Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Ethoxy Compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar energy silicon crystal chip scavenger

ActiveCN101020866AImprove washing effectImprove stabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsScavengerPotassium hydroxide

The solar energy silicon crystal chip scavenger is compounded with sodium triacetate complex 10-30 wt%, C10-C13 carbonyl ethoxyl compound surfactant 5-10 wt%, fatty alcohol alkoxyl surfactant 3-5 wt%, sodium salt of acylate copolymer 0.05-0.15 wt%, hydrogen peroxide as oxidant 0.5-2 wt%, butyl glycol ether as organic solvent 5-10 wt%, potassium hydroxide 1-5 wt%, and water for the rest. It contains no toxic, harmful and pollutant matter, and has high detergency, biodegradability and environment friendship.

Owner:CHANGZHOU JUNHE TECH

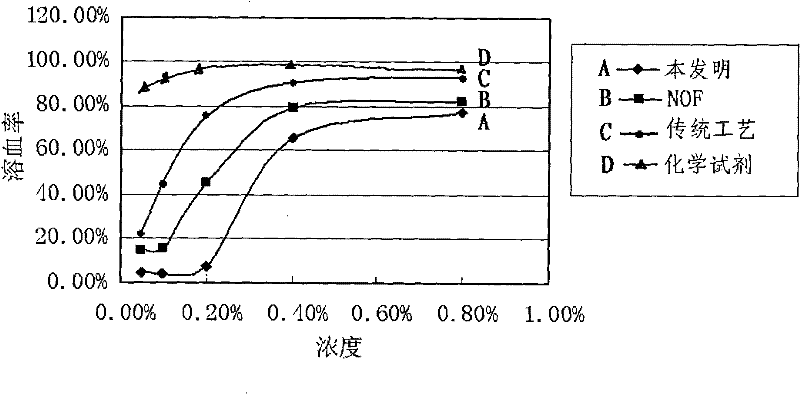

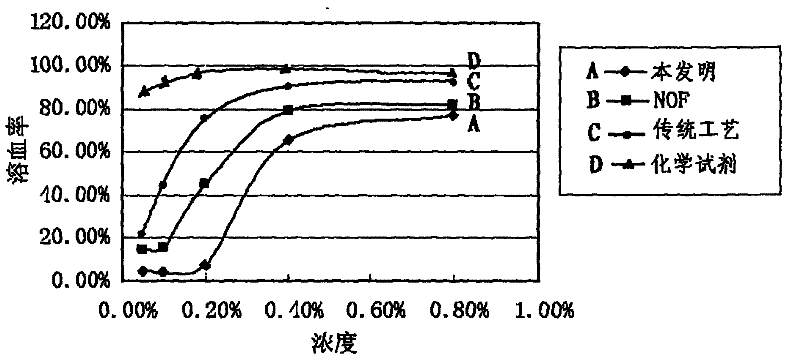

Method for synthesizing high-purity polysorbate-80

ActiveCN101701065AHigh purityLight colorTransportation and packagingMixingSorbitanOleic Acid Triglyceride

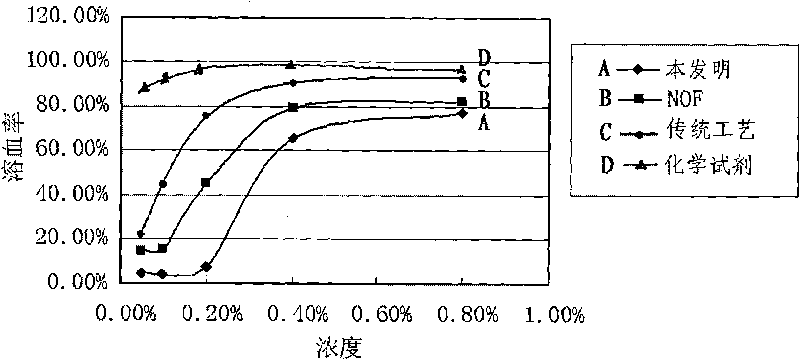

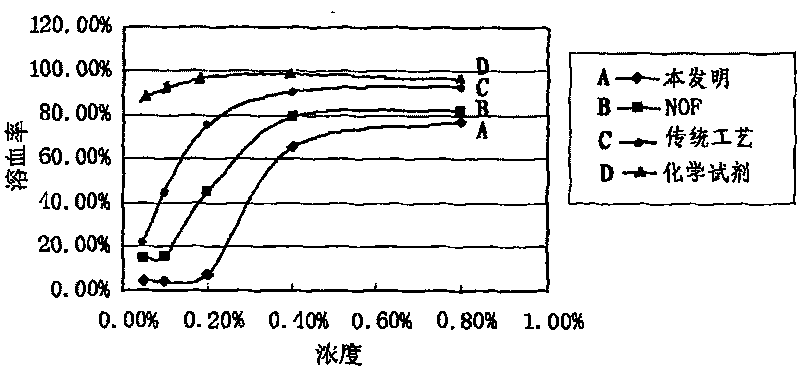

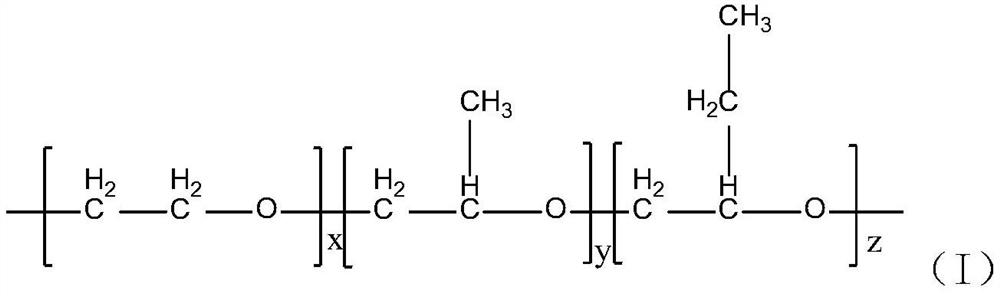

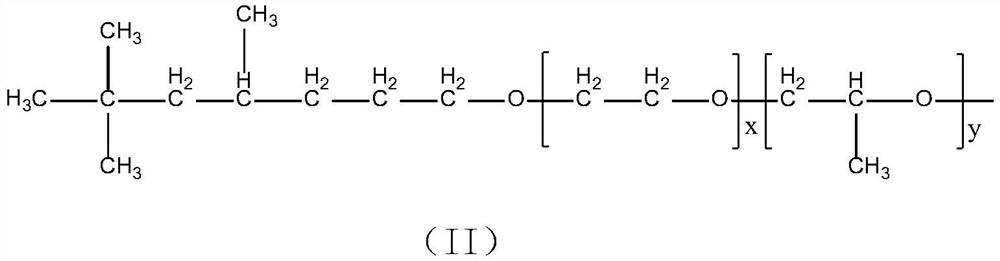

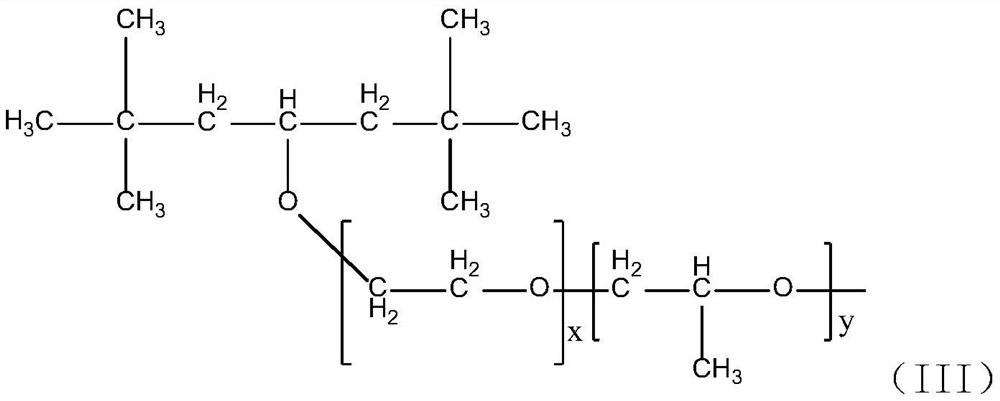

The invention relates to a method for synthesizing high-purity polysorbate-80. The polysorbate-80 (I) is a partial esterified product of a sorbitan ethyoxyl compound and oleic acid. The method comprises the following steps of: (1) partially dehydrating sorbitol as a raw material under the action of an acid catalyst in a state of vacuum to obtain sorbitan (II); (2) carrying out addition polymerization on the sorbitan (II) and oxirane under the action of a base catalyst to obtain sorbitan polyethenoxy ether (III), wherein the addition number of the oxirane is 20; (3) reacting the sorbitan polyethenoxy ether (III) with the high-purity oleic acid under the action of an esterifying catalyst and refining to obtain the high-purity polysorbate-80. The invention leads the emulsifying and solubilizing performance of products to be more perfect and the quality of the products to easily meet the requirement of an injection class and has easily controlled quality and good stability; and the high-purity polysorbate-80 has lower blood dissolving rate in same concentration, and predictable and safer clinical use by being used as an auxiliary material for injection.

Owner:NANJING WELL BIOCHEM

Ingredients of catalyst for vinyl polymerization and catalyst

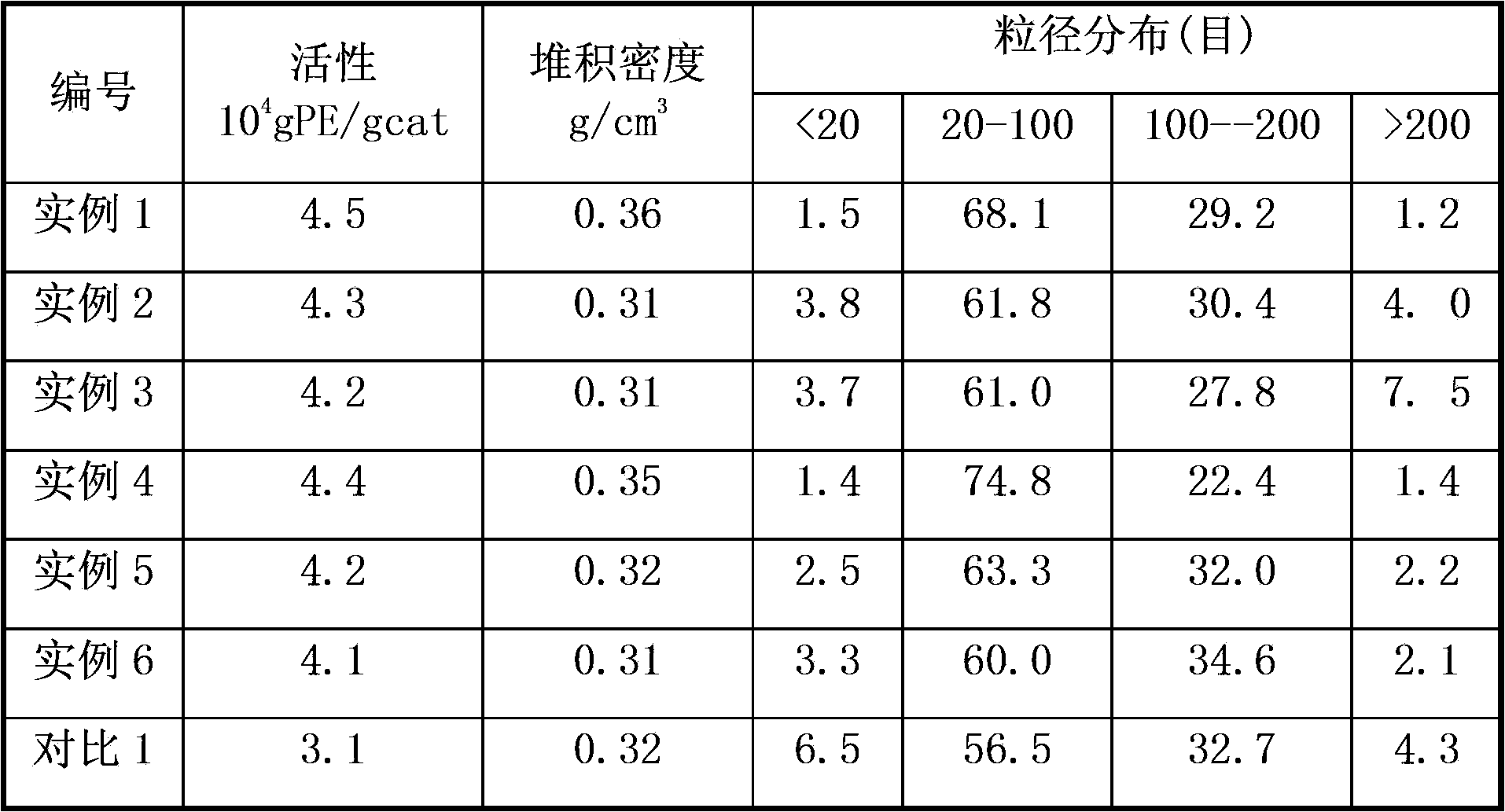

The invention relates to ingredients of a catalyst for vinyl polymerization. The ingredients comprise the following reaction products: (1) a magnesium compound, (2) an organic alcoholic compound, (3) an organic silicon compound, (4) a non-ionic surfactant, and (5) a titanium compound, wherein the structural formula of the organic silicon compound is at least one of R<1>xR<2>ySi(OR<3>)z, wherein R<1> and R<2> are respectively alkyl or halogen of which the carbon numbers are 1 to 10; R<3> is alkyl of which the carbon number is 1 to 10; x, y and z are integral numbers; x is larger than or equal to 0 and smaller than or equal to 2; y is larger than or equal to 0 and smaller than or equal to 2; z is larger than or equal to 0 and smaller than or equal to 4; x+y+z=4; the non-ionic surfactant is at least one of the periodic copolymers of a poly-oxyethylene ether compound, a carbon oxo alcohol ethoxy compound and an epoxy compound. The catalyst is relatively high in catalytic activity and copolymerization performance; a polymer prepared with the catalyst is relatively high in bulk density and relatively small in size distribution; the catalyst is suitable for homopolymerization of ethylene or copolymerization of ethylene and other Alpha-olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

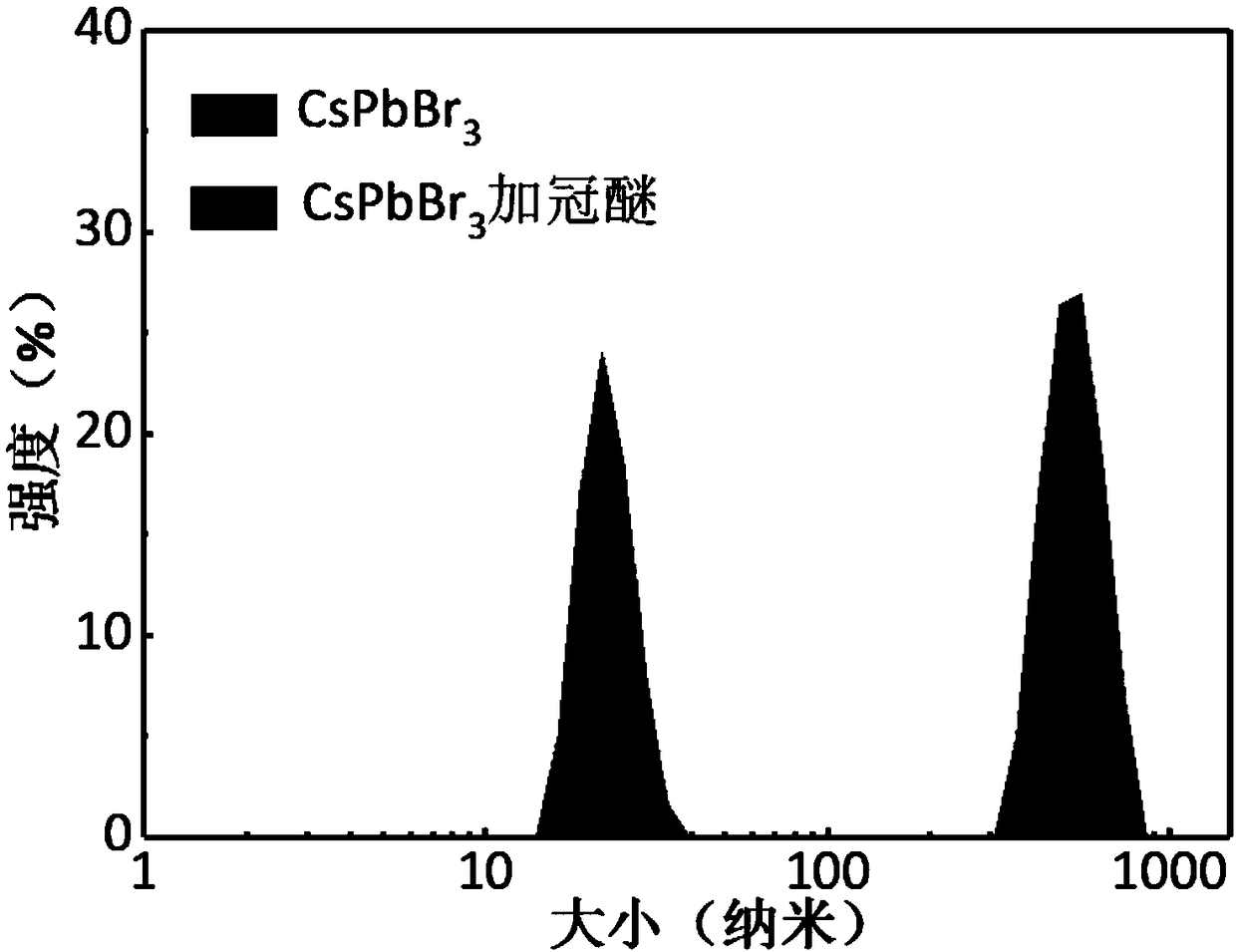

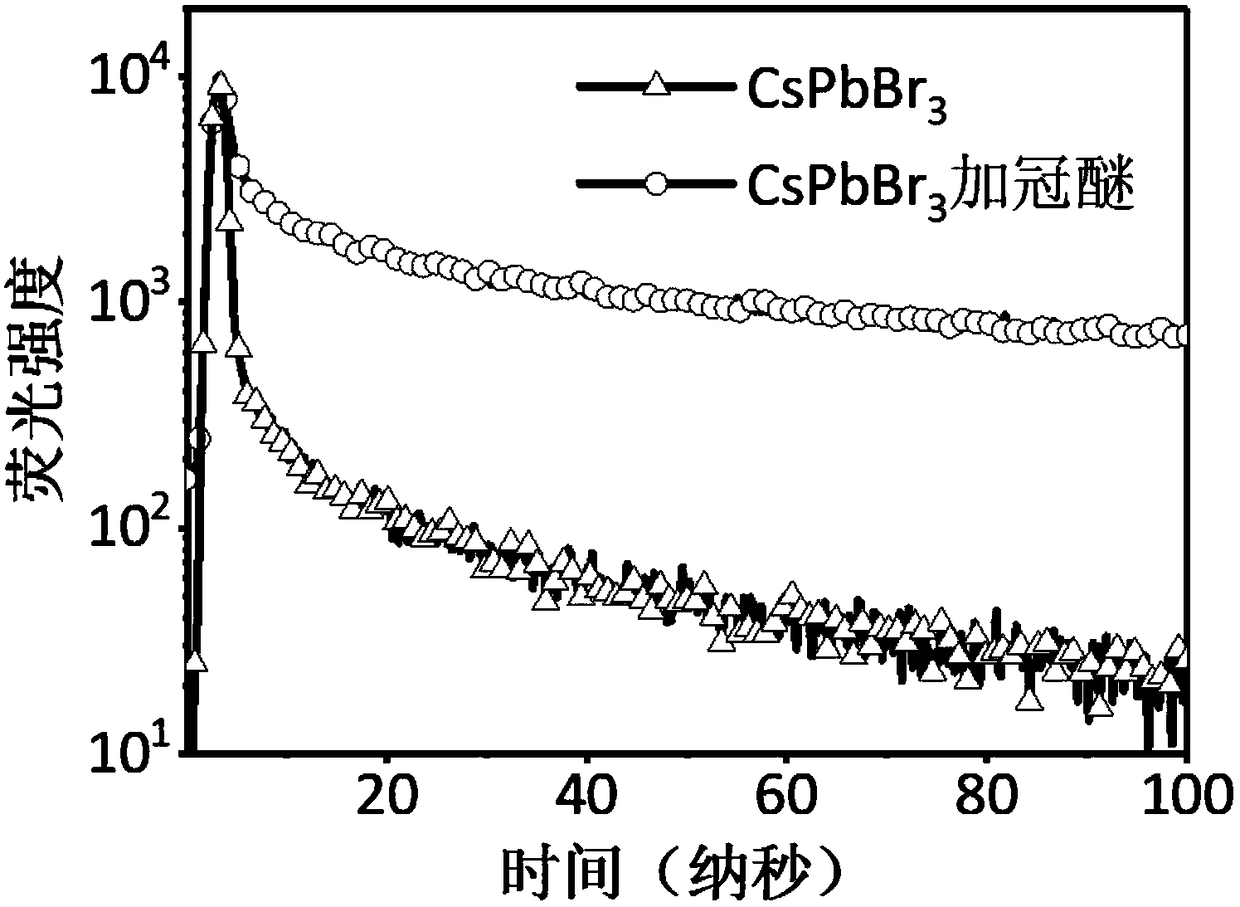

Perovskite light emitting diode with compounds containing CH2CH2O and method for preparing perovskite light emitting diode

ActiveCN108281572AImprove efficiencyEffective compoundSolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerEthoxy Compounds

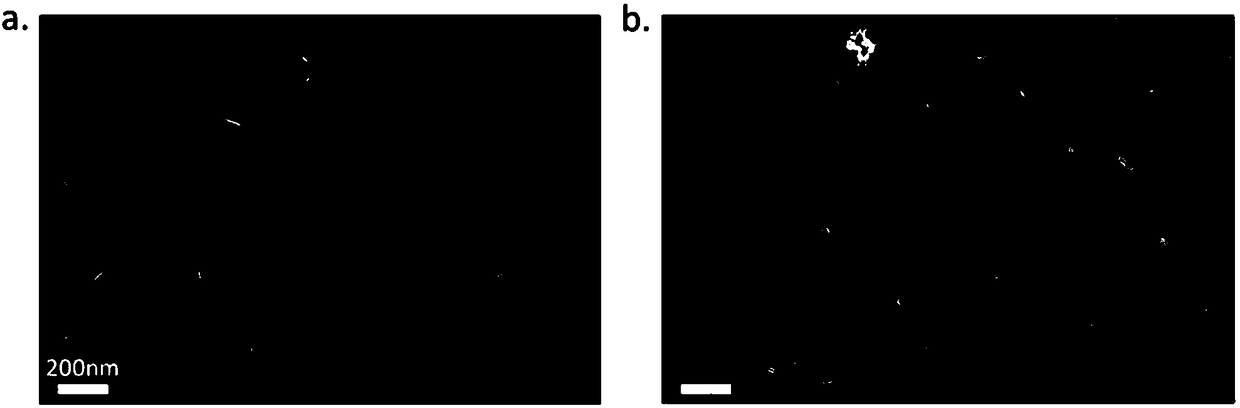

The invention relates to a perovskite light emitting diode with compounds containing CH2CH2O. The perovskite light emitting diode comprises a substrate, a hole transport layer, an active light emitting layer, an electron transport layer, electrode modification layers and electrodes. The thickness of the active light emitting layer is 5-100 nanometers, the active light emitting layer comprises perovskite and the compounds containing the CH2CH2O, and the compounds containing the CH2CH2O are doped in the perovskite; the molecular formula of the perovskite is MAPbX3, FAPbX3 or CsPbX3, wherein X represents one or two of Cl, Br and I; the compounds containing the CH2CH2O are 12-crown ether-4, 15-crown ether-5, benzo-15-crown ether-5, 18-crown ether-6 and the like. The invention further providesa method for preparing the perovskite light emitting diode. The method includes: forming the hole transport layer or the electron transport layer on the substrate; modifying a perovskite precursor solution with the compounds containing the CH2CH2O on the hole transport layer or the electron transport layer to form the active light emitting layer; sequentially forming the electron transport layer,the negative electrode modification layer and the negative electrode at the top of the active light emitting layer or sequentially forming the hole transport layer, the positive electrode modificationlayer and the positive electrode at the top of the active light emitting layer; carrying out encapsulation.

Owner:SUZHOU UNIV

Natural environment-friendly kitchen cleaning agent and preparation method thereof

ActiveCN102827712ASurface-active non-soap compounds and soap mixture detergentsEnvironmental resistanceIrritation

The invention discloses a natural environment-friendly kitchen cleaning agent which comprises the following raw materials in parts by mass: 2-15 parts of orange plant essential oil, 1-20 parts of C10 Guerbet alcohol ethoxylate, 0.2-5 parts of natural glucoside surfactant, 0.2-10 parts of propanediol, 0.5-10 parts of ethanol, 0.01-5 parts of citric acid, 0.01-5 parts of sodium citrate and 60-90 parts of deionized water. The invention has the following advantages: the raw materials are natural, non-toxic and non-irritating, and are very healthy for human body; the cleaning agent is green and environment-friendly; the cleaning agent is free of perfume, and the natural essential oil can emit subtle fragrance to delight body and mind and effectively remove peculiar smell; the cleaning agent has good bactericidal performance and an antibacterial effect; the microemulsion system is incombustible, thereby ensuring use safety; the pH value is weakly acidic and is consistent with the skin acidic and basic capacity of human body, thereby avoiding burning irritation; the cleaning agent is free of strong base and thickener, thereby being safer; and the cleaning agent is simple and convenient in production process, can be produced under normal temperature and achieves the advantages of low carbon content and environment friendliness.

Owner:朱禾中

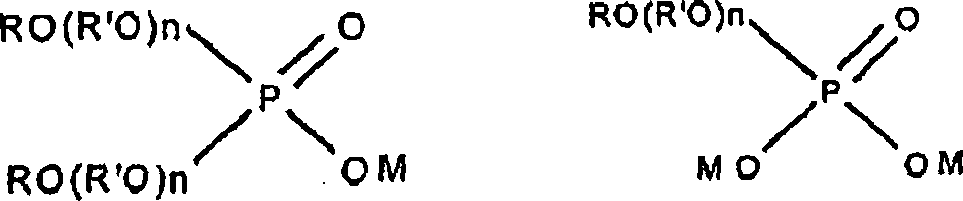

Electroplating solution for gold-tin eutectic alloy

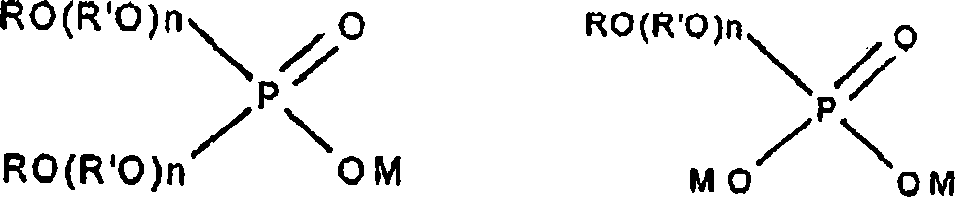

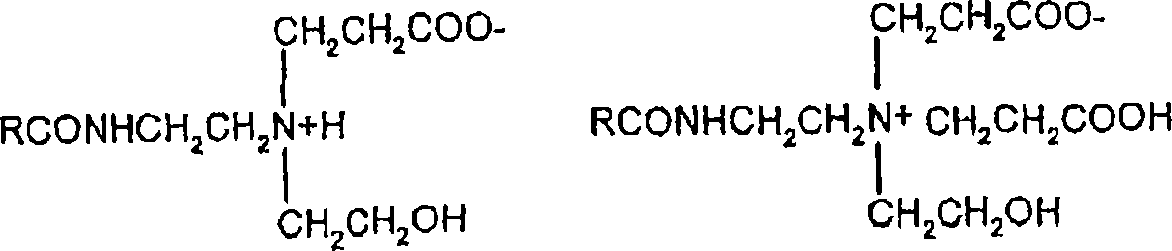

The invention relates to an electrolyte used in connection with the deposition of a gold-tin alloy on an electroplatable substrate. This solution generally includes water; stannous and / or stannic tin ions, a complexing agent to render the stannous and / or stannic tin ions soluble, complexed gold ions, and an alloy stabilizing agent that includes ethoxylated compounds with phosphate ester functional group, brightening additives based on ethoxylated phosphate esters and alkali metal fatty acids dipropionates. The brighteners may be used alone or in conjunction with each other to achieve beneficial synergistic effect. The alloy stabilizing agent is present in an amount sufficient to stabilize the composition of the gold-tin deposit over a usable current density range. The solution has a pH of between 2 and 10 and the gold ions and tin ions are present in relative amounts sufficient to provide a deposit having a gold content less than 90% by weight and a tin content greater than 10% by weight.

Owner:B F TECHNOLOGY INC

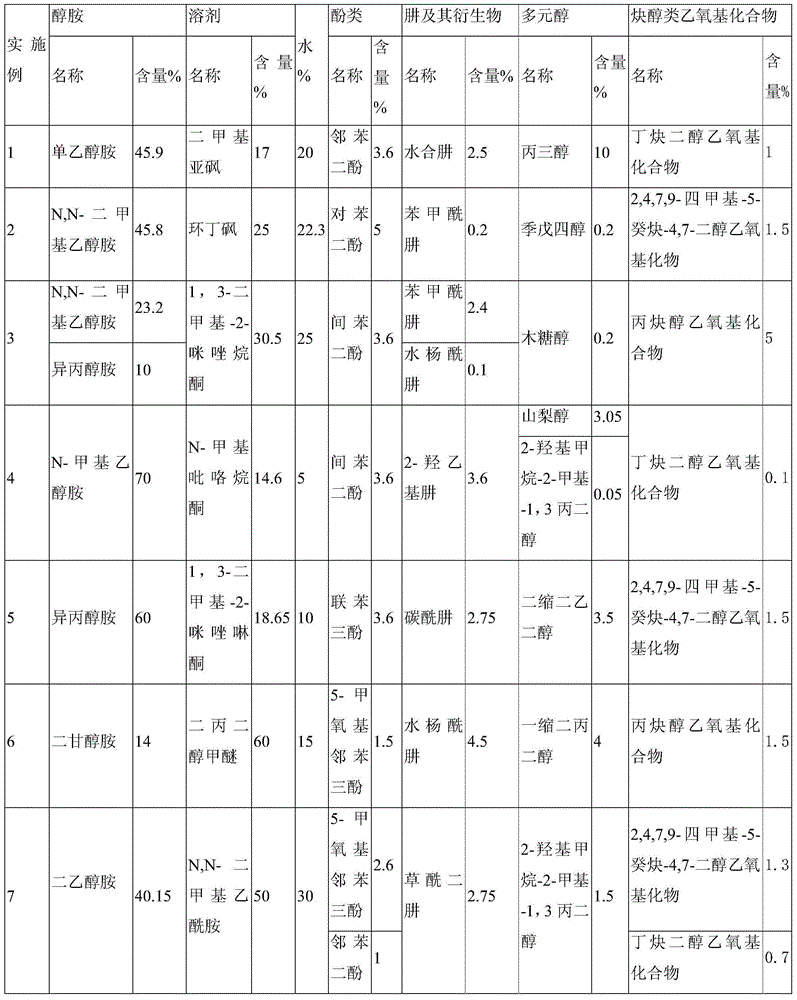

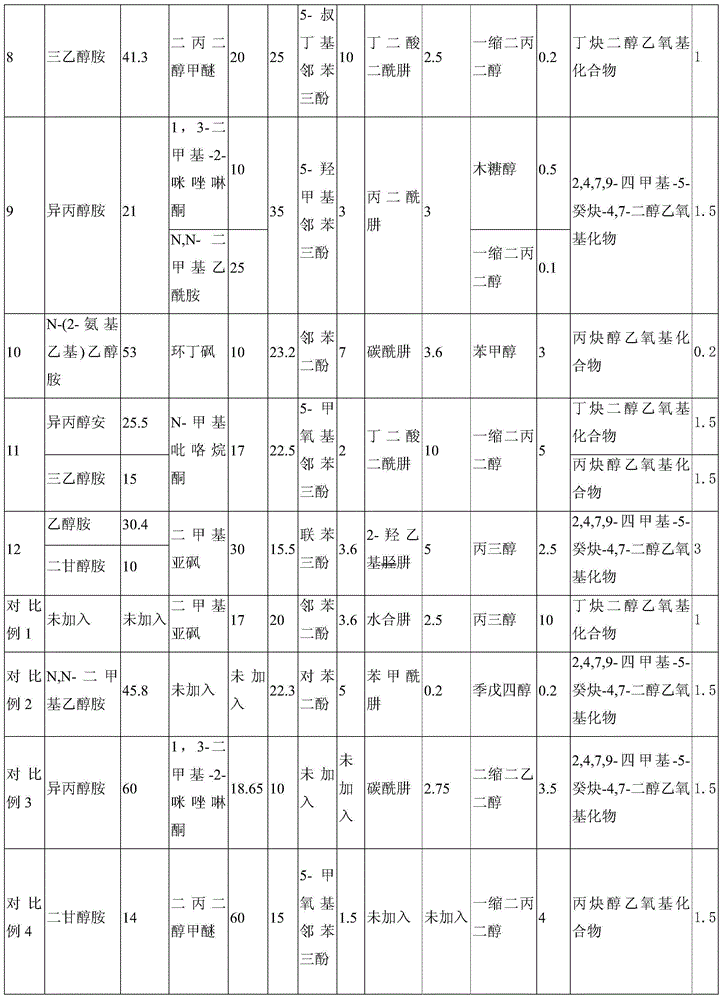

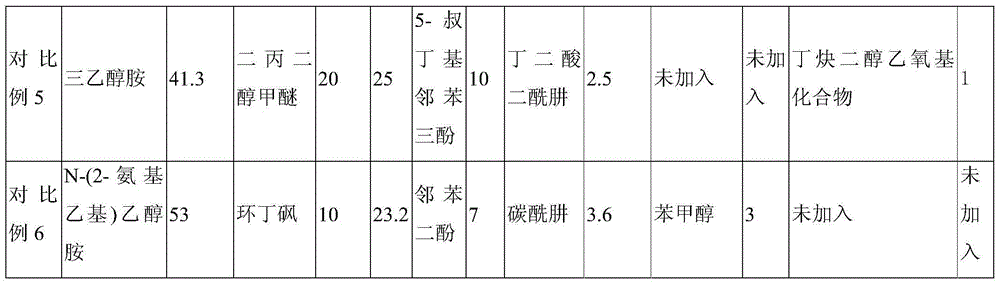

Soldering flux for improving film-forming property

InactiveCN103801860AImprove performanceHalogen freeWelding/cutting media/materialsSoldering mediaTriclosanGlutaric acid

The invention discloses soldering flux for improving the film-forming property. The soldering flux is prepared from 10-20 parts of activating agent, 2-6 parts of surface active agent, 0.3-0.8 part of cosolvent, 0.2-2 parts of film-forming agent, 0.04-0.09 part of corrosion inhibitor, 1-4 parts of antioxidant and the balance of deionized water, wherein the film-forming agent is prepared from at least one of PEG-1000, PEG-2000, PEG-4000 and PEG-6000, the surface active agent is prepared from at least one of FMEE and lutensol to (3,5,7,9) compounds, BTA and BIA are mixed to form the corrosion inhibitor, the antioxidant is prepared from at least one of tertiary butylhydroquinone, triclosan, tetrachloroisophthalonitrile and allicin, and the activating agent is prepared from at least two of glutaric acid, DL-malic acid, methylsuccinic acid and itaconic acid. With the method, the soldering flux for improving the film-forming property has the advantages of being free of halogen, low in residue, free of washing, environmentally friendly and the like.

Owner:SUZHOU LOTTE CHEM TECH

Low-temperature degreasing cleaning agent

The invention discloses a low-temperature degreasing cleaning agent, comprising, by mass, 10-30% of chemically pure sodium hydroxide, 2-5% of chemically pure sodium hypochlorite, 5% of a chemically pure surfactant, 0.1% of a chemically pure chelating auxiliary agent, 1-3% of a chemically pure antibacterial agent, and the balance being chemically pure deionized water. The surfactant comprises at least one of an NP series surfactant, fatty acid methyl ester (FMEE), a heterogeneous tridecane alcohol ethoxylated compound and an RF series surfactant; the chelating auxiliary agent comprises ethylenediamine tetraacetic acid (EDTA); and the surfactant comprises an RF-25-1 surfactant; and the antibacterial agent is triclosan. With the above way, the low-temperature degreasing cleaning agent provided by the invention can be used at a low temperature lower than or equal to 60 DEG C, contains low bubble content or no bubble, can be used for cleaning rotating steel belts, can be used for cleaning rotating metal products with a contact time longer than 20 seconds at a low temperature environment, and has antibacterial property as well as environmental protection property.

Owner:SUZHOU LOTTE CHEM TECH

Photoresist residue cleaning liquid

InactiveCN105785725AEfficient removalAvoid corrosionOrganic detergent compounding agentsSemiconductor/solid-state device manufacturingCross-linkCooking & baking

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

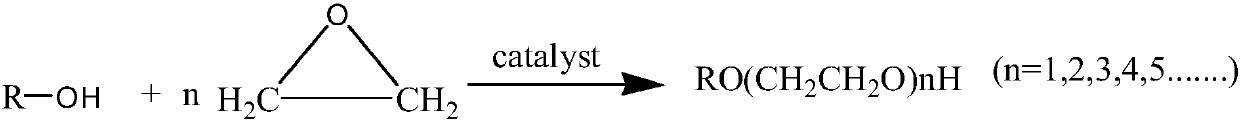

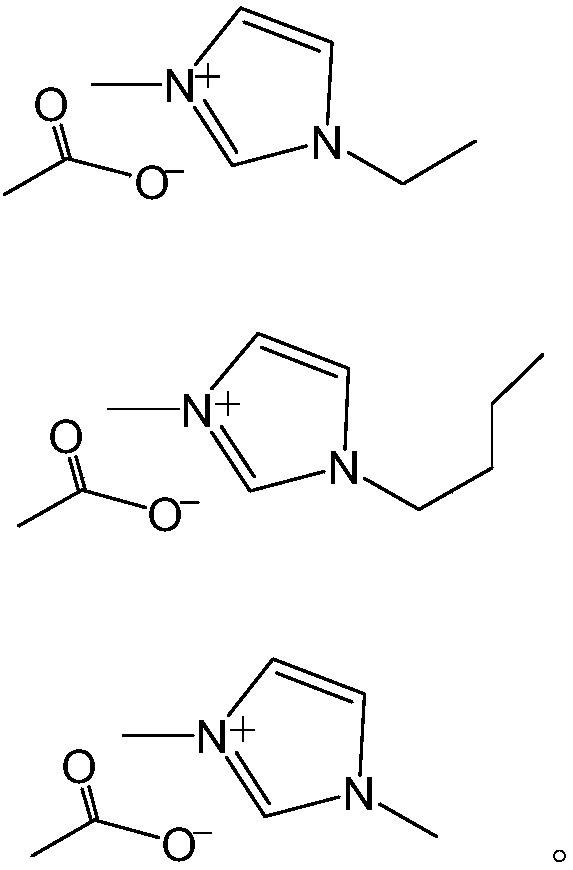

Catalyst for ethylene oxide ring-opening reaction and preparation method for oxethyl compound

InactiveCN107661778AHybrid configuration is easyImprove catalytic reaction efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation from oxiranesLiquid stateEthylene oxide

The invention provides a catalyst for ethylene oxide ring-opening reaction and a preparation method for an oxethyl compound. The catalyst comprises one or more of imidazole acetate, quaternary ammonium acetate and pyridine acetate. The catalyst in the execution mode of the invention is ionic liquid; the ionic liquid is under a liquid state, so that the catalyst is easily mixed with an initiator ofthe ring-opening reaction; besides, the catalytic reaction efficiency is higher under the synergistic effect of alkaline group of ionic liquid and hydrogen bond.

Owner:辽宁奥克药业股份有限公司

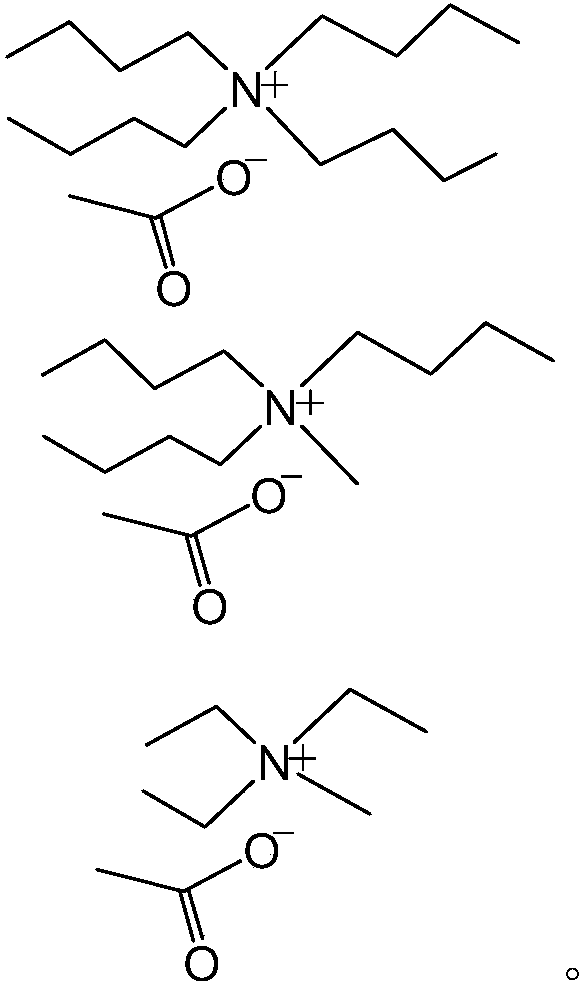

A nickel-cobalt alloy electroplating solution and an electroplating method

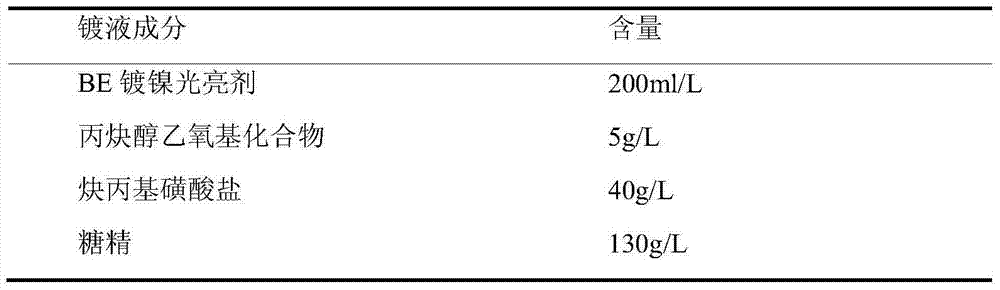

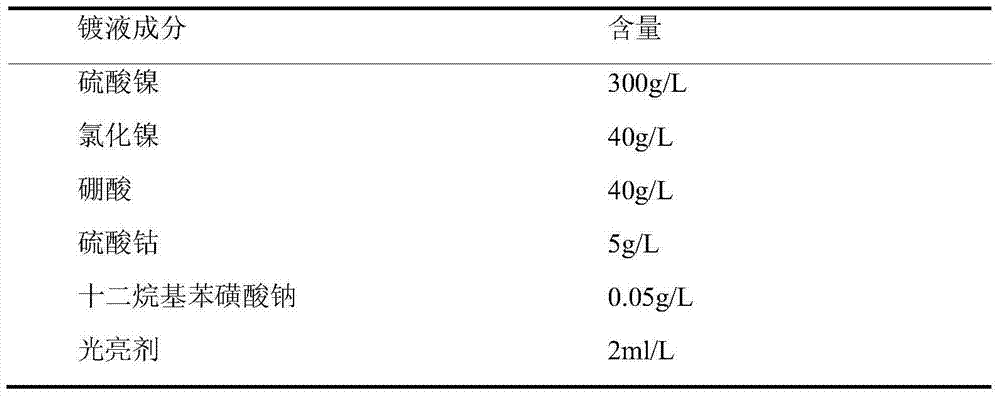

A nickel-cobalt alloy electroplating solution and an electroplating method are disclosed. The electroplating solution comprises 260-300 g / L of nickel sulfate, 40-60 g / L of nickel chloride, 25-40 g / L of boric acid, 5-15 g / L of cobaltous sulfate, 0.5-2 mL / L of a brightener and 0.05-0.2 g / L of an emulsifier, wherein the brightener is a mixture of a BE nickel plating brightener, propynol ethoxylate, propargyl sulfonate and saccharin. Divalent cobalt ions and divalent nickel ions in the electroplating solution are co-deposited on the surface of a workpiece to be plated in a cathode. The cobalt element introduced into a plating reduces porosity of the plating and enhances hardness, wear resistance and brightness of the plating.

Owner:WUXI HUAYE IRON & STEEL

Electroless nickel plating compound brightener and use method thereof

InactiveCN102181848AIncrease brightnessDoes not affect bath stabilityLiquid/solution decomposition chemical coatingElectroless nickelPyridinium

The invention discloses an electroless nickel plating compound brightener and a use method thereof. Each liter of aqueous solution of the brightener contains 2-4g of cerous sulfate, 10-35g of propynol ethoxylate, 100-150g of pyridinium and 14-20g of propynol. Compared with the prior art, the electroless nickel plating compound brightener can obviously improve the brightness of the electroless plating and can not affect the stability of the plating solution for electroless nickel plating.

Owner:CHERY AUTOMOBILE CO LTD

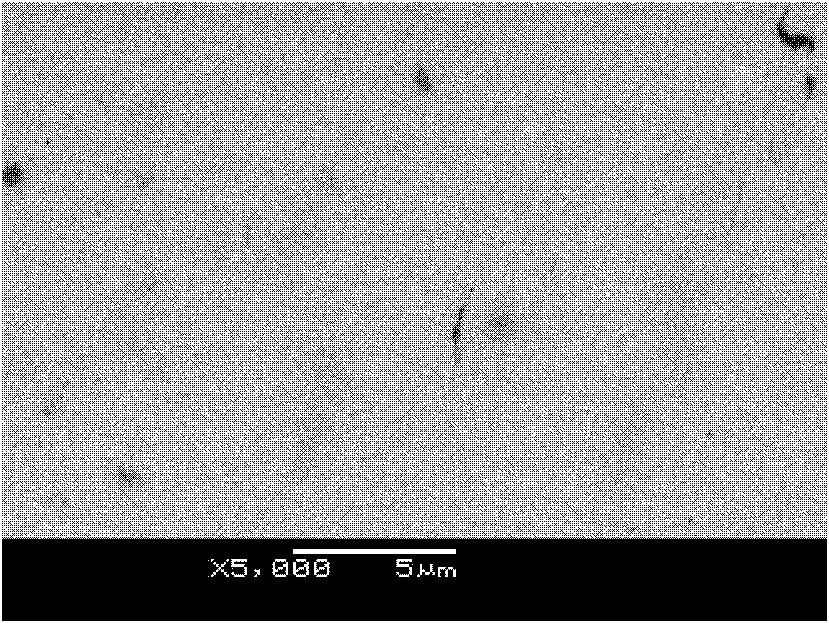

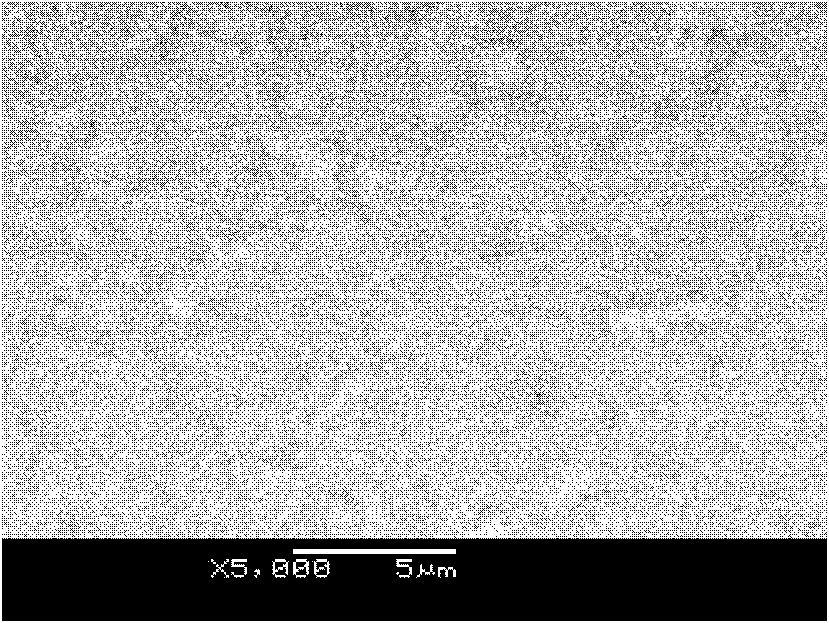

One-step preparation method and application of propargyl alcohol ethoxylate

InactiveCN109183089AOvercome the deep colorOvercoming the problem of low retention of alkynyl groupsDistillationReaction temperature

The invention discloses a one-step preparation method and application of propargyl alcohol ethoxylate. Propargyl alcohol ethoxylate is prepared from propargyl alcohol and ethylene oxide through synthesis. The method specifically comprises the steps of adding propargyl alcohol and a quaternary ammonium alkali catalyst into a reaction kettle, carrying out nitrogen displacement and vacuumizing for several times, introducing ethylene oxide, controlling the reaction temperature at 82-88 DEG C and the reaction pressure at 0.3MPa-0.5MPa, carrying out after-treatment ageing on the product, maintainingthe temperature of the reaction kettle until the pressure of the reaction kettle no longer decreases, cooling to 60 DEG C, then neutralizing by virtue of glacial acetic acid, and removing low-boiling-point substances. Propargyl alcohol ethoxylate prepared by virtue of the one-step preparation method has lots of advantages of high conversion rate and acetylene bond retention rate, light color andthe like, and an original required distillation purification manner can be replaced, so that the amount of waste is greatly reduced, and compared with preparation methods in the prior art, the one-step preparation method is relatively environment-friendly. By applying propargyl alcohol ethoxylate to an electronickelling process, an obtained plating layer is plump, and a skip plating phenomenon isbasically avoided.

Owner:WUHAN OXIRAN SPECIALTY CHEM CO +1

Waterborne environment-friendly residual gum cleaning agent and preparation method thereof

InactiveCN109456840AStable emulsification and dispersion effectGuaranteed long-term stabilityInorganic/elemental detergent compounding agentsSurface-active detergent compositionsSodium bicarbonateCleansing Agents

The invention relates to a waterborne environment-friendly residual gum cleaning agent and a preparation method thereof. The cleaning agent is prepared from, by weight, 25-40 parts of deionized water,30-55 parts of natural plant extracts, 0.3-0.8 part of anionic emulsifiers, 0.2-1.0 part of nonionic emulsifiers, 8-15 parts of biological ester environment-friendly plasticizers and 5-10 parts of sodium bicarbonate. The anionic emulsifiers are sodium alkyl sulfate, a HLB (hydrophile-lipophile balance) value of the sodium alkyl sulfate is 35-40, the nonionic emulsifiers are acetylenediol ethoxy compounds, and a HLB value of the acetylenediol ethoxy compounds is 3-6. The waterborne environment-friendly residual gum cleaning agent has high residual gum and stain removal capability and good stability and the advantages of being green and environmentally friendly.

Owner:DONGGUAN STAR COSM POLYMER

Crystalline silicon cutting fluid as well as preparation method and application thereof

ActiveCN112779079APromote wettingEasy to cleanFine working devicesLubricant compositionAntibacterial propertyMaterials science

The invention discloses a crystal silicon cutting fluid. The crystal silicon cutting fluid comprises the following components including macromolecular block polyether, an alcohol wetting agent A and an alcohol wetting agent B, the macromolecular block polyether is a block copolymer of ethylene oxide, epoxypropane and epoxybutane; the alcohol wetting agent A is an alcohol modified by ethylene oxide and epoxypropane; and the alcohol wetting agent B is an alkynediol ethyoxyl compound modified by ethylene oxide, propylene oxide and epoxybutane. The crystal silicon cutting fluid provided by the invention has excellent wetting, cooling, lubricating, cleaning, chip carrying and low-foam properties, also has high permeability and antibacterial property, and can be recycled; the crystal silicon cutting fluid can effectively reduce TTV on the surface of a silicon wafer, reduce line marks, reduce friction between a diamond wire and the surface of the silicon wafer and improve the first-grade product rate; and in addition, the crystal silicon cutting fluid can effectively protect a diamond wire, reduce abrasion of the diamond wire, improve durability of the diamond wire and further improve productivity and economic benefits.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

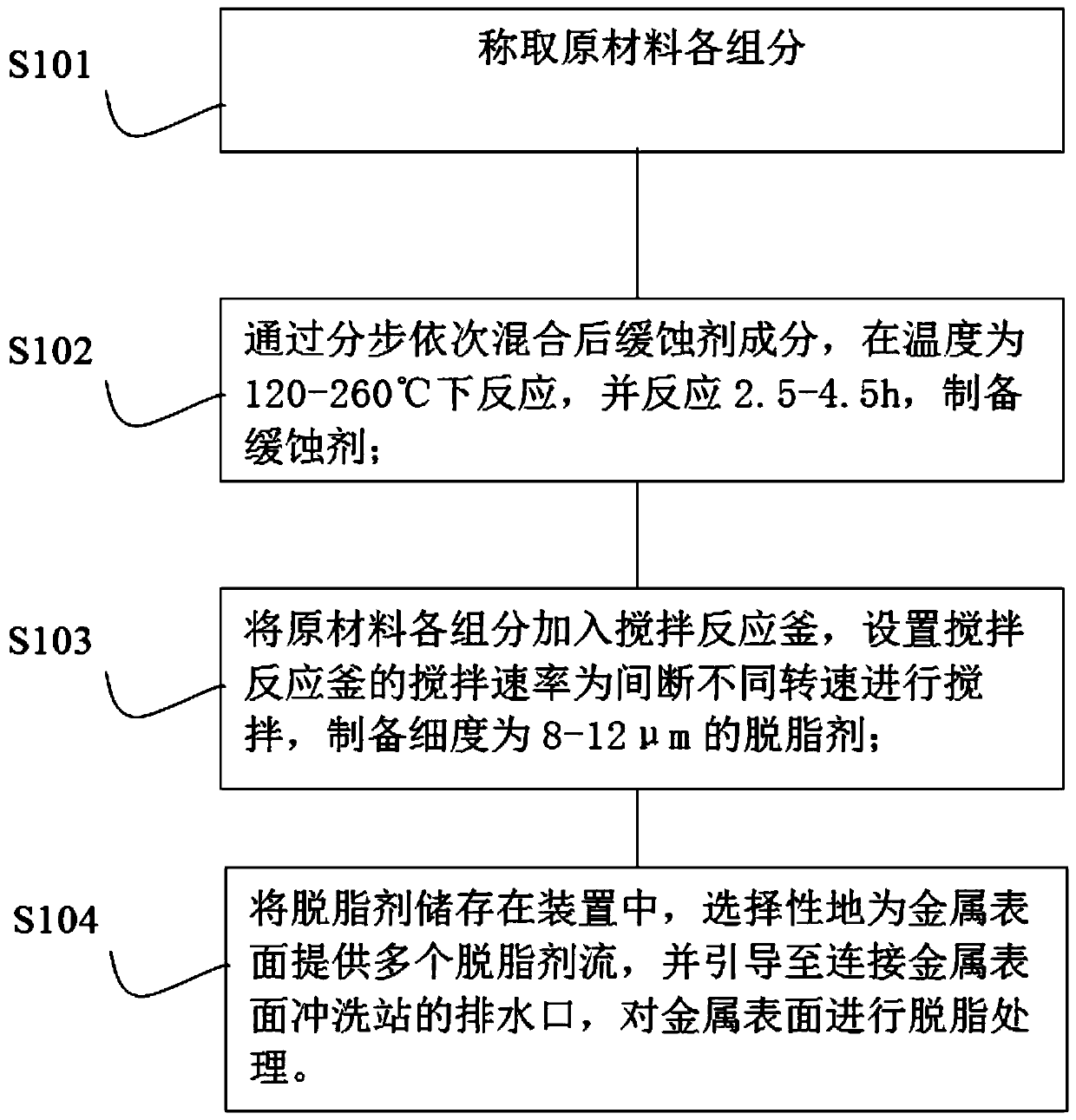

Environmentally-friendly efficient degreasing agent and application thereof

The invention provides an environmentally-friendly efficient degreasing agent. The environmentally-friendly efficient degreasing agent comprises the following components: dodecylbenzene sulfonic acid,monoethanolamine, disodium ethylenediamine tetracylate, potassium silicate, sodium hexadecyl benzene sulfonate, a corrosion inhibitor and various surfactants; furthermore, the various surfactants comprise sodium lignin sulfonate, a fatty alcohol ethoxy compound and a carbonyl alcohol ethoxy compound; and the degreasing agent is applied to a metal surface treatment process. The degreasing agent can wet the metal surface, has extremely strong permeating, dispersing, solubilizing and emulsifying effects and has extremely strong grease-removing effect; furthermore, the fineness of the degreasingagent is 8 to 12 microns, stable degreasing agent flow can be formed, large contact area is formed on a metal surface flushing station and the metal surface, the oil dirt adhesion force is significantly reduced and removal of the oil dirt is accelerated; in addition, the degreasing agent has extremely low corrosivity on metal, is green and environmentally-friendly, and can effectively protect thesurface of the cleaned material from being eroded and guarantee the healthiness of the working environment while cleaning.

Owner:佛山市骏虎表面技术有限公司

Dye ink compatible with original inkjet pigment ink

The invention discloses a dye ink compatible with an original inkjet pigment ink, which comprises the following components in percentage by mass: 10-35% of a pigment, a solvent, a cosolvent, 0.05-0.3%of an auxiliary agent and water, wherein the mass sum of the solvent and the cosolvent is 10%-40%, the solvent is a monohydric alcohol or a dihydric alcohol, the cosolvent is an alcohol ether solvent, and the auxiliary agent is an alkynediol ethoxy compound. The added cosolvent and auxiliary agent have a certain synergistic effect, and after the ink is mixed with the original inkjet pigment ink under the condition that the smoothness of the ink in the successive printing process is ensured, the incompatibility (such as white exposure, ink shortage, fuzzy handwriting, nozzle blockage, no ink discharge and the like during printing) does not occur, so that the printing quality is improved. The problem that an ink-jet printer using pigment ink is incompatible after dye ink is replaced is solved.

Owner:深圳市墨库图文技术有限公司

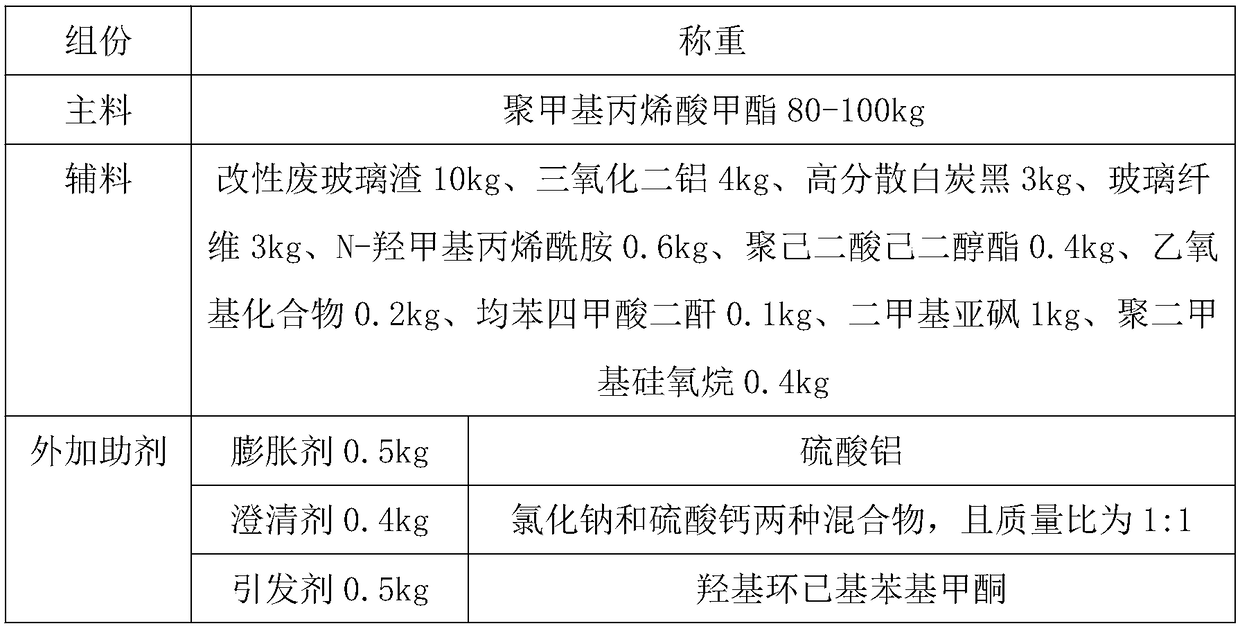

Organic glass material and preparation method thereof

Relating to the field of organic glass materials, the invention discloses an organic glass material and a preparation method thereof. The material comprises the following raw materials: polymethyl methacrylate, modified waste glass slag, aluminum oxide, highly dispersed white carbon black, glass fiber, N-hydroxymethyl acrylamide, polyhexanediol adipate, an ethoxylated compound, pyromellitic dianhydride, dimethyl sulfoxide, polydimethylsiloxane, an expansion agent, a clarifying agent, an initiating agent and a plasticizer. The preparation method includes: raw material mixing, heating and reaction. The organic glass material provided by the invention is simple and convenient to prepare, and has the characteristics of high flexural and compressive strength, good impact toughness, good machining properties, high temperature resistance and chemical reagent corrosion resistance, greatly widens the application fields of the organic glass material, prolongs the service life of organic glass products and improves the practicability of organic glass products, and has broad market prospects.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

Method for synthesizing high-purity polysorbate-80

The invention relates to a method for synthesizing high-purity polysorbate-80. The polysorbate-80 (I) is a partial esterified product of a sorbitan ethyoxyl compound and oleic acid. The method comprises the following steps of: (1) partially dehydrating sorbitol as a raw material under the action of an acid catalyst in a state of vacuum to obtain sorbitan (II); (2) carrying out addition polymerization on the sorbitan (II) and oxirane under the action of a base catalyst to obtain sorbitan polyethenoxy ether (III), wherein the addition number of the oxirane is 20; (3) reacting the sorbitan polyethenoxy ether (III) with the high-purity oleic acid under the action of an esterifying catalyst and refining to obtain the high-purity polysorbate-80. The invention leads the emulsifying and solubilizing performance of products to be more perfect and the quality of the products to easily meet the requirement of an injection class and has easily controlled quality and good stability; and the high-purity polysorbate-80 has lower blood dissolving rate in same concentration, and predictable and safer clinical use by being used as an auxiliary material for injection.

Owner:NANJING WELL BIOCHEM

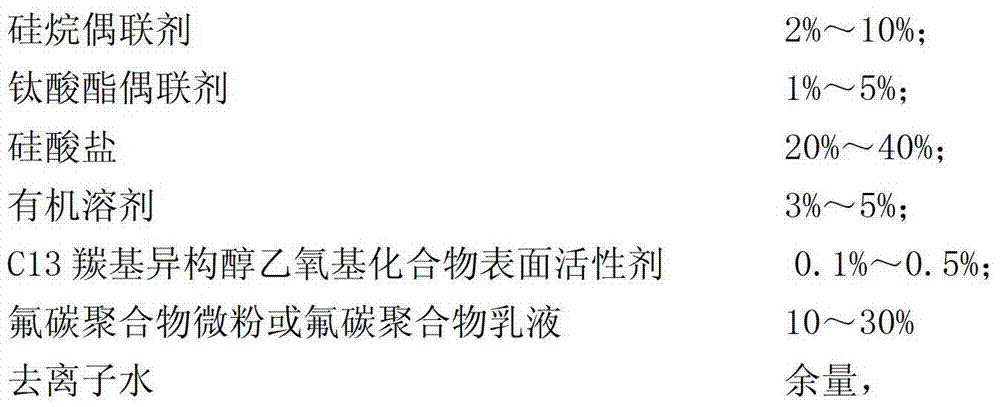

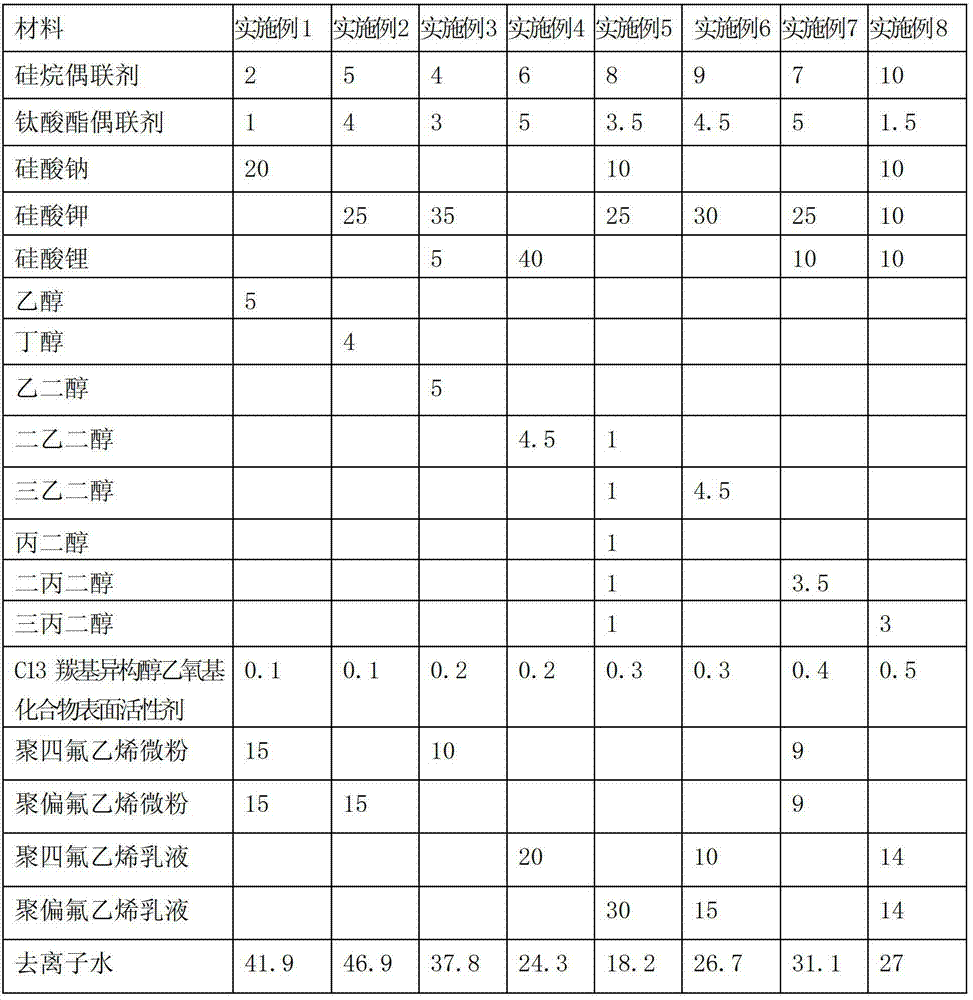

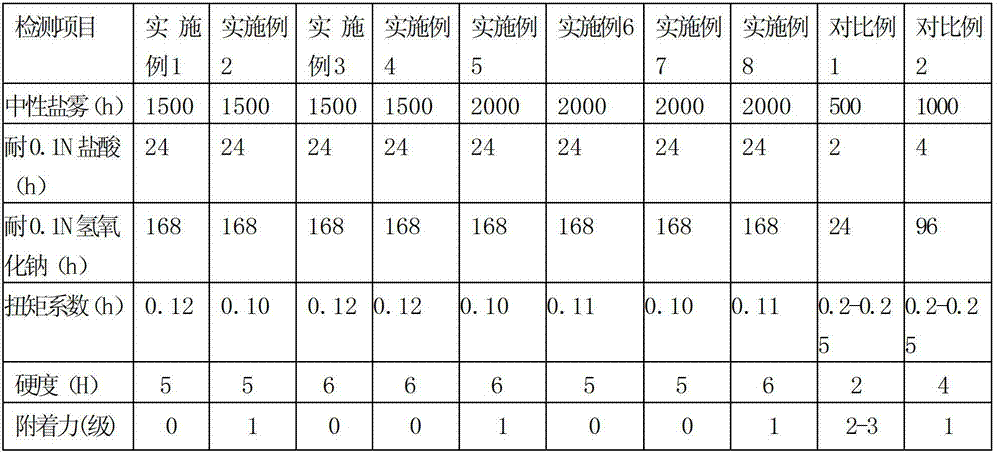

Waterborne sealing agent for zinc-based micro coating and preparation method of waterborne sealing agent

InactiveCN103397327AStrong adhesionImprove adhesionMetallic material coating processesTorque coefficientCoating adhesion

The invention relates to a waterborne sealing agent for a zinc-based micro coating and a preparation method of the waterborne sealing agent. The raw materials of the waterborne sealing agent are composed of the following components in percentage by mass: 2-10% of silane coupling agent, 1-5% of titanate coupling agent, 20-40% of silicate, 3-5% of organic solvent, 0.1-0.5% of C13 carbonyl isomeric alcohol ethoxylate surfactant, 10-30% of fluorocarbon polymer micropowder or fluorocarbon polymer emulsion and the balance of deionized water. The waterborne sealing agent has the characteristics of environment friendliness, safety and capability of improving the adhesive force, hardness, acid and alkaline resistance and high temperature resistance of the zinc-based micro coating and reducing the friction and torque coefficients.

Owner:JIANGSU BOYE COATING ENG CO LTD

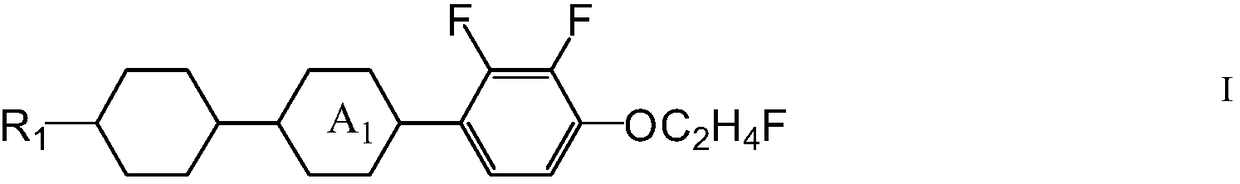

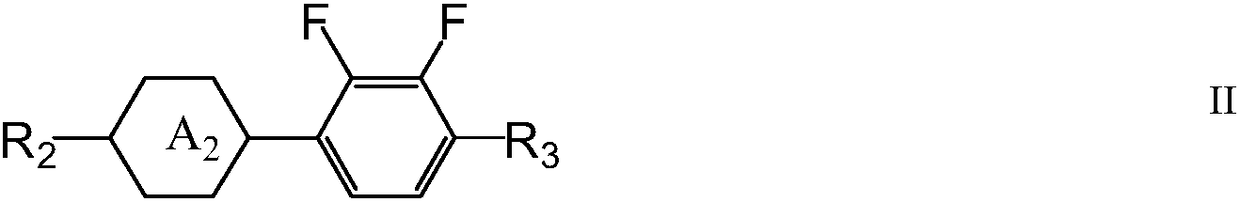

Liquid-crystal composition containing fluoroethoxy compound and application of liquid-crystal composition

The invention relates to a liquid-crystal composition containing a fluoroethoxy compound. The liquid-crystal composition comprises at least one compound represented by a general formula I shown in thedescription and at least one compound represented by a general formula II shown in the description. According to the liquid-crystal composition, the compound represented by the general formula I is atricyclo compound with a 2,3-difluorobenzene structure, the structure is a liquid crystal compound with negative dielectric anisotropy and has high negative dielectric anisotropy, the negative dielectric anisotropy of the liquid-crystal composition can be effectively improved, the consumption of polar monomers is lowered, the consumption of low-viscosity monomers is increased, the rotational viscosity of the system is lowered, and the response time is shortened; and the compound represented by the general formula II has relatively high negative dielectric anisotropy and excellent intersolubility. The liquid-crystal composition provided by the invention has low rotational viscosity, good low-temperature intersolubility and rapid response time and is applicable to VA liquid-crystal displaydevices such as VA / MVA / PVA / PSVA and IPS and FFS mode liquid-crystal display devices. The liquid-crystal composition is very effective to improvement on response time of liquid-crystal displays.

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

PEG-free solubilizer and manufacturing method thereof

The present invention relates to a PEG-free solubilizer having an optimal composition and composition ratio, which can be used as a solubilizer for making oil and water which are not mixed with each other mix and transparent, and can replace an existing solubilizer composed of an ethoxylated compound.

Owner:李忠根

Natural environment-friendly kitchen cleaning agent and preparation method thereof

ActiveCN102827712BSurface-active non-soap compounds and soap mixture detergentsNatural sourceCleansing Agents

The invention discloses a natural environment-friendly kitchen cleaning agent which comprises the following raw materials in parts by mass: 2-15 parts of orange plant essential oil, 1-20 parts of C10 Guerbet alcohol ethoxylate, 0.2-5 parts of natural glucoside surfactant, 0.2-10 parts of propanediol, 0.5-10 parts of ethanol, 0.01-5 parts of citric acid, 0.01-5 parts of sodium citrate and 60-90 parts of deionized water. The invention has the following advantages: the raw materials are natural, non-toxic and non-irritating, and are very healthy for human body; the cleaning agent is green and environment-friendly; the cleaning agent is free of perfume, and the natural essential oil can emit subtle fragrance to delight body and mind and effectively remove peculiar smell; the cleaning agent has good bactericidal performance and an antibacterial effect; the microemulsion system is incombustible, thereby ensuring use safety; the pH value is weakly acidic and is consistent with the skin acidic and basic capacity of human body, thereby avoiding burning irritation; the cleaning agent is free of strong base and thickener, thereby being safer; and the cleaning agent is simple and convenient in production process, can be produced under normal temperature and achieves the advantages of low carbon content and environment friendliness.

Owner:朱禾中

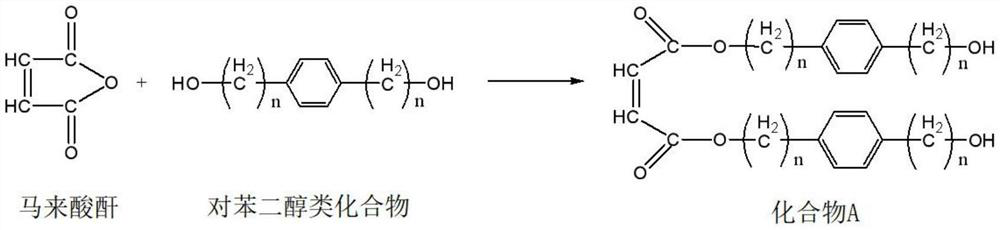

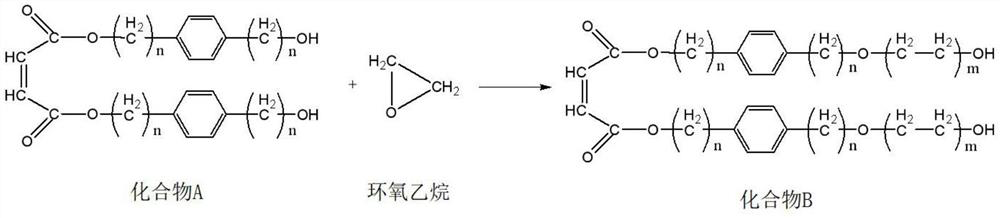

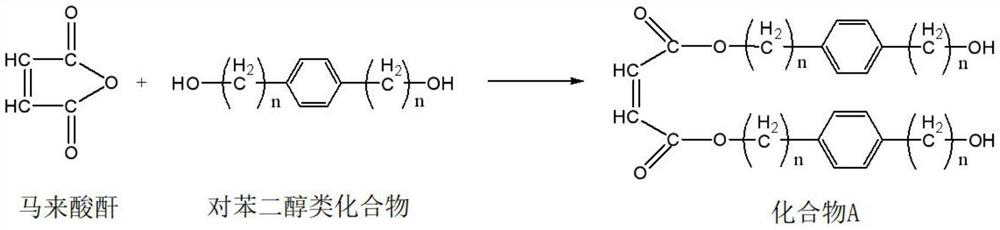

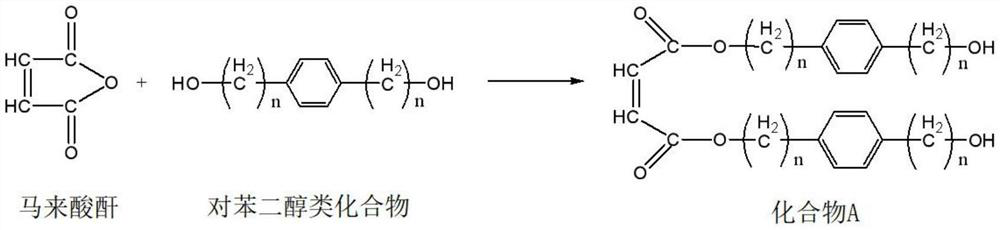

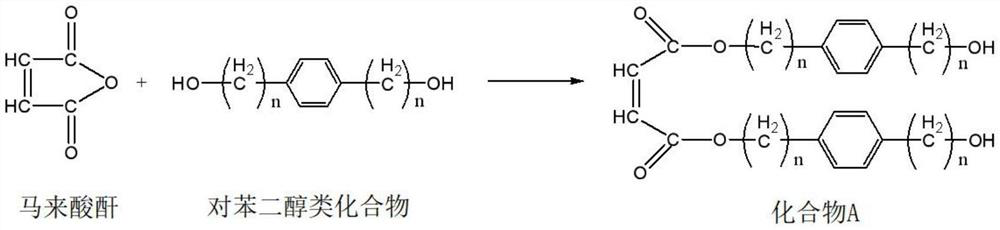

Hydrolytic water reducing agent and preparation method thereof

The invention discloses a hydrolytic water reducer and a preparation method thereof, and the preparation method comprises the following steps: step 1, taking maleic anhydride and a p-phenylene glycol compound as reaction substrates, and adding an esterification reaction catalyst to obtain a compound A; step 2, carrying out anionic polymerization reaction on the compound A and ethylene oxide under an alkaline condition, and synthesizing to obtain a compound B; and step 3, carrying out a free radical copolymerization reaction on the compound B and unsaturated carboxylic acid in the presence of an organic free radical initiator through a bulk polymerization method to prepare the hydrolytic water reducer. The prepared water reducing agent is a hydrolyzable ethoxylated polymer with a phenyl functional group and an ester functional group at the same time, the ethoxylated unsaturated polymer synthesizes an ester group in a bulk polymerization mode, and under the alkaline condition of concrete, the ester functional group can be hydrolyzed to generate carboxyl and an ethyoxyl compound containing phenyl, the adsorption consumption of the polycarboxylic acid water reducing agent is supplemented; retarding groups are provided; and the setting time of the precast concrete is prolonged.

Owner:SHANGHAI TAIJIE CHEM

Polypropylene composition and preparation method thereof

The invention discloses polypropylene composition which comprises the following compositions by weight percent: 52-92 wt% of polypropylene, 5-15 wt% of elastomers, 0.5-2 wt% of oxethyl compounds, 0-30 wt% of talcum powder, and 0.5-1 wt% of a processing agent. The preparation method of the polypropylene composition comprises the following steps: (a), weighing the compositions as per the weight matching ratio, and adding the compositions into a highly mixing machine to mix for 1-3 minutes, so as to obtain pre-mixing materials, wherein the rotating speed is 1000-2000 rpm; (b), smelting and extruding the pre-mixing materials by a double-screw extruder, and carrying out vacuum granulation, so as to obtain the pastiness resistant polypropylene composition, wherein the temperature of various areas of screw rods is 190-230 DEG C. According to the invention, the oxethyl compounds have the conventional powder dispersing function, and have the pastiness resistant effect on the surface of a polypropylene material, so that the types of pastiness resistant agents used in the polypropylene composition are increased; the preparation method is simple and feasible, the equipment requirement is low, the product yield is high, and the polypropylene composition can be widely applied to the production of automobile used interior trimming parts such as fascia boards, auxiliary fascia boards, uprights, glove boxes, door panels and thresholds.

Owner:WUHAN JINFA TECH CO LTD

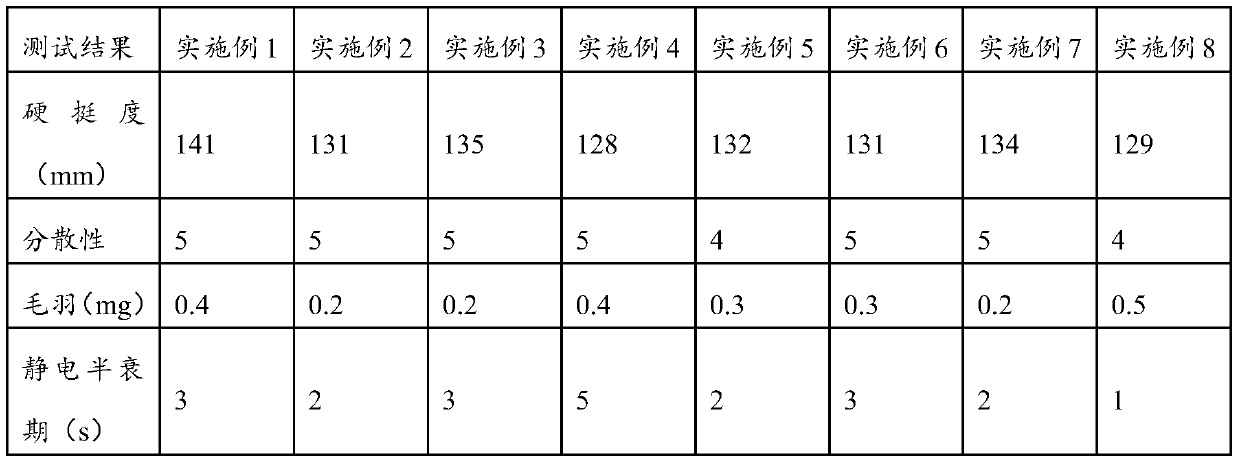

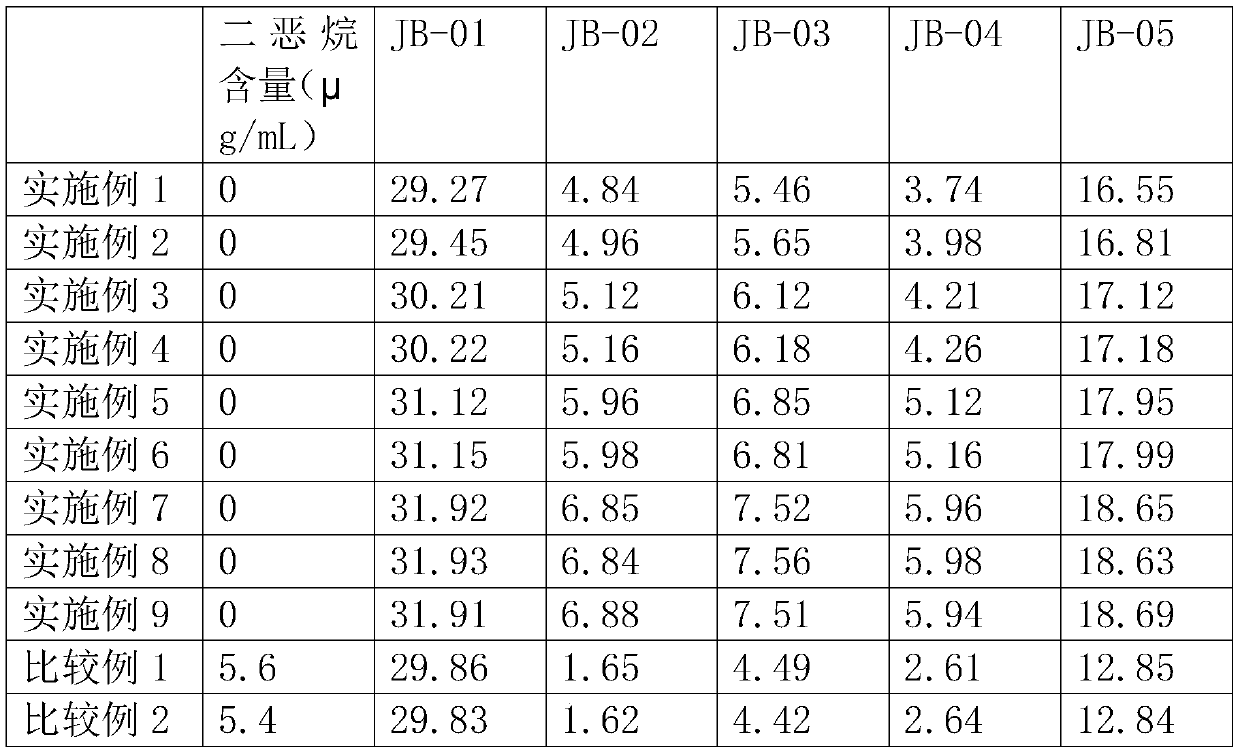

Glass fiber antistatic composition and application thereof

The invention relates to a glass fiber antistatic composition, which belongs to the technical field of glass fiber surface treatment. The composition comprises 1-35 parts by mass of an antistatic agent, 55-99 parts by mass of a polar organic solvent, and 0.02-1 part by mass of a wetting agent, wherein the wetting agent is an alkynediol ethyoxyl compound; the polar organic solvent has volatility. The invention also relates to application of the antistatic composition in preparation of antistatic glass fibers. Compared with the prior art, the composition has advantages that the composition can achieve uniform coating of the antistatic agent, the antistatic performance of the glass fibers is remarkably improved, and the problem that the product quality is influenced due to the fact that the dispersity of the glass fibers is reduced as moisture of an existing antistatic agent is not easy to volatilize can be avoided.

Owner:JUSHI GRP CO

Solid detergent without ethoxy compound

ActiveCN109837142ARapid and complete biodegradationStrong broad-spectrum antibacterial activityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsIrritationPolyvinyl alcohol

The invention relates to the field of detergents. Aiming at the problem that the health of a human body is easily influenced by an ethoxy compound contained in the traditional detergent, the inventionprovides a solid detergent without an ethoxy compound. The detergent comprises the following components in parts by mass: 4-28 parts of mono (C12-18) alkyl sulfate sodium salt; 5-25 parts of polyvinyl alcohol; 1-14 parts of alkyl glycoside; 1-12 parts of cocamidopropyl betaine; 1-10 parts of cocamidopropyl amine oxide; 0.5-5 parts of a Chinese soapberry fruit extract; 0.5 to 5 parts of glycerol;0.5-5 parts of sodium citrate; 0.1-5 parts of silicon dioxide; 0.1-5 parts of polyether modified silicone oil; 0.1-3 parts of citric acid. The total mass part of the solid detergent without the ethyoxyl compound is 120 parts, and the balance is deionized water. The alkyl glycoside nonionic surfactant is matched with the mono (C12-18) alkyl sulfate sodium salt anionic surfactant for use, and the alkyl glycoside is non-toxic and harmless, so that the detergent has no irritation to skin, is not easy to influence the health of a human body, and is not easy to pollute the environment.

Owner:GUANGZHOU JOYSON CLEANING PROD CO LTD

A kind of polypropylene composition and preparation method thereof

Owner:WUHAN JINFA TECH CO LTD

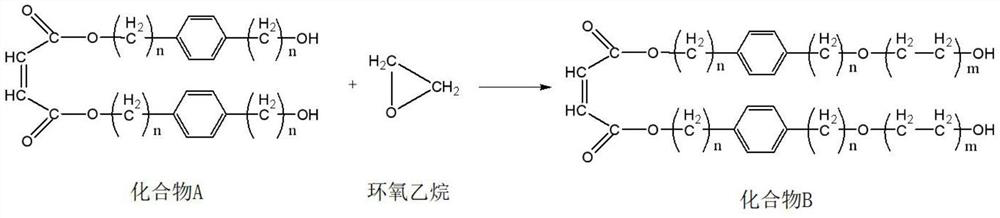

A kind of hydrolysis type water reducing agent and preparation method thereof

The invention discloses a hydrolyzed water reducer and a preparation method thereof. The preparation method comprises the following steps: step 1, taking maleic anhydride and p-phthalic acid compounds as reaction substrates, adding an esterification reaction catalyst to obtain the compound A; step 2, compound A and ethylene oxide are carried out anionic polymerization under basic conditions, and compound B is synthesized; step 3, compound B and unsaturated carboxylic acid are passed under organic free radical initiator conditions The bulk polymerization method carries out the free radical copolymerization reaction to obtain the hydrolyzed water reducer. The water reducer prepared by the present invention is a hydrolyzable ethoxylated polymer having both phenyl functional groups and ester functional groups. Under certain conditions, the ester functional group can be hydrolyzed to produce carboxyl and phenyl-containing ethoxylates, supplementing the adsorption consumption of polycarboxylate superplasticizers and providing retarding groups to prolong the setting time of precast concrete.

Owner:SHANGHAI TAIJIE CHEM

Low-VOC anti-rust oil used for thermal treatment of precise thin-wall bearing of robot

InactiveCN109971533ALow VOC contentExcellent thermal decompositionLubricant compositionDiethylene glycol monobutyl etherCopolymer

The invention discloses a low-VOC anti-rust oil used for thermal treatment of a precise thin-wall bearing of a robot. The anti-rust oil is prepared from Yubase 4 Plus, 5# white oil, palm oil, Span 80,Span 85, Tween 80, an ethylene a-olefin copolymer, C12-15 alkanol polyether-2, an isomerous C13 alcohol ethyoxyl compound, diethylene glycol monobutyl ether, 3-methoxy-3-methyl-1-butanol, Irganox L 57 and Irganox L64. The anti-rust oil is low in VOC content, excellent in thermal decomposition performance and good in anti-rust performance.

Owner:SHANGHAI YUSHIRO CHEM IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com