One-step preparation method and application of propargyl alcohol ethoxylate

A technology of ethoxylate and propynyl alcohol, which is applied in the field of nickel plating brightener, can solve the problems that cannot be solved well, and achieve the effect of overcoming the deep color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

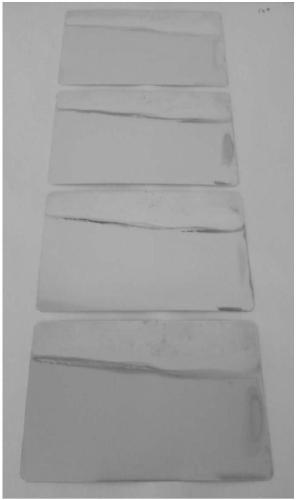

Image

Examples

Embodiment 1

[0034] Add 5mol of propynyl alcohol and 5g of tetramethylammonium hydroxide into a 1L stirred autoclave, and check the airtightness of the reactor. Carry out nitrogen replacement and vacuuming operations to ensure that the vacuuming time is greater than 30 minutes. The number of high-purity nitrogen replacement operations is 5 times, and the pressure is exhausted to 0-30KPa. Then, ethylene oxide is introduced into the reaction kettle, and the reaction temperature is controlled at 85 ° C ± 3°C and the reaction pressure is 0.3MPa~0.5MPa, until the total amount of ethylene oxide fed is 10mol, stop feeding ethylene oxide, and carry out post-treatment aging on the product to maintain the temperature of the reactor at 85°C±3°C, Until the pressure of the reactor no longer drops, it indicates that the aging reaction is completed. Decrease to 60°C and neutralize with glacial acetic acid.

[0035] The prepared propynyl alcohol ethoxylate was used as a brightener for nickel plating, and...

Embodiment 2

[0037]Add 5mol of propynyl alcohol and 5g of tetramethylammonium hydroxide and tetraethylammonium hydroxide mixture (mixture mass ratio is 1:3) in the autoclave with stirring of 1L, the airtightness inspection is carried out to reaction kettle, wait for After there is no pressure drop in the reactor within 1 hour, carry out nitrogen replacement and vacuuming operations at 50°C to ensure that the vacuuming time is greater than 30 minutes, and the number of high-purity nitrogen replacement operations is 5 times, and the pressure is discharged to 0-30KPa, and then to Feed ethylene oxide into the reaction kettle, control the reaction temperature at 85°C±3°C and the reaction pressure at 0.3MPa~0.5MPa, stop feeding ethylene oxide until the total amount of ethylene oxide fed is 10mol, Perform post-treatment aging on the product and maintain the temperature of the reactor at 85°C±3°C until the pressure of the reactor no longer drops, indicating that the aging reaction is completed. Lo...

Embodiment 3

[0040] Add 5mol of propynyl alcohol and 5g of tetraethylammonium hydroxide into a 1L stirred autoclave, and check the airtightness of the reactor. Carry out nitrogen replacement and vacuuming operations to ensure that the vacuuming time is greater than 30 minutes. The number of high-purity nitrogen replacement operations is 5 times, and the pressure is exhausted to 0-30KPa. Then, ethylene oxide is introduced into the reaction kettle, and the reaction temperature is controlled at 85 ° C ± 3°C and the reaction pressure is 0.3MPa~0.5MPa, until the total amount of ethylene oxide fed is 10mol, stop feeding ethylene oxide, and carry out post-treatment aging on the product to maintain the temperature of the reactor at 85°C±3°C, Until the pressure of the reactor no longer drops, it indicates that the aging reaction is completed. Lower to 60°C, neutralize with glacial acetic acid and remove from low boil.

[0041] The prepared propynyl alcohol ethoxylate was used as a brightener for n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com