Reduction processing method for synthesizing lithium iron phosphate materials

A technology of lithium iron phosphate and process method, which is applied in the field of reduction process of synthetic lithium iron phosphate material, and can solve the problems affecting the conductivity of positive electrode active material and uneven dispersion of conductive agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

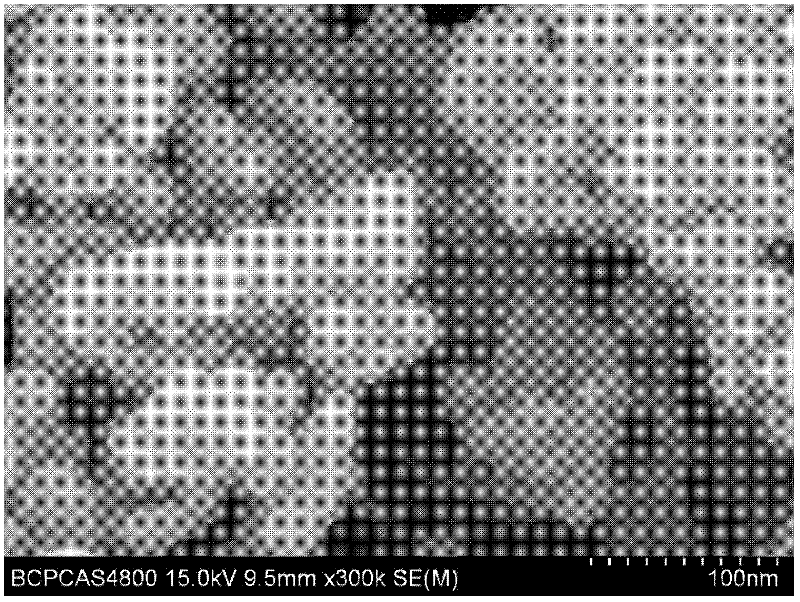

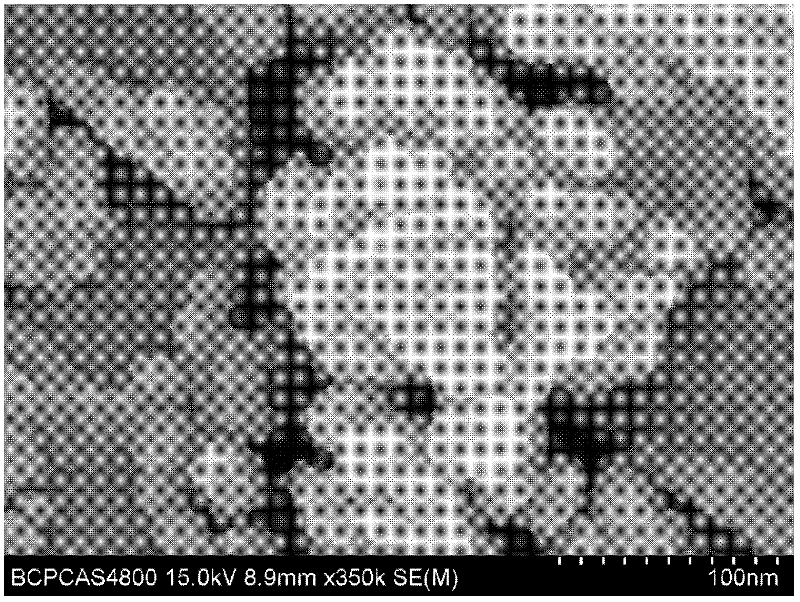

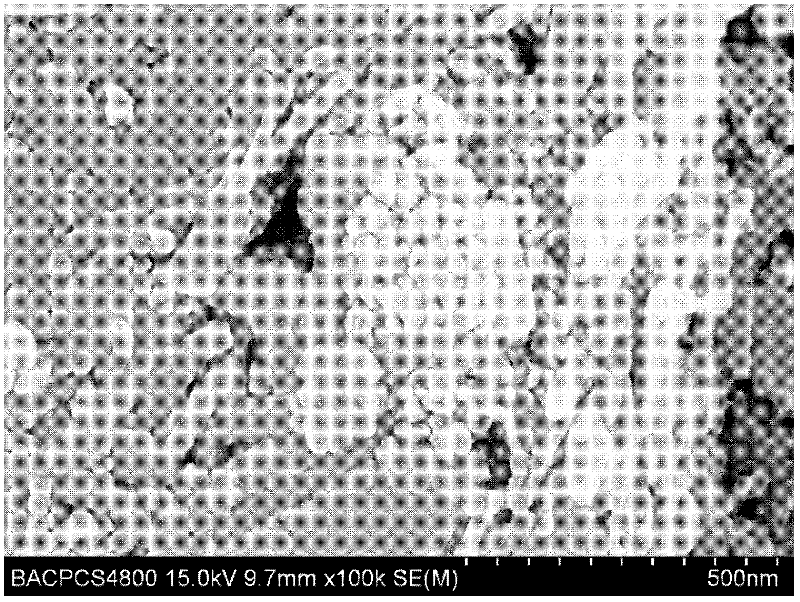

Image

Examples

Embodiment 1

[0045] Use an analytical balance to accurately weigh (NH 4 ) 3 PO 4 149g, FeCl 2 91.5g of LiF and 25g of LiF were respectively dissolved in 500ml of water and fully dissolved by magnetic stirring. After stirring for about 15 minutes, the drug was completely dissolved without visible crystal particles. At this time, under the action of a mechanical stirring paddle (rotating speed=300 rpm), three prepared solutions are poured into the reaction vessel successively while stirring, and the pH value of the solution is adjusted to 6.5 with ammonia water and nitric acid, and finally 1000ml of Ethylene glycol (high boiling point organic solvent). Keep heating at 110° C. for 3 h, and stir with a mechanical stirrer (speed = 300 rpm). While heating, the reaction vessel was fed with nitrogen as an inert gas protection, and 3% sulfurous acid was added as an antioxidant. After the reaction is completed, the mixed material liquid is filtered, and the precipitation is repeatedly washed a...

Embodiment 2

[0051] Use an analytical balance to accurately weigh (NH 4 ) 3 PO 4 1490g, FeCl 2 915g of LiF and 250g of LiF were respectively dissolved in 5000ml of water and fully dissolved by magnetic stirring. After stirring for about 15 minutes, the drug was completely dissolved without visible crystal particles. At this time, under the action of a mechanical stirring paddle (rotating speed=400 rpm), pour the three prepared solutions into the reaction vessel successively while stirring, adjust the pH value of the solution to 7.5 with ammonia and nitric acid, and finally add 10000ml of Ethylene glycol (high boiling point organic solvent). Keep heating at 120° C. for 4 h, and stir with a mechanical stirrer (speed = 400 rpm). While heating, the reaction vessel was fed with nitrogen as an inert gas protection, and 4% sulfurous acid was added as an antioxidant simultaneously. After the reaction is completed, the mixed material liquid is filtered, and the precipitate is repeatedly washe...

Embodiment 3

[0057] Use an analytical balance to accurately weigh (NH 4 ) 3 PO 4 14.9g, FeCl 2 9.15g of LiF and 2.5g of LiF were respectively dissolved in 50ml of water and fully dissolved by magnetic stirring. After stirring for about 15 minutes, the drug was completely dissolved without visible crystal particles. At this time, under the action of a mechanical stirring paddle (rotating speed=300 rpm), pour the three prepared solutions into the reaction vessel successively while stirring, adjust the pH value of the solution to 8.6 with ammonia and nitric acid, and finally add 100ml of ethyl alcohol. Glycols (high boiling point organic solvents). Keep heating at 120° C. for 3 h, and stir with a mechanical stirrer (speed = 300 rpm). While heating, the reaction vessel was fed with nitrogen as an inert gas protection, and 3% sulfurous acid was added as an antioxidant. After the reaction is completed, the mixed material liquid is filtered, and the precipitate is repeatedly washed and filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com