Preparation method and application of CdHgTe quantum dot solution, CdHgTe quantum dot and bimodal semiconductor nanometer material

A technology of quantum dot solution and nanomaterials, applied in the field of dual-mode semiconductor nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

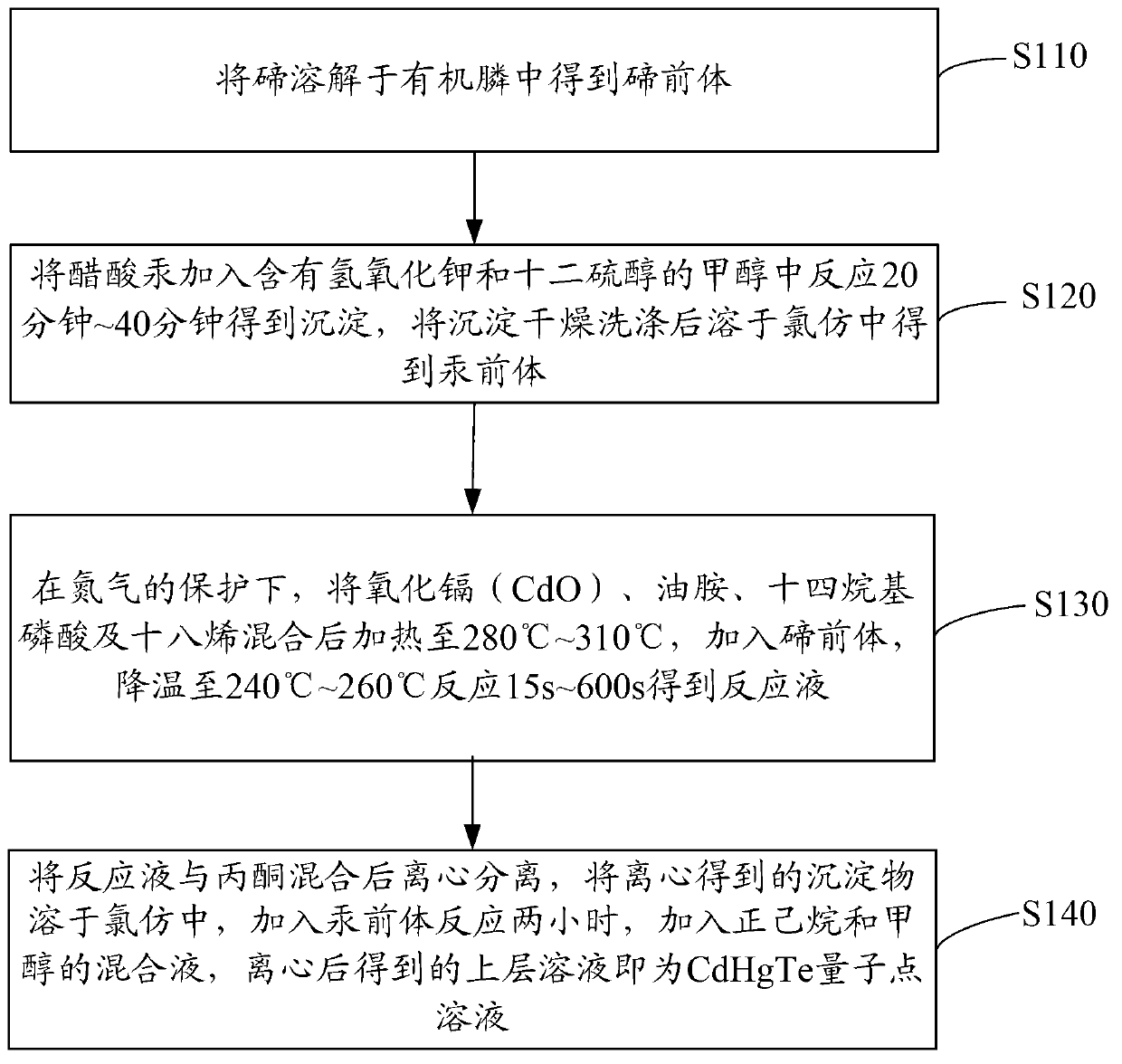

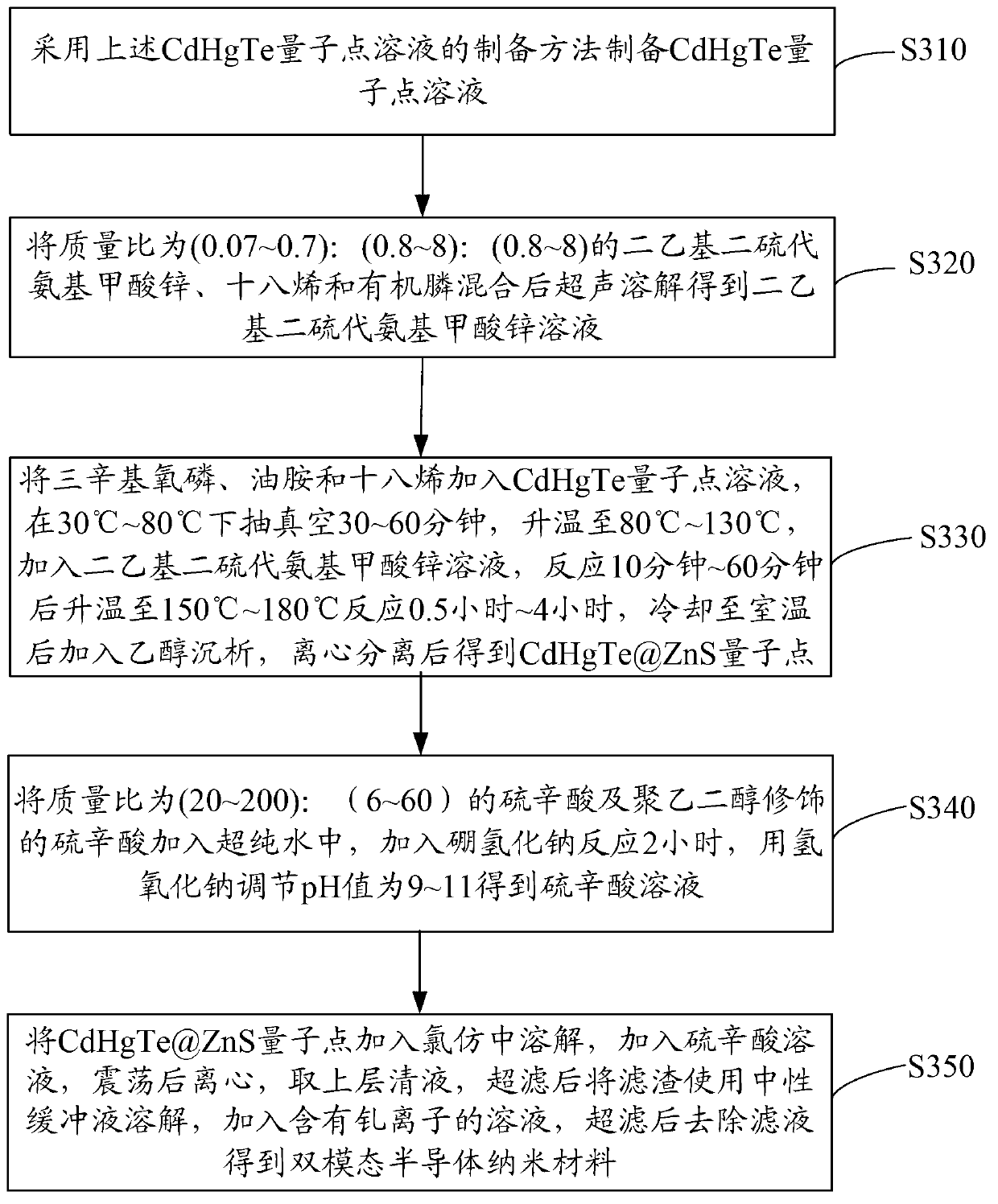

[0032] see figure 1 , the preparation method of the CdHgTe quantum dot solution of an embodiment, comprises the steps:

[0033] Step S110 , dissolving tellurium (Te) in organic phosphine to obtain a tellurium precursor.

[0034] Wherein, the organic phosphine is selected from at least one of trioctylphosphine and tributylphosphine, and the mass ratio of tellurium to organic phosphine is (0.0128-0.128):(0.1-1).

[0035] Preferably, tellurium is tellurium powder.

[0036] Preferably, the tellurium powder is dissolved in the organic phosphine by ultrasonication at 80°C to 100°C. Further, add tellurium (Te) powder into a glass bottle in the glove box, then add organic phosphine, cover the lid, take it out from the glove box and perform ultrasonication.

[0037] Step S120 , adding mercuric acetate to methanol containing potassium hydroxide and dodecanethiol to react for 20-40 minutes to obtain a precipitate, drying and washing the precipitate and dissolving it in chloroform to o...

Embodiment 1

[0080] 1. Preparation of Te precursor: Add 0.0128 Te powder into a 20 mL glass bottle in a glove box, and then add 0.1 g of trioctylphosphine. Cap and remove from the glove box and heat to 100 °C until Te is completely dissolved.

[0081] 2. Hg precursor: At room temperature, add 1 mmol of mercuric acetate dropwise to 3 mmol of dodecanethiol in methanol solution containing potassium hydroxide, react for 20 min, then filter the precipitate, wash once with methanol and ether, and dry in vacuum. Take 0.0245g and add it into 0.5ml chloroform, set aside.

[0082] 3. Zinc diethyldithiocarbamate solution: Add 0.07g zinc diethyldithiocarbamate, 0.8g octadecene and 0.8g trioctylphosphine into a 20mL glass bottle in the glove box, cover Cap and remove from glove box, sonicate until completely dissolved.

[0083] 4. Add 0.0257g of CdO, 8ml of octadecene, 1g of oleylamine and 0.122g of myristyl phosphoric acid into a 100mL three-necked round-bottomed flask, pass N 2 and heated to 300°C...

Embodiment 2

[0090] 1. Preparation of Te precursor: Add 0.064g Te powder into a 20mL glass bottle in the glove box, then add 0.5g tributylphosphine, close the lid and take it out from the glove box, ultrasonic (can be heated to 100°C ) until Te is completely dissolved.

[0091] 2. Hg precursor: At room temperature, add 1 mmol of mercuric acetate dropwise to 3 mmol of dodecanethiol in methanol solution containing potassium hydroxide, react for 20 min, then filter the precipitate, wash once with methanol and ether, and dry in vacuum. Take 0.0245g and add it into 0.5ml chloroform, set aside.

[0092] 3. Zinc diethyldithiocarbamate solution: Add 0.14g zinc diethyldithiocarbamate, 1.6g octadecene and 1.6g tributylphosphine into a 20mL glass bottle in a glove box, and cover Cap and remove from glove box, sonicate until completely dissolved.

[0093] 4. Add 0.0257g of CdO, 8ml of octadecene, 1g of oleylamine and 0.122g of myristyl phosphoric acid into a 100mL three-necked round-bottomed flask, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com