Ink printing pap+er box, printing ink and production process thereof

An ink printing and carton technology, applied in the field of printing, can solve the problems of insufficient tinting strength, glossiness and adhesion, and poor storage performance, and achieve the effects of excellent printing adaptability, excellent printing quality and excellent printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

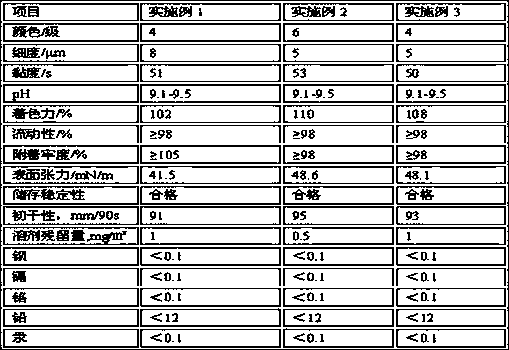

Embodiment 1

[0033] The production process of the printing ink comprises the following steps: S1, the raw materials in the following weight ratio: 10 parts of acrylic acid monomer, 1 part of pH regulator, 2 parts of emulsifier, 5 parts of soybean oil, 0.2 part of phosphite, 1 part Dodecanethiol, 1 part of hydroxyethyl acrylate and 2 parts of deionized water are mixed to form a pre-emulsion. When it is heated to 85°C, it is pre-emulsified at a stirring speed of 350r / min for 20 minutes; S2, add 0.3 parts of initiator to the pre-emulsion, maintain a stirring speed of 150r / min under a nitrogen atmosphere, and stir for 35 minutes to form a semi-emulsion; S3, add 10 parts of acrylic acid monomer to the semi-emulsion, 2 1 part of deionized water, 2 parts of pH adjuster, 2 parts of emulsifier, 0.2 part of initiator, stirred at a stirring speed of 280r / min for 3h, emulsified and cooled to 25°C to form a composite polyacrylate emulsion; S4, 40 parts Composite polyacrylate emulsion, 40 parts of color...

Embodiment 2

[0035] The production process of the printing ink comprises the following steps: S1, the raw materials in the following weight ratio: 10 parts of acrylic acid monomer, 2 parts of water, 2 parts of pH regulator, 2 parts of emulsifier, 10 parts of soybean oil, 0.2 part of phosphorous acid Ester, 1 part of dodecanethiol, 3 parts of hydroxyethyl acrylate and 2 parts of deionized water are mixed to form a pre-emulsion, and when it is heated to 85-95 ° C, it is pre-emulsified at a stirring speed of 350r / min , the stirring time is 20min; S2, add 0.2 parts of initiator to the pre-emulsion, keep the stirring speed of 150r / min under the nitrogen atmosphere, and the stirring time is 35min to form a semi-emulsion; S3, add 18 to the semi-emulsion 1 part of acrylic acid monomer, 3 parts of deionized water, 2 parts of pH adjuster, 3 parts of emulsifier, 1 part of initiator, stirred at a stirring speed of 280r / min for 3h, emulsified and cooled to 25°C to form a composite polyacrylate emulsion ...

Embodiment 3

[0037] The production process of the printing ink comprises the following steps: S1, the raw materials in the following weight ratio: 20 parts of acrylic acid monomer, 3 parts of pH regulator, 5 parts of emulsifier, 10 parts of soybean oil, 0.2 part of phosphite, 2 parts Dodecanethiol, 5 parts of hydroxyethyl acrylate and 5 parts of deionized water are mixed to form a pre-emulsion. When it is heated to 85-95°C, it is pre-emulsified at a stirring speed of 350r / min. The stirring time is 20min; S2, add 1 part of initiator to the pre-emulsion, maintain a stirring speed of 150r / min under a nitrogen atmosphere, and stir for 35 minutes to form a semi-emulsion; S3, add 15 parts of acrylic acid monomer to the semi-emulsion , 5 parts of deionized water, 2 parts of pH regulator, 5 parts of emulsifier, 1 part of initiator, stirred at a stirring speed of 280r / min for 3h, emulsified and cooled to 25°C to form a composite polyacrylate emulsion; S4, the 50 parts of composite polyacrylate emul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com