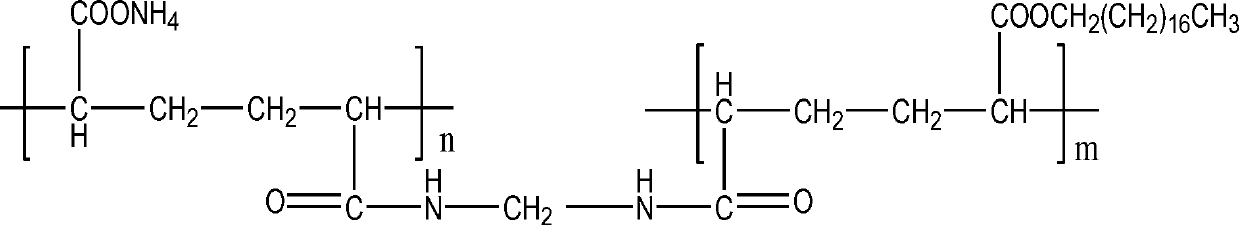

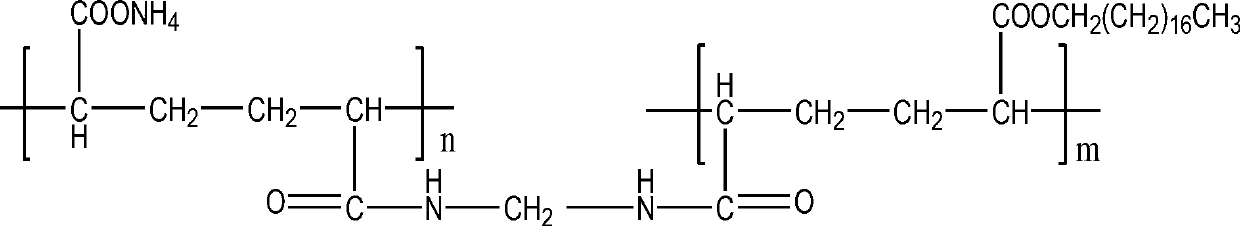

Thickening agent and preparation method thereof

A thickening agent and structural formula technology, applied in the field of thickening agent and its preparation, can solve the problems of thickening agent can not meet industrial application requirements, poor salt resistance effect, etc., achieve good salt resistance, enhanced inorganic salt resistance and resistance. Temperature performance, the effect of enhancing the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Place the four-necked flask in an ice-water bath at -10 to 0°C, add 2.5 mol of acrylic acid, 1 mol of N,N'-methylenebisacrylamide, 0.05 mol of dodecanethiol, and dropwise add 4.2 mol of ammonia water with a concentration of 30% to The pH of the solution is 6.5; under nitrogen protection, add 6.0mol kerosene, 2.5mol sorbitan oleate, 0.02mol azobisisobutyronitrile, 1.4mol octadecyl acrylate, and emulsify at high speed for 50min; be warming up to 60~65 ℃, the reaction was carried out for 3 hours; finally, 2.1 mol of polyoxyethylene sorbitan monooleate was added for inverse emulsification for 60 minutes, and the salt-tolerant thickener was obtained after discharging.

Embodiment 2

[0019] Place the four-necked flask in an ice-water bath at -10 to 0°C, add 5.2 mol of acrylic acid, 2 mol of N,N'-methylenebisacrylamide, and 0.01 mol of dodecanethiol, and dropwise add 8.2 mol of ammonia water with a concentration of 30% to The pH of the solution is 7.0; under nitrogen protection, add 12mol kerosene, 6.0mol sorbitan oleate, 0.06mol azobisisobutyronitrile, 2.6mol octadecyl acrylate, and emulsify at high speed for 60min; heat up to 60-65°C , the reaction was carried out for 3.5h; finally, 4.2mol of polyoxyethylene sorbitan monooleate was added for inverse emulsification for 60min, and the salt-tolerant thickener was obtained after discharging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com