Photoresist residue cleaning liquid

A technology of photoresist residue and cleaning solution, which is applied in the direction of photosensitive material processing, organic cleaning composition, cleaning method and utensils, can solve the problems of single source of hydroxylamine, safety and environmental protection, unstable non-metallic corrosion rate, etc. Effect of metal corrosion rate instability

Inactive Publication Date: 2016-07-20

ANJI MICROELECTRONICS (SHANGHAI) CO LTD

View PDF10 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This type of cleaning solution that does not contain hydroxylamine or fluoride not only solves the problems of single source of hydroxylamine and safety and environmental protection, but al

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

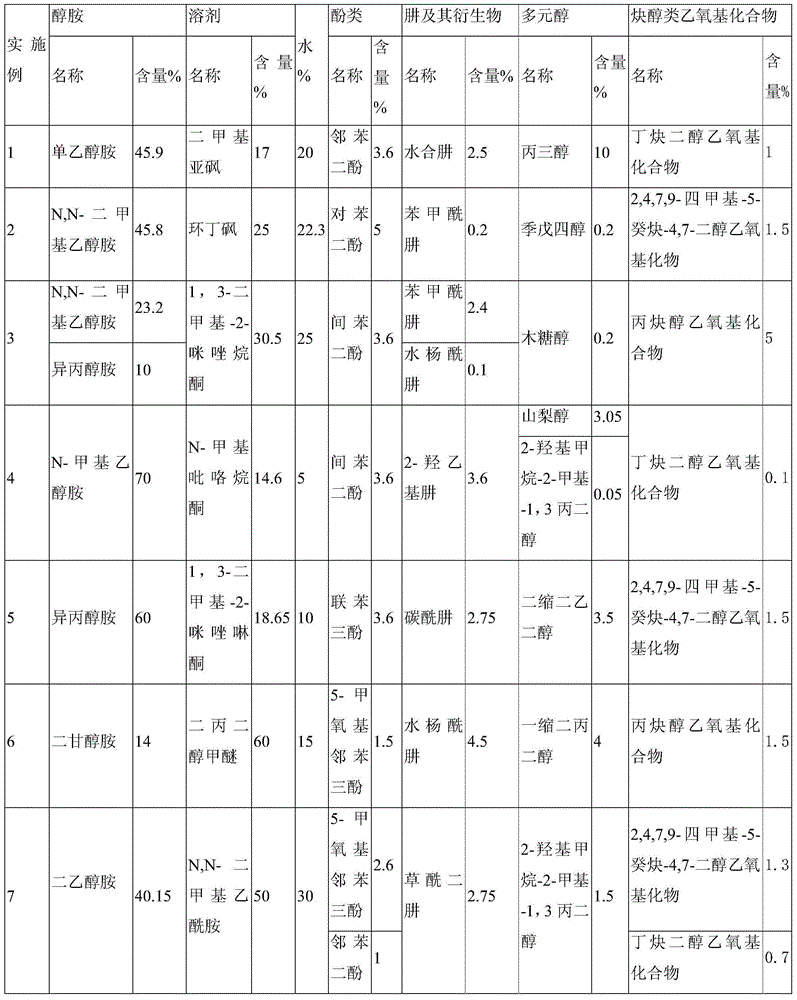

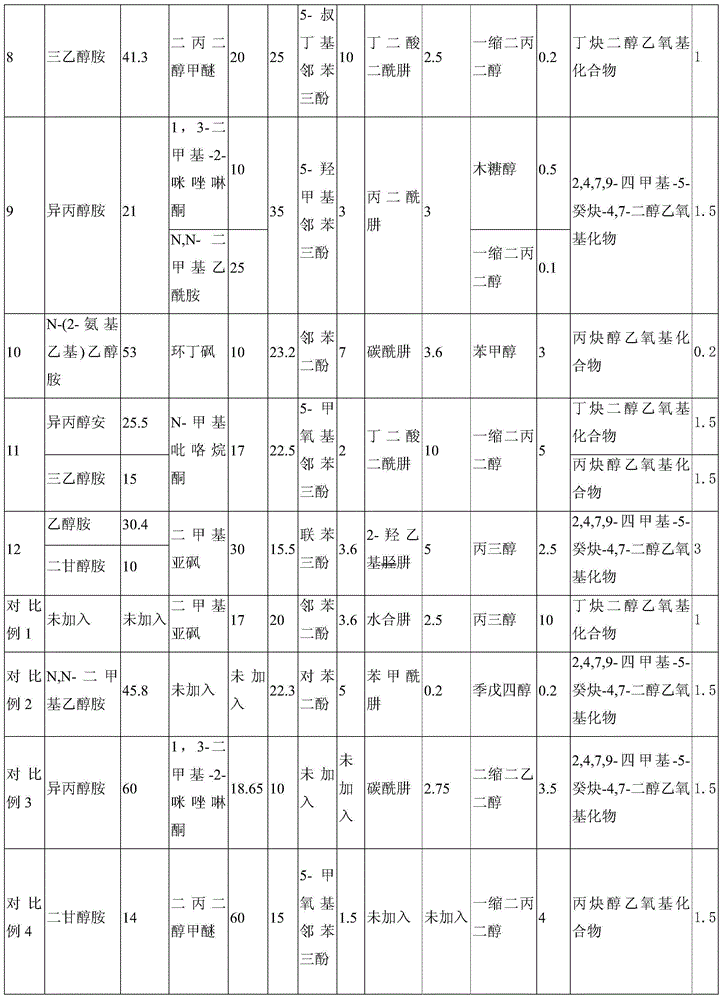

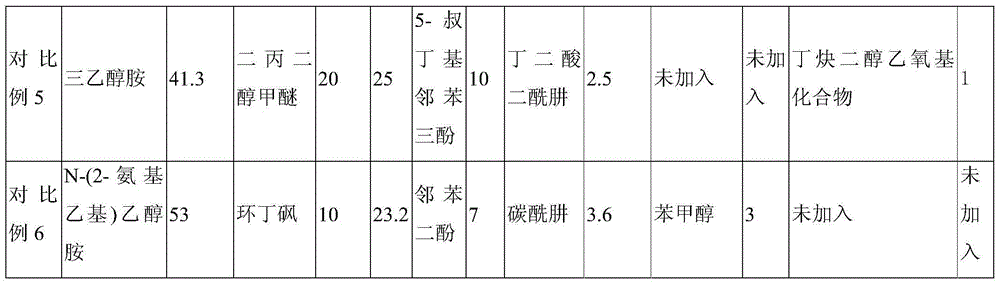

The invention discloses a cleaning liquid which does not contain fluoride and hydroxylamine and is used for removing photoresist etching residue, and constituents thereof. The low-etching cleaning liquid which does not contain the fluoride and the hydroxylamine and is used for removing the photoresist etching residue comprises (a) hydramine; (b) solvent; (c) water; (d) phenols; (e) alkynol ethoxyl compound; (f) hydrazine and derivatives thereof; and (g) polyhydric alcohols. With the low-etching cleaning liquid which does not contain the fluoride and the hydroxylamine and is used for removing the photoresist etching residue, cross-linked and hardened photoresist subjected to hard baking, dry etching, ashing and plasma injection to cause complicated chemical change can be rapidly removed, the photoresist residue on a metal line, a through hole and a metal gasket wafer can be removed, meanwhile, no attack is generated to a substrate, such as metal aluminum, metal copper and non-metal silicon dioxide. The cleaning liquid disclosed by the invention has favorable application prospect in the field of semiconductor wafer cleaning and the like.

Description

technical field [0001] The invention discloses a photoresist residue cleaning solution, in particular to a cleaning solution that does not contain hydroxylamine and fluoride. Background technique [0002] In the manufacturing process of semiconductor components, the coating, exposure and imaging of photoresist layers are necessary process steps for the pattern manufacturing of components. Residues of photoresist material need to be completely removed at the end of patterning (ie, after photoresist coating, imaging, ion implantation, and etching) before proceeding to the next process step. Usually, dozens of photolithography processes are used in the manufacturing process of semiconductor devices. Due to the complex chemical reaction with the photoresist caused by the ions and free radicals of the plasma etching gas, the photoresist is rapidly cross-linked and hardened with inorganic substances, making the photoresist The layer becomes less soluble and thus more difficult to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G03F7/42

CPCB08B3/04C11D3/30H01L21/304

Inventor 郑玢刘兵孙广胜黄达辉

Owner ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com