Preparation method of glycolide

A glycolide and ethanol technology, applied in the field of materials, can solve problems such as poor appearance and color, increased production energy consumption, environmental and human hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

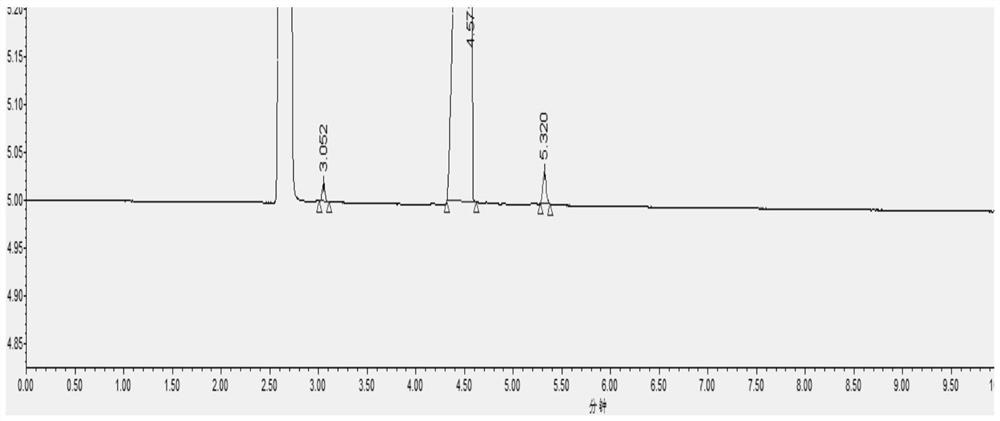

Image

Examples

Embodiment 1

[0029] 1.1 760g 100% glycolic acid, 1000g polyethylene (BASF, Luwax A) and 2g catalyst stannous benzoate were successively added to the 3L round-bottomed flask, and the temperature was raised to 160° C. Under agitation, vacuumize to carry out polycondensation reaction, P= 3000Pa, after 4h, the vacuum degree was increased to P=700Pa, and the polycondensation reaction was continued for 12 hours to obtain 570g of oligoglycolic acid.

[0030] The oligoglycolic acid obtained by the present invention is analyzed by gel permeation chromatography according to the above method, and the number-average molecular weight of the polyglycolic acid is measured to be 3100 g / mol.

[0031] 1.2 The oligoglycolic acid in Example 1.1 is heated to 220°C, when the oligoglycolic acid is completely dissolved in polyethylene, it is added dropwise to a temperature of 220°C and contains 1500g polyethylene and 10g cracking catalyst trioxide The depolymerization was carried out in a 5L round-bottomed flask ...

Embodiment 2

[0037] 2.1 900g 100% methyl glycolate, 1500g polyethylene (BASF, Luwax AH3) and 3g catalyst stannous chloride are added successively in the 3L round-bottomed flask, be warming up to 150 ℃, vacuumize under stirring and carry out polycondensation reaction, P=3000Pa, after 4 hours, the vacuum degree was increased to P=700Pa, and the polycondensation was continued for 15 hours to obtain 562 g of oligoglycolic acid.

[0038] The oligoglycolic acid obtained by the present invention is analyzed by gel permeation chromatography according to the above method, and the number-average molecular weight of the polyglycolic acid is measured to be 2600 g / mol.

[0039] 2.2 The oligoglycolic acid in Example 2.1 is heated to 220°C, when the oligoglycolic acid is completely dissolved in polyethylene, it is added dropwise to a temperature of 230°C and contains 1000g polyethylene and 5g cracking catalyst trioxide The depolymerization was carried out in a 5L round-bottomed flask of antimony, and the...

Embodiment 3

[0043] 3.1 1040g 100% ethyl glycolate, 1500g polyethylene (BASF, Luwax AH6) and 4g catalyst stannous octoate were successively added to the 3L round-bottomed flask, and the temperature was raised to 170° C. Under stirring conditions, vacuumize to carry out polycondensation reaction, P =3000Pa, after 3h, the vacuum degree was increased to P=700Pa, and the polycondensation was continued for 10 hours to obtain 565g of oligoglycolic acid.

[0044] The oligoglycolic acid obtained in the present invention is analyzed by gel permeation chromatography according to the above method, and the number-average molecular weight of the polyglycolic acid is measured to be 3500 g / mol.

[0045] 3.2 The oligoglycolic acid in Example 3.1 is heated to 220°C, and when the oligoglycolic acid is completely dissolved in polyethylene, it is added dropwise to a temperature of 240°C and contains 500 g of polyethylene and 5 g of cracking catalyst zinc oxide The depolymerization was carried out in a 5L roun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com