Environment-friendly toy material and preparation method thereof

A toy and environmental protection technology, applied in the field of environmental protection toy materials and preparation, can solve the problems of huge difference in performance, uneven mixing, long degradation time, etc., and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

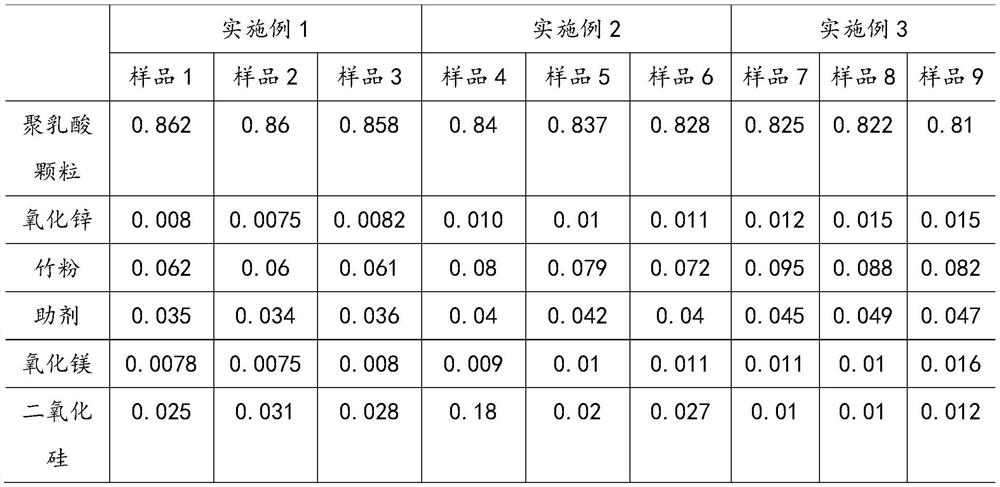

Embodiment 1

[0031] Environmentally friendly toy materials, by mass, include the following components: 70 parts of micro-foamed polylactic acid particles, 4 parts of bamboo powder, 2 parts of a combination of bamboo powder, magnesium oxide and silicon dioxide, bamboo powder, zinc oxide and 2 parts of silicon combination, 3 parts of auxiliary agent, the auxiliary agent is composed of lubricant calcium stearate and antioxidant B215 at a mass ratio of 1:1.

[0032] Concrete preparation process is as follows:

[0033] The preparation of bamboo powder, the bamboo leaf of drying is sent into pulverizer and is pulverized into powder, sieves and obtains 200 order bamboo powders, is placed in the sodium hydroxide solution of concentration 10wt% to soak 2h afterwards, soaks in distilled water and removes sodium hydroxide, Then dry to obtain the final product of bamboo powder.

[0034] Conjugate preparation

[0035] Put the zinc oxide particles in the polyacrylate emulsion and stir evenly to coat t...

Embodiment 2

[0042] Environmentally friendly toy materials, by mass, include the following components: 75 parts of micro-foamed polylactic acid particles, 5 parts of bamboo powder, 3 parts of a combination of bamboo powder, magnesium oxide and silicon dioxide, bamboo powder, zinc oxide and 3 parts of silicon combination, 4 parts of auxiliary agent, the auxiliary agent is composed of lubricant calcium stearate and antioxidant B215 at a mass ratio of 1:1.

[0043] Concrete preparation process is as follows:

[0044] The preparation of bamboo powder, the bamboo leaf of drying is sent into pulverizer and is pulverized into powder, sieves and obtains 300 order bamboo powders, is placed in the sodium hydroxide solution of concentration 10wt% to soak 1h afterwards, soaks in distilled water and removes sodium hydroxide, Then dry to obtain the final product of bamboo powder.

[0045] Conjugate preparation

[0046] Put the zinc oxide particles in the polyacrylate emulsion and stir evenly to coat t...

Embodiment 3

[0053] Environmentally friendly toy materials, by mass, include the following components: 85 parts of micro-foamed polylactic acid particles, 6 parts of bamboo powder, 4 parts of a combination of bamboo powder, magnesium oxide and silicon dioxide, bamboo powder, zinc oxide and 4 parts of silicon combination, 5 parts of auxiliary agent, the auxiliary agent is composed of lubricant calcium stearate and antioxidant B215 at a mass ratio of 1:1.

[0054] Concrete preparation process is as follows:

[0055] The preparation of bamboo powder, the bamboo leaf of drying is sent into pulverizer and is pulverized into powder, sieves and obtains 500 order bamboo powders, puts the sodium hydroxide solution of concentration 10wt% to soak 2h afterwards, soaks in distilled water and removes sodium hydroxide, Then dry to obtain the final product of bamboo powder.

[0056] Conjugate preparation

[0057] Put the zinc oxide particles in the polyacrylate emulsion and stir evenly to coat the polya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com