Antioxidant resin through benzene ethylenation of p - methyl phenol ¿C dicyclopentadiene

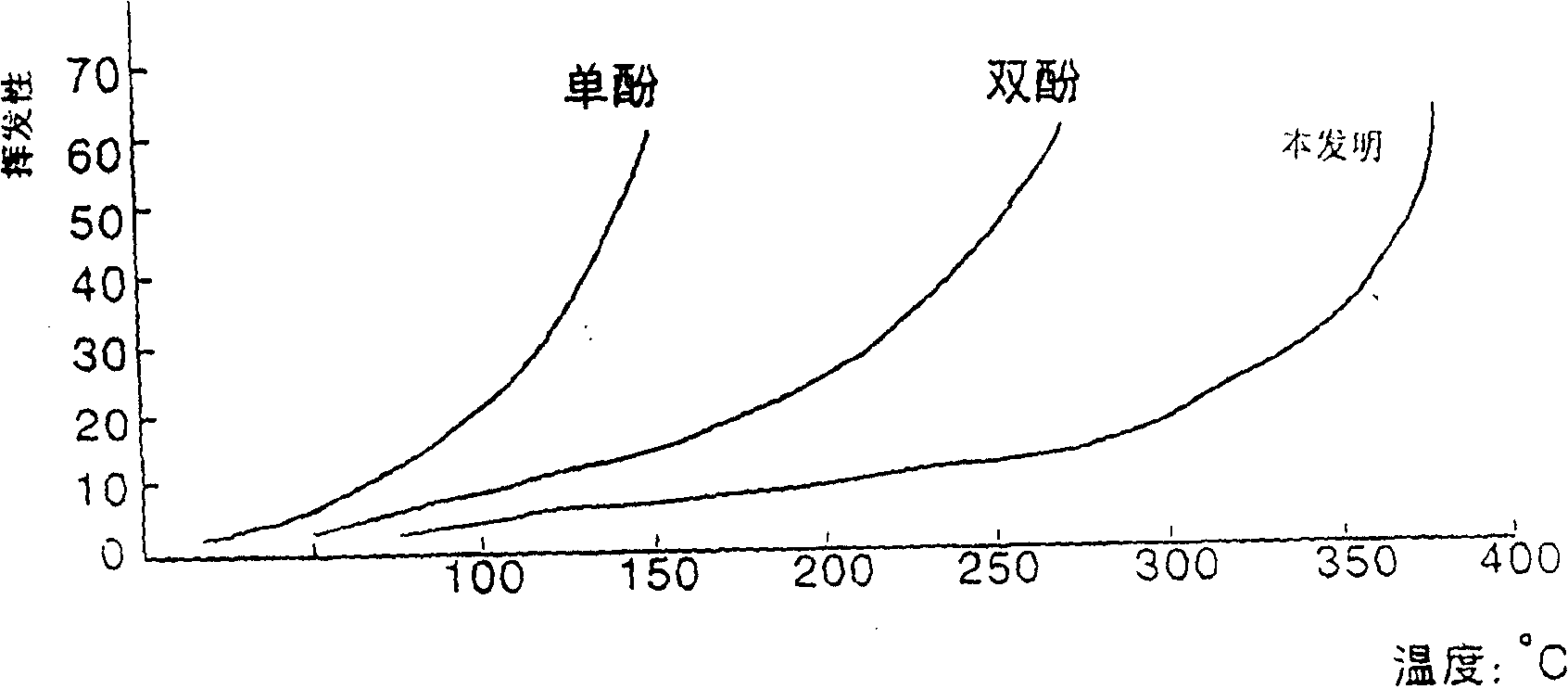

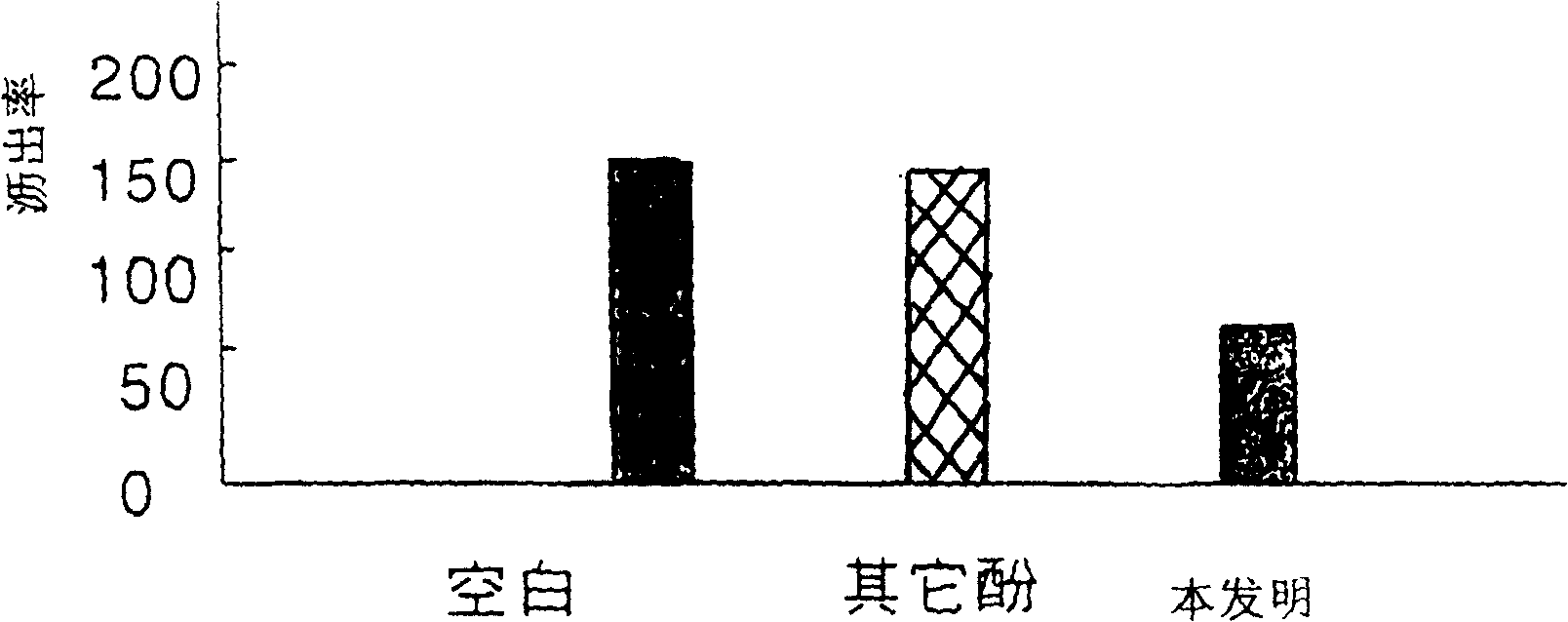

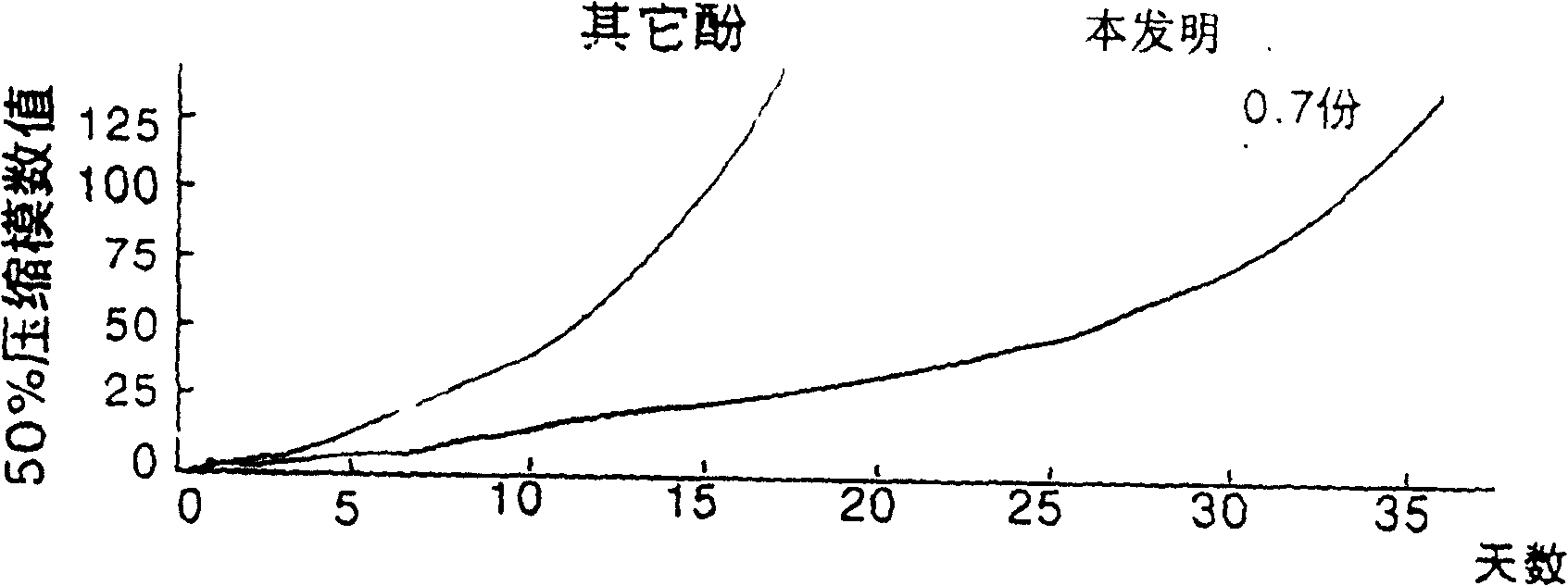

A technology of p-cresol and dicyclopentadiene, which is applied in the field of p-cresol-dicyclopentadiene styrenated antioxidant resin and antioxidant, can solve the problem of poor heat resistance, affecting the use effect, and potential safety hazards, etc. problems, to achieve the effect of safe and reliable synthesis process, economical dosage, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 10kg of p-cresol and stir in the cyclohexane solvent of 35kg, add the macroporous strong acid resin catalyst of 1kg, heat up and reflux, drop 8kg of dipentadiene and cyclohexane mixed solution (weight The ratio is 1:1), the titration time is 30 minutes, react for 5 hours, then add 3 kg of styrene dropwise, the titration time is 2 hours, react for 2 hours, filter and recover the catalyst, decolorize the reaction solution through activated carbon, filter to remove activated carbon , into the distillation pot to distill to remove the solvent, and the product of the present invention is obtained after cooling.

[0033] Appearance of this product is white or light yellow powder, average molecular weight: 650-850, melting point: 100-115°C, ash content: 0.05%, average particle size: 10-30μm, solubility: soluble in aromatic solvents, such as styrene , acetone and alcohol solvents, insoluble in water and fat solvents.

Embodiment 2

[0035] The p-cresol of 10kg and the cyclohexane solvent of 50kg are mixed and stirred evenly, add the zirconium sulfate catalyst of 1.5kg, heat up and reflux, drip the dipentadiene and cyclohexene solution of 7.5kg in the reflux process (weight ratio 1: 1), the titration time was 50 minutes, reacted for 4 hours, then added dropwise the styrene of 4kg, the titration time was 1.5 hours, reacted for 2 hours, filtered and recovered the catalyst, the reaction solution was decolorized by activated carbon, filtered to remove the activated carbon, Enter the distillation kettle to distill to remove the solvent, and obtain the product of the present invention after cooling.

[0036] Appearance of this product is white or light yellow powder, average molecular weight: 650-850, melting point: 100-115°C, ash content: 0.05%, average particle size: 10-30μm, solubility: soluble in aromatic solvents, such as styrene , acetone and alcohol solvents, insoluble in water and fat solvents.

Embodiment 3

[0038] In the p-cresol of 10kg, add the cyclohexane solvent of 45kg, stir evenly, add the solid superacid catalyst of 1kg, heat up and reflux, drop 8kg of dipentadiene and cyclohexane solution (weight ratio) in the reflux process 1:1), the titration time was 50 minutes, reacted for 4 hours, then added dropwise 3.5 kg of styrene, the titration time was 2.5 hours, reacted for 2 hours, filtered and recovered the catalyst, the reaction solution was decolorized by activated carbon, and filtered to remove activated carbon , into the distillation pot to distill to remove the solvent, and the product of the present invention is obtained after cooling.

[0039] Appearance of this product is white or light yellow powder, average molecular weight: 650-850, melting point: 100-115°C, ash content: 0.05%, average particle size: 10-30μm, solubility: soluble in aromatic solvents, such as styrene , acetone and alcohol solvents, insoluble in water and fat solvents.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com