Glass fiber antistatic composition and application thereof

A glass fiber and antistatic technology, which is applied in the application field of glass fiber antistatic composition and preparation of antistatic glass fiber, can solve the problem of increasing the processing time and difficulty of the subsequent process, and the compatibility of the sizing coating is not high , the dispersion effect is not very good and other problems, to achieve the effect of improving the chopping performance, improving the coating effect, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

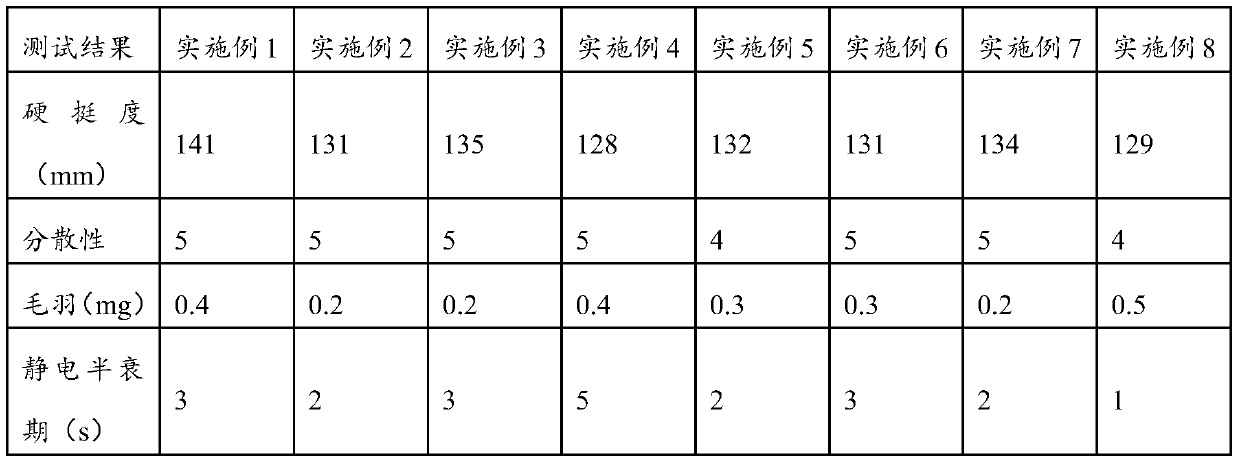

Examples

Embodiment 1

[0030] Completely dissolve 5 parts by mass of cetyltrimethylammonium bromide and 0.1 parts by mass of DYNOL 607 type acetylene glycol ethoxylate in 95 parts by mass of ethanol, mix well, and then apply it to the outside of the glass fiber spray yarn On the surface, after the solvent is completely evaporated, perform a performance test on it.

Embodiment 2

[0032]15 parts by mass of cetyltrimethylammonium bromide, 0.05 parts by mass of Surfynol 465 type acetylenic glycol ethoxylates are completely dissolved in a mixed solvent of 55 parts by mass of ethanol and 30 parts by mass of water, and then coated to The glass fiber is sprayed on the outer surface of the yarn, and the performance test is carried out after the solvent is completely evaporated.

Embodiment 3

[0034] 30 parts by mass of dodecyl dimethyl ammonium bromide and 0.8 parts by mass of DYNOL 607 type acetylenic glycol ethoxylate are completely dissolved in a mixed solvent composed of 50 parts by mass of ethanol and 20 parts by mass of acetone, fully mixed, Then it is coated on the outer surface of the glass fiber spray yarn, and after the solvent is completely volatilized, its performance is tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com