Preparation method of alkali metal intercalated transition metal disulfide

A technology of disulfides and transition metals is applied in the field of preparation of alkali metal intercalated transition metal disulfides, which can solve the problems of high price of experimental reagents, high equipment requirements, dangerous reactions, etc., and achieves easy operation, safe synthesis process, The effect of expanding the layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a, take chemically pure tin disulfide 2.0050g, join in the dehydrated alcohol of 150ml, stir 30 minutes under the condition of ice bath;

[0019] b. When the temperature of the above solution drops to 0°C, add 0.1660 g of analytically pure sodium borohydride, then keep stirring, and add 0.2203 g, 0.2067 g, 0.3012 g and 0.3029 g of sodium borohydride in four times every 8 hours, After stirring and reacting for 72 hours, centrifuge to obtain a brown solid product, then filter and wash the product with absolute ethanol, and dry naturally to obtain a compound intercalated with sodium tin disulfide.

Embodiment 2

[0021] a, take chemically pure tin disulfide 1.0150g, join in the anhydrous methanol of 100ml, stir 20 minutes under the condition of ice bath;

[0022] b. Add 0.2005g of analytically pure potassium borohydride when the temperature of the above solution drops to 0°C, and then keep stirring, and add 0.2267g, 0.2379g, 0.2013g and 0.2777g of potassium borohydride in four times every 10 hours, After stirring and reacting for 96 hours, centrifuge to obtain a brown solid product, then filter and wash the product with anhydrous methanol, and dry naturally to obtain a compound intercalated with potassium tin disulfide.

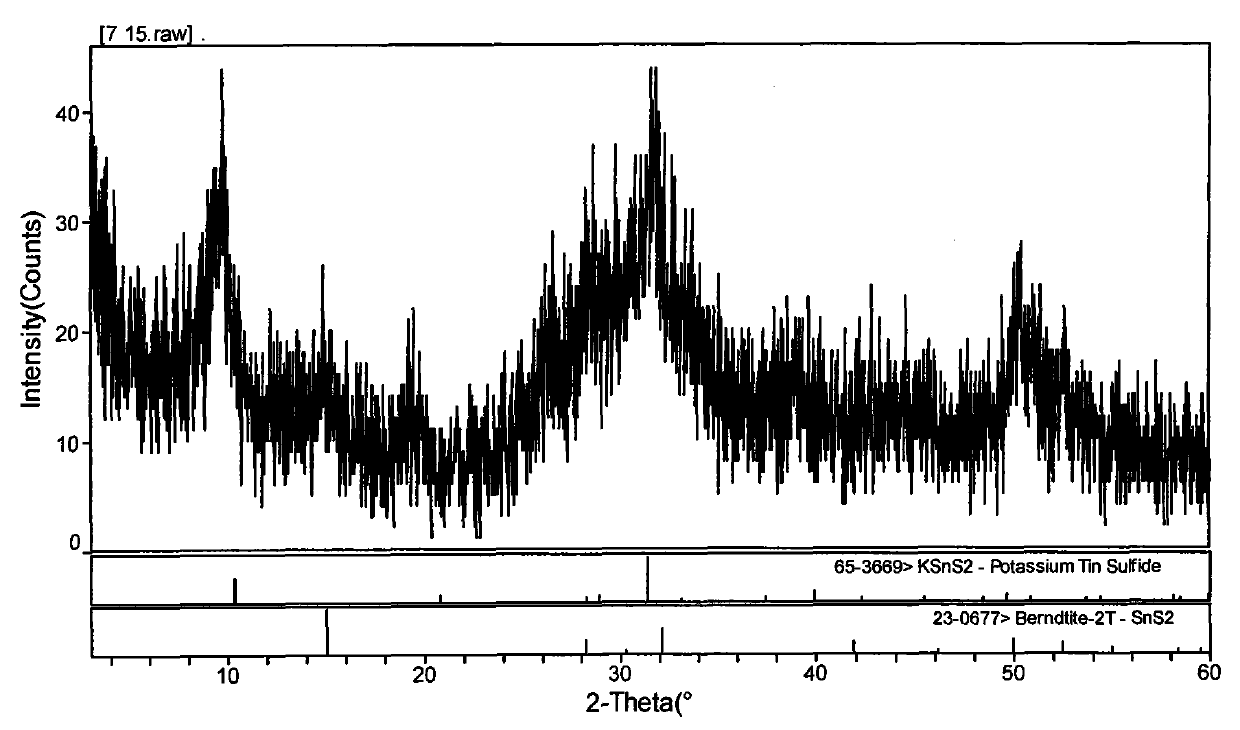

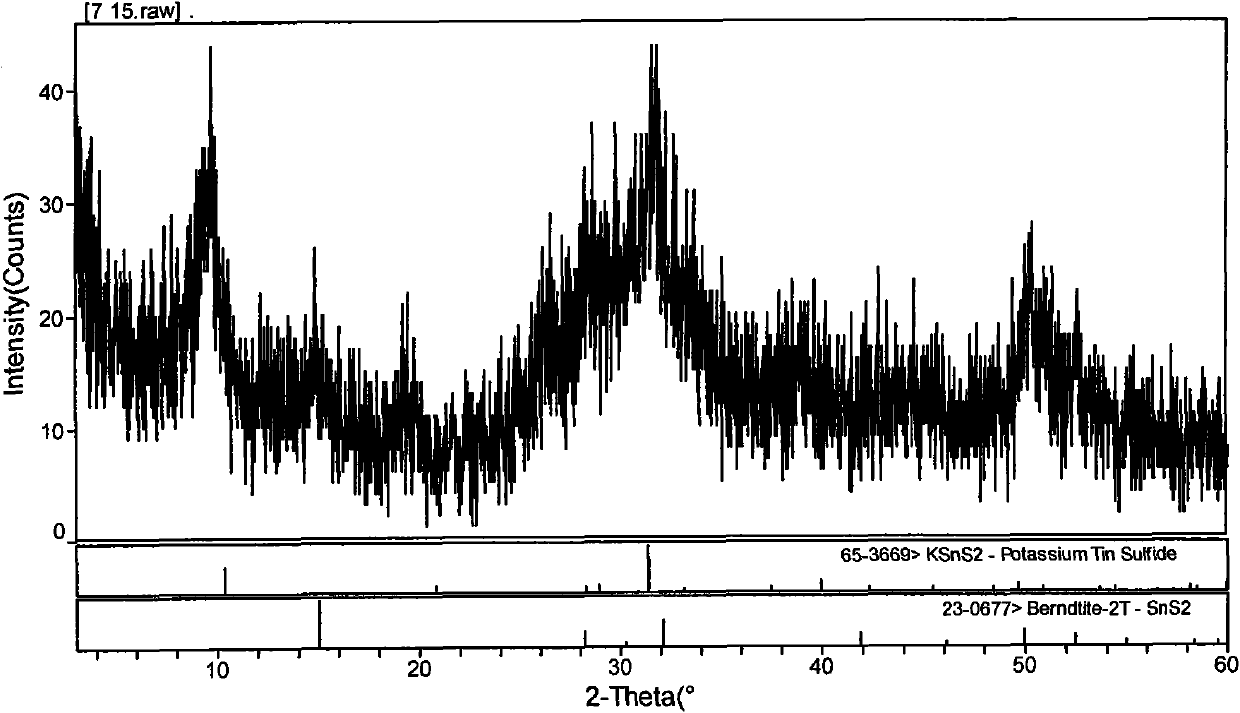

[0023] See attached figure 1 , for the product potassium tin disulfide intercalation compound (KSnS 2 ) for XRD spectrum detection, it can be seen from the spectrum that the product has a strong peak at about 10 degrees, which can confirm that the alkali metal ions have been well inserted between the sheets of the transition metal dichalcogenide inorganic material. ...

Embodiment 3

[0025] a, take chemically pure tin disulfide 1.0375g, join in the anhydrous methanol of 80ml, stir 30 minutes under the condition of ice bath;

[0026] b. When the temperature of the above solution drops to 0°C, add 0.1037g of analytically pure potassium borohydride, then keep stirring, and add 0.0637g, 0.3587g and 0.1900g of potassium borohydride three times every 10 hours, and stir for 96 hours After centrifugation, a brown solid product was obtained, and then the product was filtered and washed with anhydrous methanol, and the compound intercalated with potassium tin disulfide was obtained after natural drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com