A kind of preparation method of thin sheet type rare earth permanent magnet material

A rare earth permanent magnet and chip technology, which is applied in the direction of magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of shortened service life, easy corrosion at grain boundaries, poor wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

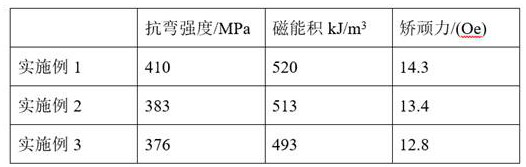

Embodiment 1

[0026] A preparation method of a thin sheet type rare earth permanent magnet material, comprising the following steps:

[0027] (1) Preparation of the main phase alloy. After mixing 11 parts of elemental neodymium, 0.4 parts of elemental dysprosium, 65 parts of elemental iron, and 4 parts of elemental boron, the main phase alloy was prepared, and then crushed, ground, and sieved to obtain the main phase alloy. gold powder;

[0028] (2) Preparation of grain boundary phase alloys, mixing 26 parts of elemental neodymium, 0.5 parts of Co, 0.5 parts of Mo, 4.3 parts of boron, and 45 parts of iron for rapid solidification, with a quenching rate of 27m / s, to prepare a grain boundary alloy , and then pulverized to obtain grain boundary phase alloy powder;

[0029] (3) Mix the main phase alloy powder, grain boundary phase alloy powder, magnesium oxide and zinc oxide evenly according to the mass ratio of 10:0.6:0.3:0.4, then mold them into a sheet-like green embryo, and put the green e...

Embodiment 2

[0031] A preparation method of a thin sheet type rare earth permanent magnet material, comprising the following steps:

[0032] (1) Preparation of the main phase alloy. After mixing 13 parts of elemental neodymium, 0.7 parts of elemental dysprosium, 73 parts of iron oxide, and 6 parts of elemental boron, the main phase alloy was prepared, and then crushed, ground, and sieved to obtain the main phase alloy. gold powder;

[0033] (2) Preparation of the grain boundary phase alloy, mixing 28 parts of elemental neodymium, 1 part of Co, 1 part of Mo, 5.5 parts of boron, and 52 parts of iron oxide, and then rapid solidification, the quenching rate is 35m / s, and the grain boundary is prepared alloy, then pulverized to obtain grain boundary phase alloy powder;

[0034] (3) Mix the main phase alloy powder, grain boundary phase alloy powder, magnesium oxide, and zinc oxide according to the mass ratio of 10: 1.5: 0.8: 0.8, then mold them into a sheet-shaped green embryo, and put the gree...

Embodiment 3

[0036] A preparation method of a thin sheet type rare earth permanent magnet material, comprising the following steps:

[0037] (1) Preparation of the main phase alloy. After mixing 12 parts of elemental neodymium, 0.5 part of elemental dysprosium, 70 parts of iron oxide, and 5 parts of elemental boron, the main phase alloy is prepared, and then crushed, ground, and sieved to obtain the main phase alloy. Gold powder, included in the main phase alloy by parts by weight. ;

[0038] (2) Preparation of grain boundary phase alloys, mixing 27 parts of neodymium, 0.6 parts of Co, 0.7 parts of Mo, 5 parts of boron, and 47 parts of iron for rapid solidification, the quenching rate is 30m / s, and prepared into grain boundary alloys. Pulverize then, obtain grain boundary phase alloy powder;

[0039] (3) Mix the main phase alloy powder, grain boundary phase alloy powder, magnesium oxide, and zinc oxide evenly according to the mass ratio of 10:1:0.5:0.5, then mold them into a sheet-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com