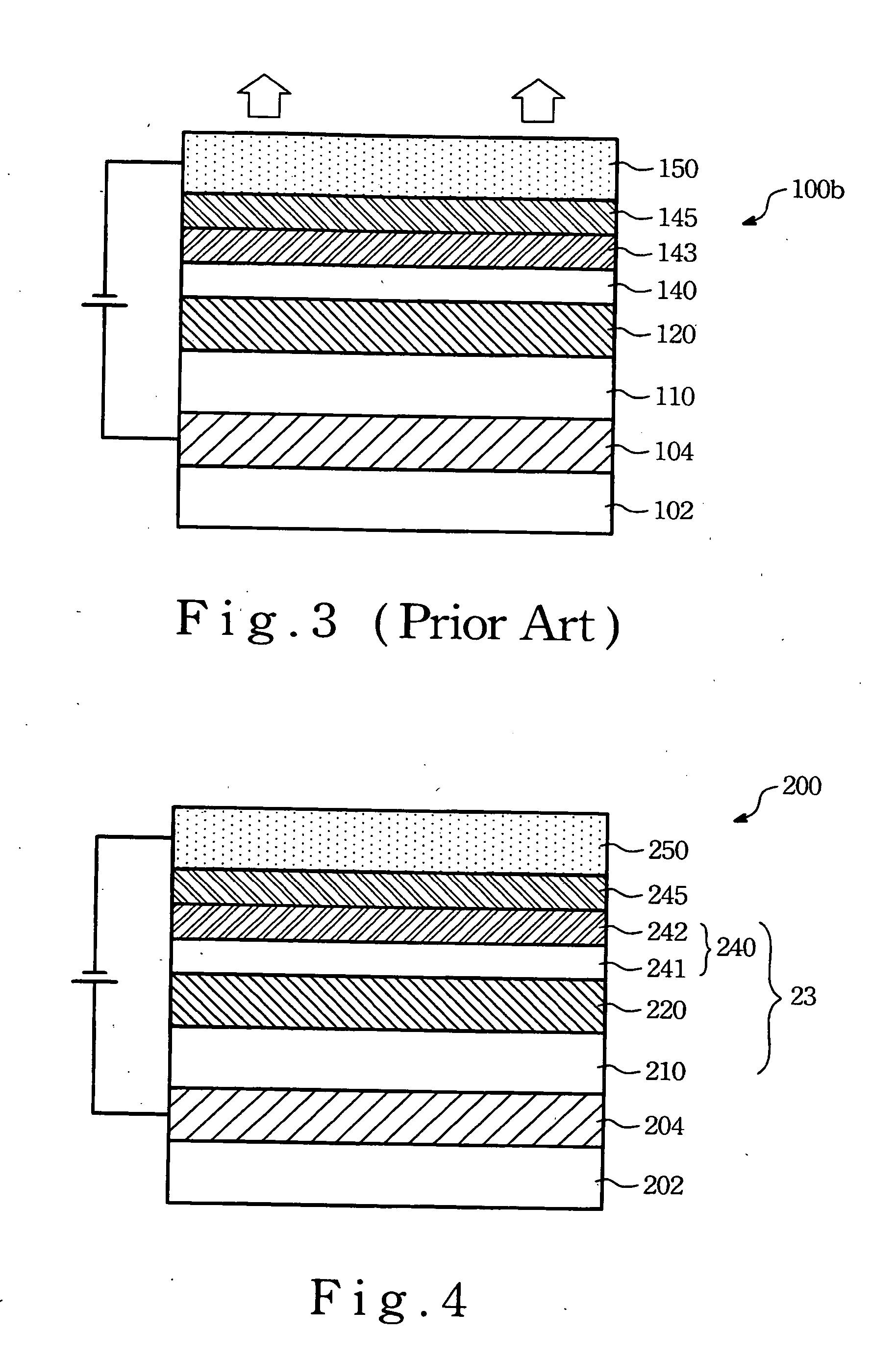

Organic light-emitting display device

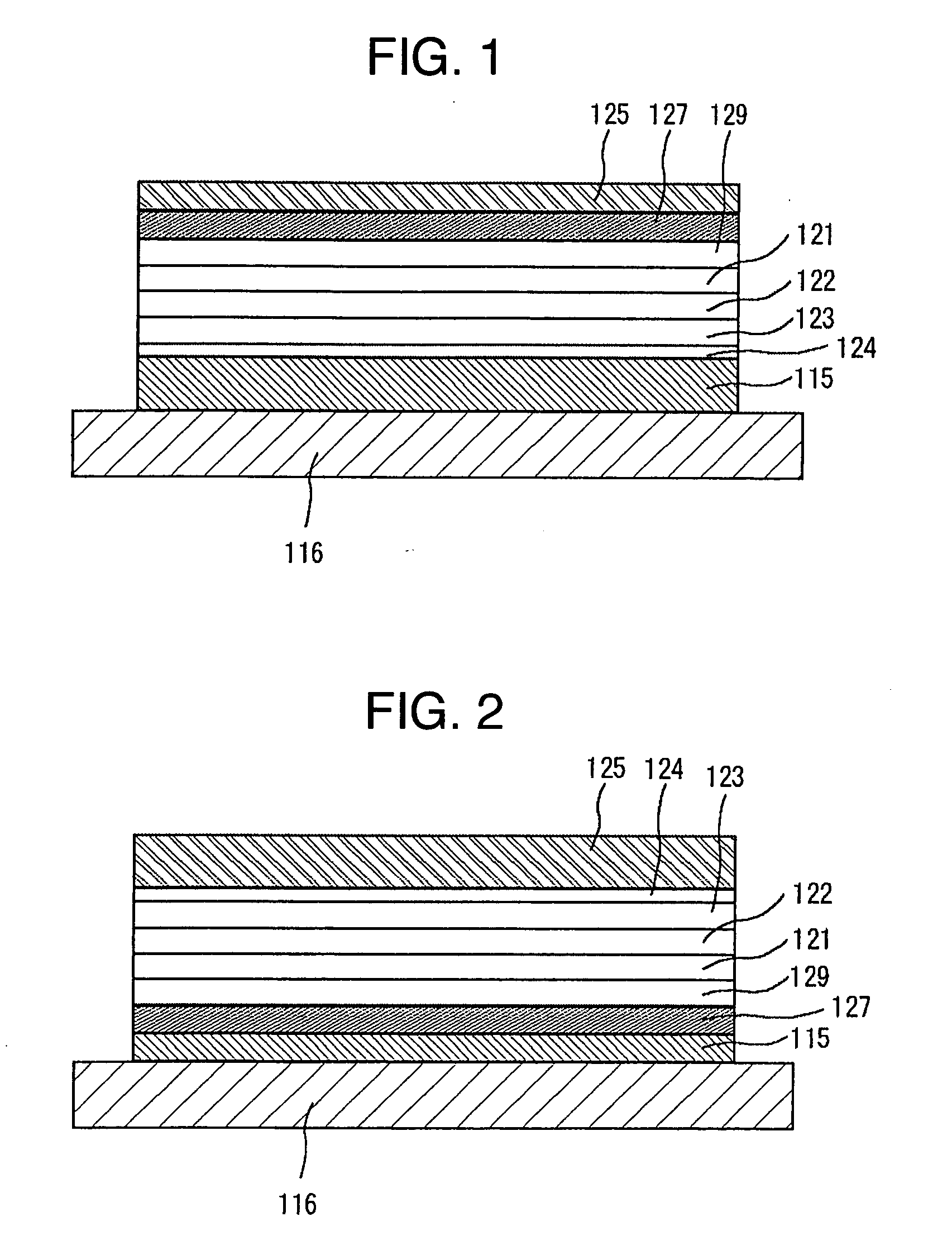

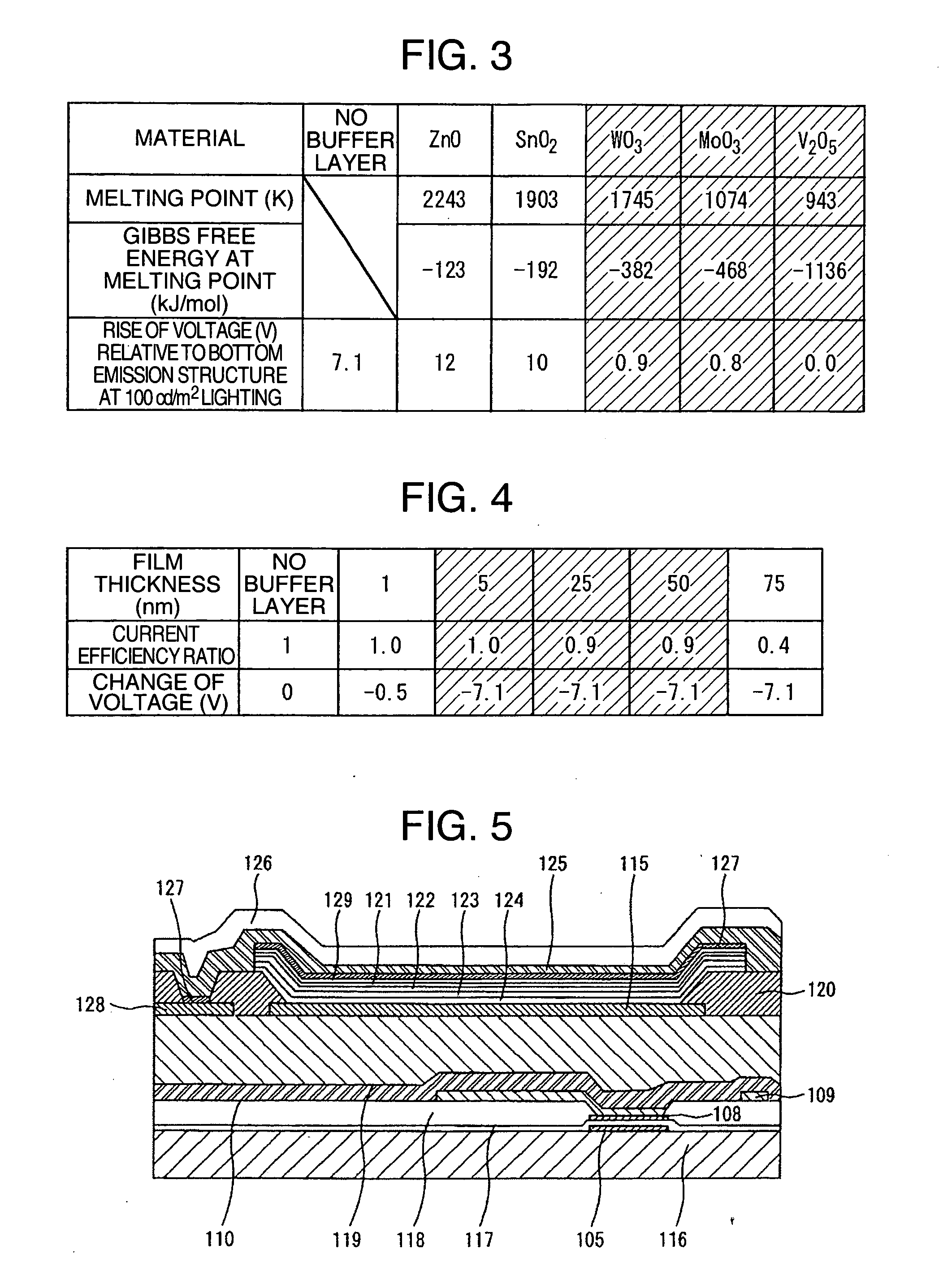

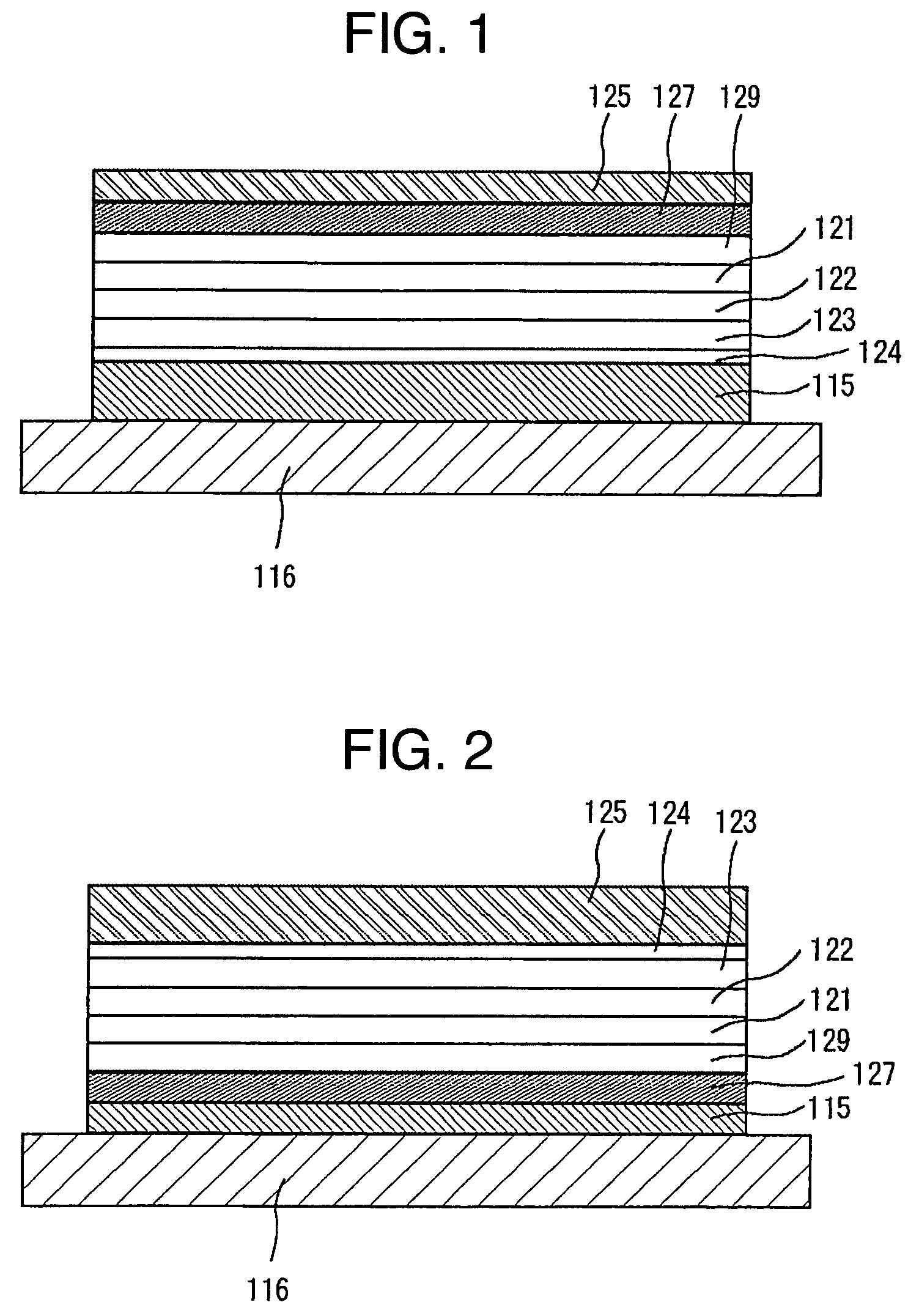

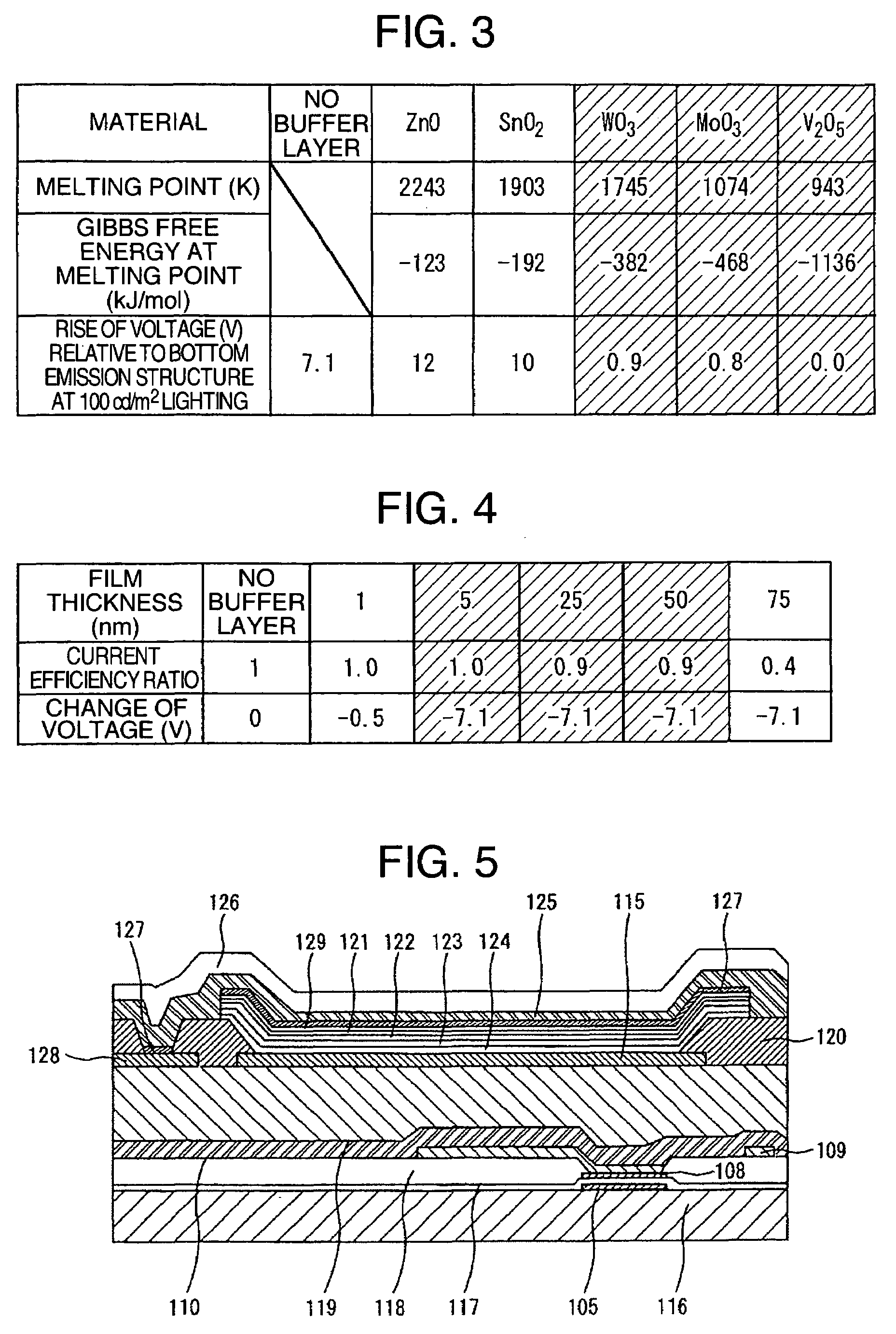

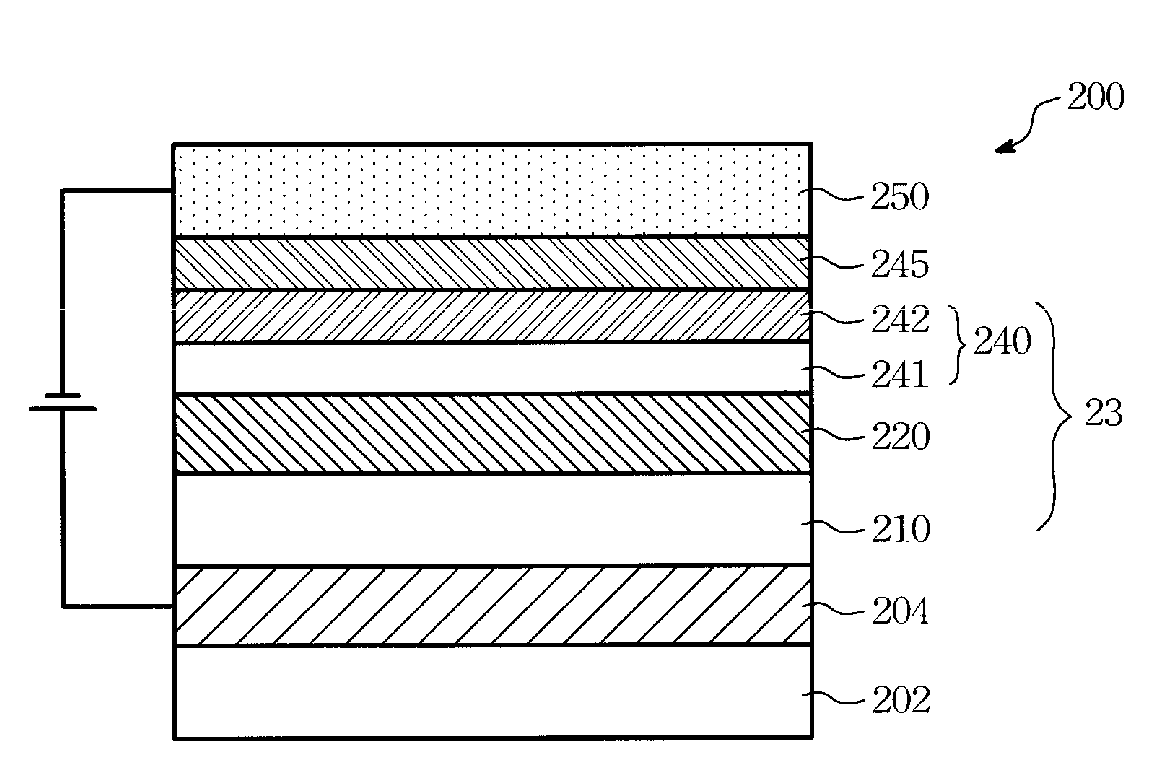

ActiveUS20050212003A1Reduce voltagePrevent oxidationOther printing matterElectroluminescent light sourcesOrganic filmDecomposition

The present invention provides a top emission type organic light-emitting display device in a production of which it is possible to prevent the organic film from being oxidized when the upper transparent electrode is formed, and which is capable of emitting light at a low voltage. This organic light-emitting display device contains an organic light-emitting layer and an upper electrode and a lower electrode sandwiching the organic light-emitting layer, and is of a structure in which the emitted light is taken out from the upper electrode side, and a buffer layer mainly made of an oxide producing less oxygen by decomposition in the film-forming process than the upper electrode material is provided between the organic light-emitting layer and the upper electrode.

Owner:SAMSUNG DISPLAY CO LTD +1

Nonvolatile memory device and method of fabricating the same

InactiveUS20080087940A1Improve electron injection efficiencyMinimize misalignmentSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

A nonvolatile memory device, includes a semiconductor substrate having a bottom part, a second vertical part positioned vertically on the bottom part, and a first vertical part having a width smaller than a width of the second vertical part and positioned on the second vertical part to have a boundary step therebetween; a charge trap layer disposed on a lateral surface of the first vertical part and on an upper surface of the boundary step; and a control gate electrode disposed on an upper surface of the bottom part and on lateral surfaces of the second vertical part and the charge trap layer.

Owner:SAMSUNG ELECTRONICS CO LTD +1

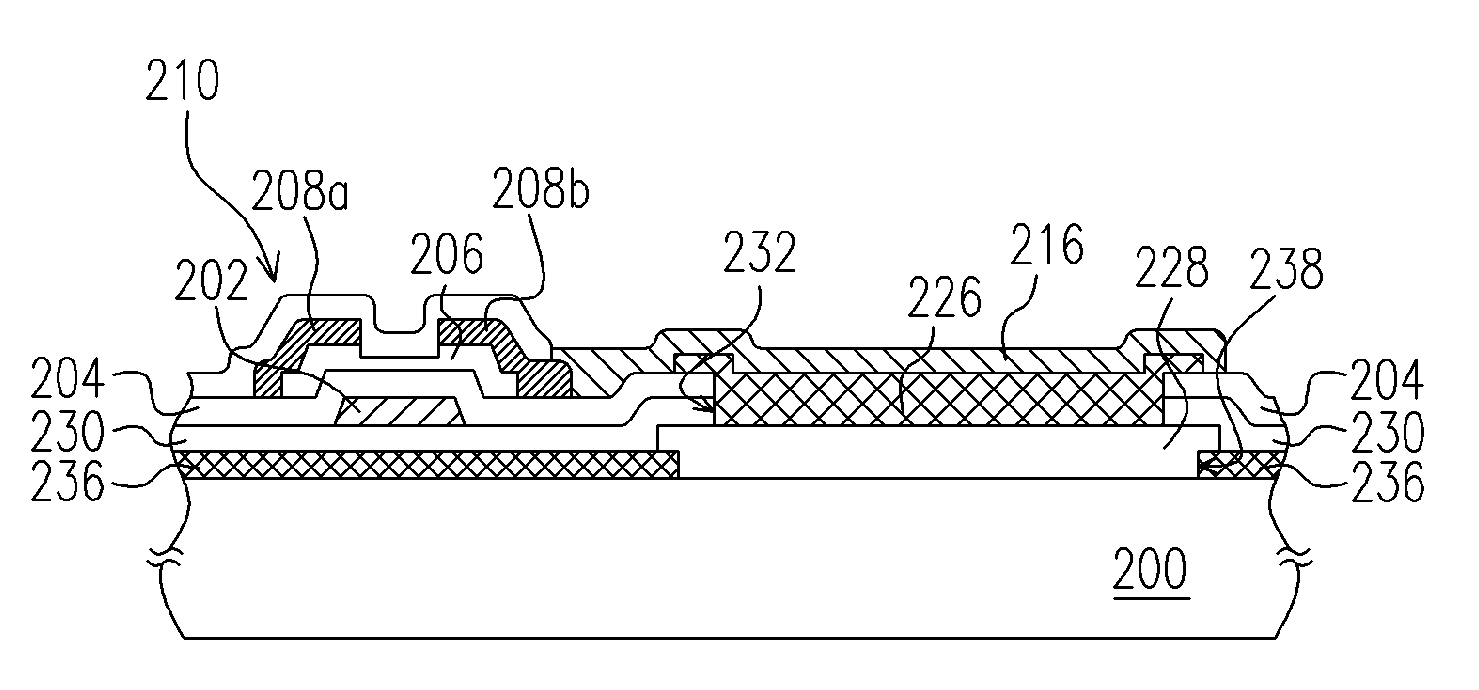

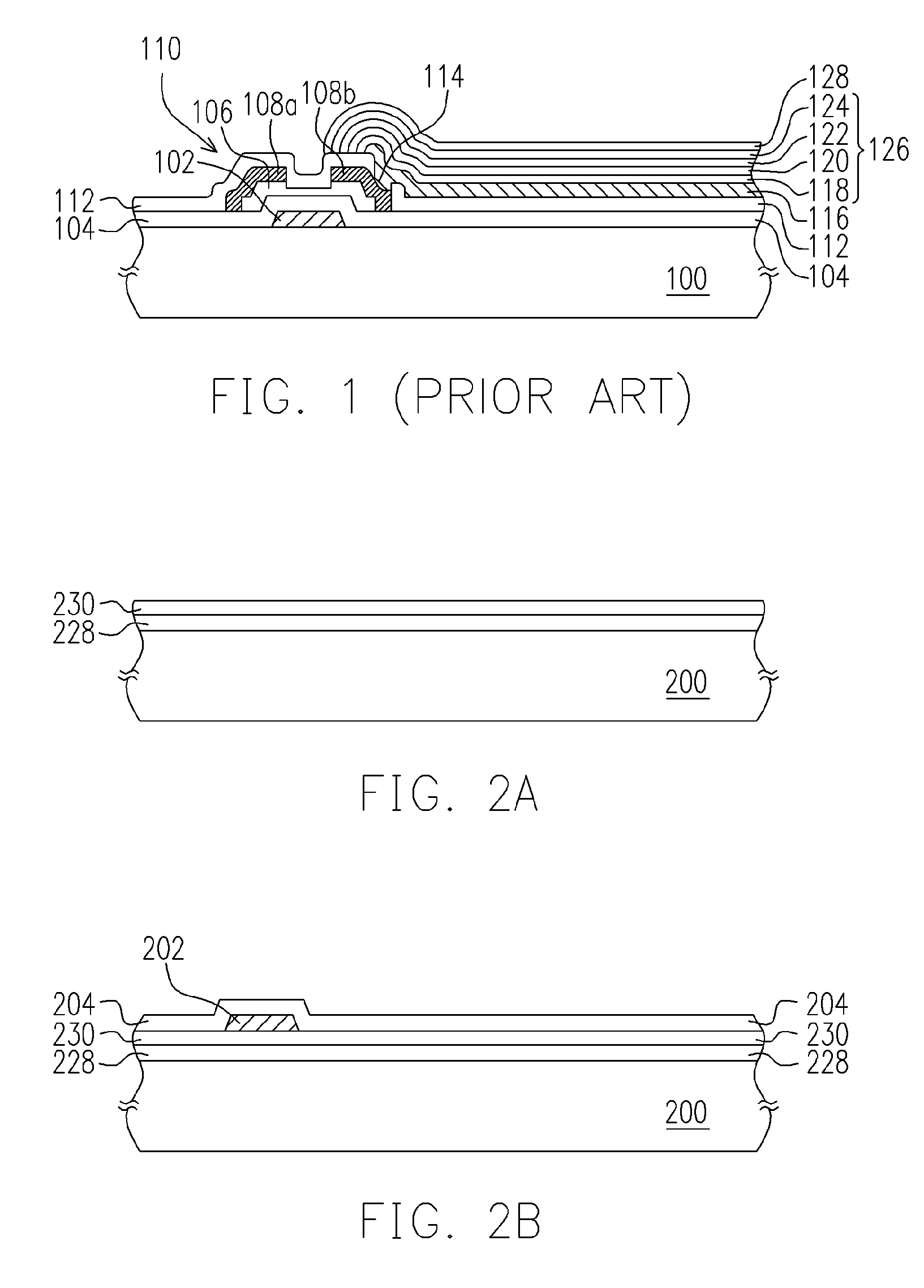

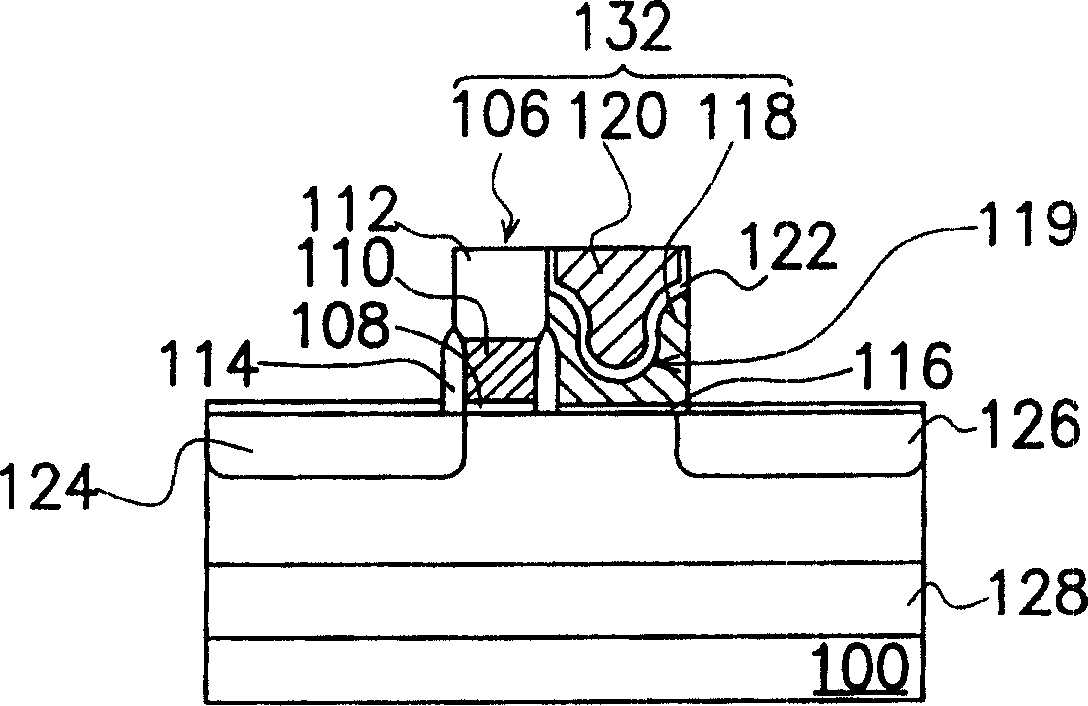

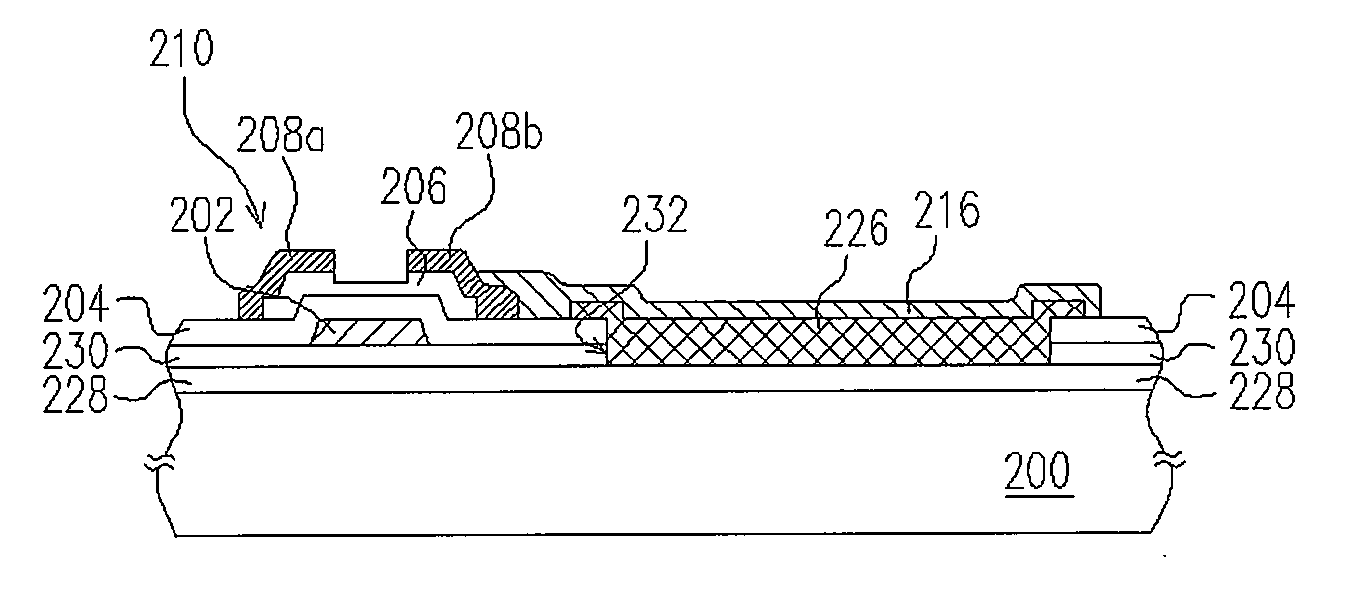

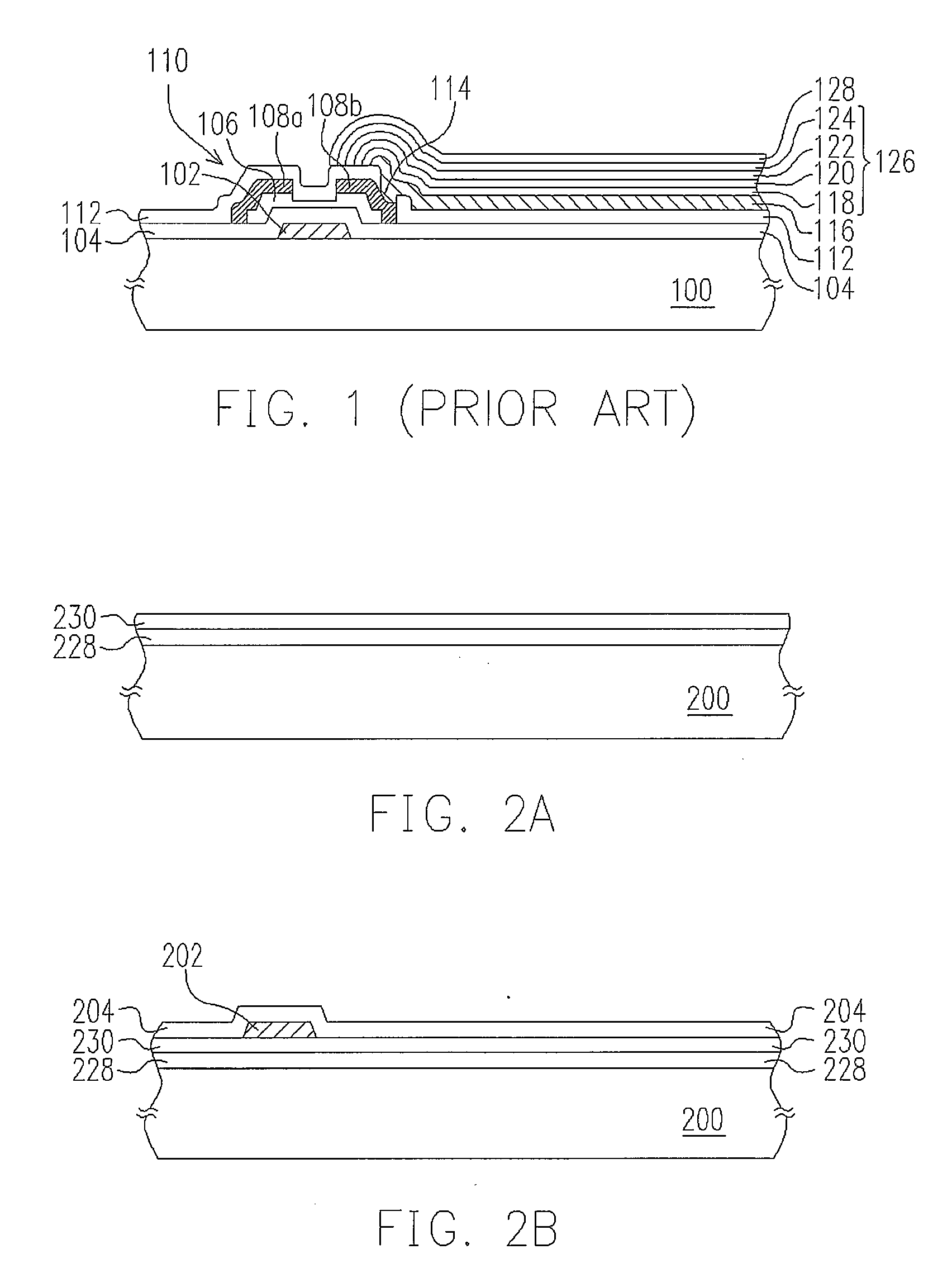

Active-matrix organic electroluminescent display panel and fabricating method thereof

ActiveUS7148622B2Reduce gate voltageImprove stabilityDischarge tube luminescnet screensElectroluminescent light sourcesPhysicsSurface plate

A method for fabricating an active-matrix organic electroluminescent (OEL) display panel is described. A transparent conductive layer is formed on a substrate as a common anode for all organic light emitting diodes (OLED), and a passivation layer is formed on the transparent conductive layer. Thin film transistors are formed on the passivation layer to serve as an active matrix, and openings are formed in the passivation layer to expose portions of the transparent conductive layer and define pixel regions. An organic function layer is formed in each opening, and a metal electrode layer is formed on each organic function layer, wherein the metal electrode layer is electrically connected with the drain of the corresponding thin film transistor.

Owner:AU OPTRONICS CORP

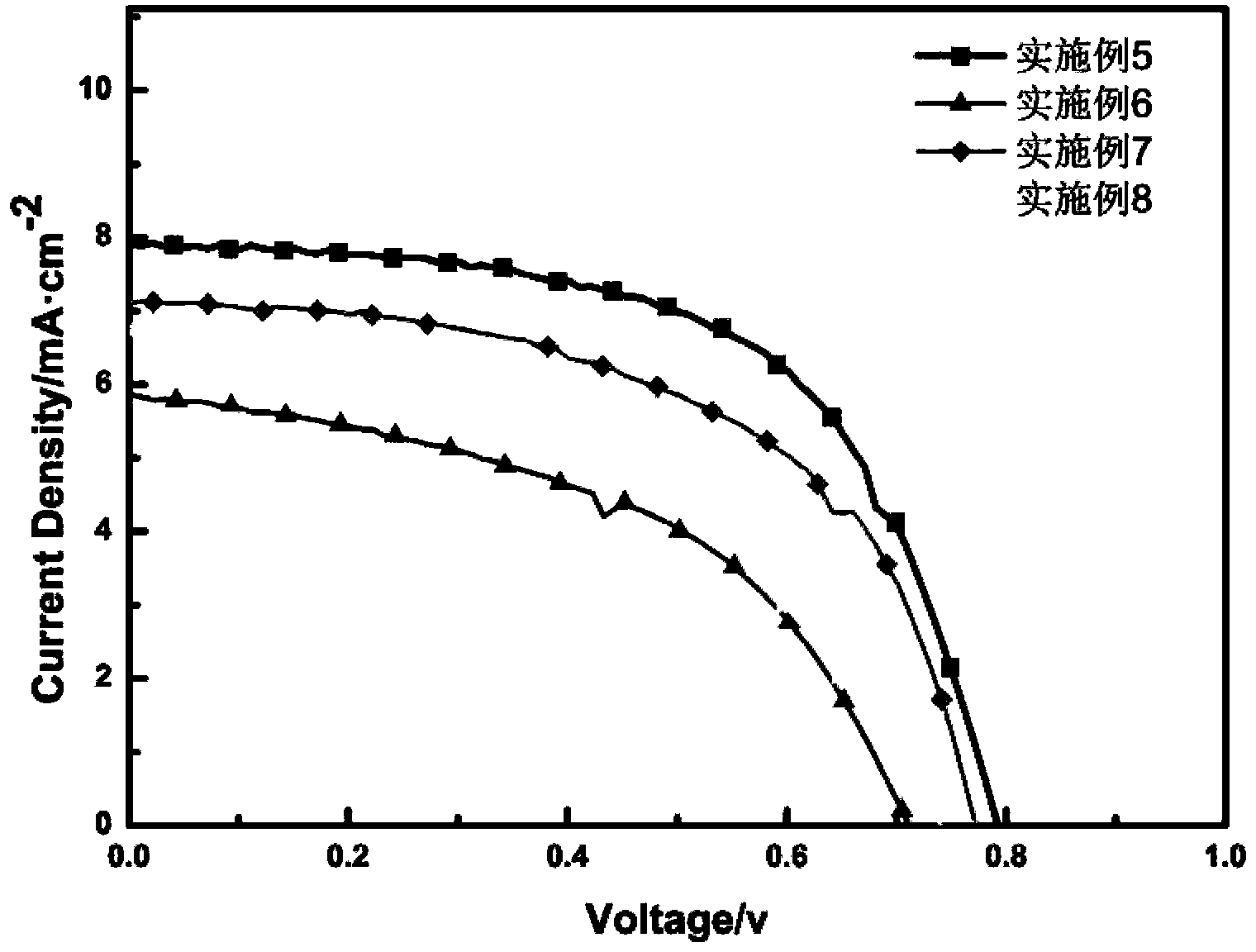

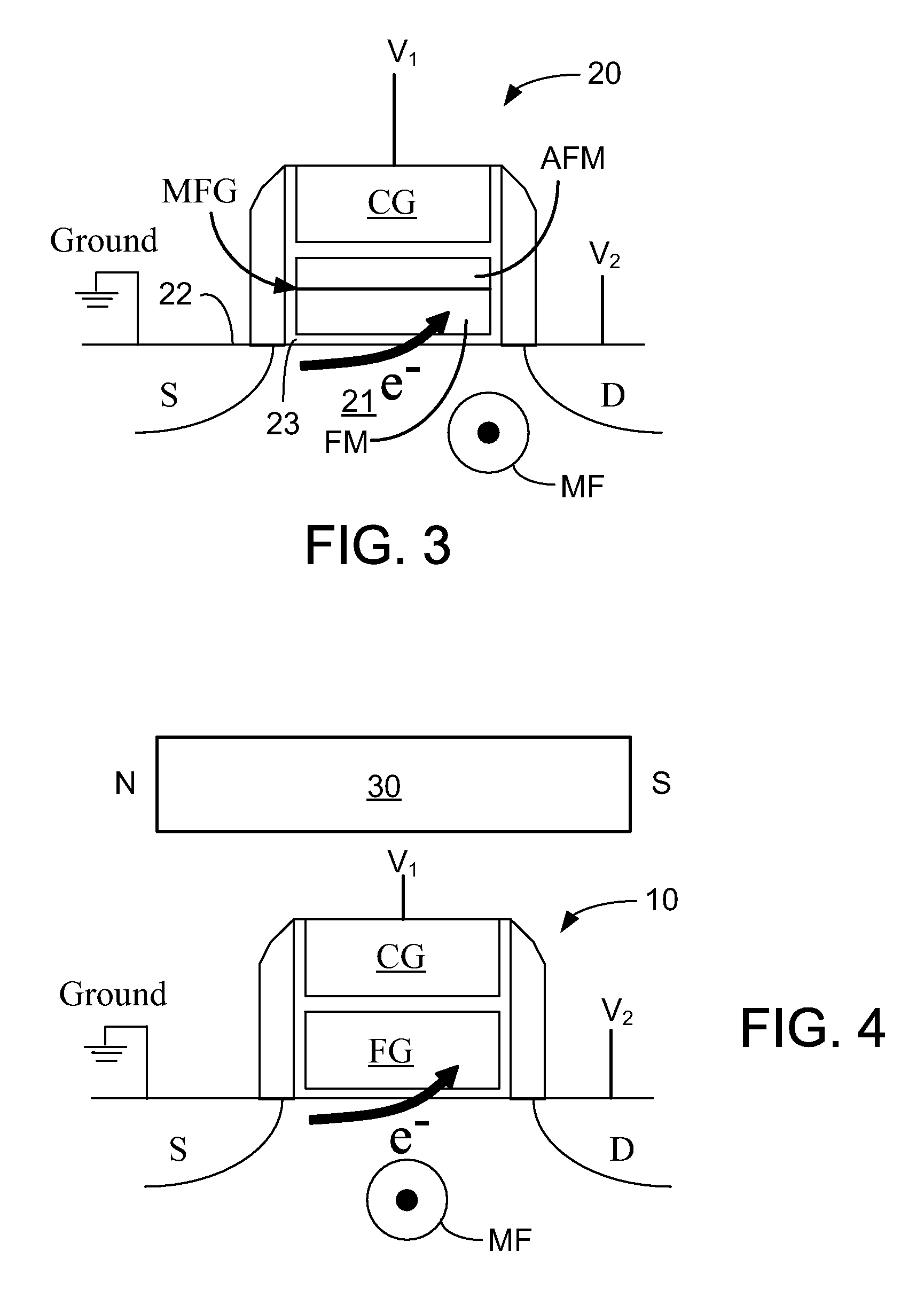

All-solid-state sensitized solar cell and preparation method thereof

InactiveCN104347275APrevent charge recombinationImprove electron injection efficiencyLight-sensitive devicesPhotovoltaic energy generationDye-sensitized solar cellTitanium dioxide

The invention discloses an all-solid-state sensitized solar cell and a preparation method thereof. The all-solid-state sensitized solar cell sequentially comprises a photo anode, an interface modification layer, a hole transport layer and a counter electrode from bottom to top, wherein the photo anode sequentially comprises a conductive glass layer, a dense film layer, a porous film layer and a sensitizer layer form bottom to top, and the dense film layer and the porous film layer are both made from titanium dioxide; the sensitizer layer is made from CH3NH3PbI3; the inference modification layer is made from aluminum oxide or magnesium oxide; the hole transport layer is made from spiro-MeOTAD or PTAA; the counter electrode is an Au electrode. The preparation method comprises the steps of during a process of preparing the solar cell, enabling a thin film to be immersed in polymeric precursor solution of the aluminum oxide after the sensitizer layer is prepared and before the spin-coating of a hole transport material is carried out, and obtaining an aluminum oxide interface modification material after natural drying, wherein the charge recombination can be prevented by the interface modification material, and the electron injection efficiency can be increased. According to the all-solid-state sensitized solar cell and the preparation method, disclosed by the invention, the cost is low, the photoelectric conversion efficiency of an all-solid-state dye-sensitized solar cell can be obviously increased, and a great significance is obtained for practical application of the all-solid-state dye-sensitized solar cell.

Owner:TSINGHUA UNIV

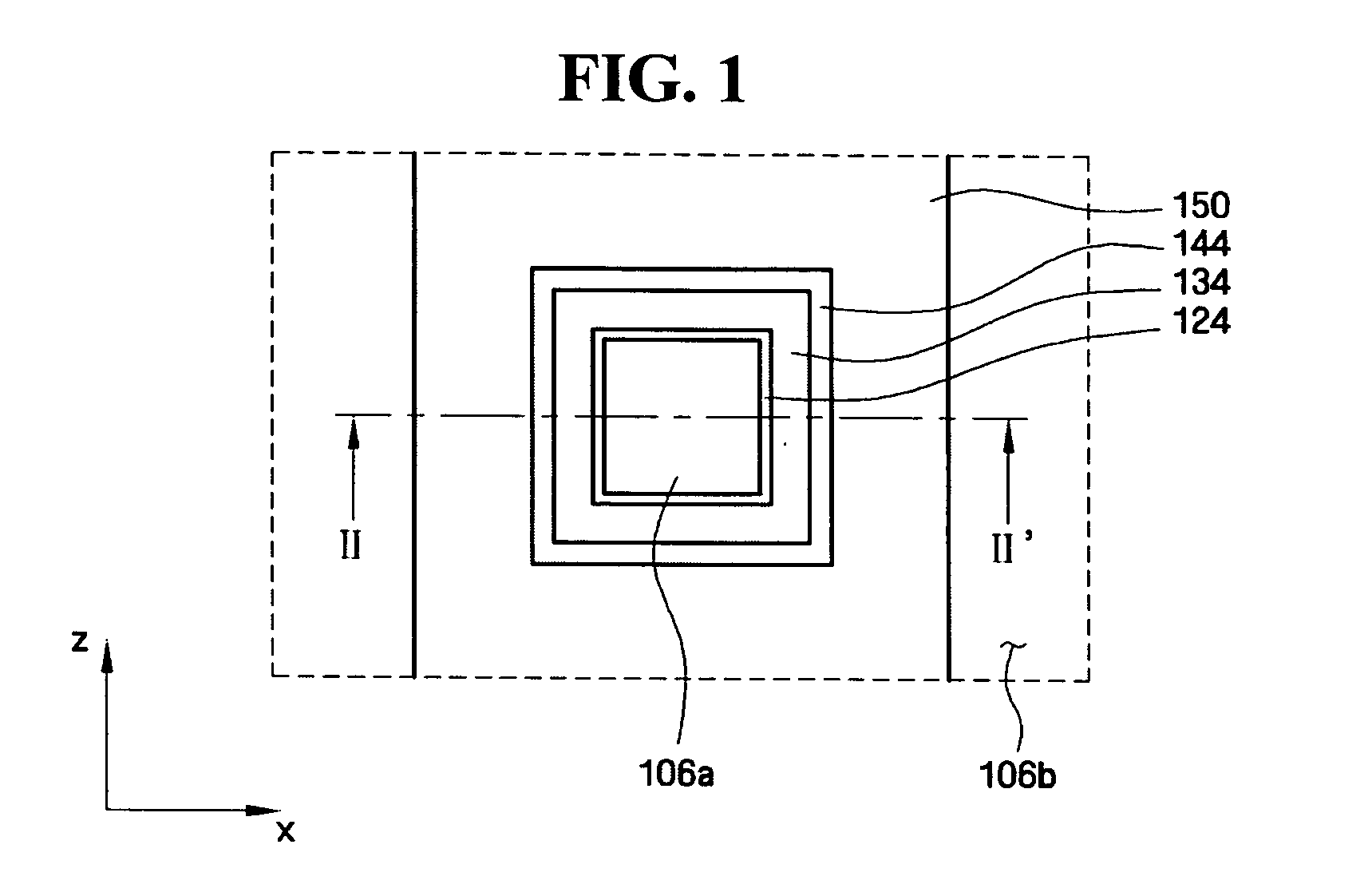

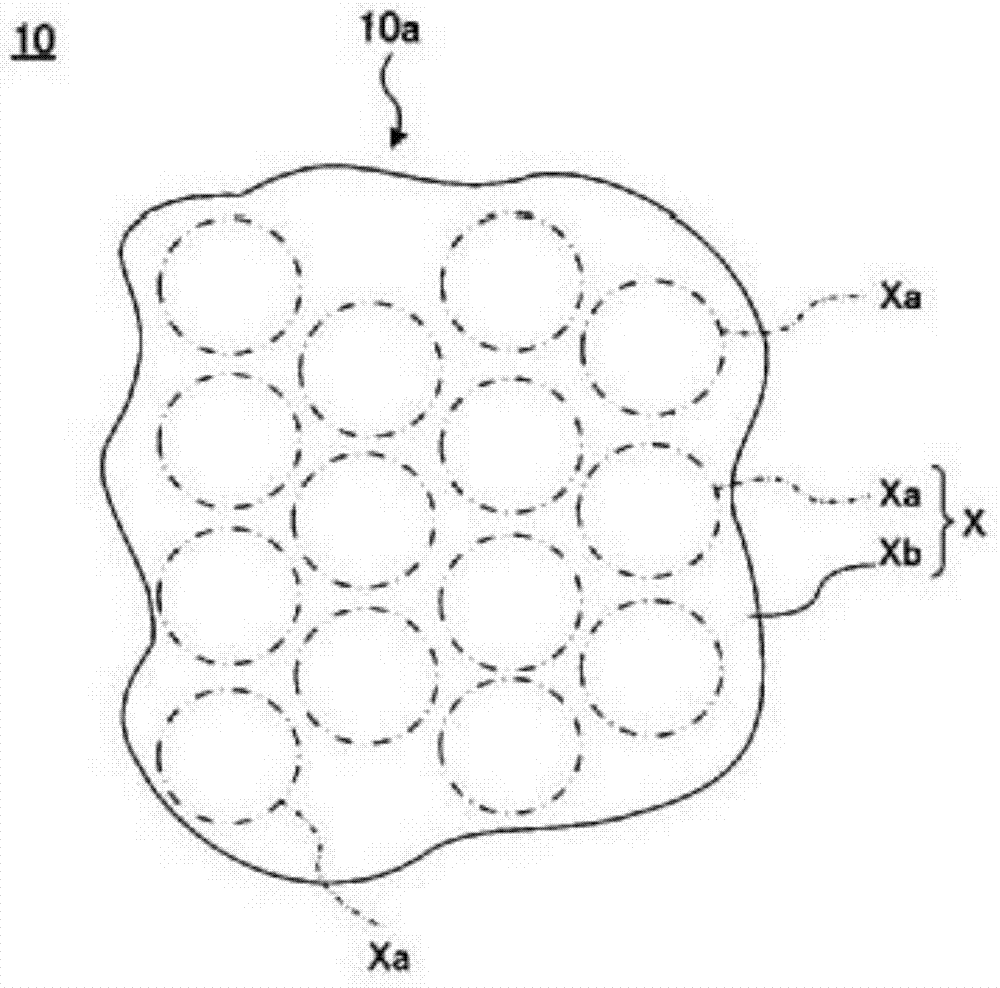

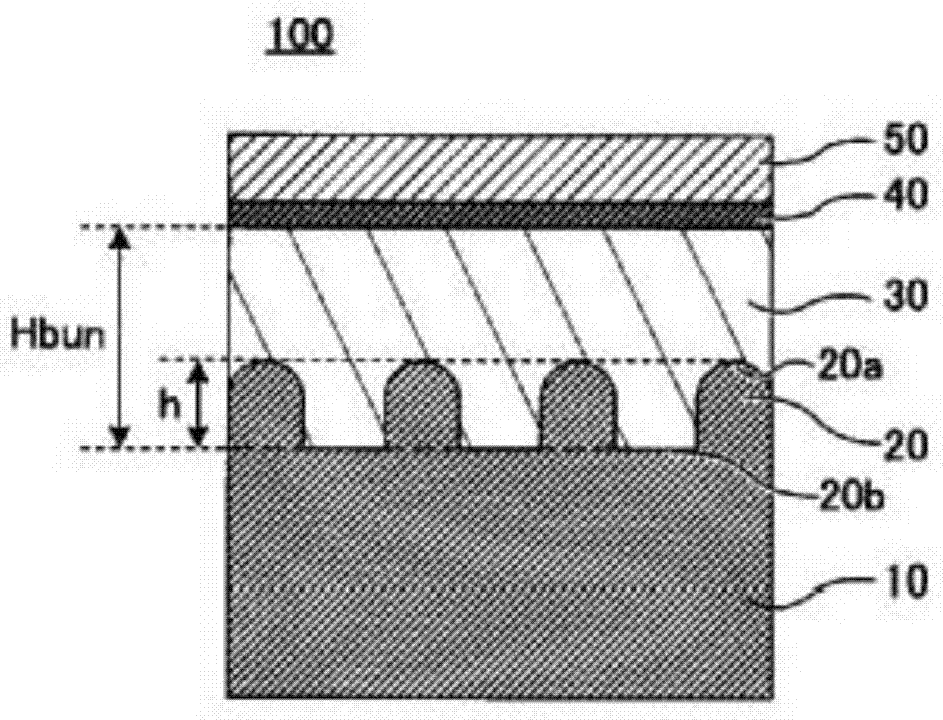

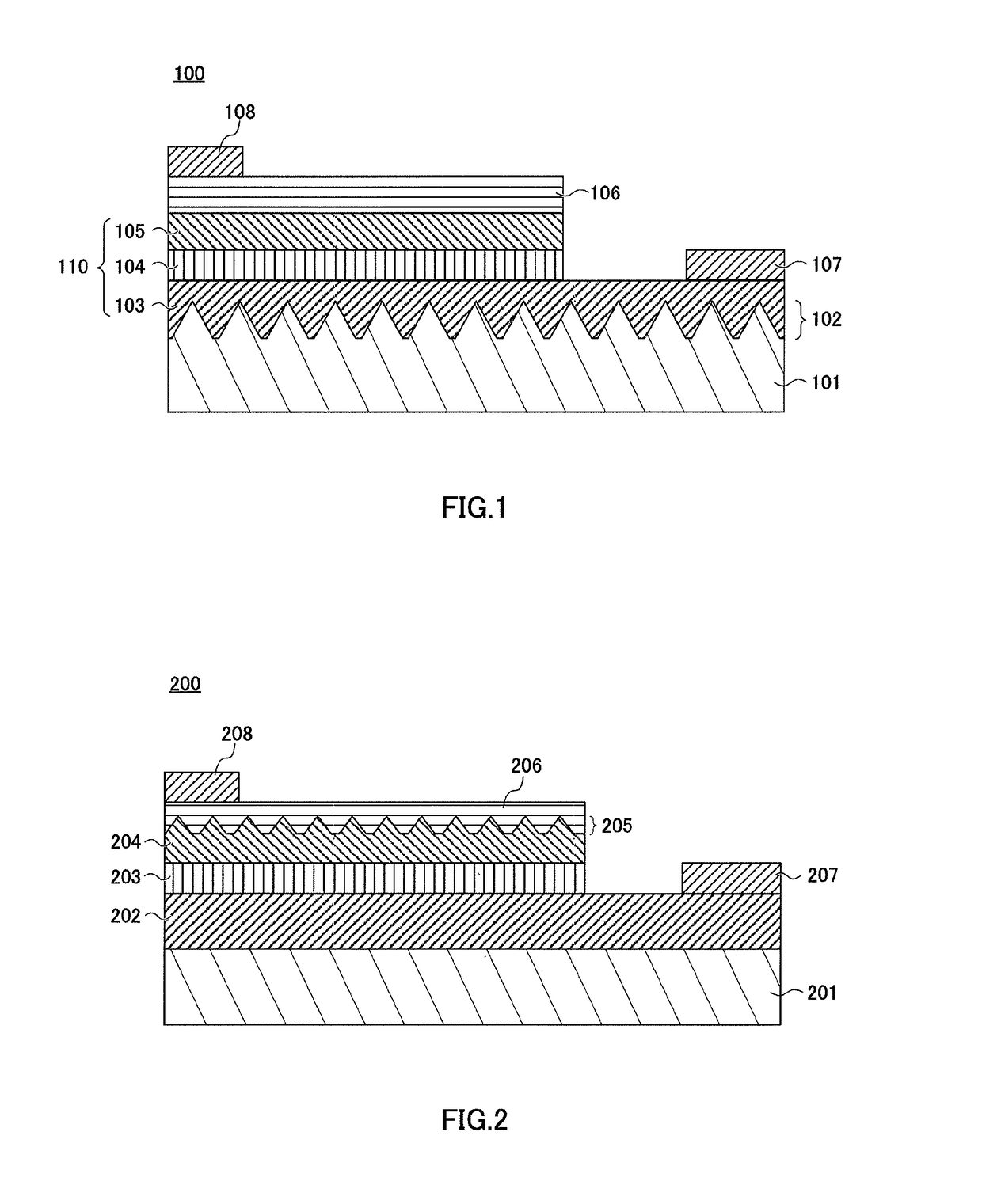

Optical substrate, semiconductor light-emitting element, and manufacturing method for same

InactiveCN104781941AImprove internal quantum efficiencyInternal Quantum Efficiency IQE ImprovementSemiconductor/solid-state device testing/measurementSemiconductor devicesQuantum efficiencyMicroscopic image

An optical substrate PP (10) includes a substrate body and a recess / bump structure (20) formed of a plurality of bumps (20a) provided on the main surface of the substrate body. Markings (X) that can be observed with an optical microscope are formed on the main surface. The interval between the markings is larger than the pitch of the recess / bump structure (20). The markings (X) can be recognized as first areas (Xa) and a second area (Xb) by a difference in brightness in an optical microscopic image of the markings (X). A plurality of first areas (Xa) are arranged at intervals, and the second area (Xb) exists among the first areas (Xa). According to the present invention, the improvement of the internal quantum efficiency (IQE) and the improvement of the light extraction efficiency (LEE) of semiconductor light-emitting elements, which have been said to be a trade-off, are achieved at the same time.

Owner:ASAHI KASEI KK

Method of manufacturing organic light emitting device and vapor deposition system

InactiveUS20070134405A1Improve electron injection efficiencyReduce voltageVacuum evaporation coatingSolid-state devicesDopantSimple Organic Compounds

Provided is a method of manufacturing an organic light emitting device including the step of forming an electron injection layer. The step of forming the electron injection layer includes the steps of: vaporizing in a container a dopant material as a raw material of a dopant; causing the vaporized dopant material to pass a heated medium between the container and the substrate; and forming the organic compound into the electron injection layer. According to the method the organic light emitting device which has high electron injection efficiency and can be driven at a low voltage can be obtained.

Owner:CANON KK

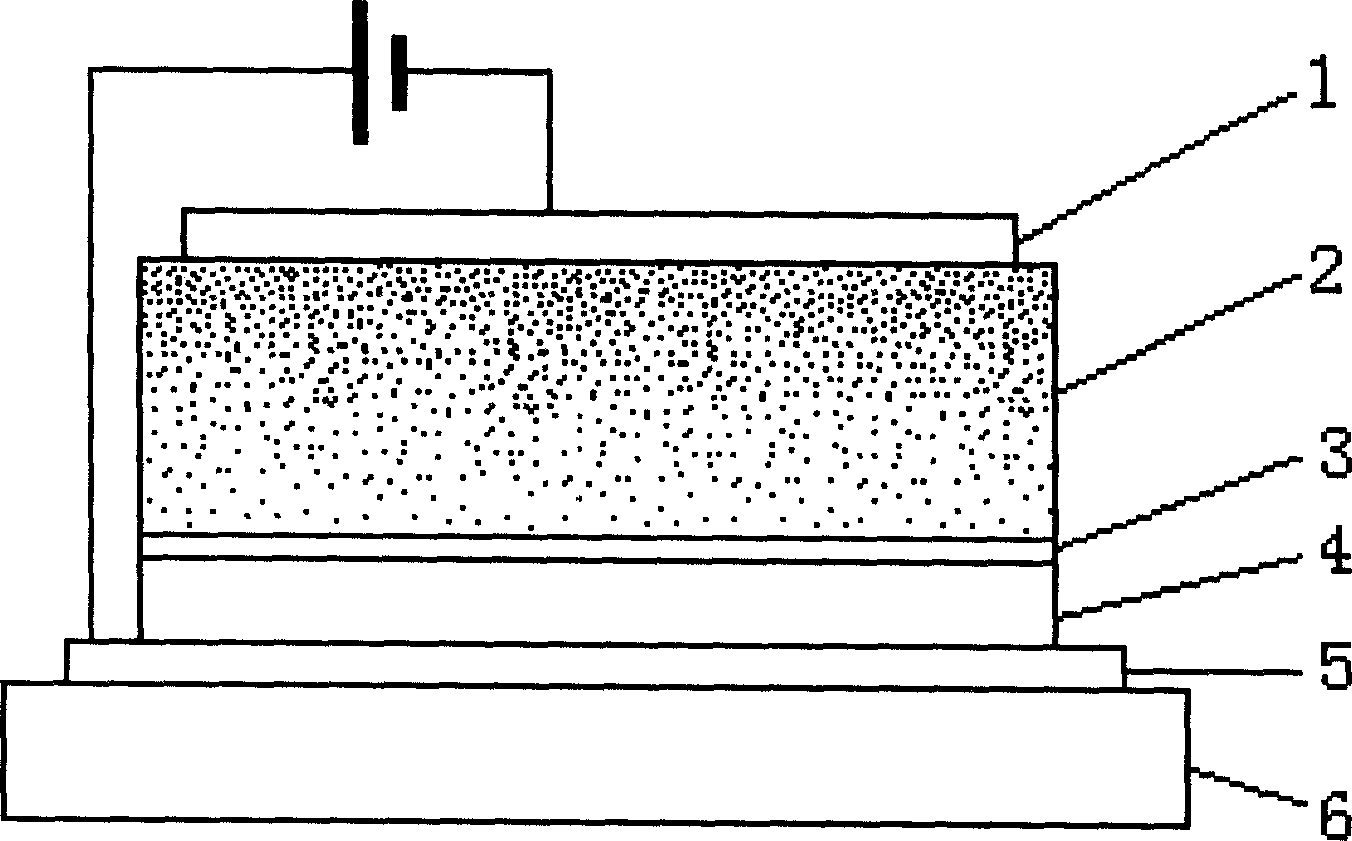

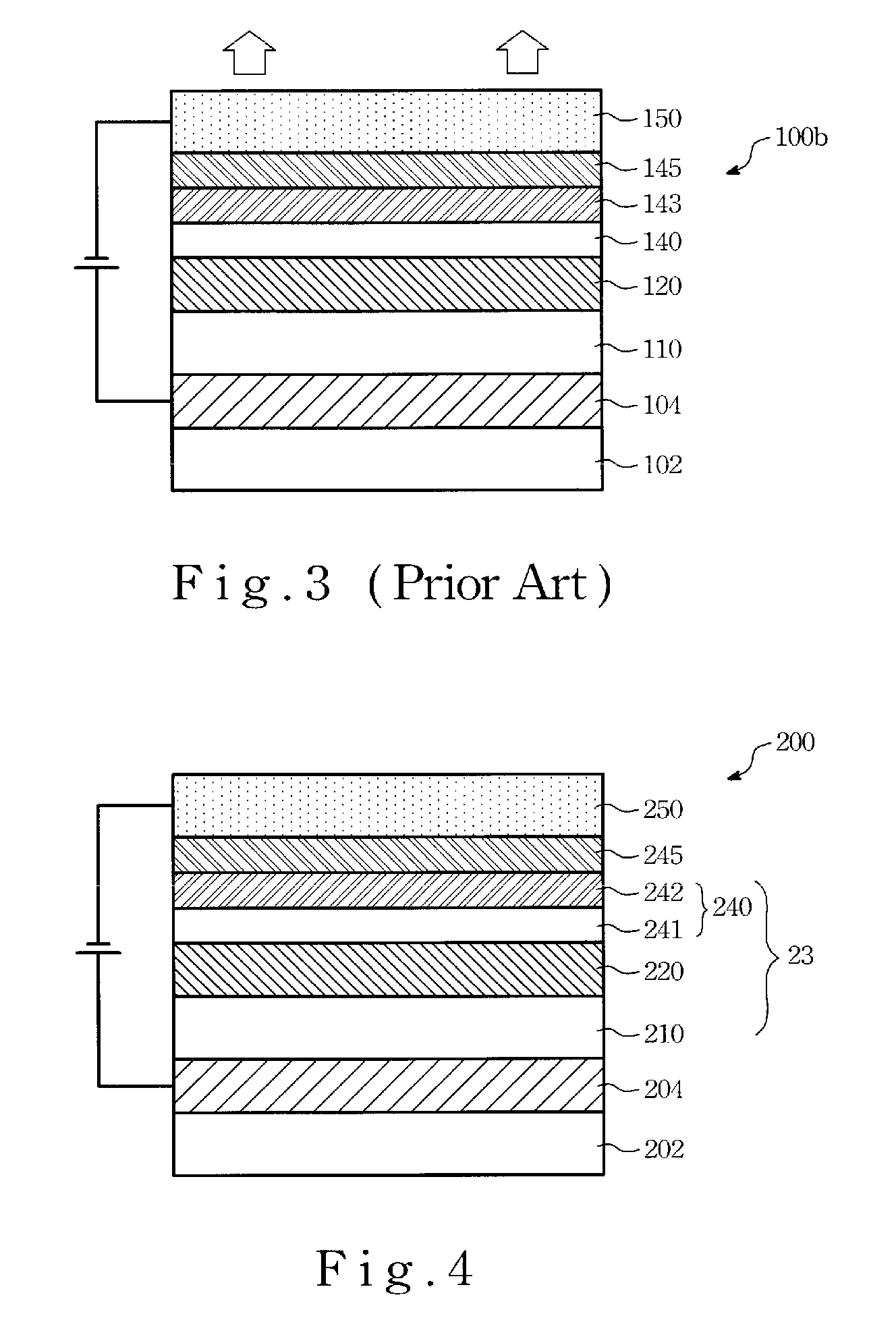

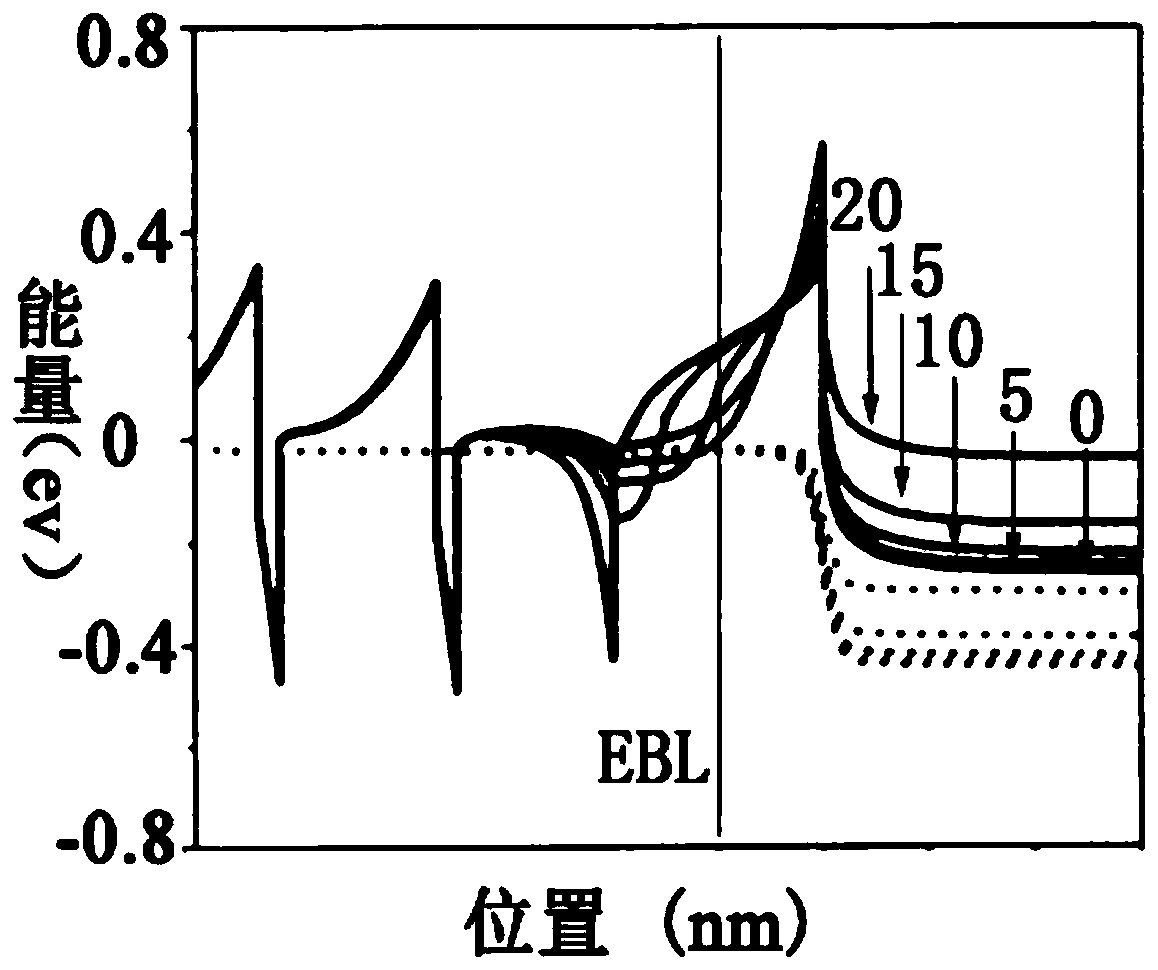

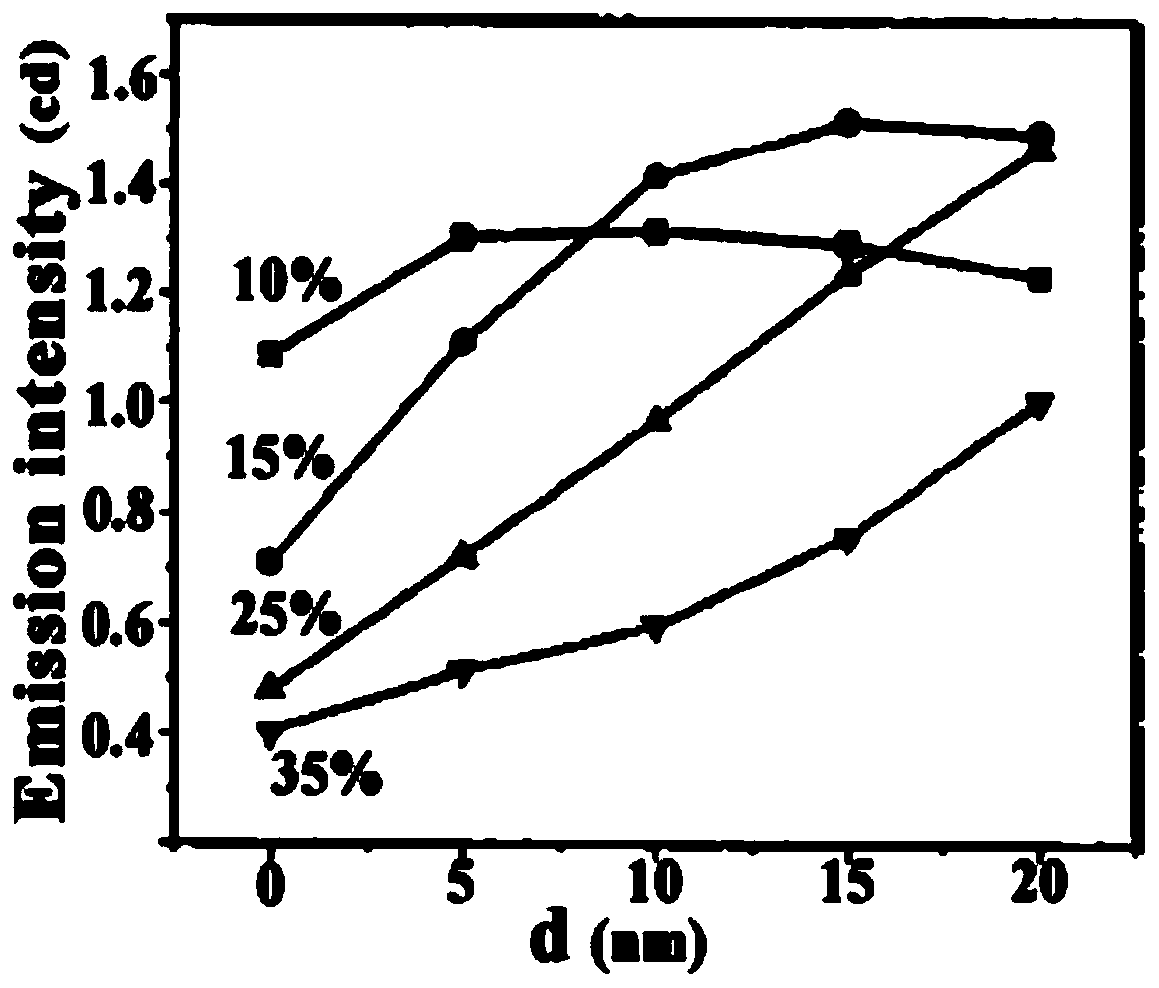

Inorganic salt blended organic electroluminescence light emitting display device

InactiveCN1822409AImprove electron injection efficiencyIncrease chanceElectroluminescent light sourcesSolid-state devicesOrganic electroluminescenceInorganic salts

An inorganic salt doping type organic electroluminescent display device includes glass substrate, ITO conducting layer in turn set on glass substrate upper surface, hole transmission layer, lower luminescent layer, upper luminescent layer and metallic cathode, wherein ITO metallic cathode and metallic cathode respectively connected with dc voltage positive and negative electrode, upper luminescent layer doped with inorganic salt material, the maximal doped proportion of inorganic salt material and luminescent material less than 80 per cent down descending according to 2 per cent / nano doping gradient. Present invention leads inorganic salt in luminescent layer of organic electroluminescence device, solving low carrier mobility problem, raising electron injection efficiency, greatly increasing electronic and hole compound luminous probability, improving OLED device luminous efficiency, luminescence brightness and service life, saving cost and reducing technology hardness.

Owner:SHAANXI UNIV OF SCI & TECH

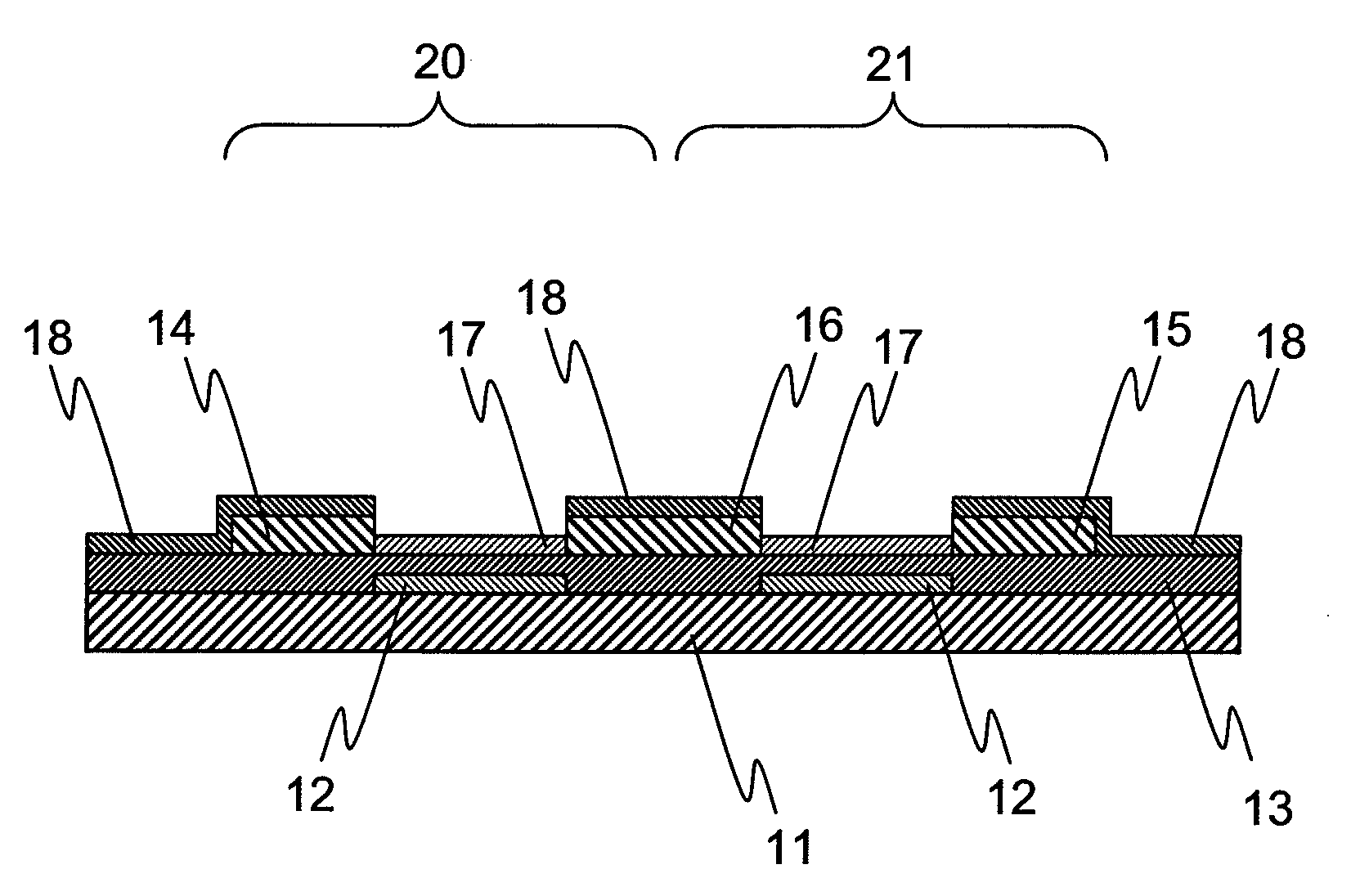

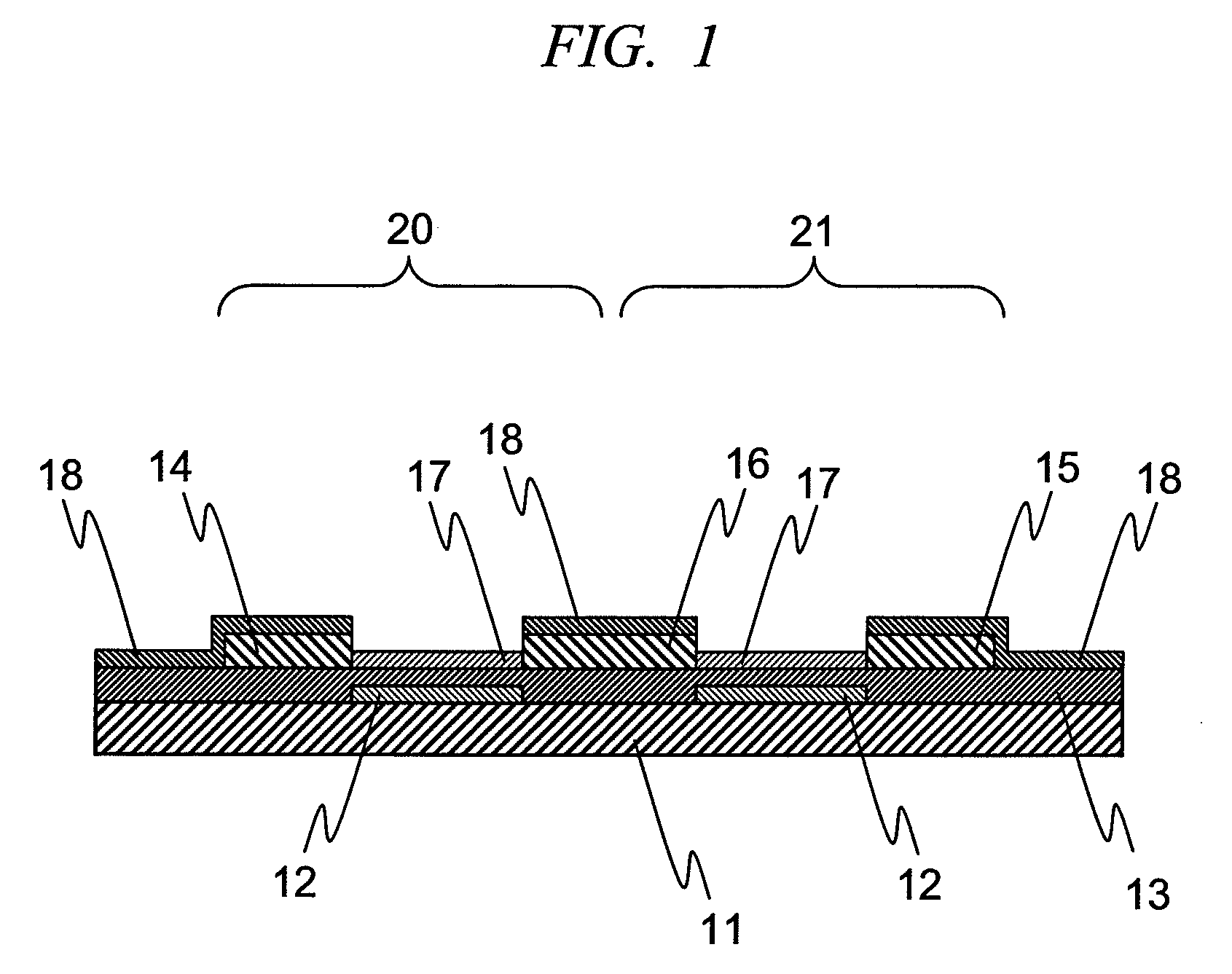

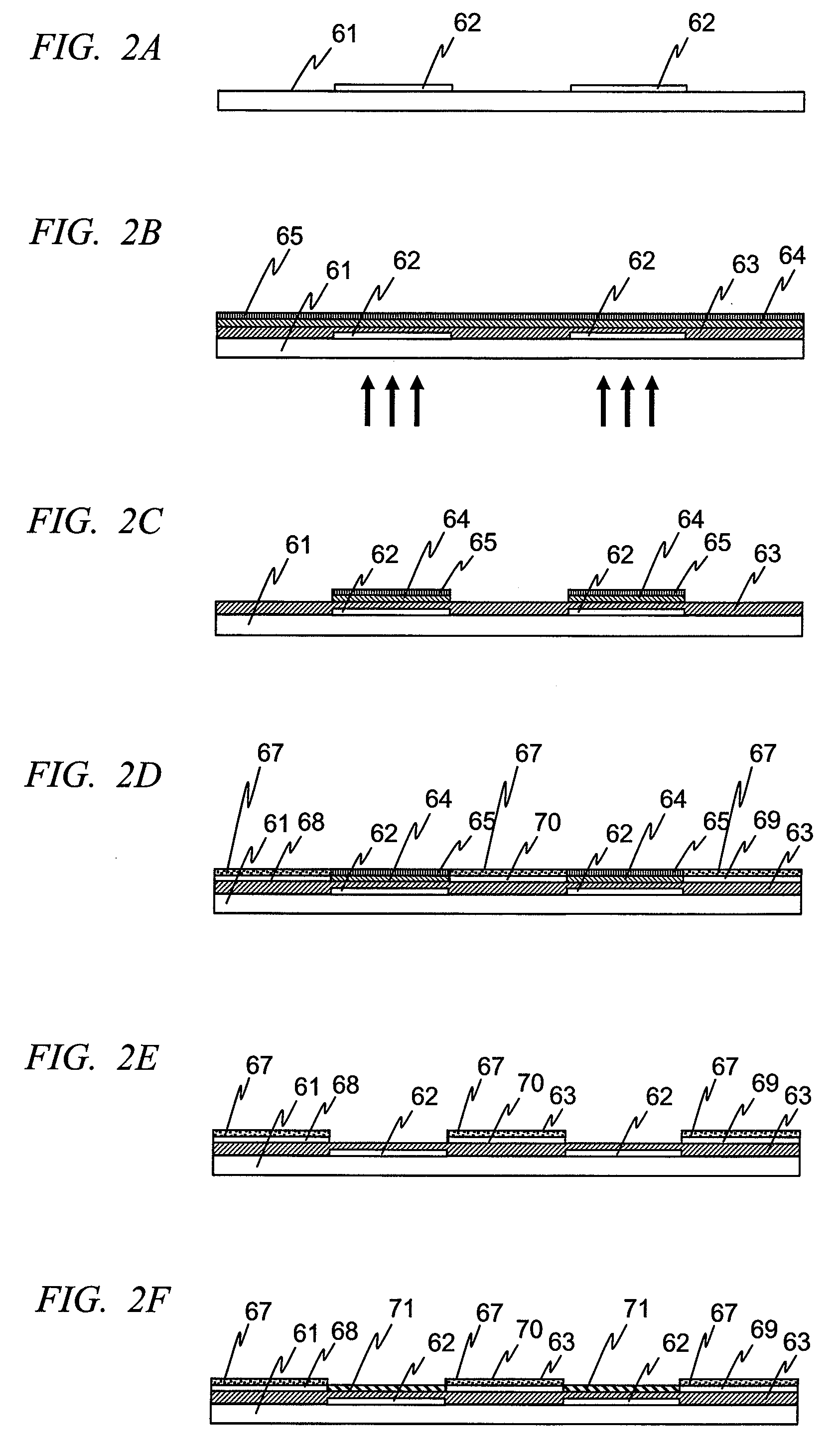

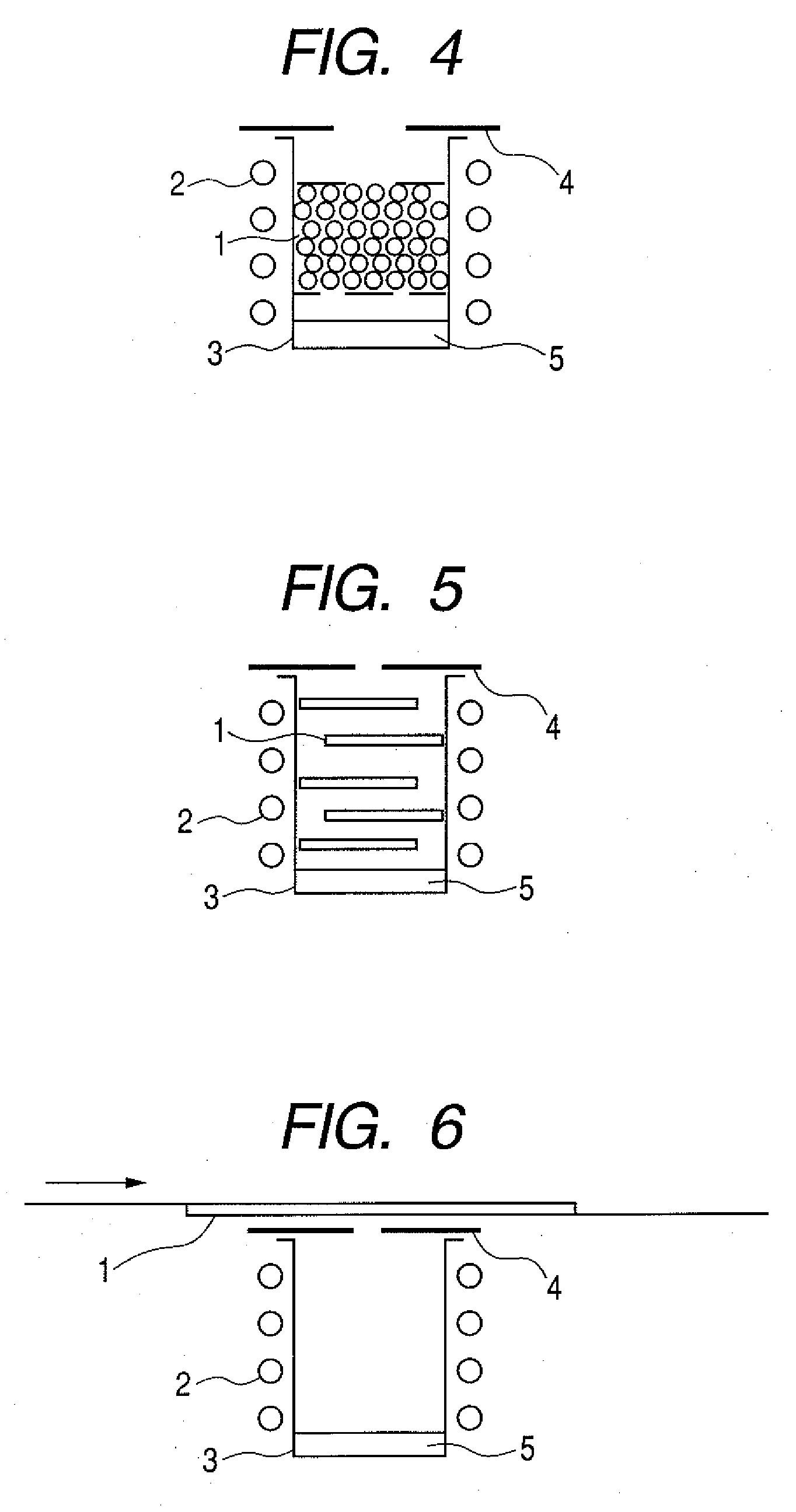

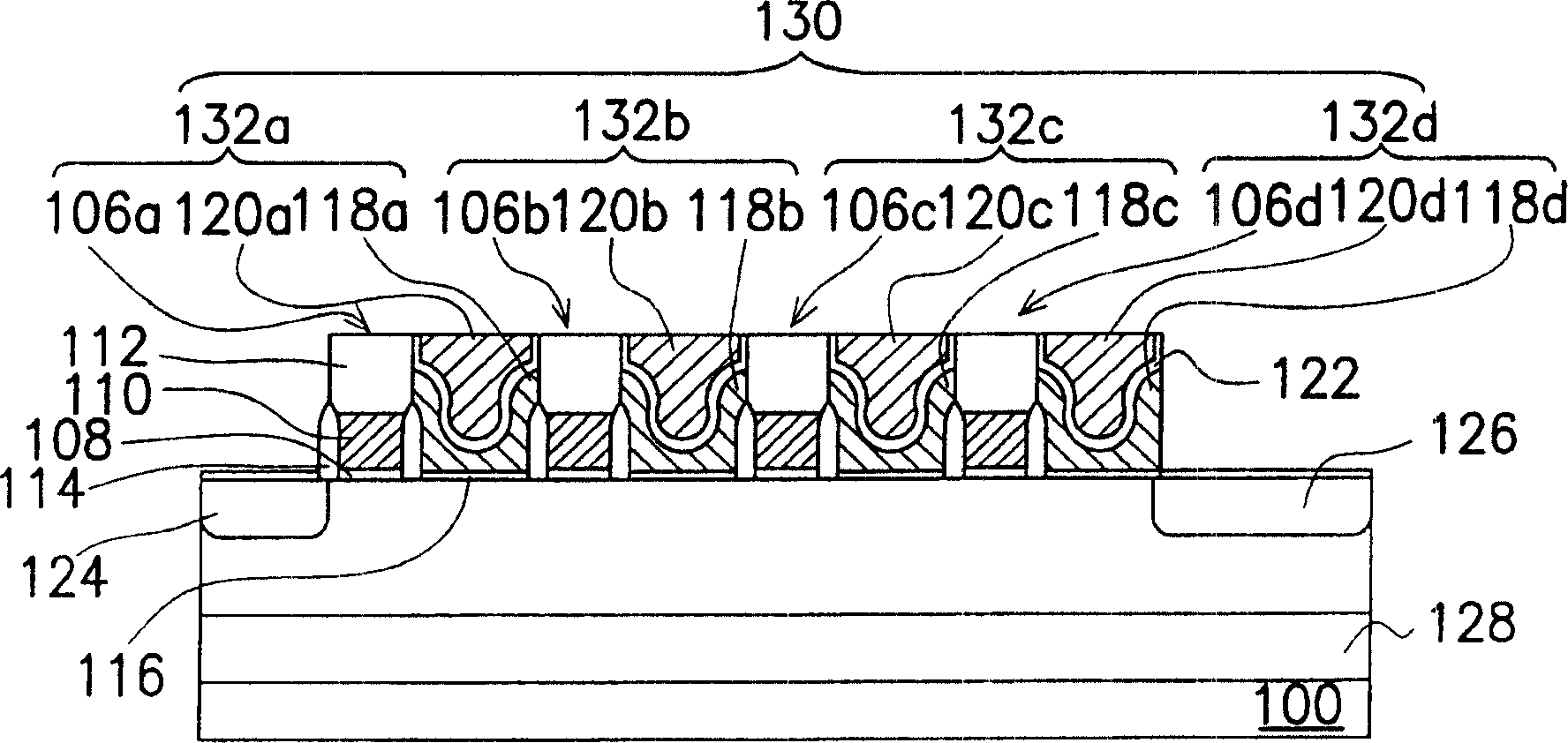

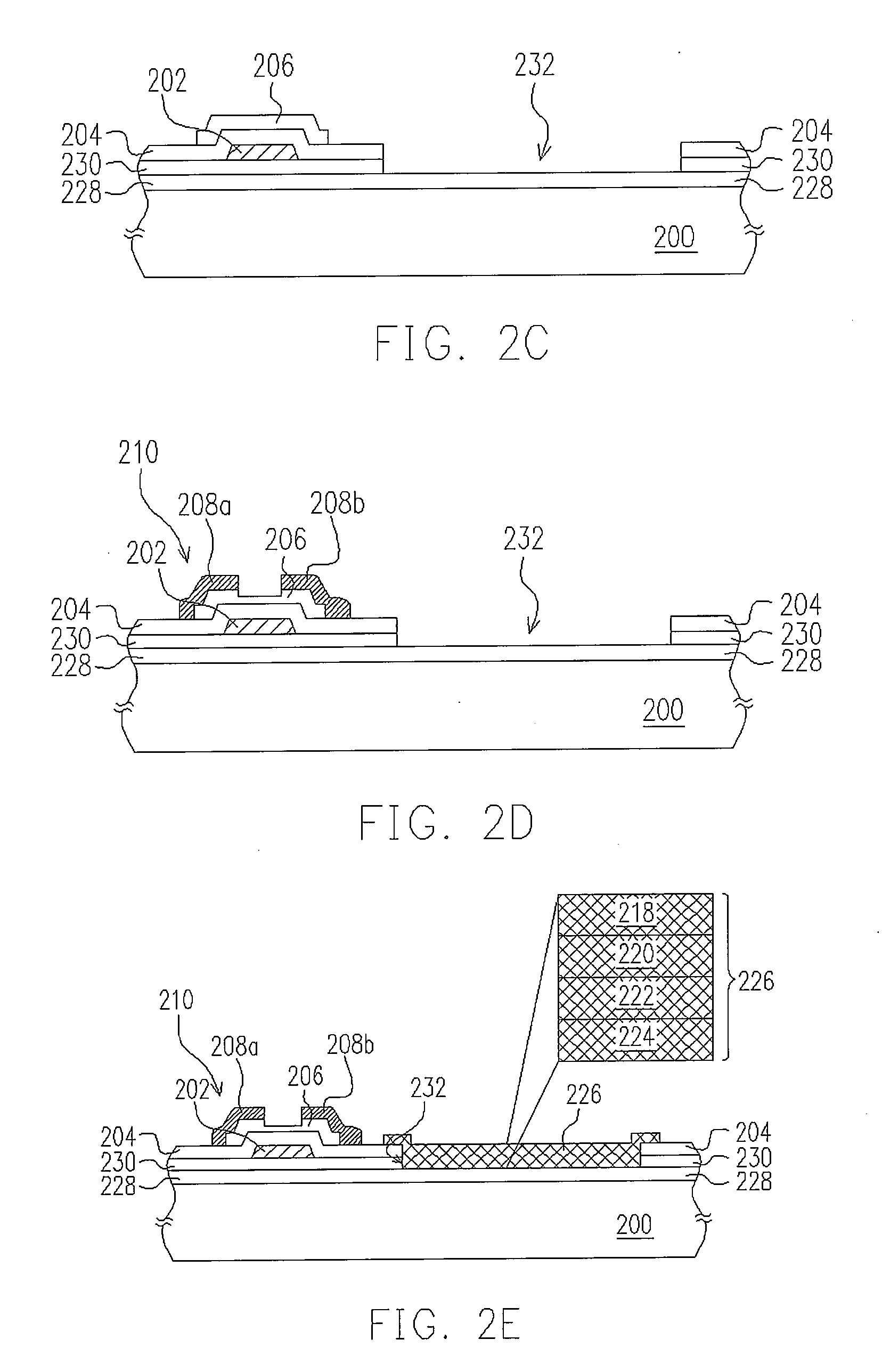

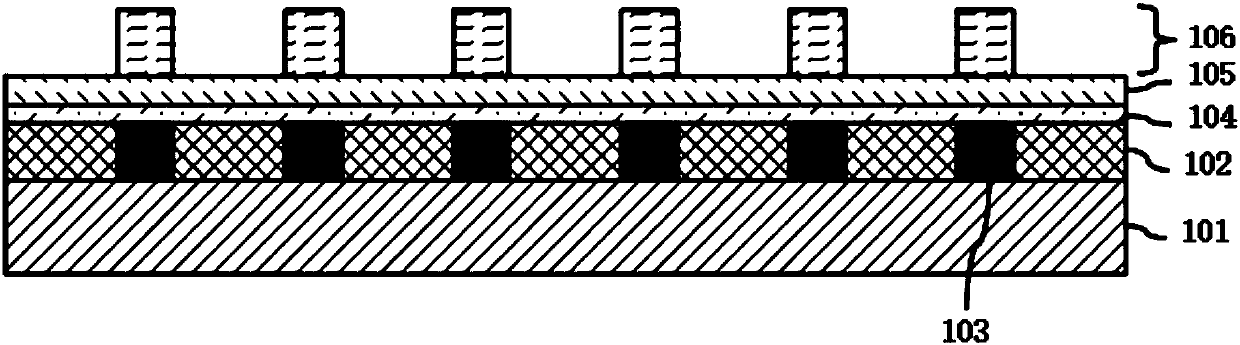

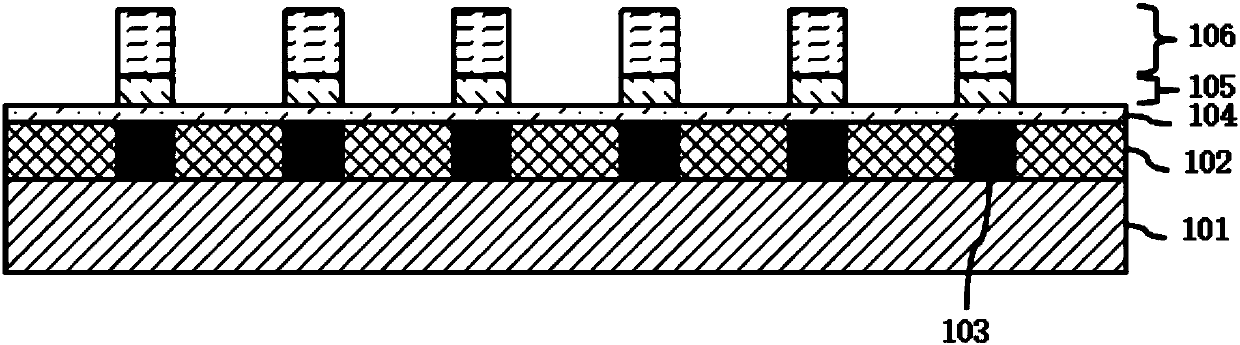

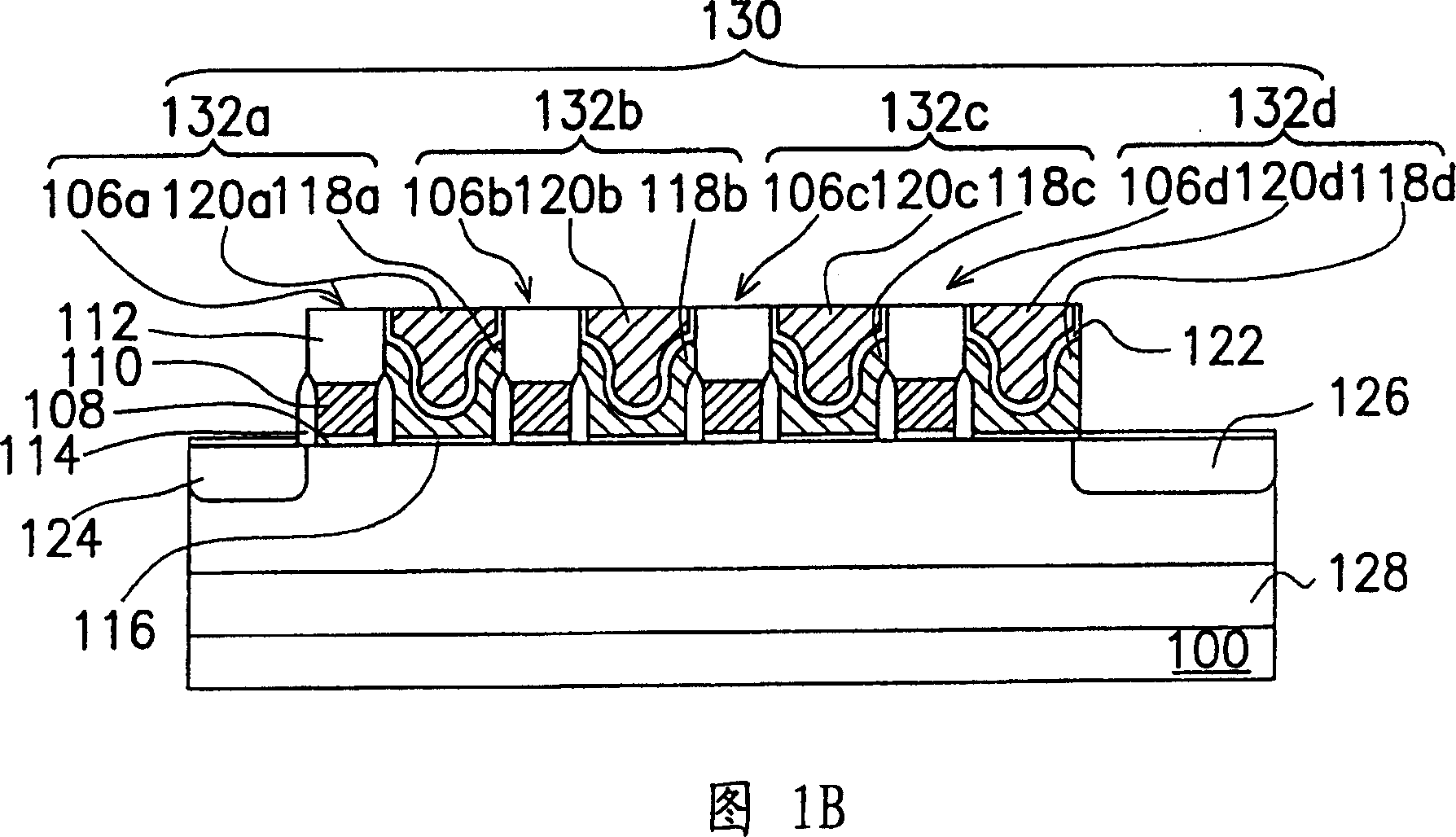

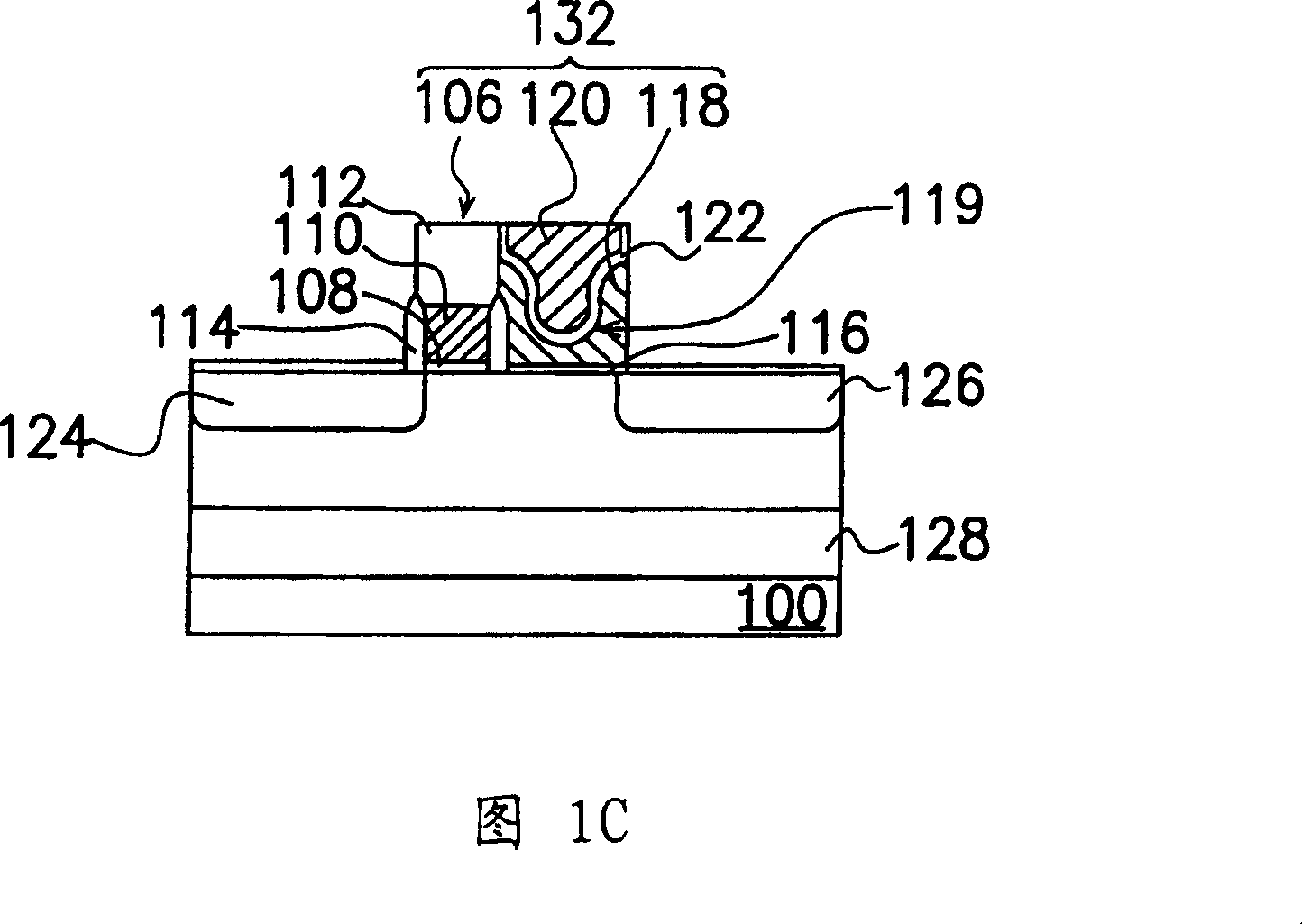

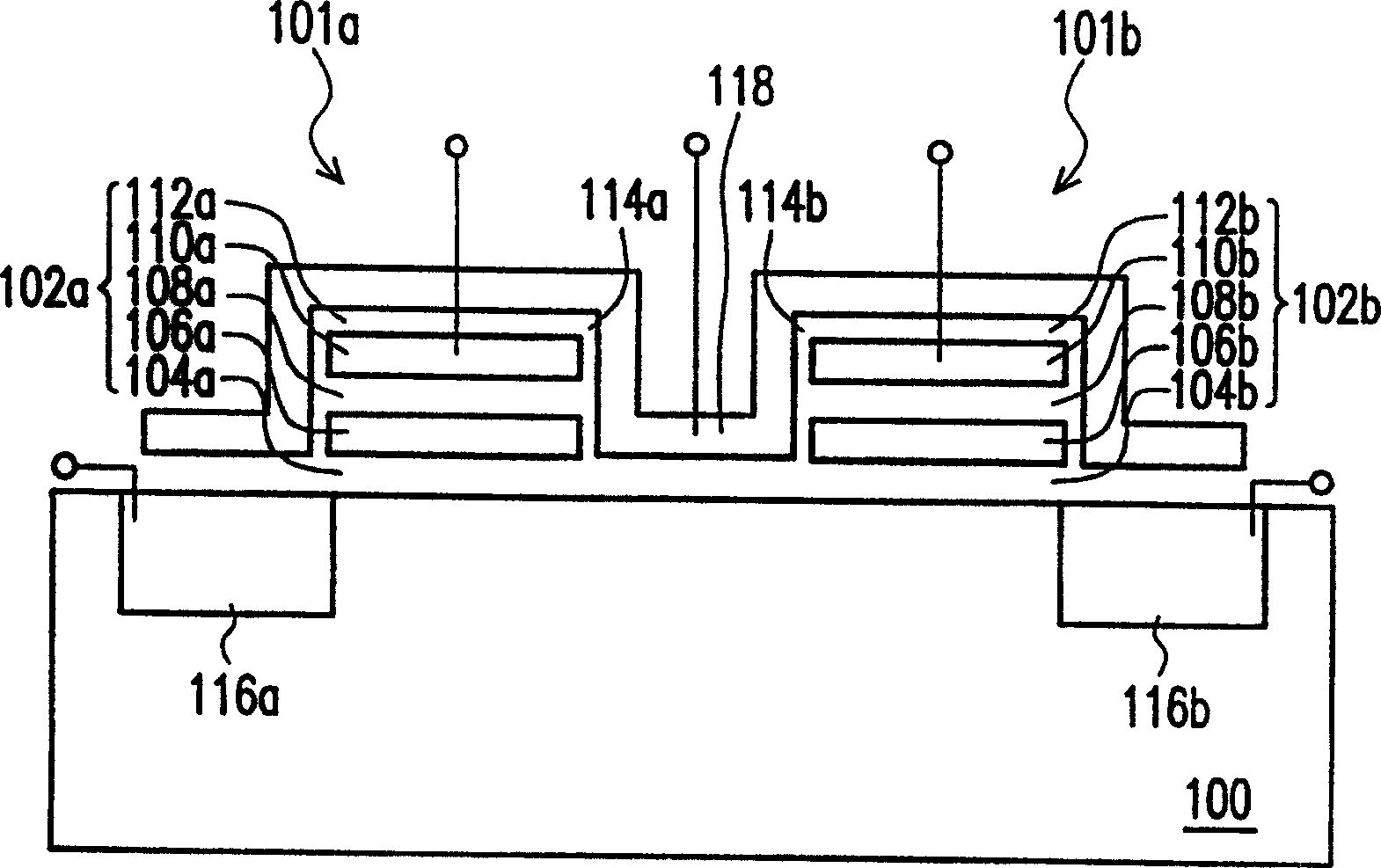

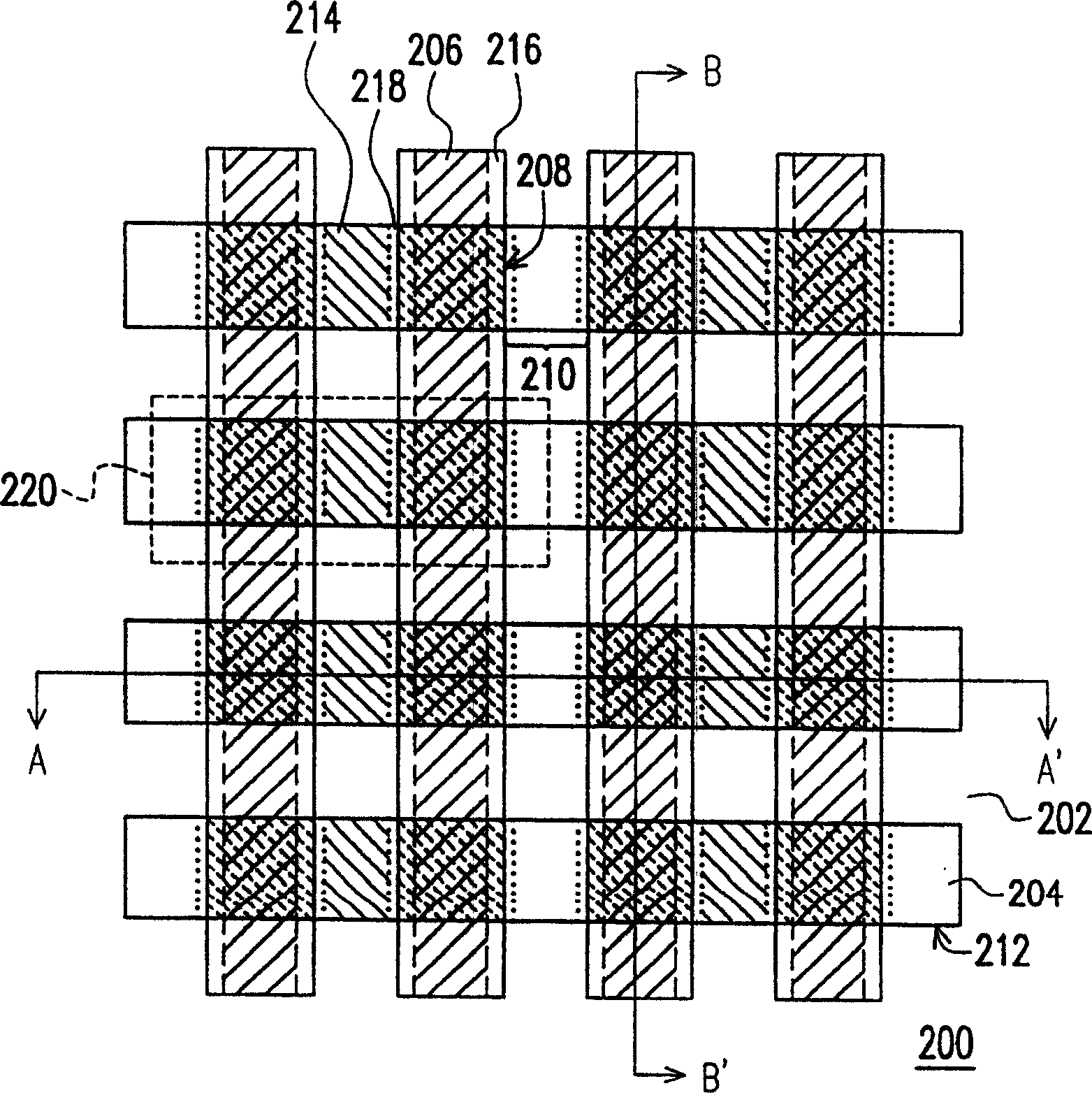

Flash memory unit, flash memory unit array and mfg. method thereof

InactiveCN1591873AImprove gate coupling ratioImprove operating speedSolid-state devicesSemiconductor/solid-state device manufacturingComputer architectureGate dielectric

The present invention discloses a flash memory storage unit, flash memory storage unit array and its making method. Said flash memory storage unit array consists of substrate, series-connected several storage unit structures and source region / drain region. Every storage unit structure is formed from stack gate structure consisting of selection gate dielectric layer, selection gate and top cover layer; gap wall placed on the side wall of selection gate; control gate which is placed on one side of the stack gate structure and is connected with stack gate structure; floating gate placed between control gate and substrate; intergate dielectric layer placed between the control gate and floating gate; tunneling dielectric layer placed between floating gate and substrate and control gate and source region / drain region respectively placed in the most external side of storage unit array and substrate of one side of stack gate structure.

Owner:POWERCHIP SEMICON CORP

Fabricating method of an active-matrix organic electroluminescent display panel

ActiveUS20070065997A1Improve electron injection efficiencyImprove efficiencyElectroluminescent light sourcesSolid-state devicesActive matrixMetal electrodes

A method for fabricating an active-matrix organic electroluminescent (OEL) display panel is described. A transparent conductive layer is formed on a substrate as a common anode for all organic light emitting diodes (OLED), and a passivation layer is formed on the transparent conductive layer. Thin film transistors are formed on the passivation layer to serve as an active matrix, and openings are formed in the passivation layer to expose portions of the transparent conductive layer and define pixel regions. An organic function layer is formed in each opening, and a metal electrode layer is formed on each organic function layer, wherein the metal electrode layer is electrically connected with the drain of the corresponding thin film transistor.

Owner:AU OPTRONICS CORP

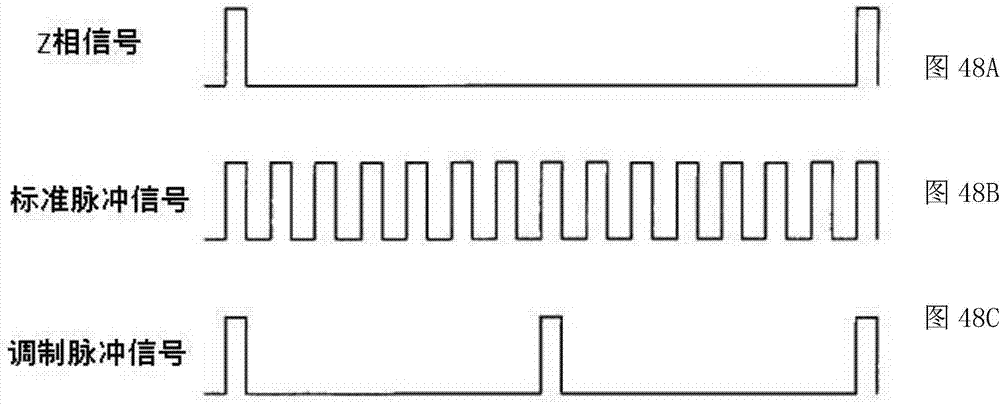

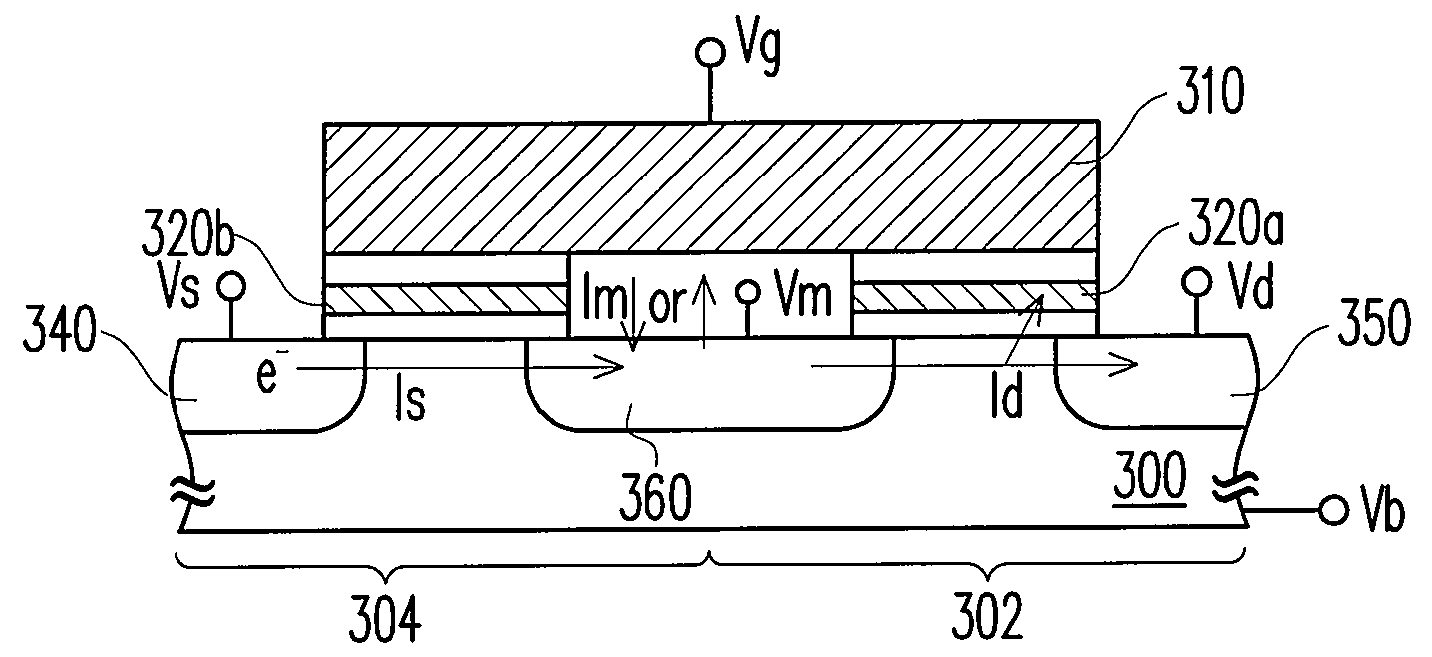

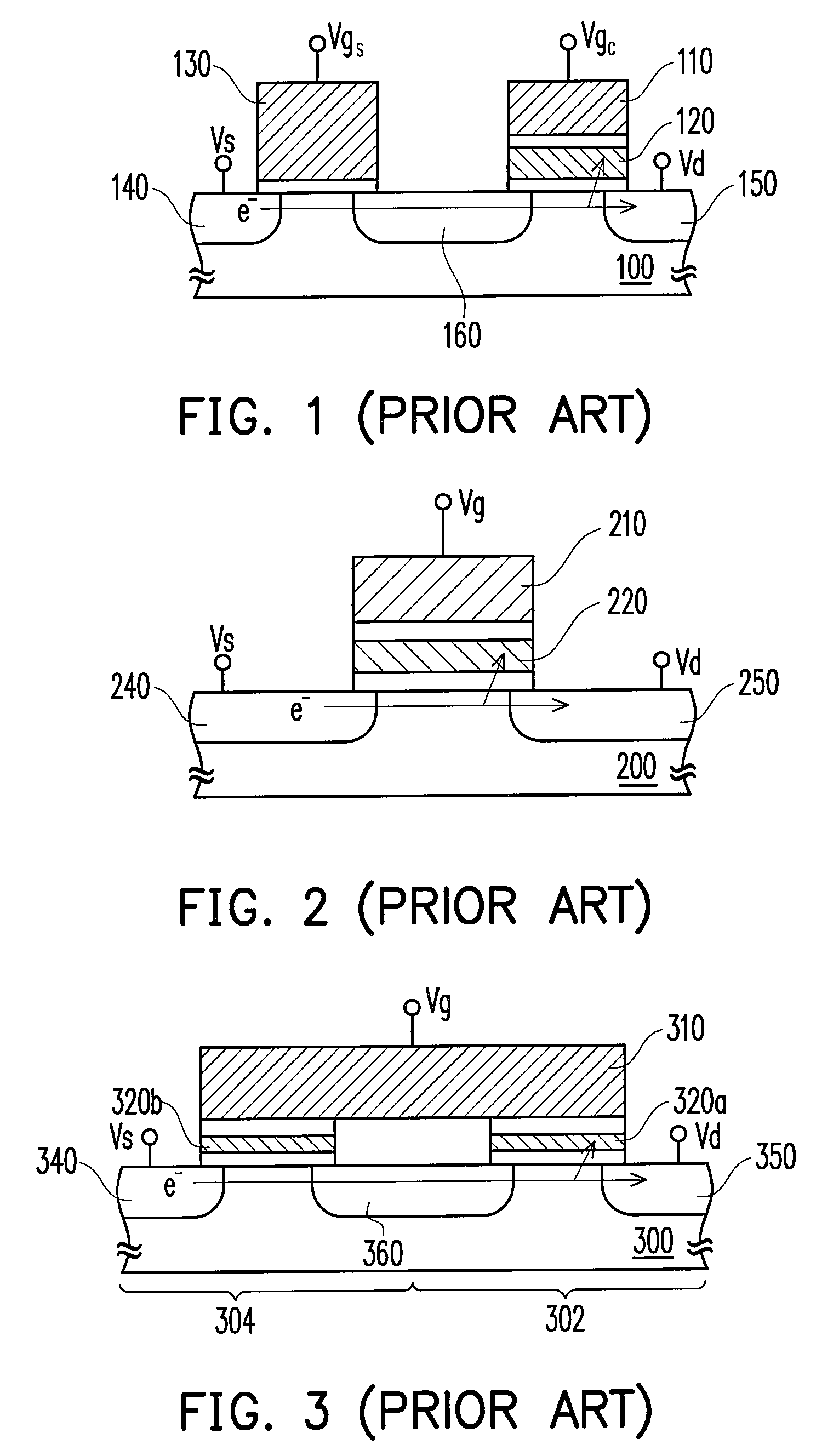

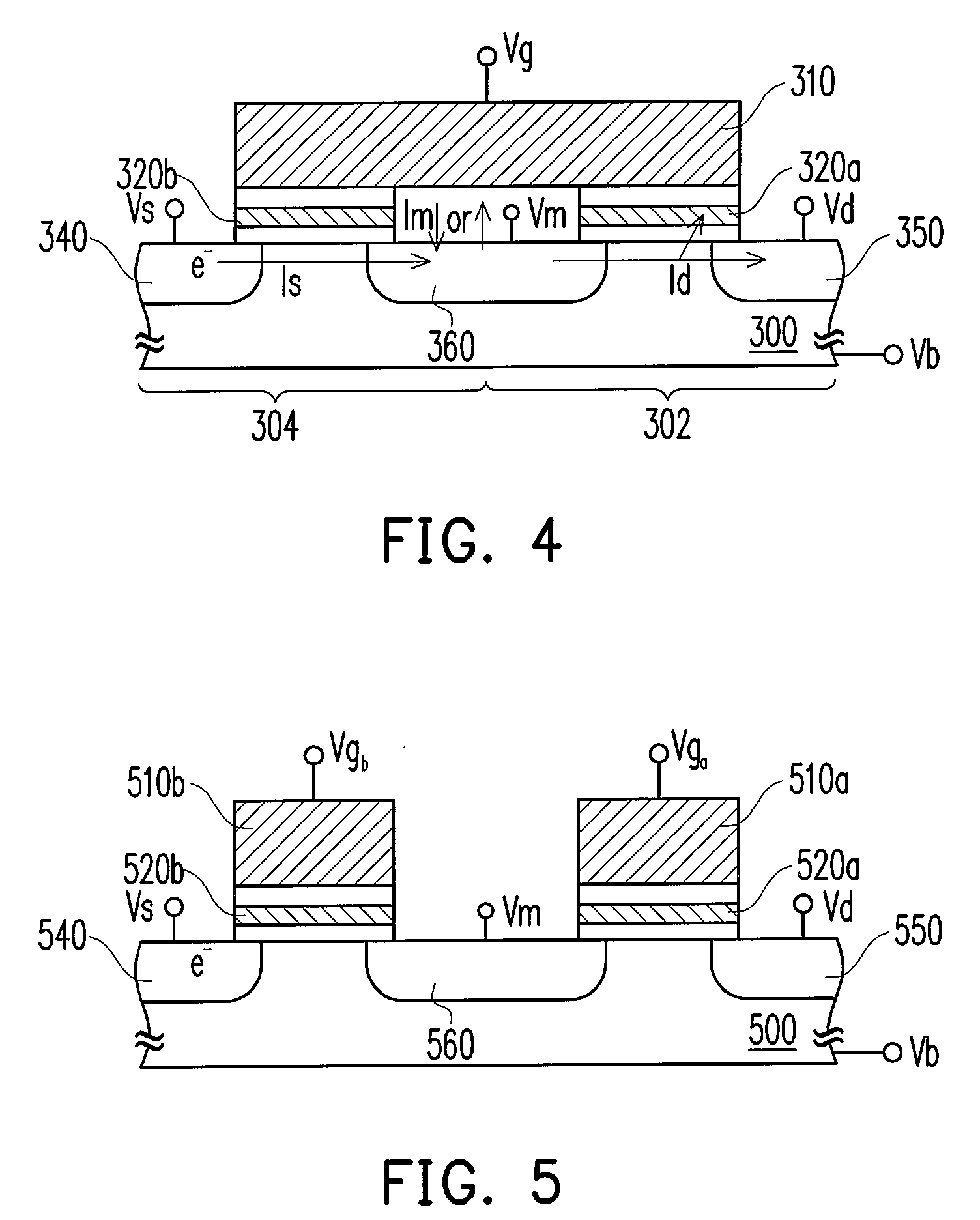

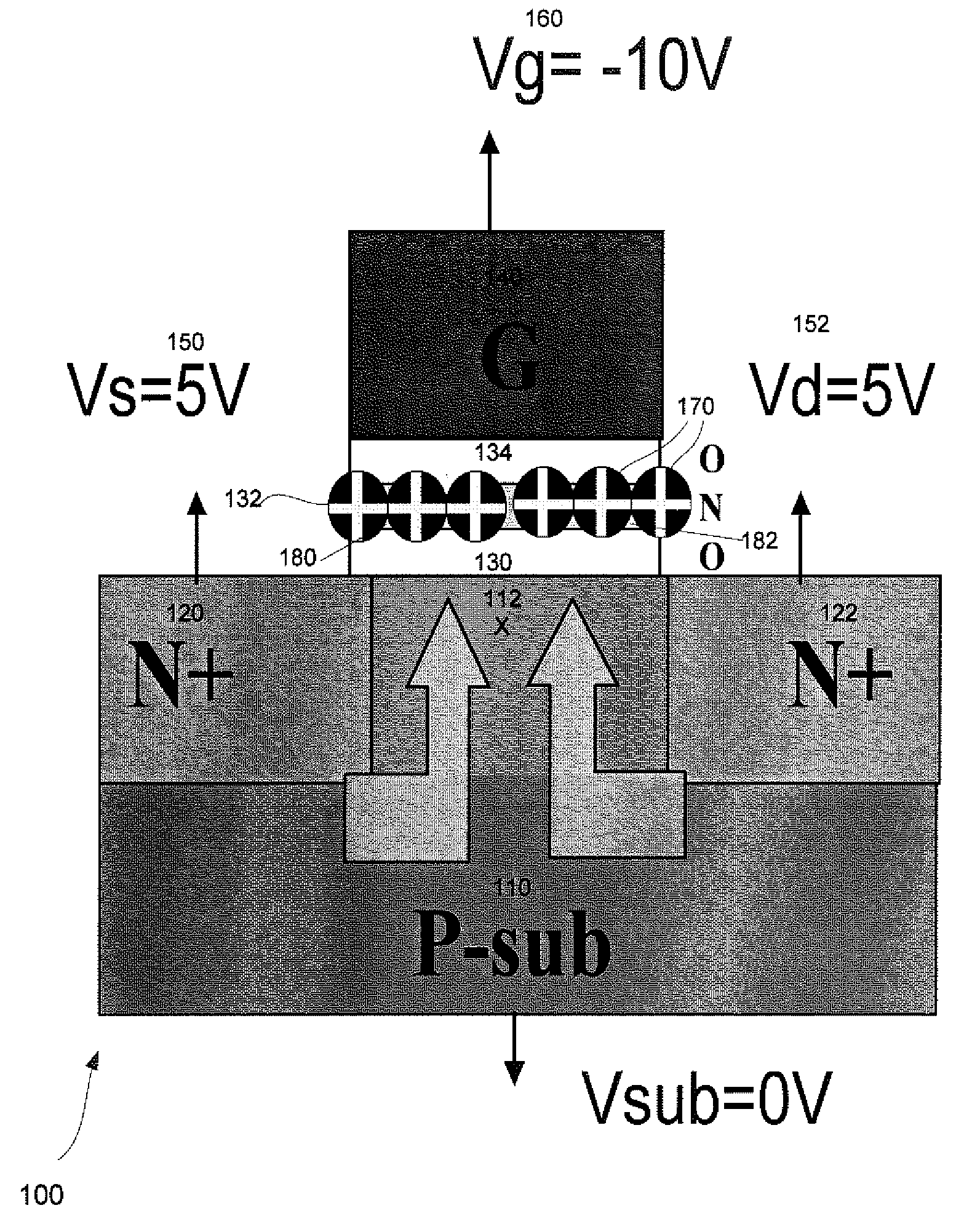

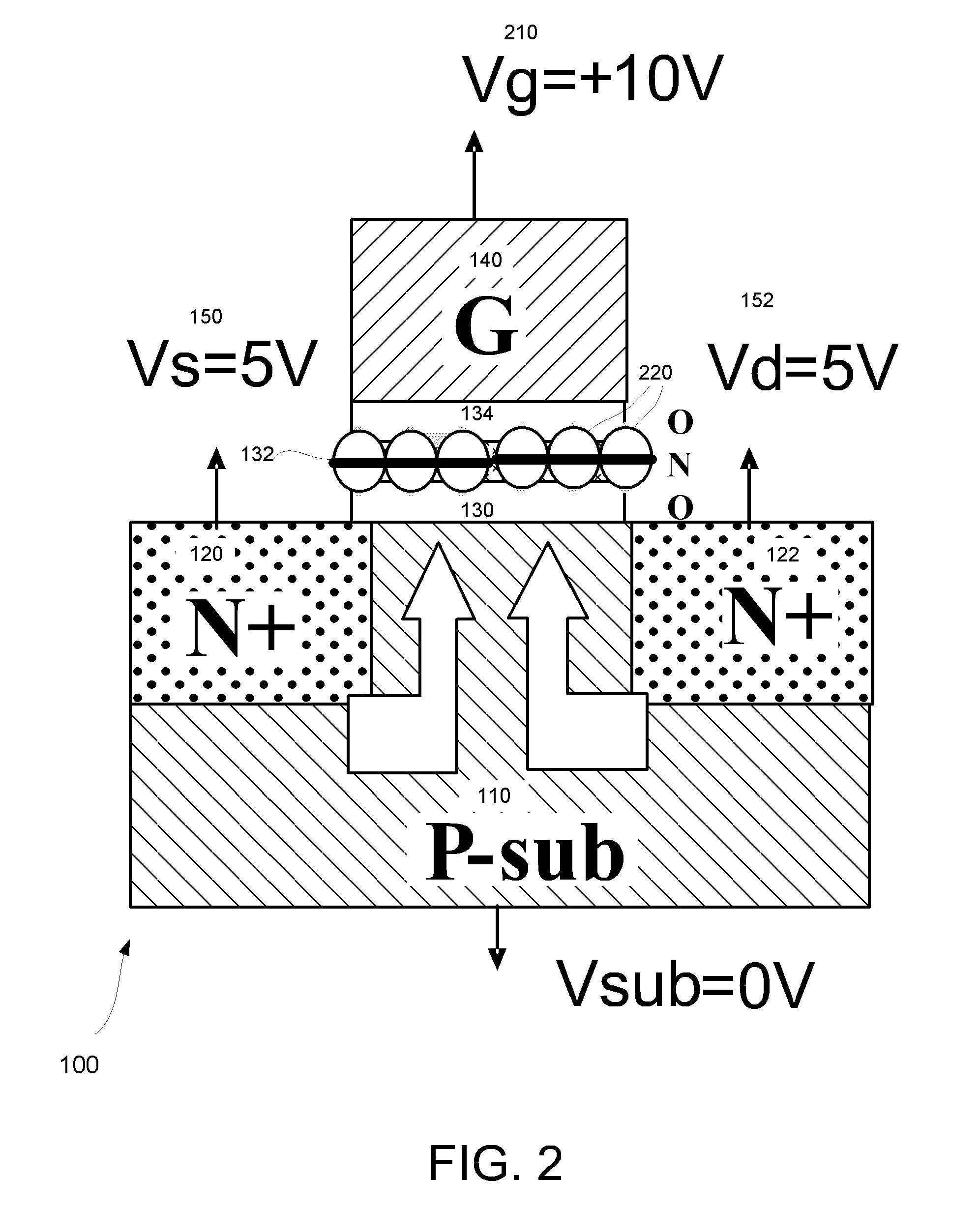

Method of programming cell in memory and memory apparatus utilizing the method

ActiveUS20090116294A1Improve hot carrier injection efficiencyPrevent punch-throughRead-only memoriesDigital storageElectrical batteryCharge carrier

A method of programming a first cell in a memory, wherein the first cell has a first S / D region and shares a second S / D region with a second cell that has a third S / D region opposite to the second S / D region. The channels of the first and the second cells are turned on, a first voltage is applied to the first S / D region, a second voltage is applied to the second S / D region and a third voltage is applied to the third S / D region. The second voltage is between the first voltage and the third voltage, and the first to third voltages make carriers flow from the third S / D region to the first S / ID region and cause hot carriers in the channel of the first cell to be injected into the charge storage layer of the first cell.

Owner:MACRONIX INT CO LTD

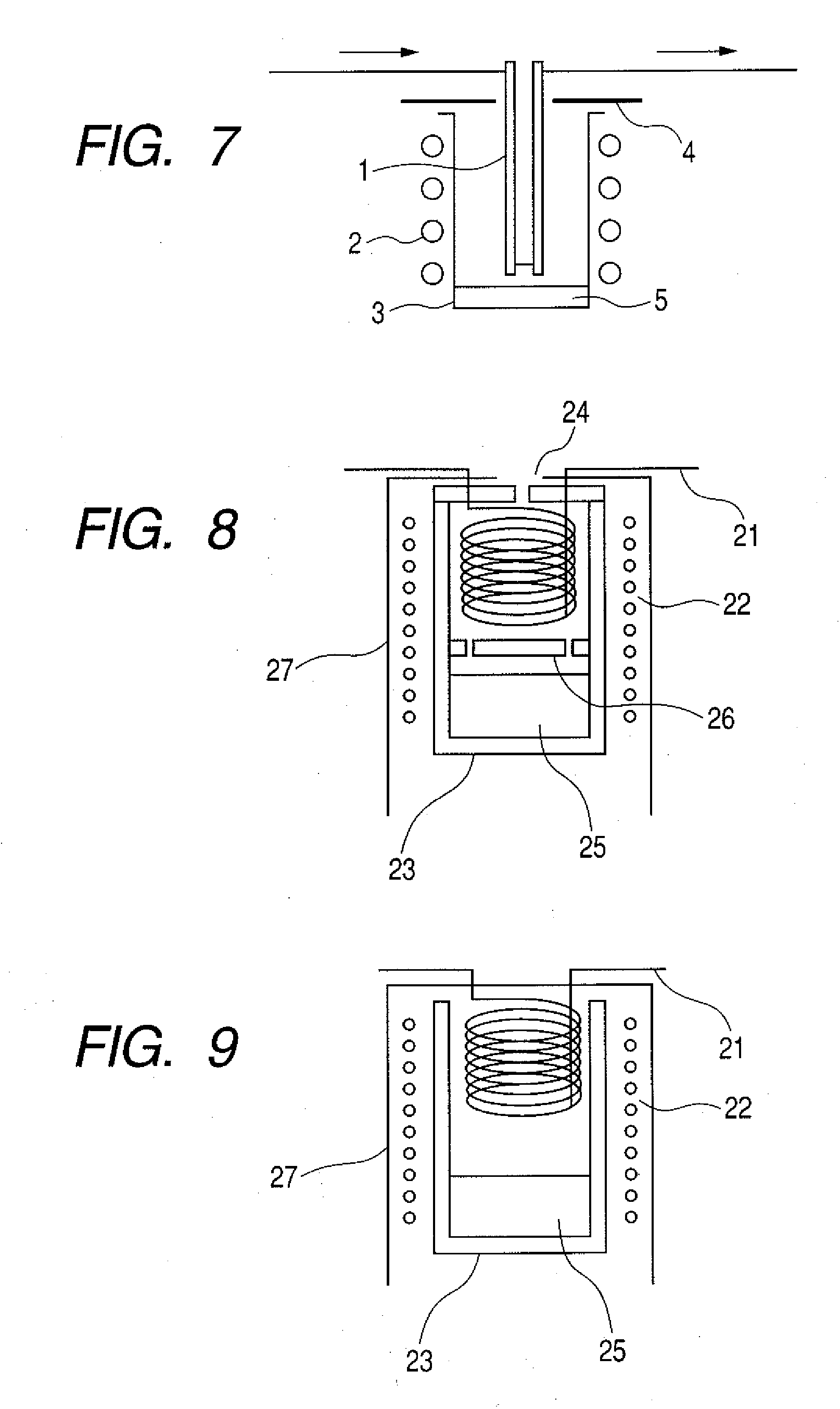

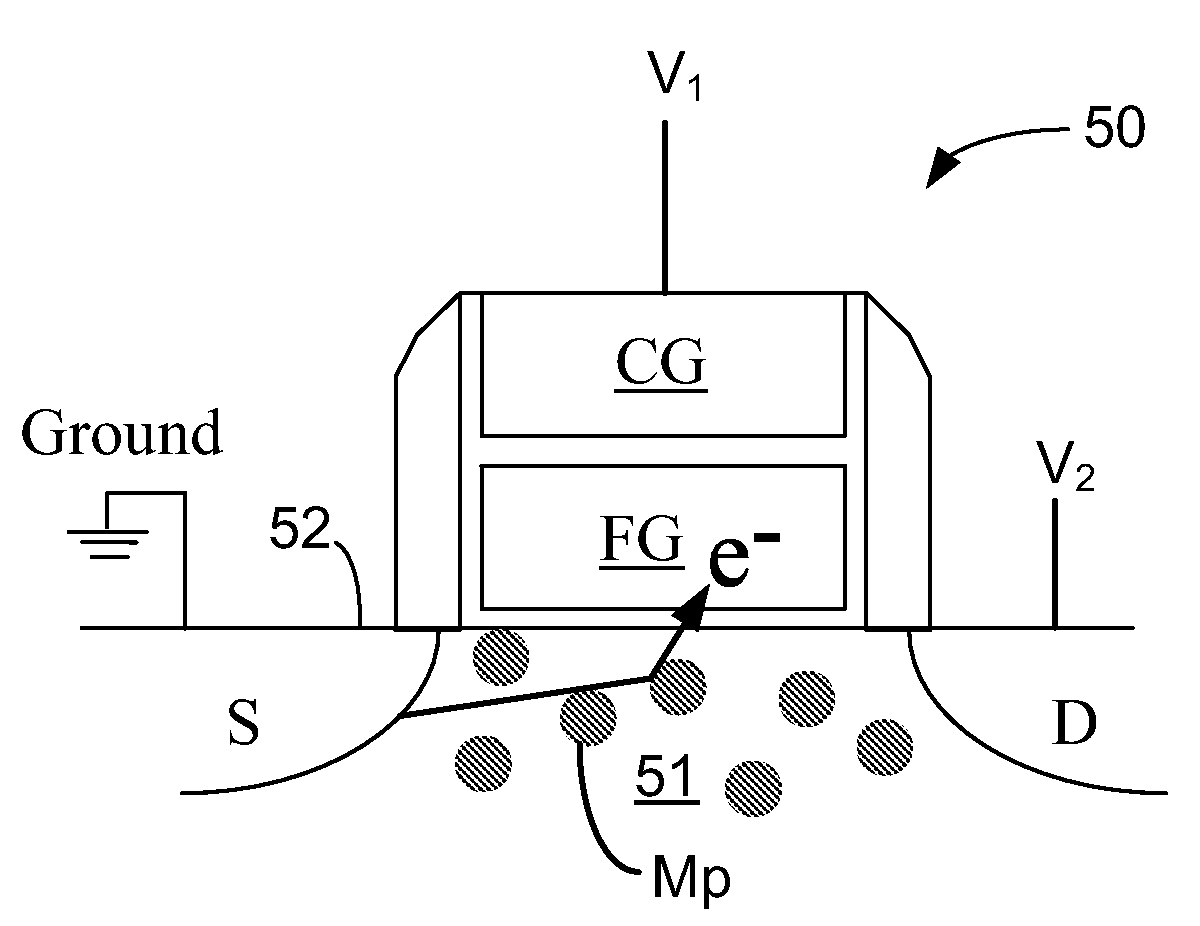

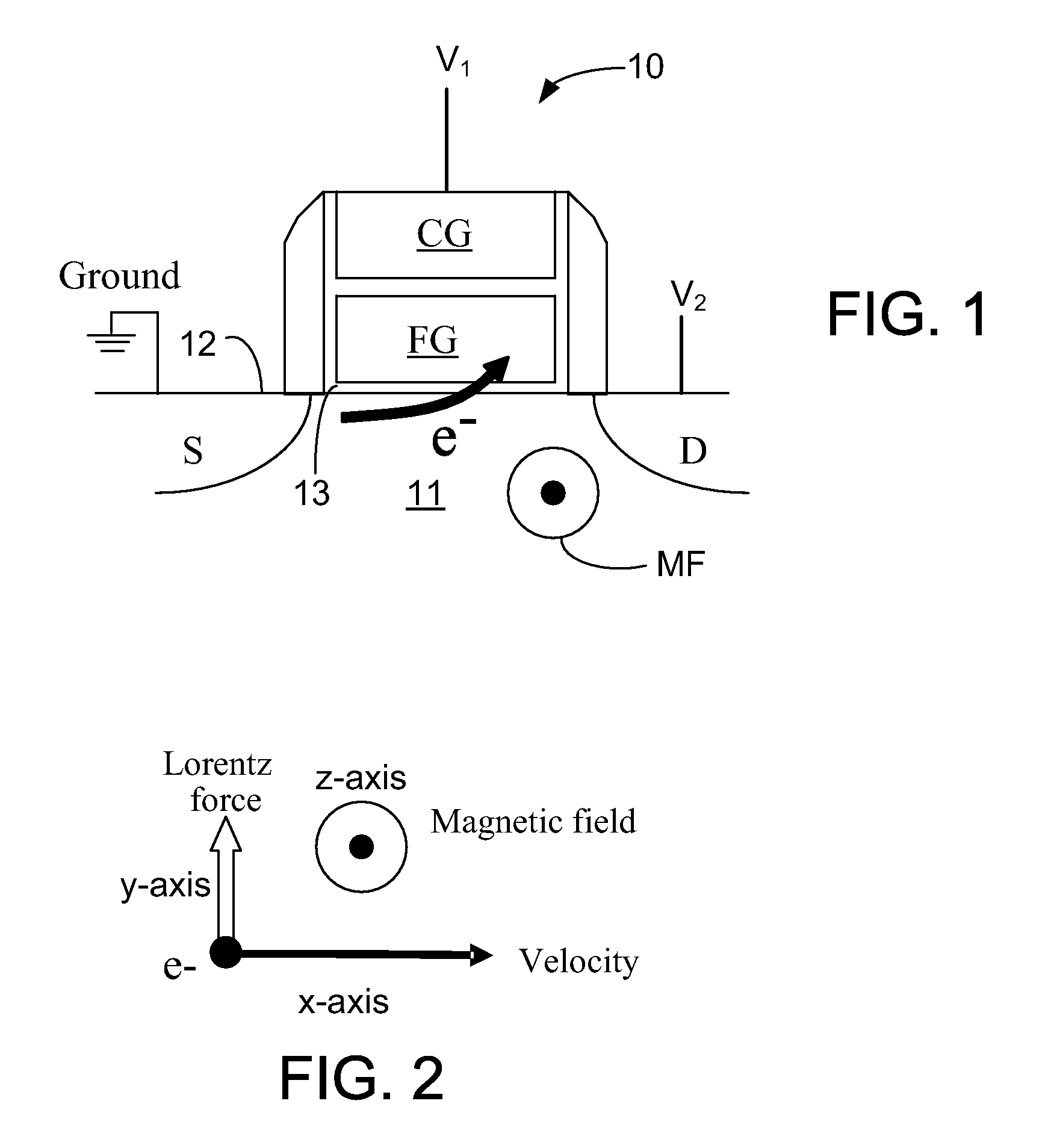

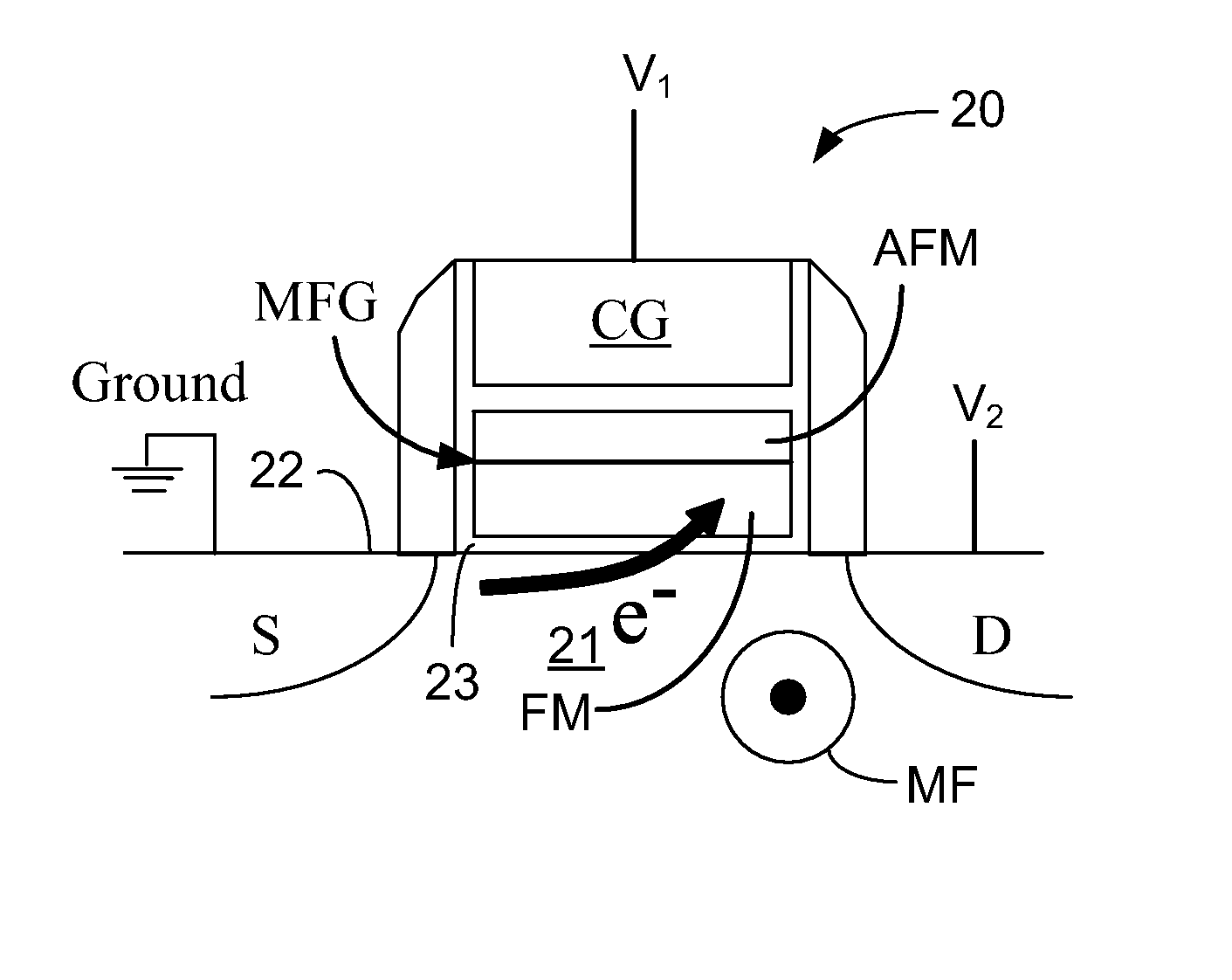

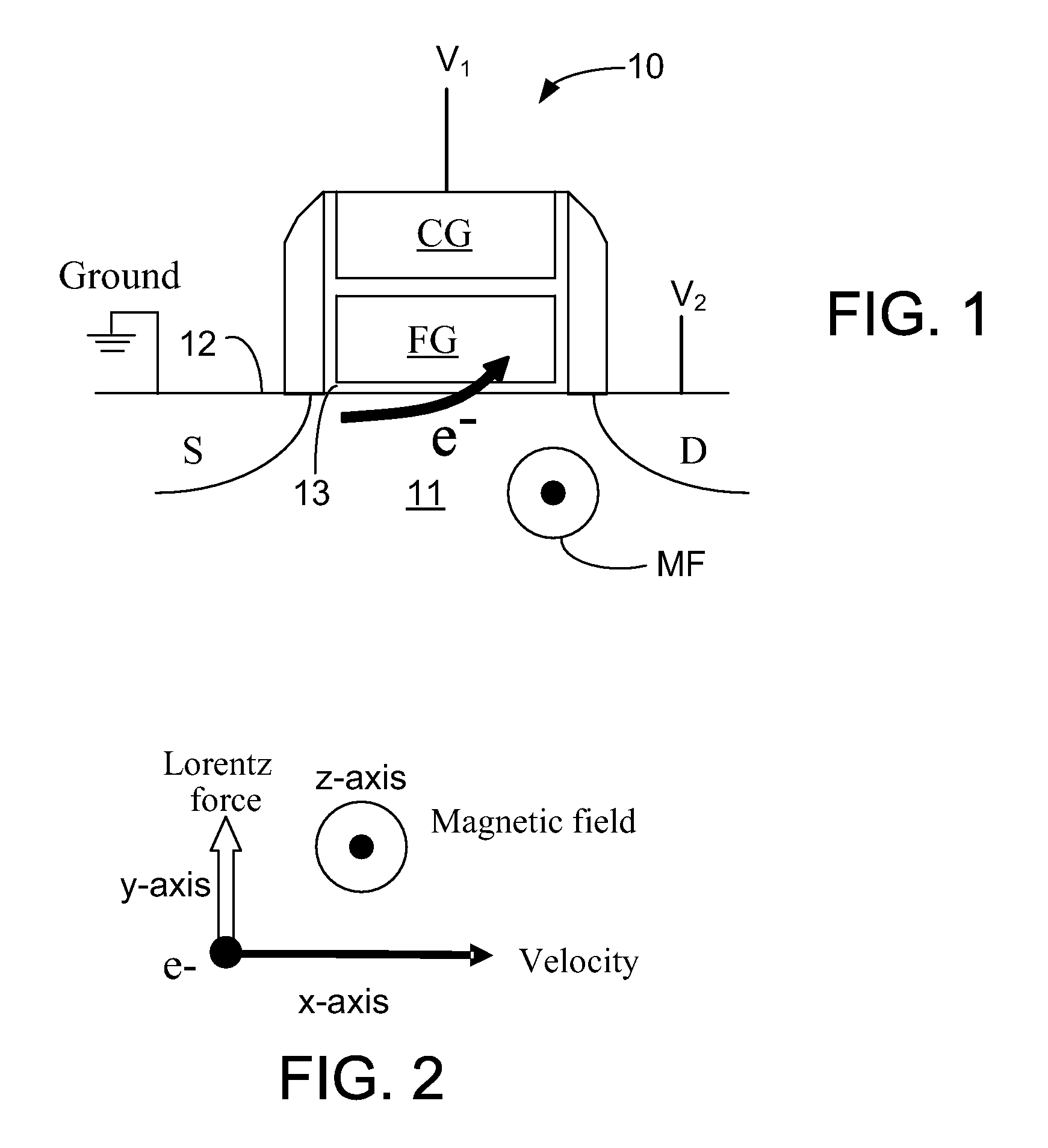

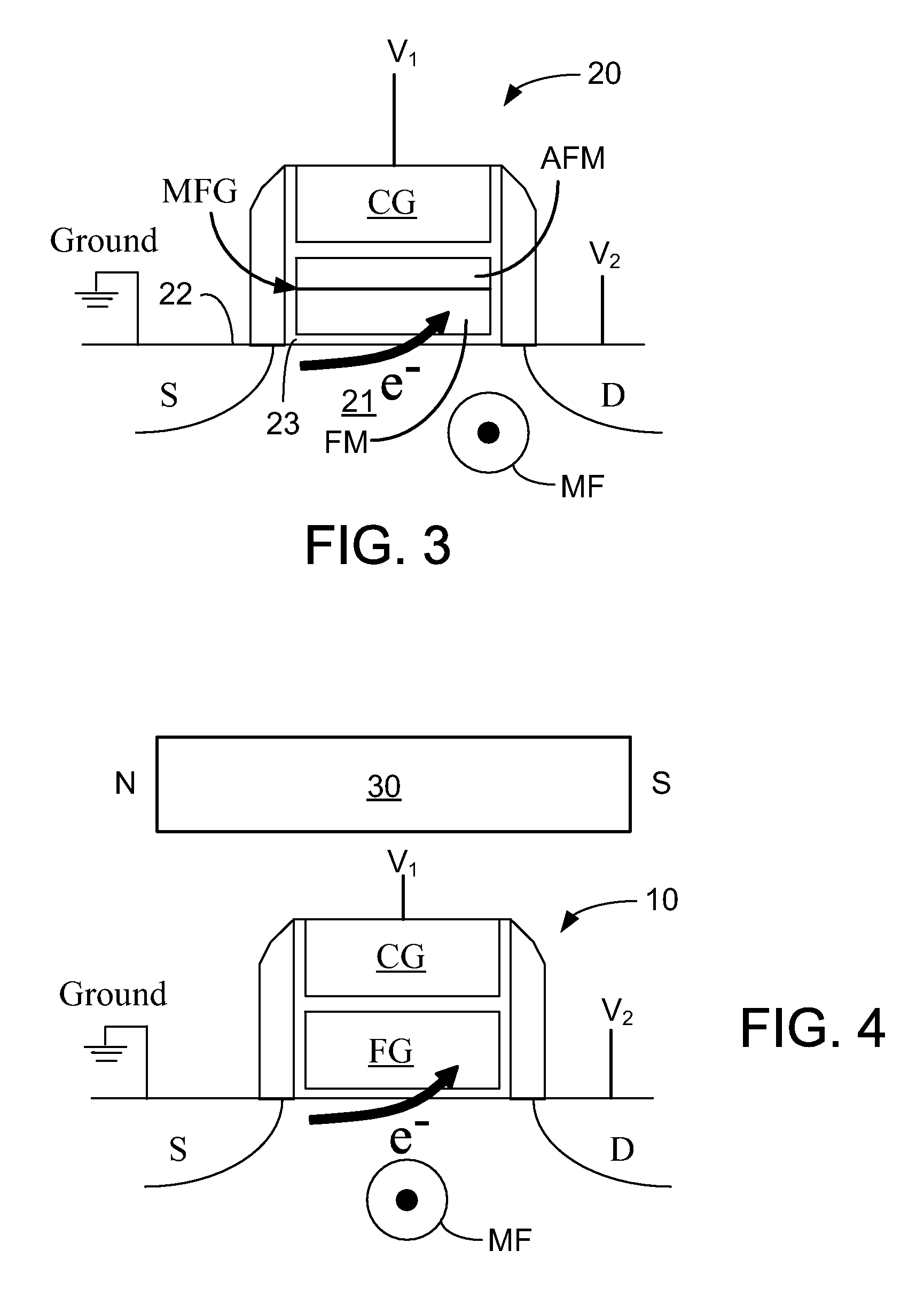

Magnetic floating gate memory

InactiveUS20100182837A1Improve electron injection efficiencyTransistorRead-only memoriesAtomic physicsElectron

An apparatus includes at least one memory device including a floating gate element and a magnetic field generator that operably applies a magnetic field to the memory device. The magnetic field directs electrons in the memory device into the floating gate element.

Owner:SEAGATE TECH LLC

Display panel and manufacturing method thereof

InactiveCN108022962AImprove electron injection efficiencyImprove display qualitySolid-state devicesSemiconductor/solid-state device manufacturingTransmittanceComputer science

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Organic electro-luminescence device

InactiveUS20060216543A1Injection efficiency be highImprove electron injection efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceFluoride salt

An organic electro-luminescence device includes a substrate, a hole injection layer disposed on the substrate, an organic layer disposed on the hole injection layer, a buffer layer disposed on the organic layer, and an electron injection layer forming above the buffer layer. The buffer layer is needed for protecting the organic layer while the electron injection layer is being formed. Within, the organic layer includes a light-emitting layer and an electron transporting layer disposed on the light-emitting layer. The electron transporting layer includes Cesium fluoride.

Owner:AU OPTRONICS CORP

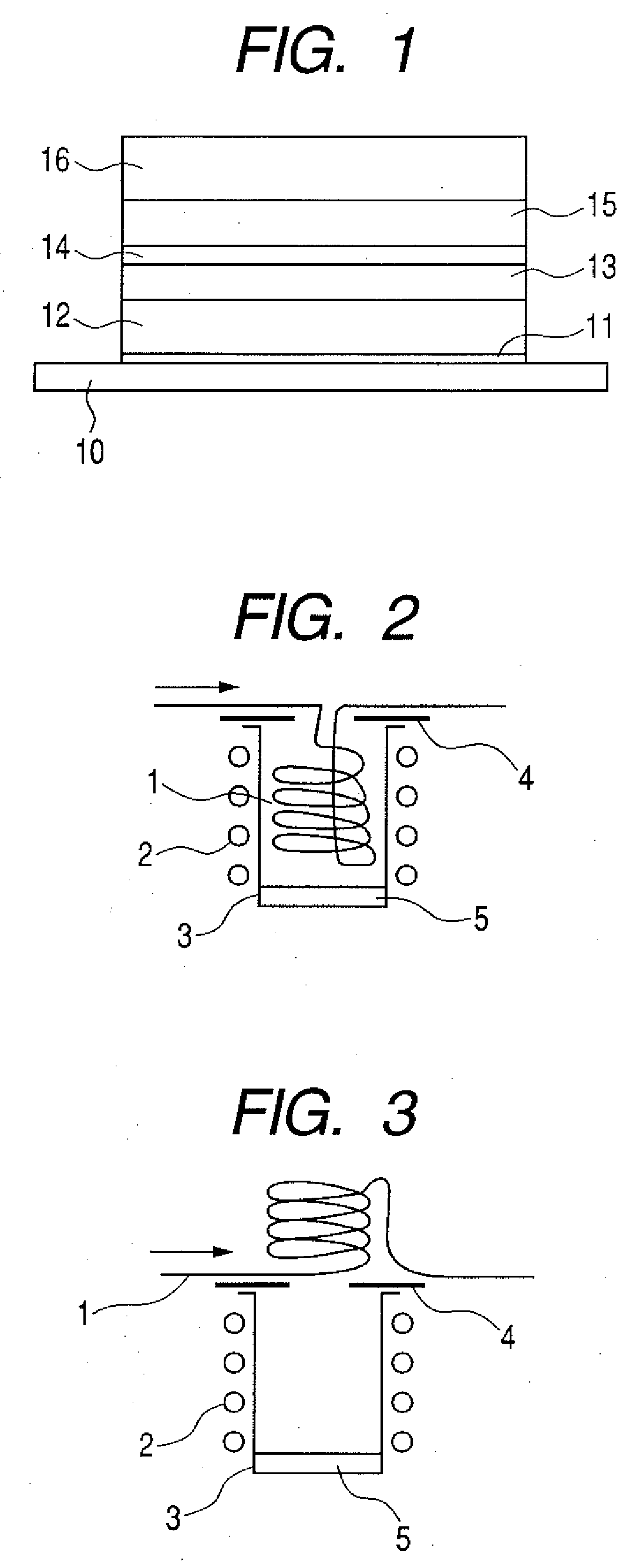

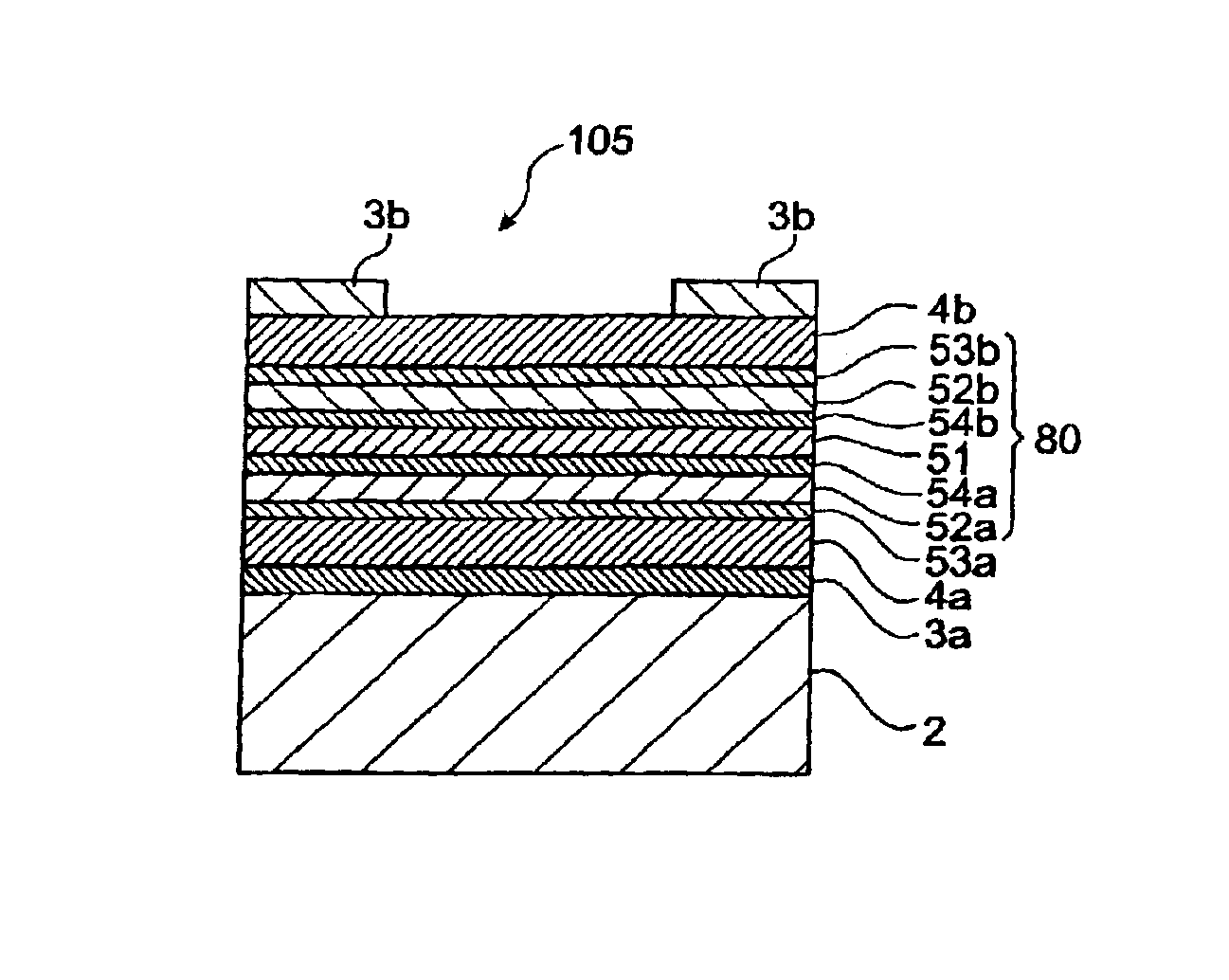

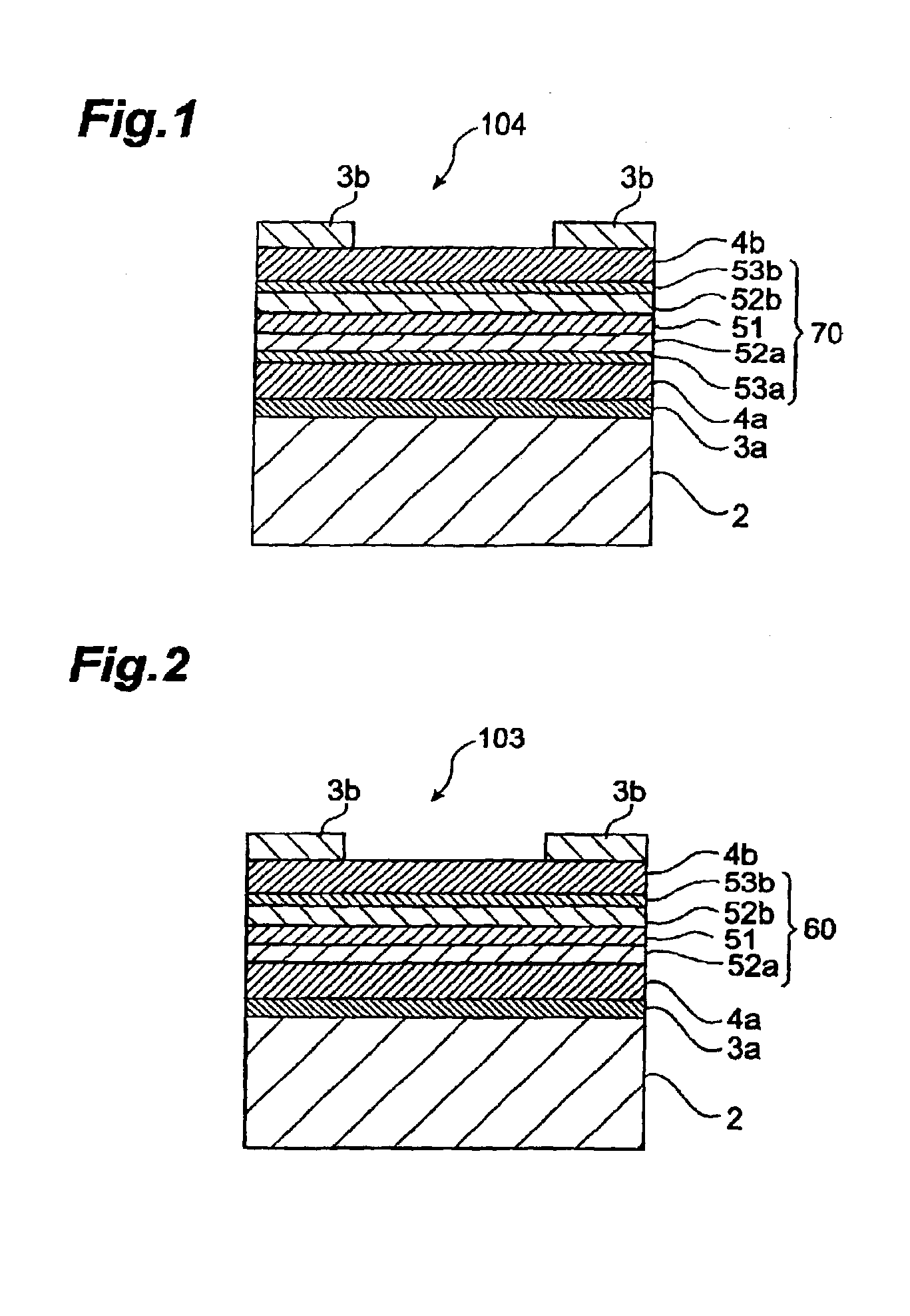

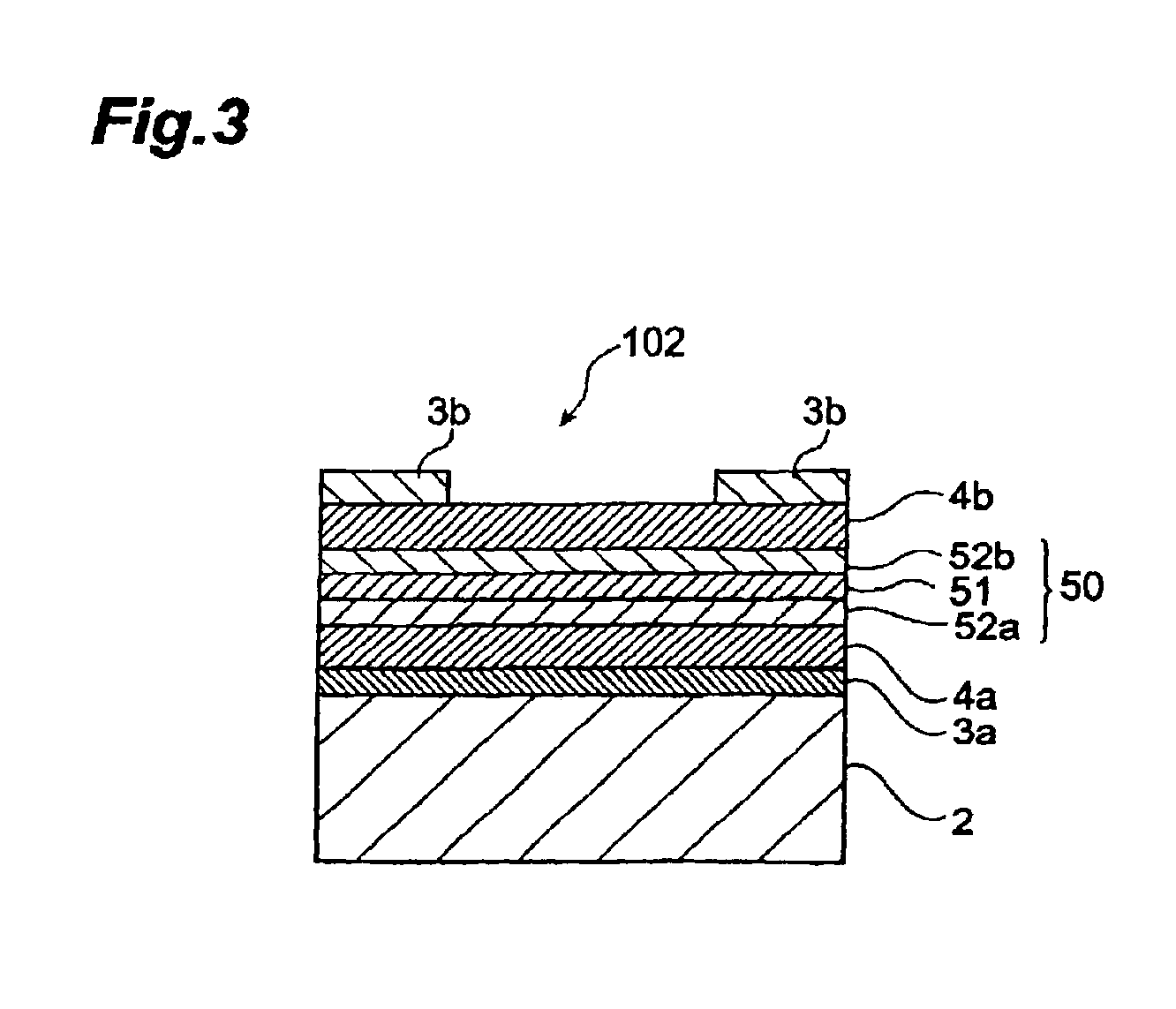

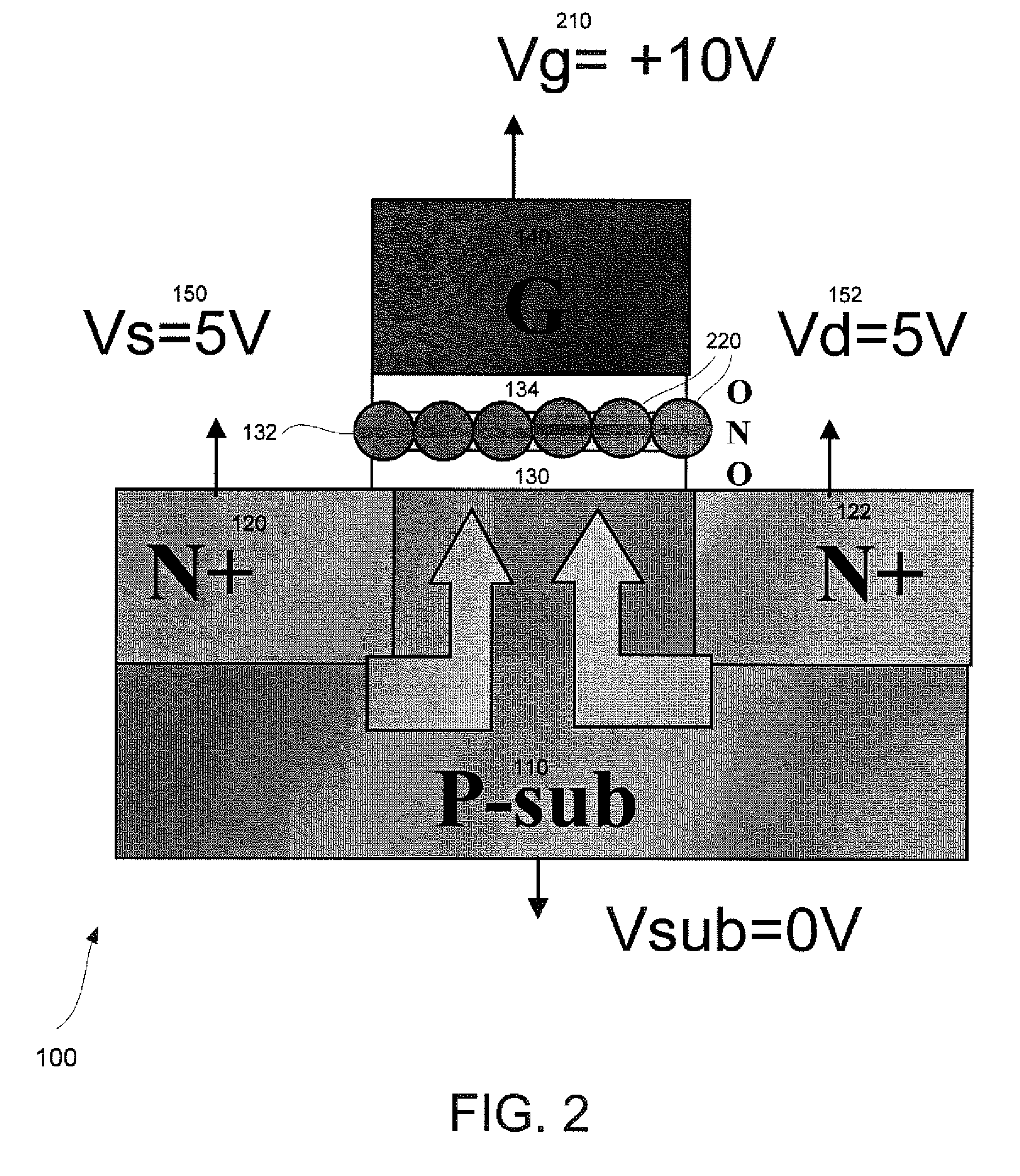

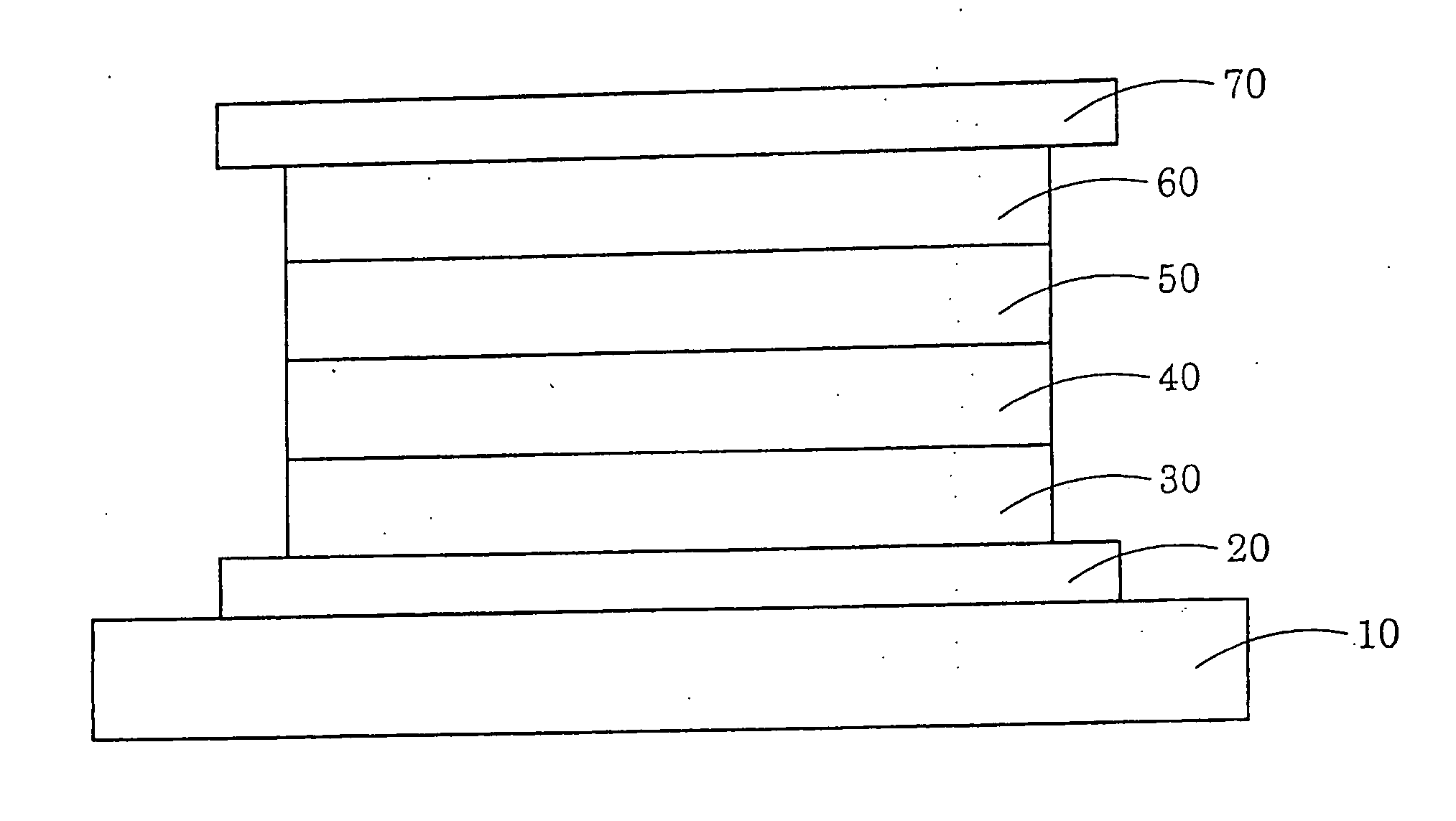

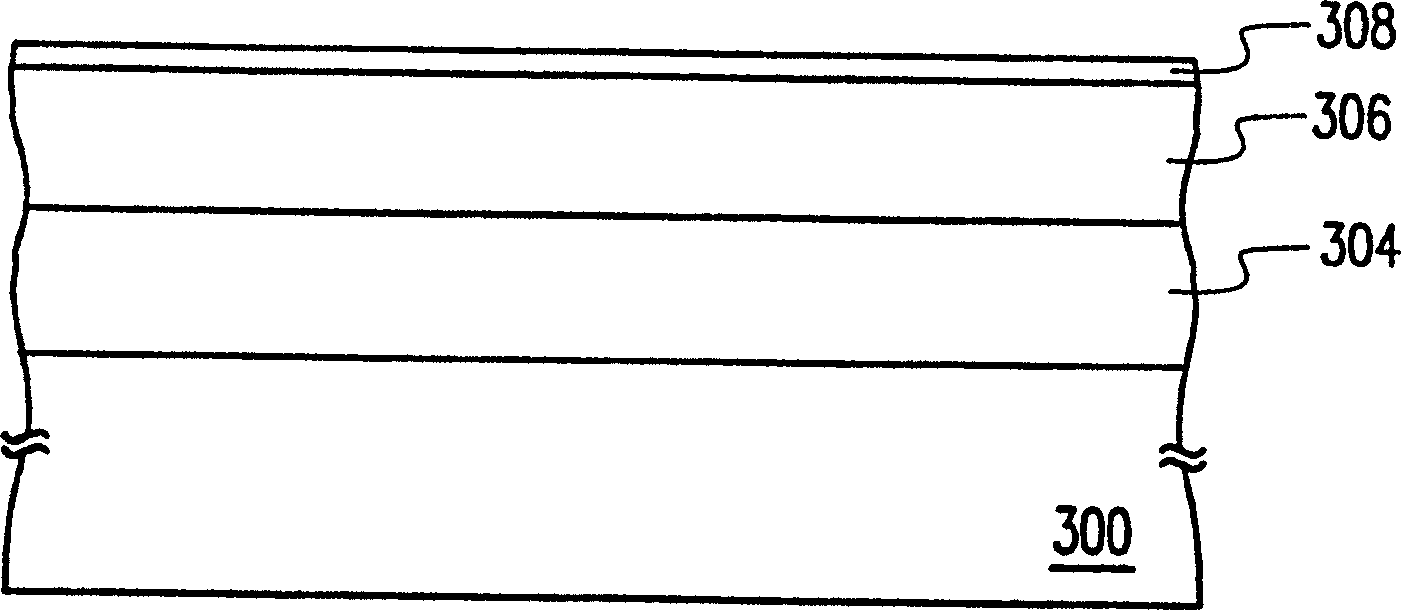

Electroluminescence phosphor multilayer thin film and electroluminescence element

InactiveUS6876146B2Improve electron injection efficiencySteep rising characteristicDischarge tube luminescnet screensLayered productsFluorescenceGallate

The present invention aims at realizing a phosphor thin film having a high luminance with a low emission threshold voltage, and an EL element comprising the same. The EL element of the present invention comprises a substrate, and a lower electrode, a lower buffer thin film containing a sulfide such as ZnS, a phosphor thin film containing an oxide such as a gallate as a matrix material, an upper buffer thin film containing a sulfide such as ZnS, and an upper electrode which are successively laminated on the substrate.

Owner:IFIRE IP CORP

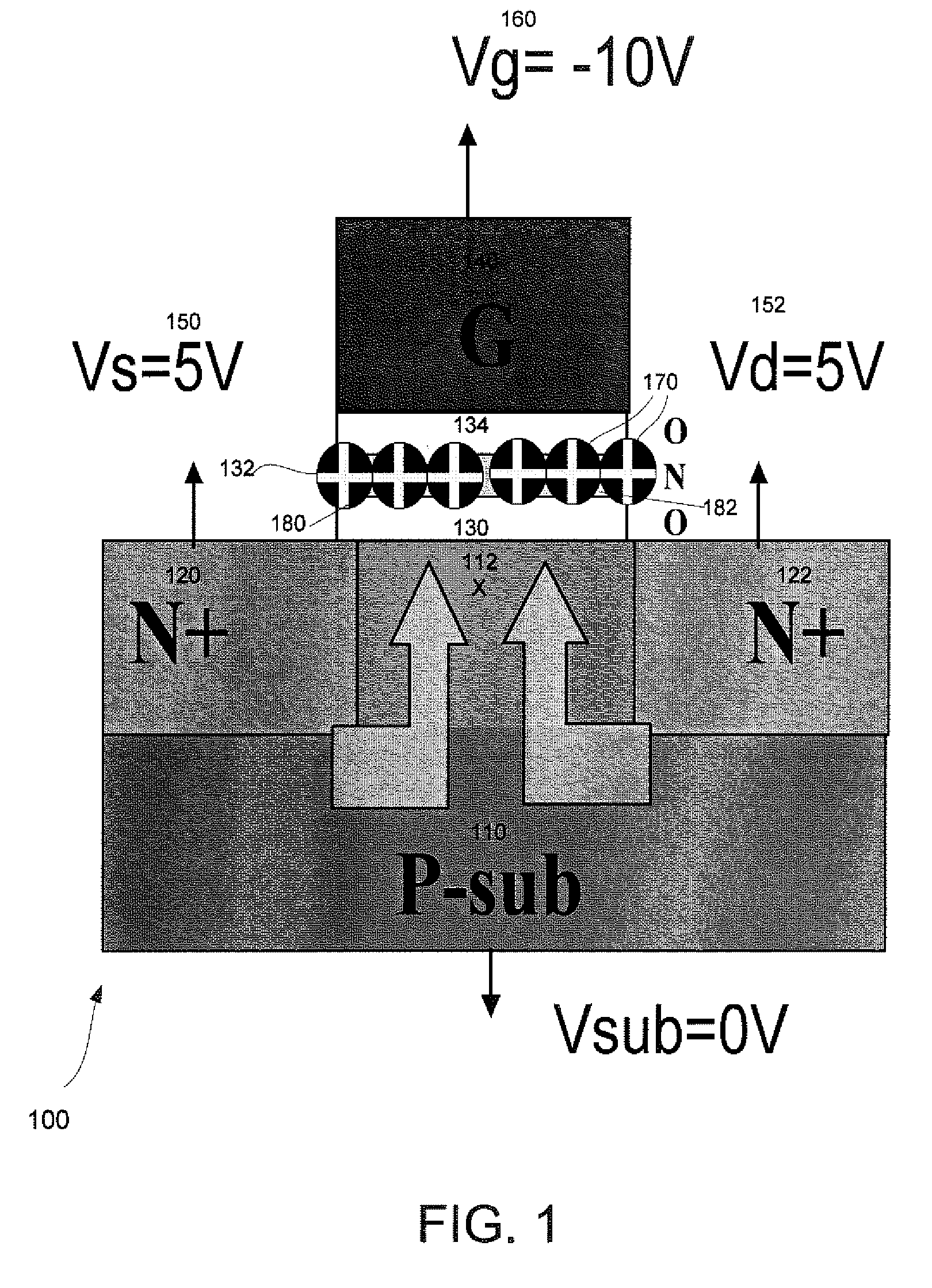

Double-Side-Bias Methods of Programming and Erasing a Virtual Ground Array Memory

InactiveUS20080151642A1Improve hole injection efficiencyReduce bias voltageRead-only memoriesDigital storageVirtual groundElectric charge

The present invention provides a method for applying a double-side-bias operation to a virtual ground array memory composed of a matrix of N-bit memory cells. In a first embodiment, the virtual ground array is programmed by a double-side-bias method which applies the same or similar biasing voltage simultaneously on the source region and drain region of a selected charge trapping memory cell so that the left bit and the right bit of the selected charge trapping memory cell are programmed together. In a second embodiment, the virtual ground array is erased by a double-side-bias method which applies the same or similar biasing voltage simultaneously on source regions and regions of a plurality of charge trapping memory cells in the virtual ground array so that the left bit and the right bit of each charge trapping memory cell are erased together.

Owner:MACRONIX INT CO LTD

Apparatus and method of employing self-assembled molecules to function as an electron injection layer of OLED

InactiveUS20050029092A1Reduce threshold voltageHigh stabilityVacuum evaporation coatingSolid-state devicesVoltageMolecular physics

An apparatus and method of employing self-assembled molecules to function as an electron injection layer of organic light emitting diodes (OLEDs) uses self-assembled molecules to function as an electron injection layer. A dipolar self-assembled molecules film is formed on a cathode metal layer to serve the electron injection layer. The self-assembled molecules have dipolar properties. The doner and the cathode metal layer form a key bond. The resulting dipolar direction formed in the self-assembled molecules can increase electron injection efficiency, thereby increase light emitting efficiency of OLED elements and reduce the threshold voltage of the OLED elements.

Owner:WINTEK CORP

Magnetic floating gate memory

InactiveUS7961503B2Improve electron injection efficiencyRead-only memoriesSemiconductor/solid-state device manufacturingElectronAtomic physics

An apparatus includes at least one memory device including a floating gate element and a magnetic field generator that operably applies a magnetic field to the memory device. The magnetic field directs electrons in the memory device into the floating gate element.

Owner:SEAGATE TECH LLC

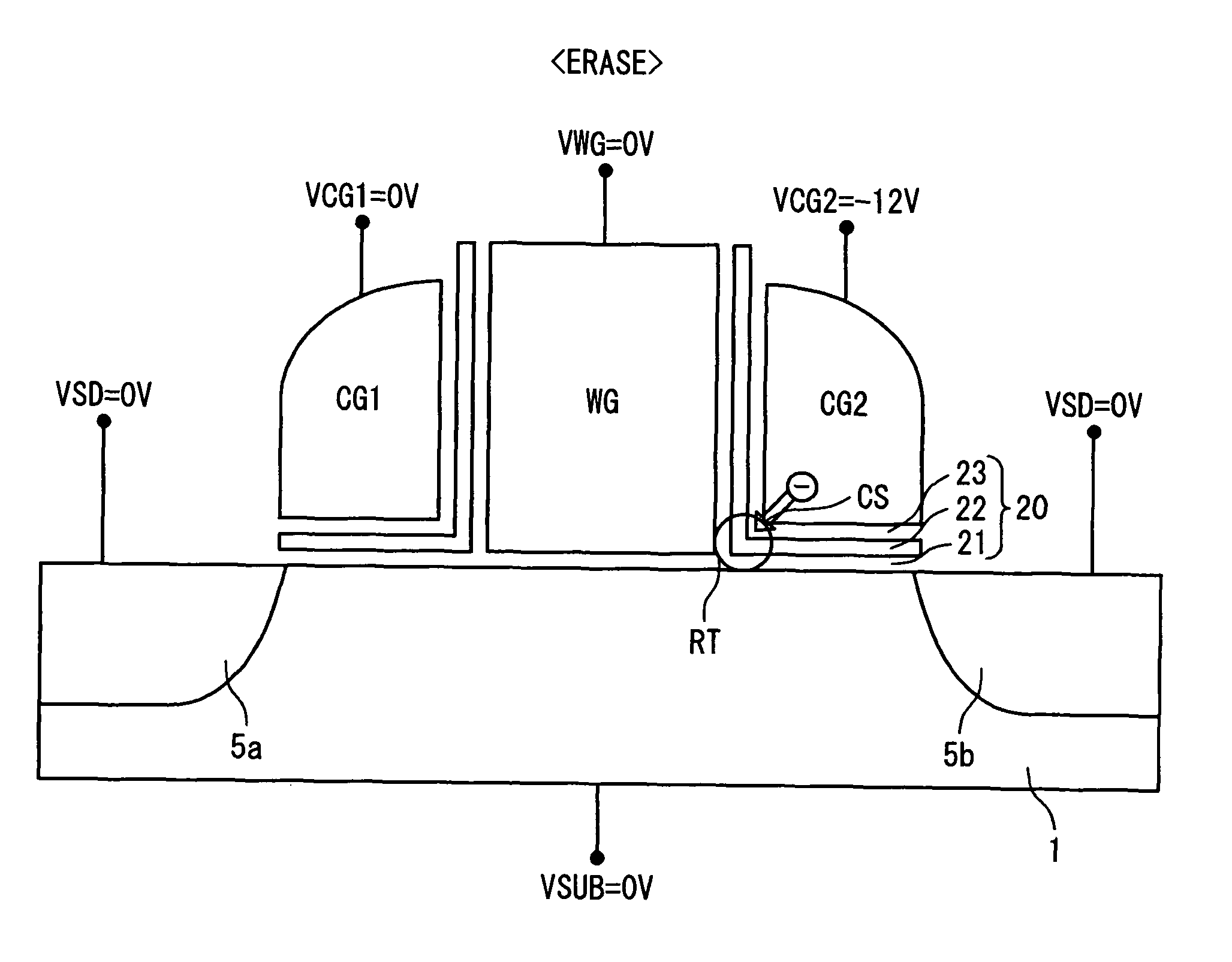

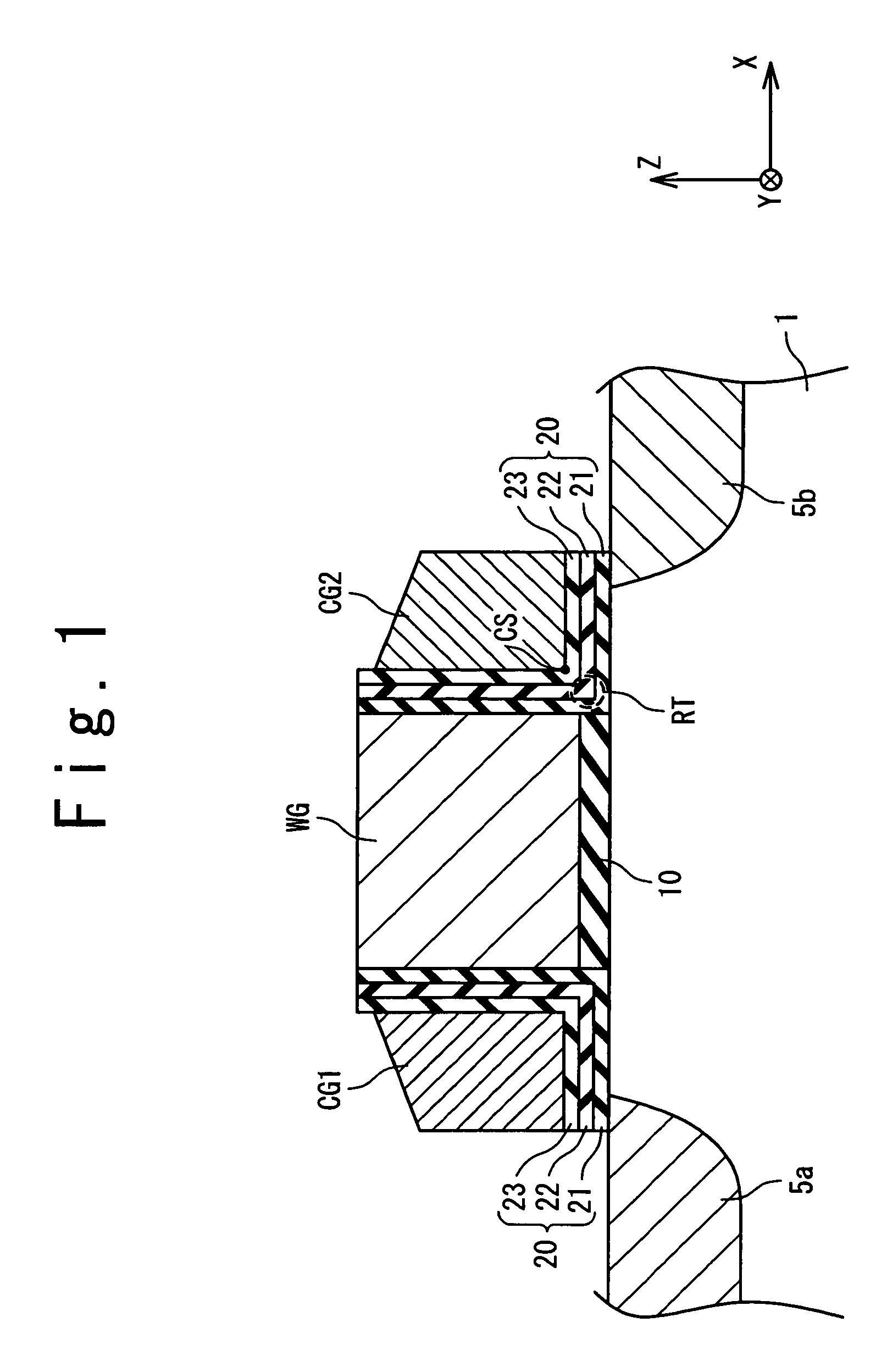

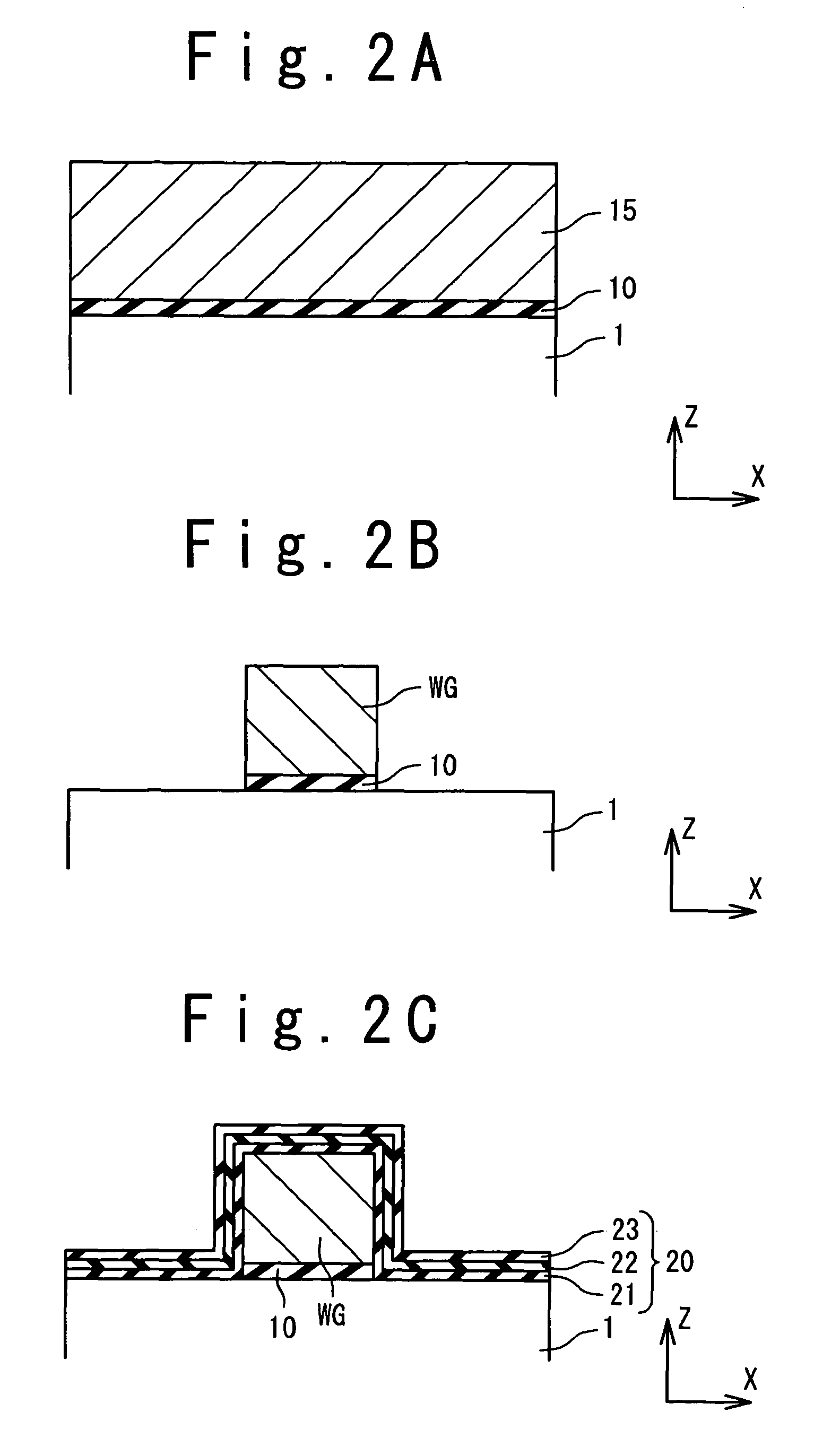

Nonvolatile semiconductor memory and data programming/erasing method

ActiveUS7889549B2Increase in sizeImprove electron injection efficiencyRead-only memoriesSemiconductor/solid-state device manufacturingFowler nordheimTrapping

A nonvolatile semiconductor memory comprises: a semiconductor substrate; a first gate electrode formed on a surface of the semiconductor substrate through a first gate insulating film; a second gate electrode formed on the surface of the semiconductor substrate through a second gate insulating film and being adjacent to the first gate electrode through an insulating film; a charge trapping film formed at least in a trap region surrounded by the semiconductor substrate, the first gate electrode and the second gate electrode; and a tunnel insulating film formed between the charge trapping film and the second gate electrode. In one of programming and erasing, electrons are injected into the charge trapping film from the second gate electrode through the tunnel insulating film by Fowler-Nordheim tunneling.

Owner:RENESAS ELECTRONICS CORP

Organic light-emitting display device

ActiveUS7943963B2Reduce voltagePrevent oxidationOther printing matterElectroluminescent light sourcesOrganic filmLow voltage

The present invention provides a top emission type organic light-emitting display device in a production of which it is possible to prevent the organic film from being oxidized when the upper transparent electrode is formed, and which is capable of emitting light at a low voltage. This organic light-emitting display device contains an organic light-emitting layer and an upper electrode and a lower electrode sandwiching the organic light-emitting layer, and is of a structure in which the emitted light is taken out from the upper electrode side, and a buffer layer mainly made of an oxide producing less oxygen by decomposition in the film-forming process than the upper electrode material is provided between the organic light-emitting layer and the upper electrode.

Owner:SAMSUNG DISPLAY CO LTD +1

Organic Electro-Luminescence Device

ActiveUS20090206747A1Improve electron injection efficiencyDecreased life-time of organic materialDischarge tube luminescnet screensElectroluminescent light sourcesHole injection layerMetal chelate

A method of fabricating an organic electro-luminescence device comprising the steps of providing a substrate, an organic chamber, and a sputtering chamber, forming a hole injection layer on the substrate, forming a hole transport layer on the hole injection layer in the organic chamber, forming a light-emitting layer on the hole transport layer in the organic chamber, disposing a metal chelate material on the light-emitting layer and partially doping a CsF compound into the metal chelate material to forming an electron transporting layer in the organic chamber, forming a buffer layer on the electron transporting layer in the organic chamber, transferring the substrate, the hole injection layer, the hole transport layer, light-emitting layer, the electron transporting layer, and the buffer layer form the organic chamber to the sputtering chamber, and forming an electron injection layer on the buffer layer in the sputtering chamber

Owner:AU OPTRONICS CORP

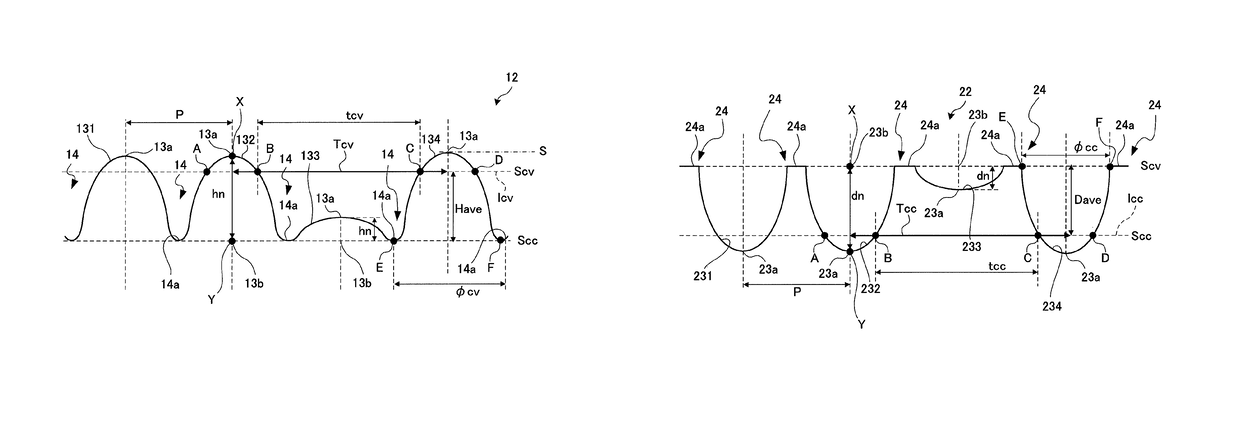

Optical substrate, semiconductor light-emitting element and method of manufacturing semiconductor light-emitting element

InactiveUS9614136B2Improvement of internal quantum efficiency IQEImprove light extractionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingQuantum efficiencyConvex structure

In an optical substrate (1), a concave-convex structure (12) including a plurality of independent convex portions (131 to 134) and concave portions (14) provided between the convex portions (131 to 134) is provided in a surface. The average interval Pave between the adjacent convex portions (131 to 134) in the concave-convex structure (12) satisfies 50 nm≦Pave≦1500 nm, and the convex portion (133) having a convex portion height hn satisfying 0.6 h≧hn≧0 h for the average convex portion height Have is present with a probability Z satisfying 1 / 10000≦Z≦1 / 5. When the optical substrate (1) is used in a semiconductor light-emitting element, dislocations in a semiconductor layer are dispersed to reduce the dislocation density, and thus internal quantum efficiency IQE is improved, and a waveguide mode is removed by light scattering and thus the light the extraction efficiency LEE is increased, with the result that the efficiency of light emission of the semiconductor light-emitting element is enhanced.

Owner:ASAHI KASEI KK

Organic EL display device and method for production of the same

ActiveCN102456711AImprove electron injection efficiencyIncrease in electron volumeElectroluminescent light sourcesSolid-state devicesOrganic electroluminescenceOptoelectronics

Disclosed herein is an organic electroluminescence display device including: a substrate; a plurality of lower electrodes formed thereon for each of a plurality of organic electroluminescence elements; a plurality of hole injecting / transporting layers capable of either hole injection or hole transportation which are formed on the lower electrodes for each of the organic electroluminescence elements; a plurality of organic light emitting layers containing a low-molecular weight material which are formed on the hole injecting / transporting layers for each of the organic electroluminescence elements; an electron injecting / transporting layer capable of either electron injection or electron transportation which is formed over the entire surface of the organic light emitting layers; and an upper electrode formed on the electron injecting / transporting layer.

Owner:JOLED INC

Double-side-bias methods of programming and erasing a virtual ground array memory

InactiveUS7561470B2Improve hole injection efficiencyReduce bias voltageRead-only memoriesDigital storageTrappingEngineering

The present invention provides a method for applying a double-side-bias operation to a virtual ground array memory composed of a matrix of N-bit memory cells. In a first embodiment, the virtual ground array is programmed by a double-side-bias method which applies the same or similar biasing voltage simultaneously on the source region and drain region of a selected charge trapping memory cell so that the left bit and the right bit of the selected charge trapping memory cell are programmed together. In a second embodiment, the virtual ground array is erased by a double-side-bias method which applies the same or similar biasing voltage simultaneously on source regions and regions of a plurality of charge trapping memory cells in the virtual ground array so that the left bit and the right bit of each charge trapping memory cell are erased together.

Owner:MACRONIX INT CO LTD

GaN-based ultraviolet LED epitaxial structure and carrier transport improvement method thereof

InactiveCN109860348AReduce overflowIncrease light intensitySemiconductor devicesCharge carrierUltraviolet

The present invention discloses a GaN-based ultraviolet LED epitaxial structure and a carrier transport improvement method thereof. The GaN-based ultraviolet LED epitaxial structure comprises from bottom to top in order: a sapphire substrate, a low-temperature GaN buffer layer, a U-GaN layer, a Si-doped N-GaN layer, an AlGaN / GaN ultraviolet MQW layer, an EBL electron blocking layer and an Mg-dopedP-GaN layer, and the electron blocking layer comprises an Al component graded AlxGa1-XN layer and an Al component fixing layer. In the process of designing the GaN-based LED device epitaxial structure on the sapphire substrate, Al component graded AlxGa1-xN layers with different thicknesses are designed in the EBL electron blocking layer to effectively improve the hole injection efficiency and reduce the electron overflowing to obviously improve the light intensity and light output power of the AlGaN / GaN ultraviolet LED compared to a traditional scheme.

Owner:江苏晶曌半导体有限公司

Flash memory unit, flash memory unit array and mfg. method thereof

InactiveCN1317767CImprove gate coupling ratioImprove operating speedSolid-state devicesSemiconductor/solid-state device manufacturingComputer architectureGate dielectric

The present invention discloses a flash memory storage unit, flash memory storage unit array and its making method. Said flash memory storage unit array consists of substrate, series-connected several storage unit structures and source region / drain region. Every storage unit structure is formed from stack gate structure consisting of selection gate dielectric layer, selection gate and top cover layer; gap wall placed on the side wall of selection gate; control gate which is placed on one side of the stack gate structure and is connected with stack gate structure; floating gate placed between control gate and substrate; intergate dielectric layer placed between the control gate and floating gate; tunneling dielectric layer placed between floating gate and substrate and control gate and source region / drain region respectively placed in the most external side of storage unit array and substrate of one side of stack gate structure.

Owner:POWERCHIP SEMICON CORP

Structure of flash memory and its operation method

InactiveCN1259723CAvoid programming asymmetry problemsSmall currentSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlash memory

Owner:POWERCHIP SEMICON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com