Perovskite light emitting diode with compounds containing CH2CH2O and method for preparing perovskite light emitting diode

An ethoxylate, light-emitting diode technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of large leakage current, poor quality of perovskite films, low efficiency of light-emitting diodes, etc. The effect of improving device efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

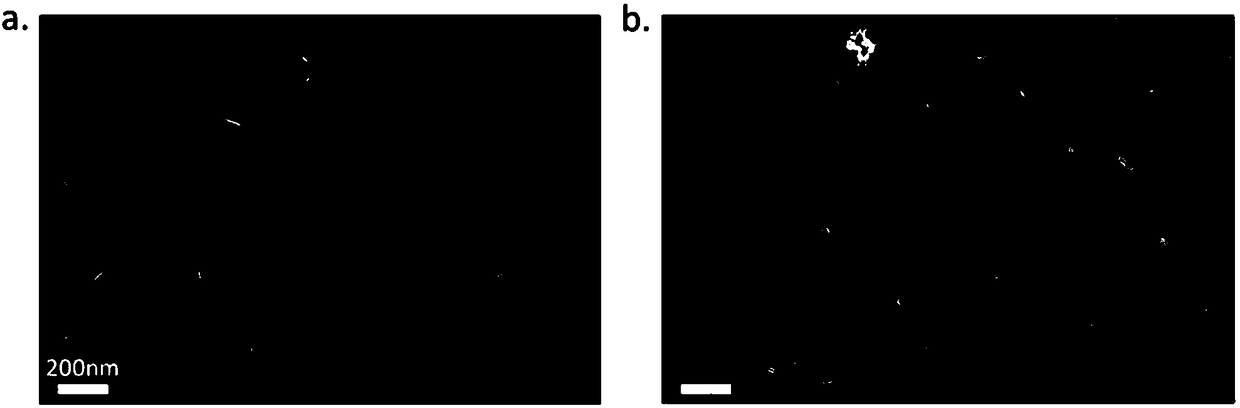

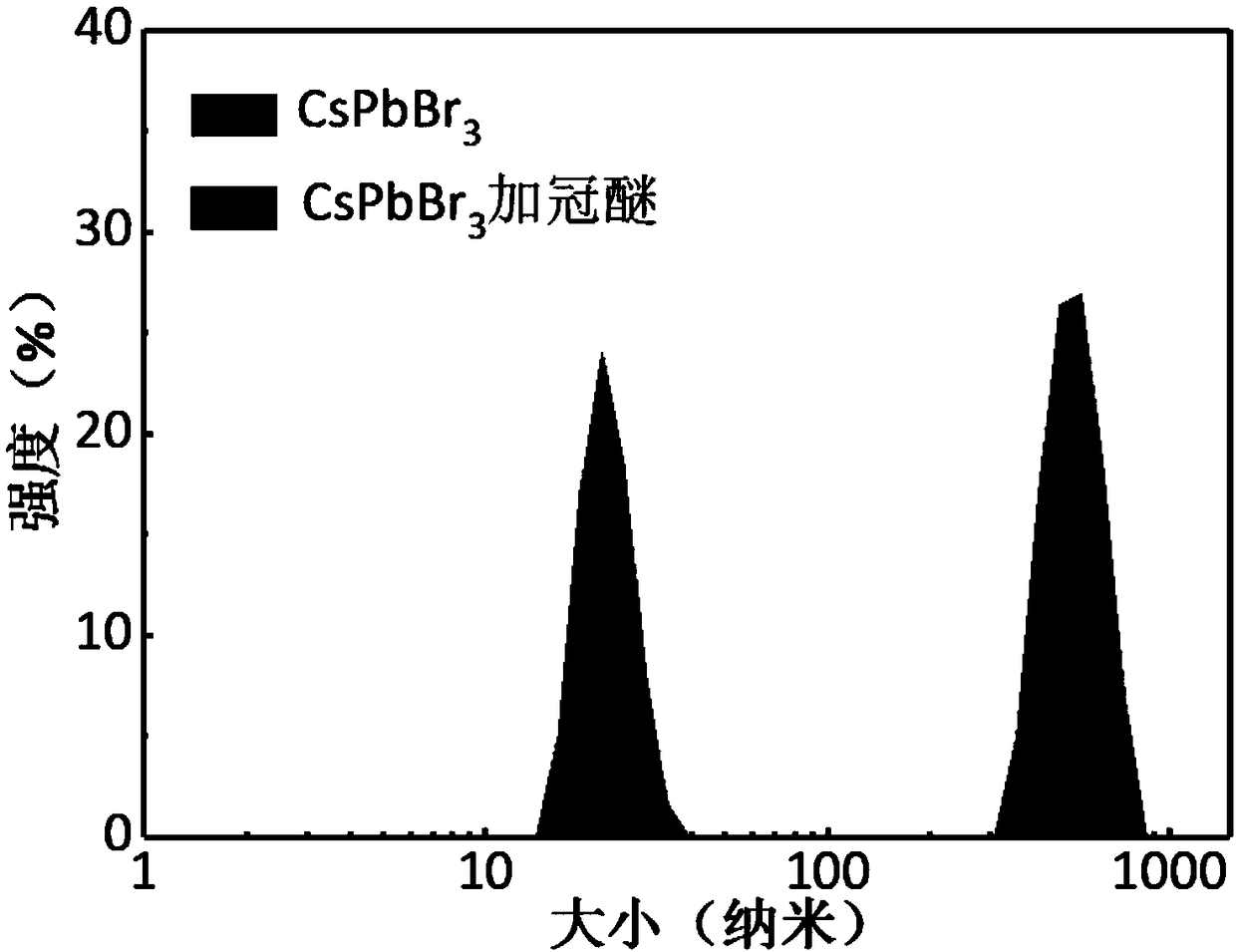

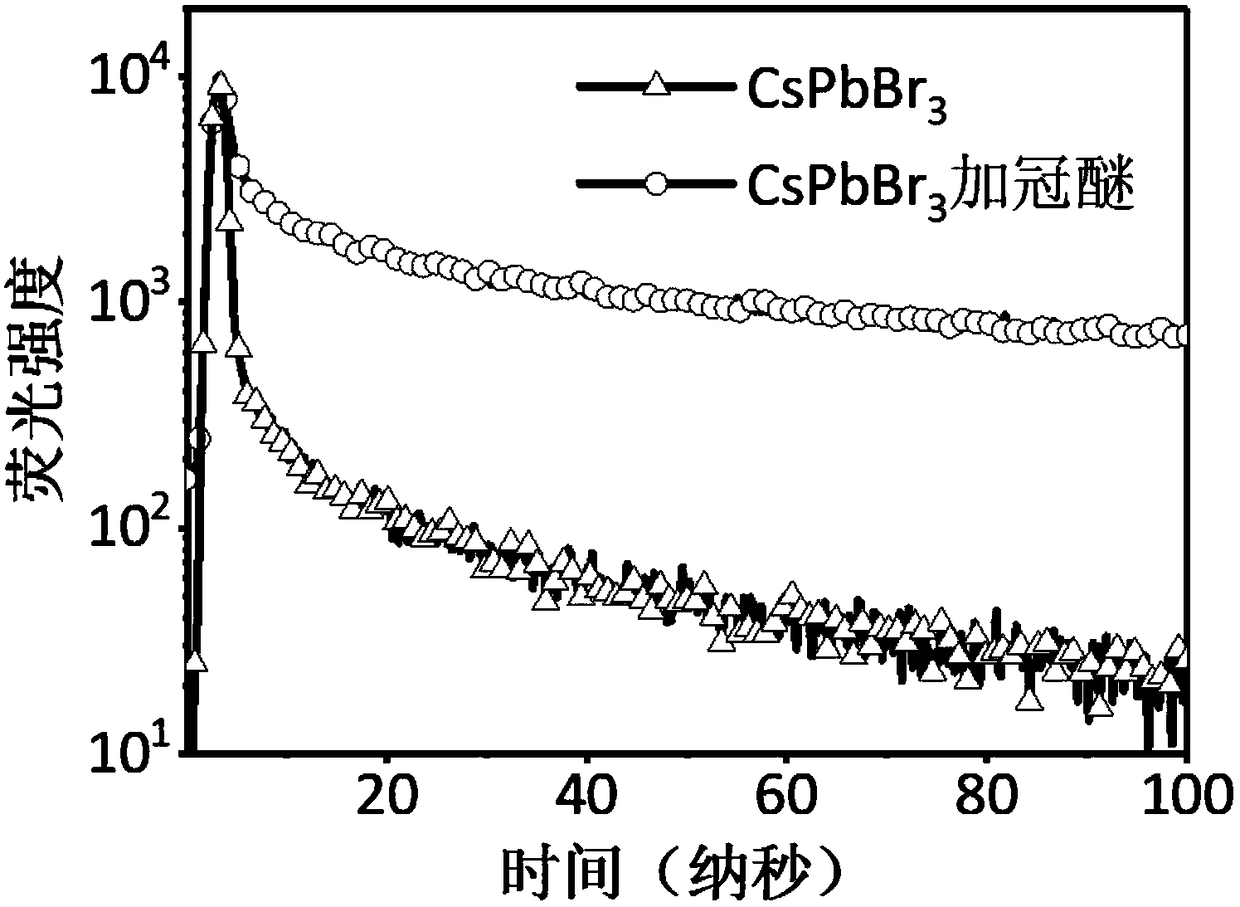

[0059] This embodiment provides a method for preparing a perovskite film as an active light-emitting layer in a perovskite light-emitting diode, comprising the following steps:

[0060] Use dimethyl sulfoxide (DMSO) as solvent to configure CsPbBr 3 Perovskite precursor solution. Wherein the molar ratio of cesium bromide and lead bromide in the precursor solution is 1:1. In the solution, the concentrations of cesium bromide and lead bromide are both 0.2mol / L. The precursor solution contained 6 mg / mL of 18-crown-6. The precursor solution prepared above was heated and stirred at 80° C. for 2 hours, and then used. Put the configured precursor solution into a cuvette, and conduct a dynamic laser light scattering experiment to obtain particle size distribution data. The prepared precursor solution was spin-coated on a quartz glass sheet at a rotation speed of 3000 rpm, the spin-coating time was 60 seconds, and annealed at 100° C. for 1 minute to obtain a perovskite film.

[006...

Embodiment 2

[0066] see Figure 4 , the present embodiment provides a three-dimensional perovskite light-emitting diode, including an anode substrate 1, a hole transport layer 2, an active light-emitting layer 3, an electron transport layer 4 (40nm), and a cathode modification layer arranged in sequence from bottom to top. 5 (1 nm) and cathode 6 (80-100 nm). Its preparation method comprises the following steps:

[0067] Use dimethyl sulfoxide (DMSO) as solvent to configure CsPbBr 3 Perovskite precursor solution. Wherein the molar ratio of cesium bromide and lead bromide in the precursor solution is 1:1. In the solution, the concentrations of cesium bromide and lead bromide are both 0.2mol / L. The precursor solution contained 6 mg / mL of 18-crown-6. The precursor solution prepared above was heated and stirred at 80° C. for 2 hours, and then used.

[0068] The ITO transparent anode substrate 1 was ultrasonically cleaned with acetone, ethanol, and deionized water for 20 minutes in sequenc...

Embodiment 3

[0078] This embodiment provides a two-dimensional perovskite light-emitting diode, including an anode substrate 1, a hole transport layer 2 (50nm), an active light-emitting layer 3 (40nm), and an electron transport layer 4 ( 30nm), cathode modification layer 5 (1nm) and cathode 6 (80-100nm). Its preparation method comprises the following steps:

[0079] Use dimethyl sulfoxide (DMSO) as solvent to configure CsPbBr 3 Perovskite precursor solution. Wherein the molar ratio of cesium bromide and lead bromide in the precursor solution is 1:1. In the solution, the concentrations of cesium bromide and lead bromide are both 0.2mol / L. The concentration of phenylethylamine is 0.08mol / L. The precursor solution contained 6 mg / mL of 18-crown-6. The precursor solution prepared above was heated and stirred at 80° C. for 2 hours, and then used.

[0080] The ITO transparent anode substrate 1 was ultrasonically cleaned with acetone, ethanol, and deionized water for 20 minutes in sequence, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com