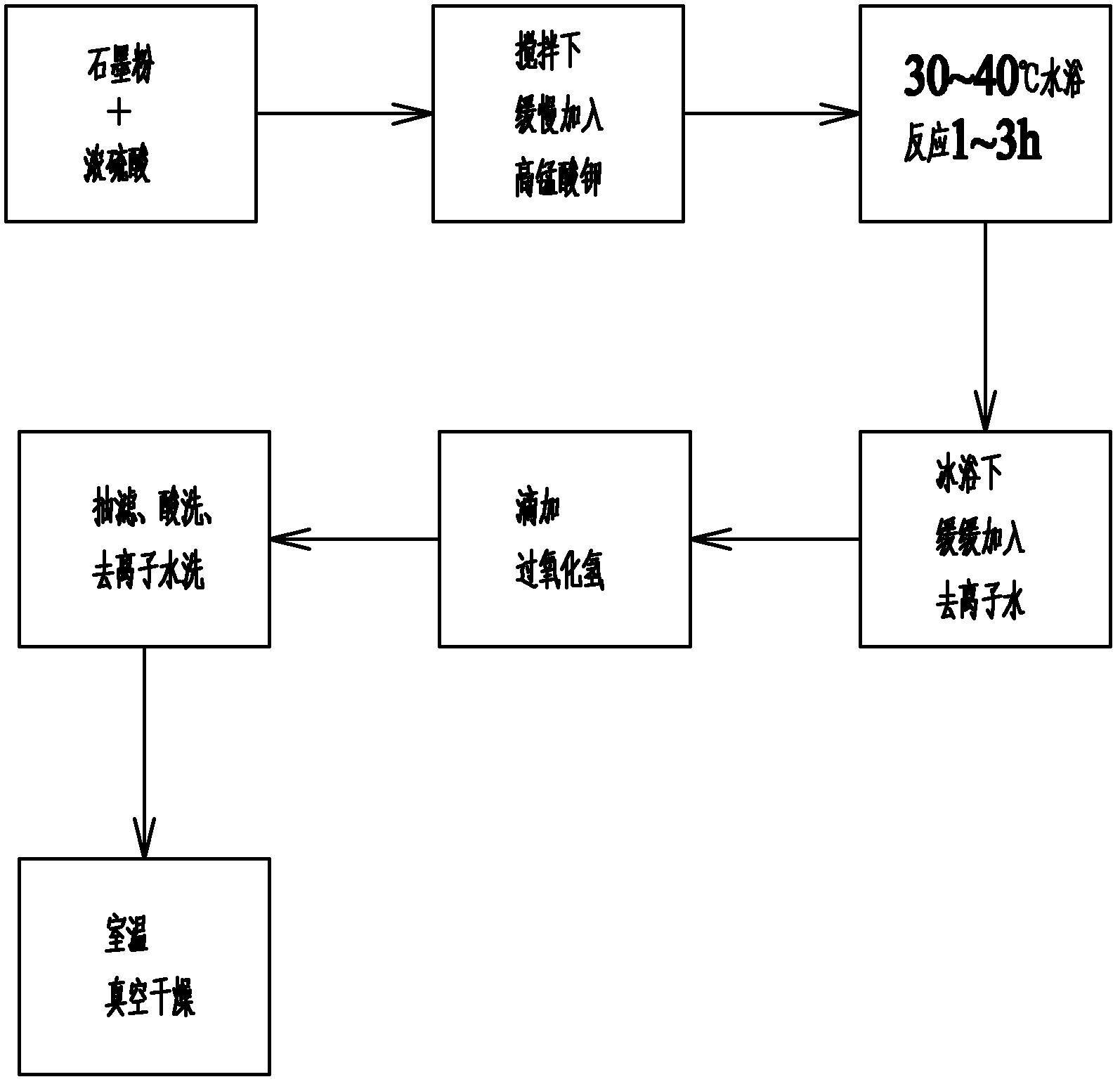

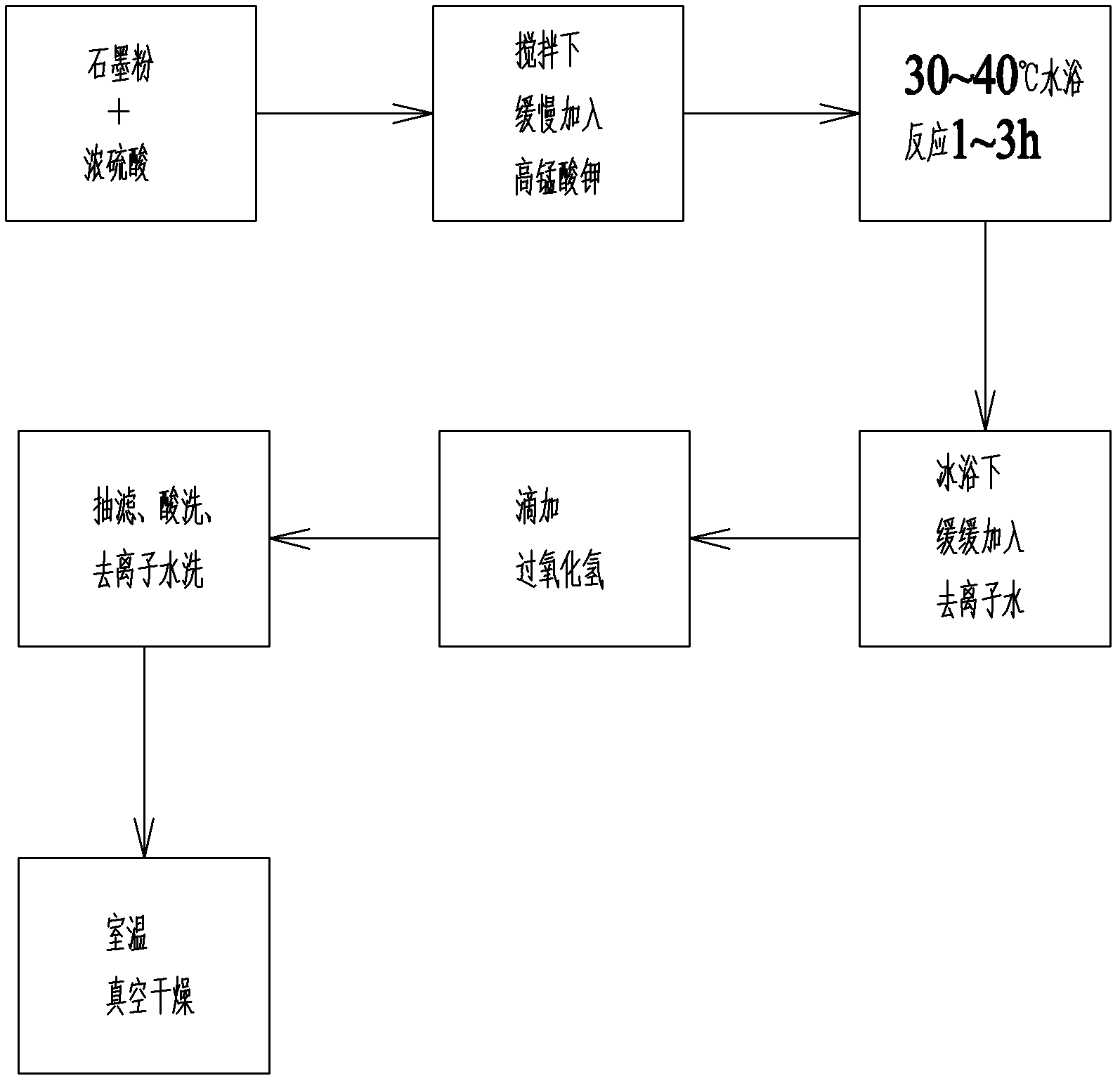

A kind of method for preparing graphite oxide by intercalation method

A technology of fossil and graphite powder, which is applied in the field of preparing graphite oxide by intercalation method, can solve the problems of easy explosion and many process factors, and achieve the effect of high degree of oxygen intercalation and short reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The method for preparing graphite oxide by Haida 100 mesh flake graphite powder intercalation method comprises the following preparation steps:

[0023] 1. Weigh 2g of Haida 100 mesh flake graphite powder, pour it into a round bottom flask with a funnel, take 100ml of concentrated sulfuric acid with a weight percentage of 98% and slowly pour it into the round bottom flask, and then put in a stirring magnet;

[0024] 2. Set the stirring speed to 200 rpm, weigh 7g of potassium permanganate and add it evenly into the concentrated sulfuric acid graphite powder solution within 18 to 20 minutes;

[0025] 3. Soak the round bottom flask in a water bath, raise the temperature of the water bath to 35°C for 2 hours, and set the stirring speed to 500 rpm;

[0026] 4. After two hours, change the round-bottomed flask to an ice bath for cooling reaction in an ice bath. Slowly add 100ml of deionized water into the round-bottomed flask to dilute concentrated sulfuric acid. The stirring ...

Embodiment 2

[0032] The method for preparing graphite oxide by Haida 500 mesh flake graphite powder intercalation method comprises the following preparation steps:

[0033] 1. Weigh 2g of Haida 500 mesh flake graphite powder, pour it into a round bottom flask with a funnel, take 100ml of concentrated sulfuric acid with a weight percentage of 98% and slowly pour it into the round bottom flask, and then put in a stirring magnet;

[0034] 2. Set the stirring speed to 200 rpm, weigh 7g of potassium permanganate and evenly add it to the concentrated sulfuric acid graphite powder solution within 15 to 16 minutes;

[0035] 3. Soak the round bottom flask in a water bath, raise the temperature of the water bath to 35°C for 2 hours, and set the stirring speed to 500 rpm;

[0036] 4. After two hours, change the round-bottomed flask to an ice bath for cooling reaction in an ice bath. Slowly add 100ml of deionized water into the round-bottomed flask to dilute concentrated sulfuric acid. The stirring sp...

Embodiment 3

[0042] The method for obtaining graphite oxide by intercalation of Haida 100 mesh flake graphite powder comprises the following preparation steps:

[0043]1. Weigh 25g of Haida 100 mesh flake graphite powder, pour it into a round bottom flask with a funnel, take 1000ml of concentrated sulfuric acid with a weight percentage of 98% and slowly pour it into the round bottom flask, and then put in a stirring magnet;

[0044] 2. Set the stirring speed to 200 rpm, weigh 87.5g of potassium permanganate and add it evenly into the concentrated sulfuric acid graphite powder solution within 16-18 minutes;

[0045] 3. Soak the round bottom flask in a water bath, raise the temperature of the water bath to 35°C for 2 hours, and set the stirring speed to 500 rpm;

[0046] 4. After two hours, change the round-bottomed flask to an ice bath for cooling reaction in an ice bath. Slowly add 1000ml of deionized water into the round-bottomed flask to dilute concentrated sulfuric acid. The stirring sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com