Process for producing white pyruric acid

A cyanuric acid and white technology, applied in the field of preparation of white cyanuric acid, can solve the problems of deep color and limit the application of liquid-phase products, and achieve the effect of improving product yield

Active Publication Date: 2010-09-08

河北冀衡化学股份有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But at the same time, due to the common problem of deep color in the current liquid-phase method products, the industrial application of liquid-phase method products is greatly limited.

For this reason, there are few liquid-phase cyanuric acid industrialization devices in production at home and abroad.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

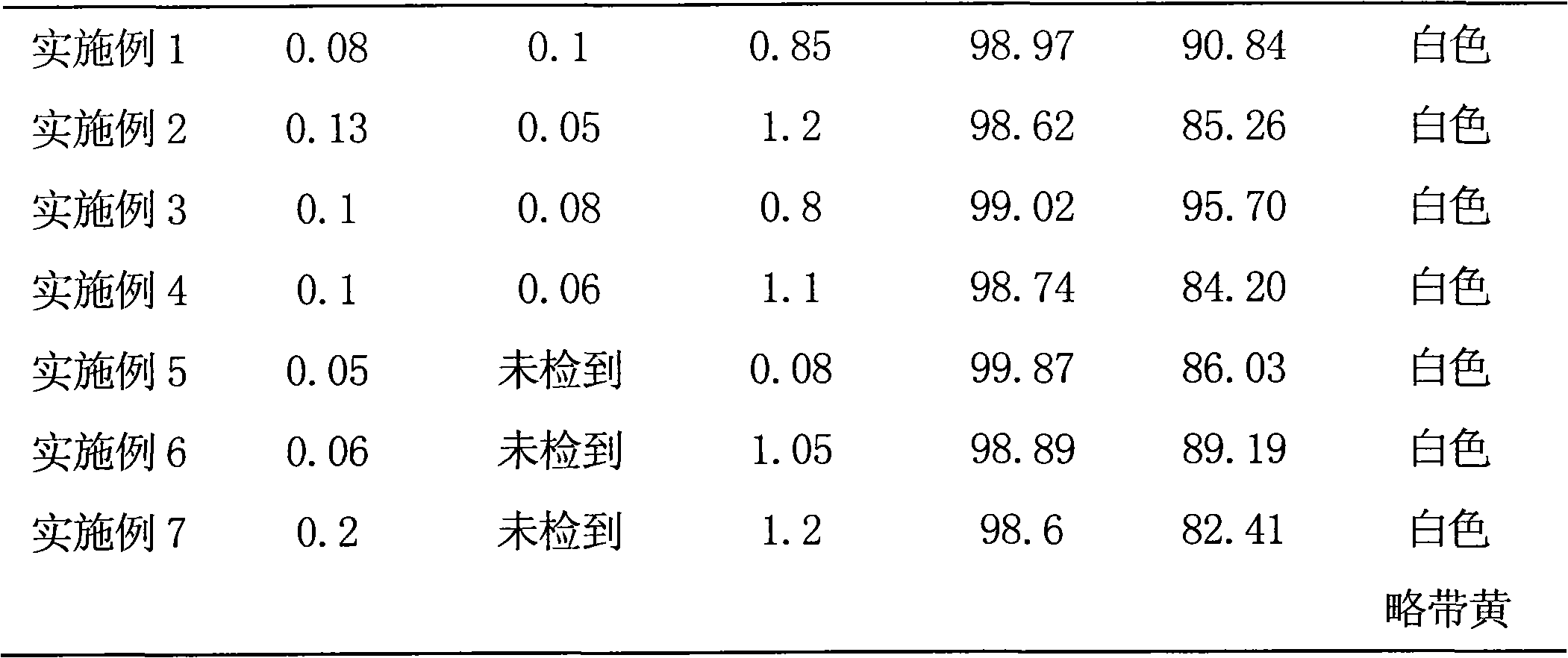

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

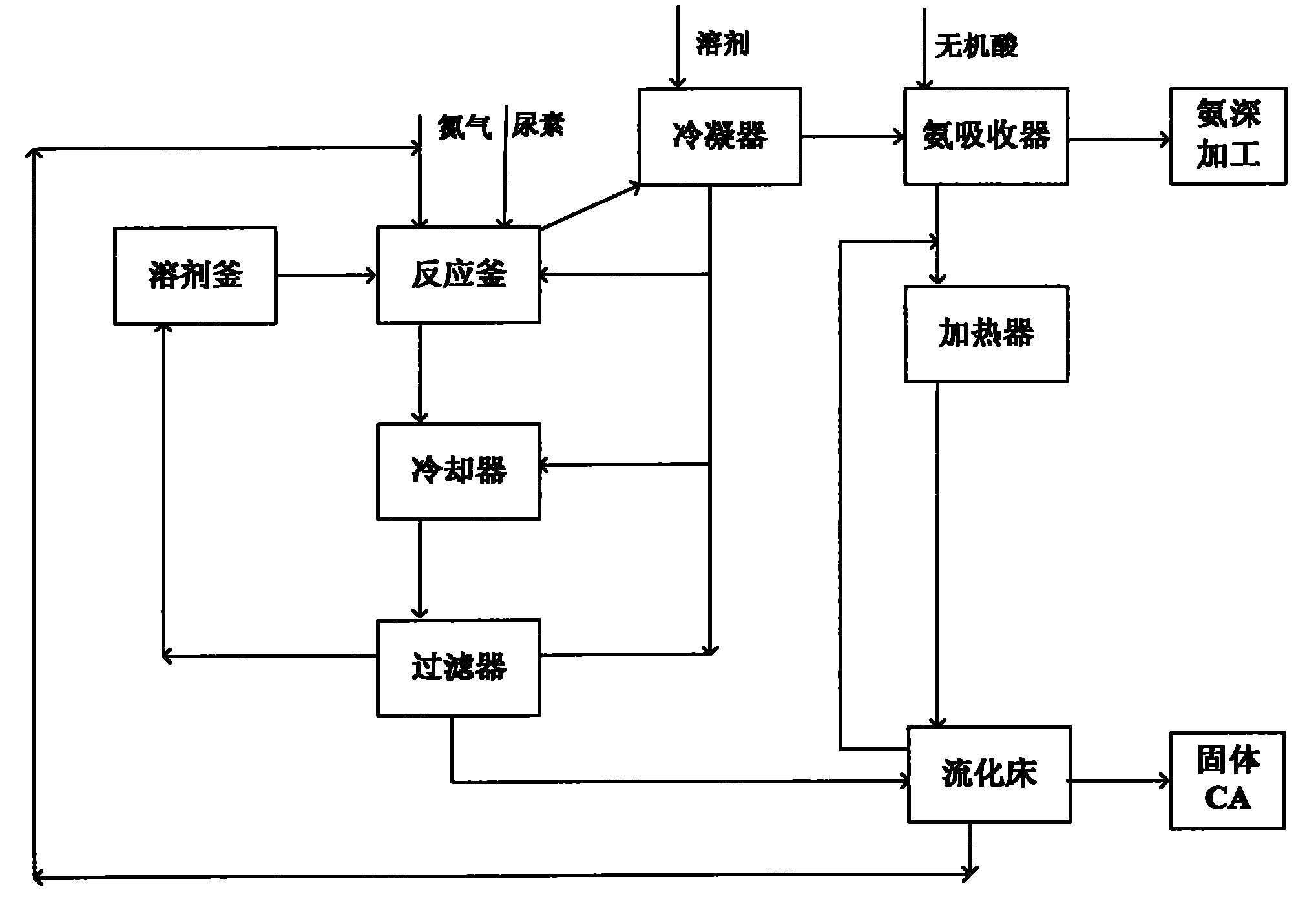

The invention discloses a method for preparing white cyanuric acid, which comprises the following steps: (1) under stirring, adding molten urea into organic solvent, and introducing inert gas into the organic solvent at the same time to obtain hot pulp stock after condensation reaction of the molten urea, the organic solvent and the inert gas; (2) under stirring condition, adding cooling fluid into the hot pulp stock to obtain cold pulp stock after the mixture is cooled; (3) carrying out solid-liquid separation on the cold pulp stock to obtain filter cakes; and (4) drying the filter cakes under the conditions of certain temperature and flowing inert gas to obtain crystals of the white cyanuric acid. The method has the advantages that the method does not need acid cleaning and refining, isenergy-saving and environment-friendly, obtains the product of the white cyanuric acid, avoids the process of water washing, and improves yield of the product greatly.

Description

technical field The invention relates to a preparation method of white cyanuric acid. Background technique Cyanuric acid (CA) is an important fine chemical intermediate synthesized from urea, and is one of the downstream products of urea that is encouraged to be developed by the state. The production of cyanuric acid mainly has two processes: solid-phase method and liquid-phase method. The crude CA content obtained by the solid-phase method is only about 75%, and it needs to be boiled with inorganic acid to reach the level of 98.5% of superior products. High consumption, long time-consuming, serious environmental pollution and other shortcomings. There are many reports on the production process of the liquid phase method, most of which are concentrated in the laboratory stage. The current research results show that the liquid phase method can obtain products with a purity greater than 96%, does not require hydrolysis and refining, and has low energy consumption. But at the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07D251/32

Inventor 赵庭栋孟烨李茂桉闫晓红

Owner 河北冀衡化学股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com