Method for preparing ferrous phosphate-based lithium salt

A ferrous phosphate, lithium iron phosphate technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of uneven dispersion of conductive agents, affecting the conductivity of positive active materials, etc., to achieve low production costs, The synthesis process is simple and easy, and the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

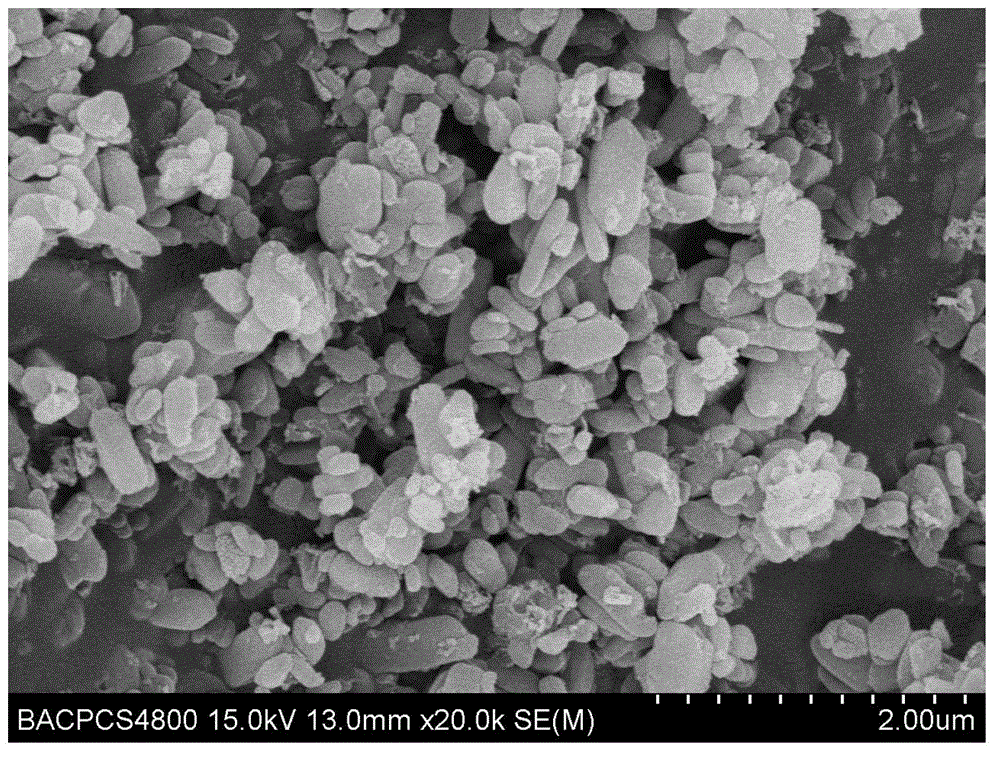

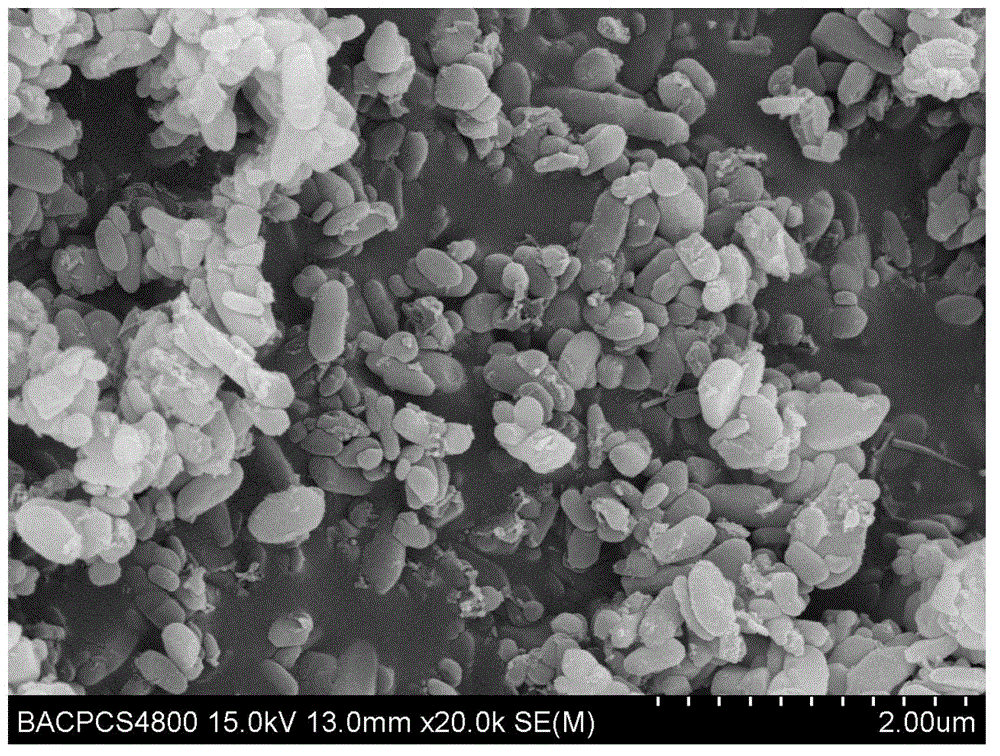

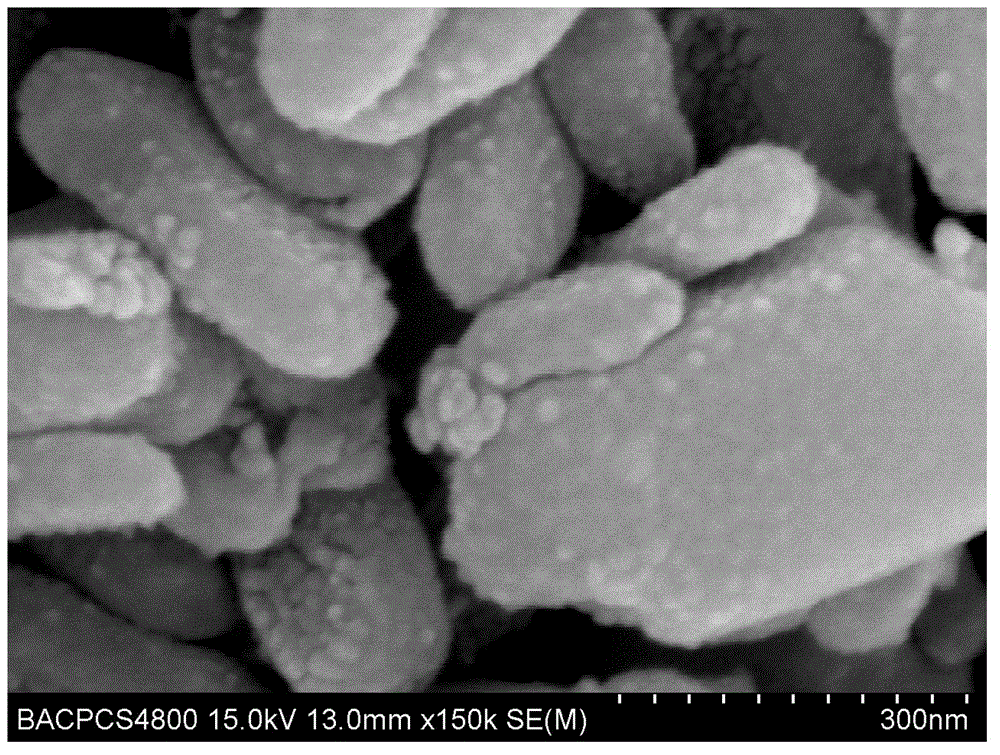

Image

Examples

Embodiment 1

[0039] Use an analytical balance to accurately weigh (NH 4 ) 3 PO 4 149g, FeCl 2 126.9g of LiF and 78g of LiF were respectively dissolved in 500ml of water, and the mechanical stirring speed was set to 300r / min for full dissolution and mixing. After stirring for 20 minutes, the raw materials were completely dissolved without visually visible crystal particles. At this time, under the action of the mechanical stirring paddle (speed = 400 rpm), the (NH 4 ) 3 PO 4 Pour the two prepared solutions with LiF into a large round bottom flask, stir for 30min, and then add FeCl 2 At the same time, 1500ml of dimethyl sulfoxide was added, 6.54g of sodium sulfite was added as an antioxidant, and the concentration of 1mol / L lithium hydroxide was added to adjust the Ph=6.5 of the solution. Use an oil bath (this example uses silicone oil) to heat at 104°C for 2 hours, and while heating, use a mechanical stirrer (rotational speed = 400 rpm) to stir. After completion, filter and wash the ...

Embodiment 2

[0045] Use an analytical balance to accurately weigh H 3 PO 4 9.8g, FeSO 4 15.2g of LiOH and 7.2g of LiOH were respectively dissolved in 50ml of water, and the mechanical stirring speed was set to 200r / min to stir for full dissolution and mixing. When the drug is completely dissolved, no visible crystal particles can be seen visually. At this time, under the action of the mechanical stirring paddle (speed = 300 rpm), the H 3 PO 4 Pour the two prepared solutions with LiOH into a large round bottom flask, stir for 30min, and then add FeSO 4 At the same time, 150ml of dimethyl sulfoxide was added, and 0.65g of sodium sulfite was added as an antioxidant, and the pH of the solution was adjusted to 7 by using 30% ammonia water. Use an oil bath (silicon oil is used in this laboratory) to heat at 110°C for 4 hours, while heating, use a mechanical stirrer (speed = 300 rpm) to stir simultaneously, filter and wash the solid at the bottom of the flask 4 times, and finally get Precur...

Embodiment 3

[0051] Use an analytical balance to accurately weigh H 3 PO 4 9.8g, FeSO 4 15.2g of LiOH and 7.2g of LiOH were respectively dissolved in 50ml of water, and the mechanical stirring speed was set to 500r / min for full dissolution and mixing. When the drug is completely dissolved, no visible crystal particles can be seen visually. At this time, under the action of the mechanical stirring paddle (speed = 400 rpm), the H 3 PO 4 Pour the two prepared solutions with LiOH into a large round bottom flask, stir for 30min, and then add FeSO 4 , while adding isophorone 150ml, adding sodium sulfite 0.65g as an antioxidant, and adjusting the pH of the solution to 6.8 with a concentration of 15% ammonia water. Use an oil bath (silicon oil is used in this laboratory) to heat at 140°C for 10 hours, while heating, use a mechanical stirrer (speed = 600 rpm) to stir simultaneously, and repeatedly wash and filter the solid at the bottom of the flask to finally get Precursor.

[0052] The fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com