Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

161results about How to "Improve chopping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

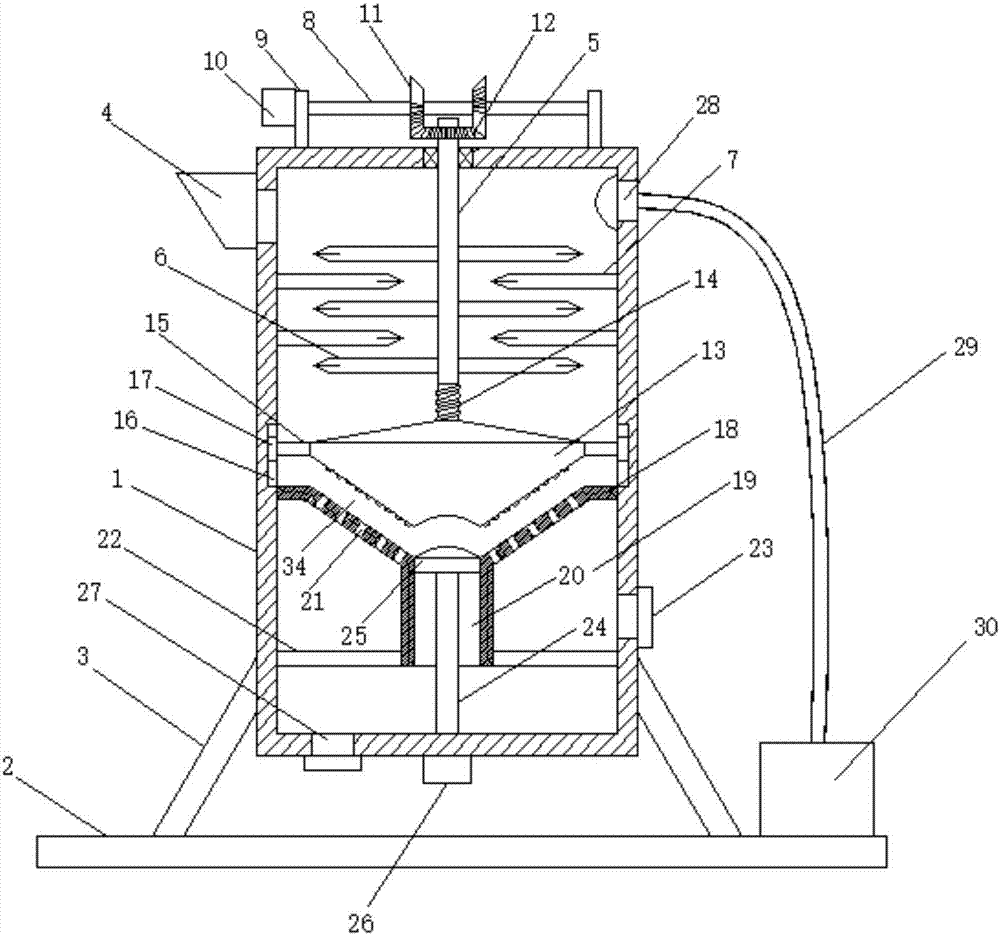

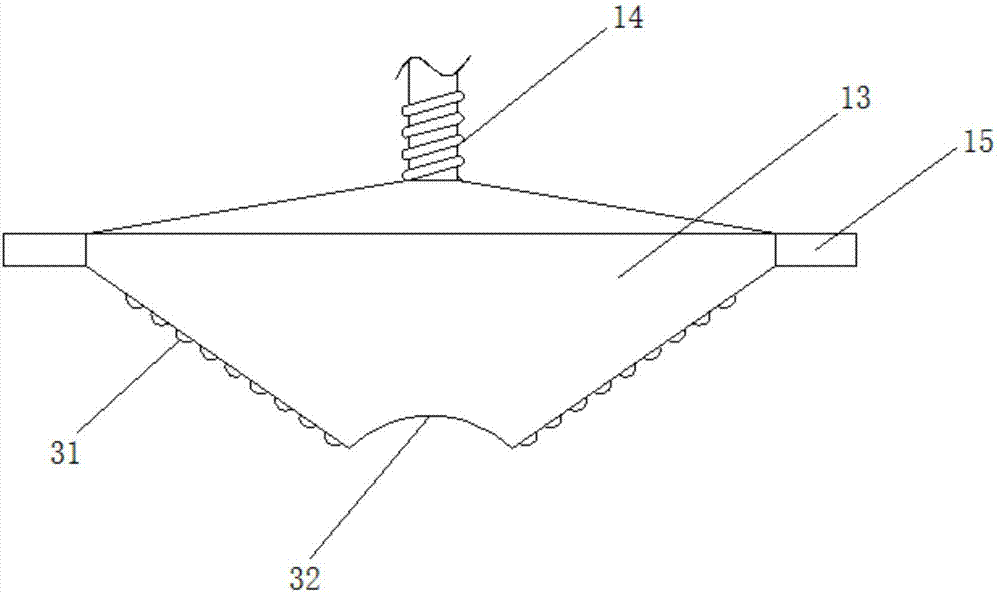

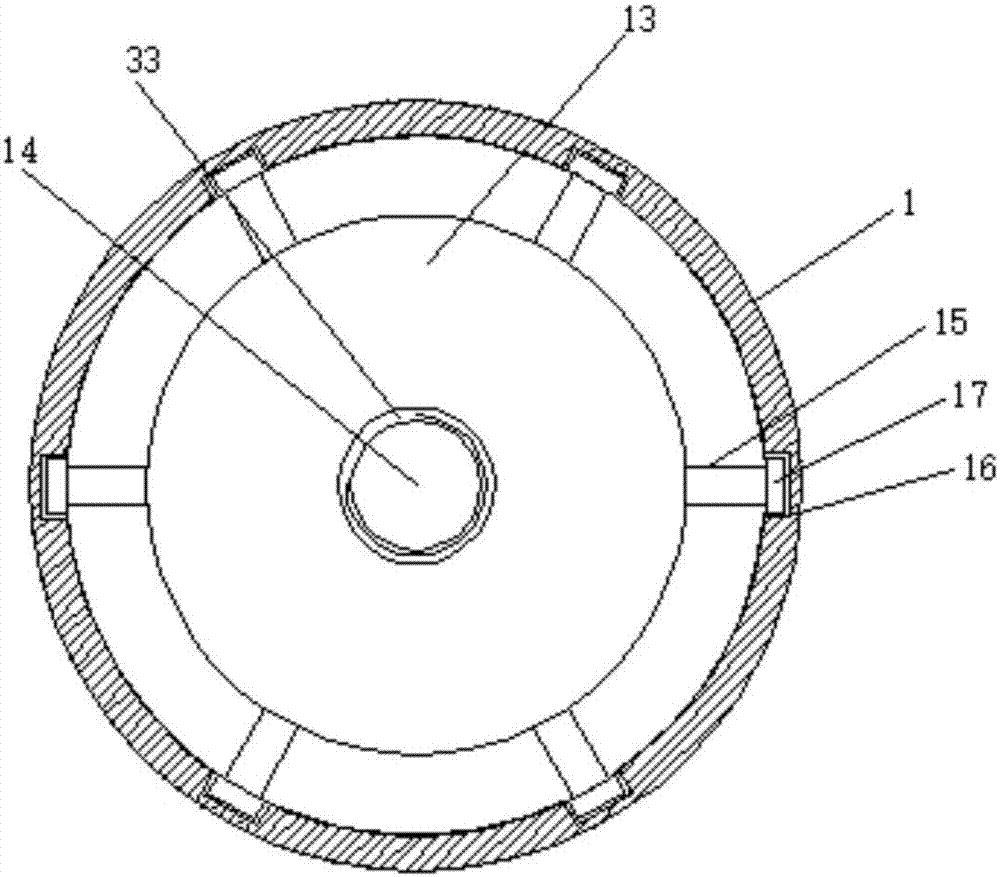

Chinese herbal medicine crushing juice extracting device convenient to discharge slag

The invention discloses a Chinese herbal medicine crushing juice extracting device convenient to discharge slag. The device comprises a crushing extraction cylinder; a driving rotating shaft coaxial with the crushing extraction cylinder is arranged in the crushing extraction cylinder; multiple rotary cutting blades are arranged on the side wall of the driving rotating shaft; an extrusion disc block is arranged in the crushing extraction cylinder; a fixed extrusion plate is arranged on the lower side of the extrusion disc block; an extrusion extracting groove cooperating with the lower end of the extrusion disc block is formed in the middle part of the fixed extrusion plate; multiple liquid passing holes are formed in the edge side of the extrusion extracting groove; a blockage plate in tight sliding connection with the inner wall of a slag removing channel is arranged in the slag removing channel; the lower end of the blockage plate is connected with a hydraulic cylinder arranged on the bottom wall of the crushing extracting cylinder through a hydraulic push rod; and a slag discharge port is formed in the bottom wall of the crushing extracting cylinder. The device is simple in structure, convenient to discharge Chinese herbal medicine slag, better in crushing effect, better in extracting effect of Chinese herbal medicine extruding juice, convenient to collect and flow out, convenient to operate and higher in practicability.

Owner:四川康晨生物科技有限公司

Rapid waste plastic shredding device for food production

ActiveCN106239774AAvoid overheatingExtended service lifePlastic recyclingGrain treatmentsPulleyWaste management

The invention relates to a waste plastic shredding device, in particular to a rapid waste plastic shredding device for food production and aims to provide the rapid waste plastic shredding device for food production which is thorough in shredding, convenient to operate and high in shredding speed. The rapid waste plastic shredding device for food production comprises a cutter, a lifting rod, a first connecting rod, a planetary gear, a crank, a gear ring, a second connecting rod, a right rack, a first motor, a top plate, a first sliding rail, a first sliding block and the like; a left rack and a mounting base are arranged on the left side of top of a bottom plate; the mounting base is positioned on the right side of the left rack; and a small belt pulley is mounted on the mounting base. The rapid waste plastic shredding device for food production realizes the effects of thorough shredding, convenience in operation and high shredding speed and plays the important roles in realizing an excellent shredding effect, improving the working efficiency and realizing high safety.

Owner:江苏通发环保科技有限公司

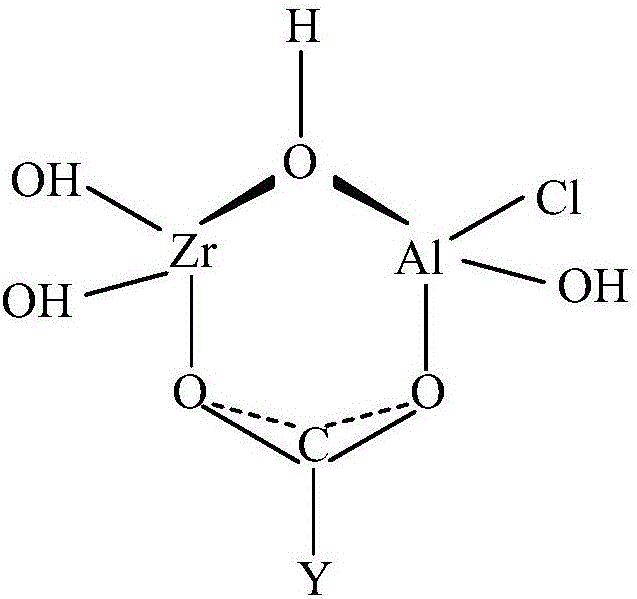

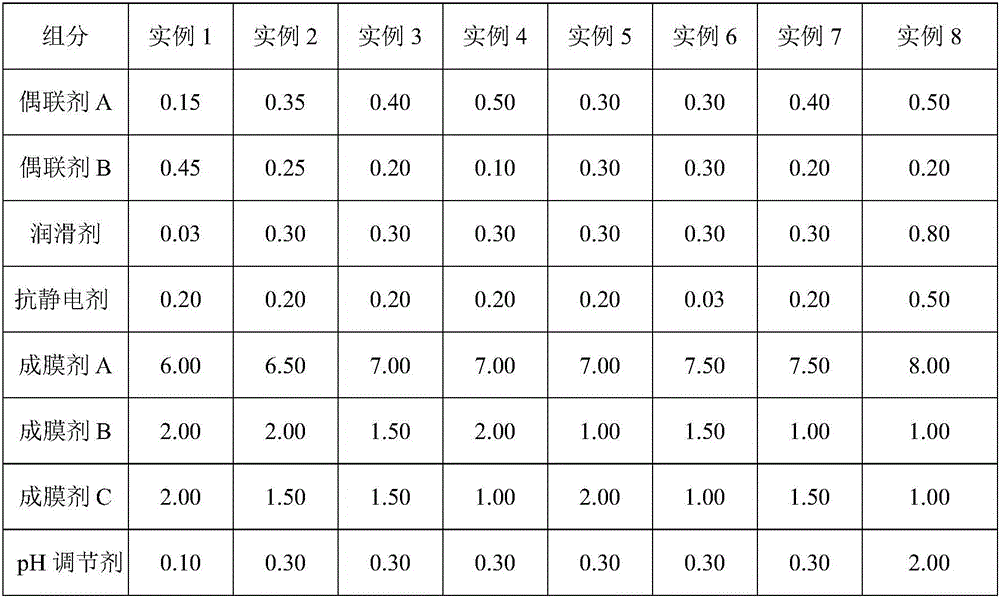

Chopped glass fiber sizing agent for bulk molding compounds (BMC) for reinforcing thermosetting resin

The invention discloses a chopped glass fiber sizing agent for reinforcing thermosetting resin, which is prepared by the components by weight percent: (1) 0.2-1.5% of coupling agent; (2) 3.0-20.0% of binding agent that is cross-linked polyurethane emulsion or the mixture of the cross-linked polyurethane emulsion and medium and high molecular weight epoxy emulsion, wherein the contents of the cross-linked polyurethane emulsion and the medium and high molecular weight elastic epoxy ester emulsion are based on the respective solid content; (3) 0.0-1.2% of lubricating agent; (4) 0.05-0.8% of antistatic agent; (5) 0.1-2% of pH value conditioning agent; and (6) the balance of deionized water, wherein the total weight of all the components is 100%. The chopped glass fiber sizing agent improves the bundling property of chopped glass fiber, reduces the broken filament, improves the mixing uniformity and the fluidity of the glass fiber and the BMC resin paste, and improves the mechanical strength and the appearance performance of BMC products.

Owner:JUSHI GRP CO

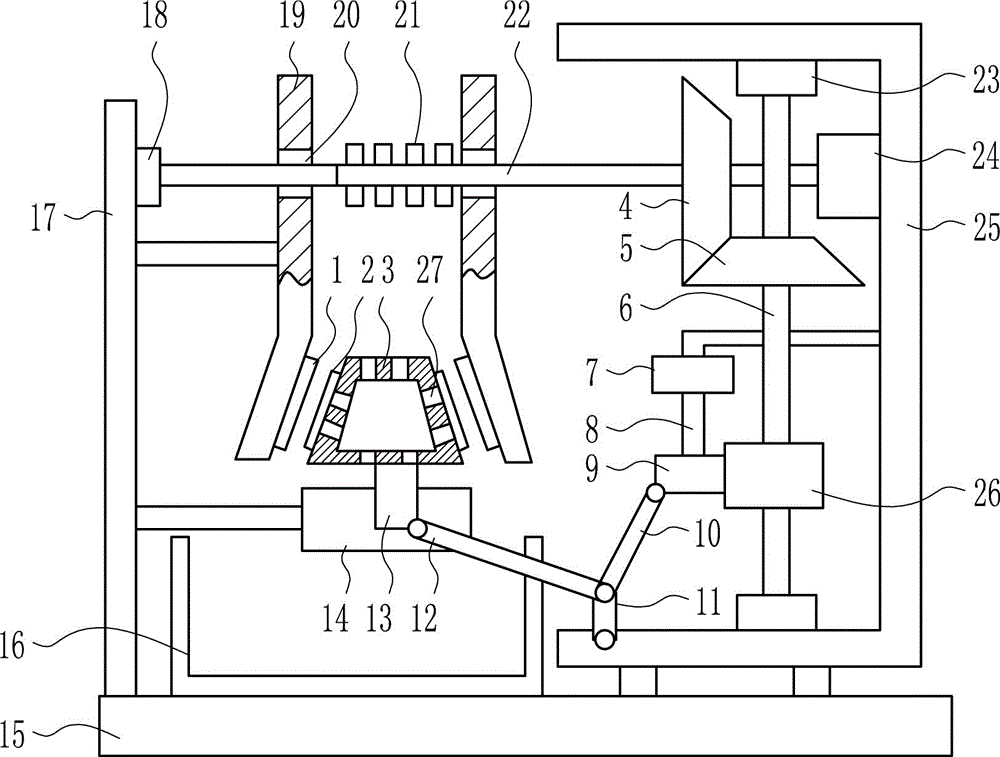

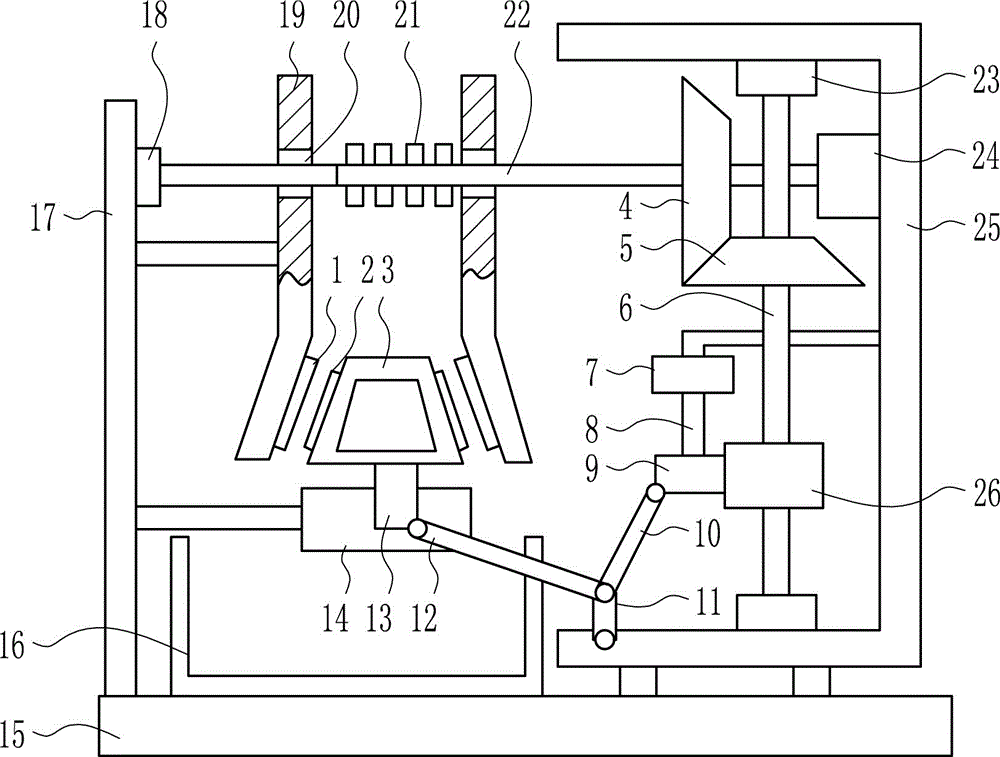

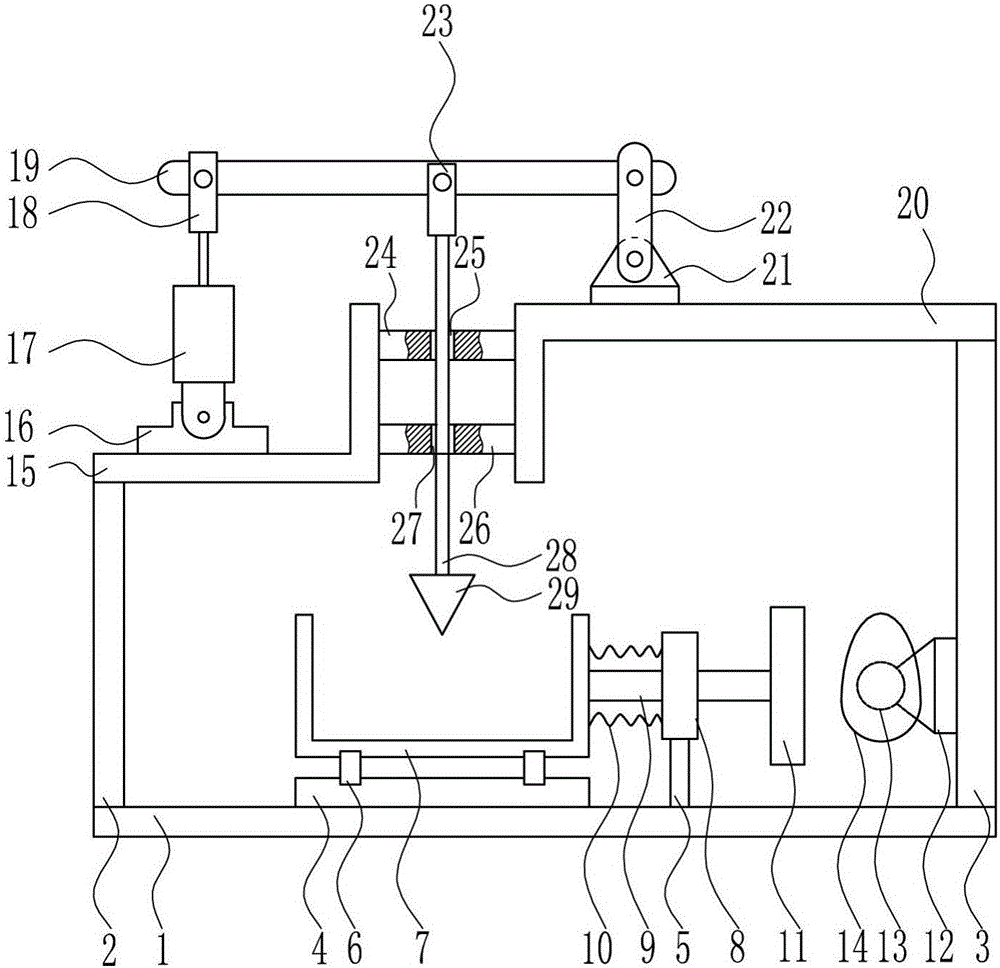

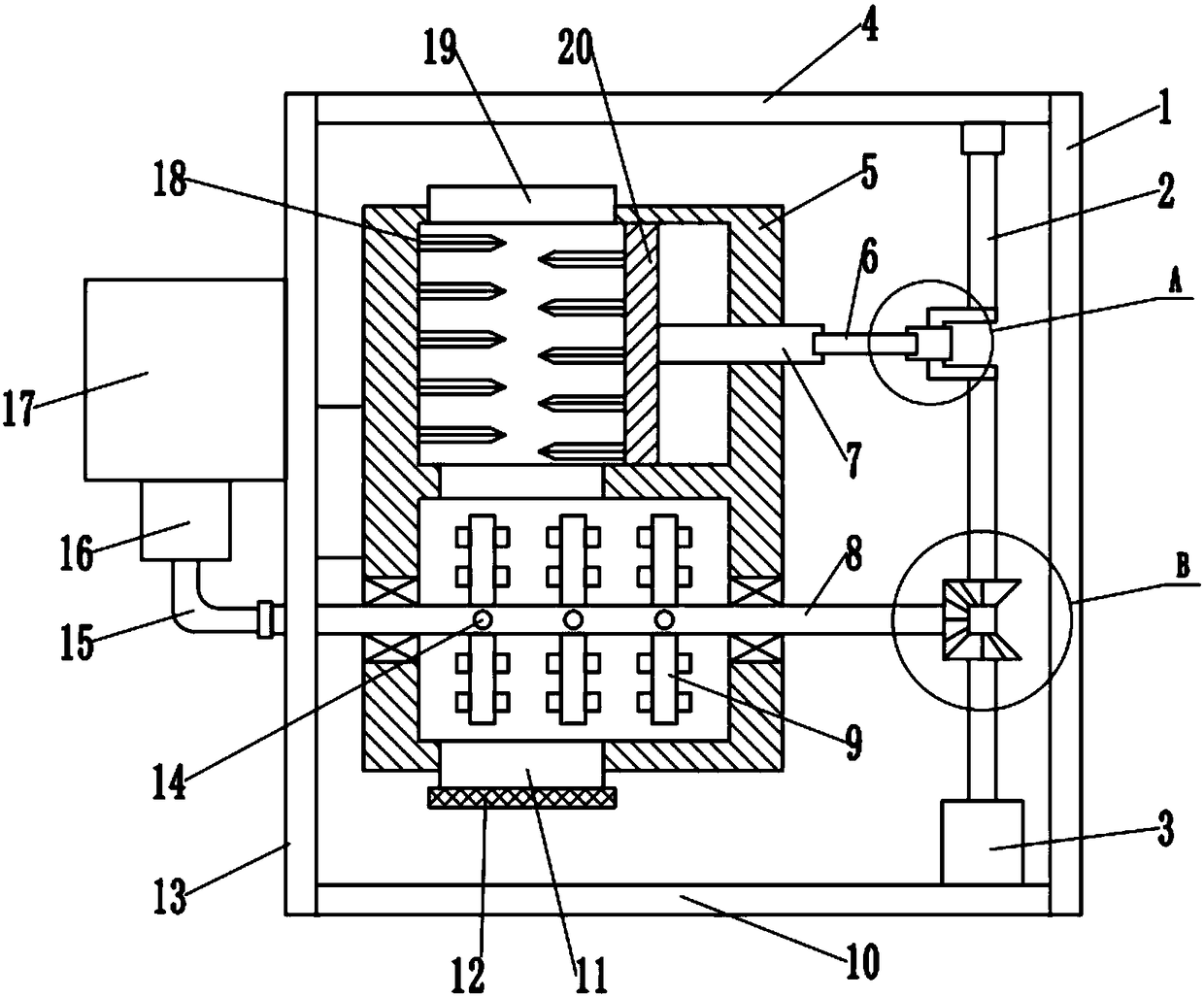

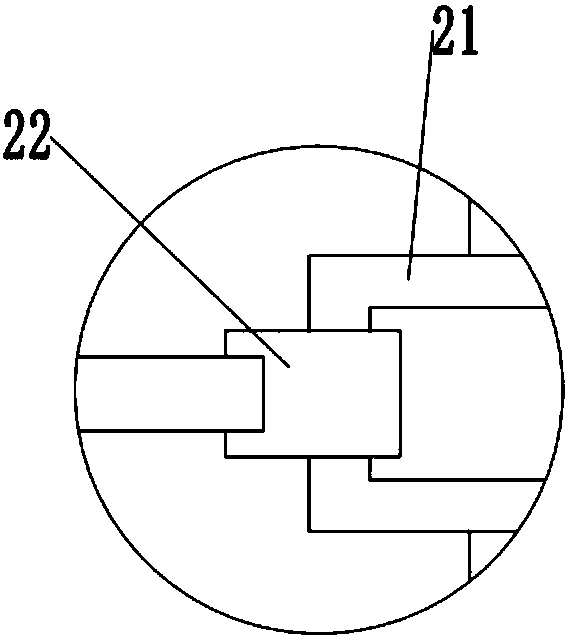

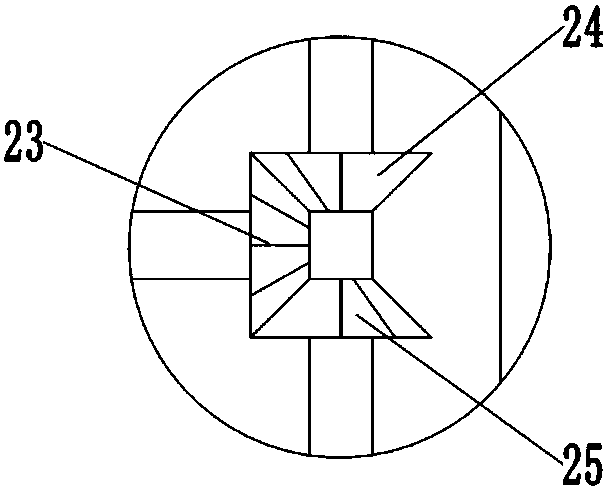

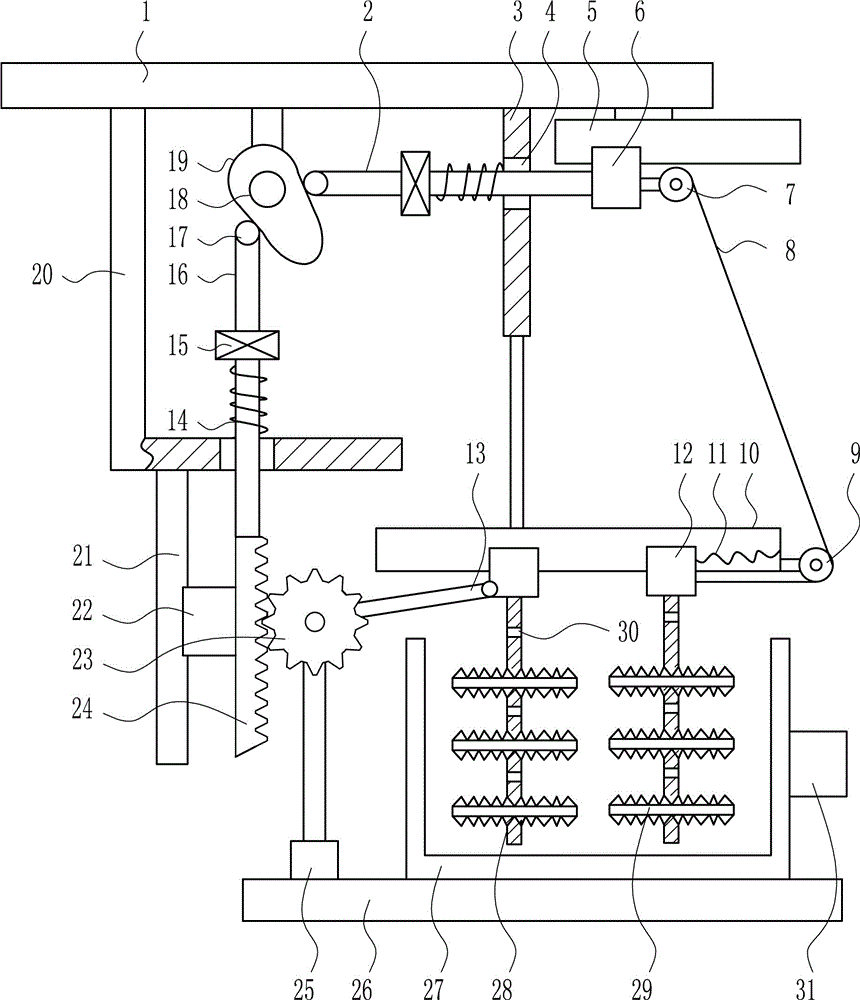

Medical plastic waste rapid-treatment device

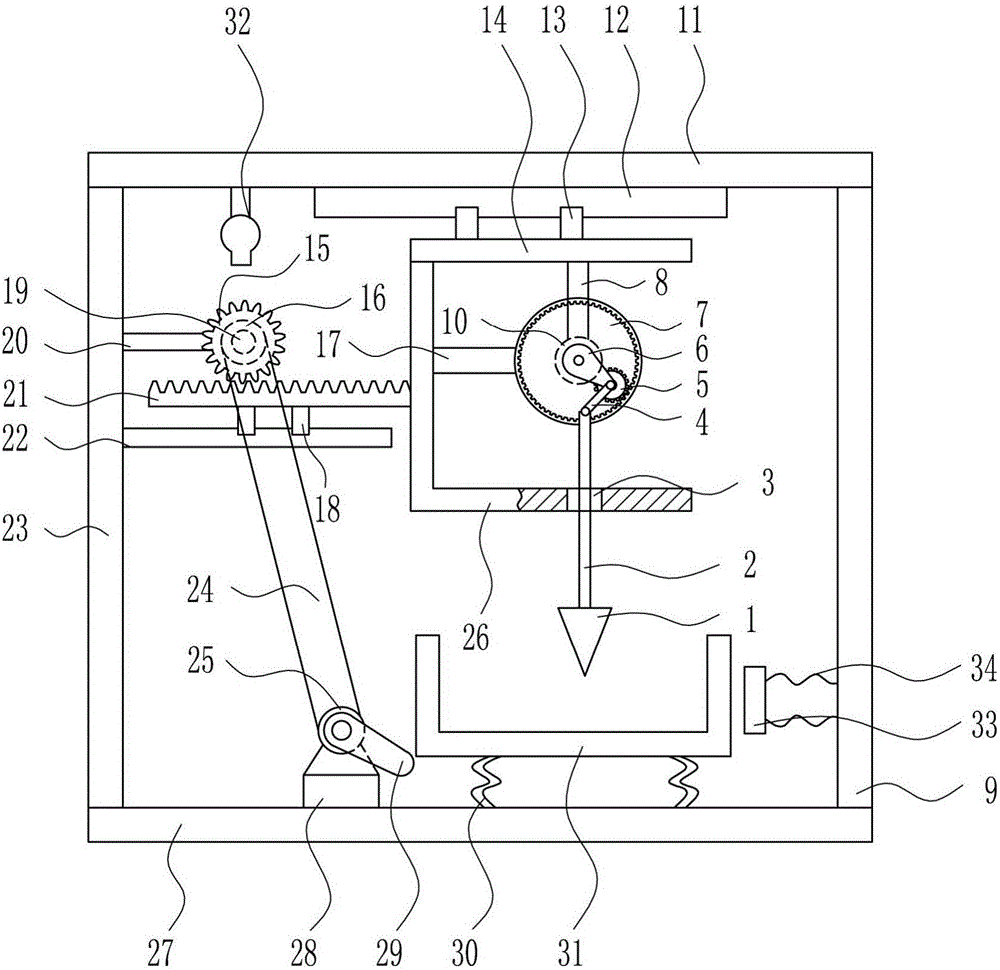

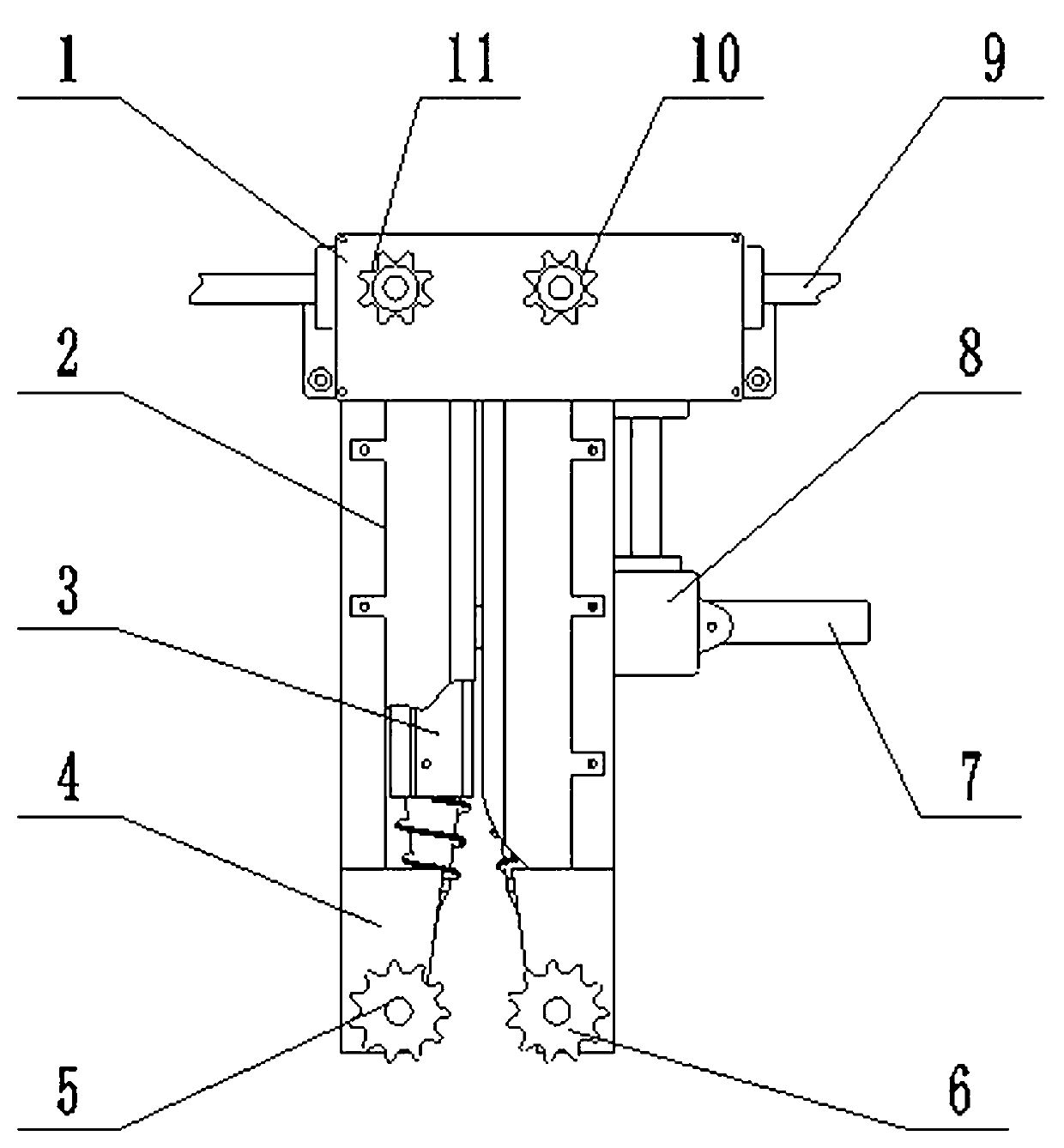

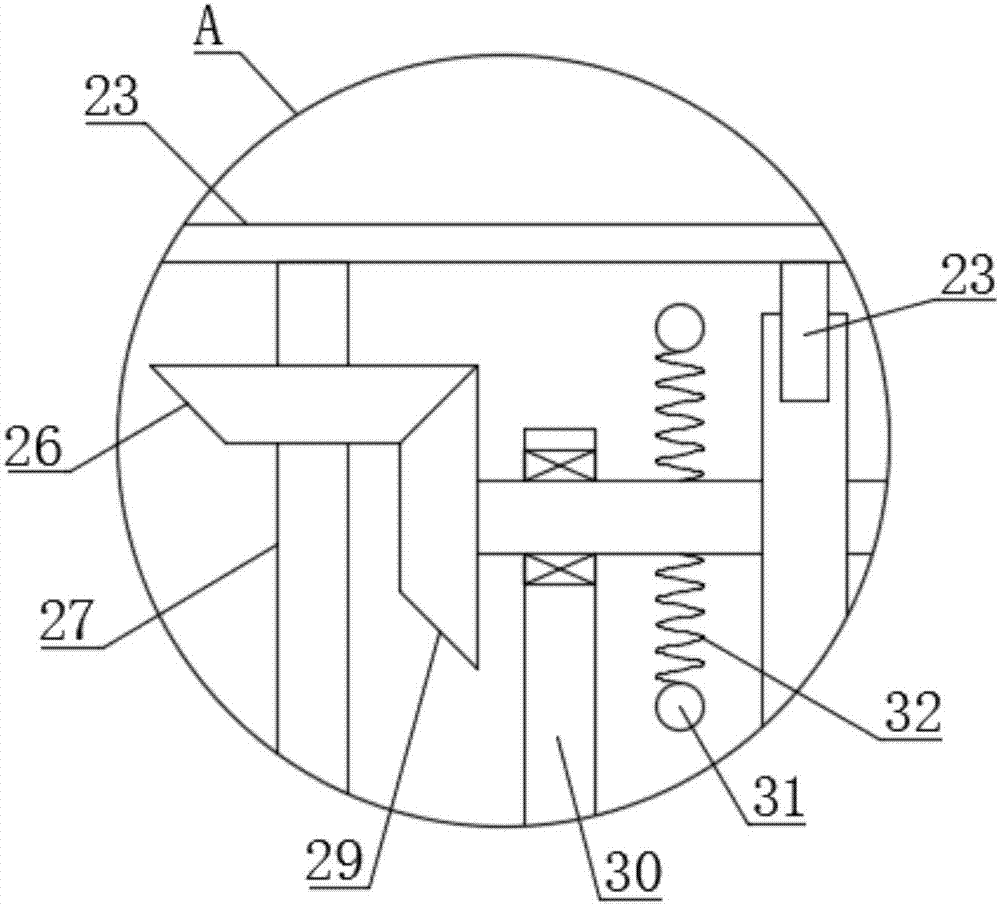

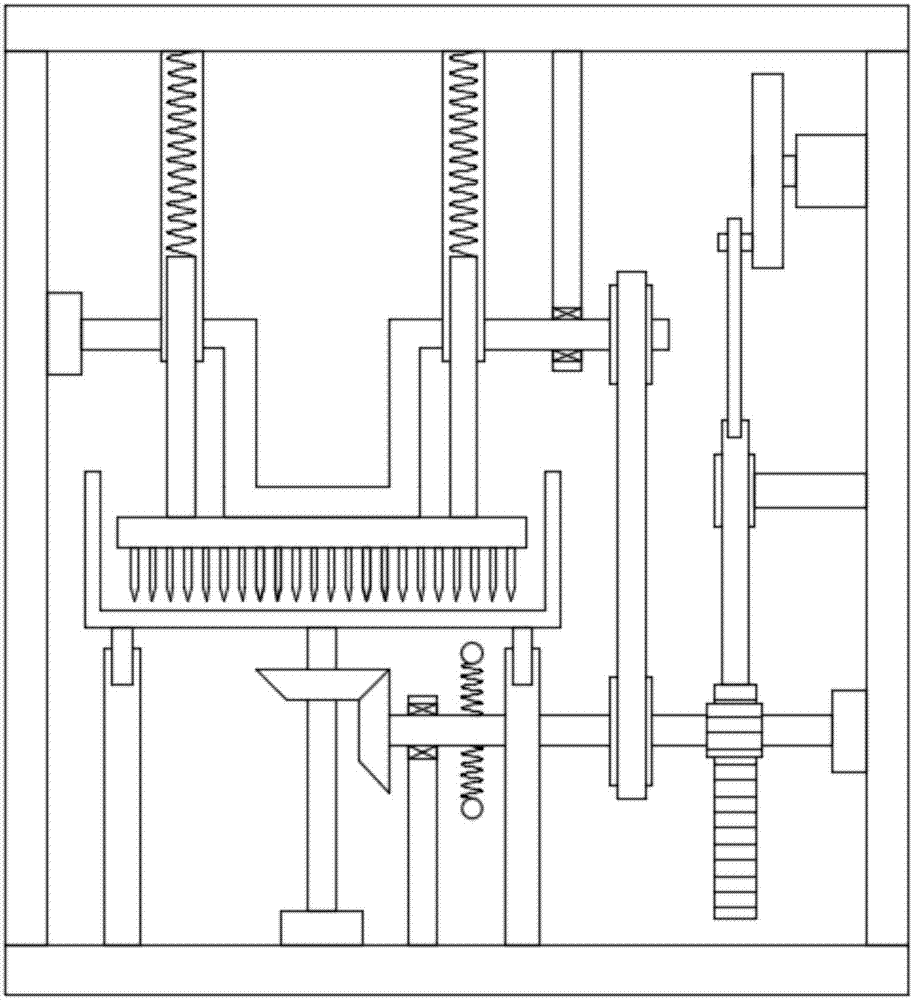

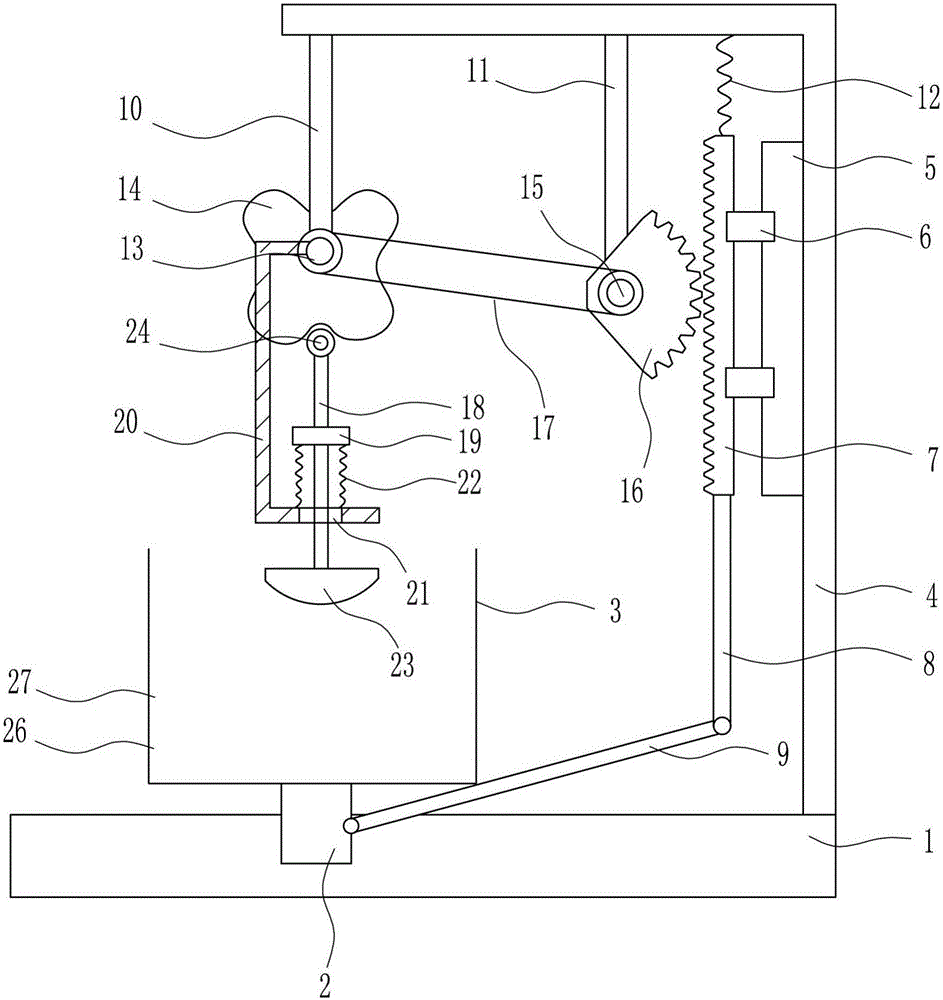

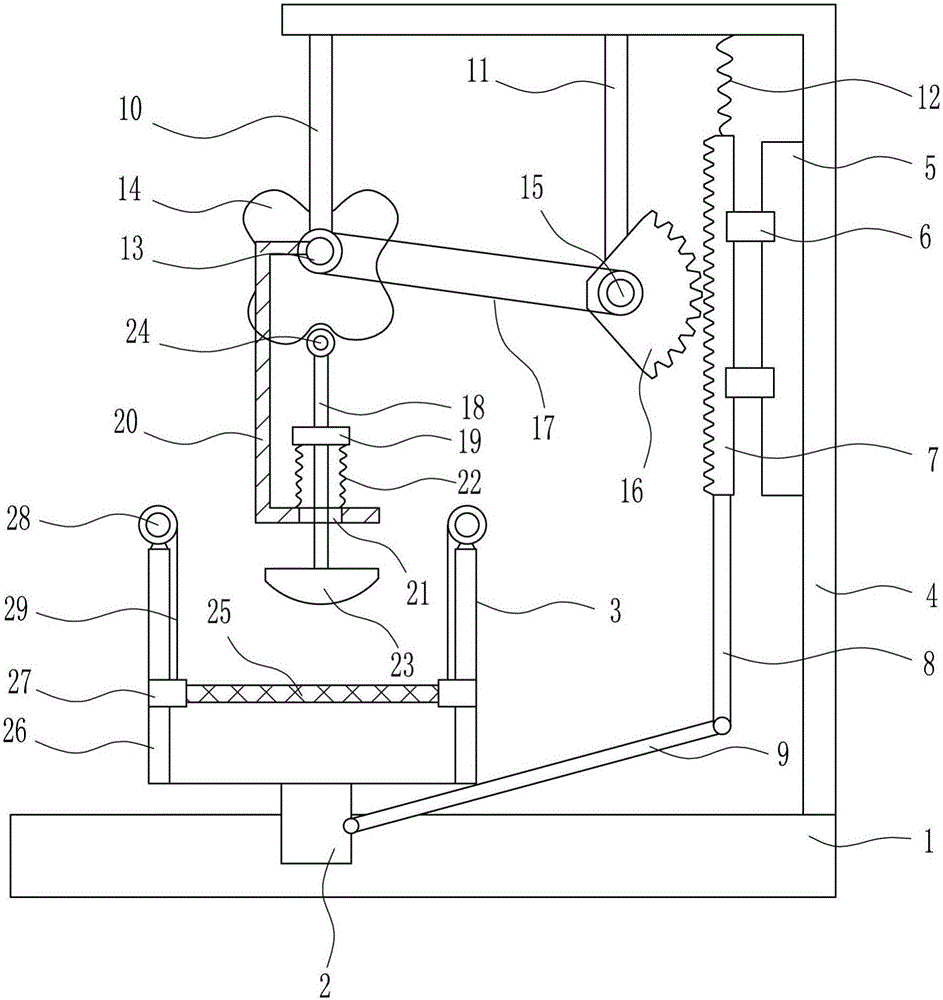

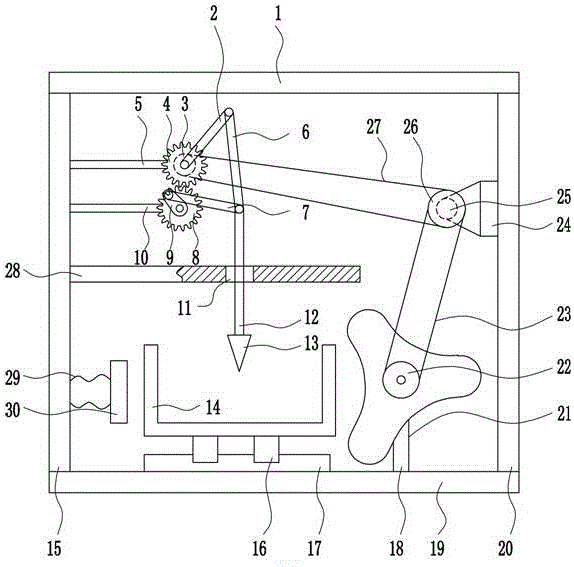

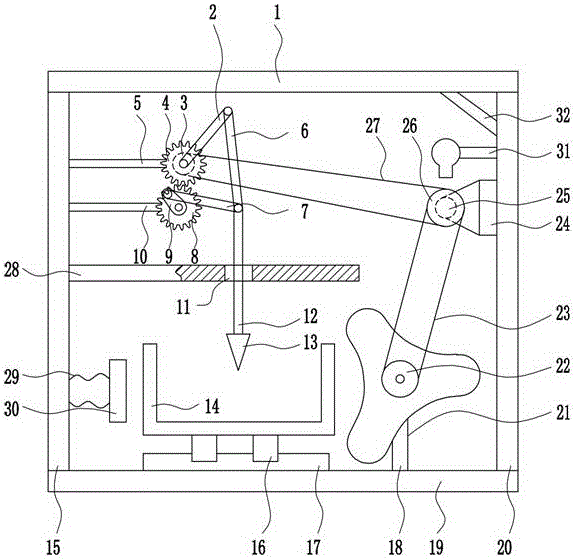

ActiveCN106393497AImprove chopping effectEasy to chopPlastic recyclingGrain treatmentsDrive wheelPlastic waste

The invention relates to a plastic waste treatment device, in particular to a medical plastic waste rapid-treatment device. The medical plastic waste rapid-treatment device is high in treatment efficiency, easy to operate and reasonable in design. The medical plastic waste rapid-treatment device comprises a bottom plate, a left side plate, a first pulley, a first sliding rail, a top plate, a second pulley, a guide plate, a first sliding block, a spring, a cutting-up frame, a wire spool, a second sliding rail, a driven wheel, a second sliding block, a rack, blades, a first baffle, a first pulling rope, a second baffle, a first motor, a driving wheel, a flat belt, a supporting rod, a gear, a rolling shaft and a second pulling rope. The left side plate, the first pulley and the first sliding rail are sequentially arranged on the bottom plate from left to right. The medical plastic waste rapid-treatment device has the effects of being high in treatment efficiency, easy to operate, and reasonable in design.

Owner:宁夏红远汇达实业集团有限公司

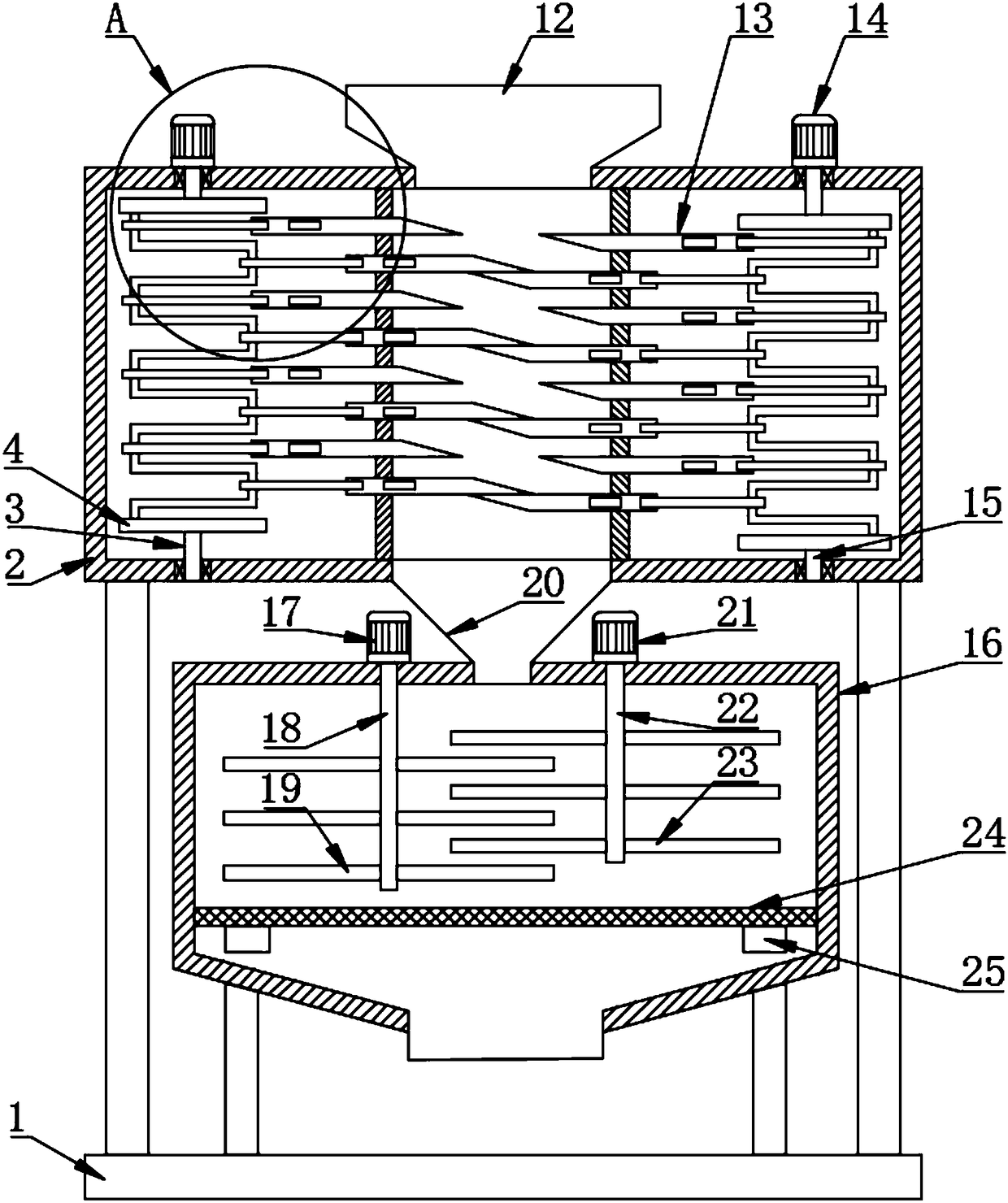

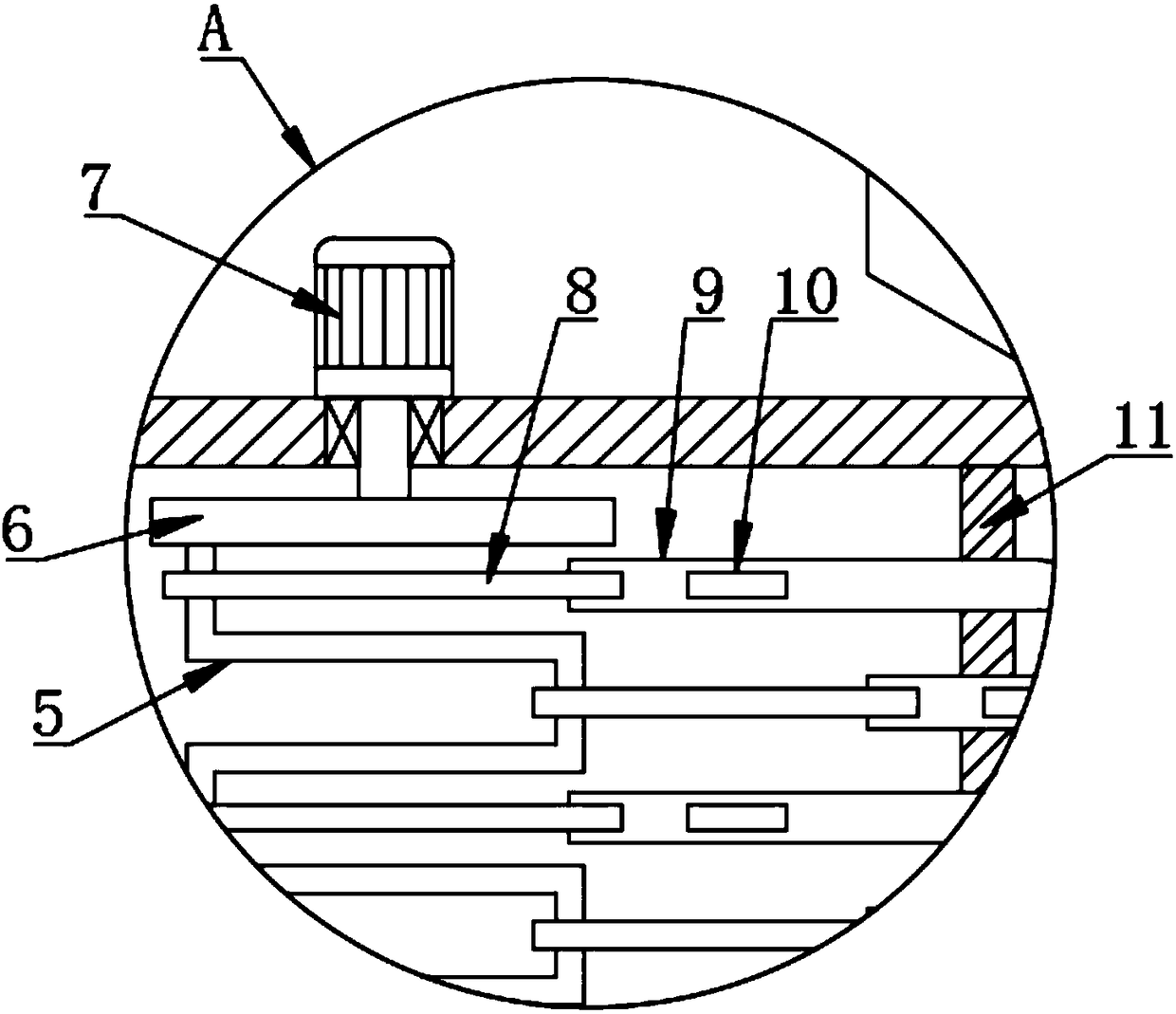

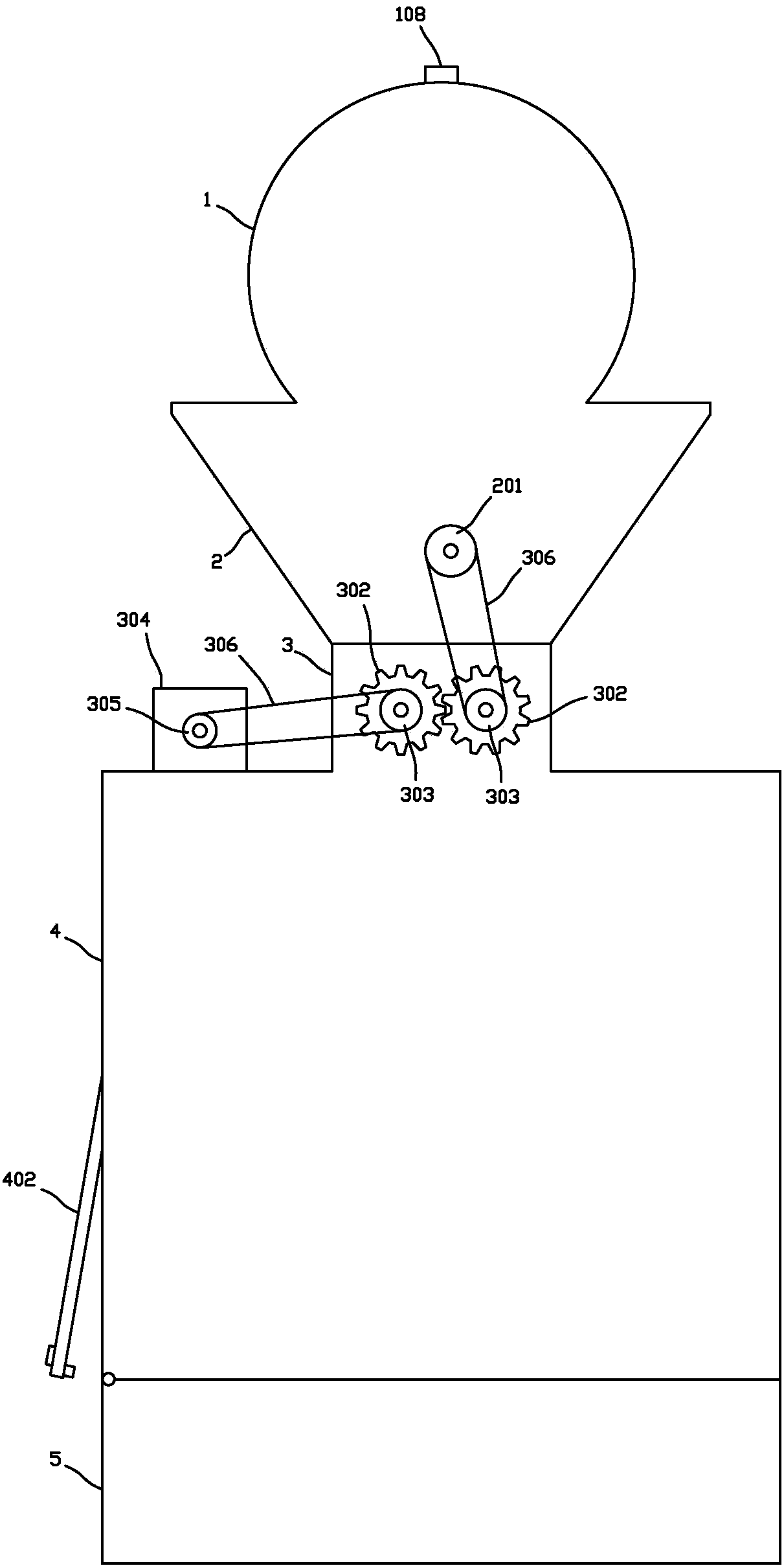

Device for quickly cutting and crushing forage of animal husbandry

PendingCN108093893AAvoid a direct fallConvenient for subsequent crushingCuttersEngineeringAnimal husbandry

The invention discloses a device for quickly cutting and crushing forage of animal husbandry. The device comprises a base; the top of the base is fixedly provided with a cutting box through a supportframe; the left side and the right side of the inner bottom of the cutting box are respectively rotatably connected with one lower round plate through a first rotating shaft and a second rotating shaft; the left side and the right side of the top of the cutting box are respectively fixedly provided with a first speed reduction motor and a second speed reduction motor; the motor shafts at the bottom ends of the first speed reduction motor and the second speed reduction motor pass through the top wall of the cutting box and are respectively fixedly connected with one upper round plate; a crankshaft is fixedly connected between the lower round plate and the upper round plate at the left side, and a crankshaft is fixedly connected between the lower round plate and the upper round plate at theright side; a plurality of connecting rods are respectively rotatably connected at the positions of the crankshaft journals; the right end of the connecting rods at the left side are hinge with a plurality of first cutting blades; the left ends of the connecting rods at the right side are hinged with a plurality of second cutting blades; and the first cutting blades are matched with the second cutting blades. According to the invention, forage is crushed by a plurality of cutting blades matched with each other, and vertically adjacent cutting blades move back and forth to cut the forage, so that the forage is prevented from falling directly after cutting for one time, so that the cutting effect is better and the efficiency is high.

Owner:周兰芝

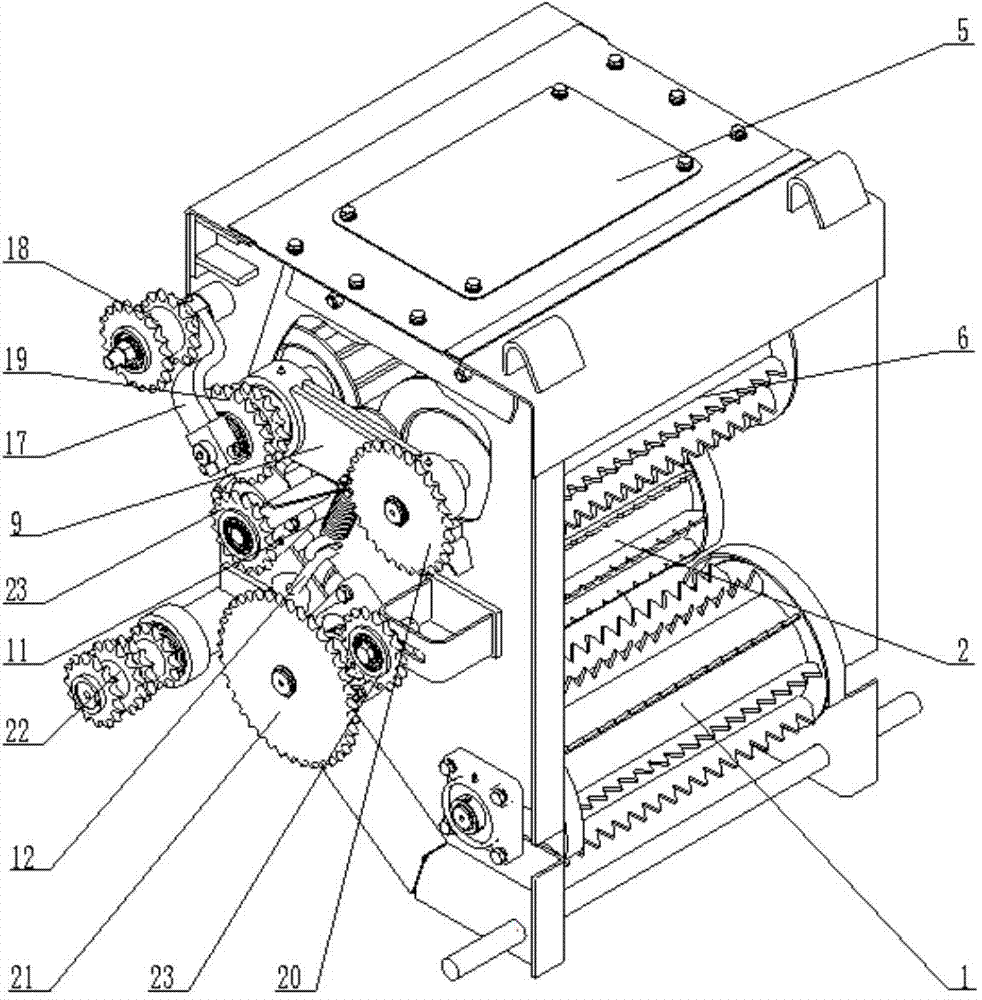

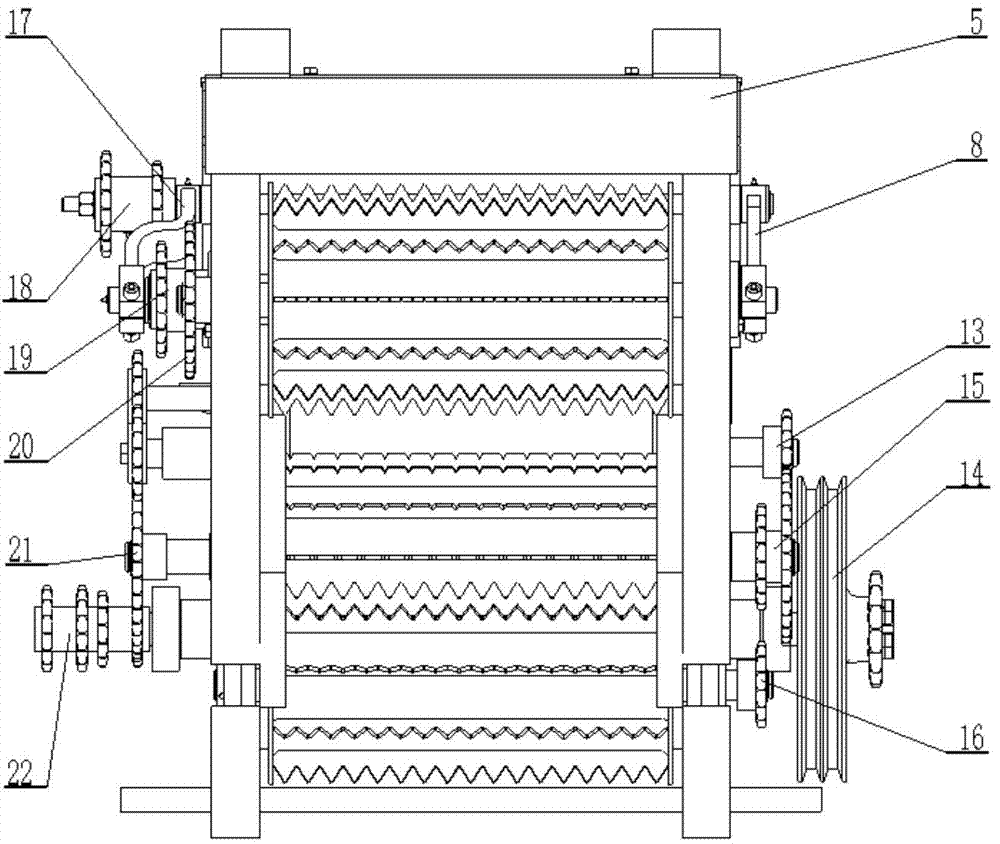

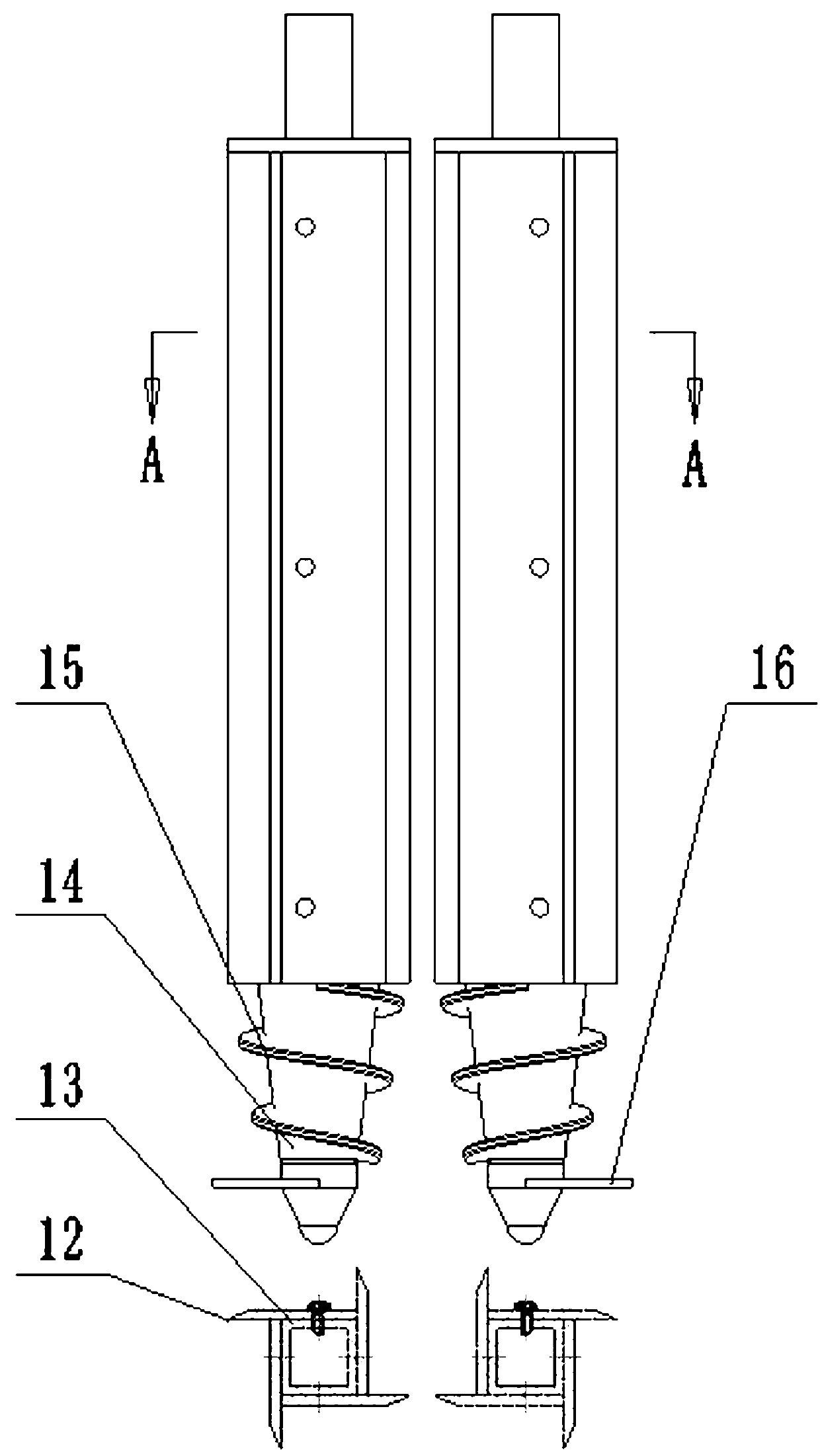

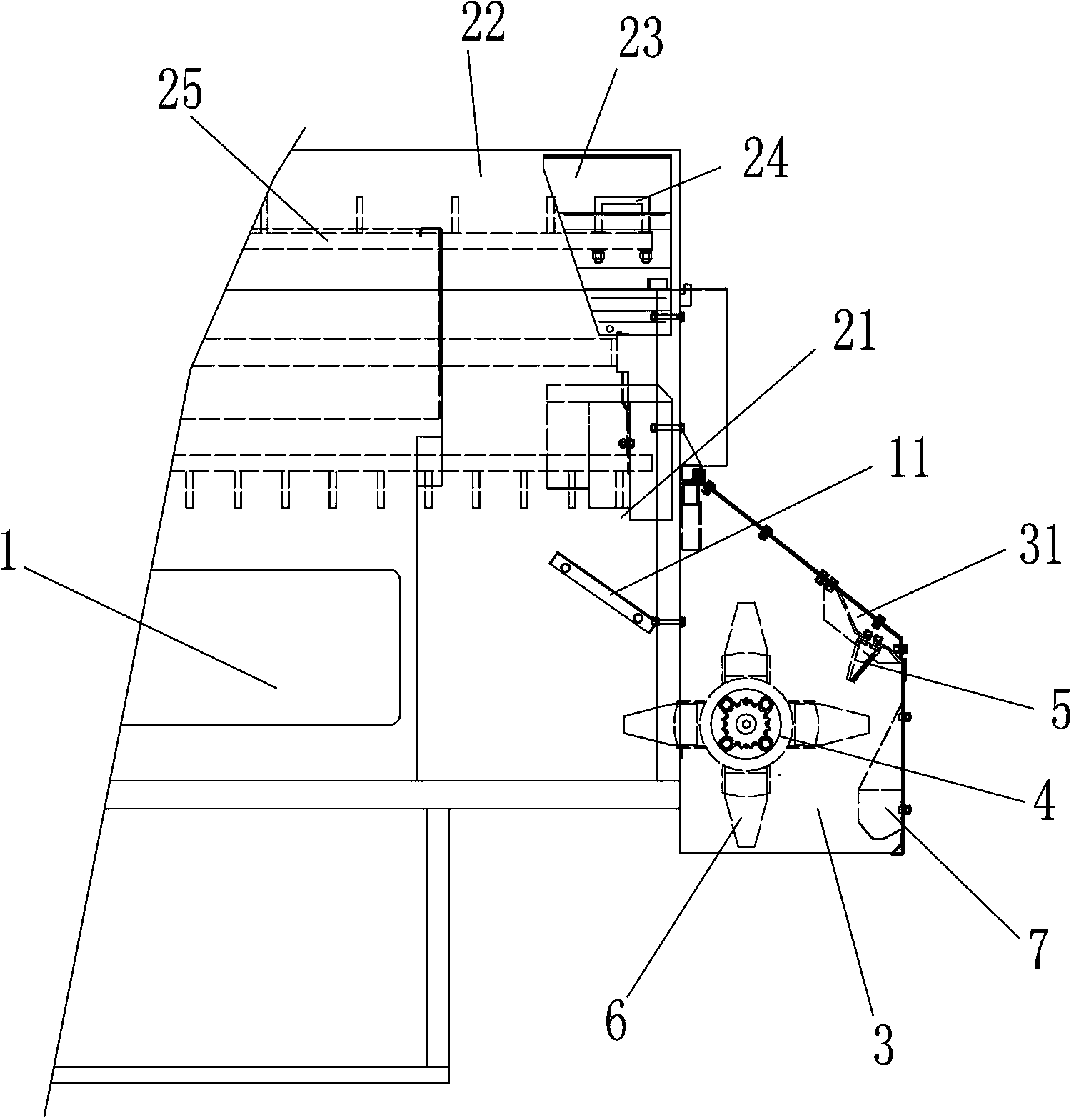

Feeding compaction device of silage harvesting machine

The invention provides a feeding compaction device of silage harvesting machine. The feeding compaction device consists of a framework, floating rotating rollers, fixed rotating rollers, a connecting device, a tensioning device and a power transmission device, wherein the three fixed rotating rollers are in step type arrangement and are fixedly arranged at the lower part of the framework, the floating rotating rollers are connected onto the upper part of the framework, the two floating rotating rollers and the three fixed rolling rollers are respectively in transverse arrangement, the two floating rotating rollers and the lower part of the framework are provided with the tensioning device, a power input wheel is respectively connected with the two floating rotating rollers and the three fixed rotating rollers through the transmission device, and a bent connecting rod is adopted for power transmission between the two floating rotating rollers. In a straw feeding process, crops are tightly compacted through the tensioning force of the tensioning device and the self weight of the floating rollers. A floating connecting rod mechanism arranged at the right side of the floating rotating rollers is made into a floating bent connecting rod mechanism, and the chain transmission power input is favorably realized, so that the floating rotating rollers are also power input rotating rollers, and the feeding efficiency is improved. The transmission process is simplified, and in addition, the fault rate is reduced.

Owner:内蒙古长明机械股份有限公司

Infiltration agent of chopped glass fiber for reinforcing cement

The invention discloses an infiltration agent of chopped glass fiber for reinforcing cement. The infiltration agent comprises the following components by weight percent: (1) 0.2-1.5% of coupling agent which is combination of 3-amino propionic triethoxy silane and 3-methacryloyloxyethyl propyl trimethoxysilane; (2) 3.0-30.0% of a film-forming agent, which is crosslinked polyacrylic dispersion or combination of crosslinked polyacrylic acid dispersion and a bisphenol A epoxy emulsion with medium-high molecular weight, wherein the molecular weight of the epoxy resin in the bisphenol A epoxy emulsion with medium-high molecular weight is 1200-6000; (3) 0.01-2.0% of a nonionic lubricant; (4) 0.05-1.0% of organic antistatic agent; (5) 0.1-2% of pH value modifier; (6) 63.5-96.64% of deionized water. A glass fiber yarn produced by using the infiltration agent has the advantages of being good in bundling property, easy to chop, and resistant to alkaline corrosion of cement, the produced cement product is high in mechanical strength, and the product is bright and clean in appearance.

Owner:JUSHI GRP CO

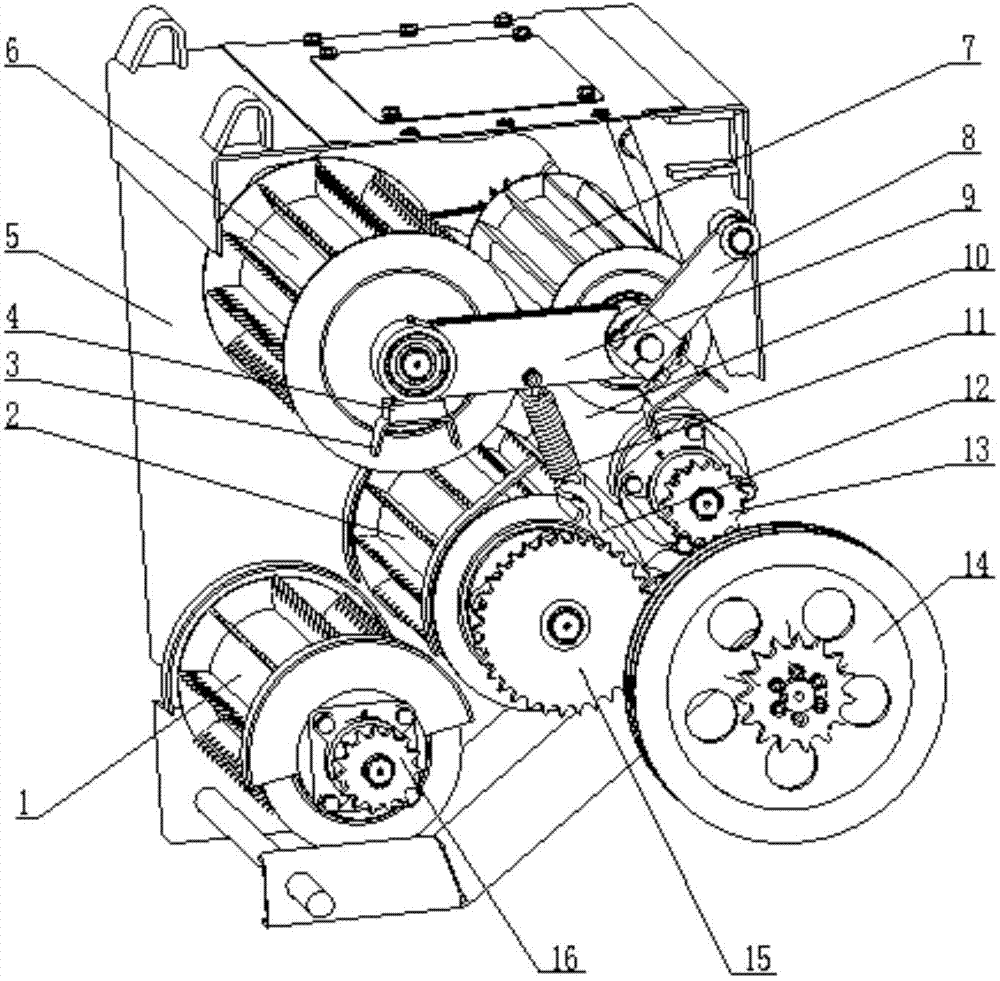

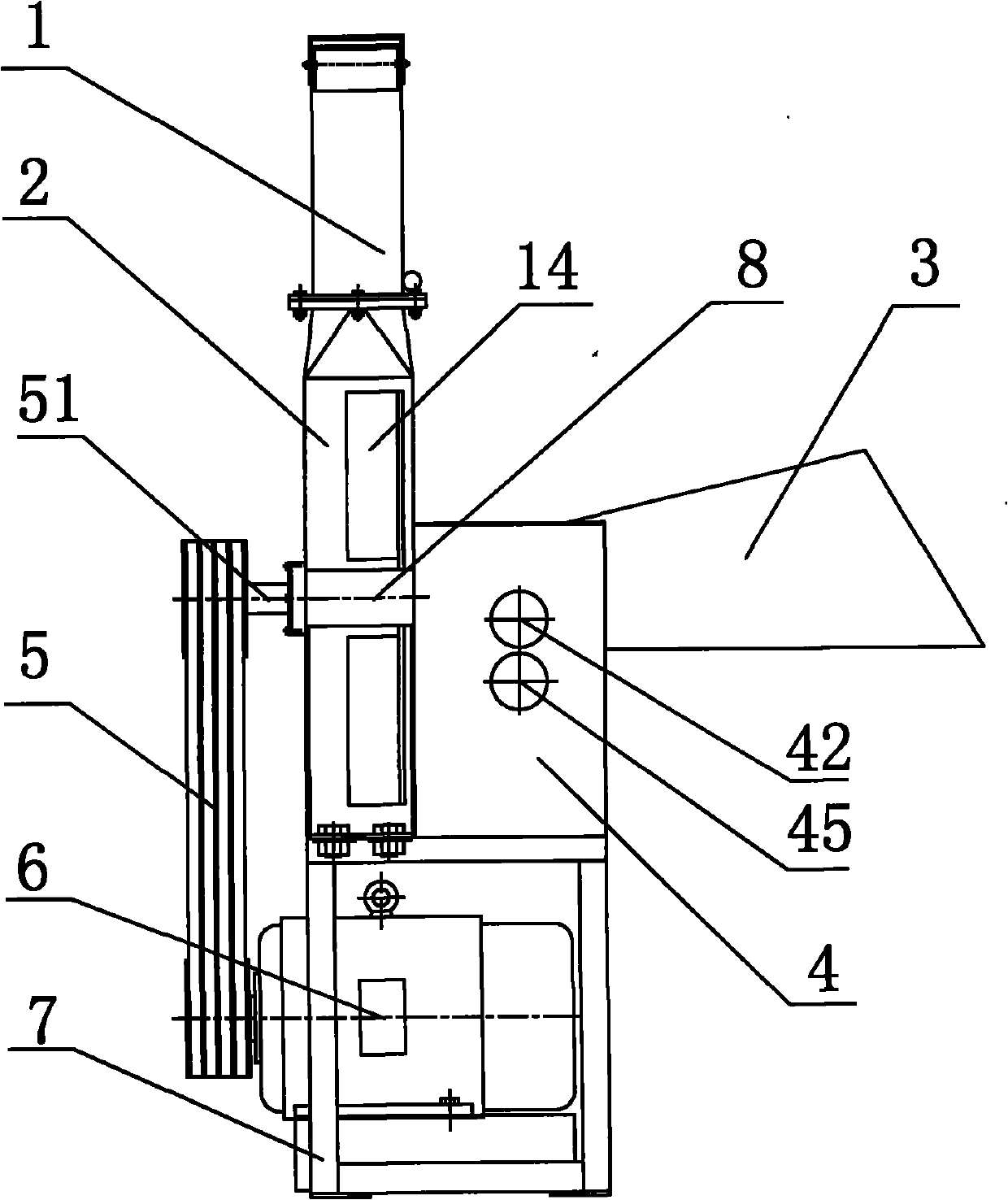

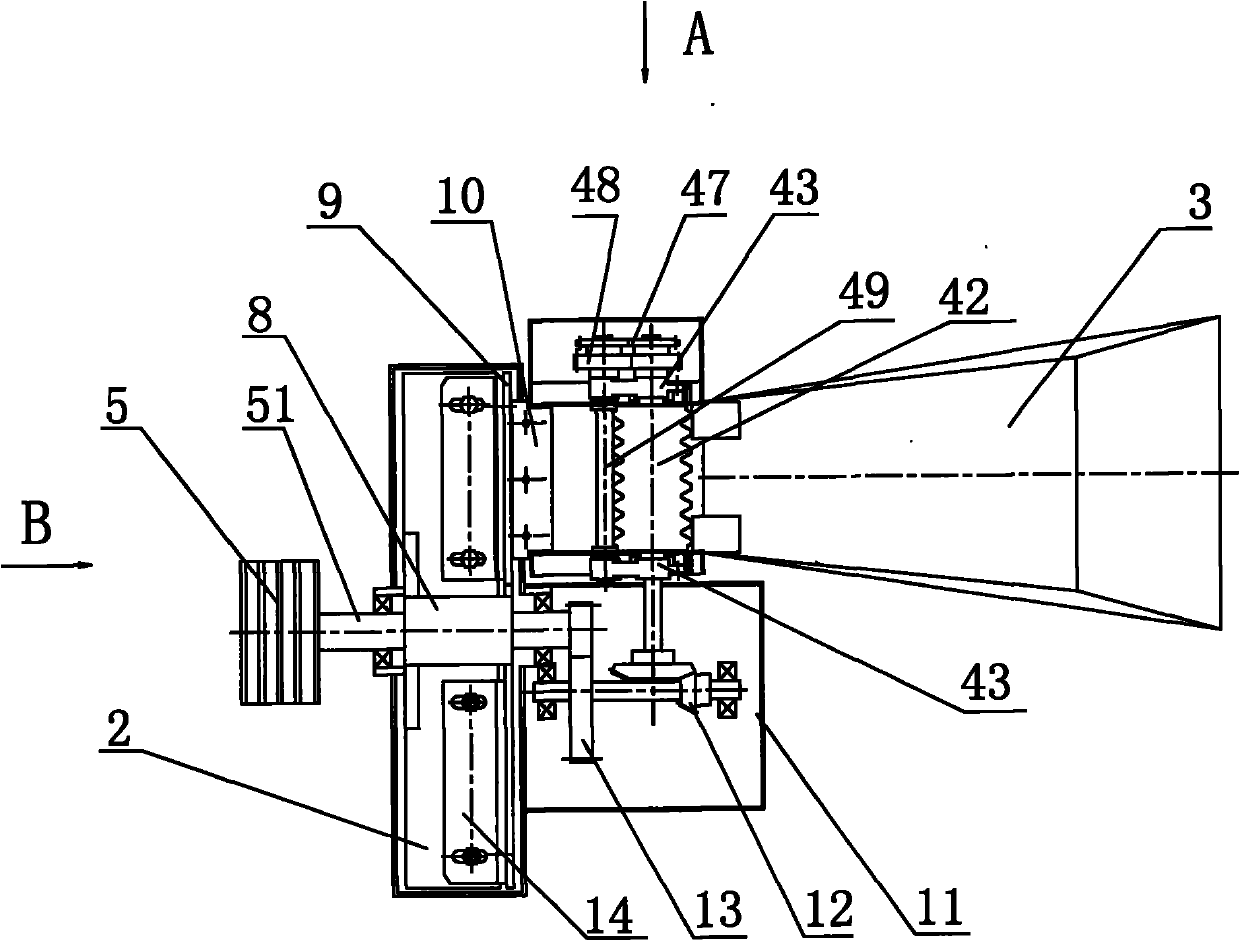

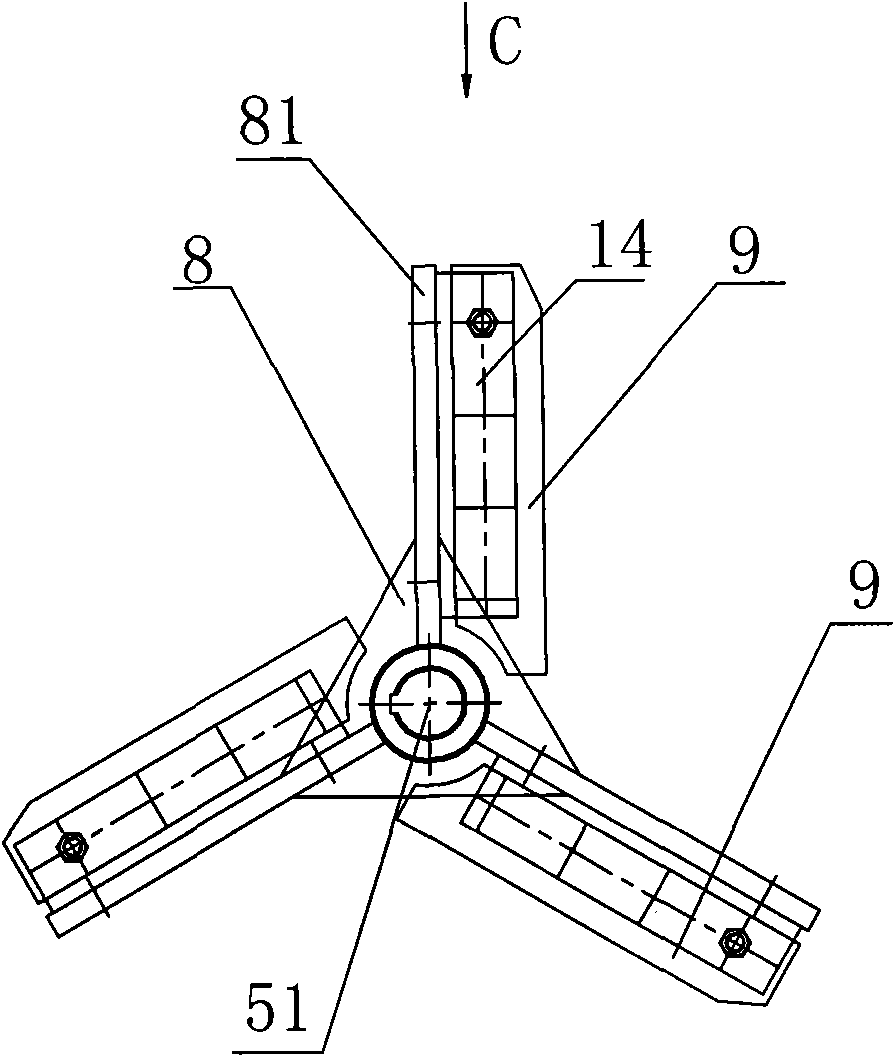

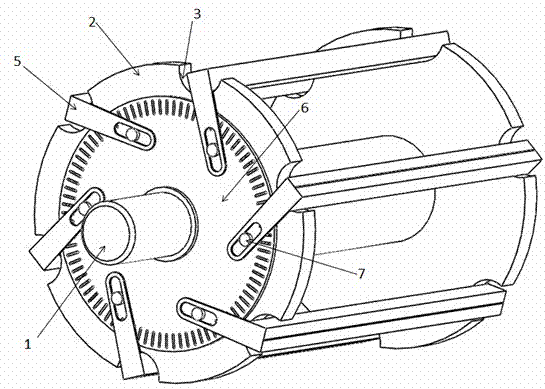

Crude stalk chopper capable of automatically adjusting feeding height

The invention discloses a crude stalk chopper capable of automatically adjusting the feeding height, which comprises a chopper component, a feeding mechanism (4) and the like. The chopper component comprises a chopper shell (2), a movable tool holder (8), a movable blade (9), a hammer leaf (14) and a fixed blade (10) which are arranged in the chopper shell (2), wherein the fixed blade (10) is fixedly connected with a rack (7), the movable blade (9) and the hammer leaf (14) are both fixedly connected with the movable tool holder (8), the movable tool holder (8) is connected with a power shaft (51), and the power shaft (51) is connected with a motor (6) through a belt transmission case (5); a throwing device (1) which is arranged above the chopper shell (2) is communicated with the outlet of the chopper shell (2); a feeding trough (3) is communicated with the inlet of the feeding mechanism (4), and the outlet of the feeding mechanism (4) is communicated with the inlet of the chopper shell (2). The chopper is applicable to the chopping of cotton stalks, mulberry twigs and other kinds of crude stalks.

Owner:ZHEJIANG UNIV

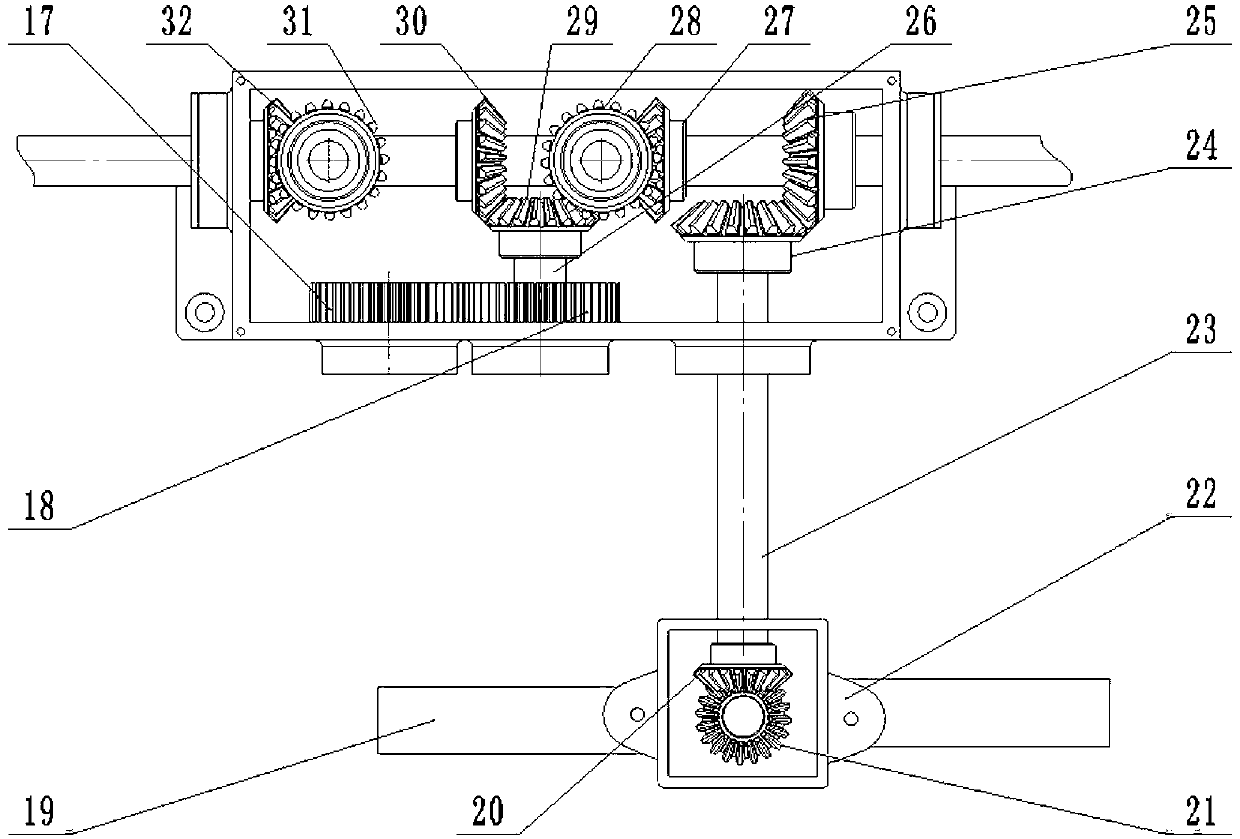

Environment-friendly waste paper multistage breaking device

The invention relates to a waste paper breaking device, in particular to an environment-friendly waste paper multistage breaking device. The environment-friendly waste paper multistage breaking device achieves the technical aims of being thorough in breaking, high in environment-friendly degree and high in practicability and comprises a second blade, a third blade, a trapezoid block, a first conical gear, a second conical gear, a first rotating rod, a small gear, a second connecting rod, a swing rod, a first connecting rod, a sliding block, a sliding rail, a base, a collection box, a left frame, a third bearing pedestal, a breaking box, a first blade, a third rotating rod, a first bearing pedestal, a speed reduction motor, a U-shaped frame, a large gear and the like. The left side of the top of the base is connected with the left frame. The effects of being thorough in breaking, high in environment-friendly degree and high in practicability are achieved. When the device is used for doing waste paper breaking work, waste paper can be cut thoroughly, and the chopping effect is better.

Owner:山西强伟纸业有限公司

Glass fiber impregnating compound high in permeating speed and application thereof in producing twistless roving

The invention discloses a glass fiber impregnating compound which is prepared from, by weight, 0.02-3.00% of a coupling agent, 3.00-30.00% of a film forming agent, 0.02-2.00% of a lubricating agent, 0.02-0.80% of an antistatic agent, 0.01-2.00% of a pH adjusting agent and deionized water. The film forming agent is prepared by mixing nanosilicon dioxide modified polyester emulsion, PVAc emulsion and polyurethane modified epoxy emulsion, and the content of the nanosilicon dioxide modified polyester emulsion is not smaller than that of the polyurethane modified epoxy emulsion. The invention further provides application of the glass fiber impregnating compound in producing twistless roving. The twistless roving produced through the impregnating compound is high in permeating speed, good in choppability, good in production smoothness and good in compatibility with enhanced resin, production efficiency and the mechanical strength of a produced composite product are greatly improved, and the glass fiber impregnating compound is applicable to an injection process or a centrifugal casting molding process.

Owner:JUSHI GRP CO

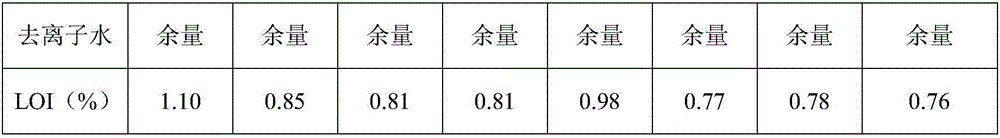

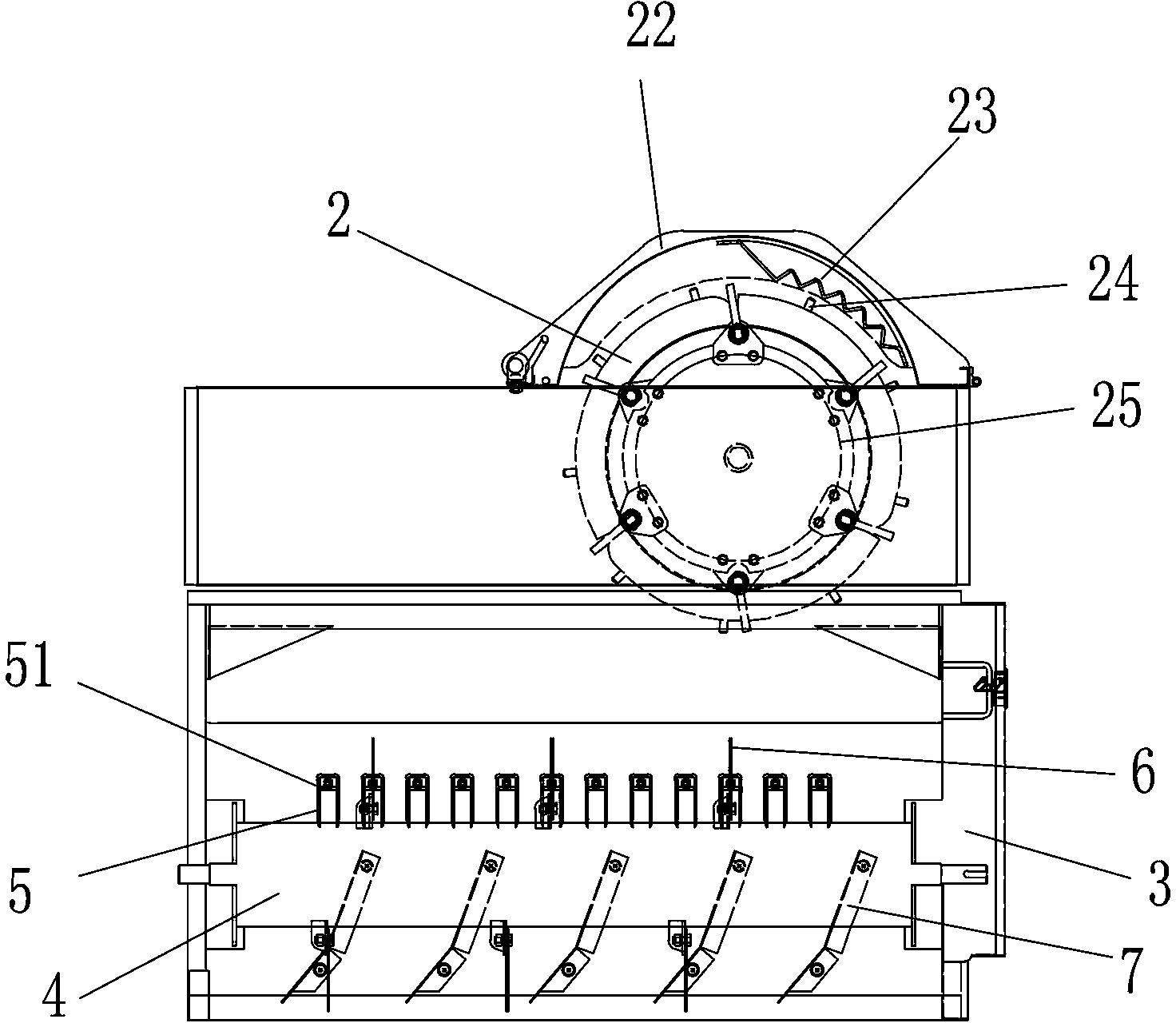

Cutter embedding type stalk pulling, ear picking and straw cutting unit body

InactiveCN103340058AGood harvesting effectImprove chopping effectMowersAgricultural engineeringSprocket

The invention particularly relates to a cutter embedding type stalk pulling, ear picking and straw cutting unit body which is composed of a millet separating device, an ear picking device, a straw re-cutting device, a transmission portion and the like. The millet separating device is arranged at the forefront end of the whole unit body, and two chain wheels are arranged on the millet separating device. The ear picking device is composed of a pair of ear picking boards and a pair of cutter embedding stalk pulling rollers, wherein the ear picking boards are arranged above the stalk pulling rollers, and the stalk pulling rollers are composed of steel pipes with square sections and straight board cutters embedded into the steel pipes. While ears are picked, straw is cut off. The rear end of the ear picking device is connected with a main gearbox, and the front end of the ear picking device is provided with the millet separating device. Two power transmission chain wheels are arranged above the main gearbox, and the straw re-cutting device is arranged below the stalk pulling rollers and composed of a small gearbox, a cutter throwing blade, a cutter seat and the like. The small gearbox is connected with the main gearbox through a power distributing shaft. Compared with the prior art, cutter embedding type stalk pulling, plate type ear picking and cutter throwing type straw re-cutting are utilized, fruit ears are harvested, and meanwhile the straw is cut into pieces and thrown back to fields.

Owner:SHANDONG UNIV OF TECH

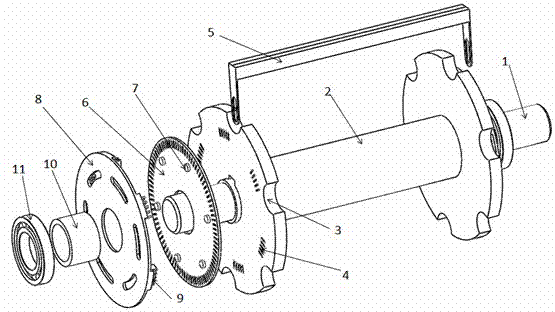

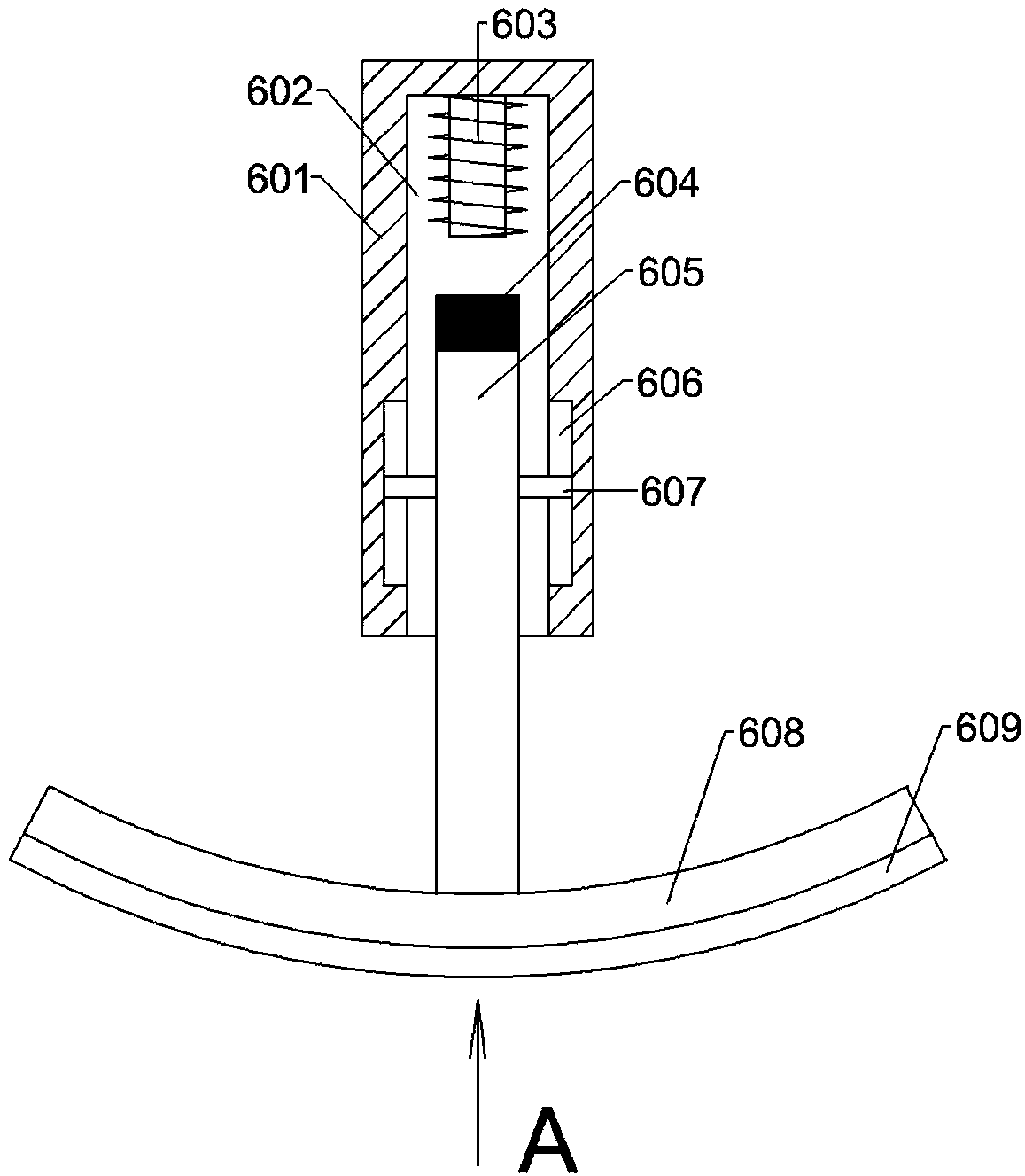

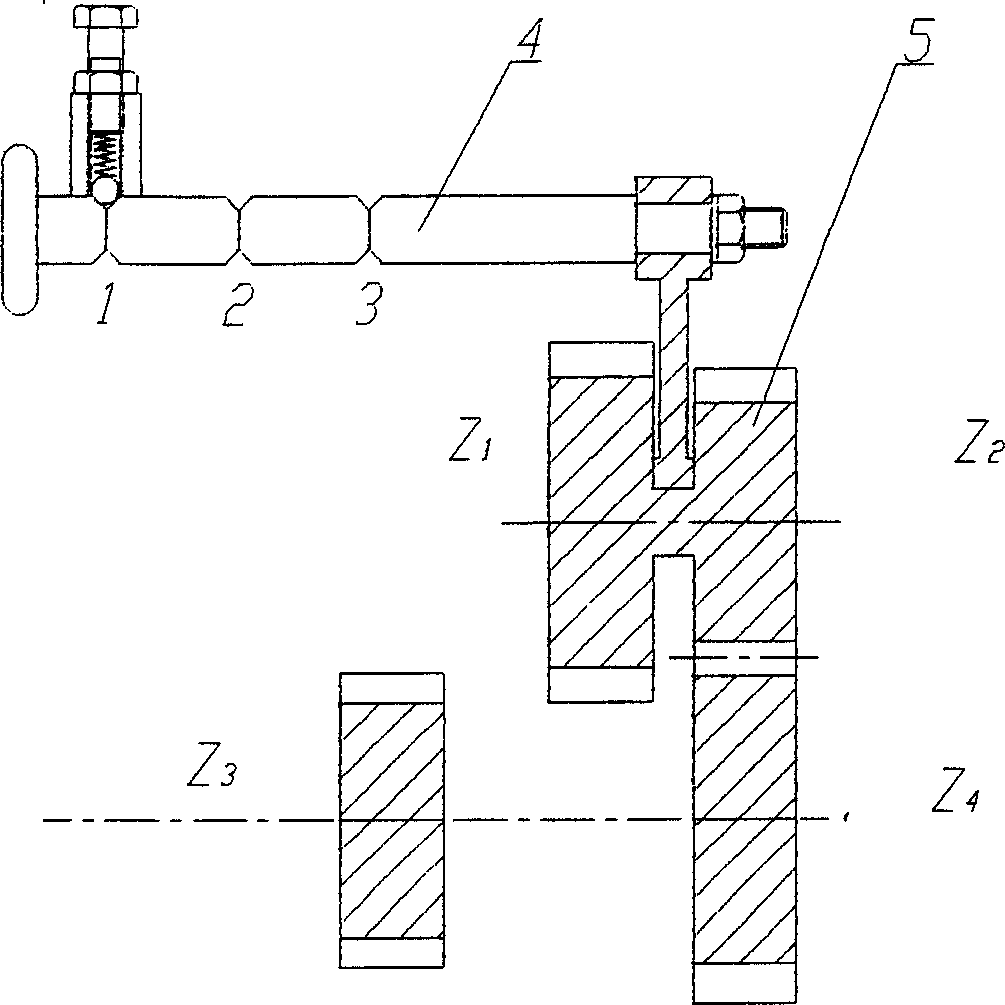

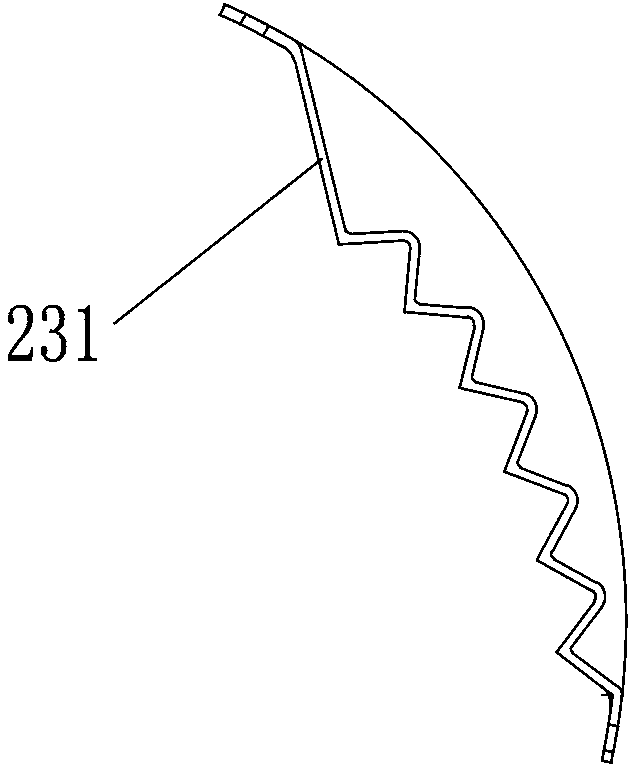

Fiber short cutter roller capable of adjusting cut-in angle of cutter in stepless mode

InactiveCN102926033AImprove chopping effectExtended service lifeMetal working apparatusSevering fibresEngineeringFiber

The invention discloses a fiber short cutter roller capable of adjusting a cut-in angle of the cutter in stepless mode. The fiber short cutter roller comprises an I-shaped cutter roller, two angle discs with the same structure, two positioning discs with the same structure and stair shafts, wherein the I-shaped cutter roller is installed in the middle of the stair shafts and fixedly connected with the stair shafts, and the angle discs, the positioning discs, sleeves and bearings are sequentially installed on the stair shafts outside two ends of the I-shaped cutter roller outwards. By means of the design of the angle discs and a rotary cutter groove, the cut-in angle of the cutter can be adjusted in stepless mode, and after the device is installed, the cut-in angles (ranging from 0 degree to 30 degrees) of all long blades can be adjusted by rotating the angle discs in one step, further the cut-in angles of all the long blades are ensured to be same, the problem that the existing short cutting devices cannot adjust the cut-in angles is solved, the short cutting effect is improved, service life of the cutter is prolonged, and production cost is reduced.

Owner:ZHEJIANG UNIV

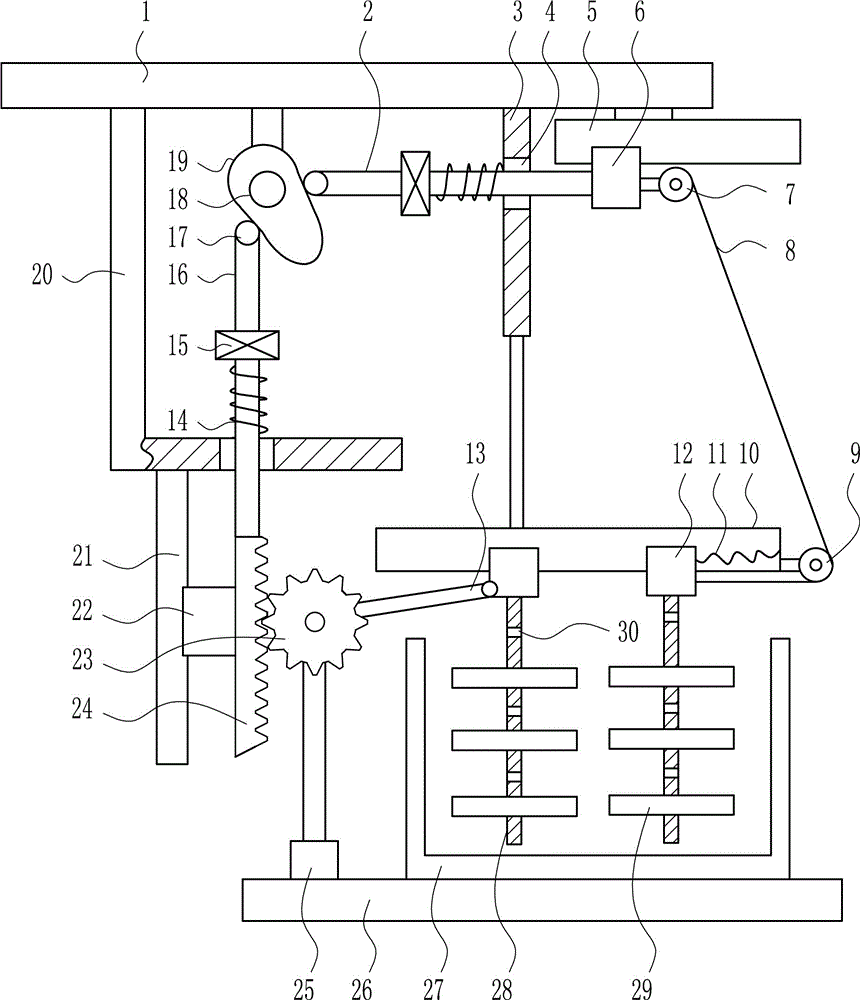

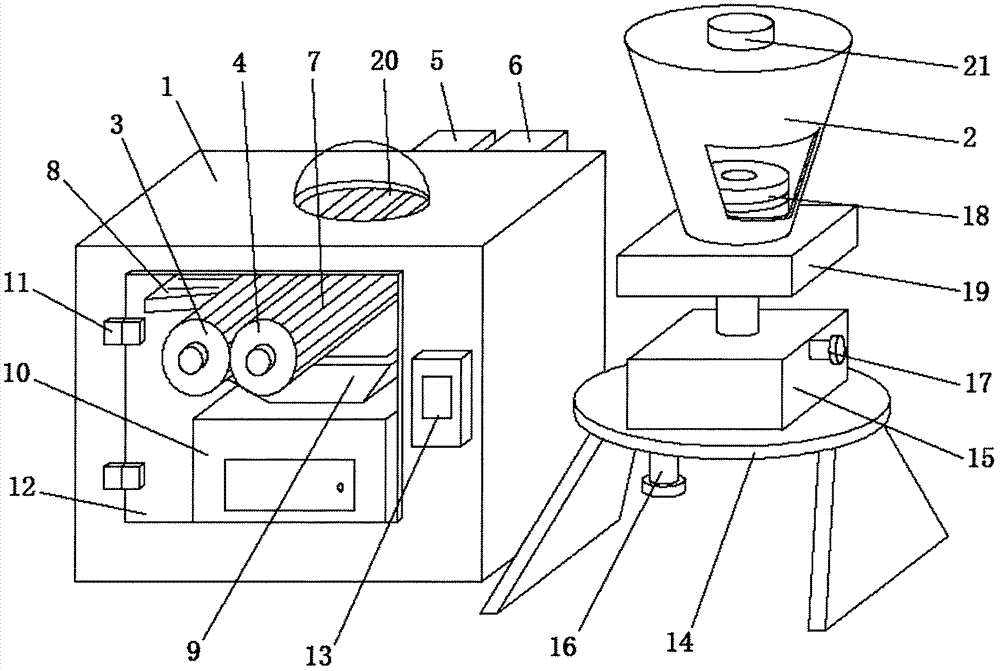

Plastic garbage fast chopping device for feed plant

The invention relates to a plastic garbage chopping device for a feed plant, in particular to a plastic garbage fast chopping device for the feed plant. The plastic garbage fast chopping device for the feed plant is good in chopping effect, high in work efficiency and simple in structure, and comprises a bottom plate, a left frame, a right frame, a sliding rail, a supporting rod, a sliding block, a chopping frame, a guide sleeve, a guide rod, a first spring, a striking plate, a first installation seat, a motor, a cam and the like. The left frame, the sliding rail, the supporting rod and the right frame are sequentially arranged at the top of the bottom plate from left to right. The sliding rail is connected with the sliding block in a sliding mode. The sliding block is provided with the chopping frame. The plastic garbage fast chopping device for the feed plant achieves the effects of good chopping effect, high work efficiency and simple structure, can fast chop plastic garbage, improves work benefits for enterprises, and is reasonably provided with reinforcement bars.

Owner:丁继来

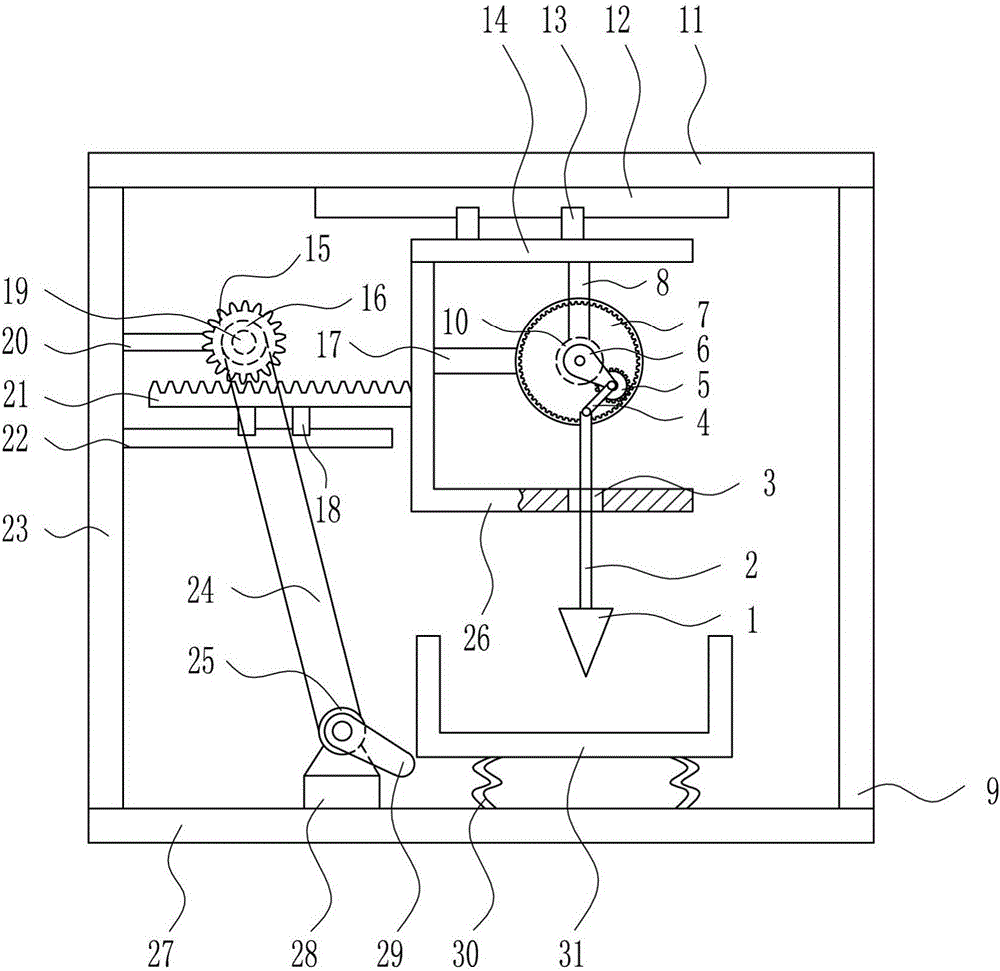

High-efficient straw chopping device for agriculture

The invention discloses a high-efficient straw chopping device for agriculture. The high-efficient straw chopping device for agriculture comprises a pedestal. A left supporting plate and a right supporting plate are arranged on the left and right sides of the pedestal; a second rotating shaft is rotationally arranged on the pedestal; a chopping case is fixed on the top of the second rotating shaft; a first rotating shaft is rotationally arranged on the left side of the right supporting plate; the left end of the first rotating shaft is equipped with a first bevel gear; the second rotating shaft is further provided with a second gear; the second bevel gear is engaged with the first bevel gear; a deceleration motor is arranged on the left side wall of the right supporting plate; a rotary disc is connected to the deceleration motor; a connection rod is rotationally connected to the left end surface of the rotary disc via a pin roll; an elevating rod is hinged to the bottom end of the connection rod; a first spacing sleeve is arranged on the left side of the right supporting plate; the elevating rod passes through the first spacing sleeve to be connected with a rack; a gear is further mounted on the first rotating shaft; and the gear is engaged with the rack. The chopping case can forwardly and backwardly rotate; due to an inertia effect during the forward and backward rotation, the straws are displaced; and therefore directions of the straws are different during each time cutting, so chopping effect can be improved.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

Structure-enhanced SMC (Sheet Moulding Compound) glass fibre impregnating agent and application thereof in production of twistless roving

Owner:JUSHI GRP CO

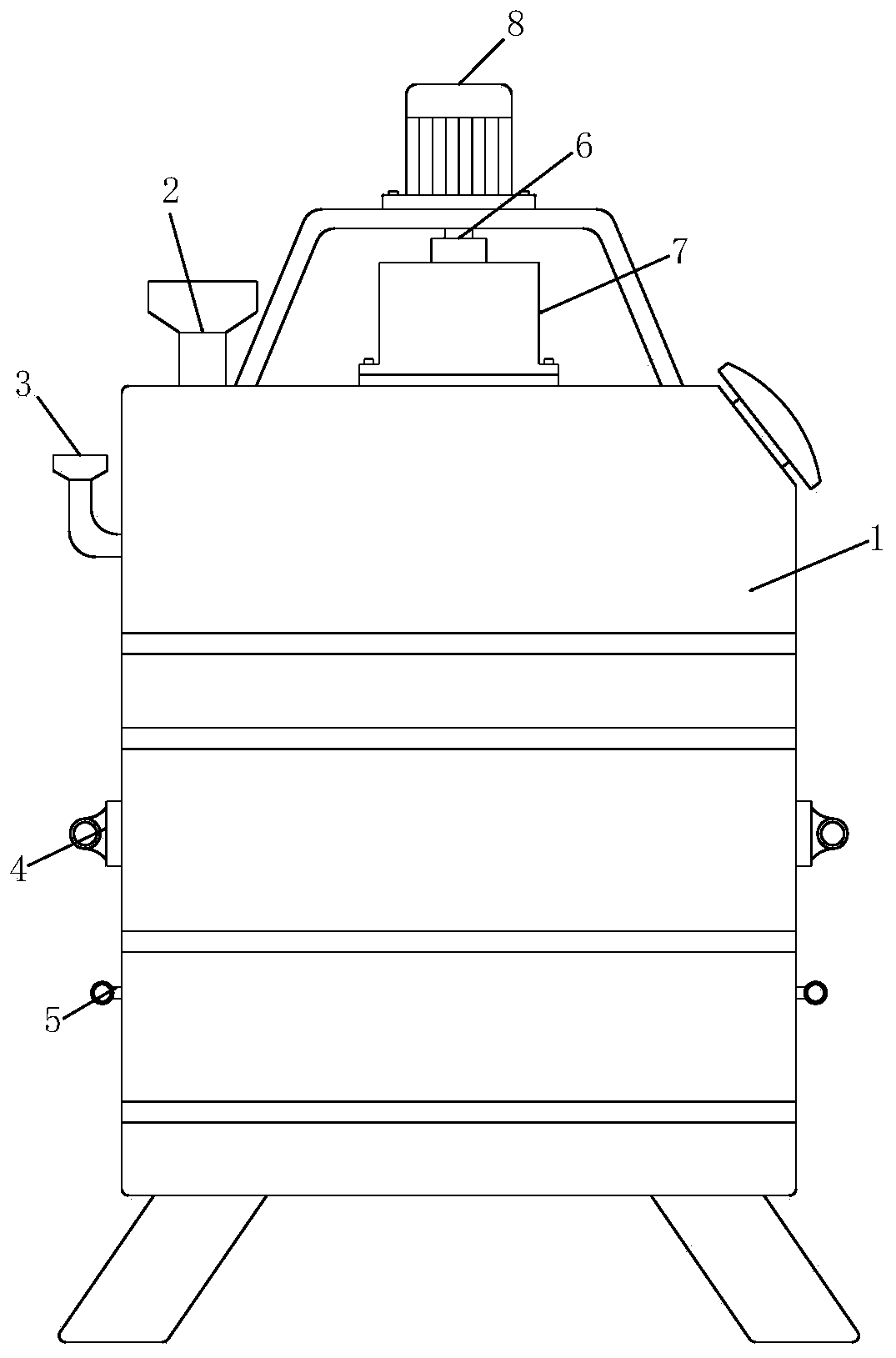

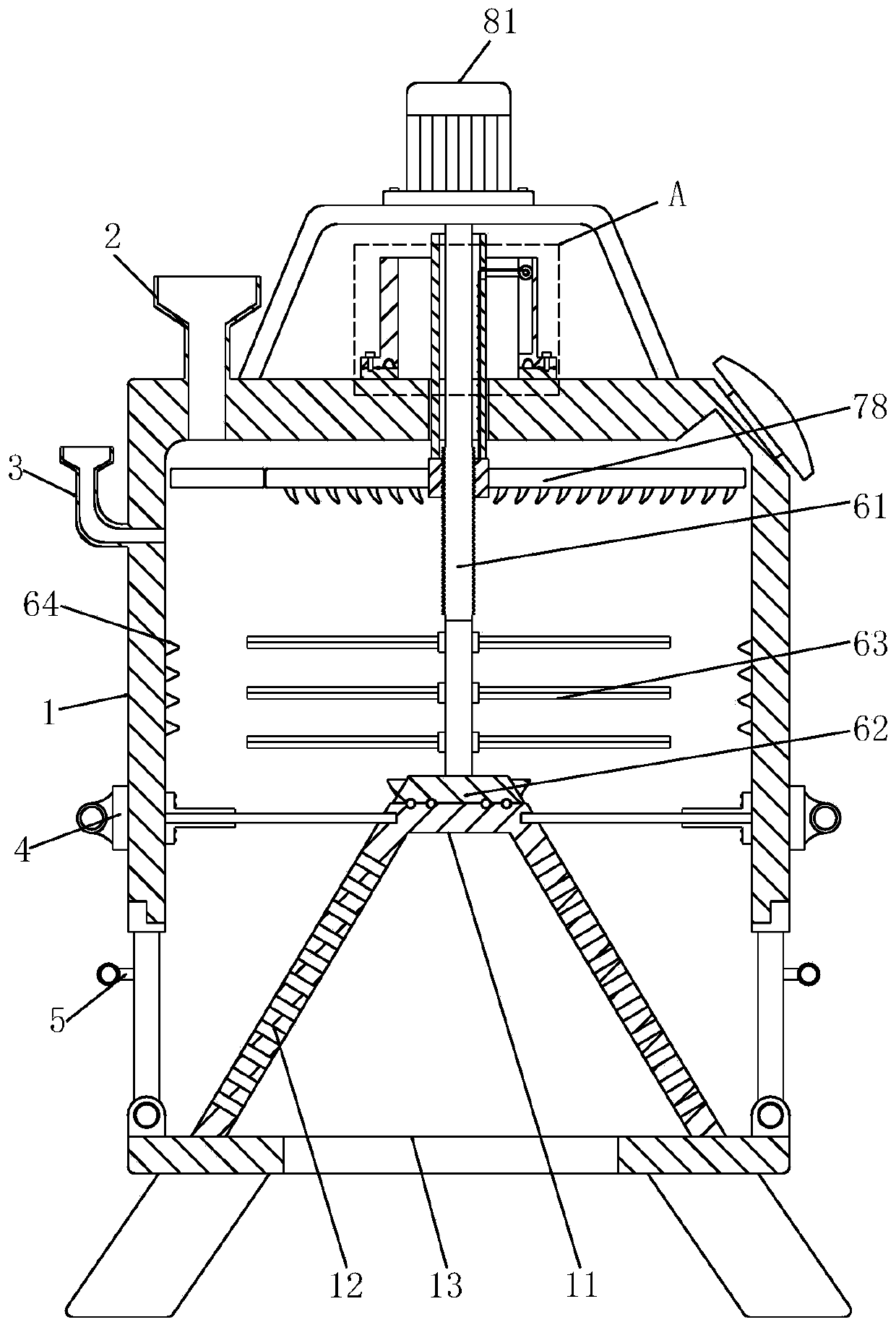

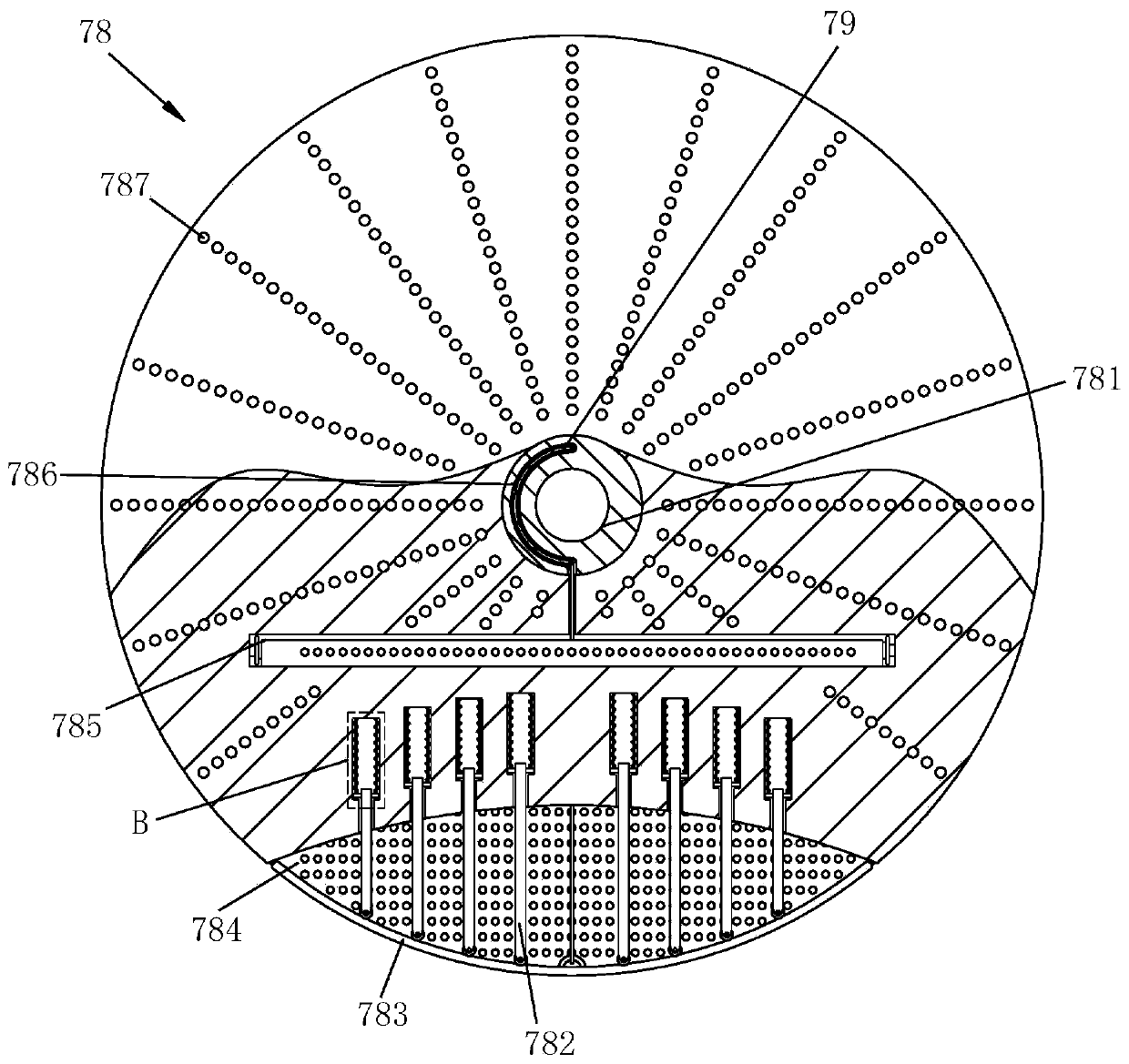

Cosmetic rose essential oil extraction raw material pretreatment system

ActiveCN111375470ANarrow down the active areaGuaranteed normal inputEssential-oils/perfumesCleaning using liquidsElectric machineryDrive motor

The invention relates to a cosmetic rose essential oil extraction raw material pretreatment system. The cosmetic rose essential oil extraction raw material pretreatment system comprises a tank body, afeeding port, a water injection port, a partition plate, unloading plates, a cleaning mechanism, a positioning mechanism and a driving motor; the unloading plates are arranged on the two sides of thebottom of the tank body; the partition plate is arranged at the middle section position of the tank body; the driving motor is mounted at the top of the tank body; the lower part of the driving motoris connected with the cleaning mechanism; the positioning mechanism is arranged on the outer side of the cleaning mechanism; the feeding port is connected to one end of the top of the tank body; thewater injection port is formed in the outer wall of the tank body; a rotating rod is connected to the central position in the tank body in an inserting manner; the top end of the rotating rod is connected with an output shaft of the driving motor; a thread groove is formed in the outer wall of the middle area of the rotating rod; cutting blades are arranged on the outer wall of the bottom of the rotating rod at equal distance; and the bottom of the rotating rod is welded with a stirring disc. The cosmetic rose essential oil extraction raw material pretreatment system effectively ensures full contact between rose petals and cleaning water as well as the cutting blades, so that the cleaning and cutting effects are better; and the device is easy, convenient and quick to operate.

Owner:两当沁香怡玫瑰生物科技有限公司

Animal husbandry forage cutting and mixing device convenient to clean

InactiveCN108401696AImprove cleanlinessConvenience for subsequent useShaking/oscillating/vibrating mixersTransportation and packagingEngineeringDrive motor

The invention discloses an animal husbandry forage cutting and mixing device convenient to clean. The animal husbandry forage cutting and mixing device comprises a crushing box and a baseboard; a rotary rod is arranged at the right side of the baseboard, the upper end of the rotary rod is fixedly connected with a top plate, and a driving motor for driving the rotary rod to rotate is arranged at the lower end of the rotary rod; the crushing box is fixedly installed at the inner side of a left lateral plate, a feeding opening is formed in the upper side of the crushing box, and a discharging opening is formed in the lower side of the crushing box; a crank is arranged at the upper side of the rotary rod, a rotary cover is rotatably installed at the shaft journal of the crank, a connecting rodis rotatably installed at the left side of the rotary cover, a push rod is slidably installed on the inner wall of the right side of an upper cavity, the right end of the push rod is rotatably connected with the connecting rod, and a grinding plate is fixedly installed at the left end of the push rod. By means of the animal husbandry forage cutting and mixing device, the forage cutting effect isimproved, the forage cutting time is shortened, the cleanliness of the crushing box is improved, and subsequent use of the crushing box is facilitated.

Owner:杨翠萍

Efficient shredding device for medicinal materials for medical use

The invention relates to a medicinal material shredding device, particularly relates to an efficient shredding device for medicinal materials for medical use, and aims at solving the technical problem of providing the efficient shredding device for the medicinal materials for medical use, which is good in shredding effect, simple in operation and high in work efficiency. In order to solve the technical problem, the invention provides the efficient shredding device for the medicinal materials for medical use, which comprises a first sliding rail, a first sliding block, a crushing box, a 7-shaped bracket, a second sliding rail, a second sliding block, a rack, a second connecting rod, a first connecting rod, a first support rod, a second support rod, a first spring, an electric wheel, a cam, a driven wheel, a gear, a belt, a lifting rod, a fixed baffle block, an n-type guide rod, a guide hole, a second spring, a cutting knife and a contact wheel, wherein the first sliding rail is connected with the first sliding block in a sliding manner; the first sliding block is provided with the crushing box; and the 7-shaped bracket is arranged at the top of the first sliding rail. According to the efficient shredding device, the effects of being good in shredding effect, simple in operation and high in work efficiency are achieved.

Owner:山东大树生命健康科技有限公司

Medical waste disposal equipment

InactiveCN108263787AClean up in timePrevent overflowRefuse receptaclesGrain treatmentsMedical wasteMedical treatment

The invention discloses medical waste disposal equipment. A rotating piece is arranged in a first barrel body of the equipment; when the rotating piece rotates, medical wastes in the first barrel bodycan be imported into a second barrel body; a rotatable straight rod is arranged in the second barrel body; the straight rod can scatter the medical waste stacked together when the medical waste falls; then the medical waste falls into a third barrel body; when a rotating roller in the third barrel body rotates, a cutting blade can cut the medical waste; when the medical waste is cut, the rotatingpiece can separate the second barrel body from outer air so as to prevent peculiar smells and bacteria generated by cutting the medical waste from being diffused from the first barrel body. Accordingto the medical waste disposal equipment disclosed by the invention, when the medical waste is crushed, peculiar smells of the medical waste does not drift out, and bacteria on the medical waste is not diffused out, and the medical waste which is input can be prevented from being stacked together.

Owner:俞海娟

Pepper chopping device based on artificial way simulation

A pepper chopping device based on artificial way simulation comprises a barrel body. Four support legs are fixedly connected to the top end of the barrel body. Two mounting seats are symmetrically andfixedly connected to the outer side wall of the barrel body. Mounting columns are fixedly connected to the mounting seats. The top ends of the two mounting columns are jointly fixedly connected witha mounting plate. A chopping device body is fixedly connected to the middle of the lower side of the mounting plate. A water distribution device is arranged in the barrel body. The water distributiondevice comprises a water distribution ring pipe. Multiple water spray holes with downward openings are formed in the water distribution ring pipe. The water distribution ring pipe communicates with awater storage tank located on the upper side of the mounting plate through a hose. A pump body is arranged on the hose. The pepper chopping device has the beneficial effects that after an electromagnet is electrified, the magnetism the same as that of a magnetic pole can be generated, so that the electromagnet and the magnetic pole repel each other, the magnetic pole drives the arc-shaped mountingplate to move downwardly through a support column, and blades arranged on the lower side of the arc-shaped mounting plate effectively chop peppers.

Owner:临泉县正伟农副产品有限公司

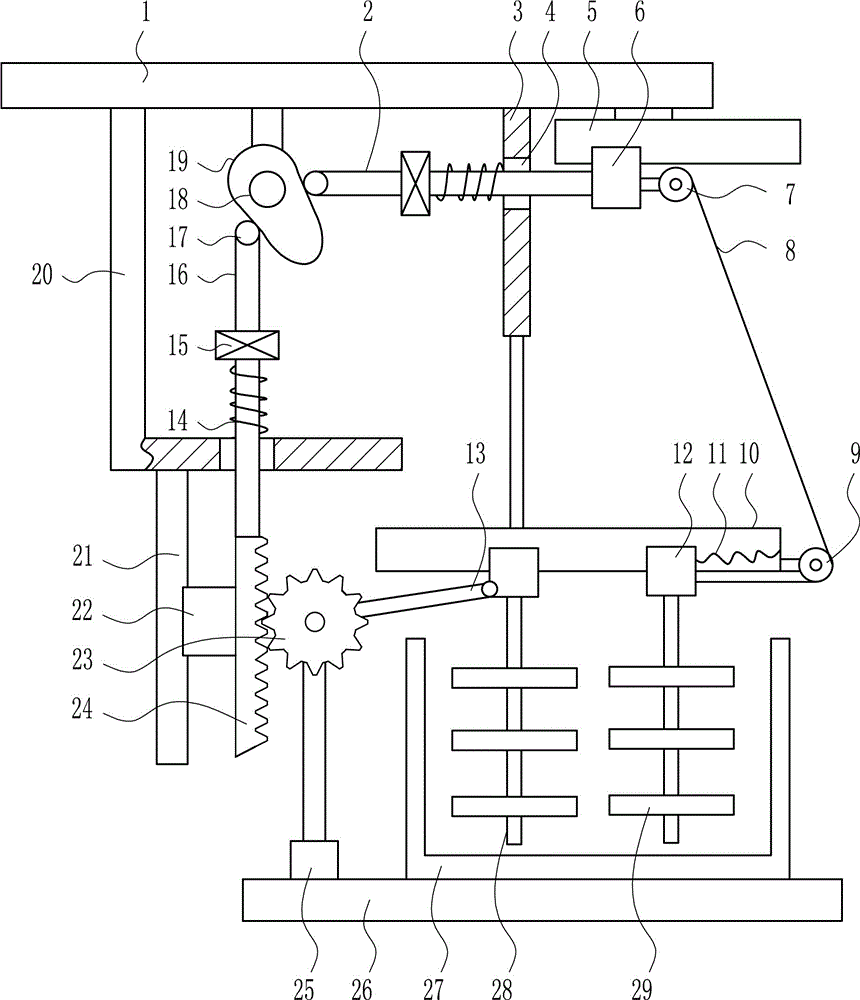

Building plastic waste fast cutting and processing device

InactiveCN106492942AShred fastEasy to operatePlastic recyclingGrain treatmentsPlastic wasteEngineering

The invention relates to a plastic waste cutting and processing device, in particular to a building plastic waste fast cutting and processing device which has the technical effects of being thorough in cutting, high in cutting speed and easy to operate. In order to achieve the effects, the building plastic waste fast cutting and processing device provided by the invention comprises a top plate, a first connecting rod, a first small belt pulley, a first gear, a first fulcrum bar, a second connecting rod, a third connecting rod, a second gear, a crank, a second fulcrum bar and the like. A left frame, a sliding rail, a third fulcrum bar and a right frame are sequentially arranged on the top of a bottom plate from left to right. Sliding blocks are slidably connected to the sliding rail. A cutting frame is arranged on the tops of the sliding blocks. The building plastic waste fast cutting and processing device achieves the effects of being thorough in cutting, high in cutting speed and easy to operate. Moreover, the building plastic waste fast cutting and processing device plays an important role, has a good cutting effect, improves the working efficiency and is high in safety performance.

Owner:WUXI TONGXIN PLASTIC PROD

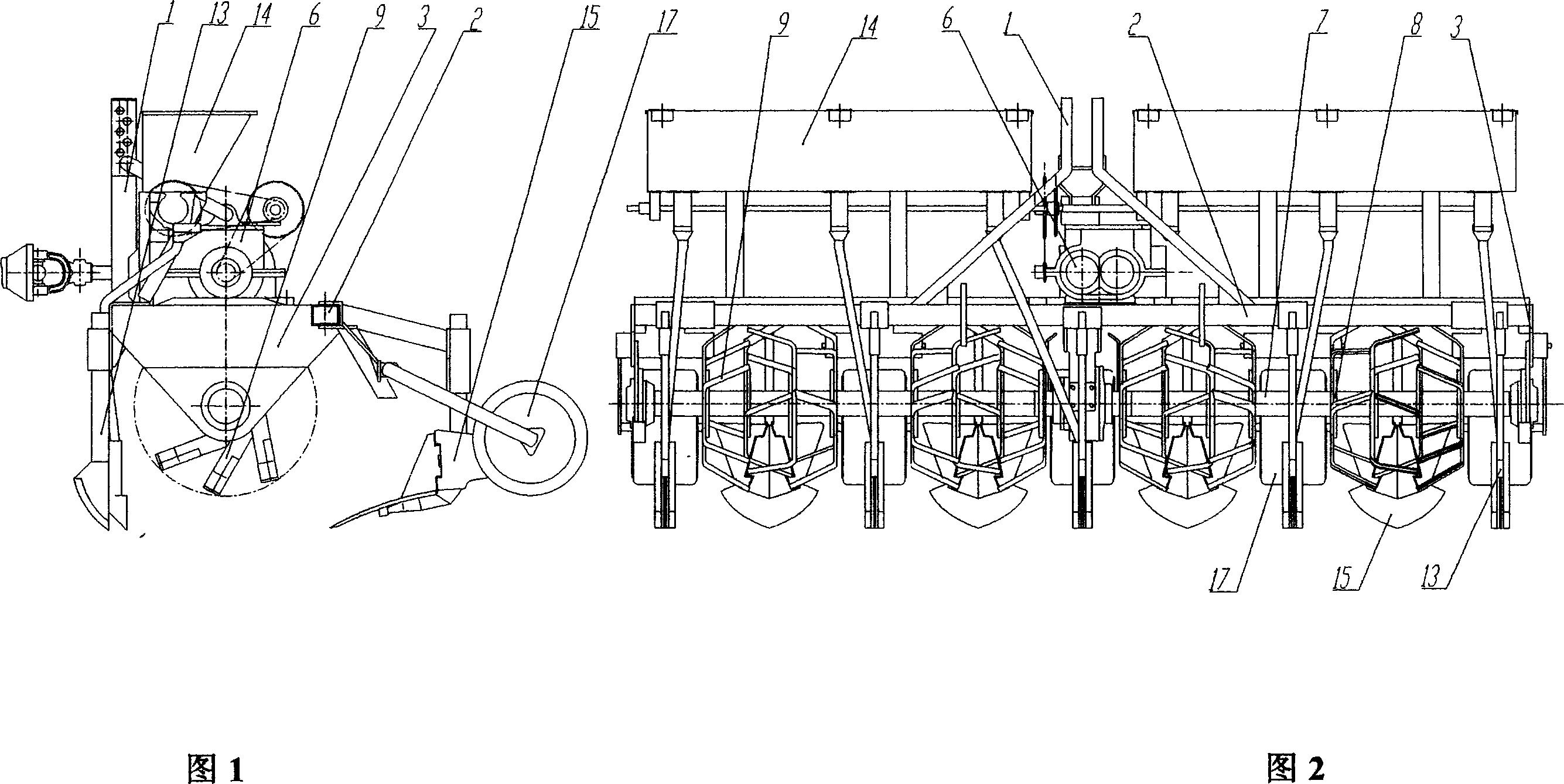

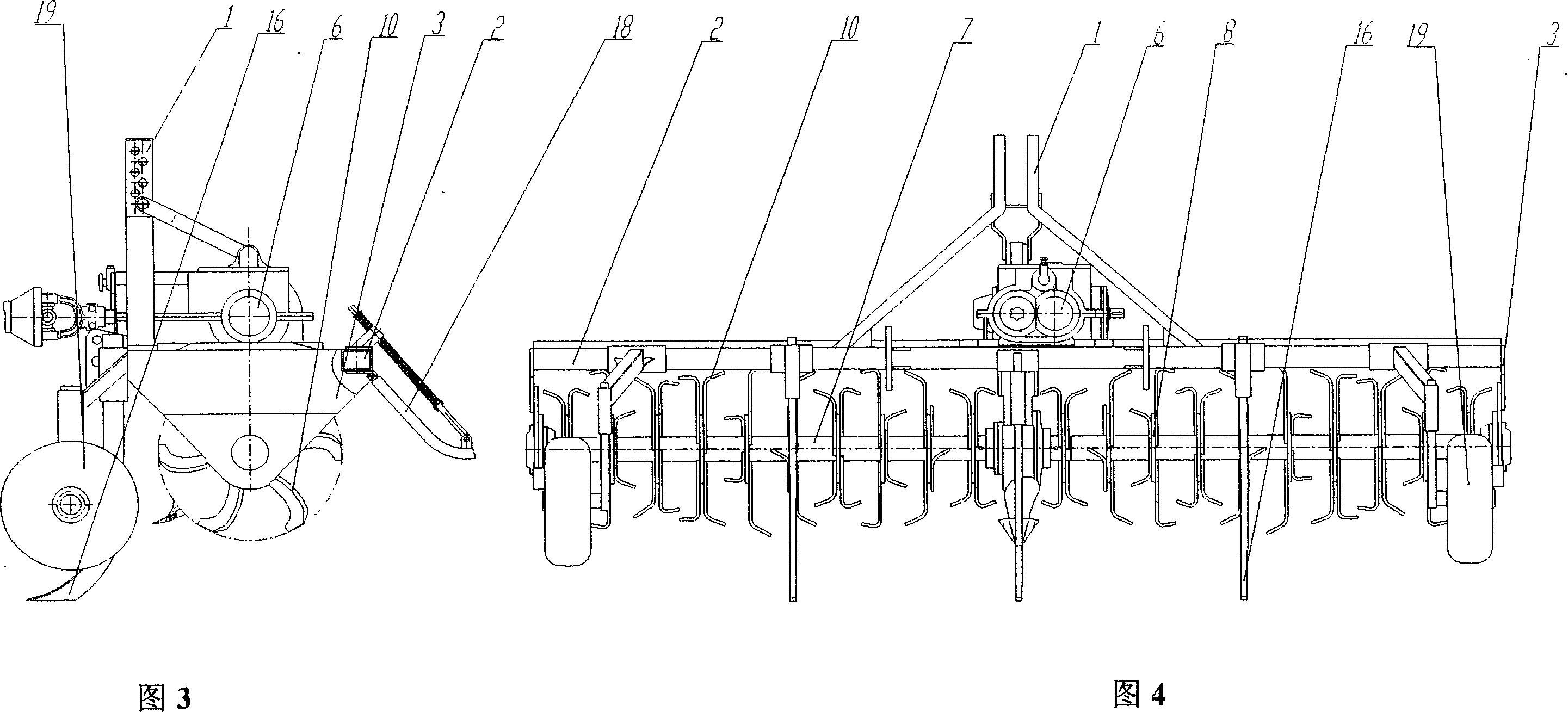

Tillage equipment

The present invention relates to a tillage machine, including machine frame, knife roller formed from knife roller shaft and knife disk, stubble-breaking knife and rotary tilling knife. The improvement lies in that a speed-change box with two rotating speed outputs is added. On the knife disk the stubble-breaking knife mounting hole and rotary tilling knife mounting hole are set, on the knife handle of the rotary tilling knife two mounting holes are set. When it is used for making stubble-breaking operation, the stubble-breaking knife is mounted on the knife disk, and when it is used for making rotary tilling operation, the rotary tilling knife is mounted on the knife disk.

Owner:JILIN ACAD OF AGRI MACHINERY

Efficient waste paper shredding device for environmental protection

ActiveCN106238162AImprove space utilizationImprove practicalityGrain treatmentsEnvironmental resistanceCam

The invention relates to a waste paper shredding device for environmental protection, in particular to an efficient waste paper shredding device for environmental protection. In order to solve technical problems in the prior art, the efficient waste paper shredding device thorough in shredding effect, high in environment-friendly degree and high in practicability is provided. The efficient waste paper shredding device comprises a top pate, a second moving rod, a third sliding block, a first roller, a steel wire rope, a first sliding rail, a second spring, first sliding blocks, a connecting rod, a first spring, a fixing block, a first moving rod, contact balls, a speed-reducing motor, a cam, a first guiding plate, a gear, a gear rack, a bearing seat, a base, a shredding box, a third moving rod, blades and the like, wherein the first guiding plate is connected with the left side of the bottom of the top plate. The efficient waste paper shredding device provided by the invention achieves the effects of being thorough in shredding effect, high in environment-friendly degree and high in practicability. When the efficient waste paper shredding device is used for shredding waste paper, the waste paper can be shredded into smaller pieces and the shredding effect is better.

Owner:广东振裕再生资源有限公司

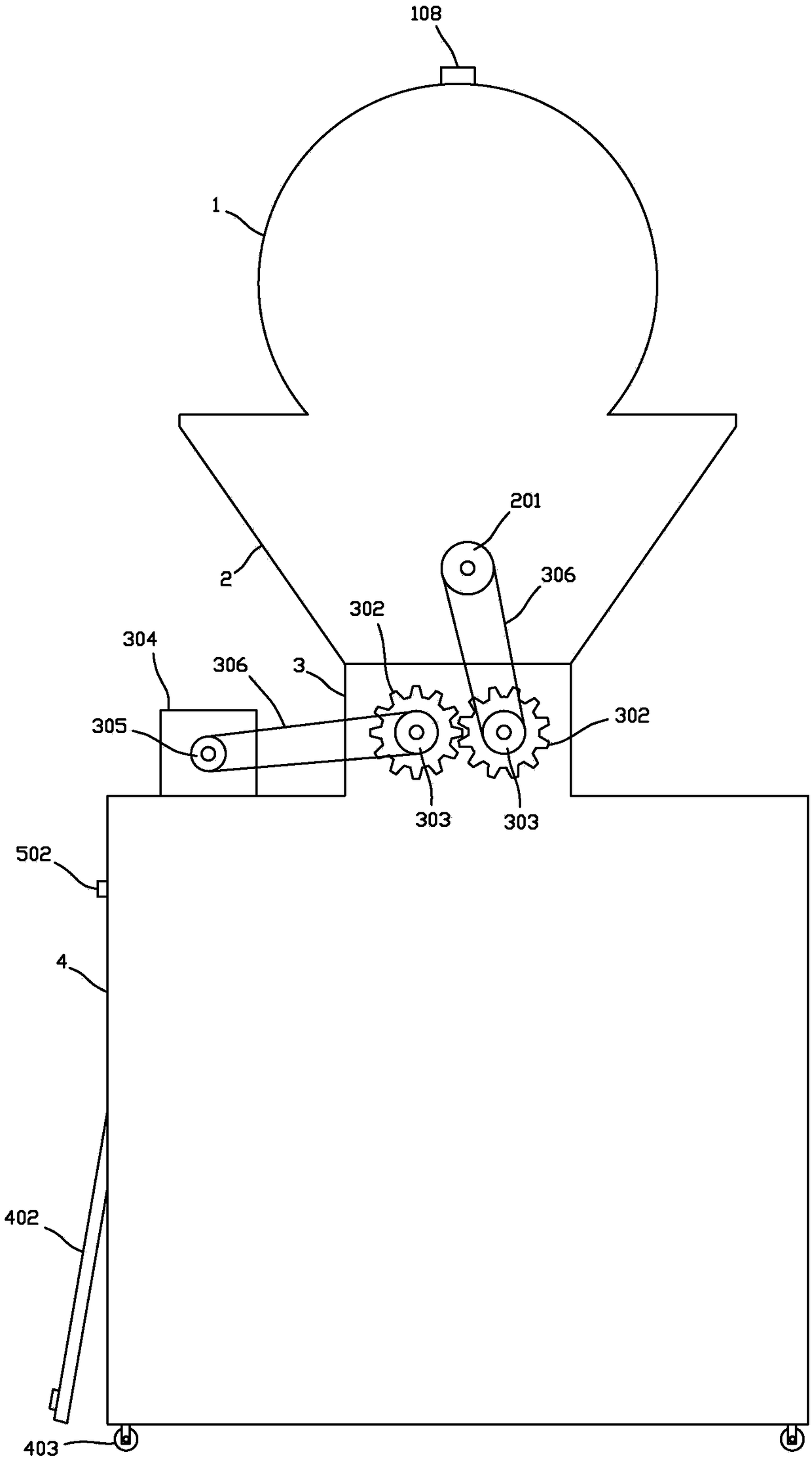

Waste garbage gear type rapid shredding device for 3D printing

The invention relates to a waste garbage shredding device, in particular to a waste garbage gear type rapid shredding device for 3D printing. The waste garbage gear type rapid shredding device for 3D printing achieves the technical purposes of being uniform in shredding, high in shredding speed and small in workload. In order to achieve the technical purpose, the waste garbage gear type rapid shredding device for 3D printing comprises a first guide sleeve, a first guide rod, a shredding frame, a first motor, a rotating rod, a shredding tool, a fixing block, a lifting block, a first gear, a second gear, a second motor and the like; a left frame, the first guide sleeve, a connecting rod, a second guide sleeve and a right frame are sequentially arranged on the top of a base plate from left to right, and the first guide rod is arranged inside the first guide sleeve. The waste garbage gear type rapid shredding device for 3D printing solves the problems of being not uniform in shredding, low in shredding speed and large in workload, and the waste garbage gear type rapid shredding device for 3D printing has the good shredding effect, improves the working efficiency and is high in safety.

Owner:山东金田生物科技有限公司

Novel combined harvester shredding device

The invention relates to the field of harvesters, in particular to a novel combined harvester shredding device. The novel combined harvester shredding device comprises a weed smashing rubbing plate arranged at the rear end of a top cover, rubbing teeth arranged on a tooth frame and matched with the weed smashing rubbing plate, and a weed smashing cutter assembly arranged below a material outlet. The weed smashing cutter assembly comprises a discharging frame arranged at the rear end of the rack, a frame cover arranged on the discharging frame, a discharging cavity located below the frame cover, a discharging cylinder arranged on the discharging frame and located in the discharging cavity, fixed cutters and movable cutters, wherein the fixed cutters are arranged on the discharging frame, and the movable cutters are arranged on the discharging cylinder. The material outlet is communicated with the discharging cavity, and a discharging port is formed in the bottom of the discharging frame. Through movement inertia of a threshing cylinder, straw or weeds to be discharged out are shredded through the rubbing force of the teeth and the rubbing plate for the first time and then separated. The straw or the weeds fall to be conveyed to the weed smashing cutter assembly to be shredded at last through the shredding action of the movable cutters and the fixed cutters, and then the straw or the weeds are discharged through the discharging port. The novel combined harvester shredding device is simple in structure, low in cost, convenient to install, good in shredding effect, low in weed winding rate and high in shredding efficiency.

Owner:曾联

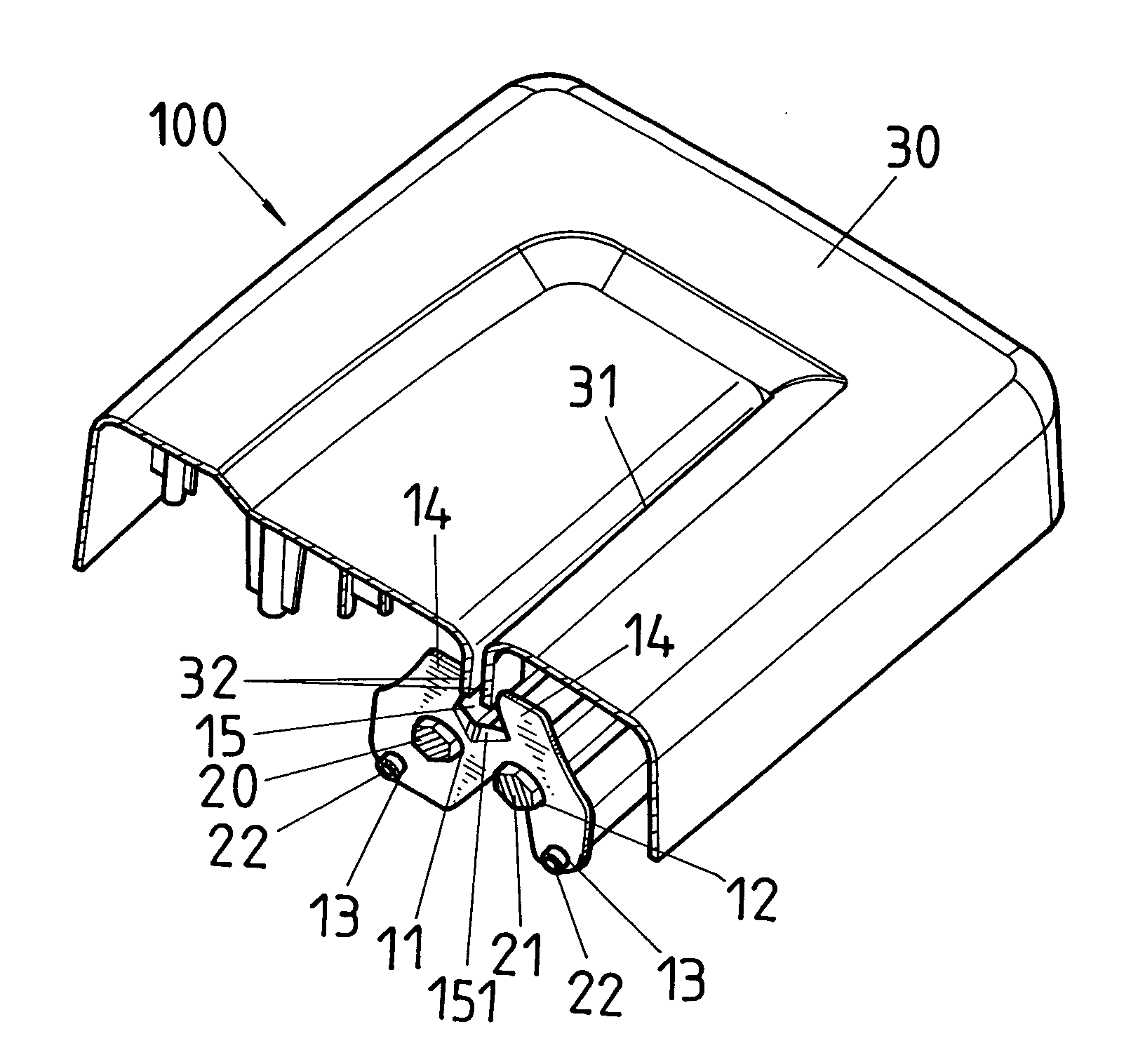

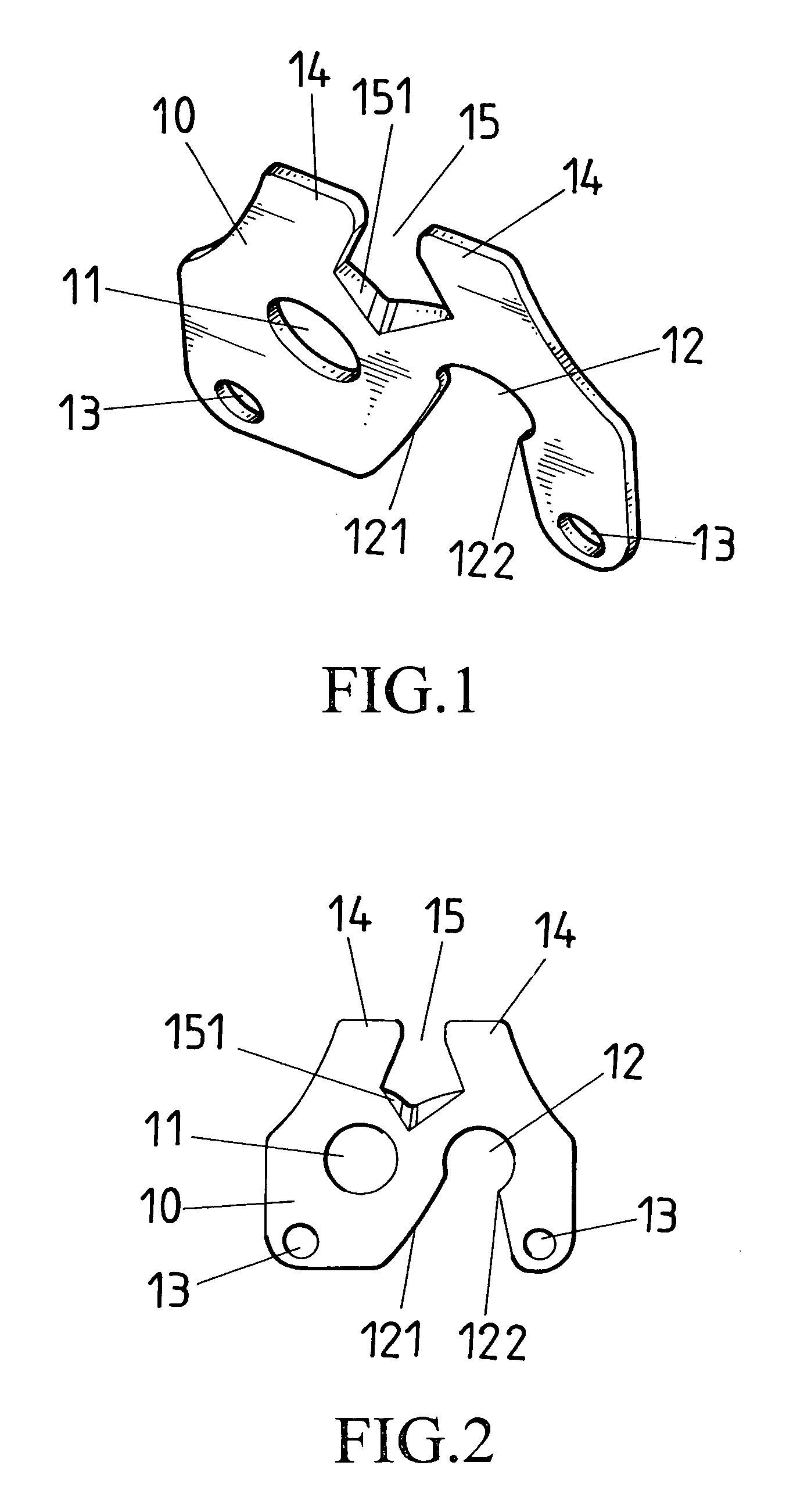

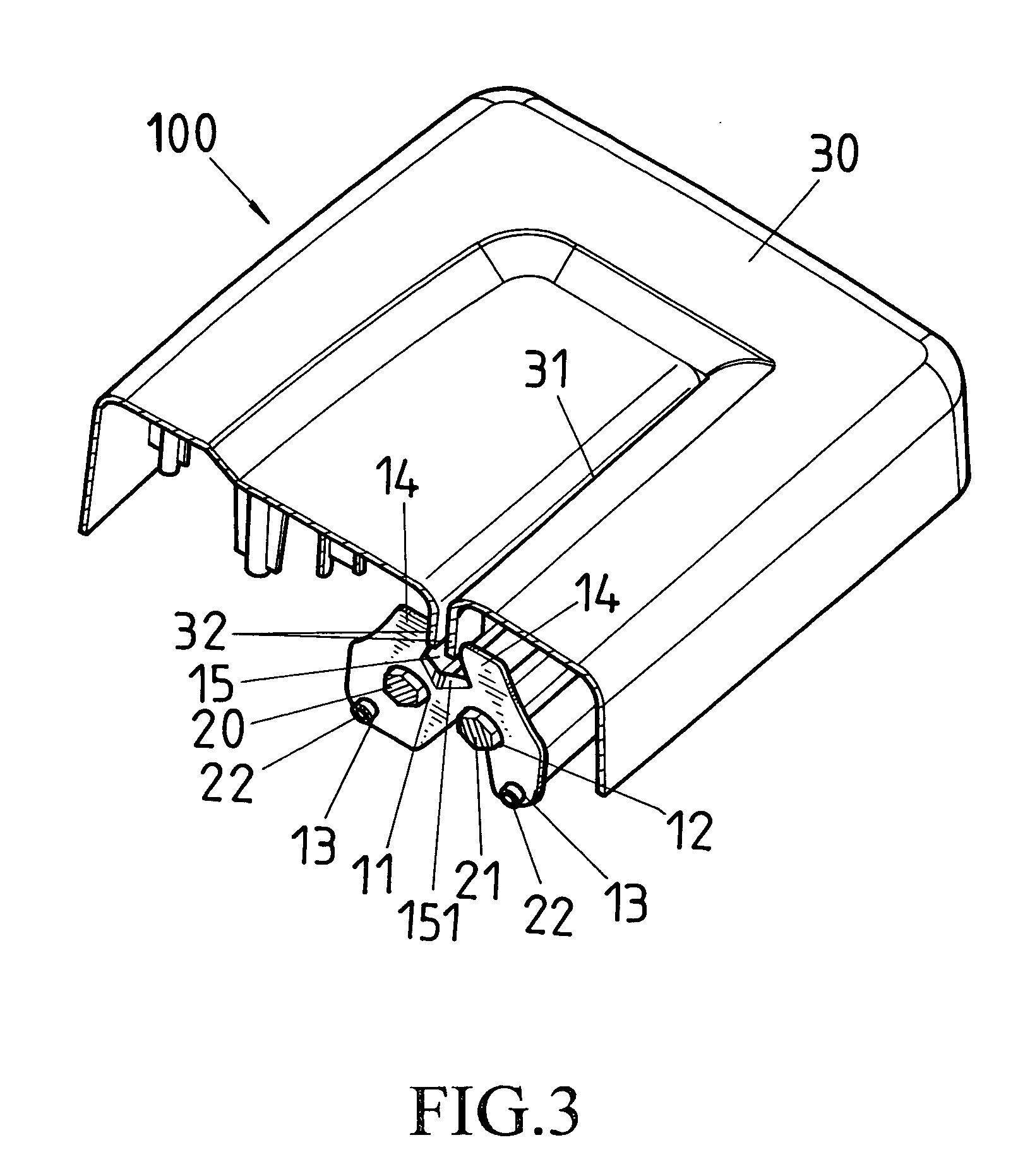

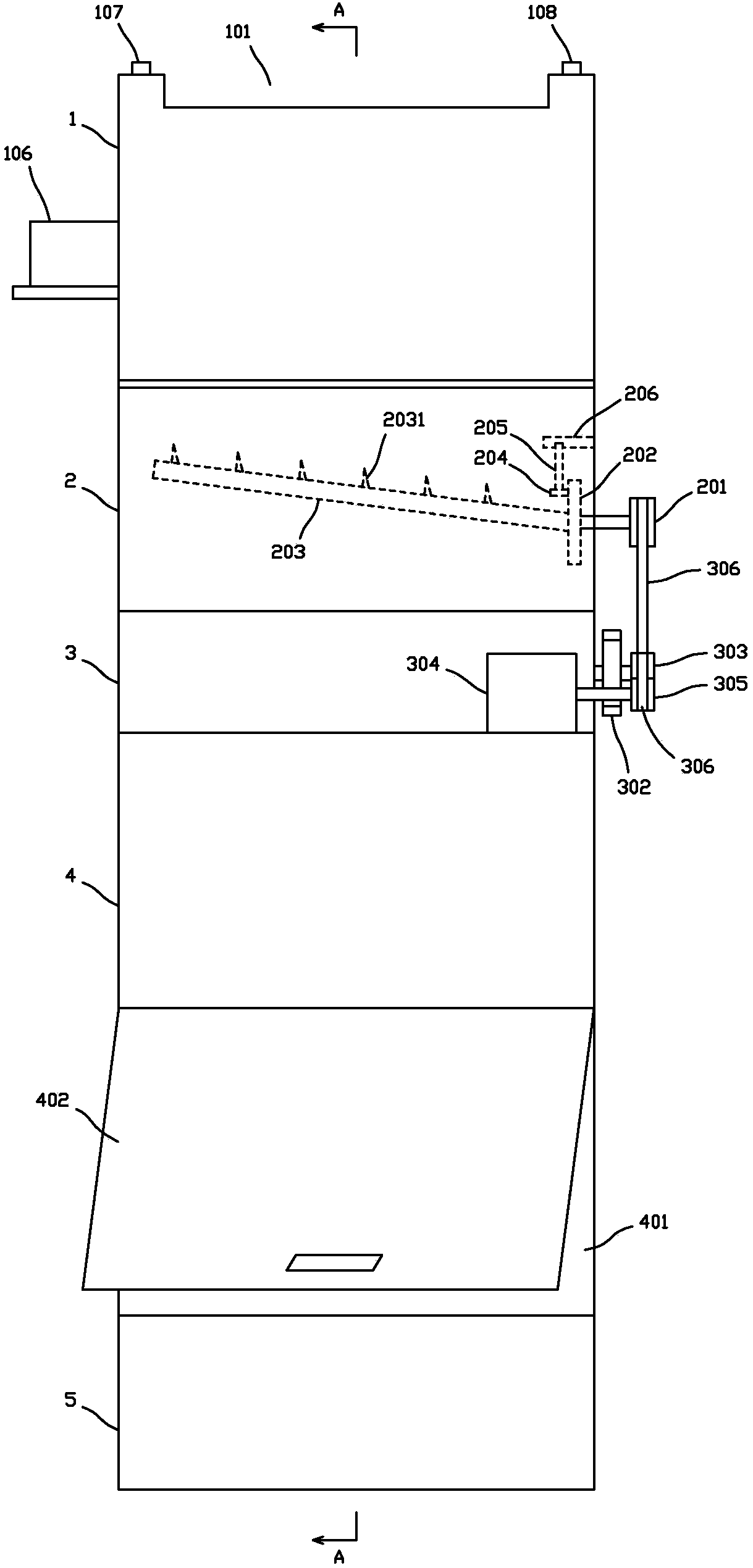

Guide-cutting plate of a cutting wheel for a paper shredder

InactiveUS7753301B1Improve chopping effectOperational securityCocoaGrain treatmentsEngineeringRabbet

A guide-cutting sheet of a cutting wheel for a paper shredder is characterized in that two sides of a centerline of a planar linear guide-cutting sheet are opened respectively with blade shaft transfix holes corresponding to a spacing between the blade shafts of two parallel cylindrical rotary cutting wheels; below or above two blade shaft transfix holes are opened respectively with fixing rod transfix holes, corresponding to a spacing between two fixing rods; the centerline part above two blade shaft transfix holes is opened with a rabbet which can be latched at two aperture walls of a strip-shape aperture on a face cover; and a bottom of the rabbet is provided with a concaved knife-edge which can cut off paper sheets.

Owner:LO EMILY

Medical waste treatment device

The invention discloses a medical waste treatment device. A rotating component is arranged in a first barrel of the medical waste treatment device. When the rotating component rotates, medical waste in a first barrel can be guided into a second barrel. A rotatable straight rod is arranged in the second barrel and can scatter the medical waste which is stacked together when falling down. Then the medical waste falls into a third barrel. The medical waste can be cut by cutting blades when a rotating roller in the third barrel rotates. When the medical waste is cut, the rotating component can isolate the second barrel from the outside atmosphere, so that odor and bacteria generated when the medical waste is cut are prevented from spreading out. According to the medical waste treatment device,when the medical waste is chopped, odor of the medical waste is prevented from being diffused out, bacteria on the medical waste are prevented from spreading out, and the medical waste can be prevented from being stacked together when thrown into the medical waste treatment device.

Owner:俞海娟

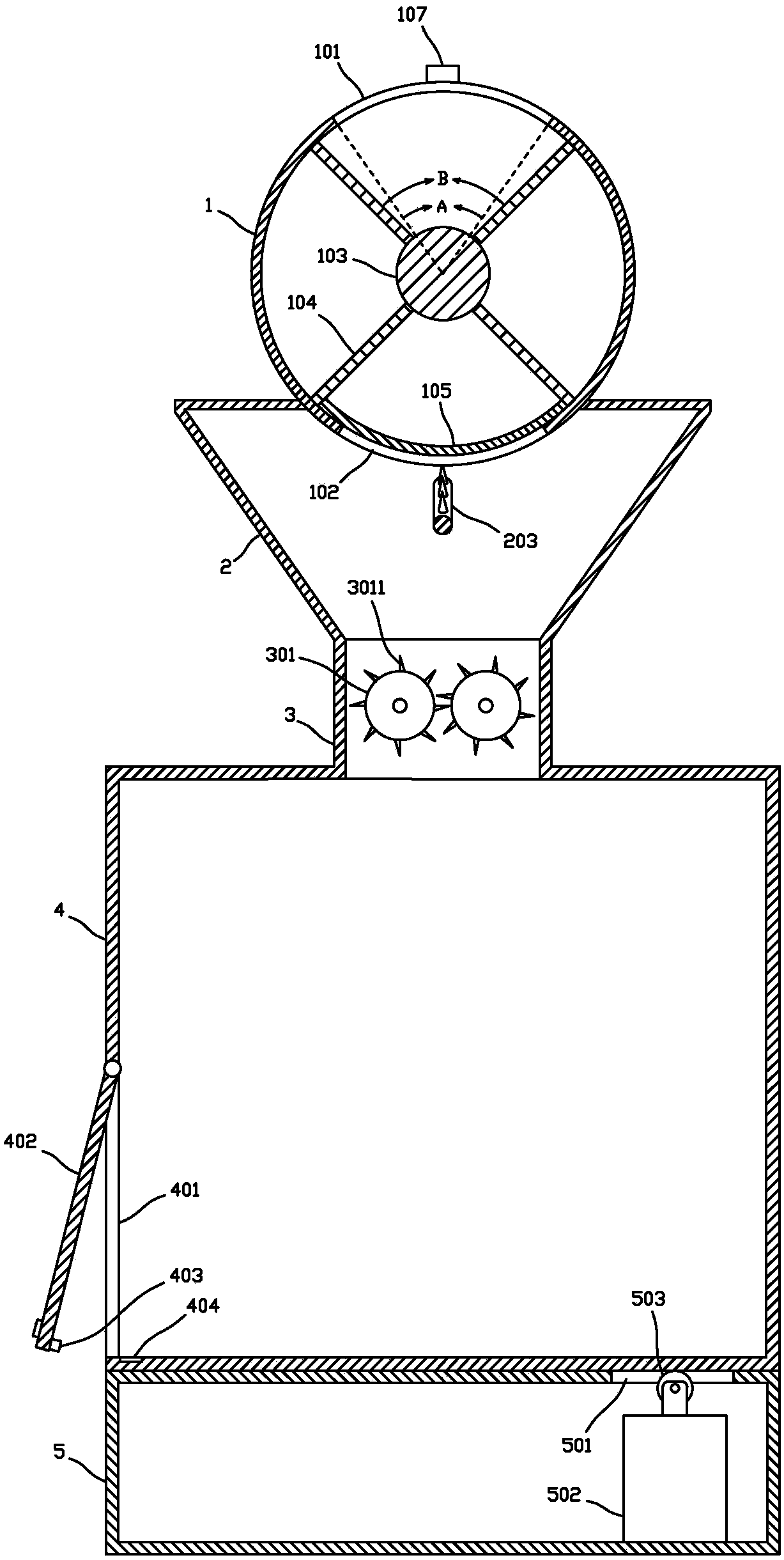

Drug crushing and preparation device of pharmacy department

InactiveCN106944188AGuaranteed storage timeRefinement diameterCocoaGrain treatmentsParticulatesPharmacy

The invention discloses a drug crushing and preparation device of a pharmacy department. The drug crushing and preparation device comprises a cutting room and a crushing room; drugs can be cut up by a first cutting roller and a second cutting roller effectively, and the diameters of cut particulate matters are thinned so that the cutting effect is better; both sides of the inner wall of the cutting room are provided with brushes which can be used for preventing the cut particulate matters from sticking to a cutting mechanism, and the working efficiency of the cutting mechanism is improved; the heads of the brushes are located on the bottom surfaces of the first cutting roller and the second cutting roller, and the cut particulate matters can be further dried in a drying room so as to ensure the preservation time of the drugs; the crushing room is internally provided with a millstone which is a double-layer impact mill, and the center seam of the millstone is provided with a groove; the outside diameter of the millstone is smaller than the inside diameter of a foundation ring of the crushing room, and the drugs can be crushed by the millstone; and different application requirements are met, and the universality of the device is further improved. A first motor, a second motor, the drying room, a grading room and a driving motor are all connected to a control switch electrically.

Owner:李玉贞

Polyester emulsion for glass fiber impregnating agent

The invention discloses a polyester emulsion for a glass fiber impregnating agent and relates to the technical field of glass fiber production. The polyester emulsion comprises the following components in percentage by weight: 30-45% of m-phthalic acid, 3.0-6.0% of phthalic anhydride, 8-15% of fumaric acid, 10-20% of polyethylene glycol, 15-25% of neopentyl glycol, 25-35% of propylene glycol and 1.0-3.5% of hydroquinone. The polyester emulsion for the impregnating agent in the percentage by weight is stable in performance and long in service life. By adopting the polyester emulsion in the production process of glass fibers, the mechanical property, choppability, bundling property and impregnating rate of the glass fibers are greatly improved. Materials for preparation are wide in source and low in cost and the whole synthetic process is good in stability and high in efficiency.

Owner:ANHUI DANFENG ELECTRONICS MATERIAL

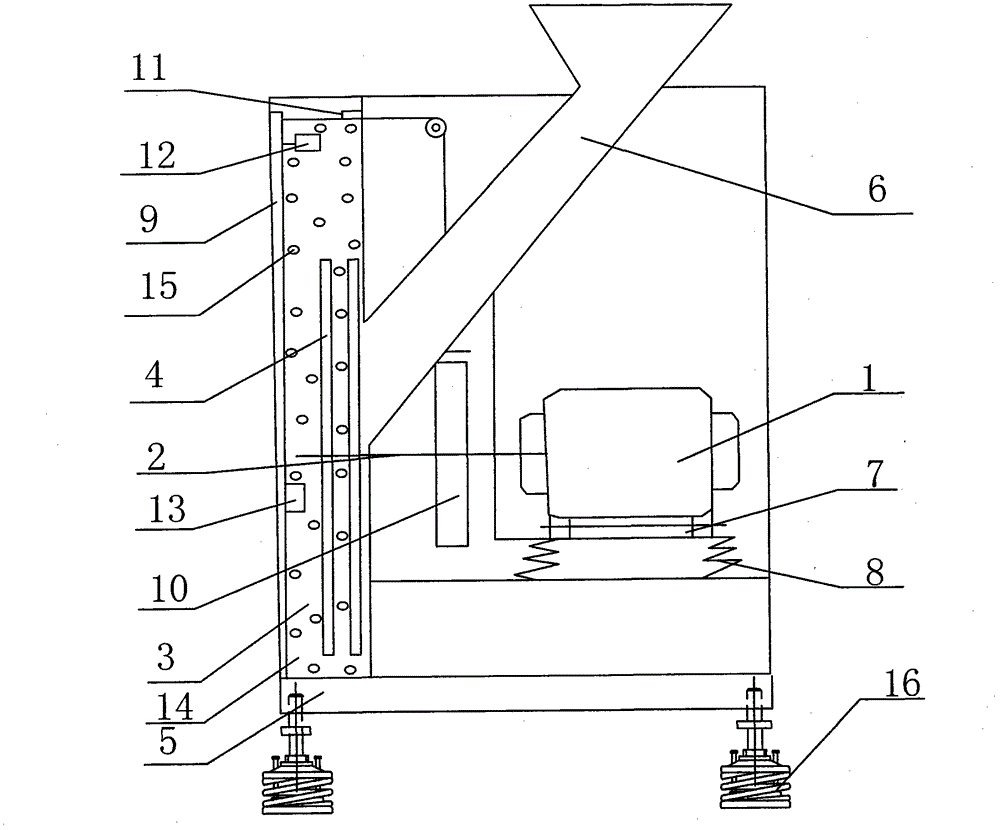

Vibration type feed cutter

InactiveCN102793258AChopped fullyImprove work efficiencyFeeding-stuffVibration attenuationElectric machinery

The invention discloses a vibration type feed cutter which comprises a motor, a motor shaft, a cutting chamber, a blade fixed at the front end of the motor shaft, a safe case and a motor seat which is hinged in the case and connected with a discharger, wherein a supporting spring is arranged below the motor seat; a case door is arranged on the safe case; a brake is arranged on the motor shaft; a controller for the brake is arranged on the case door of the safe case; and a circuit breaker is arranged on the case door. The vibration type feed cutter is characterized in that a temperature inductor is arranged on the side wall of the cutting chamber and electrically connected with the circuit breaker; the circuit breaker is linked with the opening and closing of the case door; a screening plate is arranged below the blade; screening holes are uniformly formed in the screening plate; and a vibration attenuation device is arranged below the safe case. The vibration type feed cutter has the advantages of rational structure, high safety and good cutting effect.

Owner:韩健

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com