Package substrate having embedded capacitor

a technology of capacitors and substrates, applied in the field of packaging substrates, can solve the problems of discrete capacitors b>130/b> easily damaged or broken, and hardly enhance the performance of a conventional circuit substrate, and achieve the effect of enhancing space and degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

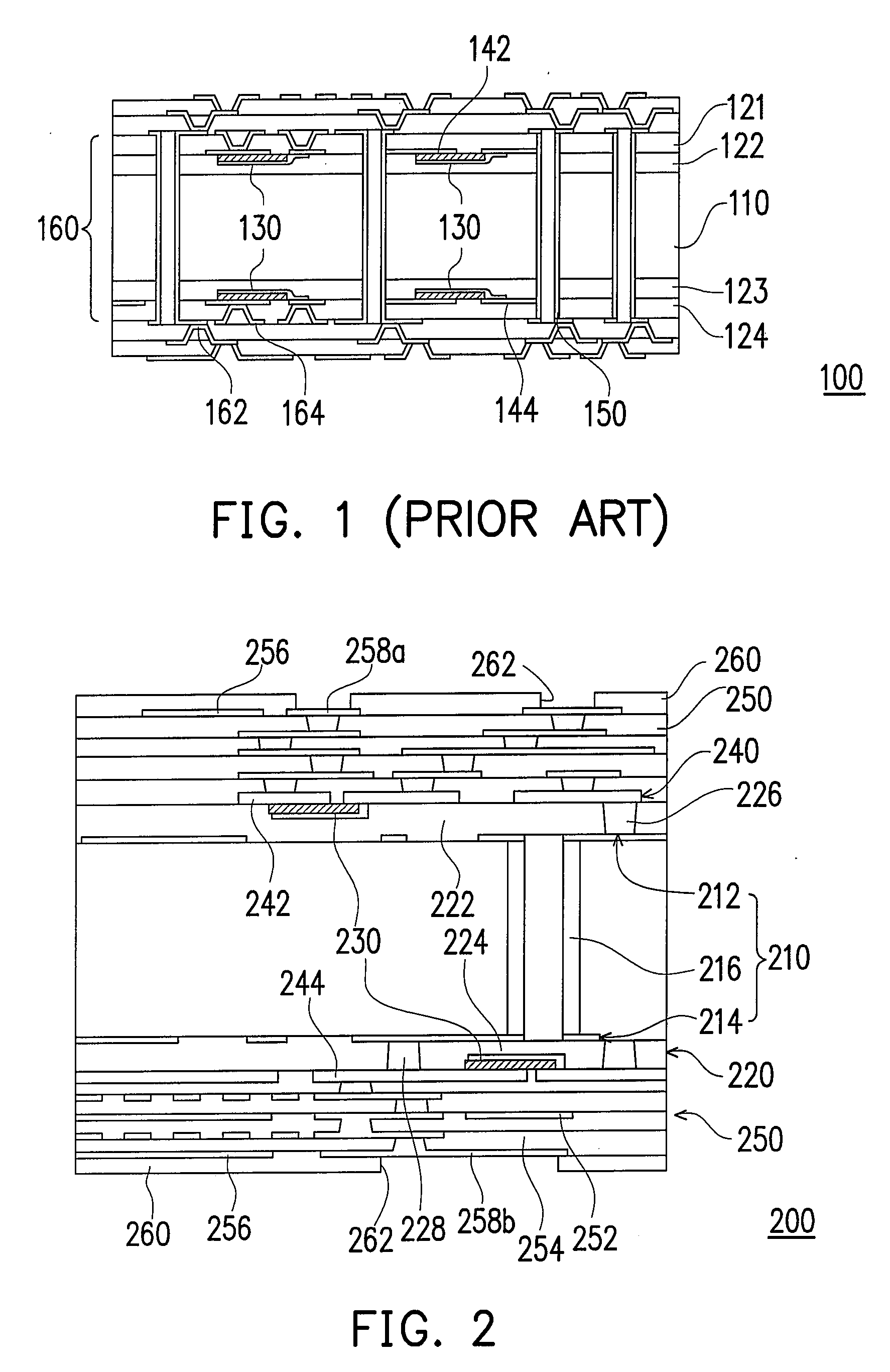

[0028]FIG. 2 is a schematic diagram of a portion of a package substrate having embedded capacitor according to the present invention. The package substrate 200 mainly includes a core circuit board 210, a dielectric layer 220, at least one embedded capacitor 230 and a metal layer 240. The core circuit board 210 is, for example, a copper foil substrate with glass fiber and epoxy resin serving as insulating material so as to enhance the strength and support of the package substrate 200. In addition, the core circuit board 210 has at least one conductive through hole 216. The method of forming the conductive through hole 216 includes, for example, performing a mechanical drilling to form a through hole and then performing an electrochemical plating to form a layer of conductive material on the inner sidewall of the through hole. As a result, the upper and lower copper foils are connected through the conductive through hole 216. After an etching operation is performed to pattern the copp...

second embodiment

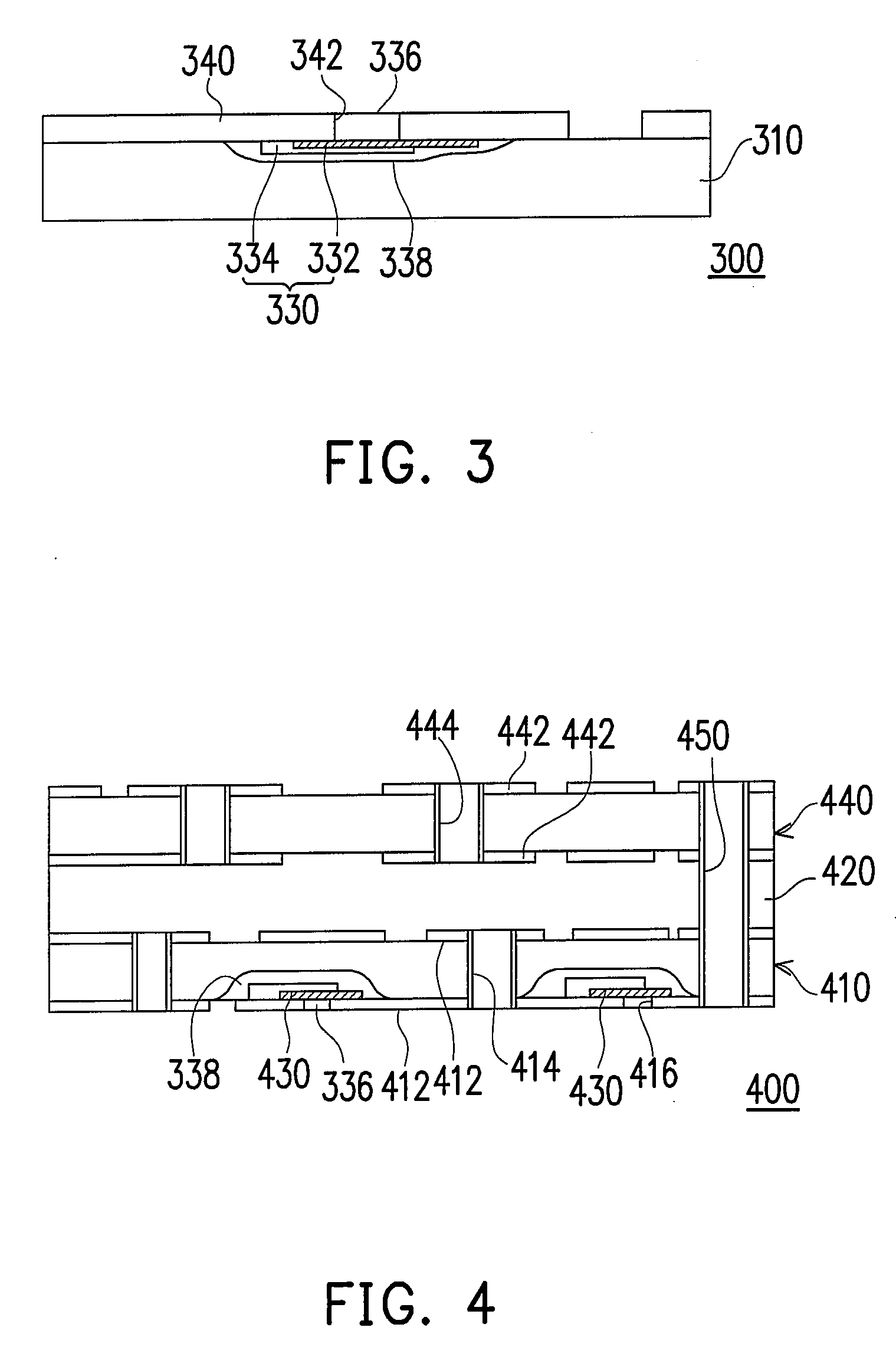

[0033]FIG. 3 is a schematic diagram of a portion of a package substrate having embedded capacitor according to the present invention. The package substrate 300 mainly includes a core board 310, at least one embedded capacitor 330, a first passivation layer 338 and a metal layer 340. The core board 310 is a substrate fabricated using glass fibers and epoxy resin as its insulating material so as to enhance the strength and support of the package substrate 300. In addition, the embedded capacitor 330 is embedded in the core board 310 and electrically connected to the metal layer 340. In the present embodiment, the embedded capacitor 330 can be an epoxy resin-ceramic composite capacitor or other ceramic / polymer composite capacitor with high dielectric constant formed on the metal layer 340 after performing a high-temperature sintering process. Afterwards, electrode material covers the dielectric material 332 to form an electrode 334 connected to the metal layer 340.

[0034]To prevent the ...

third embodiment

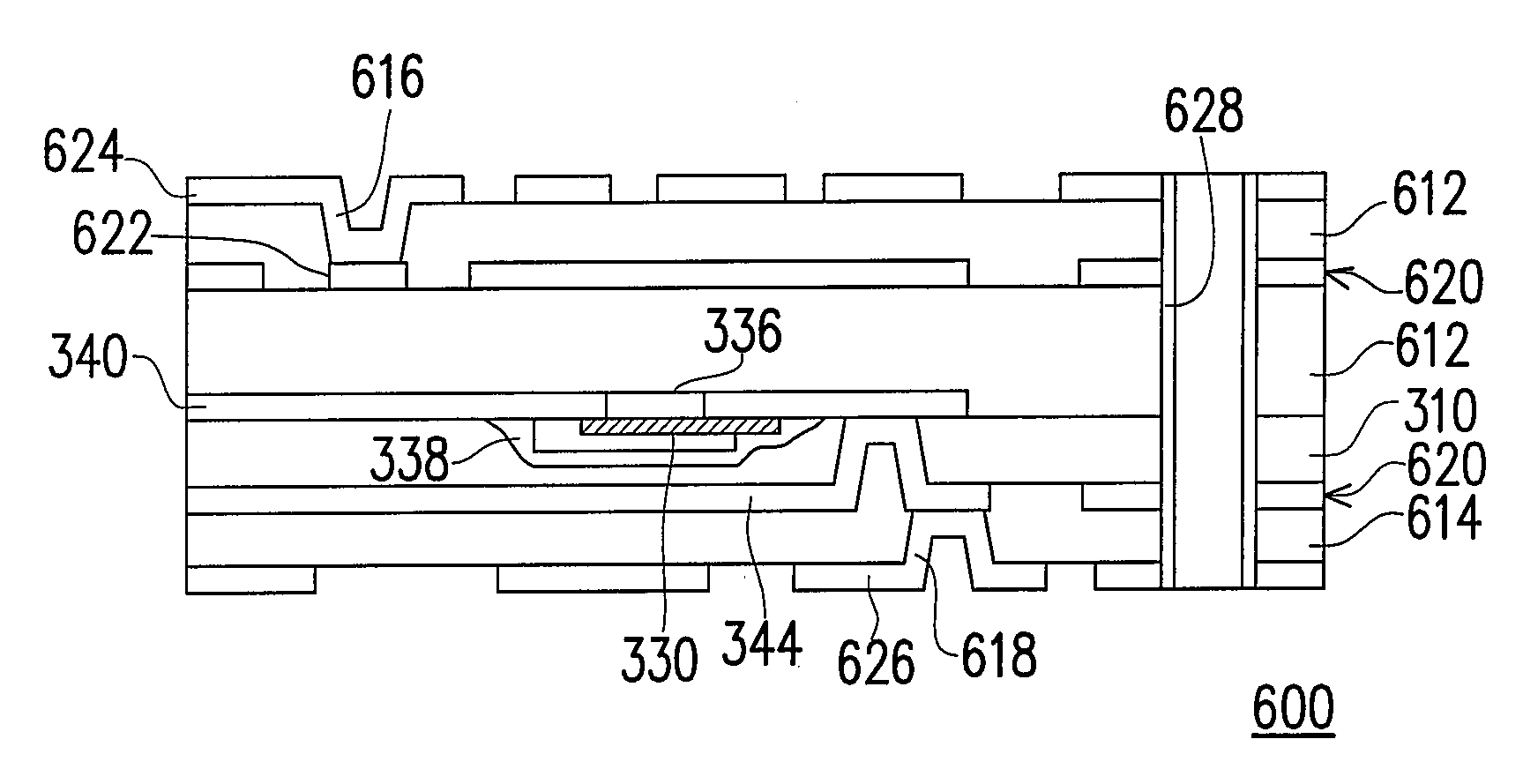

[0035]FIG. 4 is a schematic diagram of a portion of a package substrate having embedded capacitor according to the present invention. The package substrate 400 mainly includes a first core circuit board 410, a dielectric layer 420, at least one embedded capacitor 430 and a second core circuit board 440. The first and second core circuit boards 410 and 440 are, for example, copper foil substrates using glass fiber or epoxy resin as the insulating material so as to enhance the strength and support of the package substrate 400. In addition, the dielectric layer 420 can be cured or semi-cured glass fiber epoxy resin laminated between the first and the second core circuit board 410 and 440. In the present embodiment, the two opposing surfaces of the first core circuit board 410 have a metal layer 412 and at least one first conductive through hole 414 of the first core circuit board 410 is connected to the metal layer 412. The embedded capacitor 430 is embedded in the first core circuit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com