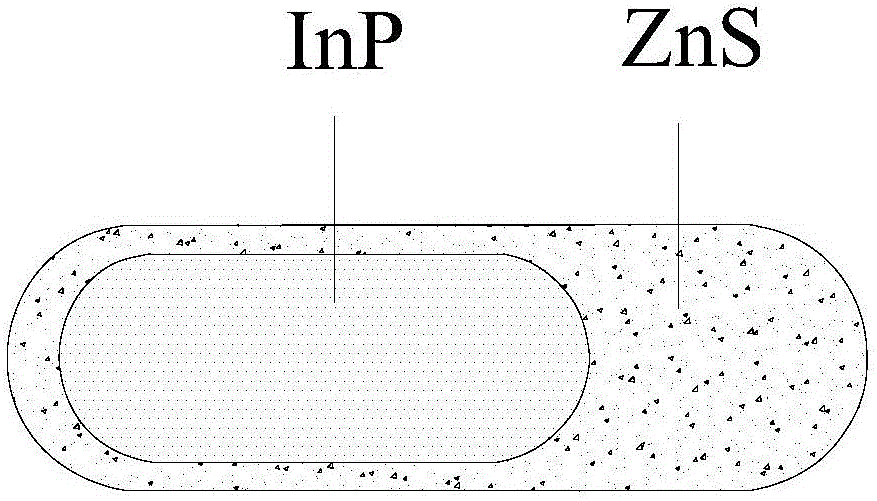

Preparation method of core-shell InP/ZnS nanorods

A core-shell structure, nanorod technology, applied in nanotechnology, nano-optics, nanotechnology and other directions, can solve the problems of high laser emission threshold, limited application fields, and quantum dots have no linear polarization absorption and polarization emission, etc. Effects of laser emission threshold, suppression of radiative recombination, large linearly polarized absorption and polarized emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The embodiment of the present invention provides a method for preparing InP / ZnS nanorods with a core-shell structure, comprising the following steps:

[0015] S01. Under an inert atmosphere, mix indium chloride or indium oxide, trioctylphosphine oxide, dodecylamine and trioctylphosphine to obtain a mixed solution, and heat and degas the mixed solution under vacuum conditions to degas the degassed solution. The gaseous mixed solution is heated to 170-270°C under an inert atmosphere until a transparent indium precursor solution is formed;

[0016] S02. Under an inert atmosphere, mix and treat tris(trimethylsilyl)phosphine, diphenyl ether and biphenyl to prepare a tris(trimethylsilyl)phosphine precursor;

[0017] S03. Under an inert atmosphere, after raising the temperature of the indium precursor solution to 290-320°C, inject the tris(trimethylsilyl)phosphine precursor into the indium precursor solution, and then adjust the temperature to 295-305°C, react to obtain InP n...

Embodiment 1

[0033] A preparation method of InP / ZnS nanorods of core-shell structure, comprising the following steps:

[0034] S11. Under an inert gas atmosphere, mix 0.45 mmol of indium chloride, 0.1 mmol of trioctyl phosphine oxide, 0.2 mmol of dodecylamine and 9 mmol of trioctyl phosphine, then heat the mixture to 120°C under vacuum and Degas for 30mins, and then heat the degassed mixed solution to 230°C under an inert atmosphere until a transparent solution is formed to obtain an indium precursor solution;

[0035] S12. Under an inert gas atmosphere, mix 0.45mmol tris(trimethylsilyl)phosphine, 0.05mmol diphenyl ether and 0.05mmol biphenyl through an oscillator to obtain a tris(trimethylsilyl)phosphine precursor;

[0036] S13. In an inert gas atmosphere, raise the temperature of the indium precursor to 310°C, then quickly inject the tris(trimethylsilyl)phosphine precursor into the indium precursor solution, then adjust the heating temperature to 300°C, and obtain InP after 120s Nanorod...

Embodiment 2

[0039] A preparation method of InP / ZnS nanorods of core-shell structure, comprising the following steps:

[0040] S21. Under an inert gas atmosphere, mix 0.5 mmol of indium oxide, 0.1 mmol of trioctyl phosphine oxide, 0.2 mmol of dodecylamine and 7.5 mmol of trioctyl phosphine, then heat the mixture to 160°C under vacuum and Degassing for 25mins, and then heating the degassed mixed solution to 250°C under an inert atmosphere until a transparent solution is formed to obtain an indium precursor solution;

[0041] S22. Under an inert gas atmosphere, mix 0.6mmol tris(trimethylsilyl)phosphine, 0.06mmol diphenyl ether and 0.06mmol biphenyl through an oscillator to obtain a tris(trimethylsilyl)phosphine precursor;

[0042] S23. In an inert gas atmosphere, raise the temperature of the indium precursor to 300°C, then quickly inject the tris(trimethylsilyl)phosphine precursor into the indium precursor solution, then adjust the heating temperature to 298°C, and obtain InP after 200s Nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com