Hydrolytic water reducing agent and preparation method thereof

A water reducing agent and catalyst technology, applied in the field of hydrolyzable water reducing agent and its preparation, can solve the problems of affecting the dispersion of cementitious materials, restricting the adjustment of precast concrete setting time, and limited intermolecular steric hindrance, etc. Storage and transport, the effect of prolonging the setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a preparation method of a hydrolyzed water reducer, including the following steps:

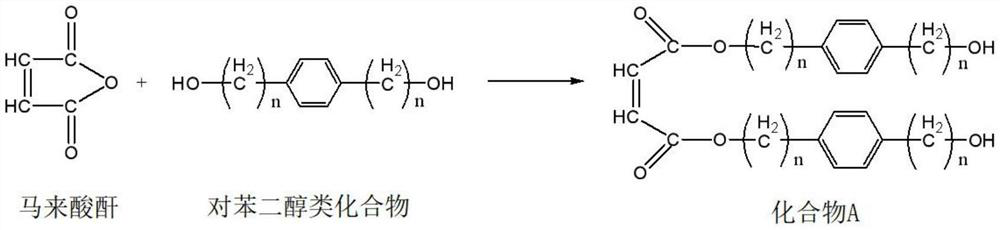

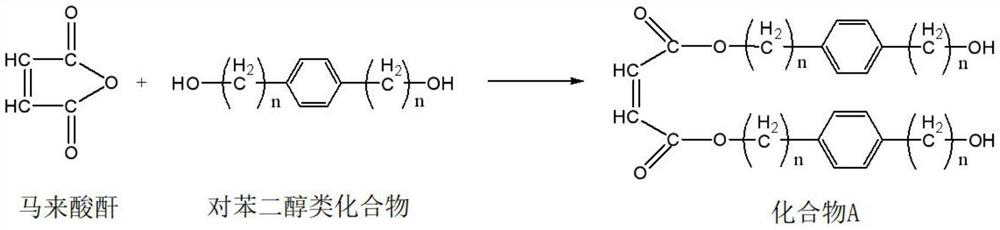

[0028] Step 1: Add 1100 g of maleic anhydride and 1400 g of terephthalic acid to the reaction vessel, add 20 g of toluenesulfonic acid, and the reaction temperature is 105° C.; the reaction time is 4 hours. By performing an esterification reaction, compound A containing a phenyl group linked through an ester functional group is synthesized.

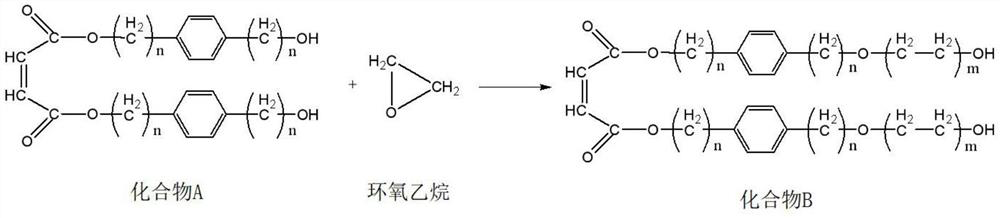

[0029] Step 2: 3500 g of compound A synthesized in step 1 was subjected to anionic polymerization reaction under basic conditions with 26.4 kg of ethylene oxide, the reaction temperature was 125° C., and the reaction time was 6 hours. The synthesized product is ethoxylate compound B.

[0030] Step 3: Add 3000 g of the ethoxy compound B synthesized in Step 2 and 350 g of acrylic acid to the reaction device for bulk polymerization. Add 50 g of azobisisobutylcyanide. The reaction time is 4.5 hours and the reaction temperature...

Embodiment 2

[0033] This embodiment provides a preparation method of a hydrolyzed water reducer, including the following steps:

[0034] Step 1: Add 1200g of maleic anhydride and 1400g of p-phenylene dipropanol into the reaction vessel, add 25g of toluenesulfonic acid, the reaction temperature is 110°C; the reaction time is 4.5 hours. By performing an esterification reaction, compound A containing a phenyl group linked through an ester functional group is synthesized.

[0035] Step 2: 3000 g of compound A synthesized in step 1 was subjected to anionic polymerization reaction under basic conditions with 30 kg of ethylene oxide, the reaction temperature was 120° C., and the reaction time was 5 hours. The synthesized product is ethoxylate compound B.

[0036] Step 3: Add 3000g of the ethoxy compound B synthesized in Step 2 and 400g of methacrylic acid to the reaction device for bulk polymerization. Add 60g of benzoyl peroxide. The reaction time is 5 hours and the reaction temperature is 80°C...

Embodiment 3

[0039] This embodiment provides a preparation method of a hydrolyzed water reducer, including the following steps:

[0040] Step 1: Add 1000g of maleic anhydride and 1200g of p-phenylene glycol compound into the reaction vessel, add 25g of toluenesulfonic acid, the reaction temperature is 115°C; the reaction time is 3.5 hours. By performing an esterification reaction, compound A containing a phenyl group linked through an ester functional group is synthesized.

[0041] Step 2: 3000 g of compound A synthesized in step 1 was subjected to anionic polymerization reaction under basic conditions with 30 kg of ethylene oxide, the reaction temperature was 120° C., and the reaction time was 4 hours. The synthesized product is ethoxylate compound B.

[0042] Step 3: 3000g of ethoxy compound B synthesized in step 2 and 450g of maleic anhydride are added to the reaction device, added for bulk polymerization, 25g of azobisisobutyronitrile and 25g of azobisisoheptylcyanide are added, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com