Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Synthetic process safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

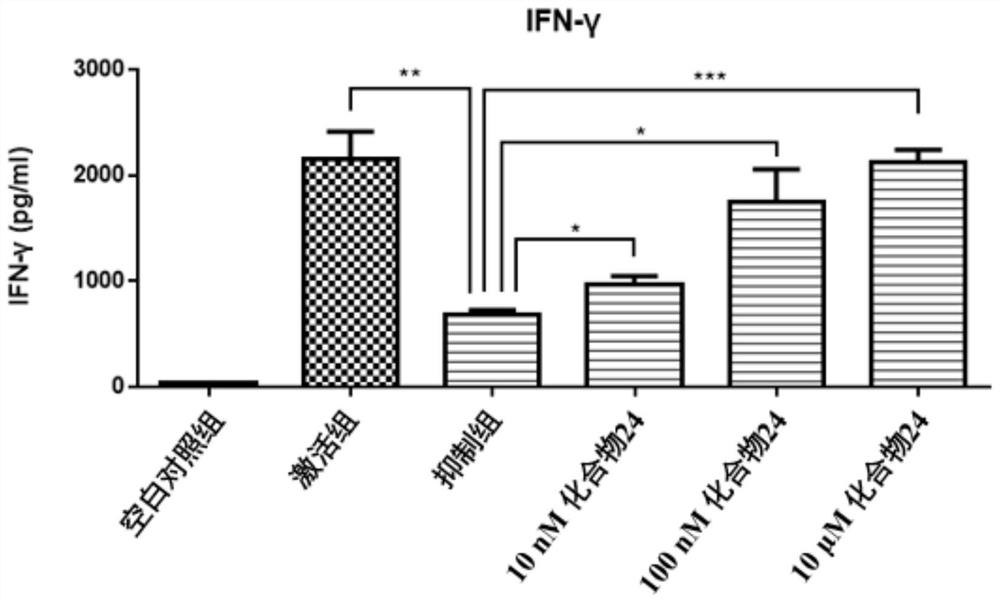

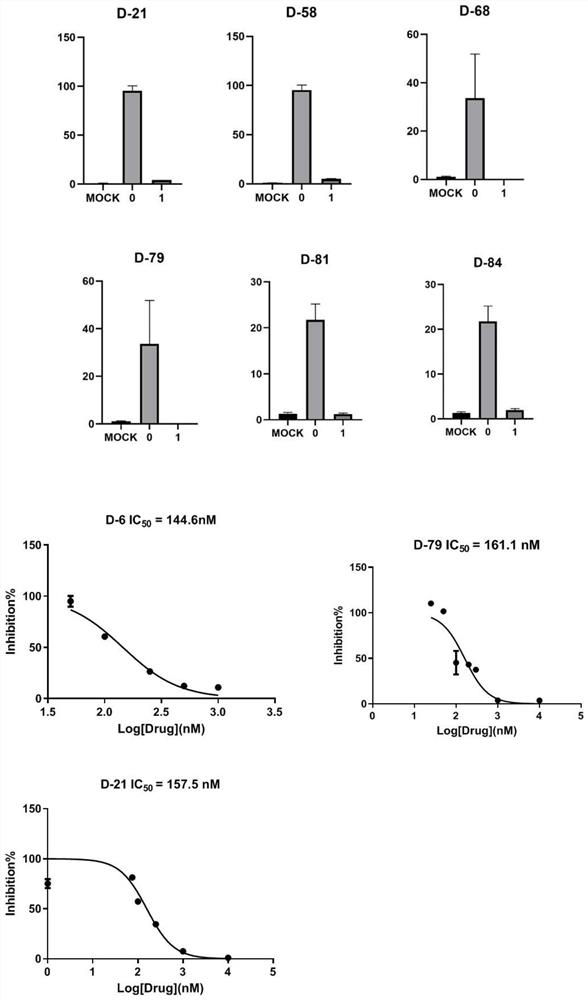

Benzoxadiazole compound and preparation method and medical use thereof

ActiveCN109776445AAvoid interactionPrevent proliferationOrganic active ingredientsOrganic chemistryMetaboliteImmunotherapy

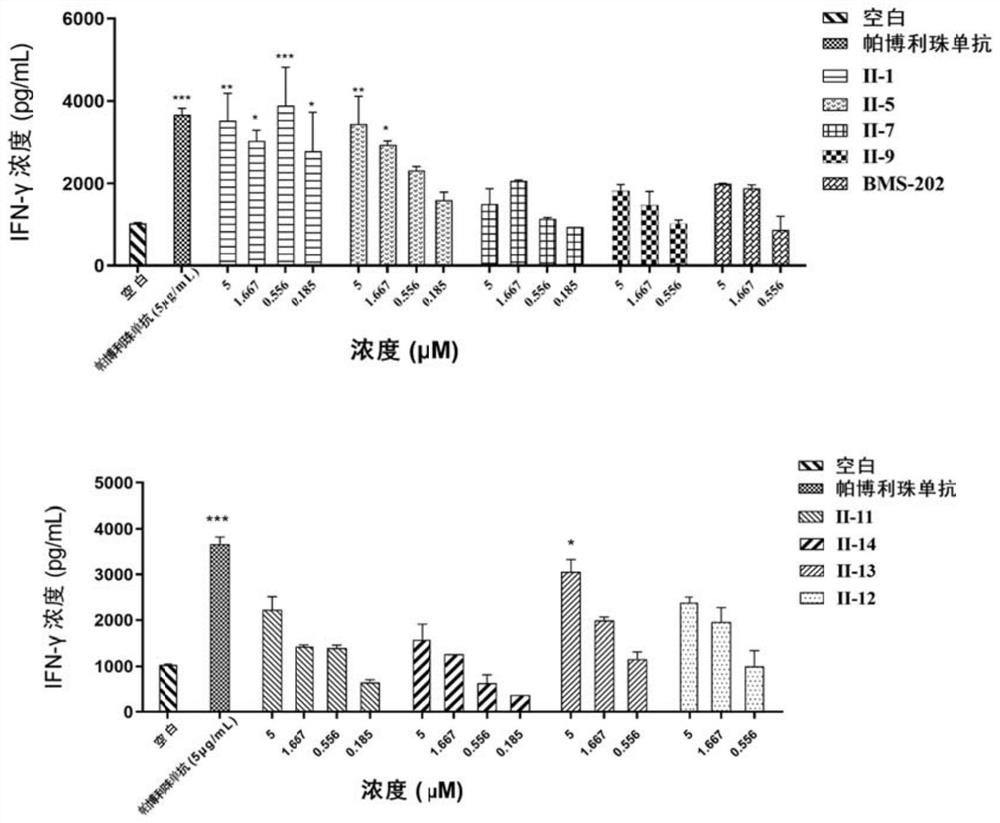

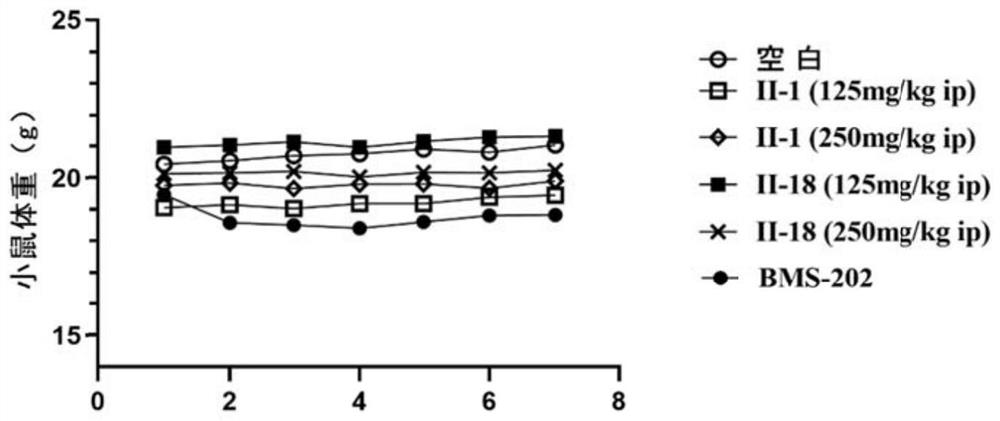

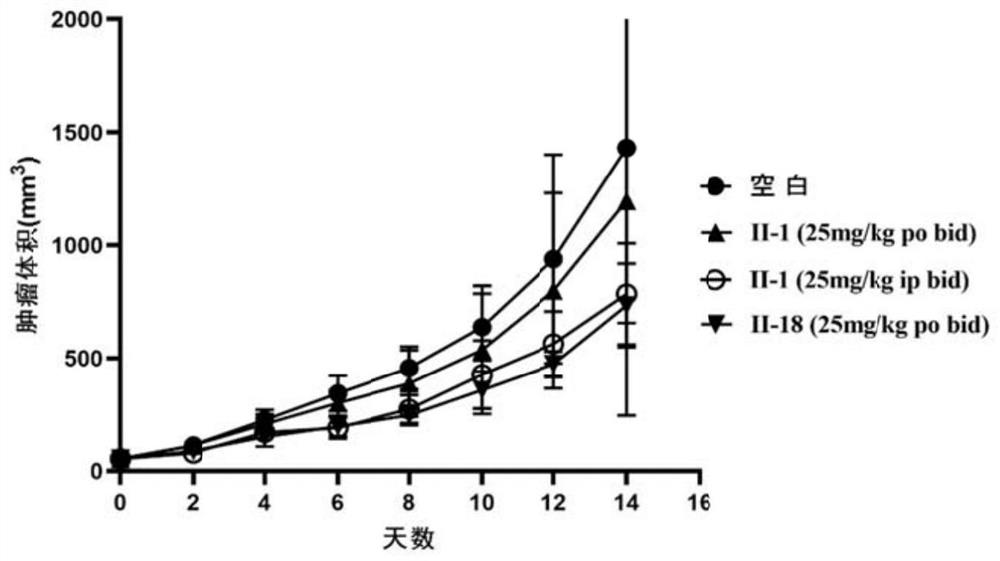

The invention discloses a benzoxadiazole compound and a preparation method and medical use thereof. The benzoxadiazole compound has the general structure shown in formula (I). The compound or pharmaceutically acceptable salts, tautomers, mesomers, racemates, stereoisomers, metabolites, metabolic precursors, prodrugs or solvates of the benzoxadiazole compound have an obvious inhibiting effect on PD-1 / PD-L1 protein-protein interaction, so that the benzoxadiazole compound shown in the description can be applied to the preparation of an inhibitor with a PD-1 / PD-L1 inhibitory activity and the immunotherapy of tumors as an immunocheckpoint inhibitor.

Owner:CHINA PHARM UNIV

Oil-based polyamide assistant emulsifier for drilling fluids, and preparation method thereof

InactiveCN105907381AStrong emulsifying abilityHigh temperature resistanceDrilling compositionPolymer sciencePolyamide

The invention discloses an oil-based polyamide assistant emulsifier for drilling fluids, and a preparation method thereof. The oil-based polyamide assistant emulsifier is prepared through a dehydration polycondensation reaction of diacid anhydrides, polyalkenepolyamine and aliphatic acid, wherein a molar ratio of the diacid anhydrides to polyalkenepolyamine to aliphatic acid is 1:1:1.4-4. The emulsifier is a macromolecular polymer surfactant, per unit mass of the emulsifier contains more lipophilic and hydrophilic groups, and the emulsifying efficiency is high; hydrophilic groups in the molecular structure is an amido structure, so the emulsifier has good high-temperature resistance; and the emulsifier and a wetting agent have synergism, so the wetting reversal of solid phase surface is facilitated.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

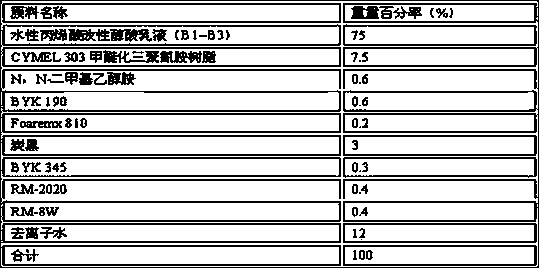

Preparation method for water-based acrylic acid modified alkyd emulsion and its amino baking varnish

InactiveCN103467747AReduce reactivityThe synthesis process is simplePolyester coatingsMethacrylatePolymer science

The invention relates to a water-based acrylic acid modified alkyd emulsion, the synthetic formula of which consists of the following components (by weight percentage): 9%-11% of diol or polyol; 9%-11% of polycarboxylic acid or anhydride; 0.01%-0.2% of a catalyst; 14%-19% of unsaturated fatty acid; 4%-6% of (methyl) acrylic ester or a vinyl monomer; 2%-4% of methacrylic acid; 0.1%-0.5% of an initiator; 4%-6% of a cosolvent; 1.5%-2.5% of a neutralizing agent; and 45%-55% of deionized water. The water-based alkyd amino baking varnish based on the water-based acrylic acid modified alkyd emulsion involved in the invention has the advantages of: (1) good storage stability; (2) good self-crosslinking; (3) excellent water resistance and rust resistance; and (4) safe and convenient use.

Owner:JIAXING QINGHE GAOLI INSULATION MATERIAL

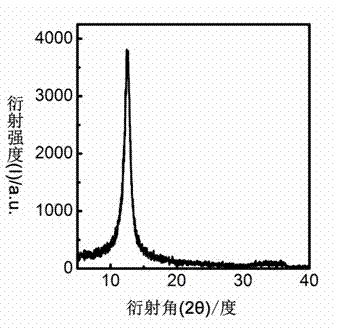

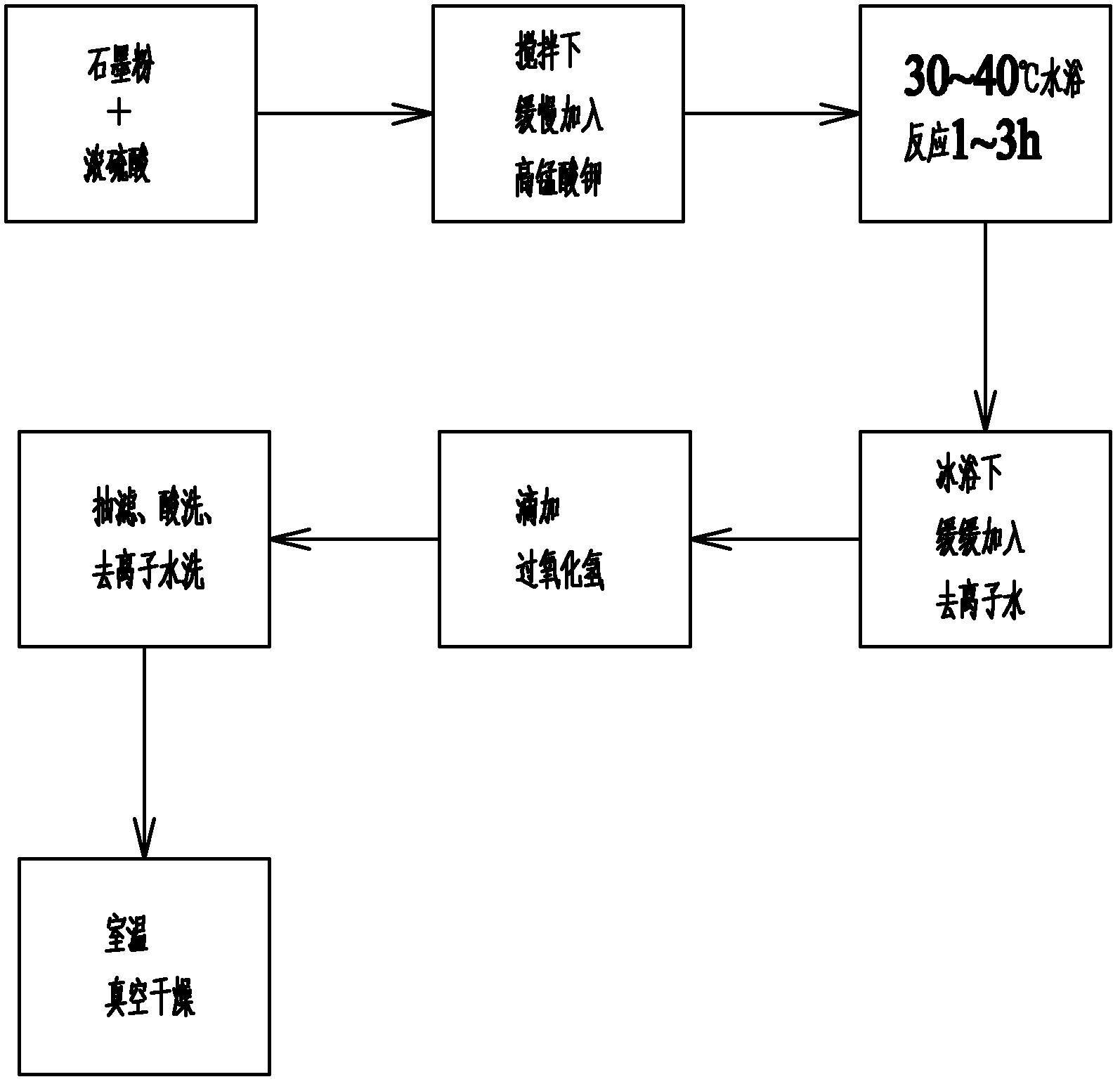

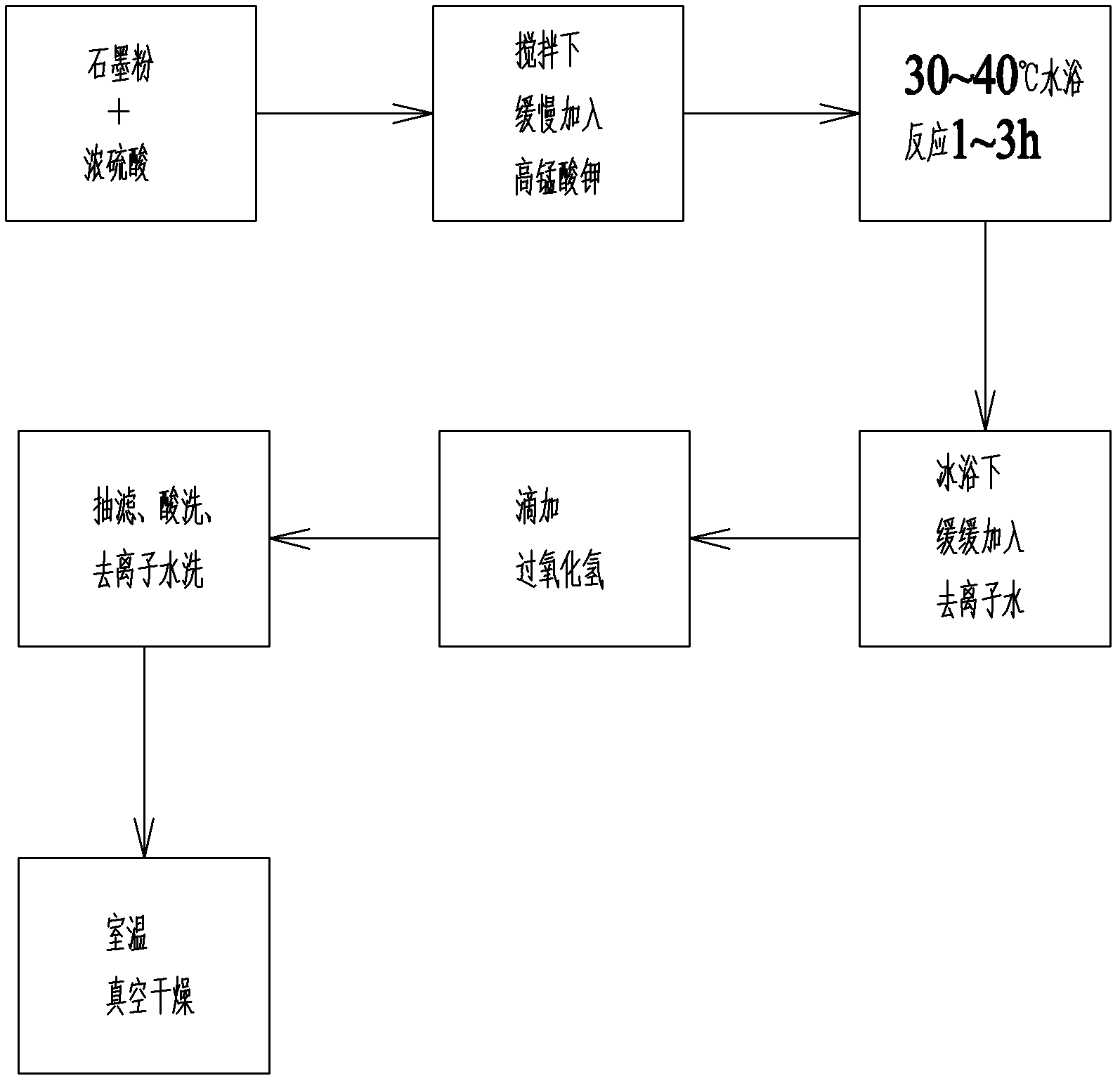

A kind of method for preparing graphite oxide by intercalation method

InactiveCN102275896AShort reaction timeHigh degree of oxygen insertionChemistryPotassium permanganate

The present invention relates to a method for preparing graphite oxide by intercalation, which comprises the following steps: firstly take graphite powder and place it in a reaction vessel, then add concentrated sulfuric acid and stir; then add potassium permanganate and stir; place the reaction vessel at 30 In a water bath at ~40°C; put the reaction vessel in an ice bath after heating in the water bath, add deionized water into the reaction vessel and stir; after cooling down in the ice bath, continue to add deionized water into the reaction vessel and stir; continue Stir, add hydrogen peroxide dropwise to the stepping container until no bubbles are generated; filter the insoluble matter in the suspension, wash with dilute hydrochloric acid and deionized water several times; filter the insoluble matter, and remove the The insoluble matter is placed in a vacuum oven and dried at room temperature for 1 to 2 days to obtain graphite oxide. The method of the invention has the advantages of short reaction time, high degree of oxygen intercalation, relatively safe synthesis process, suitable for large-scale production and the like.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

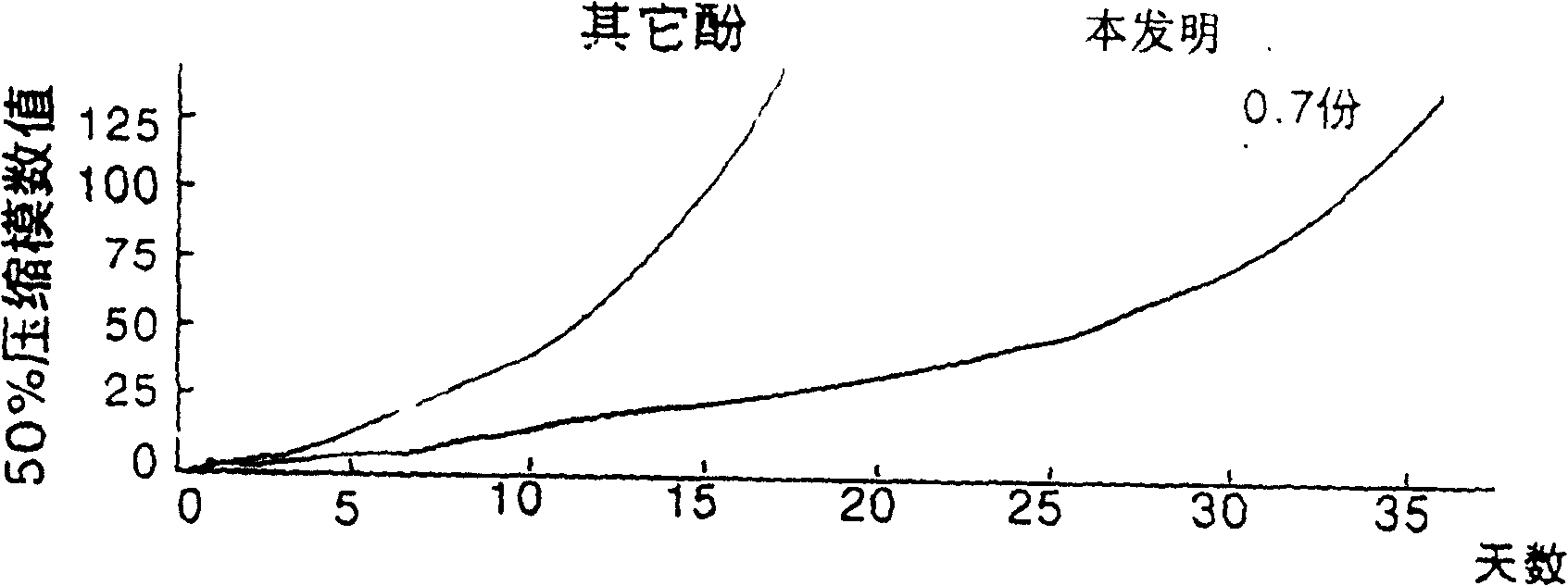

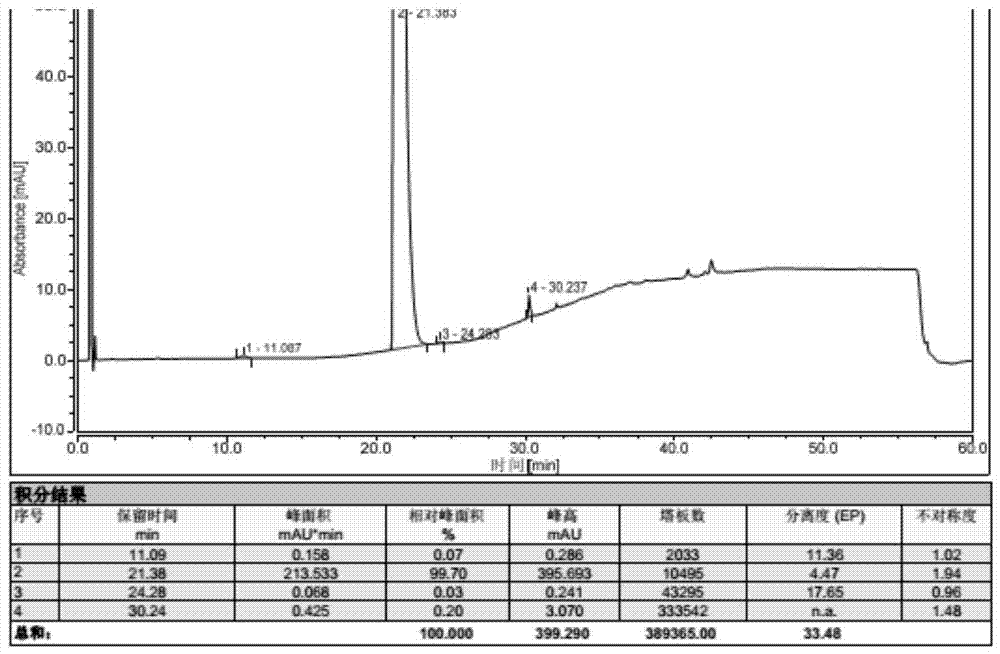

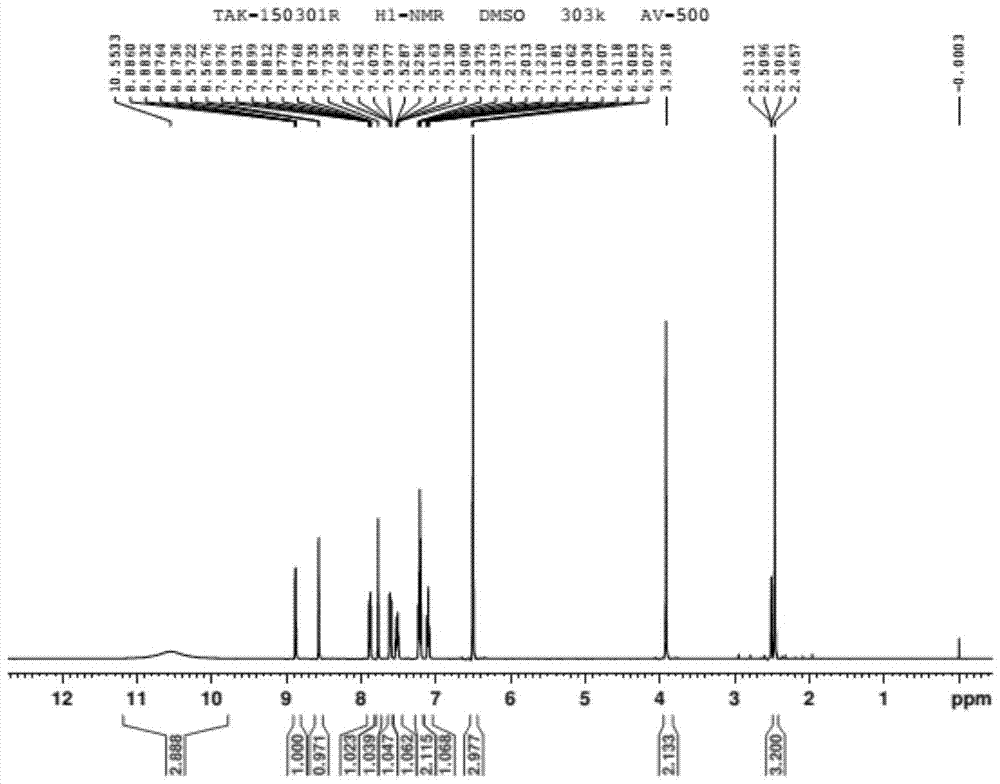

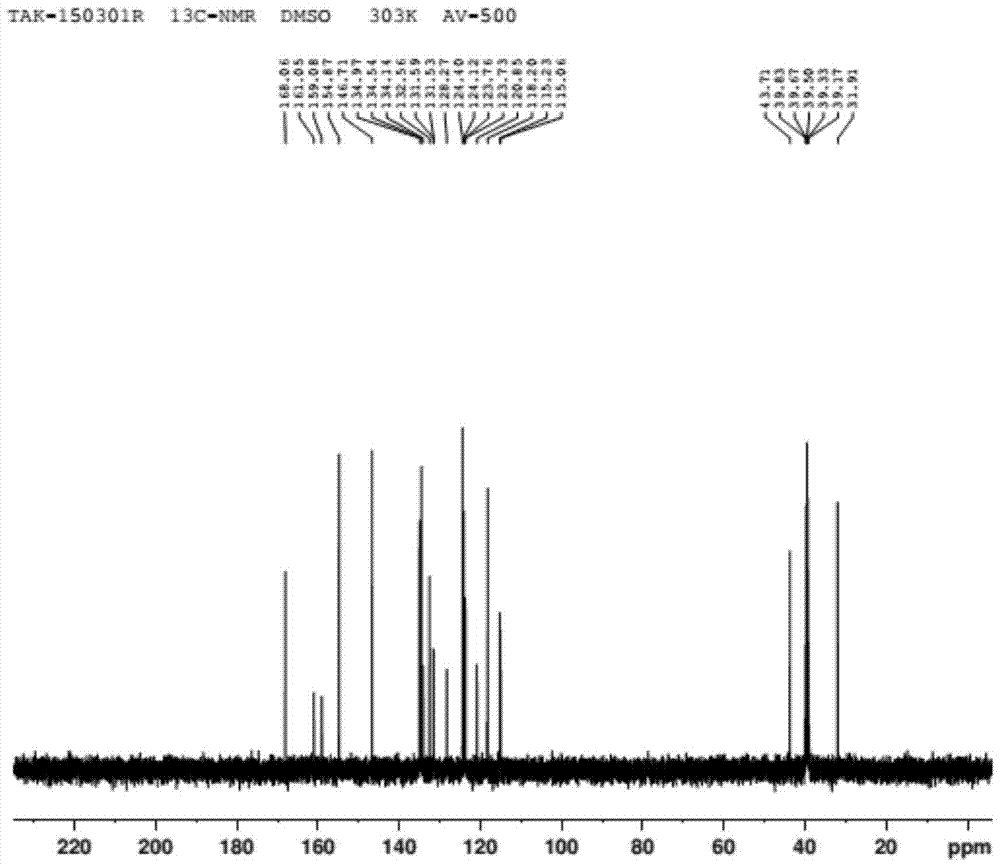

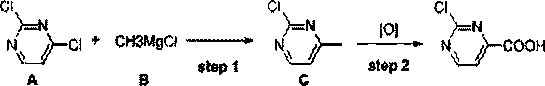

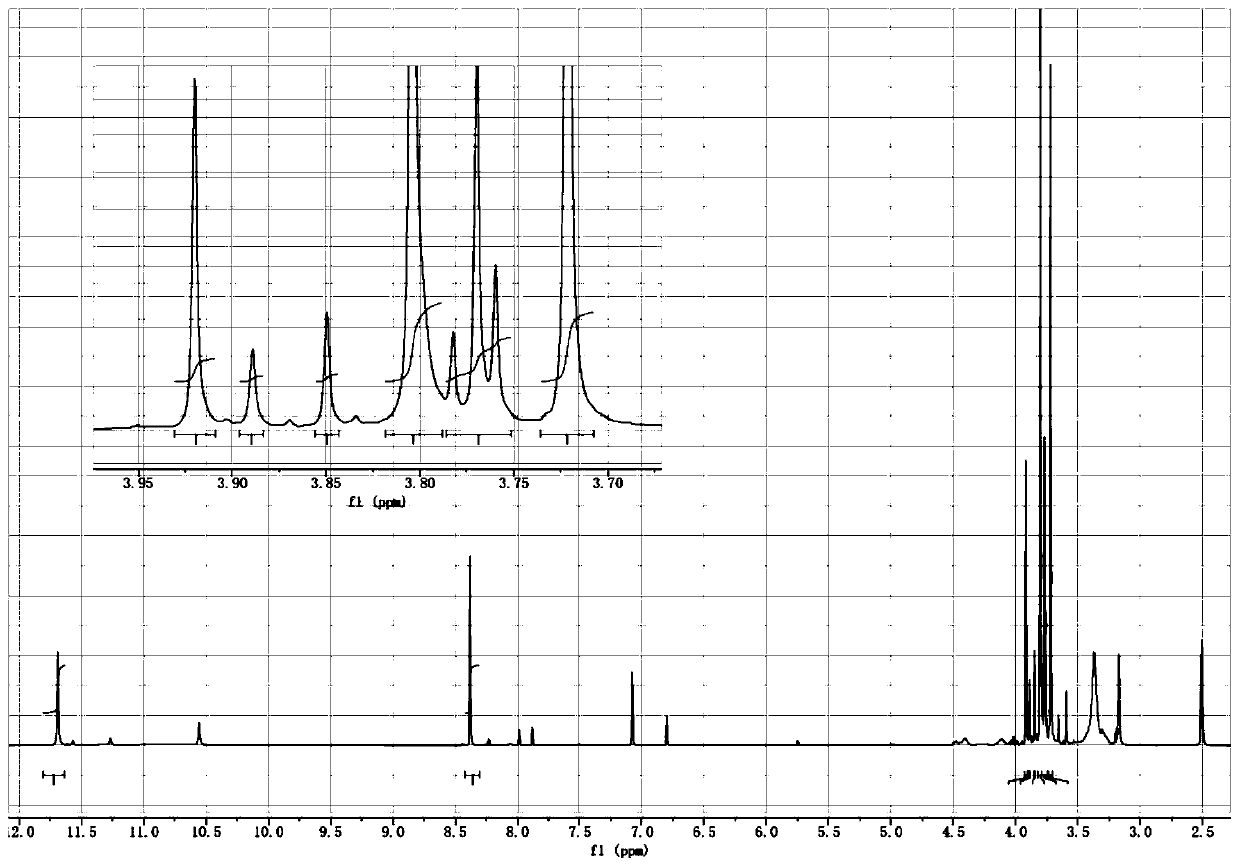

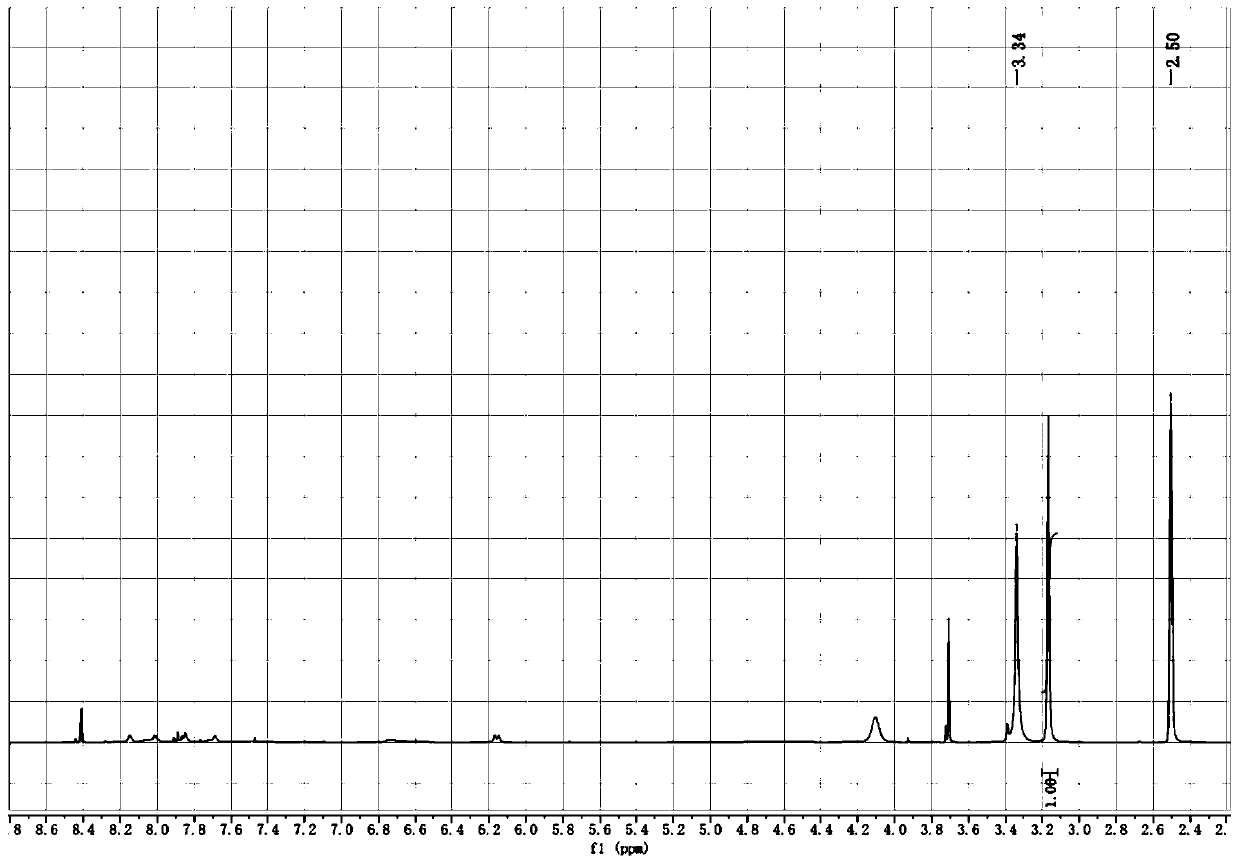

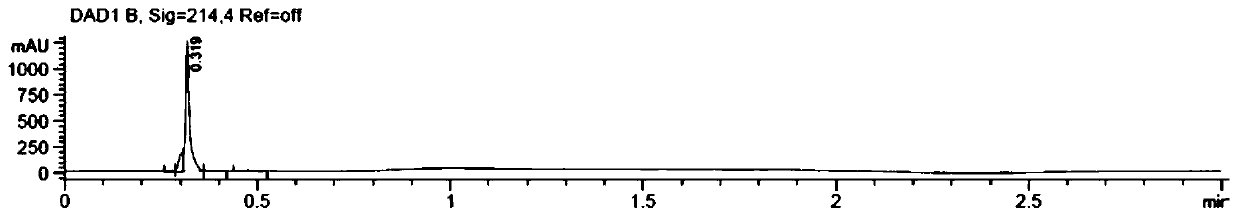

Preparation method of 4-chloropyrrolo[2,3-d]pyrimidine

InactiveCN101830904AShort process routeShorten the production cycleOrganic chemistryChemical synthesisSodium acetate

The invention provides a novel method for synthesizing 4-chloropyrrolo[2,3-d]pyrimidine, belonging to the technical field of chemical synthesis. The method comprises the steps of carrying out four-step reaction by using ethyl cyanoacetate, thiourea, caustic alcohol, 2-chloroacetaldehyde and sodium acetate as raw materials and using alcohol, ammonia water, water and phosphorus oxychloride as solvents as well as using active nickel as a catalyst to obtain the 4-chloropyrrolo[2,3-d]pyrimidine as a target product; and carrying out data representation by liquid chromatogram, nuclear magnetism spectrogram and mass spectrum. The invention has short process route and production cycle, low synthesis cost, safe and reliable synthesis and simple and convenient posttreatment method, and avoids the use of dangerous goods of sodium hydride. The product prepared by the method has high yield (50-58 percent) and high purity (98-99 percent).

Owner:兰州五龙新能源科技有限公司

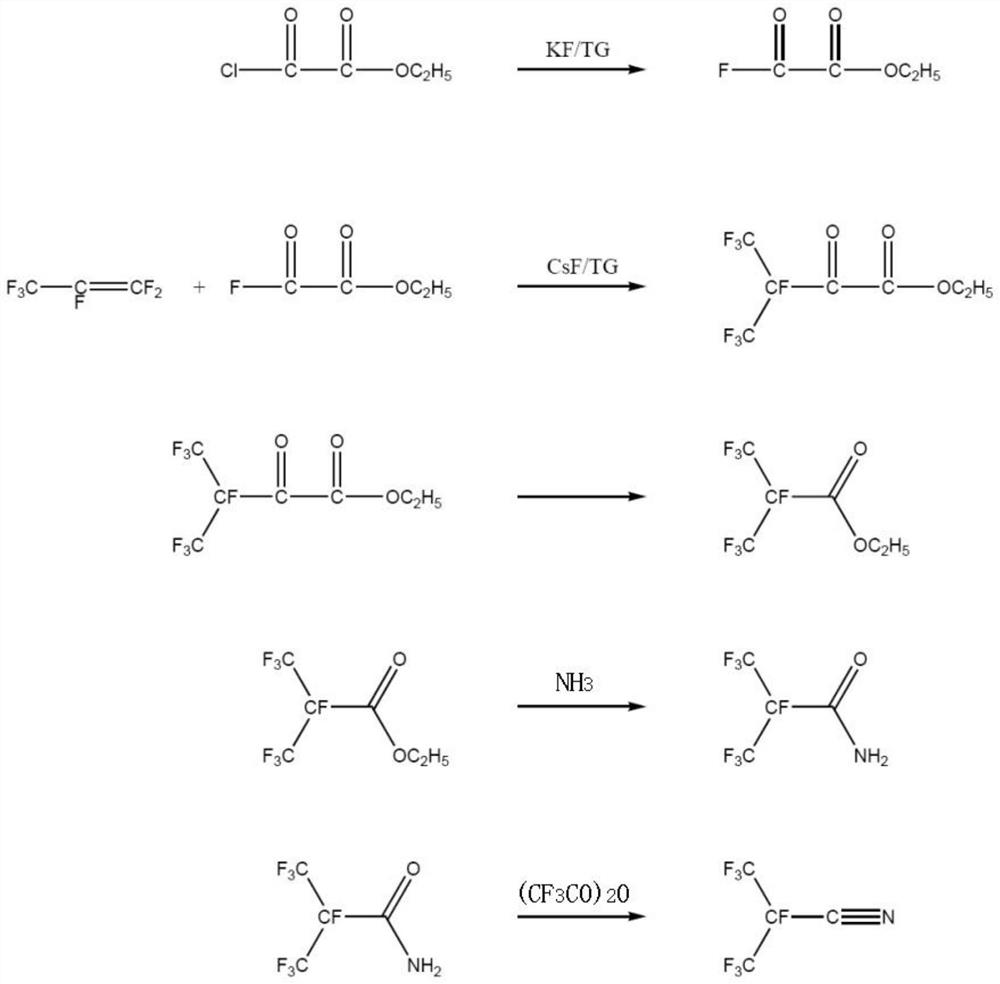

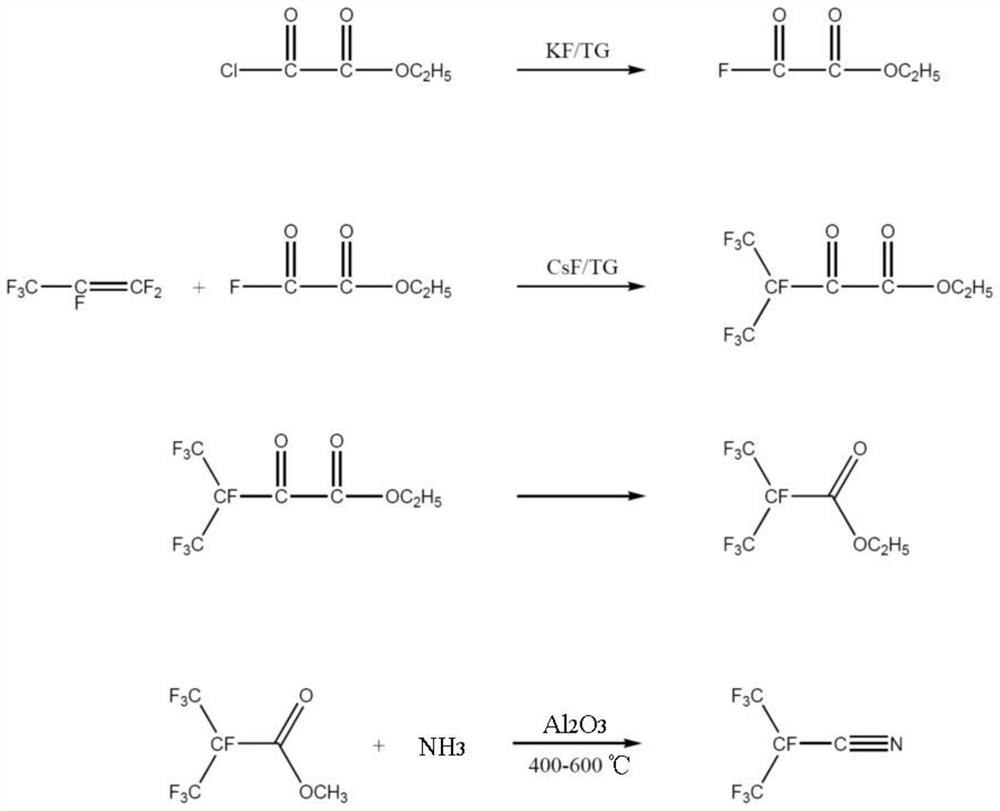

Synthetic method of perfluoroisobutyronitrile

PendingCN111825568ASynthetic process safetyEfficient synthesis processOrganic compound preparationCarboxylic acid esters preparationOxalyl fluoridePtru catalyst

Owner:福建省漳平市九鼎氟化工有限公司

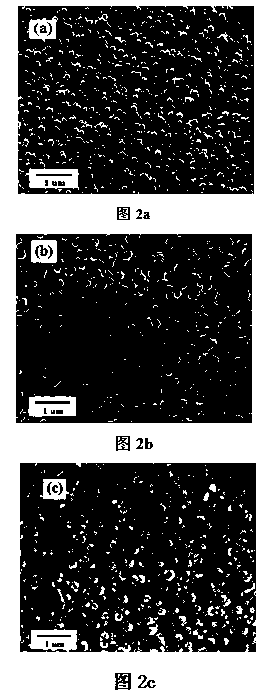

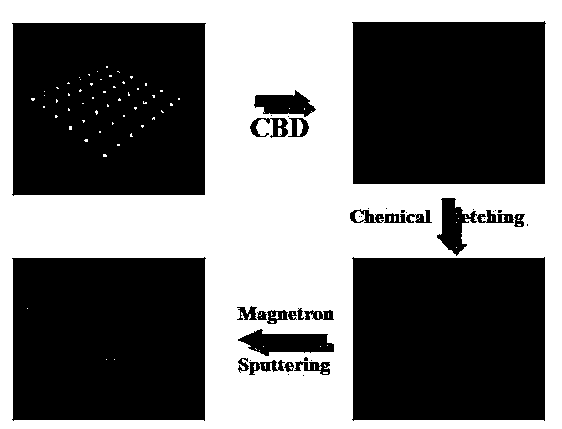

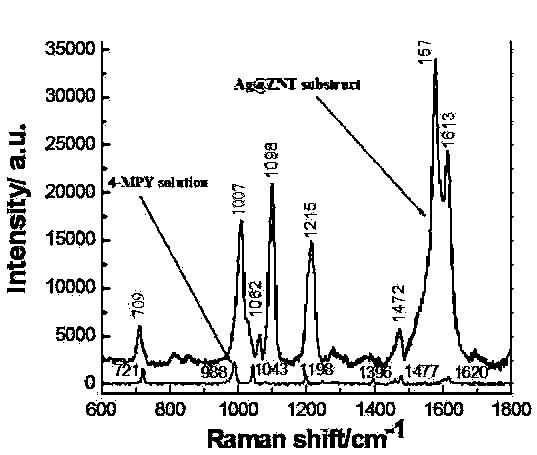

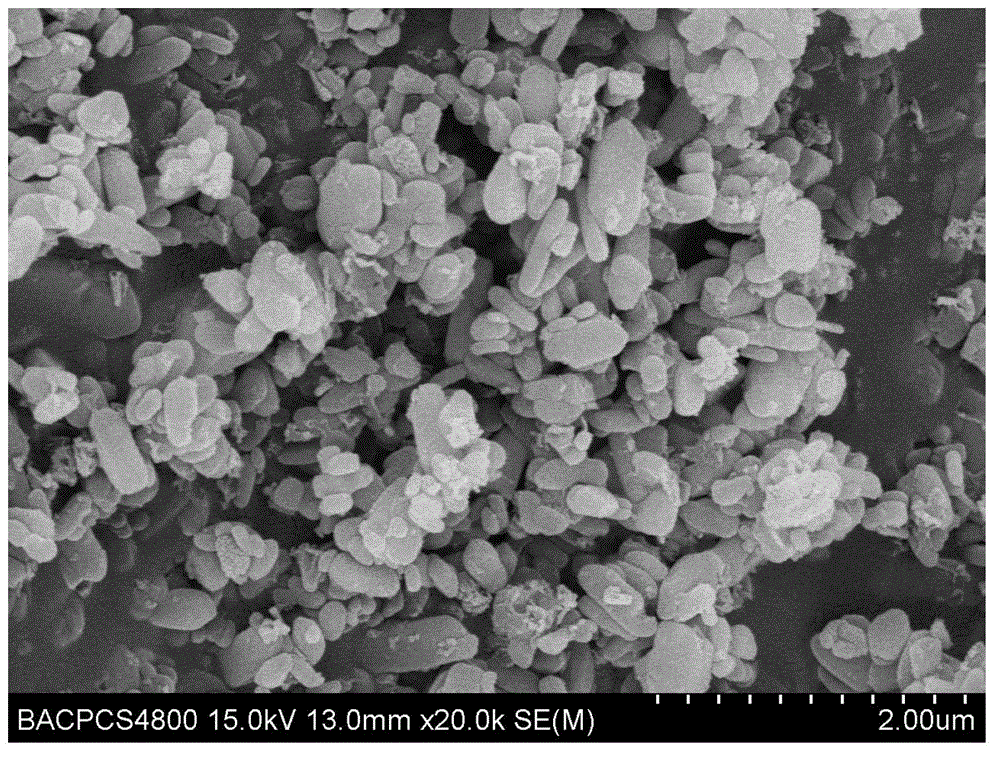

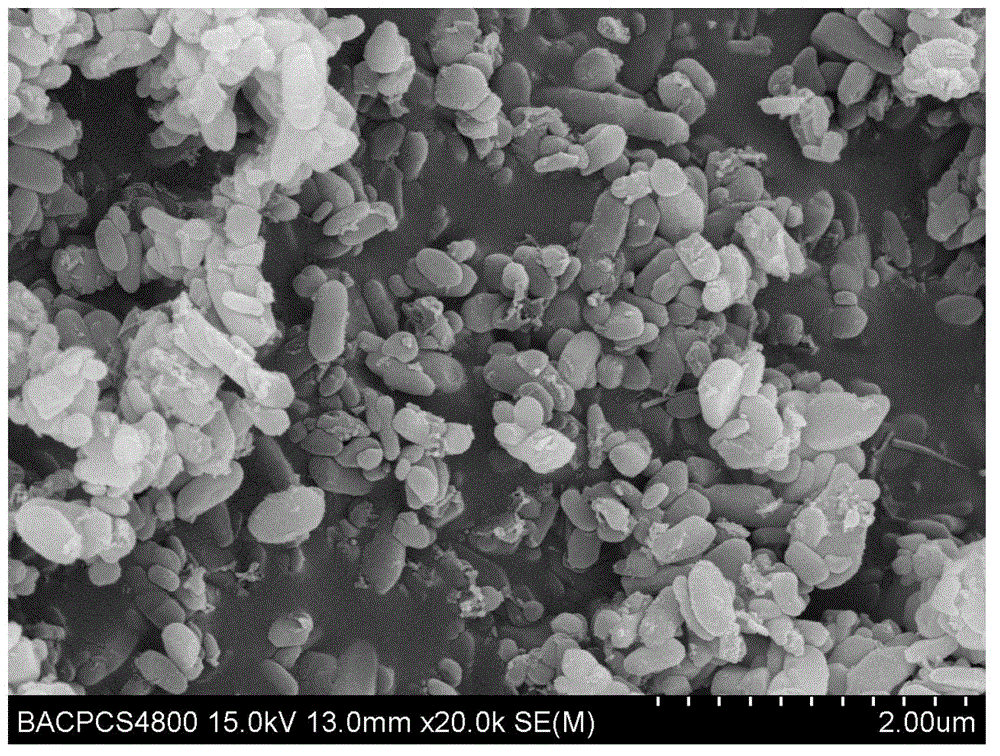

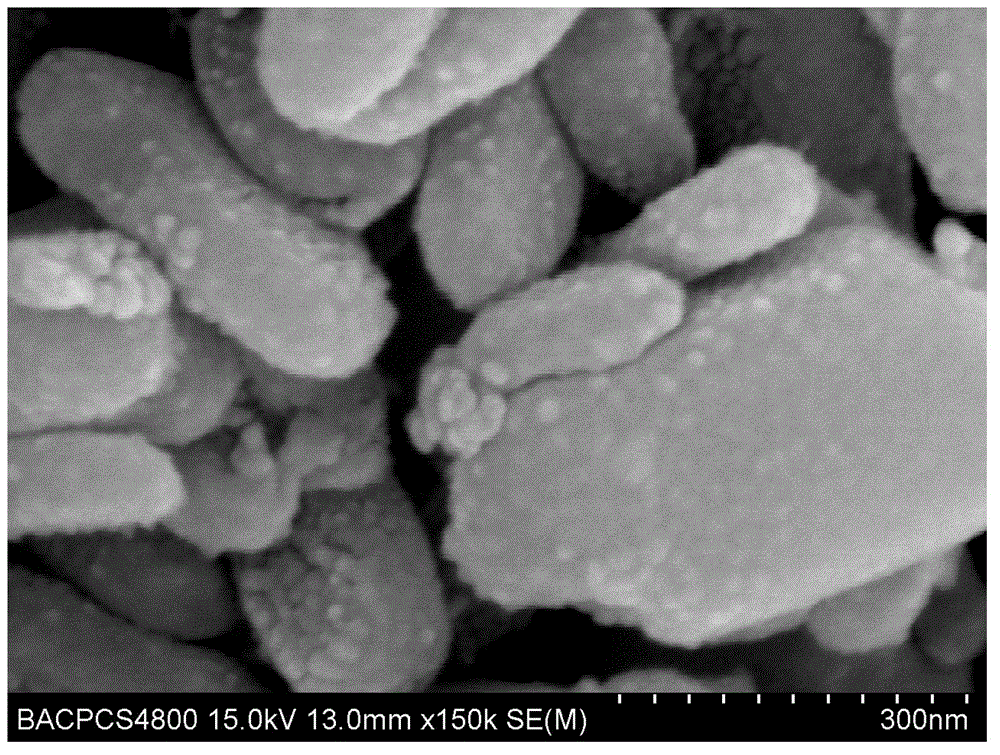

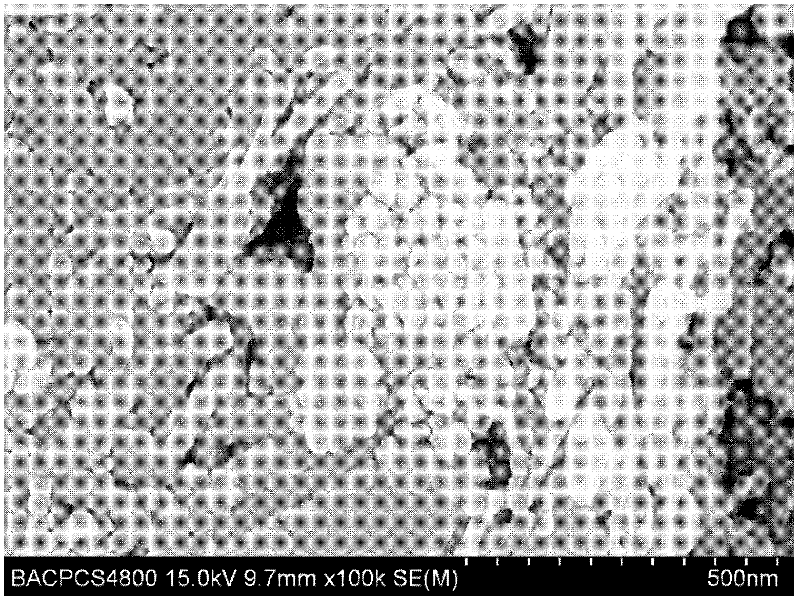

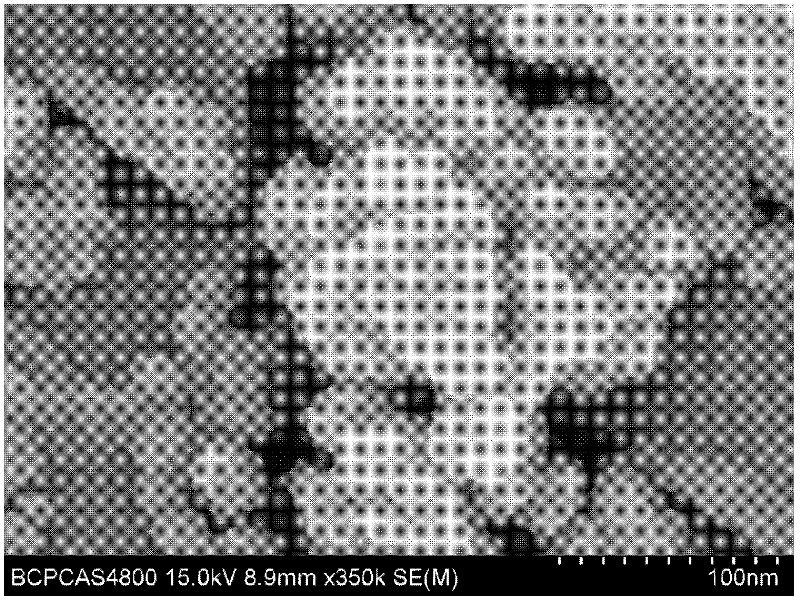

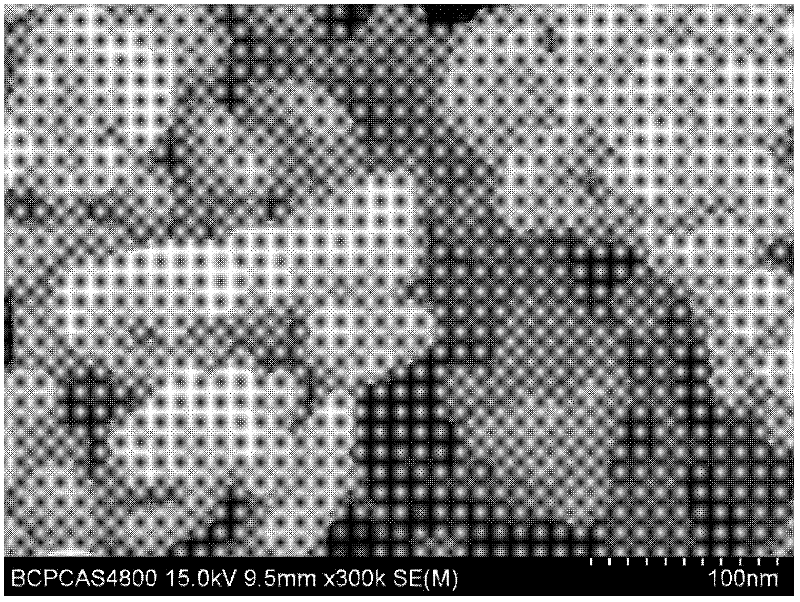

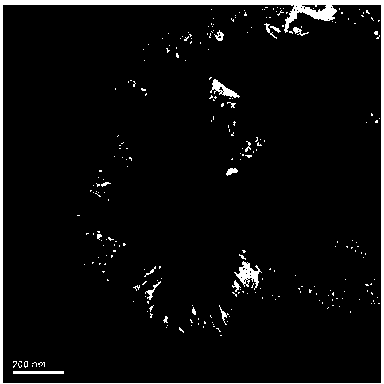

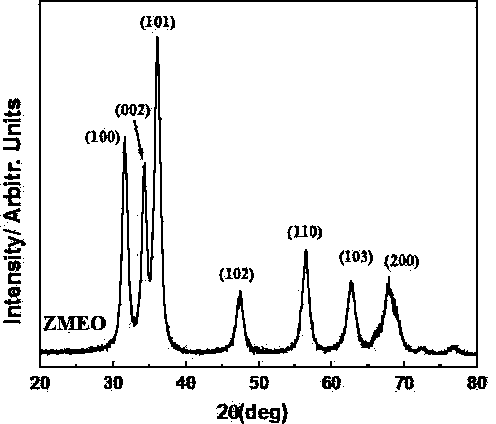

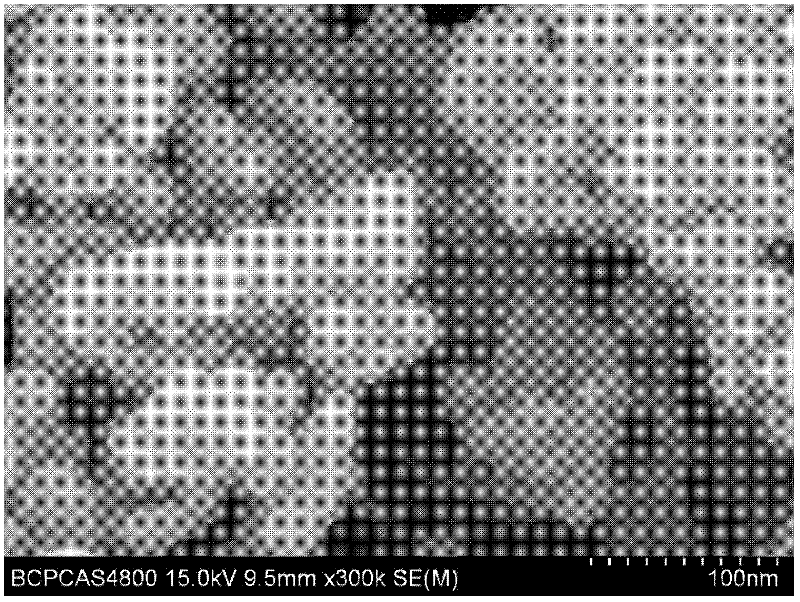

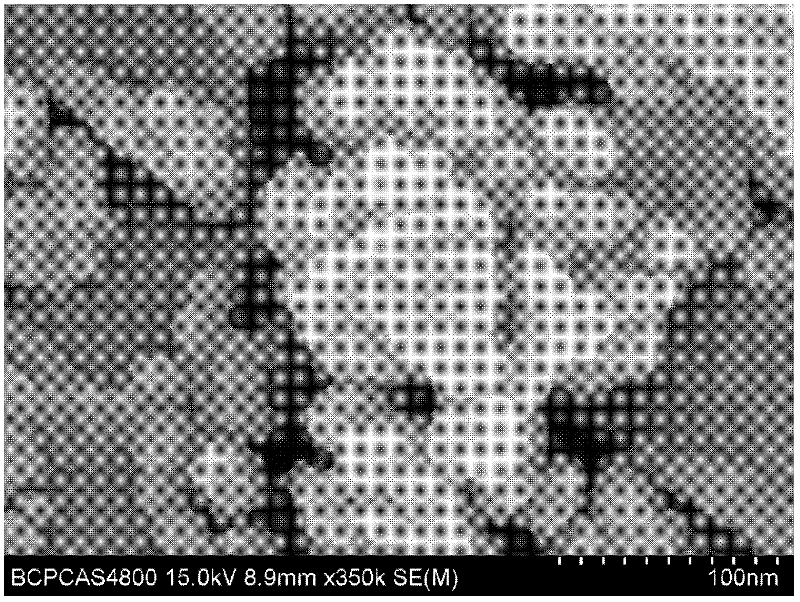

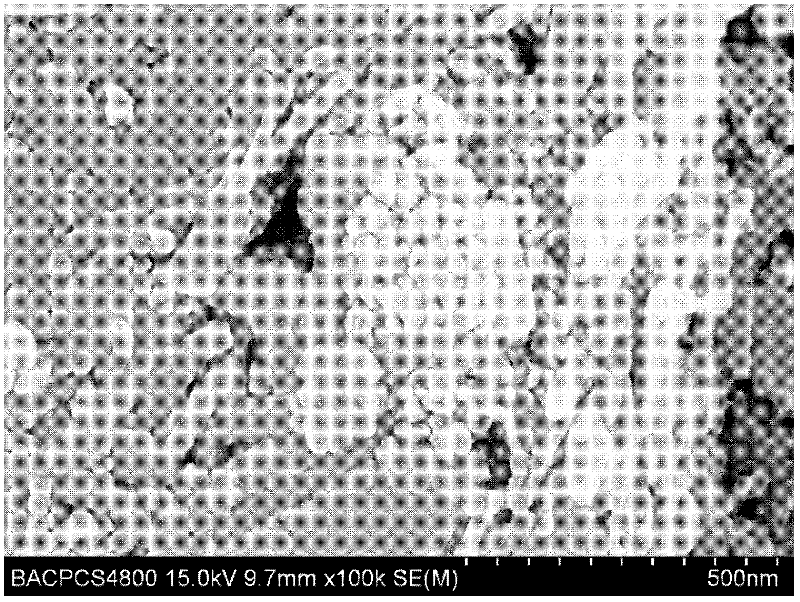

Preparation method of silver nano particle coated zinc oxide nano tube substrate

InactiveCN103451652AImprove stabilityGood repeatabilitySuperimposed coating processTetramineRepeatability

The invention relates to a preparation method of silver nano particle coated zinc oxide nano tube substrate. The preparation method adopts a combination of a chemical method and a magnetron sputtering method. The target product Ag@ZNT substrate is prepared from following raw materials: Zn(OOCCH3)2.2H2O, Zn(NO3)2.6H2O, KCl, absolute ethanol, hexamethylene tetramine, and silver target. The substrate has the advantages of very good Raman activity, stability and repeatability, is an ideal SERS substrate, and is capable of being applied to fields of chemistry, materials science, and biomedicine.

Owner:JILIN NORMAL UNIV

Method for preparing ferrous phosphate-based lithium salt

The invention relates to a method for preparing a lithium iron phosphate material through a solvothermal method, in particular to a method for preparing a ferrous phosphate-based lithium salt. The method is characterized by comprising the following steps of: (1) preparing primary nano-grade lithium iron phosphate particles; (2) atomizing to form secondary particles; and (3) sintering lithium iron phosphate: sintering the obtained secondary lithium iron phosphate particles, baking in a nitrogen atmosphere or a mixed atmosphere of nitrogen and hydrogen in the volume ratio of (1-5):(95-99) at the high temperature of 400-800 DEG C for 6-25 hours, and cooling. The method for preparing the ferrous phosphate-based lithium salt provided by the invention has the advantages of rich raw material source, low price, simple and practicable synthesizing process, safety, reliability, low production cost, high yield and freeness from environmental pollution; and a product has high electrochemical performance. A high-boiling-point solvent is adopted partially instead of water, so that preparation of nano-grade lithium iron phosphate through a normal-pressure low-temperature hydrothermal method is realized.

Owner:IRICO

Method for preparing glycerin zinc

InactiveCN101704721AAvoid reaction conditionsExtended reaction timePreparation of metal alcoholatesMicrowave ovenZinc Acetate Dihydrate

The invention relates to a method for preparing glycerin zinc. The method comprises the steps of placing zinc acetate glycerite into a microwave oven, carrying out reflux reaction by microwave heating under stirring till the solution becomes faint yellow and then stopping microwave heating to obtain the glycerin zinc. In the invention, the reaction occurs under normal pressure without any catalyst, the reaction condition of high-temperature heating is avoided, the reaction time is shortened to be within 10 minutes, any impurity can not be introduced, and any treatment is not needed for the reactant and product. The invention has simple and easy process, is safe and reliable and has no danger or environmental pollution. The glycerin zinc nanometer particles can be obtained by controlling the concentration of the zinc acetate glycerite, the microwave heating power and the reaction time.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Biphenyl compound as well as preparation method and medical application thereof

ActiveCN111909108AAvoid interactionEnhance the efficacy of anti-tumor immunityOrganic active ingredientsOrganic chemistryAutoimmune conditionMetabolite

The invention discloses a biphenyl compound as well as a preparation method and medical application thereof, the structure of the biphenyl compound is shown as a formula (I) or a formula (II), and thebiphenyl compound or pharmaceutically acceptable salt, tautomer, meso-isomer, raceme, stereoisomer, metabolite, metabolite precursor, prodrug or solvate thereof is a PD-L1 inhibitor. The compound hasa remarkable inhibiting effect on the interaction of PD-1 and PD-L1 protein, so that the compound can be applied to the preparation of PD-L1 inhibitors and immunomodulator drugs for preventing or treating tumors, autoimmune diseases, organ transplant rejection, infectious diseases and inflammatory diseases.

Owner:CHINA PHARM UNIV

Preparation method of polyamine inhibitor for drilling fluid

InactiveCN106190064AEnhanced inhibitory effectGood compatibilityDrilling compositionTetramineReaction temperature

The invention discloses a preparation method of a polyamine inhibitor for drilling fluid. The method comprises the following steps: an amine compound of low molecular weight and heterocyclic compounds are reacted in a setting condition for synthesis, and the amine compound is one of triethylene tetramine, trimethylethylamine hydroxide, N-methylethylamine, and trimethylhexamethylenediamine; the heterocyclic compound is 1,2-epoxypropane or 2,3-epoxybutane or 1,3-epoxybutane; the setting condition is as follows: alkali metal is used as a catalyst, and the reaction temperature is 80-100 DEG C; charging mol ratio between the amine compound and the heterocyclic compound is 1:2.5; the mass ratio between the amine compound and the alkali metal catalyst is 1200:1. The inhibitor has high inhibition capability for shale, and has good compatibleness to other common drilling fluid additives; the inhibitor is nontoxic and environmentally friendly.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

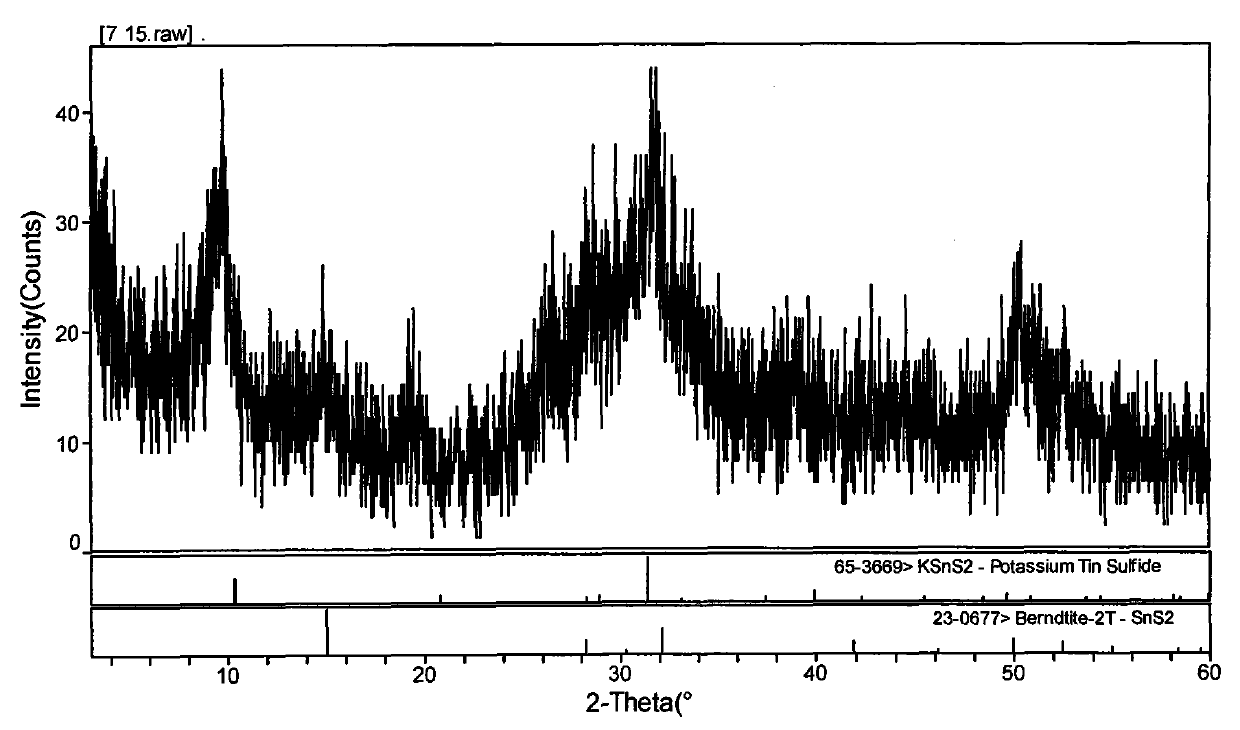

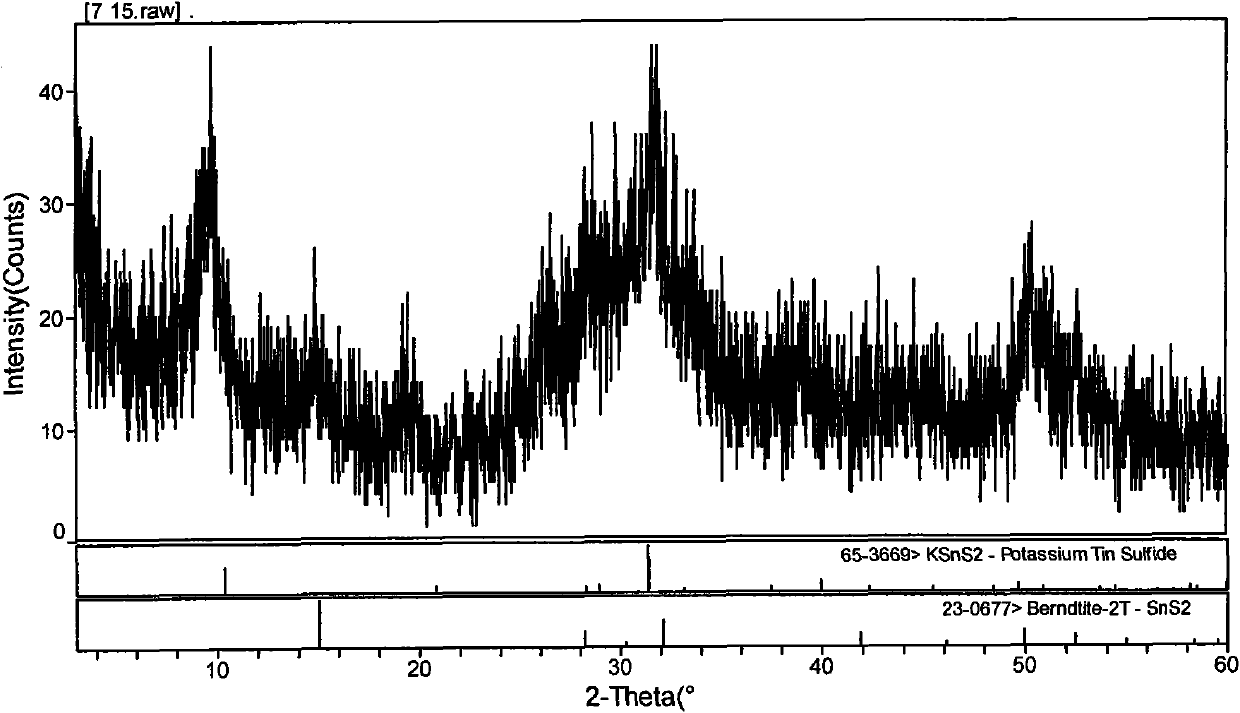

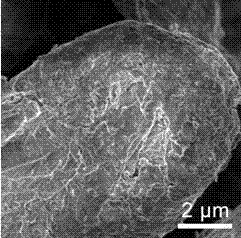

Preparation method of alkali metal intercalated transition metal disulfide

InactiveCN101948099AIncrease layer spacingSynthetic process safetyTin compoundsSulfide/polysulfide preparationHybridization reactionInorganic materials

The invention discloses a preparation method of alkali metal intercalated transition metal disulfide, which is characterized by taking the disulfide as the intercalated subject and borohydride as the intercalated object and intercalating the alkali metal ions among the lamellae of the transition metal disulfide inorganic materials through hybridization reaction to prepare the compound of the alkali metal ion intercalated disulfide. Compared with the prior art, the method has safe and simple synthesis process, is convenient to operate, expands the interlamellar spacing of the disulfide, provides cheap and easily-obtained raw materials for synthesis of functional intercalated composite materials and has broad application prospect.

Owner:EAST CHINA NORMAL UNIV

Synthetic technology of graphite oxide

A synthetic technology of graphite oxide comprises the following steps: placing graphite powder, concentrated sulfuric acid, a persulfate and an oxide in a reaction container according to a ratio of the graphite powder to the concentrated sulfuric acid to the persulfate to the oxide of 5-30g:50-300ml:5-30g:3-30g, stir-mixing, carrying out ultrasonic treatment for 3-25min, stirring in a 20-200DEG C water or oil bath for 2-24h, allowing to stand for 1-16h, filtering, drying, adding the concentrated sulfuric acid having an amount 2-7 times higher than the previous amount of the concentrated sulfuric acid, carrying out the ultrasonic treatment for 3-150min, slowly adding potassium permanganate having an amount 1-7 times higher than the addition amount of the graphite powder, continuously stirring for 2-24h, adding deionized water having an amount equal to the secondary addition amount of the concentrated sulfuric acid under an ice bath cooling condition, stirring for 5-h, adding hydrogen peroxide while stirring until no bubbles appear to obtain a graphite oxide solution, filtering the graphite oxide solution, and drying to obtain the graphite oxide. The synthetic technology has the advantages of no pollution, high raw material utilization rate, simple preparation process, high oxide insertion degree, and easy operation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

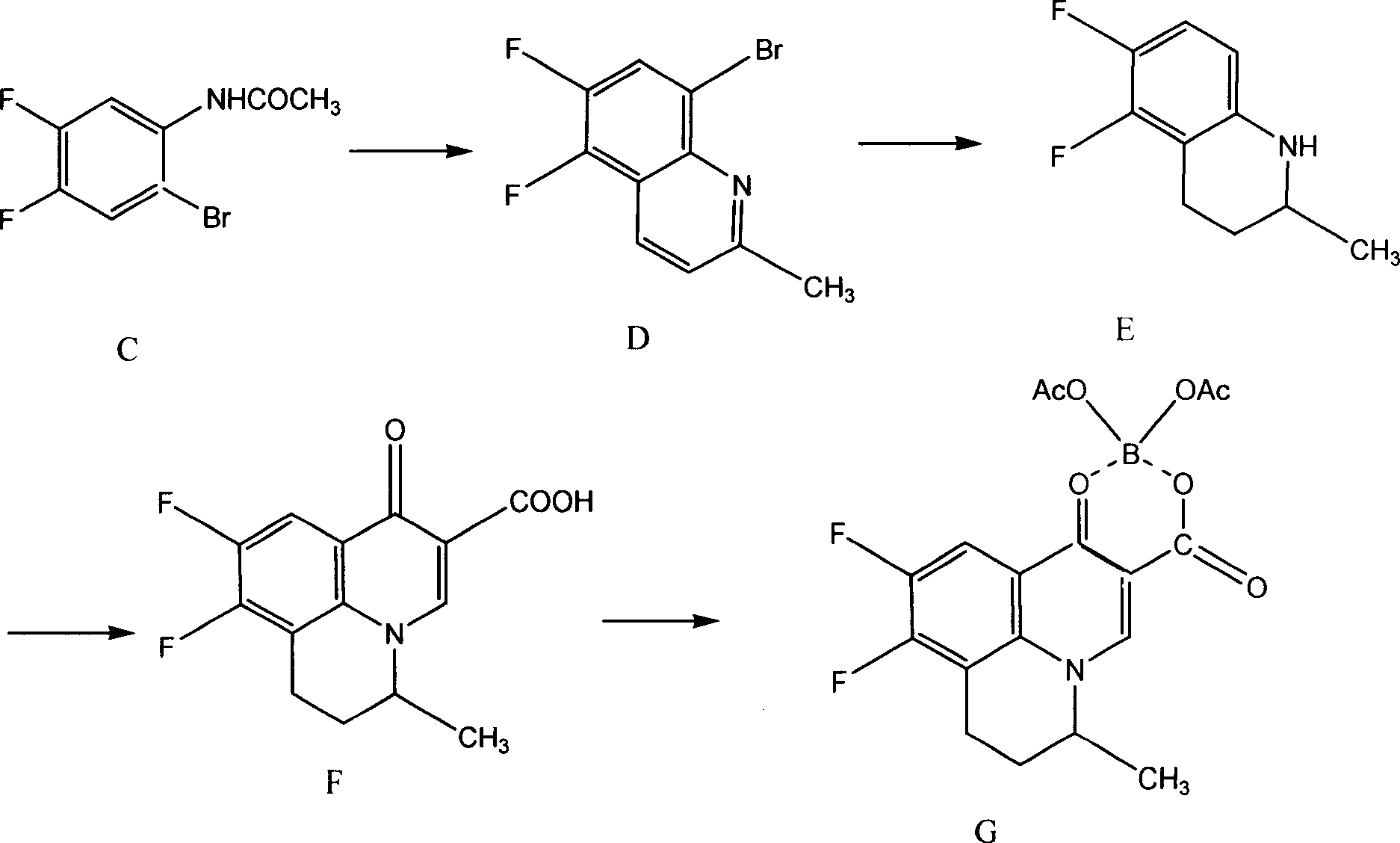

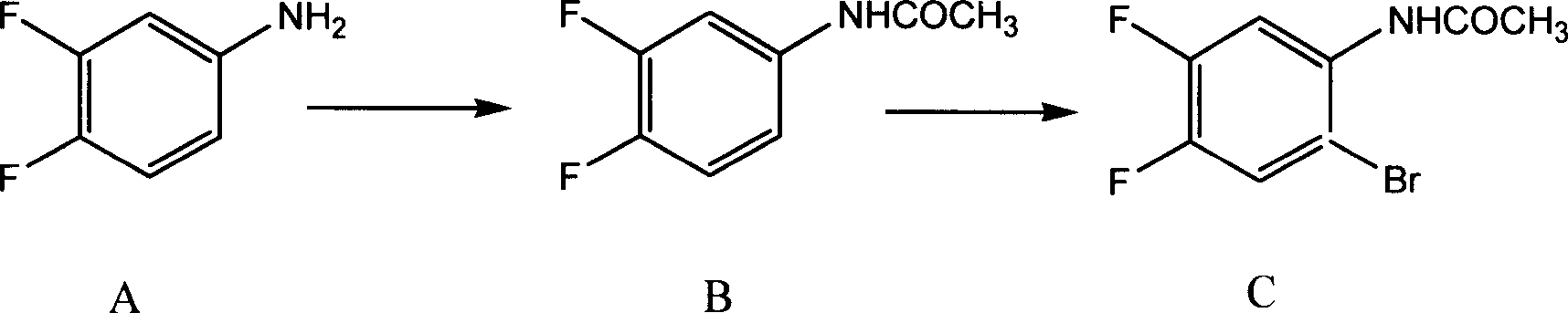

Preparing method of 8-bromo-5,6-difluoro-2-methylquinoline

The invention discloses a making method of 8-bromine-5, 6-difluo-2-methyl quinoline as key intermediate of broad spectrum antibiotic nafuxacin, which comprises the following steps: adopting 3, 4-difluo-6-difluo phenylamine as original raw material; acylating to produce 3, 4-difluo aceto phenylamine; bromidizing to make 3, 4-difluo-6-difluo aceto phenylamine as cyclic starting material; ringing 3, 4-difluo-6-difluo aceto phenylamine, oxidizer, alleviator, condensed sulfuric acid, ferric sulfate, trans-crotonaldehyde; selecting condensed sulfuric acid and condensed nitric acid as oxidizer; fitting for industrial manufacturing with low cost and high receiving rate.

Owner:CHANGZHOU YABANG PHARMA

Preparation method of lithium iron phosphate material

The invention discloses a processing method for synthesizing lithium iron phosphate materials. The method comprises the following steps: (1), preparing nanometer lithium iron phosphate primary particles to obtain nanometer precursor particles LFP of a lithium iron phosphate precursor; (2), drying and carbon coating, and sufficiently grinding and stirring the precursor and carbon soot evenly; and (3) sintering lithium iron phosphate to obtain lithium iron phosphate cathode material. According to the invention, the nanometer primary particles can be obtained by using a coprecipitation method, isophoron is used as abstersion which has the advantages of high boiling point and strong dissolubility, reaction temperature in wet synthesis can be increased greatly, and the purity of LFP products can be improved. The synthetic method has the advantages that raw materials are rich, the price is low, the synthesis process is simple, easy, safe and reliable, the production cost is low, the yield is high, environment pollutions are avoided, and the products have better electrochemical performance.

Owner:IRICO

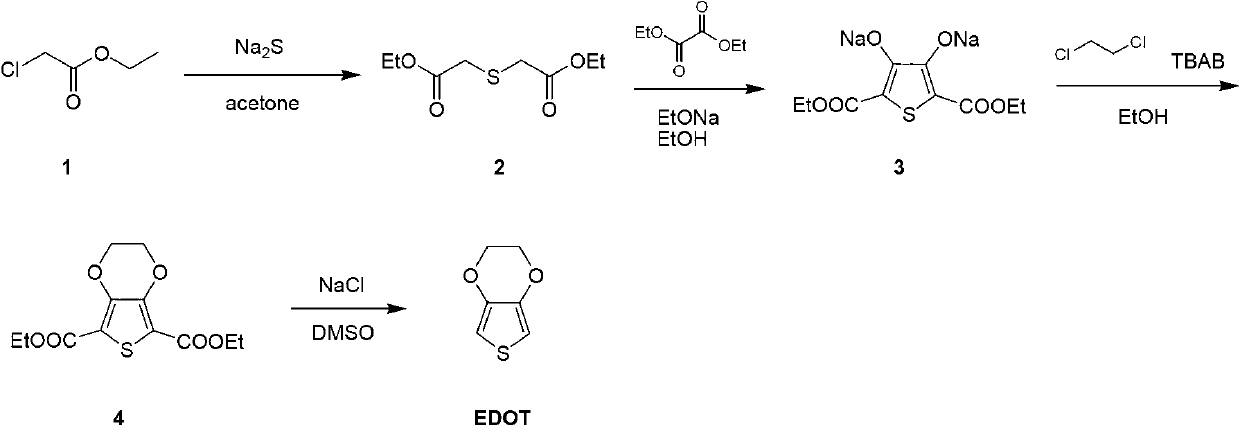

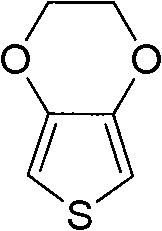

Method for preparing polymer monomer 3,4-ethylenedioxythiophene

ActiveCN102775423AShort routeShorten the production cycleOrganic chemistryPolymer scienceEthylenedioxy

The invention relates to a method for preparing polymer monomer 3,4-ethylenedioxythiophene. The method includes firstly dissolving ethyl chloroacetate and sodium sulphide in acetone to react to obtain diethyl thioglycolate; secondly, dissolving the diethyl thioglycolate to ethanol, adding sodium ethoxide and diethyl oxalate into the ethanol, heating and reflowing to obtain ethanol solution of 2,5-dioctyl phthalate ethyl ester-3,4-thiophene glycol sodium; thirdly, adding dichloroethane and tetrabutylammonium bromide into the ethanol solution of the 2,5-dioctyl phthalate ethyl ester-3,4-thiophene glycol sodium, heating and reflowing to obtain 3,4-ethylenedioxy-2,5-dioctyl phthalate ethyl ester thiophene; fourthly, dissolving the 3,4-ethylenedioxy-2,5-dioctyl phthalate ethyl ester thiophene in mixed solvent, adding sodium chloride, heating and reacting, and finally reducing pressure and rectifying. The method for preparing polymer monomer 3,4-ethylenedioxythiophene is few in procedures, low in cost, safe and reliable in technique, simple and fast in post-treatment method, and products are high in yield and purity.

Owner:TAISHAN MEDICAL UNIV

Industrial synthesis method for acetoxylpropyltrimethoxysilane

ActiveCN108059639AHigh yieldThe synthesis process is simpleGroup 4/14 element organic compoundsAllyl acetateSynthesis methods

The invention relates to an industrial synthesis method for acetoxylpropyltrimethoxysilane, which belongs to the technical field of fine chemical engineering. According to the industrial synthesis method, trichlorosilane and allyl acetate first undergo hydrosilylation under catalyst, so that acetoxylpropyltrichlorosilane is obtained, and methanol is then used for esterifying acetoxylpropyltrichlorosilane so that acetoxylpropyltrimethoxysilane and hydrochloric acid are obtained. The yield of acetoxylpropyltrimethoxysilane disclosed by the invention is high, the synthesis process is simple and safe, and the environment is not polluted.

Owner:JINGZHOU JIANGHAN FINE CHEM

Method for improving characteristic luminescent peak intensity of Eu ions in ZnO matrix

InactiveCN103450892AHigh luminous intensityEasy to operateLuminescent compositionsPlateauMagnesium ion

The invention relates to a method for improving the characteristic luminescent peak intensity of Eu ions in a ZnO matrix. The method employs a precipitation technique, adopts Mg(NO3)3.6H2O, Zn(NO3)2.6H2O, Eu2O3, nitric acid and ammonium bicarbonate as raw materials, and the mole ratio of the ammonium bicarbonate to the sum of Eu<3+>, Mg<2+> and Zn<2+> is 1:1. By utilizing magnesium ions to serve as an energy storage center in the ZnO matrix, the energy transfer from the ZnO matrix to the Eu ions is effectively improved. Therefore, the intensity of an Eu ion characteristic luminescent peak in the ZnO matrix is greatly enhanced. Thus, the red fluorescent material prepared in the invention is more suitable for the cold north, the hot south and plateau areas with strong ultraviolet radiation, and also can be widely used in spacecraft coating pigments.

Owner:JILIN NORMAL UNIV

Reduction processing method for synthesizing lithium iron phosphate materials

The invention discloses a reduction processing method for synthesizing lithium iron phosphate materials, which comprises the following steps: (1) preparing nanometer lithium iron phosphate primary particles to obtain nanometer precursor particles LFP of a lithium iron phosphate precursor; (2), drying and carbon coating, and sufficiently grinding and stirring the precursor and carbon soot evenly; and (3), sintering lithium iron phosphate to obtain lithium iron phosphate cathode material. According to the invention, the nanometer primary particles can be obtained by using a coprecipitation method, isophoron is used as abstersion which has the advantages of high boiling point and strong dissolubility, reaction temperature in wet synthesis can be increased greatly, and the purity of LFP products can be improved. The synthetic method has the advantages that raw materials are rich, the price is low, the synthesis process is simple, easy, safe and reliable, the production cost is low, the yield is high, environment pollutions are avoided, and the products have better electrochemical performance.

Owner:IRICO

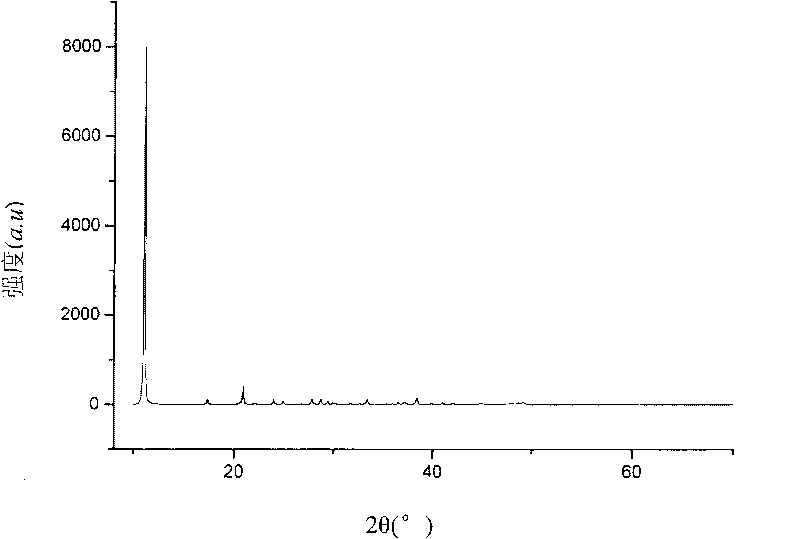

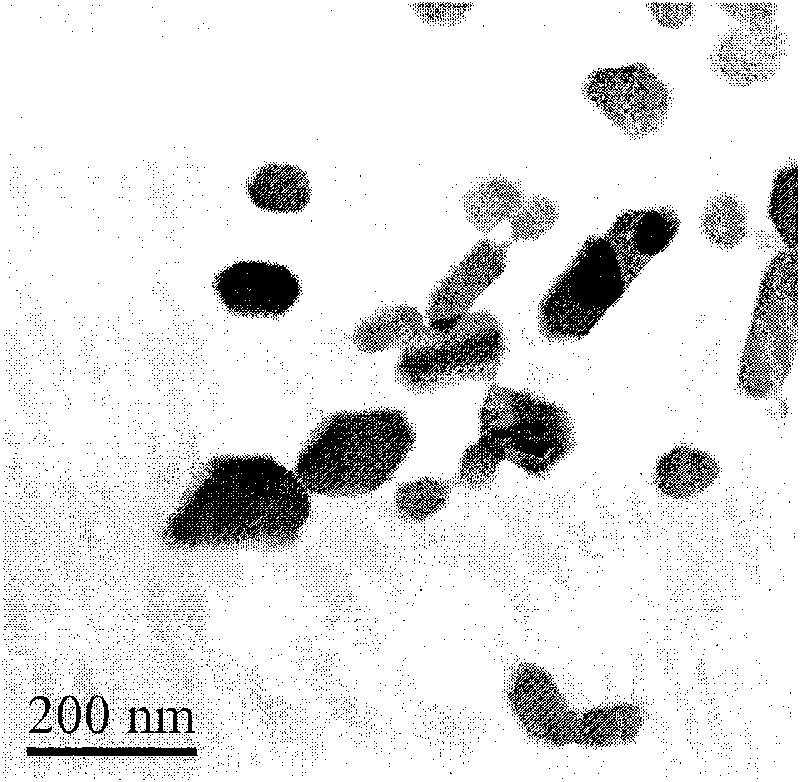

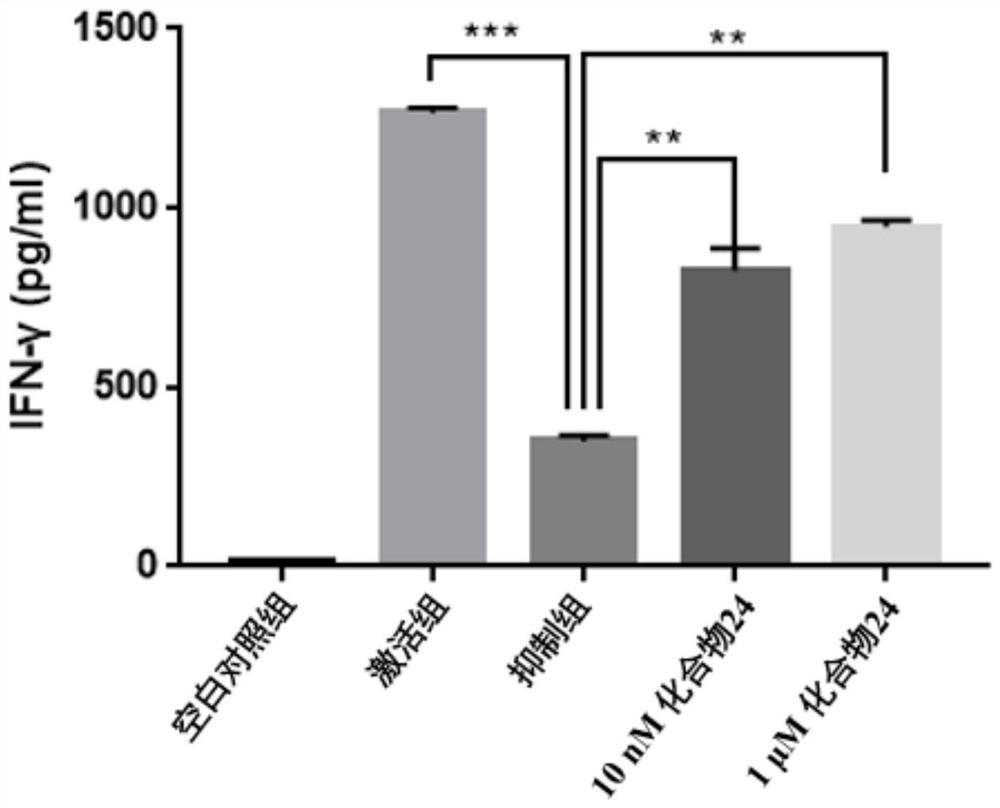

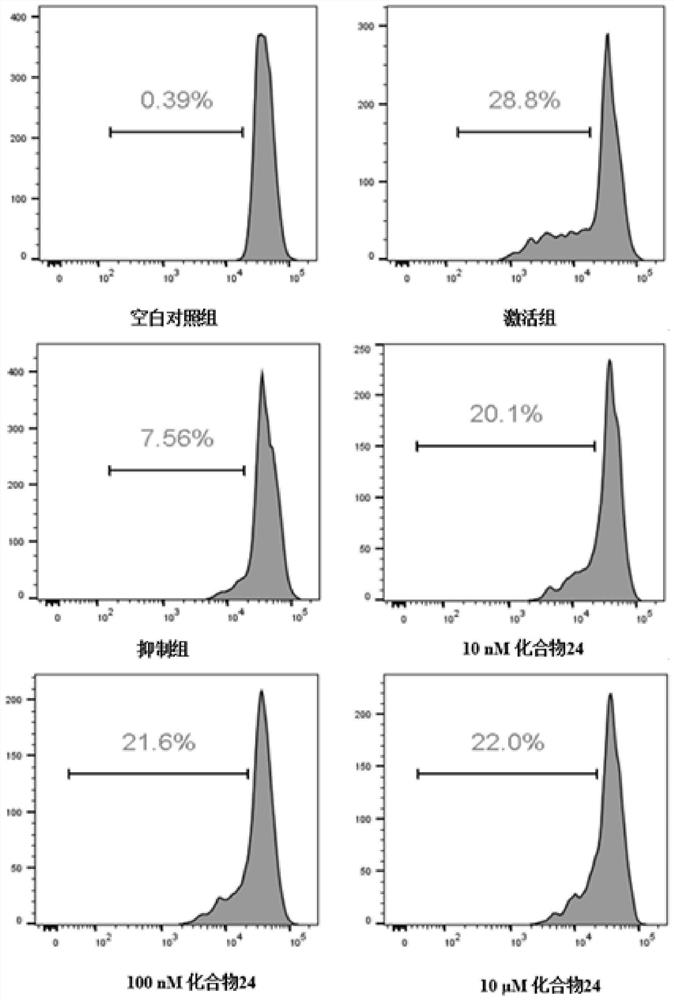

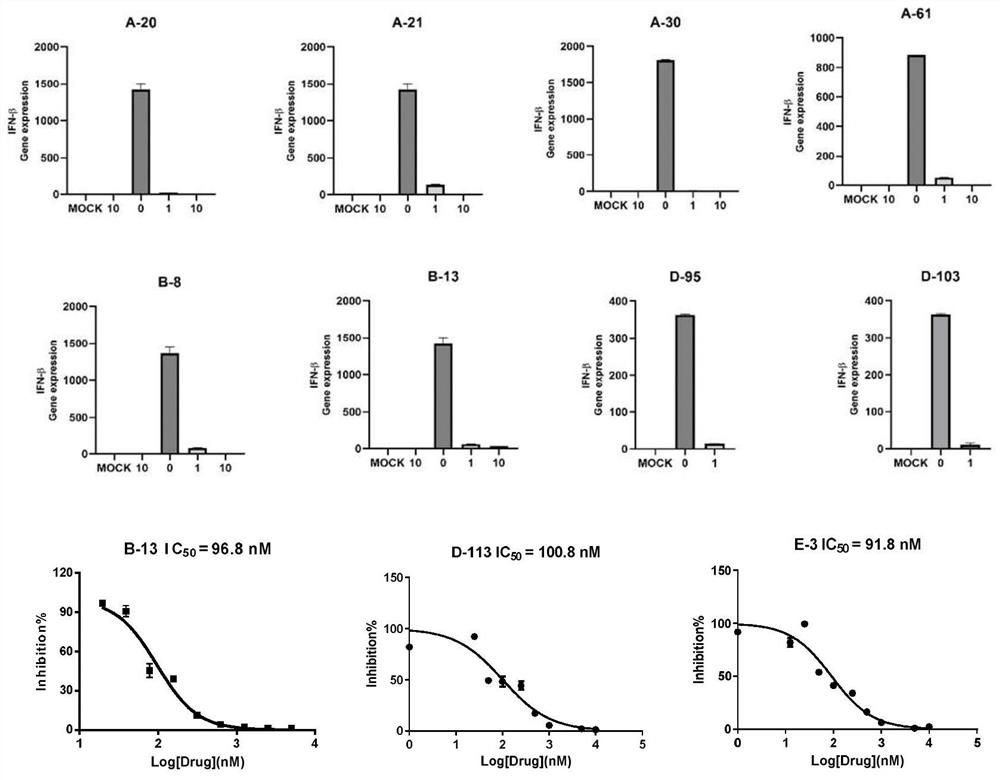

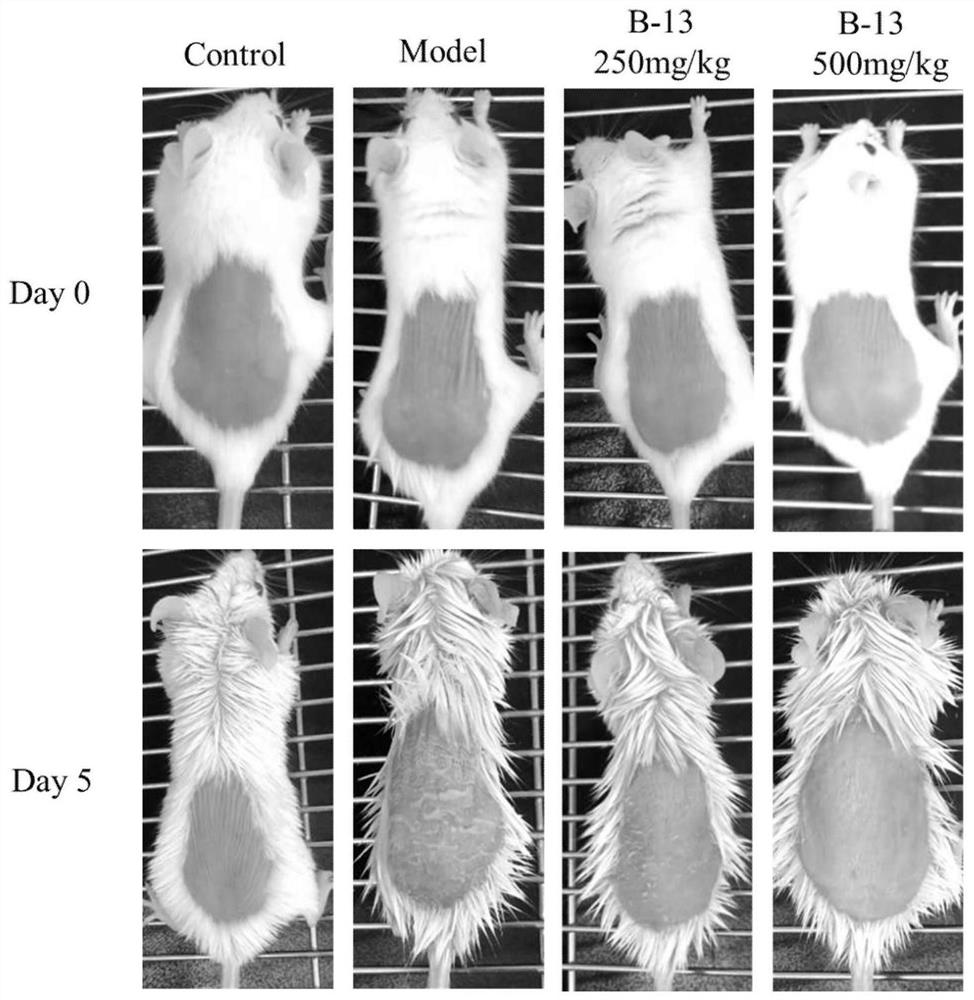

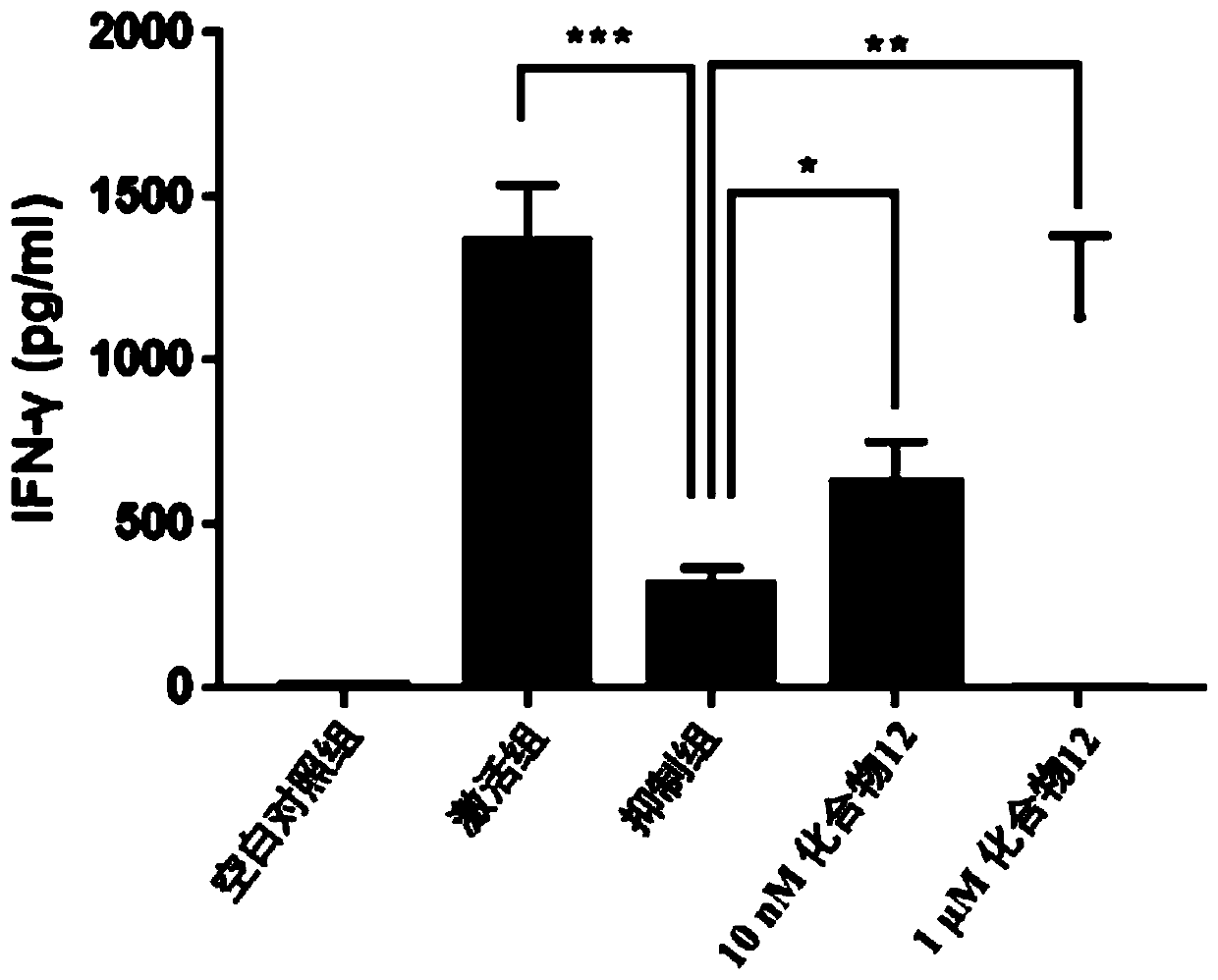

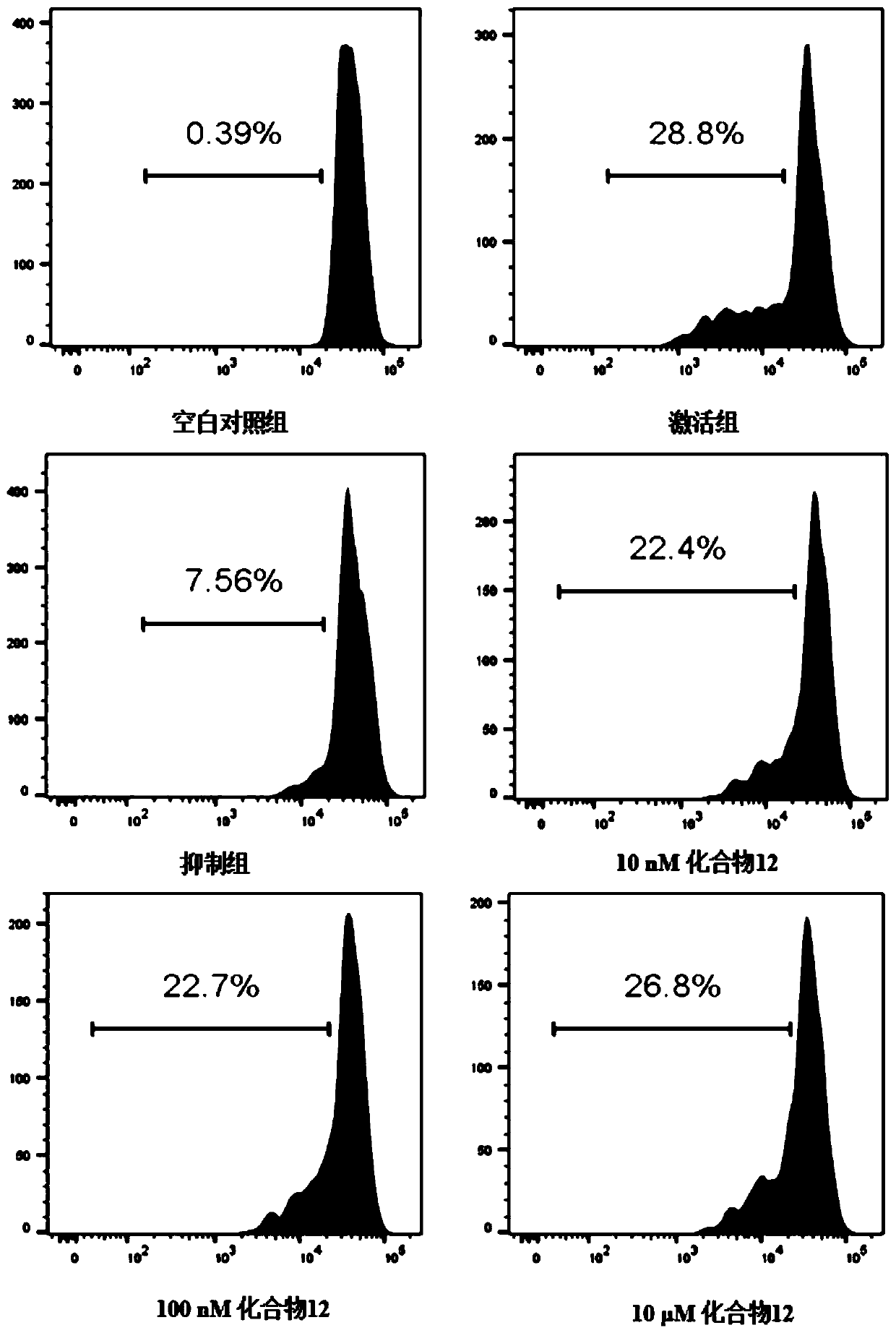

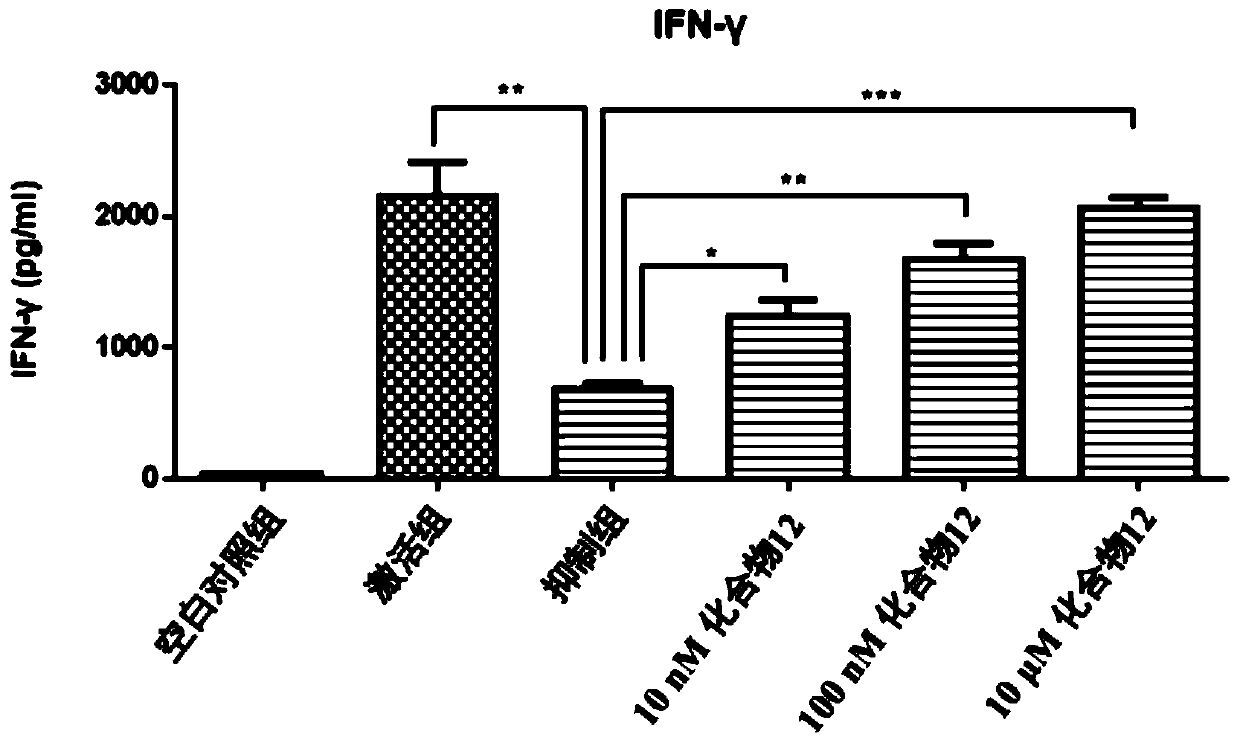

Amide compound and medical application thereof as STING inhibitor

ActiveCN112409223AStrong STING inhibitory activityStrong inhibitory activityAntibacterial agentsSenses disorderDiseasePharmaceutical drug

The invention discloses an amide compound and medical application thereof as an STING inhibitor, and particularly relates to a compound shown as a formula I or a formula II or pharmaceutically acceptable salt or ester or solvate thereof, which can be used for preparing the STING inhibitor or medicine for inhibiting STING signal path activation and preparing medicine for preventing or treating STING mediated diseases.

Owner:CHINA PHARM UNIV

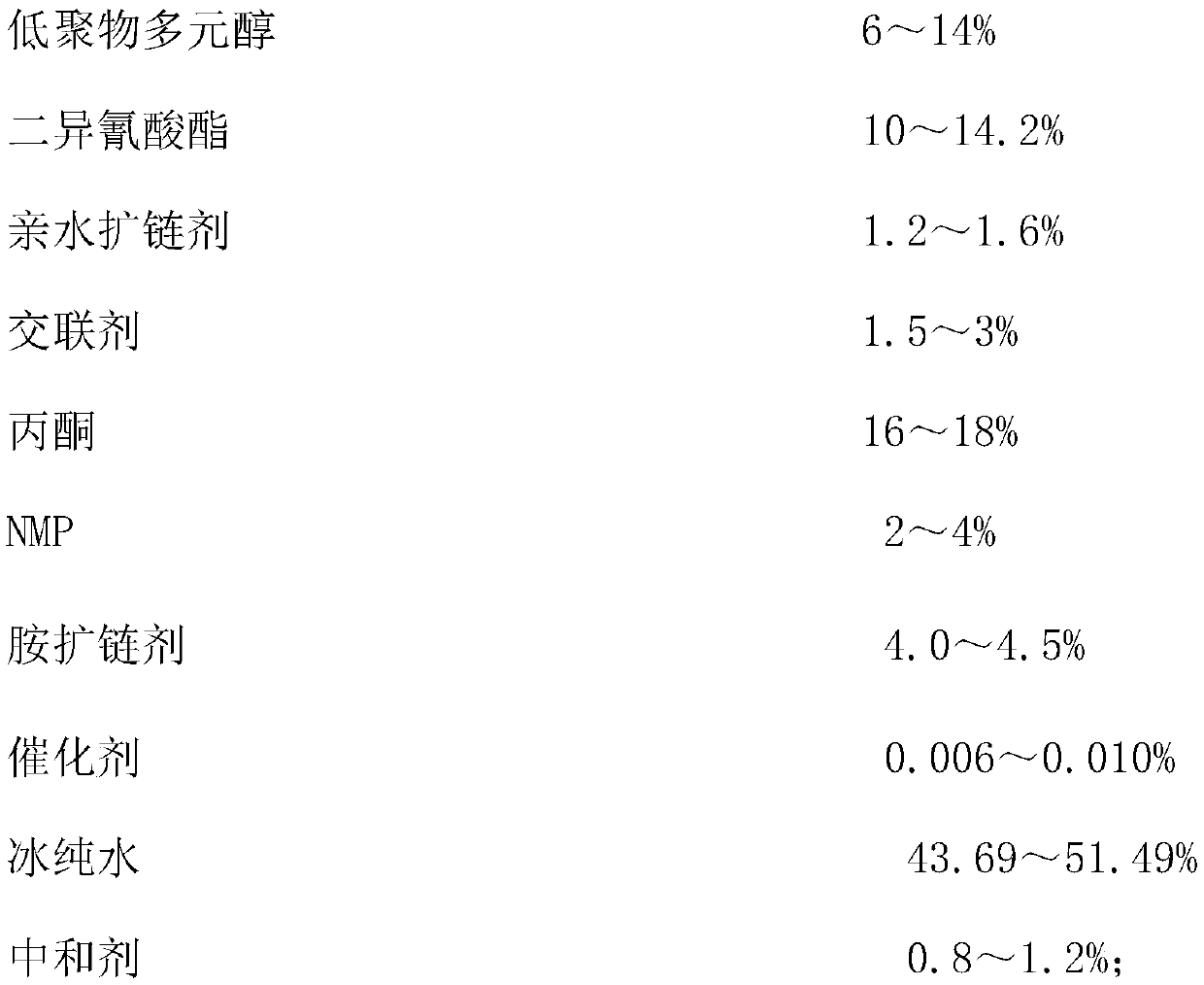

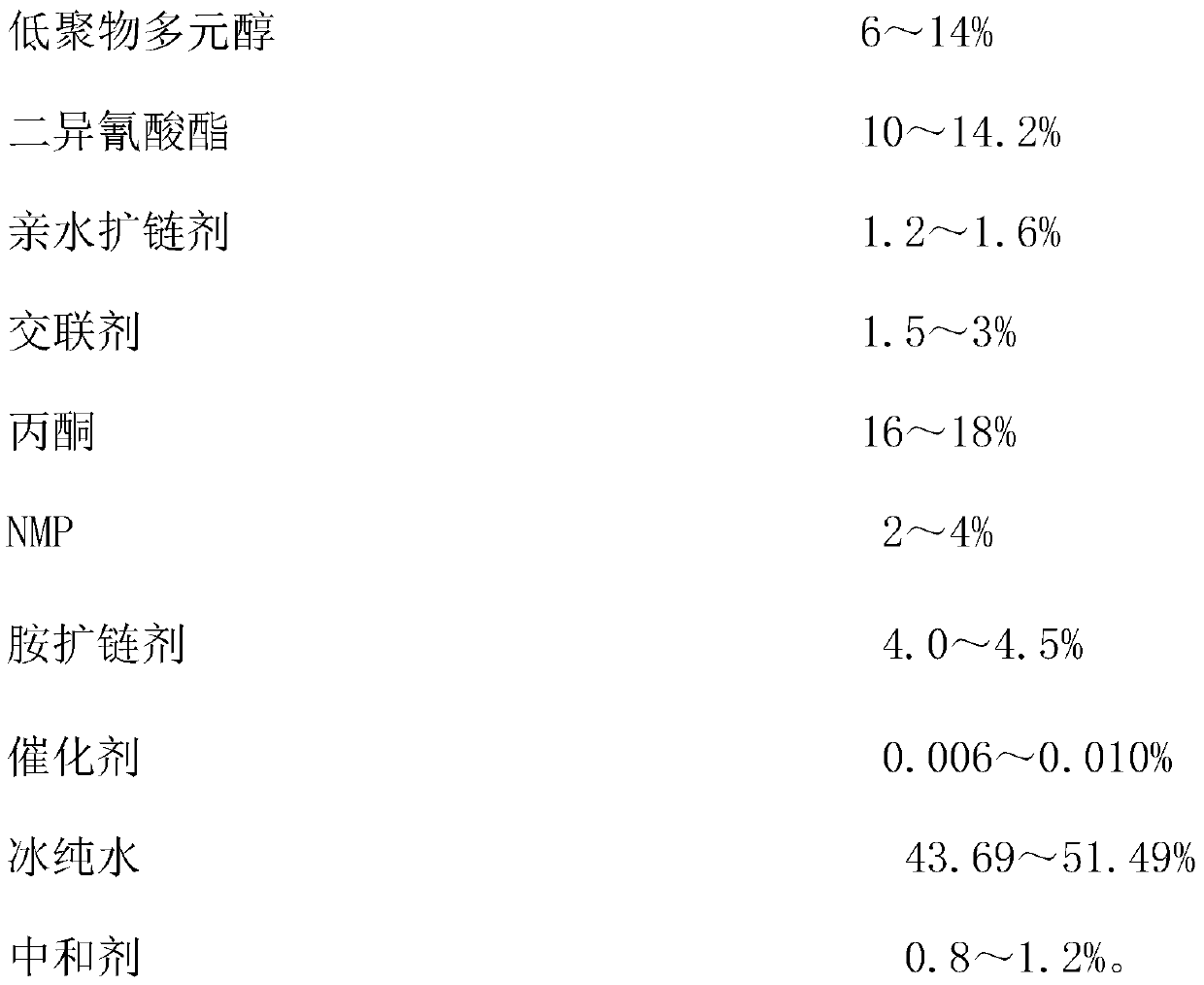

Water-based polyurethane emulsion for heat-resistant transfer coating and preparation method thereof

ActiveCN106589310BHigh molecular weightSmall particle sizeFireproof paintsPolyurea/polyurethane coatingsWater basedWater resistant

The invention discloses a water-based polyurethane emulsion for heat-resistant transfer coatings and a preparation method thereof. The key points of the technical scheme are: the material composition comprising the following components by weight: 6-14% of oligomer polyol, 10-14.2% of diisocyanate , hydrophilic chain extender 1.2-1.6%, cross-linking agent 1.5-3%, acetone 16-18%, NMP 2-4%, amine chain extender 4.0-4.5%, catalyst 0.006-0.010%, ice pure water 43.69- 51.49%, neutralizer 0.8-1.2%. The present invention uses the main raw materials such as oligomer polyol, diisocyanate, hydrophilic chain extender, crosslinking agent and amine chain extender, and uses the two-step method of prepolymer method without increasing the cost of raw materials. A water-based polyurethane emulsion for a temperature-resistant transfer coating with good transferability and good temperature resistance is provided.

Owner:广东博海化工科技有限公司

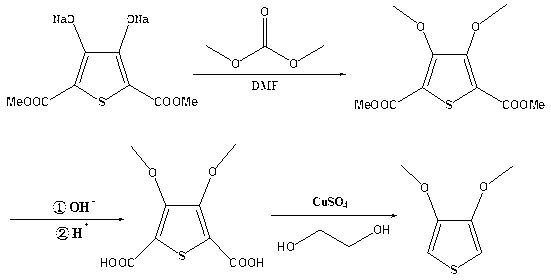

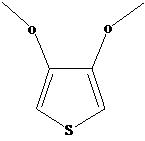

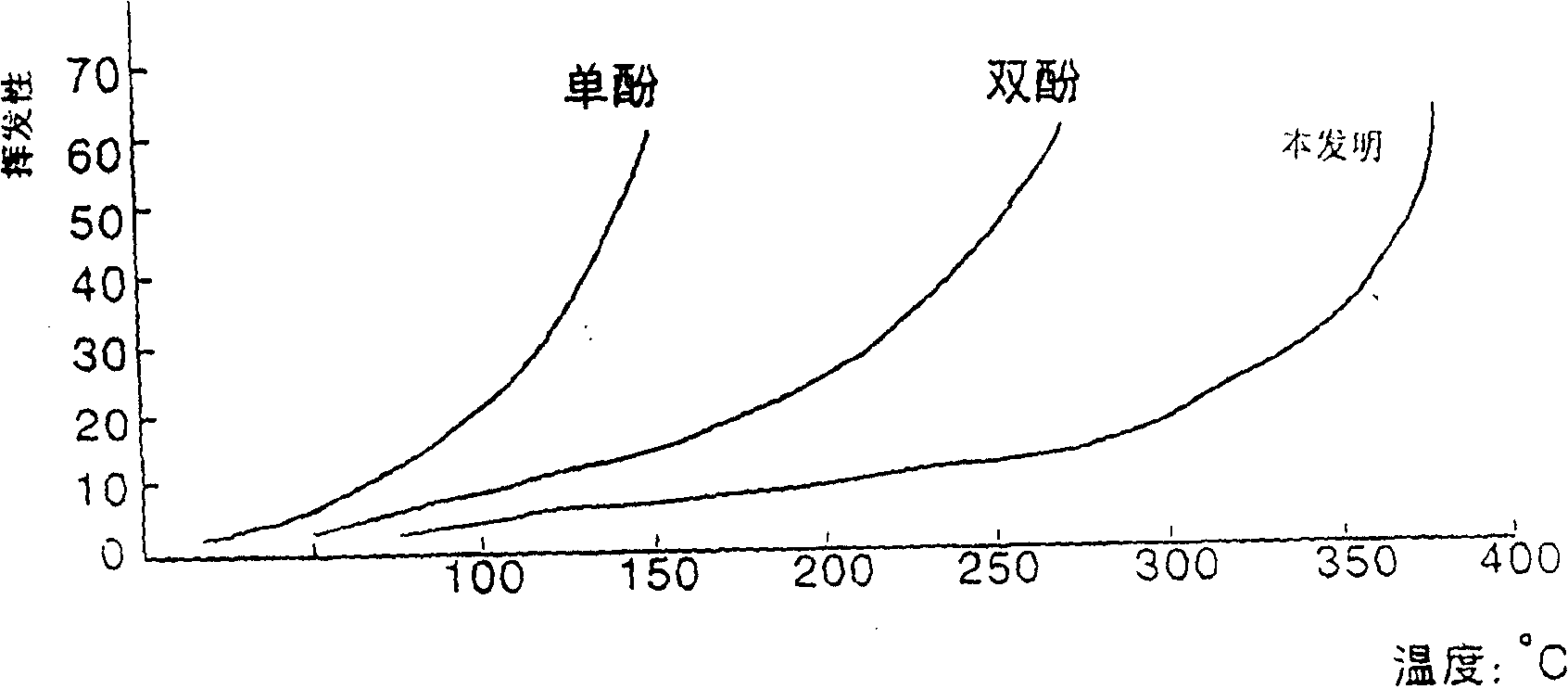

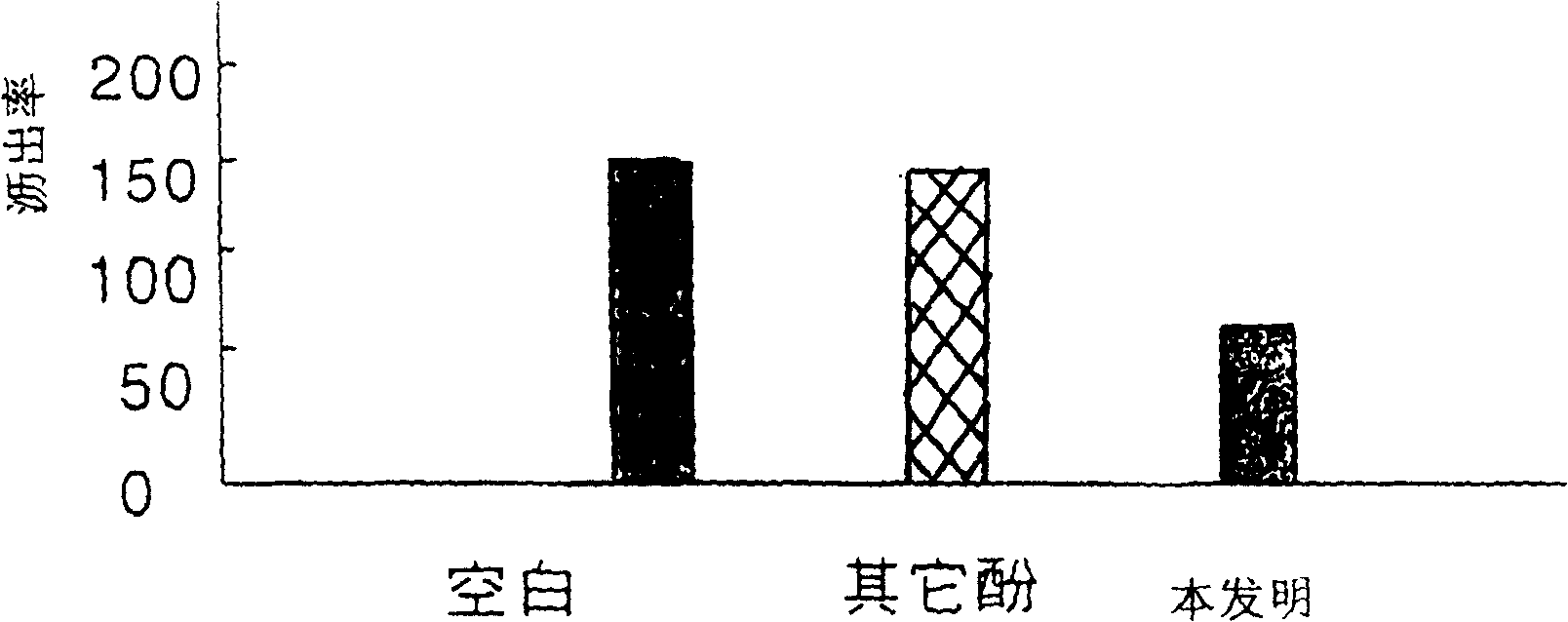

Process for synthesizing 3, 4-dimethoxythiophene

InactiveCN103254169ASynthetic process safetyRaw materials are easy to getOrganic chemistryDimethyl formamideFormate Esters

The invention discloses a process for synthesizing 3, 4-dimethoxythiophene. The process comprises the steps that (1) 2, 5-dimethyl formate-3,4-thiophene disodium alkoxide is dissolved in N, N-dicarboxylic thiophene to obtain 2, 5-dicarboxylic formate-3, 4-dimethoxy thiophene crude product by adding an alkylating reagent and based on heating reflux; (2) sodium hydroxide solution is added into the 3, 4-dimethoxy-2, 5-dicarboxylic thiophene crude product to obtain 3, 4-methoxy-2, 5-dicarboxylic thiophene crude product; (3) decarboxylation catalyst is added into a mixture of the 3, 4-dimethoxy-2, 5-dicarboxylic thiophene crude product and ethylene glycol solvent to obtain 3, 4-dimethoxythiophene finished product based on heating decarboxylation and rectification. The ethylene glycol solvent can be repeatedly used; and the process for synthesizing 3, 4-dimethoxythiophene has an environment-friendly process route, the production raw materials are easily obtained, the post treatment method is simple, the yield of the product obtained according to the process is high, the cost is low, and the quality is stable.

Owner:QINGDAO HECHENG PHARMA

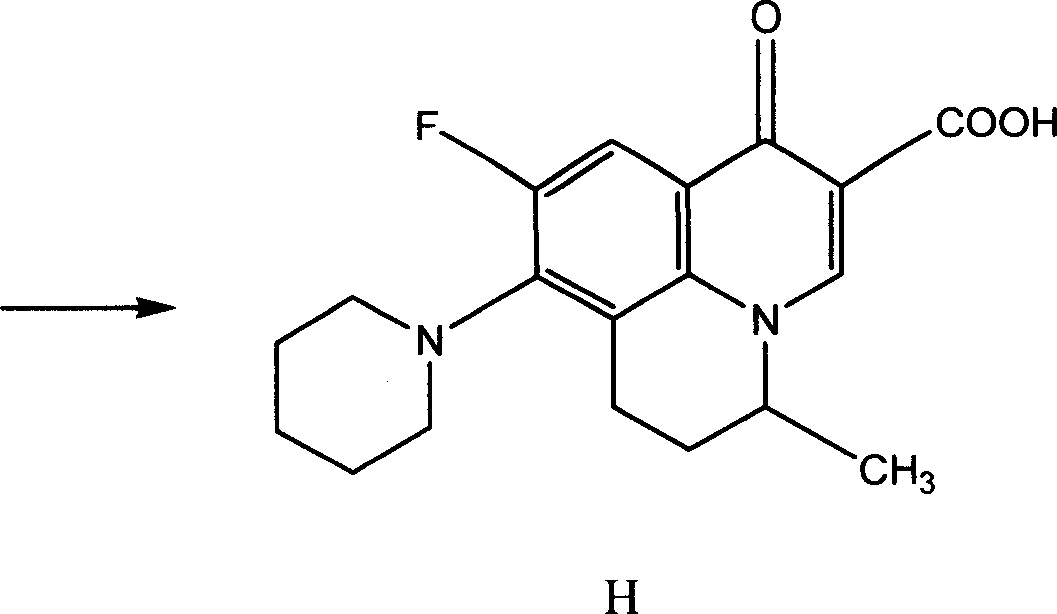

A kind of preparation method of fumaric acid vonoprazan

ActiveCN105085484BGet efficientlyLow costOrganic chemistryBulk chemical productionVonoprazanMethylene Dichloride

The invention discloses a preparation method of vonoprazan fumarate. The preparation method includes: S1, dissolving 5-(2-fluorophenyl)-1H-pyrrole-3-carboxaldehyde (I) in organic solvent, mixing with methylamine alcohol solution for 6-8h to generate imine, reducing with metal borohydride for 1-2h, and performing post-treatment to obtain a compound according to a formula II; S2, dissolving the compound prepared in the step S1 according to the formula II, in organic solvent, performing ice bathing and mixing with Boc anhydride to allow reaction for 1-2h, and performing post-treatment to obtain a compound according to a formula III; S3, dissolving the compound prepared in the step S2 according to the formula III, in organic solvent, adding sodium hydride and crown ether, adding 3-pyridine sulfuryl chloride, mixing for reaction for 1-2h, and performing post-treatment to obtain a compound according to a formula IV; S4, reacting the compound prepared in the step S3 according to the formula IV, in trifluoroacetic acid and methylene dichloride solution to obtain a compound according to a formula V; and S5, dissolving the compound prepared in the step S4 according to the formula V, in organic solvent to be salified with fumaric acid, thereby obtaining the vonoprazan fumarate (VI). The preparation method has few side reactions and high intermediate purity and allows simple post-treatment.

Owner:NANJING GRITPHARMA CO LTD

Continuous synthesis method of 2-chloropyrimidine-4-formic acid compound

ActiveCN110642789AImprove reaction efficiency and yieldLower synthesis costOrganic chemistryPyrimidineFormic acid

The invention provides a continuous synthesis method of a 2-chloropyrimidine-4-formic acid compound. The 2-chloropyrimidine-4-formic acid compound has a structure represented by a formula I, wherein in the formula I, R1 and R2 are respectively and independently selected from hydrogen, alkoxy, aryl, benzyl or fluorine. The synthesis method comprises the following steps: S1, under the action of a non-noble metal catalyst, carrying out continuous methylation reaction on a compound A and a methyl Grignard reagent B to obtain a compound C, wherein the compound A is a compound shown in the specification, the compound C is a compound shown in the specification, R1 and R2 are respectively and independently selected from hydrogen, alkoxy, aryl, benzyl or fluorine, and the non-noble metal catalyst is one or more of ferric salt, cobalt salt and nickel salt; and S2, carrying out continuous oxidation reaction on the compound C under the action of oxygen, an oxidation catalyst and an additive, and thus obtaining the 2-chloropyrimidine-4-formic acid compound. By adopting the process provided by the invention to synthesize the 2-chloropyrimidine-4-formic acid compound, the aspects of cost, yield,environmental friendliness and the like can be considered.

Owner:TIANJIN ASYMCHEM PHARMA

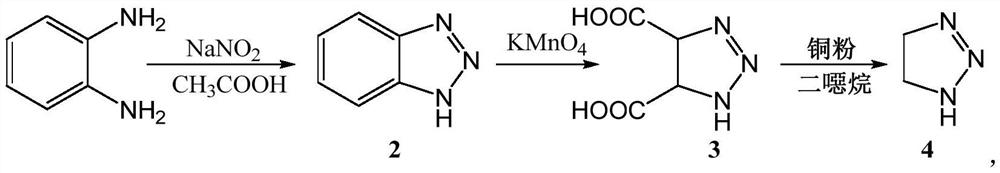

Synthesis process of ribavirin intermediate and the intermediate

The invention discloses a synthesis process of a ribavirin intermediate and the intermediate. 2-hydrazinyl-2-oxoacetate is used as a raw material, and the ribavirin intermediate 1,2,4-triazole-3-formamide is obtained by condensation with orthoformate triester, ammonolysis and cyclization in sequence. According to the process, the 2-hydrazinyl-2-oxoacetate is adopted as the initial raw material, the raw material is easily available and cheap, the synthesis route is short, expensive raw materials such as hypophosphorous acid are not adopted, dangerous raw materials such as hydrogen peroxide arenot used, a diazotization reaction which is a dangerous process is not adopted, reaction condition is mild, the whole process is almost free of generation of wastewater and solid waste; and the process is green, simple to operate and high in yield.

Owner:广安润康药业有限公司

Novel biphenyl derivative as well as preparation method and medical application thereof

ActiveCN113461668AAvoid interactionInteraction blockingOrganic active ingredientsOrganic chemistryPharmaceutical drugPharmaceutical medicine

The invention relates to the field of medicinal chemistry, and discloses a biphenyl derivative with PD-1 / PD-L1 inhibitory activity as well as a preparation method and application thereof. The invention further discloses a composition containing the biphenyl derivative with the PD-1 / PD-L1 inhibitory activity or the pharmaceutically acceptable salt of the biphenyl derivative and a pharmaceutically acceptable carrier of the biphenyl derivative, and an application of the composition in preparation of a PD-1 / PD-L1 inhibitor. The compound can be used for treating tumors.

Owner:XIAN XINTONG PHARM RES CO LTD

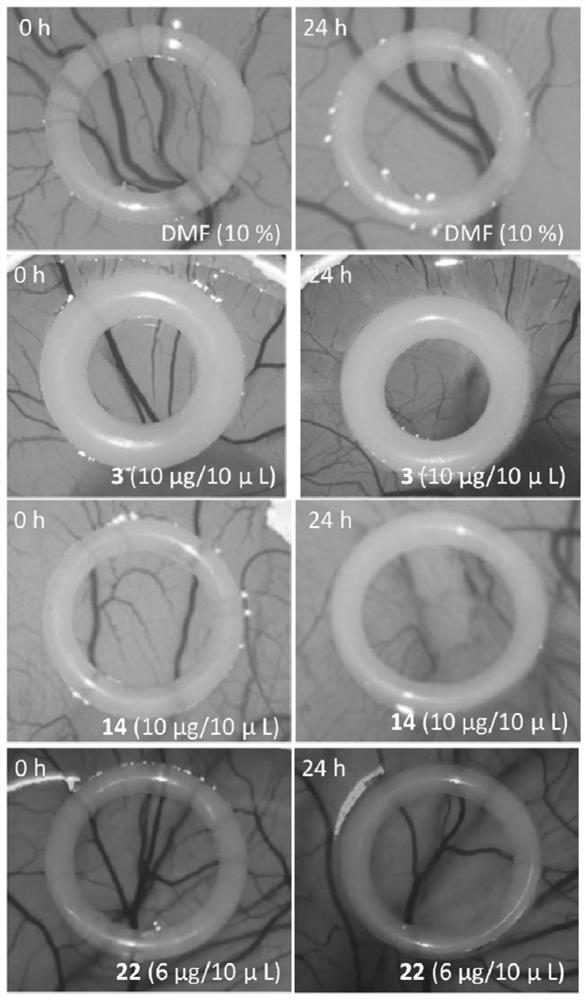

Metal complex containing tridentate ligand and xanthine derivative ligand and preparation method and medical application of metal complex

ActiveCN111704634AHas inhibitory activityInhibition of multiple antitumor effectsOrganic active ingredientsGroup 1/11 element organic compoundsCancer cellVascular proliferation

The invention discloses a metal complex containing a tridentate ligand and a xanthine derivative ligand and a preparation method and medical application of the metal complex. Specifically, the metal complex containing the tridentate ligand and the xanthine derivative ligand is shown as a formula I. The complex has inhibitory activity on tumor cells, tumor stem cells and angiogenesis at the same time, and can be used for preparing drugs for treating various malignant tumors, especially drugs for treating malignant tumors resistant to existing chemotherapeutic drugs. The metal complex disclosedby the invention has the characteristic of multiple anti-tumor effects, overcomes drug resistance caused by tumor stem cells and cancer cell metastasis caused by vascular proliferation, and improves the anti-tumor curative effect.

Owner:CHINA PHARM UNIV

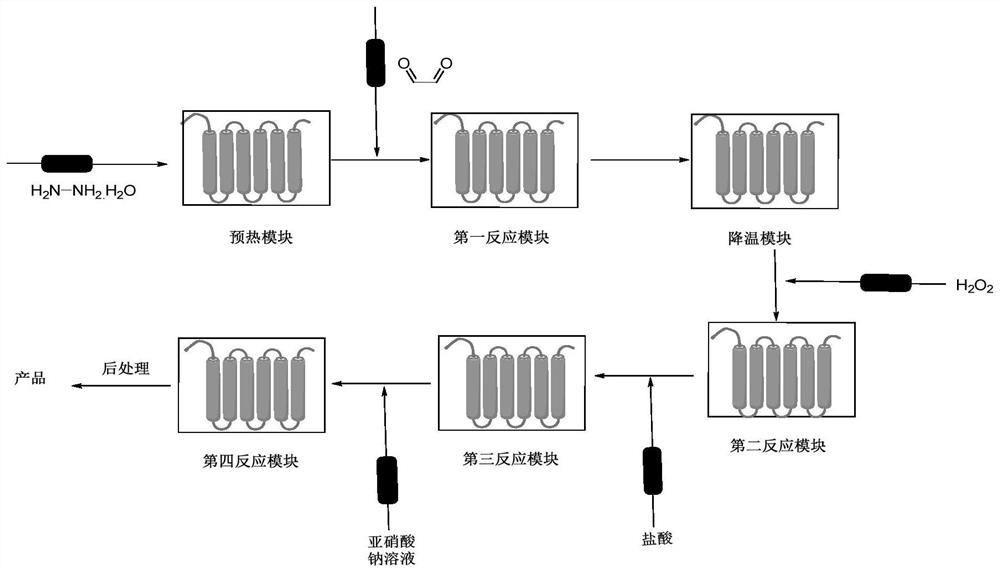

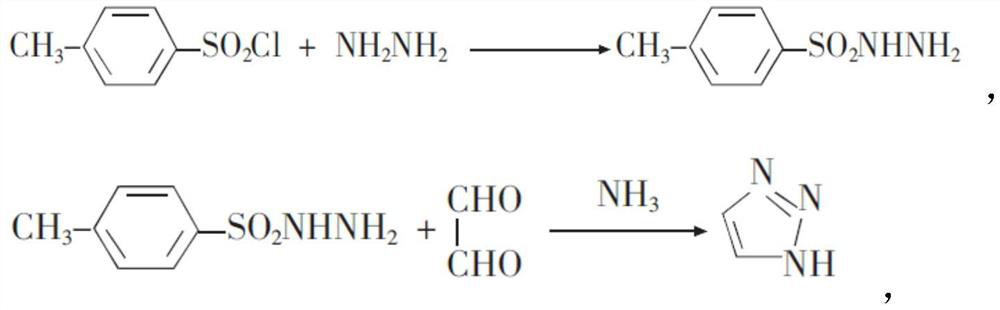

Method for continuously synthesizing 1H-1,2,3-triazole by using microchannel reactor

ActiveCN112812071ALow toxicityClean Synthesis ProcessChemical/physical/physico-chemical microreactorsHydrazone preparationEnvironmental chemistryPotassium permanganate

The invention relates to a method for continuously synthesizing 1H-1,2,3-triazole through a microchannel reactor, and belongs to the technical field of medicine synthesis. The method comprises the following steps: reacting a hydrazine hydrate aqueous solution and a glyoxal aqueous solution in a micro-channel reactor to prepare a material 1, continuously reacting the material 1 with hydrogen peroxide in the micro-channel reactor to prepare a material 2, and continuously mixing the material 2 with concentrated hydrochloric acid in the micro-channel reactor to obtain a material 3; conducting reaction on the material 3 and a sodium nitrite aqueous solution in the micro-channel reactor, and conducting post-treatment to obtian 1H-1,2,3-triazole. No solvent needs to be added or replaced in the reaction process, manganese dioxide and potassium permanganate which can generate solid waste are prevented from being used, and toxic substances such as toluenesulfonyl chloride and dioxane which are harmful to the environment are not used either; and the 1H-1,2,3-triazole can be safely produced.

Owner:SHANDONG JINCHENG KERUI CHEMICAL CO LTD

Modified fatty acid type primary emulsion for high-temperature-resistant oil based drilling fluid and preparation method of modified fatty acid type primary emulsion

ActiveCN105315973AReduce high temperature and high pressure filtration lossHigh practical valueDrilling compositionEmulsionFatty acid

The invention discloses a modified fatty acid type primary emulsion for high-temperature-resistant oil based drilling fluid and a preparation method of the modified fatty acid type primary emulsion. The modified fatty acid type primary emulsion for the high-temperature-resistant oil based drilling fluid consists of the following components: dicarboxylic anhydride, fatty acid and epoxy chloropropane, wherein the mass ratio of dicarboxylic anhydride to fatty acid is 1:20-1:30, and the mass of the epoxy chloropropane accounts for 15-25% of the mass of the fatty acid. The modified fatty acid type primary emulsion disclosed by the invention is obtained by modifying the fatty acid, has stronger emulsifying capacity and high temperature resistance, and has an effect of reducing the high-temperature high-pressure filtration losses of the oil based drilling fluid at the same time.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of 4-chloropyrrolo[2,3-d]pyrimidine Preparation method of 4-chloropyrrolo[2,3-d]pyrimidine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/e595af4f-6fd7-4780-8b9f-d31fa561dd1a/GSA00000123074400021.PNG)

![Preparation method of 4-chloropyrrolo[2,3-d]pyrimidine Preparation method of 4-chloropyrrolo[2,3-d]pyrimidine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/e595af4f-6fd7-4780-8b9f-d31fa561dd1a/GSA00000123074400031.PNG)