Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "1-dodecanethiol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1-Dodecanethiol ≥98% Synonym: n-Dodecyl mercaptan, Dodecyl mercaptan, Lauryl mercaptan, Mercaptan C 12, NDM CAS Number 112-55-0. Linear Formula CH 3 (CH 2) 11 SH . Molecular Weight 202.40 . Beilstein Registry Number 969337 . EC Number 203-984-1. MDL number MFCD00004885. PubChem Substance ID 24870727

Preparation method of super-hydrophobic polyurethane sponge/iron oxide composite material used for oil-water separation

ActiveCN105413656AImprove oil absorption capacitySelective separationOther chemical processesLiquid separationMicro nano1-dodecanethiol

The invention discloses a preparation method of a super-hydrophobic polyurethane sponge / iron oxide composite material used for oil-water separation and belongs to the field of composite materials. The preparation method comprises the following steps: carrying out ultrasonic washing on polyurethane sponge by dichloromethane and de-ionized water respectively to prepare a coarsening solution; coarsening the washed polyurethane sponge; preparing magnetic iron oxide particles from substances including ferric trichloride hexahydrate, glycol and the like through a magnetic separation method; adding 1-dodecanethiol into the magnetic iron oxide, adjusting the pH value and carrying out ultrasonic dispersion; adding tri-hydroxymethyl aminomethane into the dispersion solution, uniformly mixing and adding the polyurethane sponge; and stirring, washing and drying to obtain the super-hydrophobic polyurethane sponge / iron oxide composite material. According to the prepared iron oxide particles, a micro-nano structure is constructed on the surface of the sponge and low-surface-energy substances are introduced to prepare the composite material with super-hydrophobic and super-oleophylic properties, so that the composite material has the advantages of high oil absorption capability, selective separation of oil-water mixtures, rapid recycling of oil products and cyclic utilization of the material.

Owner:江苏固诺新材料科技有限公司

Nonmetallic bifunctional oxygen catalyst based on ZIF-8 and double-doped with phosphorus and sulfur, and preparation method and application thereof

PendingCN109012749AImprove conductivityIncrease the areaCell electrodesOrganic-compounds/hydrides/coordination-complexes catalystsBifunctionalPorous carbon

The invention discloses a nonmetallic bifunctional oxygen catalyst based on ZIF-8 and double-doped with phosphorus and sulfur, and a preparation method and an application thereof. A nonmetal carbon porous nano-compound is prepared through calcination in an inert atmosphere with ZIF-8 as a template, sodium phytate as a phosphorus source and 1-dodecanethiol as a sulfur source, the porous skeleton structure of ZIF makes the carbon material obtained after calcination inherit the porous structure, and metal Zn is sublimated and removed due to the low boiling point, so the carbon material uniformlyco-doped with phosphorus and sulfur is obtained. The obtained catalyst has a high specific surface area and a high conductivity, and has good oxygen reduction and oxygen evolution electrocatalytic activity in an alkaline medium, because the porous carbon material catalyst effectively increases the specific surface area and the conductivity; and the phosphorus and sulfur partially replace C-C sp<2>hybrid orbital to form C-P and C-S links, so active sites are increased, the conduction of electrons is benefited, the electrocatalytic performance of the material is greatly improved, and the material has potential application values in the field of energy conversion and storage.

Owner:QINGDAO UNIV OF SCI & TECH

Catalytic platinum-copper alloy nanoparticles

High-quality bimetallic PtxCu100-x (x=54-80 at. %) nanocubes can be prepared from a hot organic solution. Synthetic conditions, such as the ratio of oleylamine / tetraoctylammonium bromide as well as the doses of 1-dodecanethiol and 1,2-tetradecanediol have been optimized to ensure a formation of Pt—Cu nanocubes. Electrochemical evaluation shows that the catalytic activity of Pt60Cu40 nanocubes for methanol oxidation is superior, in comparison with those of spherical Pt60Cu40 nanocubes and Pt nanocubes with similar sizes, implying that the {100}-terminated Pt60Cu40 nanocubes offer a higher activity for methanol oxidation reaction than those with mixed crystallographic facets do. As another example, it was identified that Pt80Cu20 nanocubes is the best electrocatalyst on the basis of the maintainable electrocatalytic activity (which is even slightly superior to that of pure Pt nanocubes) and remarkable long-term stability (˜300 hours vs 3 hours for Pt nanocubes) when being performed towards formic acid oxidation reaction.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Polymer latex for ultraviolet absorption on different substrates

InactiveUS6482757B2Reduce the degree of polymerizationImprove propertiesImpression capsOrganic chemistryFunctional monomerPolymer science

A process for the production of an ultra violet absorbing polymer latex is provided. The inventive process involves the emulsion polymerization of a benzotriazole- or benzophenone-containing monomer with a vinyl functional monomer in the presence of a chain transfer agent, preferably 1-dodecanethiol. The latex provides excellent long-lasting, easy to apply, difficult to remove, ultraviolet absorption properties for many different substrates, most notably fabrics. Different articles and fabrics coated, covered, laminated, and the like, with the inventive latex are also provided.

Owner:MILLIKEN & CO

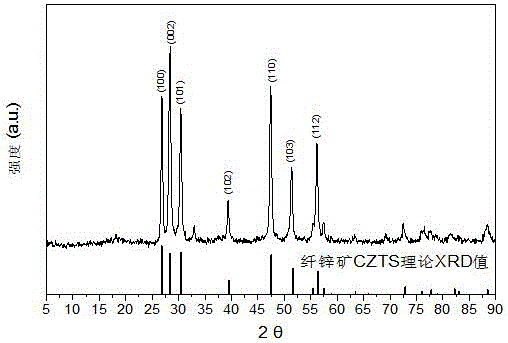

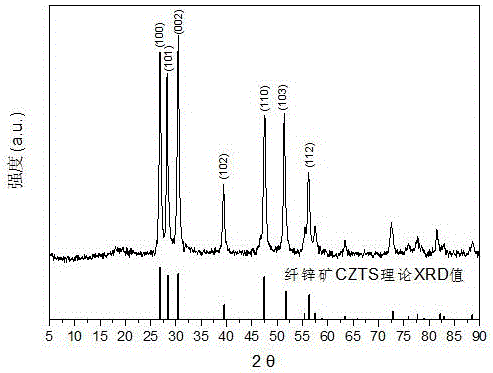

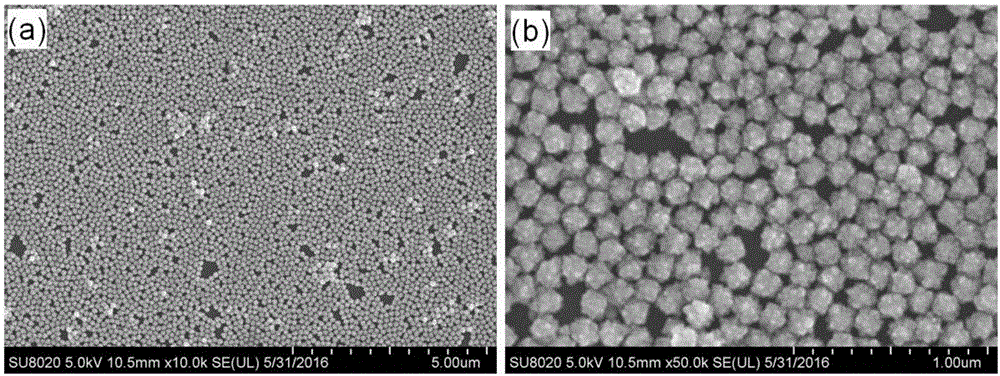

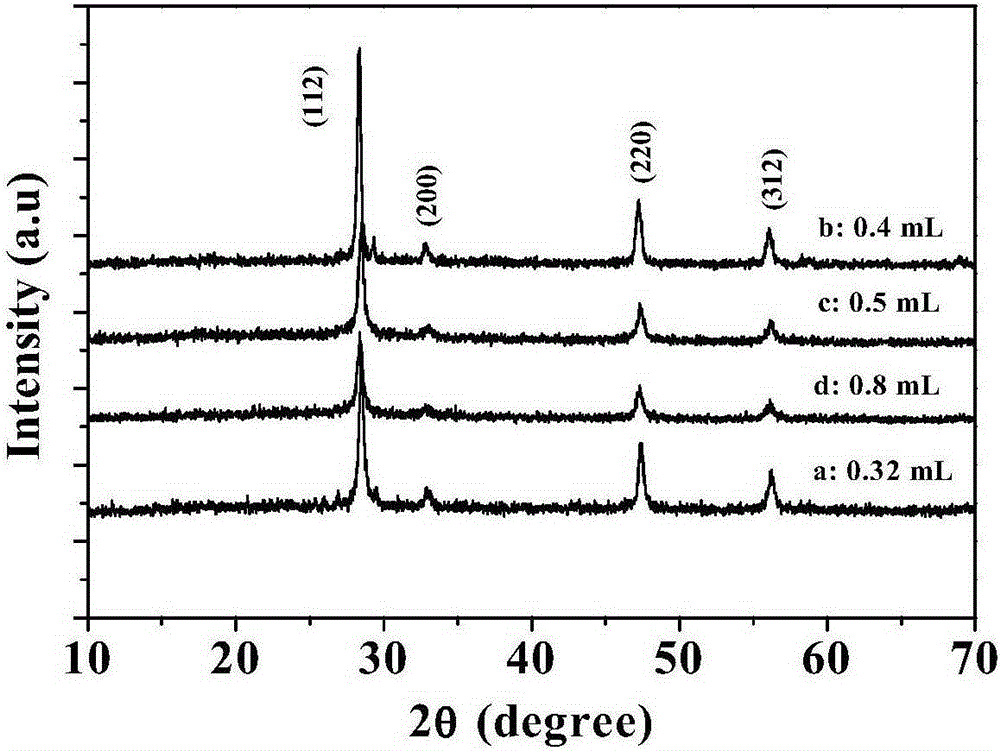

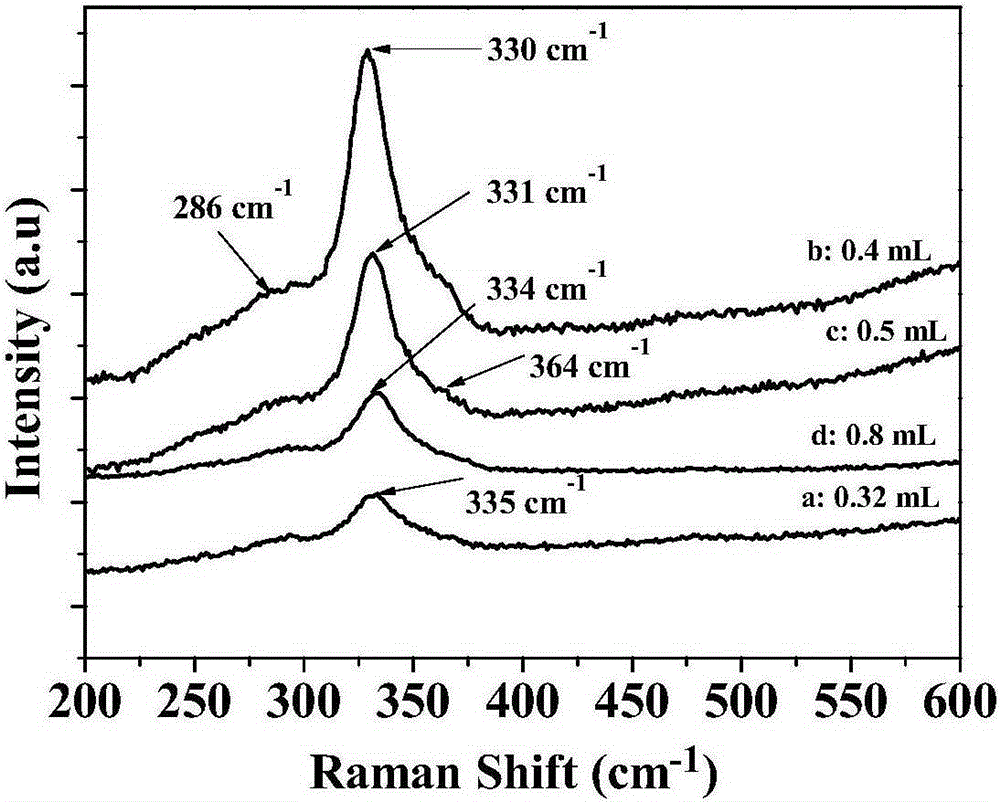

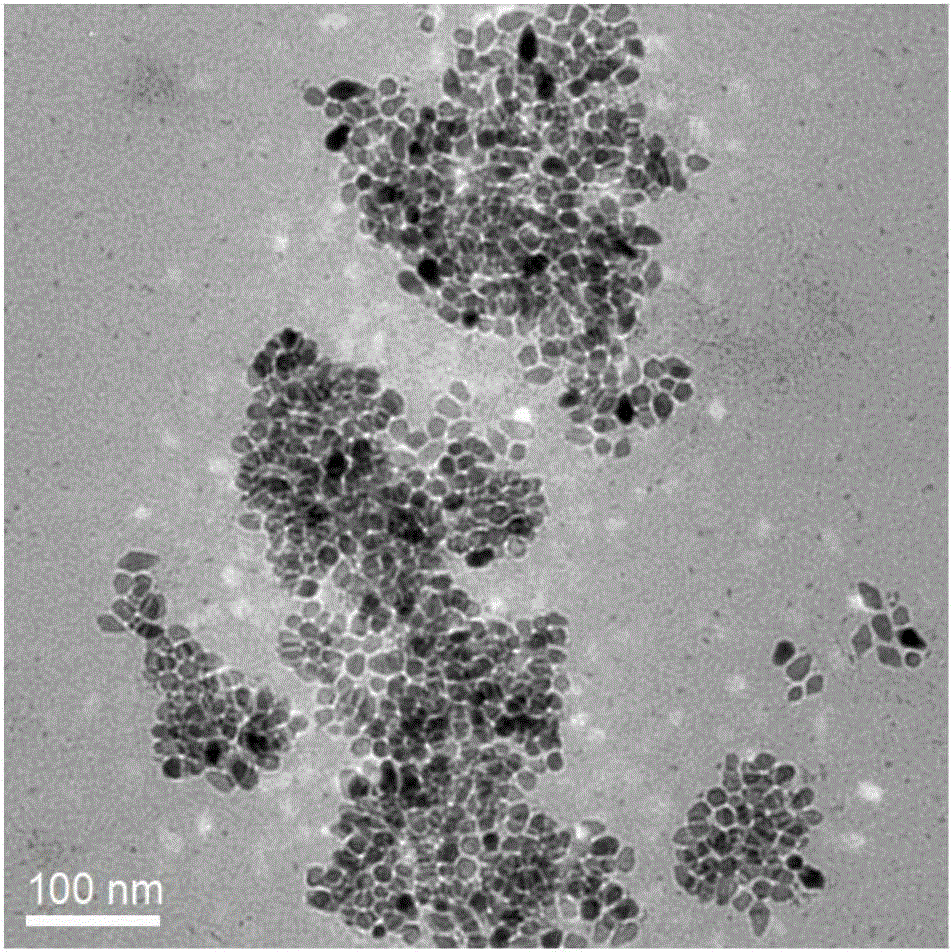

Large-scale preparation method for wurtzite Cu2ZnSnS4 nanocrystal

ActiveCN106395886ALow costImprove product qualityTin compoundsNanotechnologyNew energy1-dodecanethiol

The invention discloses a large-scale preparation method for a wurtzite Cu2ZnSnS4 nanocrystal, belonging to the field of photoelectric material new-energy technology. The method comprises the following steps: weighing a monovalent copper salt, a zinc salt and a tin salt, adding the monovalent copper salt, the zinc salt and the tin salt into a three-neck flask, adding oleylamine as a solvent and successively carrying out heating and cooling to room temperature; adding 1-dodecanethiol and carbon disulfide as sulfur sources, carrying out a reaction under heating and then carrying out cooling to room temperature; carrying out centrifugation and discarding supernatant; carrying out cleaning with a mixed solution of hexane, methanol and ethanol a plurality of times and collecting a precipitate; and drying the precipitate so as to obtain the wurtzite Cu2ZnSnS4 nanocrystal. The method provided by the invention is simple, great in output and high in yield and can produce plural grams of the wurtzite Cu2ZnSnS4 nanocrystal at a time; the output of the method at a time is one magnitude order higher than the output of conventional methods; and the prepared nanocrystal has an easily regulable atomic ratio, and an ideal wurtzite Cu2ZnSnS4 nanocrystal can be obtained by simply changing the ratio of a precursor.

Owner:KUNMING UNIV OF SCI & TECH

One-step synthesis of monodisperse au-cu nanocubes

ActiveUS20110283834A1Material nanotechnologyTransportation and packagingDiphenyl etherCelsius Degree

A one-step process for synthesizing gold-copper bimetallic nanocubes. The process comprises the step of simultaneously reducing a copper II salt and a gold halide by 1,2-hexadecanediol in diphenyl ether, and 1-dodecanethiol as well as surfactants 1-adamantanecarboxylic acid and 1-hexadecylamine. The copper II salt may be copper (II) acetylacetonate, copper chloride, copper sulfate, or copper phosphate. The gold halide may be chloroauric acid, gold chloride, gold bromide, or tetrabromoauric acid. The reduction may occur at a temperature between about 160 and 180 degrees Celsius. The copper II salt may be copper (II) acetylacetonate and the gold halide may be chloroauric acid.

Owner:GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF COMMERCE THE NAT INST OF STANDARDS & TEHCNOLOGY

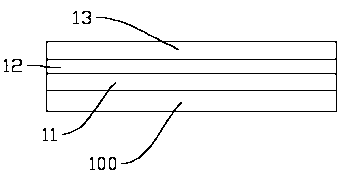

Method for preparing multi-quantum-dot core-silicon dioxide shell composite structure and application of structure to LED

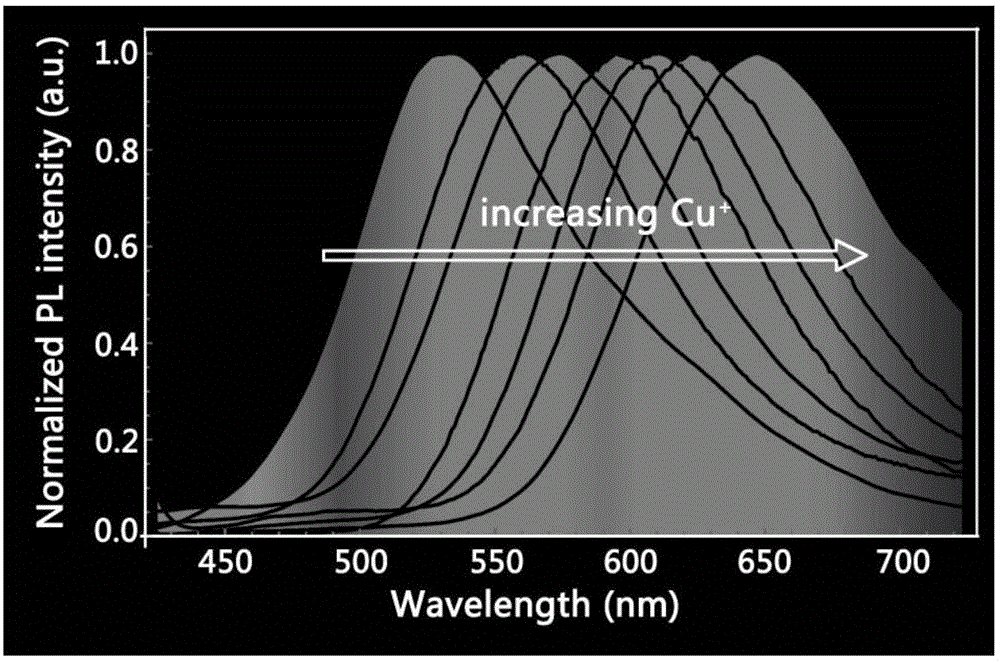

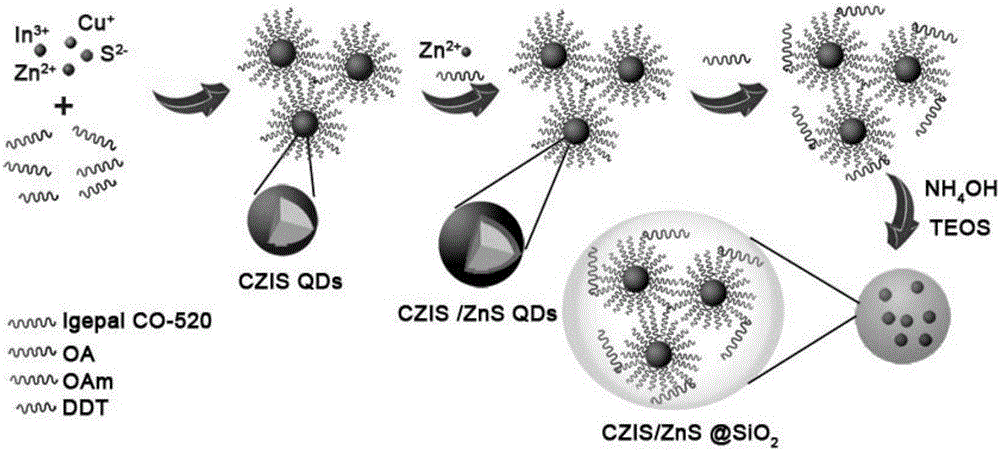

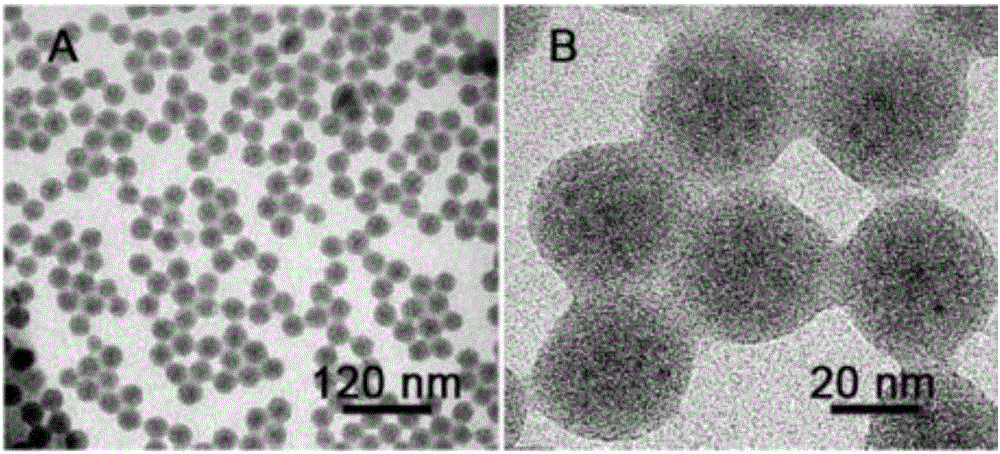

ActiveCN106318374AAvoid reabsorptionRealize white light LEDMaterial nanotechnologyLuminescent compositionsFluorescence1-dodecanethiol

The invention relates to a method for preparing a multi-quantum-dot core-silicon dioxide shell composite structure and application of the structure to an LED. By means of the method modification of chemical reagents such as oleic acid, 1-dodecanethiol and oleylamine, the Cu-doped Zn-In-S quantum dot structure of a multi-surface modifier is synthesized. By controlling and changing the doping amount of Cu, different quantum dot structures emitting fluorescence are synthesized. The quantum dot structures are wrapped in small silicon dioxide spheres with the diameter of tens of nanometers in a liquid-phase environment, the composite structure is placed on the surface of a GaN chip, and the color-adjustable quantum dot LED is successfully obtained. Besides, a quantum dot white light LED is obtained more easily by means of wide emission peaks of doped quantum dots.

Owner:ANHUI UNIVERSITY

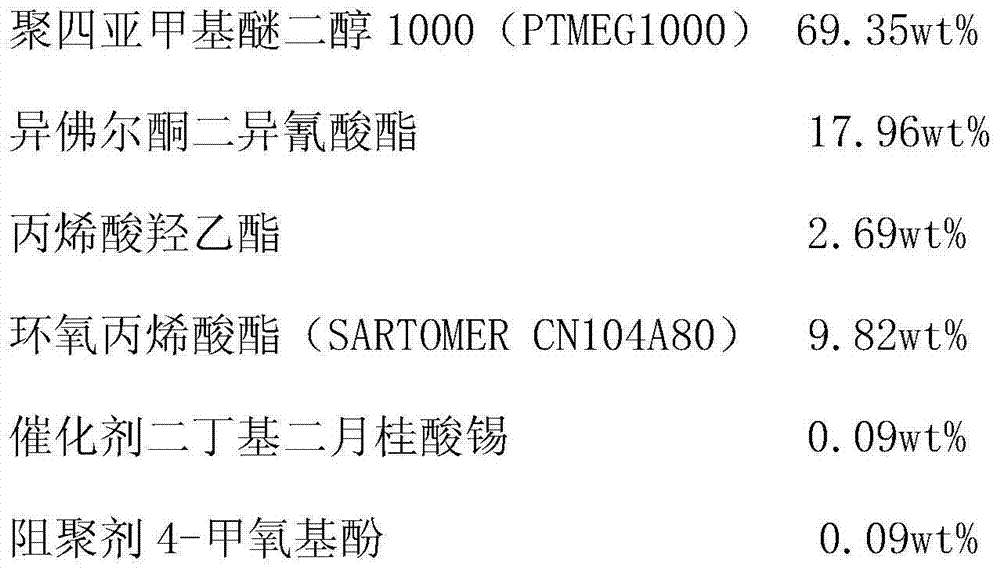

Optical coating and application thereof

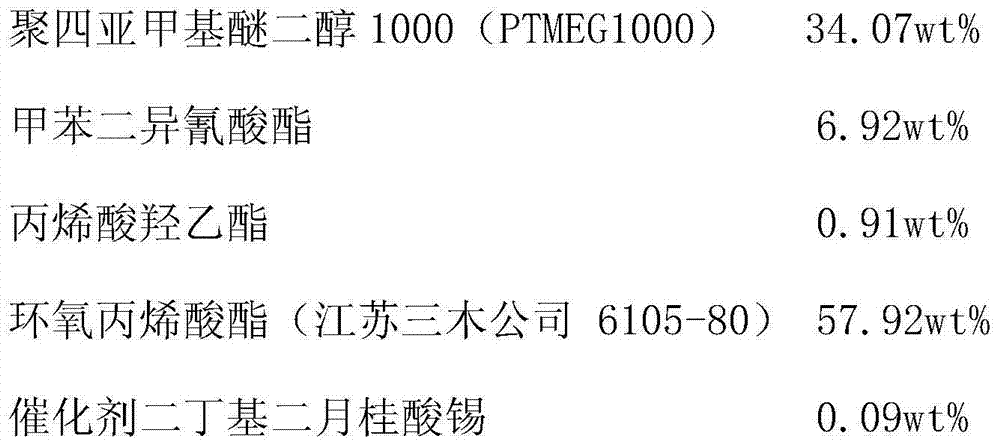

InactiveCN104774549AAdjust mechanical propertiesChange mechanical propertiesPolyurea/polyurethane coatingsEpoxyMeth-

The invention relates to an optical coating. The optical coating comprises 20-70wt% of oligomer, 20-70wt% of an active monomer diluent, 1-10wt% of a photoinitiator, 1-10wt% of an assistant and 0.1-2wt% of a molecular weight adjusting agent; and the oligomer is epoxy polyurethane (meth)acrylate, and the molecular weight adjusting agent is one or two or above of 1-dodecanethiol, tert-dodecanethiol, ethylhexyl 3-mercaptopropionate, pentaerythritol tetra(3-mercaptopropionate), isooctyl 3-mercaptopropionate and 2,4-diphenyl-4-methyl-1-pentene. A certain amount of the molecular weight adjusting agent is added to the formula of the coating in order to adjust the molecular weight and the curing degree in the coating radiation curing process, so the mechanical performances of the coating are changed, and the obtained coating is especially suitable for being used as a fiber coating and optical fiber ribbon.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

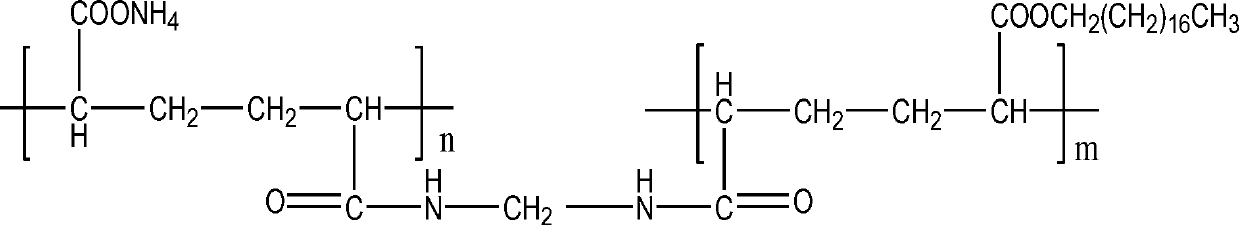

Thickening agent and preparation method thereof

InactiveCN102964504AImprove temperature resistanceImprove salt toleranceDyeing processCross-linkPolymer science

The invention discloses a thickening agent. The structure formula of the thickening agent is shown in the specification, wherein n is equal to 10-15, m is equal to 8-20, and n and m are integers. The preparation of the thickening agent comprises the following steps of: mixing crylic acid, N, N'-methylene bisacrylamide and 1-dodecanethiol and regulating a pH value to 6.5-7.5 at a low temperature; adding kerosene, sorbide oleate, azodiisobutyronitrile and octadecyl acrylate under the protection of nitrogen, emulsifying, warming and reacting; finally, adding polyoxyethylene sorbitan oleate for reverse emulsification, discharging and instantly obtaining a salt resistant thickening agent. A small amount of octadecyl hydrophobic long chain is introduced on an ammonium polyacrylate main chain, so that a thickening agent with better temperature resistance and salt resistance can be obtained. Through the hydrophobic association action among the variety of polymer molecules, macromolecule chains are cross-linked to form a space net structure with certain strength, so that the thickening agent is provided with great hydrodynamic volume and very strong viscosity enhancement property; and the inorganic salt resistance and temperature resistance performances are enhanced through the reversible space net structure formed by the hydrophobic association action.

Owner:ZHANGJIAGANG SHUNCHANG CHEM

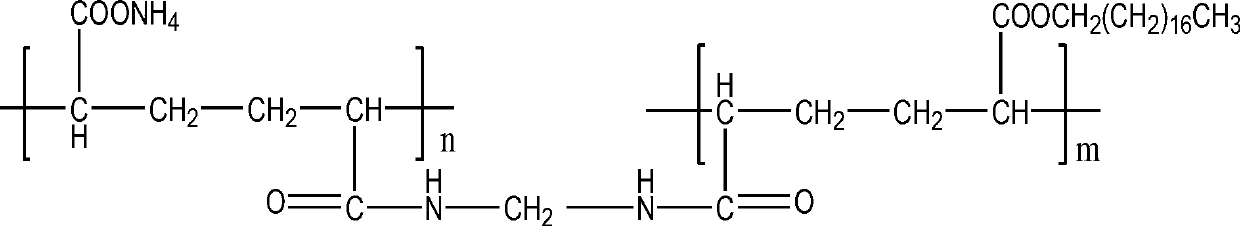

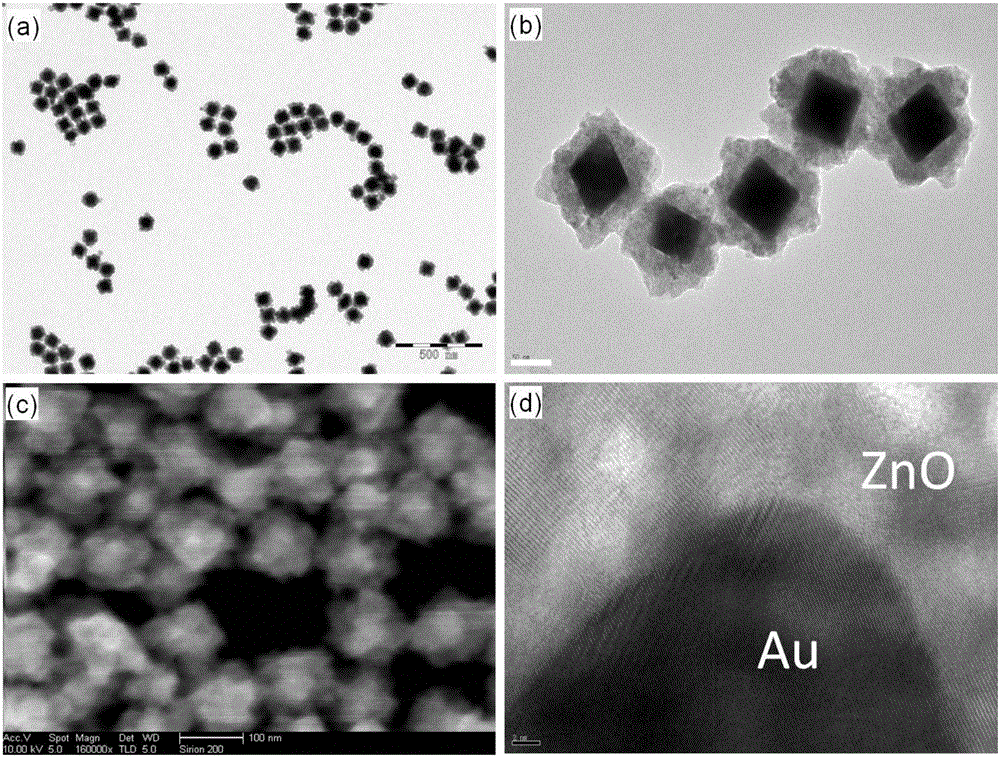

Gold@zinc oxide nuclear shell heterojunction film and preparation method and application thereof

ActiveCN106367774AExcellent photoelectrochemical hydrogen production capacityImprove photoelectric stabilityLiquid surface applicatorsTransportation and packagingHeterojunctionUltraviolet lights

The invention discloses a gold@zinc oxide nuclear shell heterojunction film and a preparation method and application thereof. According to the gold@zinc oxide nuclear shell heterojunction film, 1-dodecanethiol is adopted for conducting surface hydrophobic treatment on gold@zinc oxide nuclear shell heterogeneous composite nano particles firstly, then the gold@zinc oxide nuclear shell heterogeneous composite nano particles subjected to surface hydrophobic treatment are dispersed in n-butyl alcohol, a single-layer nano particle array is prepared through a gas-liquid interface self-assembly method and then fished up through a substrate, and thus the ordered single-layer gold@zinc oxide nuclear shell heterojunction film is obtained. The gold@zinc oxide nuclear shell heterojunction film can be used as a working electrode in photo-electrochemical decomposition water, and has excellent photo-electrochemical hydrogen production capacity and good photoelectric stability, the technical problems that existing single zinc oxide nano particles can only absorb ultraviolet light and are low in catalytic reaction efficiency can be solved, and the situation that gold is separated from zinc oxide is avoided in actual application.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

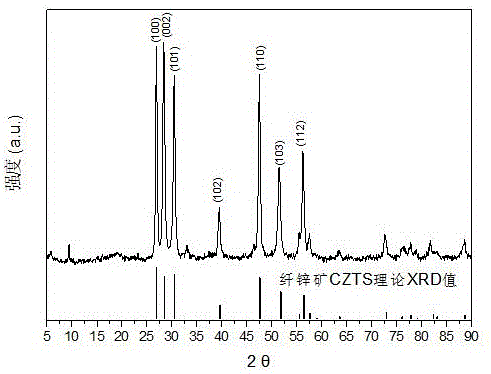

Preparation method of copper zinc tin sulfide nanocrystal with custerite structure

InactiveCN105253909AHigh phase purityGood dispersionMaterial nanotechnologyTin compounds1-dodecanethiolSolvent

The invention relates to a preparation method of a copper zinc tin sulfide nanocrystal with a custerite structure. The method includes the following steps: 1) adding copper salt, zinc salt and tin salt into a reactor after weigh the salts, adding oleylamine solvent and stirring the mixture fully to obtain a metal ligand complex solution; 2) adding sulfur powder into the oleylamine solvent, performing ultrasonic dispersion to form a sulfur-oleylamine solution, and then adding 1-dodecanethiol to obtain a sulfur-source precursor; 3) heating the metal ligand complex solution to the temperature of 150-200 DEG C in the presence of argon, injecting the sulfur-source precursor rapidly, mixing the mixture to obtain a sulfur-based metal complex solution, heating the complex solution to the temperature of 240-280 DEG C and reacting for 0.5-1 hour to obtain a copper zinc tin sulfide nanocrystal; and 4) adding the copper zinc tin sulfide nanocrystal into ethanol, performing centrifugal separation to obtain a precipitate, washing the prepared precipitate with the mixed liquor containing n-hexane and ethanol in a centrifugal manner, drying the prepared solid to obtain the copper zinc tin sulfide nanocrystal with the custerite structure.

Owner:WUHAN UNIV OF TECH

Catalytic platinum-copper alloy nanoparticles

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

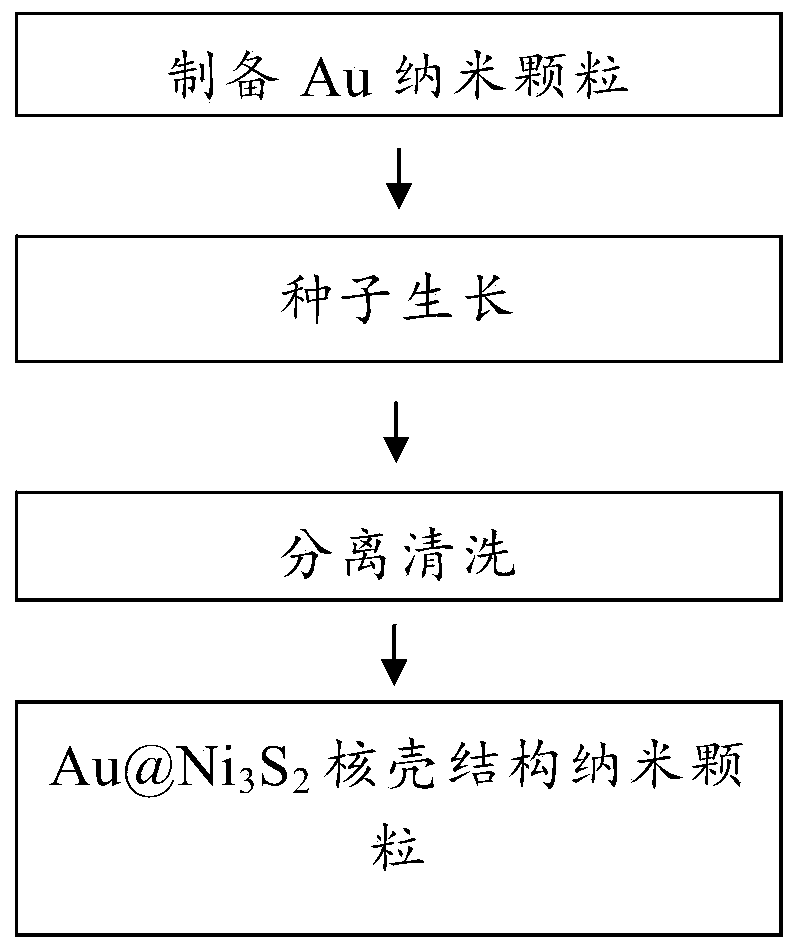

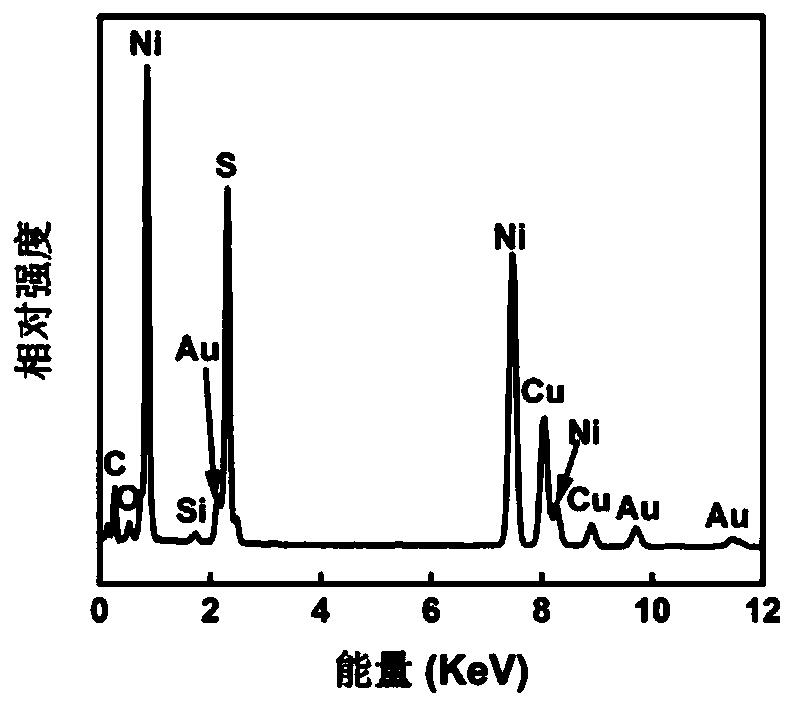

Nanoparticle with single crystal shell and Au@Ni3S2 core-shell structure, and preparation method thereof

ActiveCN110026566AImprove performanceGood lookingMaterial nanotechnologyTransportation and packagingHydrogen1-dodecanethiol

The invention discloses a nanoparticle with a single crystal shell and an Au@Ni3S2 core-shell structure. The nanoparticle is formed by a face-centered cubic-phase Au core and a rhombus-phase Ni3S2 shell, wherein the Ni3S2 shell is of a single crystal structure. A preparation method of the nanoparticle is a seed growth method which is characterized by adopting a pre-synthesized Au nanoparticle as aseed, adding 1-dodecanethiol, and epitaxially growing generated Ni3S2 along the Au nanoparticle so as to form the Au@Ni3S2 core-shell structure. The method provides the way of simply and effectivelypreparing the novel nanometer material with the single crystal semiconductor shell and the metal-semiconductor core-shell structure, and is simple in operation, and the product homogeneity is good; and the obtained Au@Ni3S2 core-shell structure has good stability and physicochemical property, has an excellent hydrogen evolution catalytic performance so as to provide a favorable basis for the application of the Au@Ni3S2 core-shell structure in high-efficiency electrolyzed water, and can be widely applied to the fields such as catalysts and supercapacitors.

Owner:UNIV OF SCI & TECH BEIJING

Heat-resistant crack-resistant organic glass and preparation method thereof

InactiveCN107057254AIncrease steric hindranceImprove molecular weightEthyl hydroxybenzoateMethacrylate

The invention discloses heat-resistant crack-resistant organic glass and a preparation method thereof; the heat-resistant crack-resistant organic glass comprises, by weight, methyl methacrylate, polycyclic norbornene methacrylate, butanediol diacrylate, epoxidized soybean oil acrylate, an impact modifier, 1-dodecanethiol, polyacrylamide, rubber particles, poly(butyl acrylate), nylon terpolymer, rare earth, azobisisobutyronitrile, dicumyl peroxide, diisobutyl phthalate, and ethyl 4-hydroxybenzoate. The heat-resistant crack-resistant organic glass and the preparation method thereof are provided herein; the organic glass has high glass transition temperature, good heat resistance and good mechanical properties, rarely cracks and has good economic benefit.

Owner:蚌埠承永玻璃制品有限公司

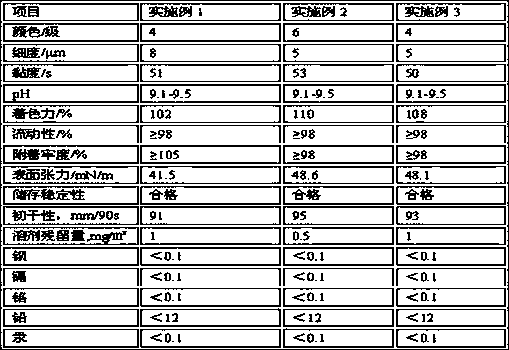

Ink printing pap+er box, printing ink and production process thereof

InactiveCN108178948AImprove packaging effectImprove printing effectInksRigid containersGas phase1-dodecanethiol

The invention discloses an ink printing paper box which comprises a box body, wherein a first printing layer is arranged outside the box body; a film layer is arranged on the first printing layer; a second printing layer formed by printing ink is arranged on the film layer; the ink printing paper box has a better appearance; the printing ink comprises 40-50 parts of a composite polyacrylate emulsion, 40-50 parts of color paste, 0.2-0.5 part of a defoamer, 0.4-0.8 part of a leveling agent, 0.1-1 part of a thickener, 0.5-2 parts of fumed silica, 0.1-0.5 part of a moisturizer, 1-5 parts of a pH regulator and 5-10 parts of water; the polyacrylate emulsion comprises the following components in parts by weight: 20-35 parts of an acrylic monomer, 1-3 parts of 1-dodecanethiol, 1-5 parts of hydroxyethyl acrylate, 1-10 parts of an emulsifier, 5-15 parts of soybean oil, 0.1-0.5 part of a phosphite ester, 0.5-1.5 parts of an initiator, 1-5 parts of a pH regulator and 1-10 parts of deionized water.The invention further provides a production process of the printing ink; and the ink has the characteristics of low pollution, good storage performance, strong adhesion to PP, PE and other plastic substrates, and good printing effect.

Owner:嘉兴市星原印刷股份有限公司

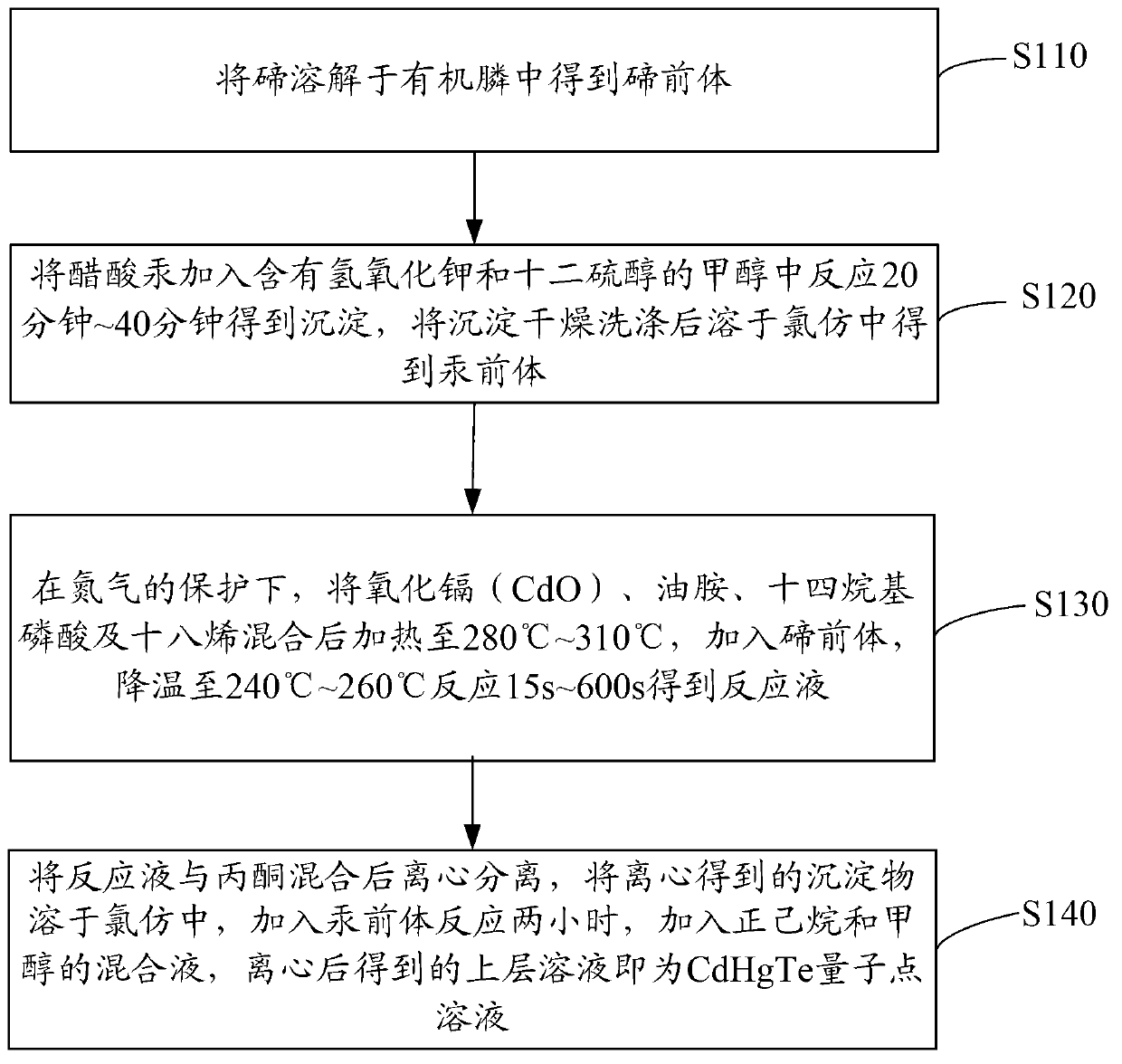

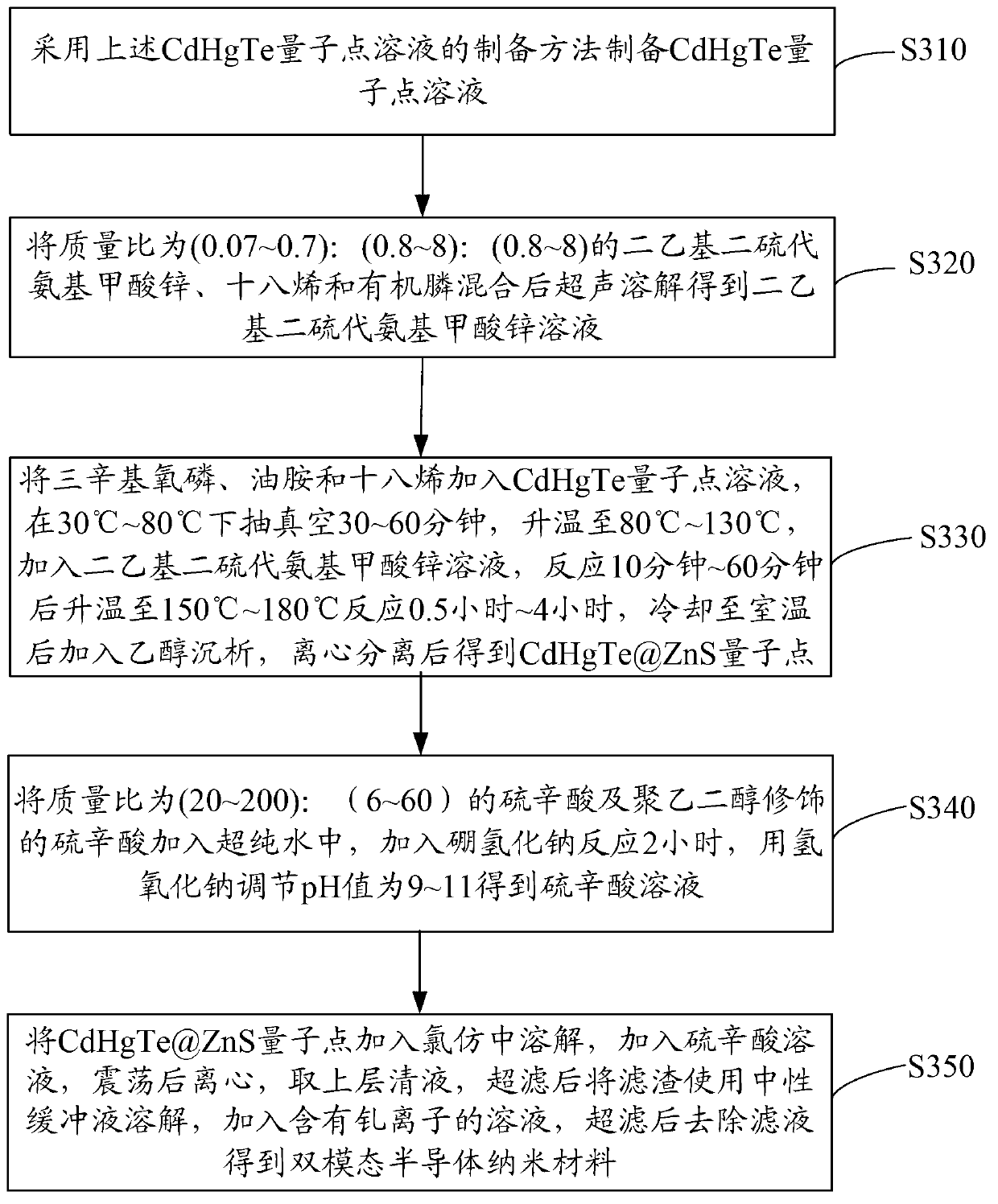

Preparation method and application of CdHgTe quantum dot solution, CdHgTe quantum dot and bimodal semiconductor nanometer material

ActiveCN103131420AEasy to makeFunctionalMaterial nanotechnologyLuminescent compositionsPhosphoric acid1-dodecanethiol

The invention provides a preparation method of CdHgTe quantum dot solution, CdHgTe quantum dot, bimodal semiconductor nanometer material and bimodal semiconductor nanometer material. The preparation method of the CdHgTe quantum dot comprises the following steps: dissolving tellurium in organic phosphine to obtain tellurium precursor; adding mercuric acetate into carbinol containing potassium hydroxide and 1-dodecanethiol to react to obtain sedimentation,and drying and washing the sedimentation and dissolving the sedimentation in chloroform to obtain mercury precursor; under protection of nitrogen, heating mixed cadmium oxide, oleylamine, myristyl phosphoric acid and octadecene to 280-310 DEG C, adding the tellurium precursor, cooling to 240-260 DEG C to react to obtain reaction liquid; and conducting centrifugal separation after mixing the reaction liquid and acetone, dissolving a sedimentation obtained through centrifuging in the chloroform, adding the mercury precursor to react for two hours, adding mixing liquid of normal hexane and the carbinol, centrifuging the mixed liquid and obtaining the CdHgTe quantum dot solution. The preparation method of the CdHgTe quantum dot solution is easy to operate.

Owner:SHENZHEN INST OF ADVANCED TECH

Pressure sensitive adhesive with high stripping force and preparation method thereof

ActiveCN110041860AImprove peel forceGood initial adhesionEster polymer adhesivesRosin adhesivesIsooctyl acrylate1-dodecanethiol

The invention discloses a pressure sensitive adhesive with the high stripping force. The pressure sensitive adhesive is prepared from the following raw materials, in parts by weight: 45-55 parts of 2-ethylhexyl acrylate, 4-9 parts of acrylamide, 40-50 parts of butyl acrylate, 7-12 parts of hydroxypropyl acrylate, 3-7 parts of methyl acrylate, 70-90 parts of ethyl acetate and butanone with the massratio being 1 to 1, 1.3-2.2 parts of azodiisobutyronitrile, 0.6-1 part of 1-dodecanethiol and 3-5 parts of tuluene diisocynate. The pressure sensitive adhesive with the high stripping force has the good initial adhesion and persistent adhesion, the 180-degree stripping force is high and can be held at the temperature of 90 DEG C, and the pressure sensitive adhesive can adhere firmly, and has thegood anti-plasticizer property and temperature resistance. No benzene and methylbenzene serves as solvents in the synthesis process of the pressure sensitive adhesive, and the pressure sensitive adhesion is low in toxicity, environmentally friendly, and wide in application range.

Owner:浙江铂淳新材料股份有限公司

Preparation method of coal water slurry with dispersion stability

ActiveCN106010695AReduce digestionReduce storage areaLiquid carbonaceous fuelsDispersion stabilityFiber

The invention discloses a preparation method of coal water slurry with dispersion stability and belongs to the technical field of preparation of the coal water slurry. The preparation method of the coal water slurry comprises the steps that wheat fibers and bamboo pulp black liquor are mixed, the pH value is regulated with sodium hydroxide, then ferric chloride and oleum are added to the mixture for a sulfonation reaction, suction filtration is performed after the reaction, and a filter residue is obtained for standby application; corn starch, ammonium persulfate and deionized water are mixed, the pH value is regulated, then ferrous sulfate, the filter residue, methyl methacrylate, butyl acrylate, 1-dodecanethiol are added for a mixed reaction, and a dispersing agent is obtained; the dispersing agent is mixed with pulverized coal and water, a mixture is stirred and dried, slurry is obtained and subjected to shearing treatment finally, and the coal water slurry with dispersion stability is obtained. Examples prove that the operation is simple and convenient, the raw materials are easily available, the prepared coal water slurry has the advantages of good slurry flow pattern, high stability, low viscosity and excellent performance, can meet industrial production requirements and can realize excellent performance without compositing with other dispersing agents, and the process is environment-friendly.

Owner:佛山市南海港能燃料物料有限公司

Flame-retardant automobile clutch friction material and preparing method thereof

InactiveCN105086938APrevent soft agglomerationGood dispersionOther chemical processesFriction liningAluminum magnesium silicateSilanes

The invention discloses a flame-retardant automobile clutch friction material. The flame-retardant automobile clutch friction material is composed of, by weight, 1-2 parts of decabromodiphenyl ethane, 1-2 parts of sldium lauryl sulfate, 3-5 parts of aluminum-magnesium silicate, 3-4 parts of dioctyl sebacate, 1-2 parts of calcium fluoride, 2-4 parts of ammonium polyphosphate, 2-3 parts of anionic polyacrylamide, 3-5 parts of vinyl trimethoxy silane, 50-60 parts of acetone, 20-30 parts of dimethyl sulfoxide, 25-30 parts of absolute ethyl alcohol, 50-60 parts of methyl methacrylate, 20-26 parts of butyl acrylate, 0.3-1 part of 1-dodecanethiol, 20-34 parts of titanous sulfate, 16-20 parts of glucose, 60-70 parts of nanocarbon powder, 200-300 parts of isopropanol, 80-100 parts of nylon 66 and 0.04-0.06 part of azodiisobutyronitrile. The added decabromodiphenyl ethane is free of toxins and pollution, good in heat resistance, not prone to dialysis and capable of achieving a good synergistic flame retardant effect when mixed with the aluminum-magnesium silicate, the ammonium polyphosphate and the like.

Owner:来安县隆华摩擦材料有限公司

Bone black automobile clutch friction material and preparation method thereof

InactiveCN105062418ALower surface energyReduce surface activityOther chemical processesFriction liningFiberN-dodecane

The invention discloses a bone black automobile clutch friction material. The bone black automobile clutch friction material comprises, by weight, 1-2 parts of propylene glycol alginate, 1-2 parts of diphenylsilanediol, 2-3 parts of ammonium aluminum sulfate, 6-10 parts of acrylonitrile-styrene copolymer, 3-5 parts of bone black, 0.3-1 part of acetylacetone, 3-4 parts of polytetrafluoroethylene fibers, 3-5 parts of vinyltrimethoxy silane, 50-60 parts of acetone, 20-30 parts of dimethyl sulfoxide, 6-8 parts of anhydrous ethanol, 50-60 parts of methyl methacrylate, 20-26 parts of butyl acrylate, 0.3-1 part of 1-dodecanethiol, 20-34 parts of titanium sulfate, 16-20 parts of glucose, 60-70 parts of nanometer carbon powder, 200-300 parts of isopropanol, 80-100 parts of nylon66 and 0.04-0.06 parts of azodiisobutyronitrile. The automobile friction material has the advantages of good wear resistance, long service life, good oil resistance, good weatherability and superior comprehensive performances.

Owner:来安县隆华摩擦材料有限公司

Au/NiSx eggshell-structured nanoparticles and preparation method thereof

ActiveCN110026565AImprove performanceExcellent hydrogen evolution catalytic performanceMaterial nanotechnologyTransportation and packagingEggshell1-dodecanethiol

The invention discloses Au / NiSx eggshell-structured nanoparticles, and belongs to the field of nanomaterials. The nanoparticles are composed of cubic phase Au cores and diamond phase Ni3S2 or cubic phase Ni3S4 shell layers. A preparation method of the nanoparticles is an in-situ conversion method, a pre-synthesized Au-Ni dimer structure is used as a precursor, 1-dodecanethiol is added, and the Au-Ni dimer structure is transformed into an Au / NiSx eggshell structure in situ. According to the preparation method of the nanoparticles, a simple and effective way for preparing novel precious metal-transition metal sulfide eggshell-structured nanomaterials, and operation is easy; and the obtained Au / NiSx eggshell-structured nanoparticles are provided with single crystal shell layers, the excellenthydrogen evolution catalytic performance of the Au / NiSx eggshell-structured nanoparticles provides a good foundation on application of the Au / NiSx eggshell-structured nanoparticles in high-efficiencyelectrolytic water, the Au / NiSx eggshell-structured nanoparticles can be widely used the fields such as catalysts and super capacitors.

Owner:UNIV OF SCI & TECH BEIJING

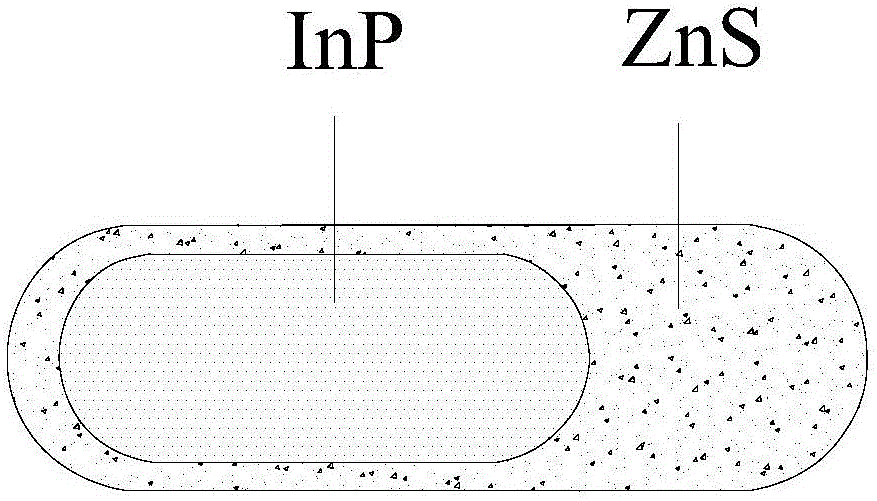

Preparation method of core-shell InP/ZnS nanorods

ActiveCN106433613AAdjustable aspect ratioImprove luminous efficiencyNanoopticsLuminescent compositions1-dodecanethiolTrioctylphosphine

The invention provides a preparation method of core-shell InP / ZnS nanorods, comprising: in inert atmosphere, mixing indium chloride or indium oxide, trioctyl phosphine oxide, dodecylamine and tri-n-octylphosphine to obtain mixed liquid, heating and degassing in vacuum, heating in the inert atmosphere to form transparent indium precursor solution; in inert atmosphere, preparing tris(trimethylsilyl)phosphine precursor with tris(trimethylsilyl)phosphine, diphenyl ether and biphenyl; in inert atmosphere, heating the indium precursor solution to 290-320 DEG C, injecting the tris(trimethylsilyl)phosphine precursor into the indium precursor solution, adjusting the temperature to 295-305 DEG C, and reacting to obtain an InP nanorods; in inert atmosphere, injecting zinc fatty acid and 1-dodecanethiol into InP nanorod solution under heating to prepare the core-shell InP / ZnS nanorods.

Owner:TCL CORPORATION

Sizing material for producing high-strength synchronous belt

The invention discloses a sizing material for producing a high-strength synchronous belt. The sizing material for producing the high-strength synchronous belt is prepared from, by weight, 37.89%-42.64% of chloroprene rubber, 14.87%-18.67% of butadiene styrene rubber, 8.14%-12.48% of high styrene rubber, 1.23%-4.35% of zinc oxide, 1.14%-3.15% of magnesium oxide, 0.26%-0.67% of stearic acid, 0.25%-0.75% of an anti-aging agent 4010 NA, 1.98%-4.87% of 1-dodecanethiol, 0.67%-1.95% of an anti-aging agent ODA, 0.24%-0.65% of antiozonant, 21.68%-26.89% of carbon black N762 and 0.14%-0.37% of accelerant. According to the sizing material for producing the high-strength synchronous belt, by synchronously using the chloroprene rubber, the butadiene styrene rubber, the high styrene rubber, stearic acid, the anti-aging agents, 1-dodecanethiol, the antiozonant, the carbon black N762 and the accelerant, the properties of the raw materials complement each other, so that the cost of the sizing materialis reduced; by adding the butadiene styrene rubber and the high styrene rubber, the toughness and the strength are improved; by adding the anti-aging agents and the antiozonant, the anti-aging performance is improved, and the service life of the synchronous belt is improved.

Owner:江西康琪实业有限公司

Powdered ink for novel printer

The invention relates to powdered ink for a novel printer, and belongs to the technical field of office supplies. The powdered ink is characterized by comprising the constituents based on parts by weight: 50-95 parts of polylactic resin, 3-50 parts of coloring agent, 1-10 parts of releasing agent, 0.3-5 parts of charge control agent, 0.01-5 parts of flavoring agent, 0.5-5 parts of 1-dodecanethiol,1-5 parts of hydroquinone and 1-5 parts of ammonium persulfate. The powdered ink has the beneficial effects that pigment and wax are coated by resin to form uniform powder, and the powdered ink is uniform in coating, is approximate to a spherical shape, is controllable in size, smooth in edge, uniform in color, is durable and is particularly and suitably used as color laser printing powdered ink.

Owner:成都丰睿视觉科技有限公司

Silver nanowires, and production method and dispersion of the same

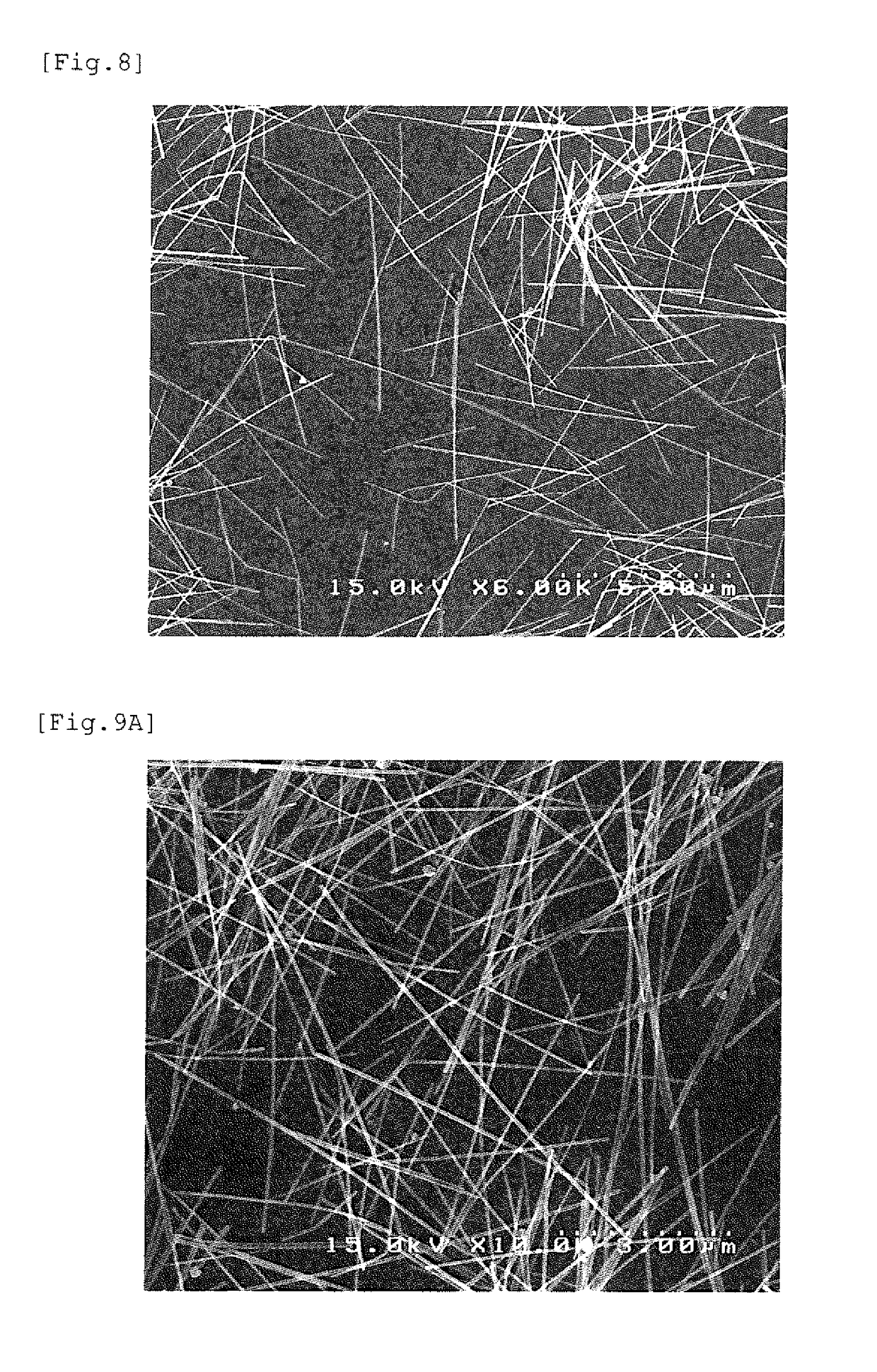

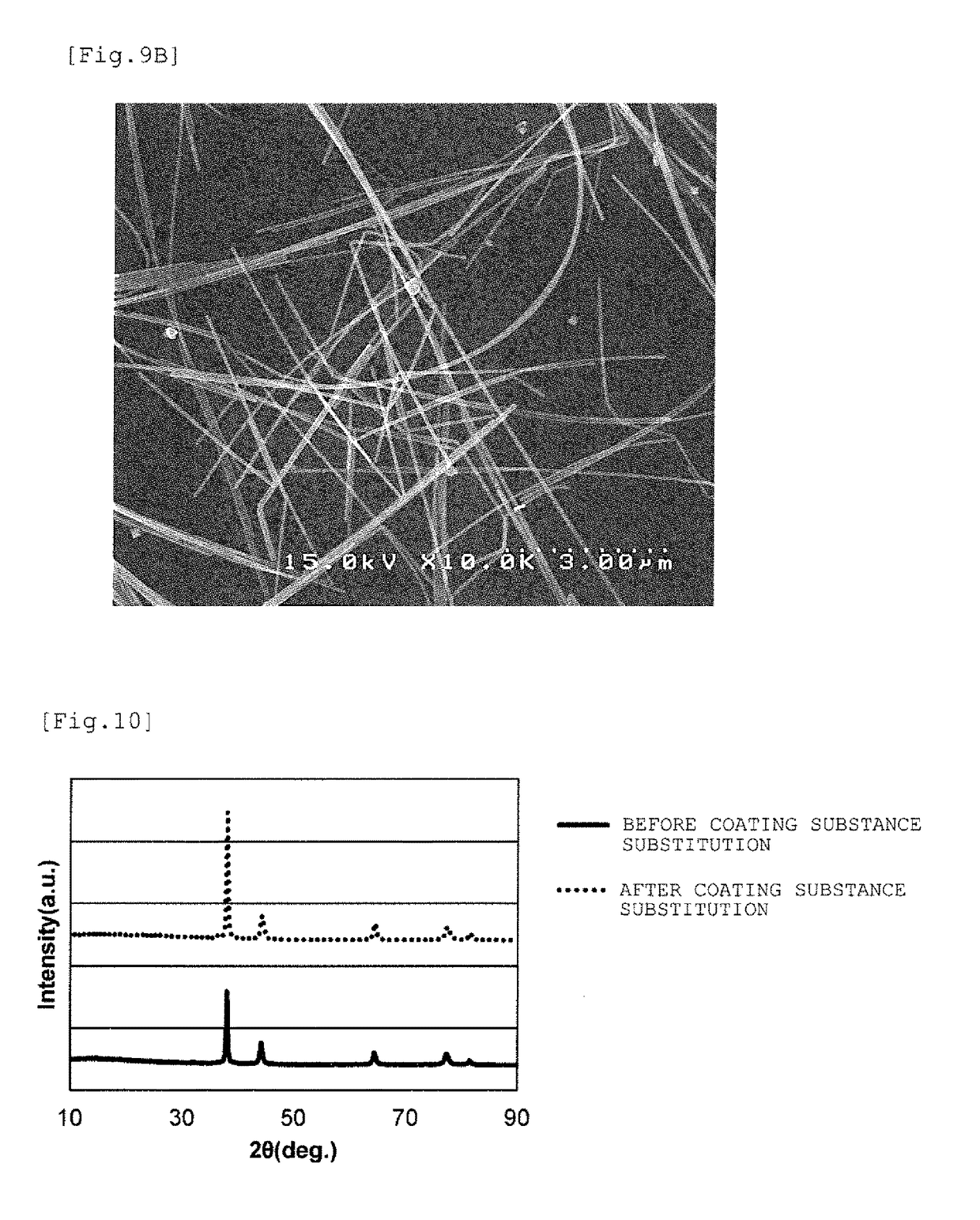

InactiveUS20170120327A1Good dispersionRaise the sintering temperatureTransportation and packagingMetal-working apparatusMONOETHANOLAMINE THIOGLYCOLATEThiomalic acid

Silver nanowires coated with, instead of a polymer protective agent such as PVP, an organic protective agent having a smaller molecular weight are provided. The silver nanowires have an average diameter of 100 nm or less and an average length of 5 μm or more, and a thiol having a molecular weight of 75 to 300 is adhered on surfaces of the metal silver. The silver nanowires have a thiol containing one thiol group in the structure adhered thereon. A thiol having only one thiol group (—S—H) in a molecule is a suitable target. Examples thereof include 1-dodecanethiol, 1-decanethiol, 1-octanethiol, 3-mercapto-1,2-propanediol, monoethanolamine thioglycolate, ammonium thioglycolate, and thiomalic acid.

Owner:UNIVERSITY OF SHIGA PREFECTURE +1

Aquatic feed containing starch adhesive and preparation method thereof

InactiveCN108157686AFull of nutritionImprove stabilityFood processingAnimal feeding stuffPotato starchAdhesive

The invention discloses aquatic feed containing a starch adhesive and a preparation method thereof. The aquatic feed comprises the following raw materials in parts by weight: 20-30 parts of the starchadhesive, 10-25 parts of ginger powder, 10-15 parts of beer residue, 20-25 parts of sugar beet pulp, 15-30 parts of seaweed powder, 1-2 parts of sodium diacetate, 3-7 parts of bamboo rat excrement, 10-15 parts of poultry feather meal, 1-3 parts of vitamin E and 10-15 parts of whey powder; and the starch adhesive comprises the following raw materials in parts by weight: 10-18 parts of cassava starch, 5-11 parts of potato starch, 1-5 parts of fullerene, 1-4 parts of sodium hyaluronate, 3-8 parts of acrylic acid and 2-7 parts of 1-dodecanethiol. The aquatic feed disclosed by the invention contains rich nutrients, such as protein, amino acids and vitamins, and is favorable for growth and breeding of aquatic livestock; the aquatic feed has good stability in water and less water body pollution;and a preparation process is simple, has easily-available raw materials and is favorable for production and processing.

Owner:枣庄市金科化工有限公司

Cationic rosin size prepared by using Gemini emulsifier and preparation method thereof

InactiveCN109957995AGood emulsifying effectImprove stabilityWater-repelling agents additionPaper coating1-dodecanethiolSodium sulfate

The invention discloses a cationic rosin size prepared by using a Gemini emulsifier. The cationic rosin size comprises the following components in parts by weight: 100-200 parts of rosin, 20-80 partsof fortified rosin, 25-80 parts of a Gemini emulsifier, 50-200 parts of an aluminum salt, and an appropriate amount of water, wherein the Gemini emulsifier is prepared by carrying out reactions of thefollowing components in parts by weight: 10-50 parts of a rosin monomer, 10-60 parts of styrene, 10-60 parts of acrylamide, 10-50 parts of diethyl diallyl ammonium chloride, 10-50 parts of OP-10, 0.4-200 parts of 1-dodecanethiol, 10-300 parts of ethanol, and 1-50 parts of sodium persulfate. According to the method, the Gemini emulsifier is adopted, and thus a stable system can be formed in the rosin solution, the reaction time is reduced, the preparation process is simplified, the production cost is reduced, and the obtained cationic rosin size has fine grain size, small foams, high whitenessand high stability.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Nylon rubber composite automobile clutch friction material and preparation method thereof

InactiveCN105038702APrevent soft agglomerationGood dispersionOther chemical processesFriction liningThioureaSilanes

The invention discloses a nylon rubber composite automobile clutch friction material. The nylon rubber composite automobile clutch friction material is composed of, by weight, 20-34 parts of titanium sulfate, 3-5 parts of vinyl trimethoxy silane, 50-60 parts of acetone, 20-30 parts of dimethyl sulfoxide, 6-8 parts of absolute ethyl alcohol, 50-60 parts of methyl methacrylate, 0.3-1 part of 1-dodecanethiol, 16-20 parts of glucose, 60-70 parts of nanometer carbon powder, 200-300 parts of isopropyl alcohol, 80-100 parts of nylon 66, 0.04-0.06 part of azodiisobutyronitrile, 1-2 parts of polydimethylsiloxane, 3-5 parts of caprylic capric triglycerride, 3-4 parts of molybdenum boride, 6-8 parts of ethylene propylene terpolymer, 0.6-1 part of tetramethylthiourea, 1.4-2 parts of dimethyldioctylammonium chloride and 20-26 parts of butyl acrylate. According to the nylon rubber composite automobile clutch friction material, the ethylene propylene terpolymer is added, and the hardness and the weather resistance of a finished product can be effectively improved.

Owner:来安县隆华摩擦材料有限公司

Non-adherent automobile clutch friction material and preparation method thereof

InactiveCN105062419ALower surface energyReduce surface activityOther chemical processesFriction liningCelluloseHydrogen Sulfate

The invention discloses a non-adherent automobile clutch friction material. The non-adherent automobile clutch friction material comprises, by weight, 20-34 parts of titanium sulfate, 3-5 parts of vinyltrimethoxy silane, 50-60 parts of acetone, 20-30 parts of dimethyl sulfoxide, 6-8 parts of anhydrous ethanol, 50-60 parts of methyl methacrylate, 0.3-1 part of 1-dodecanethiol, 16-20 parts of glucose, 60-70 parts of nanometer carbon powder, 200-300 parts of isopropanol, 80-100 parts of nylon66, 0.04-0.06 parts of azodiisobutyronitrile, 1-2 parts of potassium tetraborate, 2-3 parts of aluminum triphosphate, 0.7-1 part of potassium hydrogen sulfate, 1-2 parts of polyacrylamide, 4-7 parts of rosin glycerin ester, 2-4 parts of cellulose propionate, 4-6 parts of epoxidized soybean oil and 4-5 parts of triethylene glycol di-2-ethylhexoate. Friction plates can bear impact, difficultly rupture and spall at a high speed, and have the advantages of wear resistance, high temperature resistance, corrosion resistance, good heat conductivity, small thermal deformation, and non-adhesion in the long-term standing process.

Owner:来安县隆华摩擦材料有限公司

Modified foamed material

The invention discloses a modified foamed material, which is composed of the following materials: 100-120 parts of polyaniline, 10-12 parts of ammonium persulfate, 80-90 parts of polyvinyl chloride, 8-10 parts of isocyanate, 6-8 parts of isopropanol, 75-80 parts of dammar resin, 60-65 parts of dicyclopentadiene resin, 60-70 parts of terpene resin, 65-70 parts of copal resin, 45-50 parts of polycarbonate, 15-18 parts of tetramethyl tetravinyl cyclotetrasiloxane, 6-8 parts of methylene bisacrylamide, 5-10 parts of microcrystalline graphite powder, 6-8 parts of ferroferric oxide, 5-6 parts of zinc carbonate, 4-5 parts of disodium hydrogen phosphate, 3-5 parts of magnesium stearate, 4-6 parts of 1-dodecanethiol, 8-10 parts of butyl acrylate, and 8-10 parts of organic modified bentonite. The process of the modified foamed material is simple and practicable, can economically and effectively prepare the modified foamed material with electrical conductivity, excellent comprehensive mechanical properties, good heat resistance and controllable density, so that the original composite foam material without conductive ability has conductivity, the impact toughness of the material is greatly improved, and the cell size is well controlled.

Owner:李兆源

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com