Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Stable processing technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

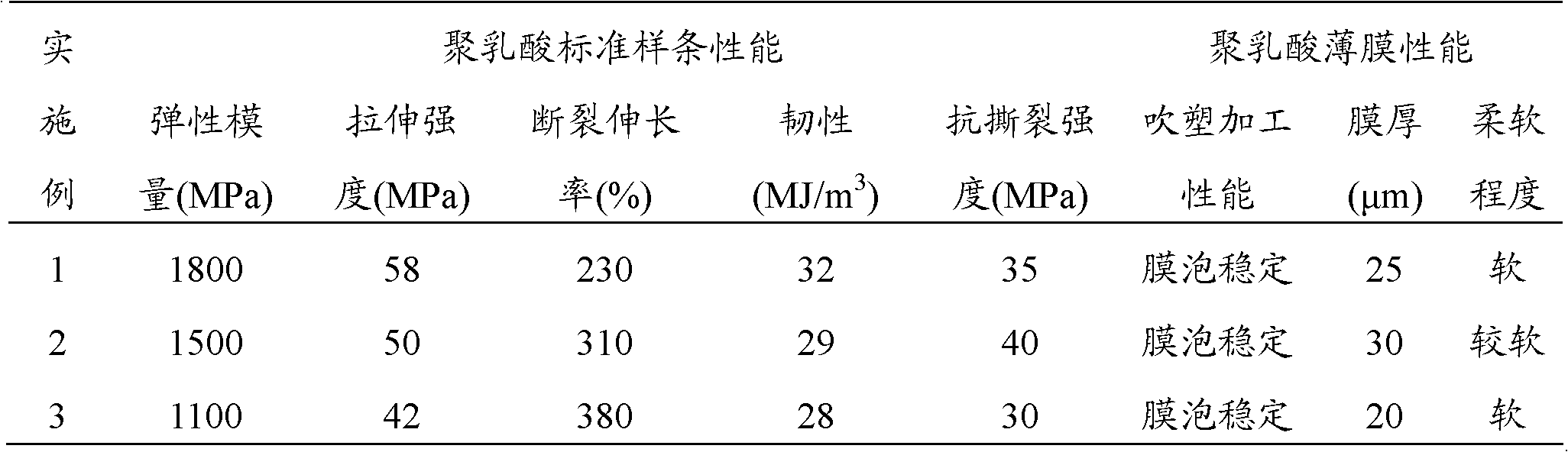

Polylactic acid composition and polylactic acid product

InactiveCN102618003AGood comprehensive mechanical propertiesImprove blow molding processabilityPlasticizerPolylactic acid

The invention provides a polylactic acid composition and a polylactic acid product. The polylactic acid composition comprises the following components by weight percent: 50 to 80 percent of polylactic acid, 0 to 35 percent of adipic acid-polybutylene terephthalate, 0 to 35 percent of poly(butylene succinate), 0.05 to 0.5 percent of peroxide, 0.05 to 0.5 percent of chain extendor and 3 to 15 percent of plasticizer, wherein the content of the adipic acid-polybutylene terephthalate and the content of the poly(butylene succinate) are not 0 percent. The mechanical properties such as melt strength, elongation at break, tenacity and anti-tear strength of the polylactic acid composition provided by the invention are improved, so that the polylactic acid composition with better comprehensive mechanical properties can be obtained, and the polylactic acid composition has more stable processability and better film forming stability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

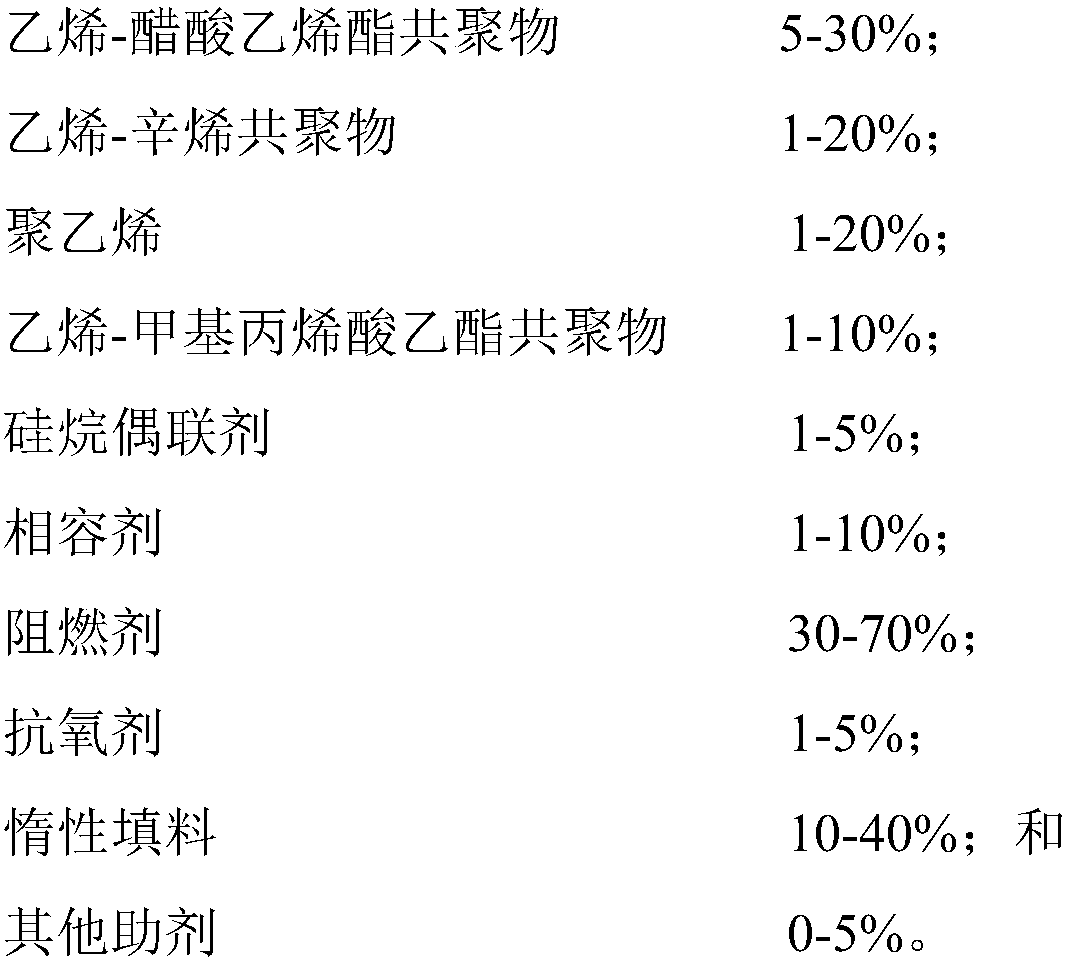

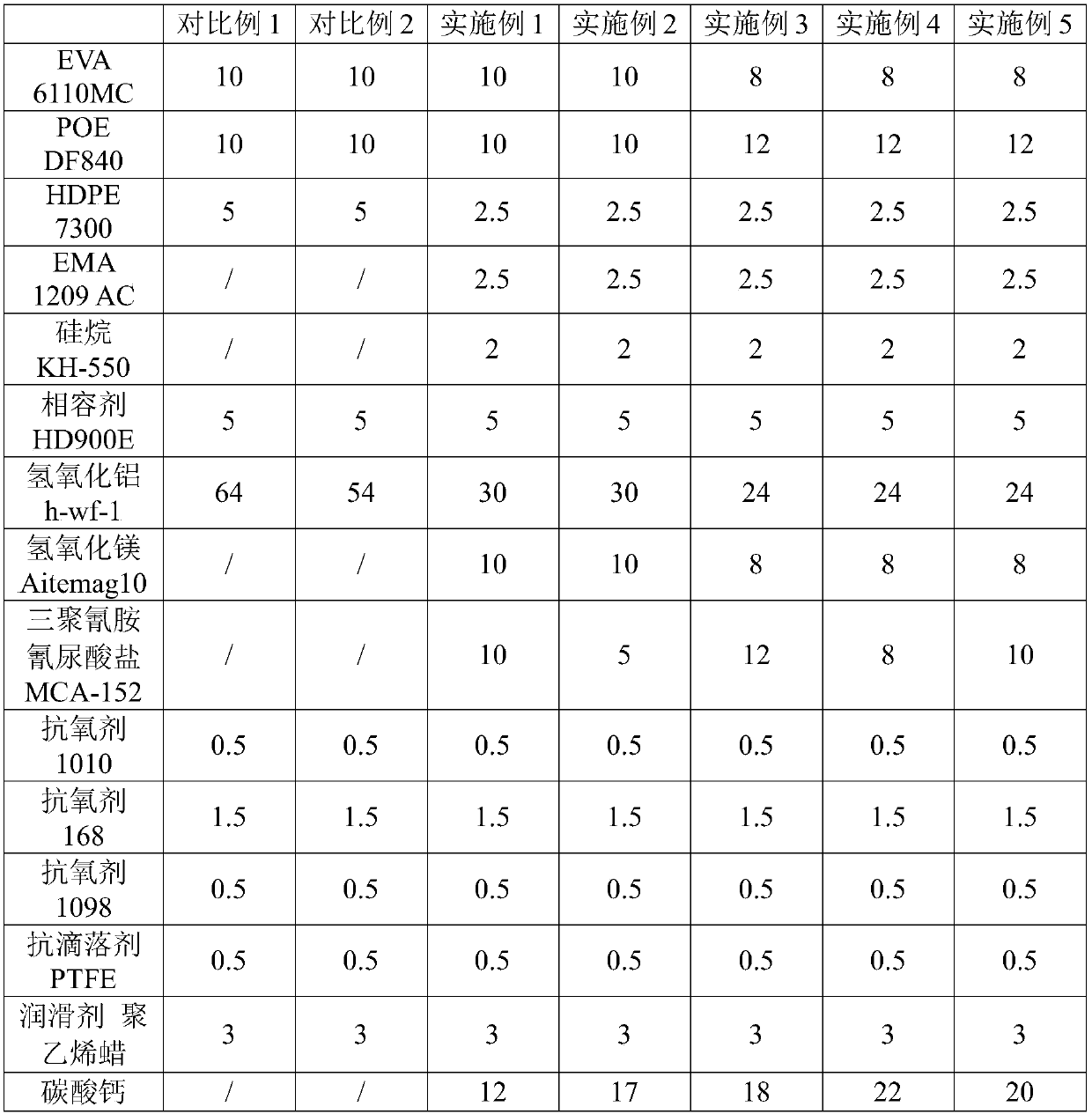

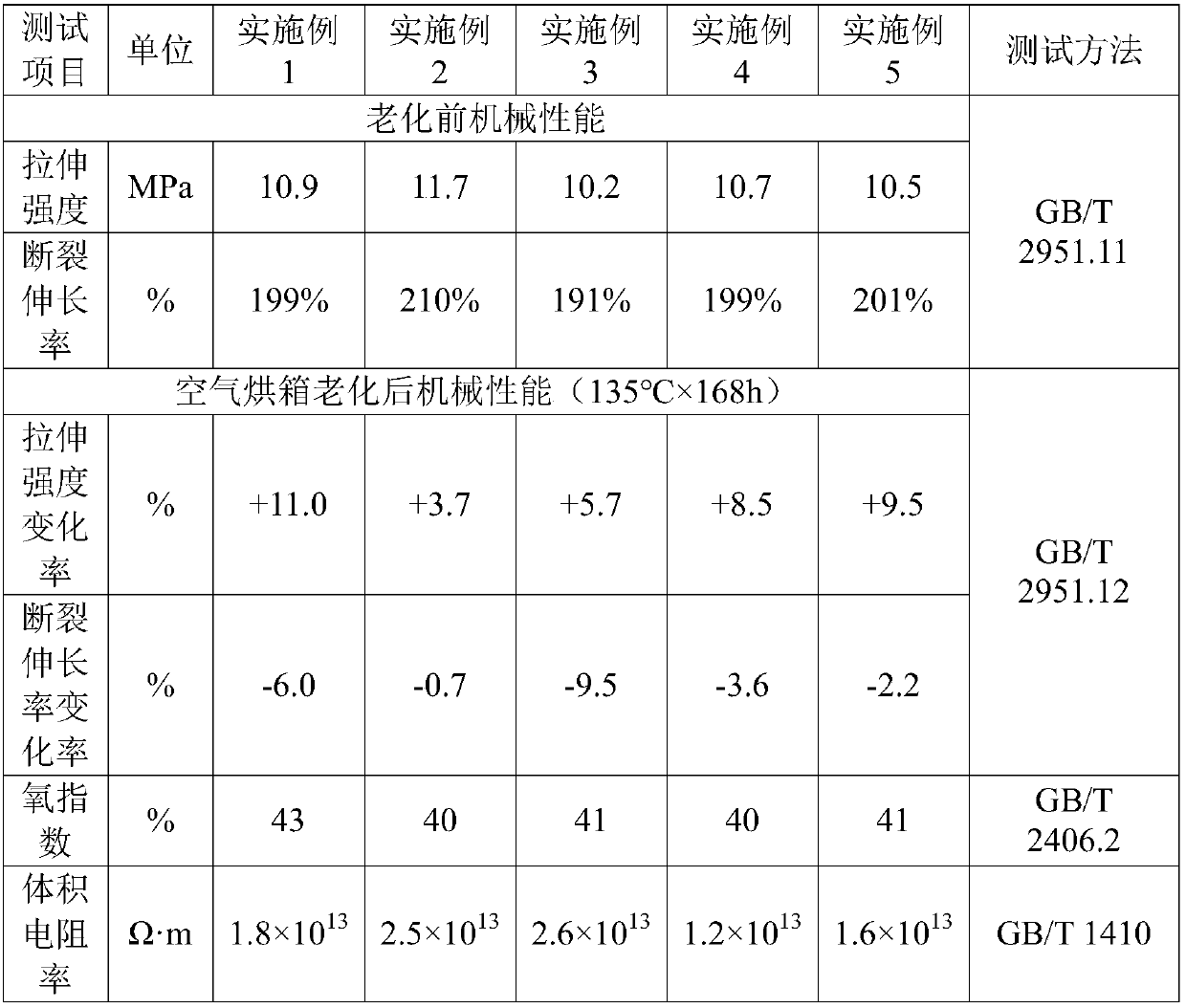

B1-grade flame-retardant irradiation crosslinking low-smoke halogen-free insulated cable material and preparation method thereof

InactiveCN109627567AStable processing technologyIncrease productionPlastic/resin/waxes insulatorsPolymer scienceAntioxidant

The invention discloses a B1-grade flame-retardant irradiation crosslinking low-smoke halogen-free insulated cable material and a preparation method thereof. The B1-grade flame-retardant irradiation crosslinking low-smoke halogen-free insulated cable material is prepared from, by mass, 5-30% of ethylene-vinyl acetate copolymer (EVA), 1-20% of ethylene-octylene copolymer (POE), 1-20% of polyethylene (PE), 1-10% of ethylene-ethyl methacrylate copolymer (EMA), 1-5% of silane, 1-10% of a compatilizer, 40-70% of a flame retardant, 1-5% of an antioxidant, 0-5% of other auxiliaries and 10-40% of inert filler. The cable material can meet B1-grade flame-retardant requirements and has good mechanical performance and processing performance.

Owner:上海至正新材料有限公司

Production method of polypropylene cooling masterbatch

InactiveCN101798422AFast degradationReduce volatilityMonocomponent polyolefin artificial filamentMasterbatchPolymer science

The invention discloses a production method of polypropylene cooling masterbatch, including the following steps: (1) mixing: the following components by parts by weight are mixed for 10-20 minutes: 50-90 parts of polypropylene resin, 0.5-9.5 parts of dispersing agent, 0.1-0.6 part of surface modifier, 0.1-2.7 parts of lubricant and 0.2-0.8 part of liquidity regulator, and then the following components by parts by weight are sequentially added: 0.1-0.9 part of light stabilizer, 0.1-1.6 parts of antioxidant and 0.2-7 parts of molecular weight regulator, and mixing is carried out for 5-15 minutes; (2) pelletizing: the mixed material is subject to melt extrusion at 130-230 DEG C and then grain-sized dicing is carried out. The invention adopts compound peroxide as molecular weight regulator and adopts compound antioxidant, compound dispersing agent, compound light stabilizer and compound lubricant, and the produced polypropylene cooling masterbatch has the advantages of high initiator content, good dispersity and obvious cooling effect and modification effect.

Owner:郭学阳

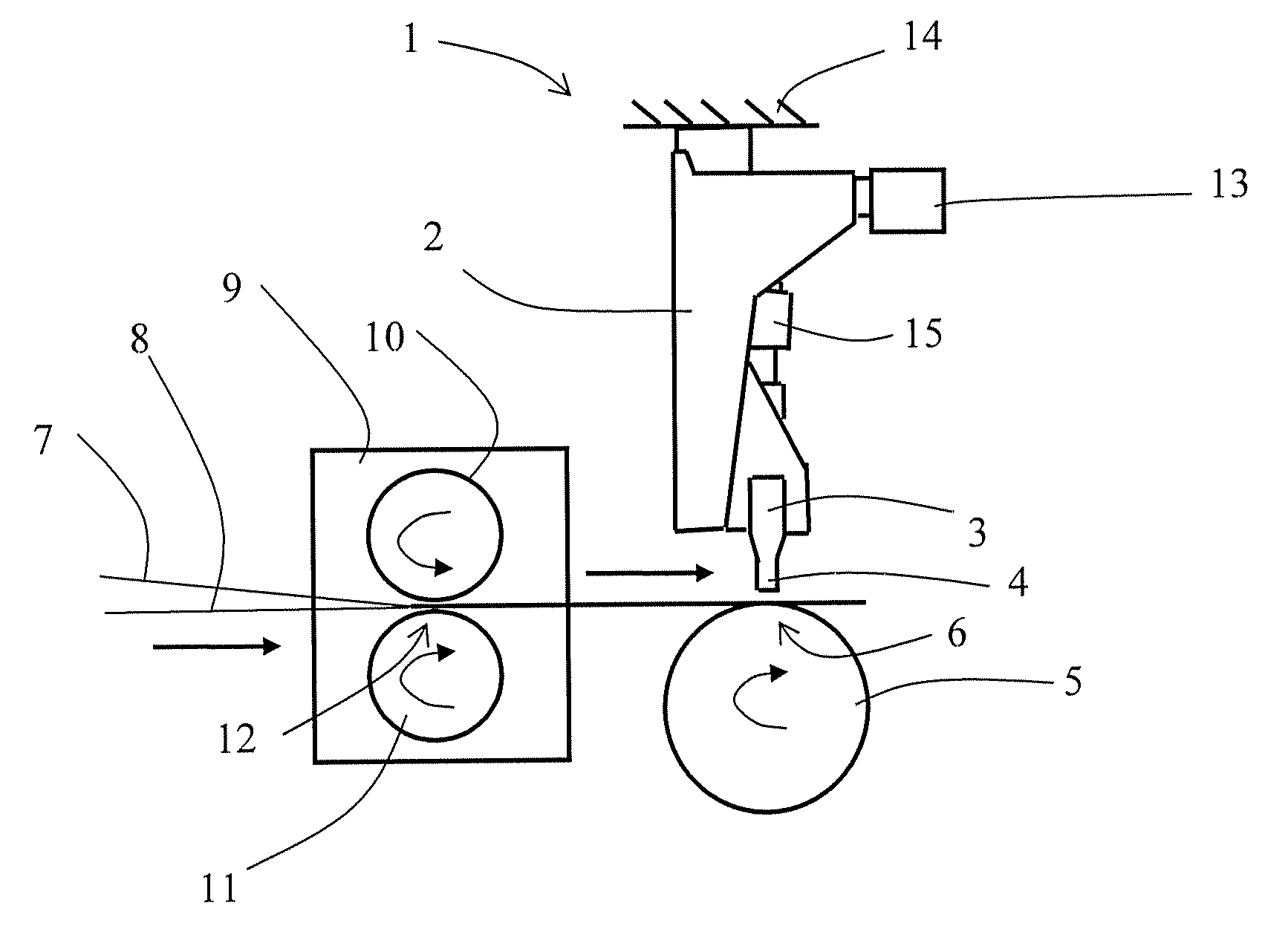

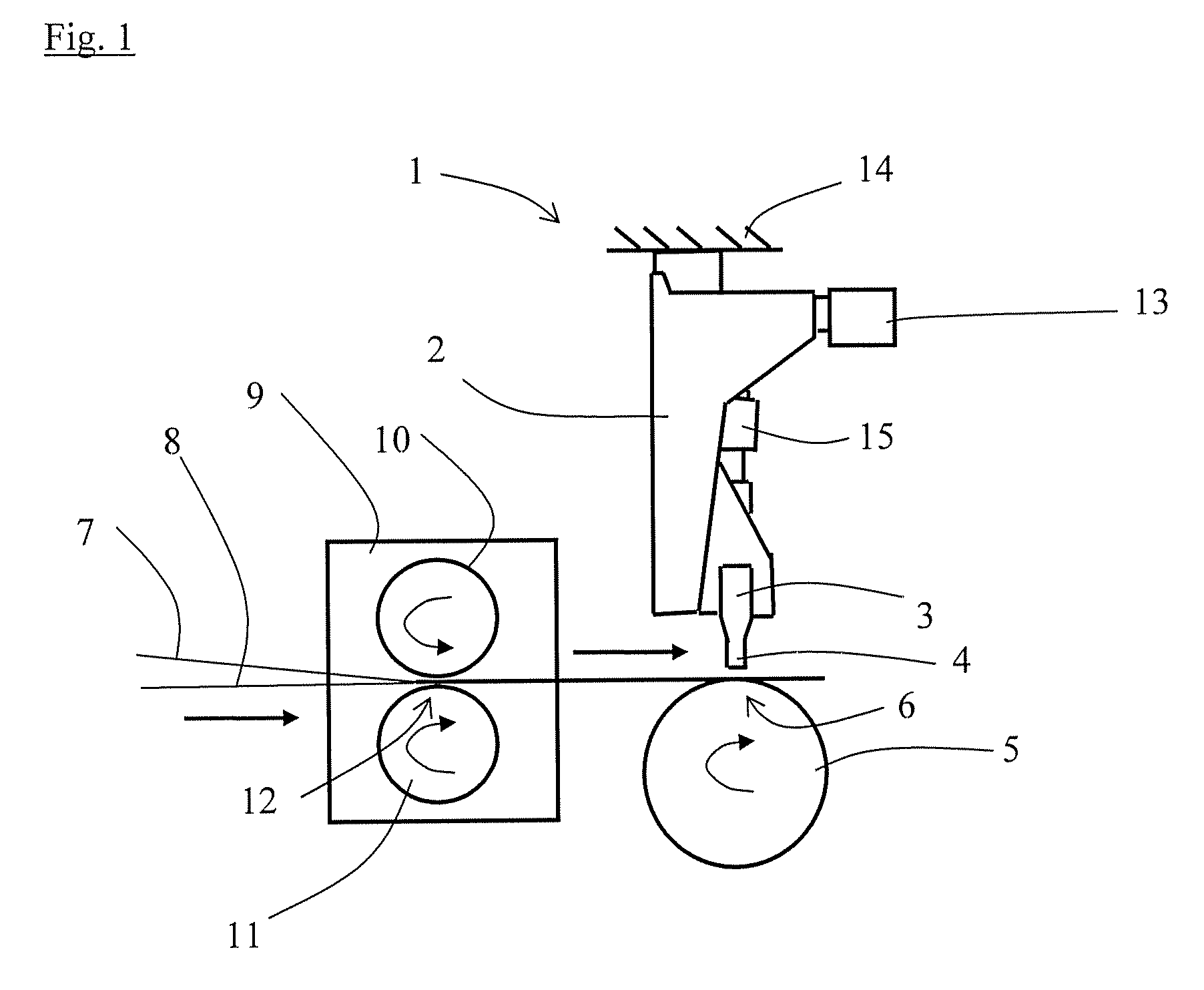

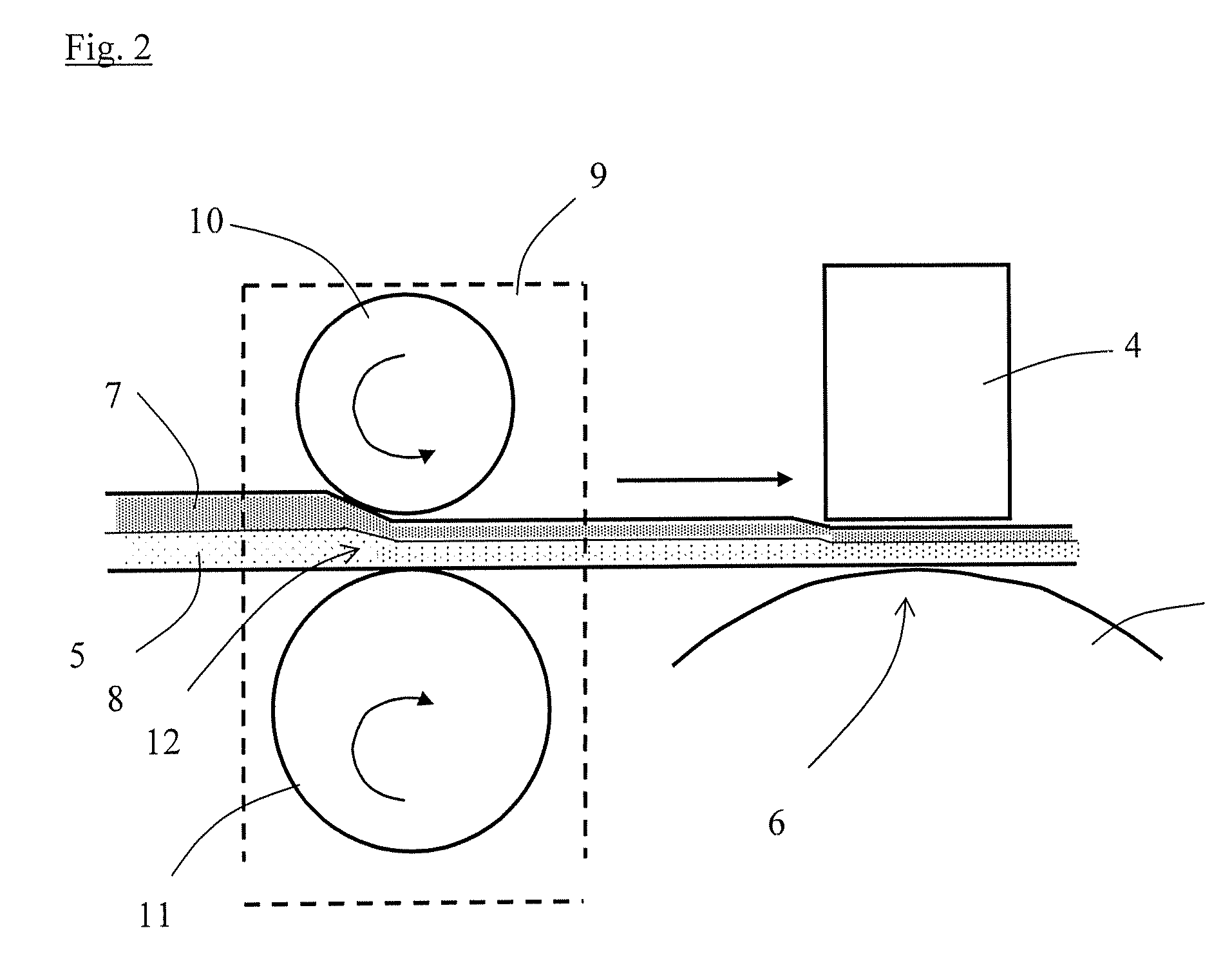

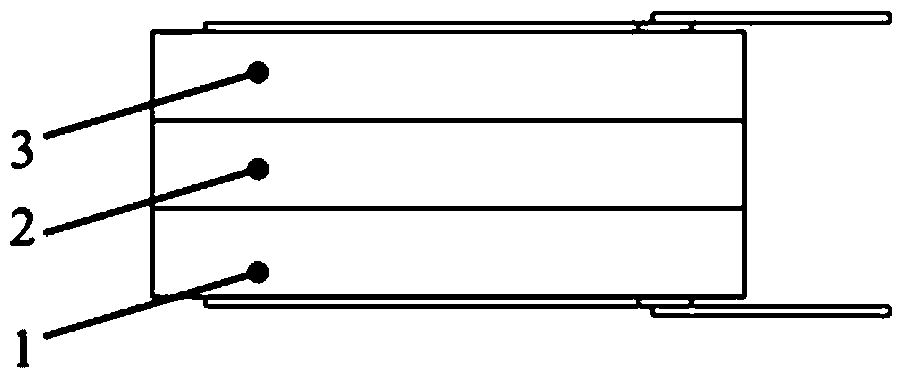

Device and Means of Processing a Material by Means of an Ultrasonic Device

InactiveUS20090133803A1Increased process windowProcess stabilityLamination ancillary operationsLayered product treatmentPre compressionAbutment

An arrangement for processing of a material including at least one layer of material by an ultrasonic device having an ultrasound horn arranged adjacent to an abutment, in conjunction with which a gap is defined between the aforementioned ultrasound horn and the aforementioned abutment, in conjunction with which the aforementioned ultrasonic device is arranged for the purpose of feeding the aforementioned material through the aforementioned gap. The arrangement includes a pre-compression unit for the mechanical compression of the aforementioned material before it is fed through the aforementioned gap.

Owner:SCA HYGIENE PROD AB

Novel processing technology of green tea

The invention discloses a novel processing technology of green tea. The novel processing technology comprises the following steps: sorting fresh tea leaves; performing water removal by adopting a long-roller tea water-removing machine; spreading and cooling the water-removed tea leaves, twisting the cooled tea leaves, performing deblocking and rolling, spreading and cooling the rolled tea leaves again, drying the rolled tea leaves, spreading and cooling the dry tea leaves for the third time, sorting the cooled tea leaves, and storing the sorted tea leaves so as to obtain tea products. The novel processing technology of the green tea, which is disclosed by the invention, is stable, the quality of the processed green tea is stable, and the efficiency is high. The green tea processed by the processing technology disclosed by the invention has the characteristics that the tea leaves are bent and look like the moon, the color of the tea leaves is green, the liquor color is dark green, and the aroma can keep for a long time; the green tea is resistant to brewing, few short and broken dry tea products are generated, the tea leaves are complete after tea is brewed, and the contents of tea polyphenol and caffeine are greatly increased.

Owner:ANHUI LVYUE TEA

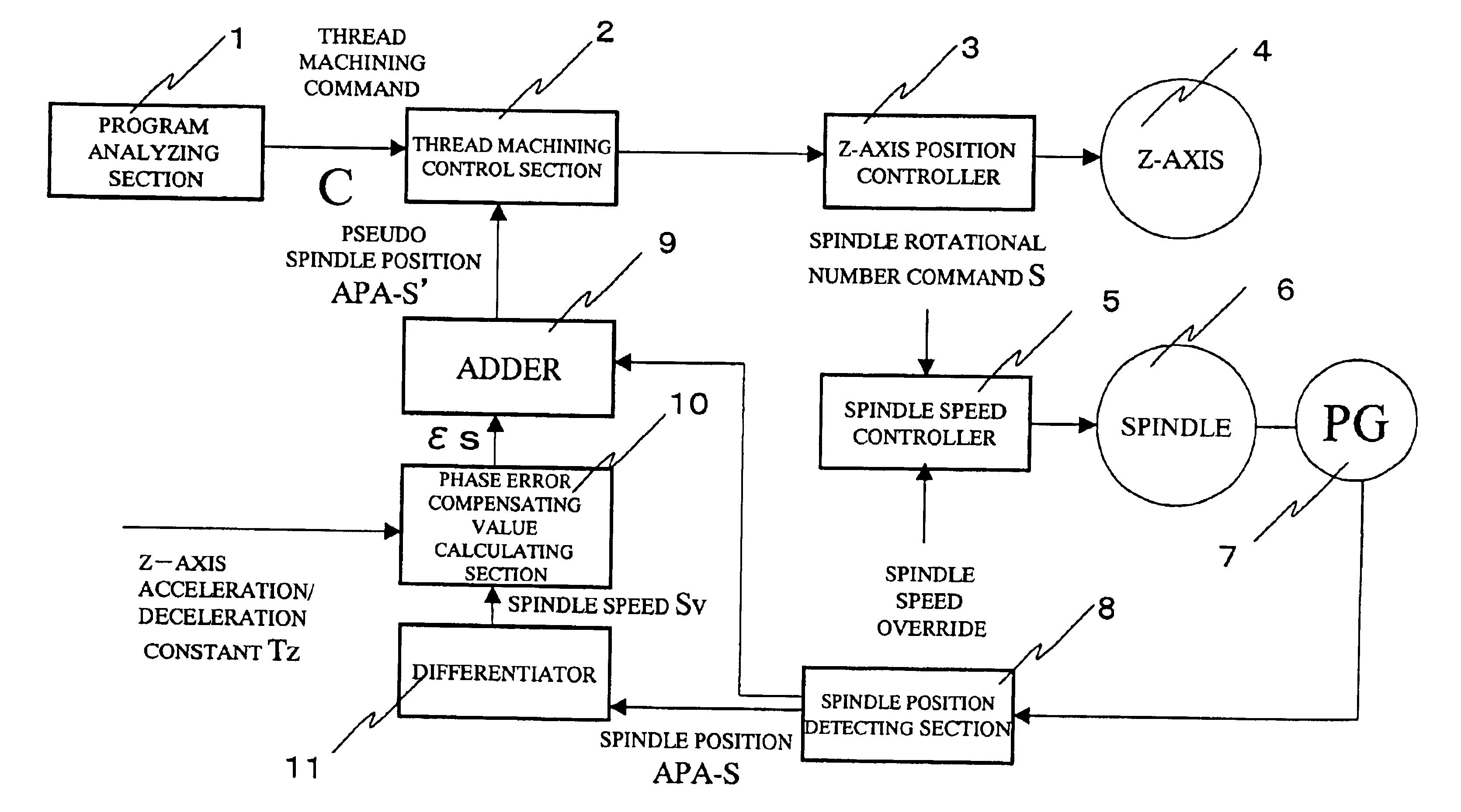

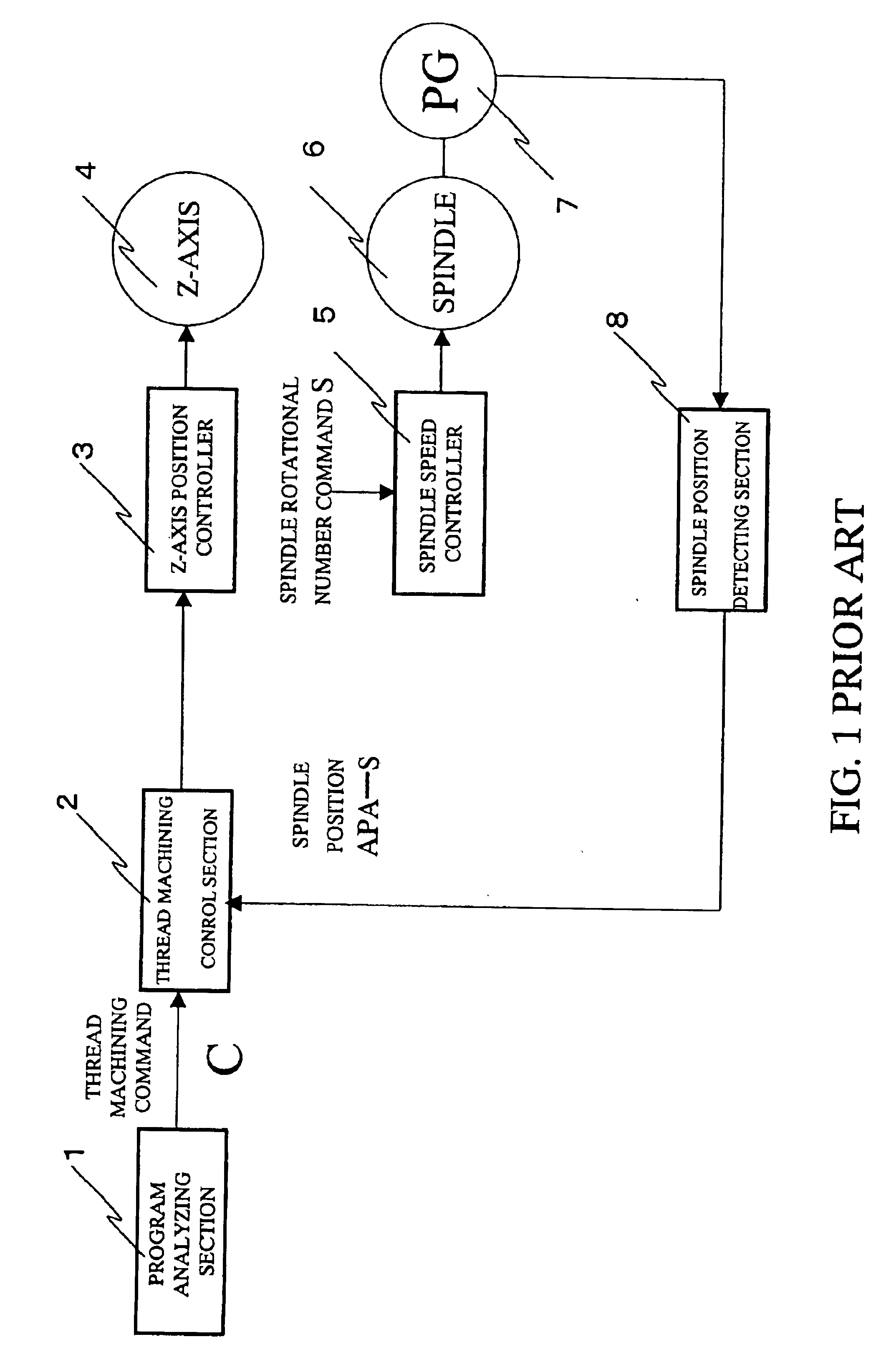

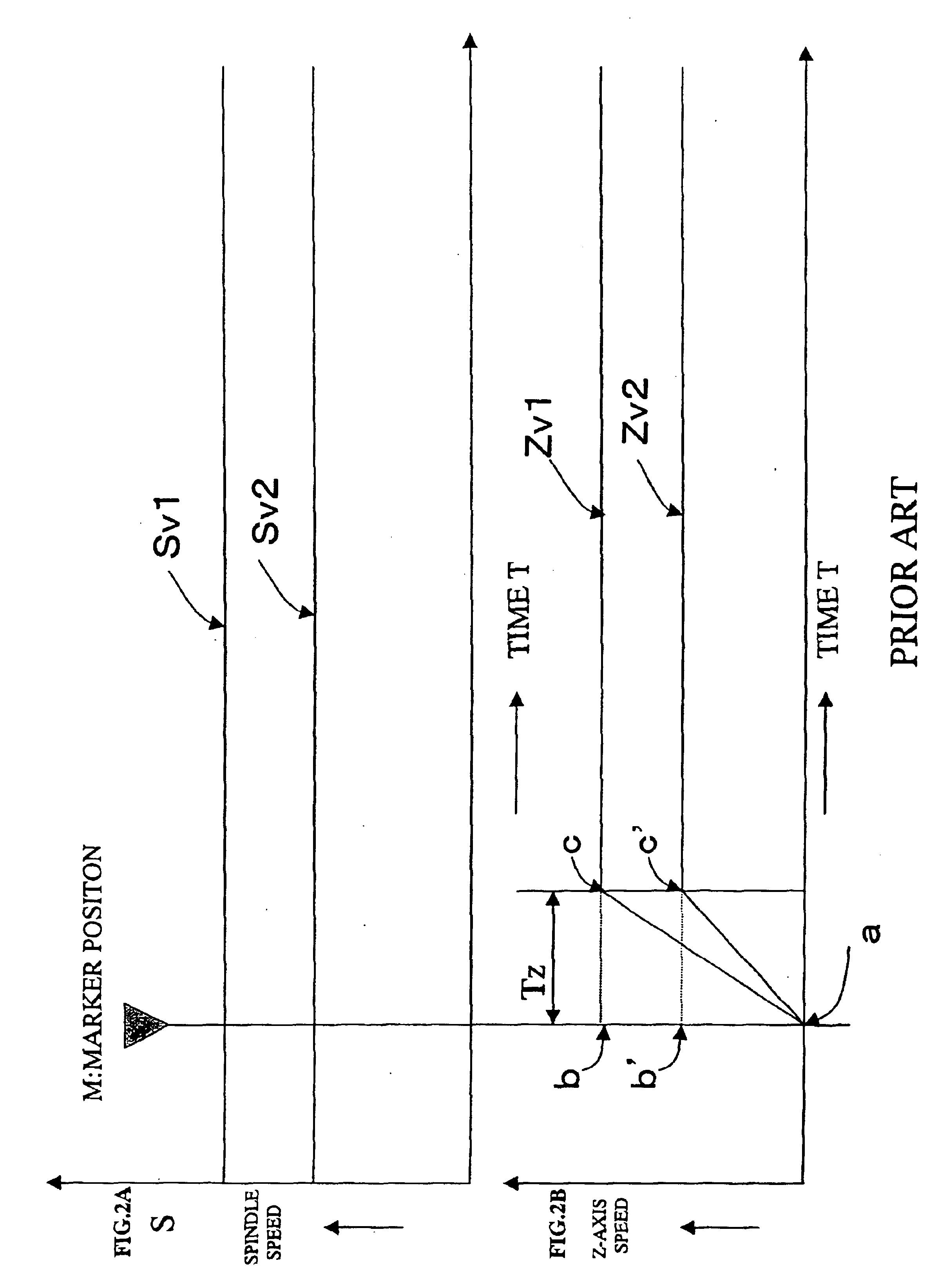

Thread machining control method and apparatus therefor

ActiveUS6847857B2Stable processing technologyAutomatic control devicesThread cutting machinesMachining processMachine control

It is strongly demanded that a stable thread machining process be attained by carrying out a thread machining operation while varying the rotational frequency of a spindle, and thereby restraining the occurrence of cutting chatter. According to the present invention, in which a thread machining process is carried out on the basis of a rotation of the spindle and a movement of a feed axis, the above-mentioned demand is met by executing the steps of determining a relative phase error of the spindle positions and feed axis during a thread machining operation, and determining a movement quantity of the feed axis on the basis of a pseudo spindle position set by error-compensating the quantity of the relative phase error with respect to the spindle position.

Owner:OKUMA CORP

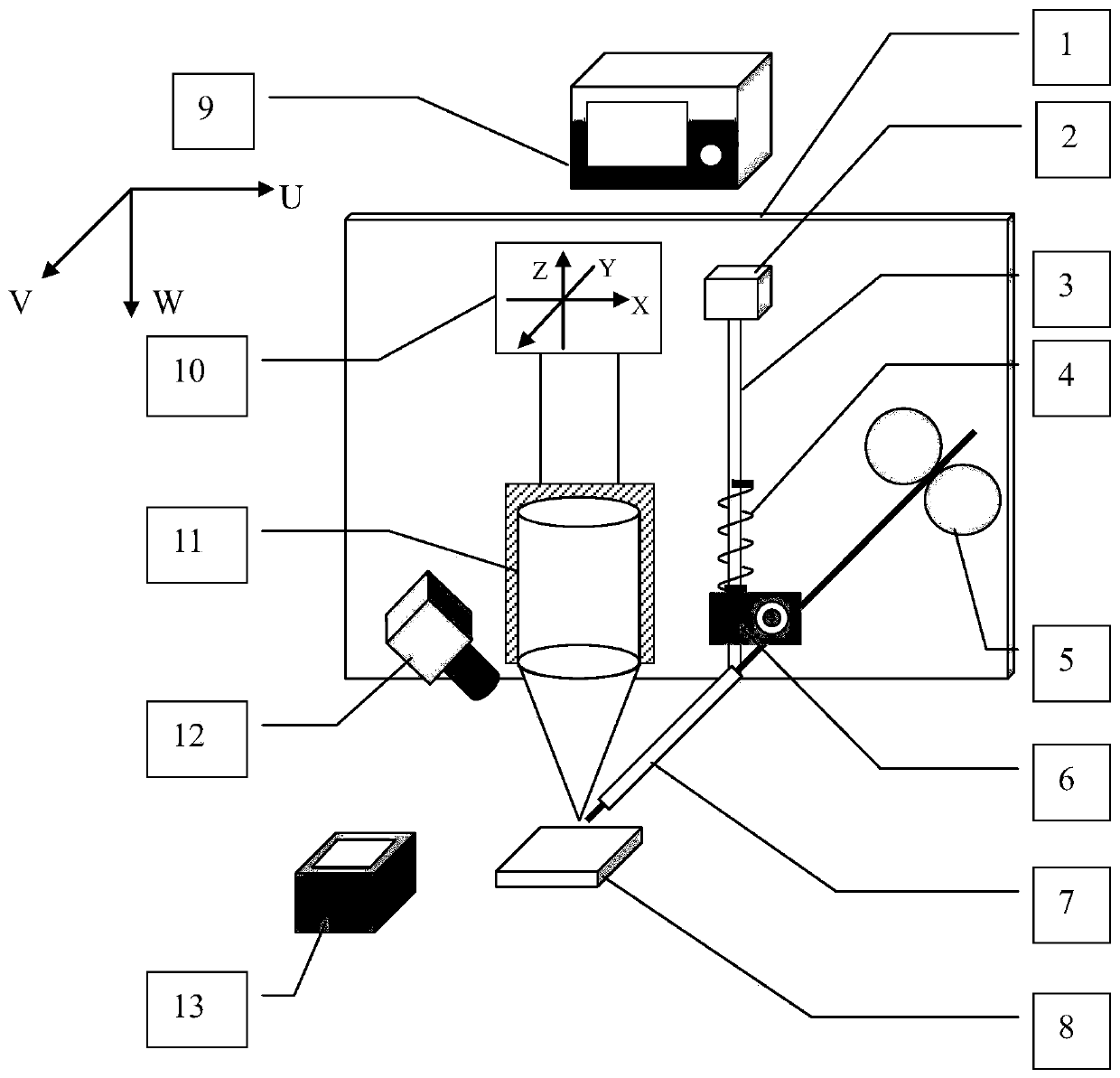

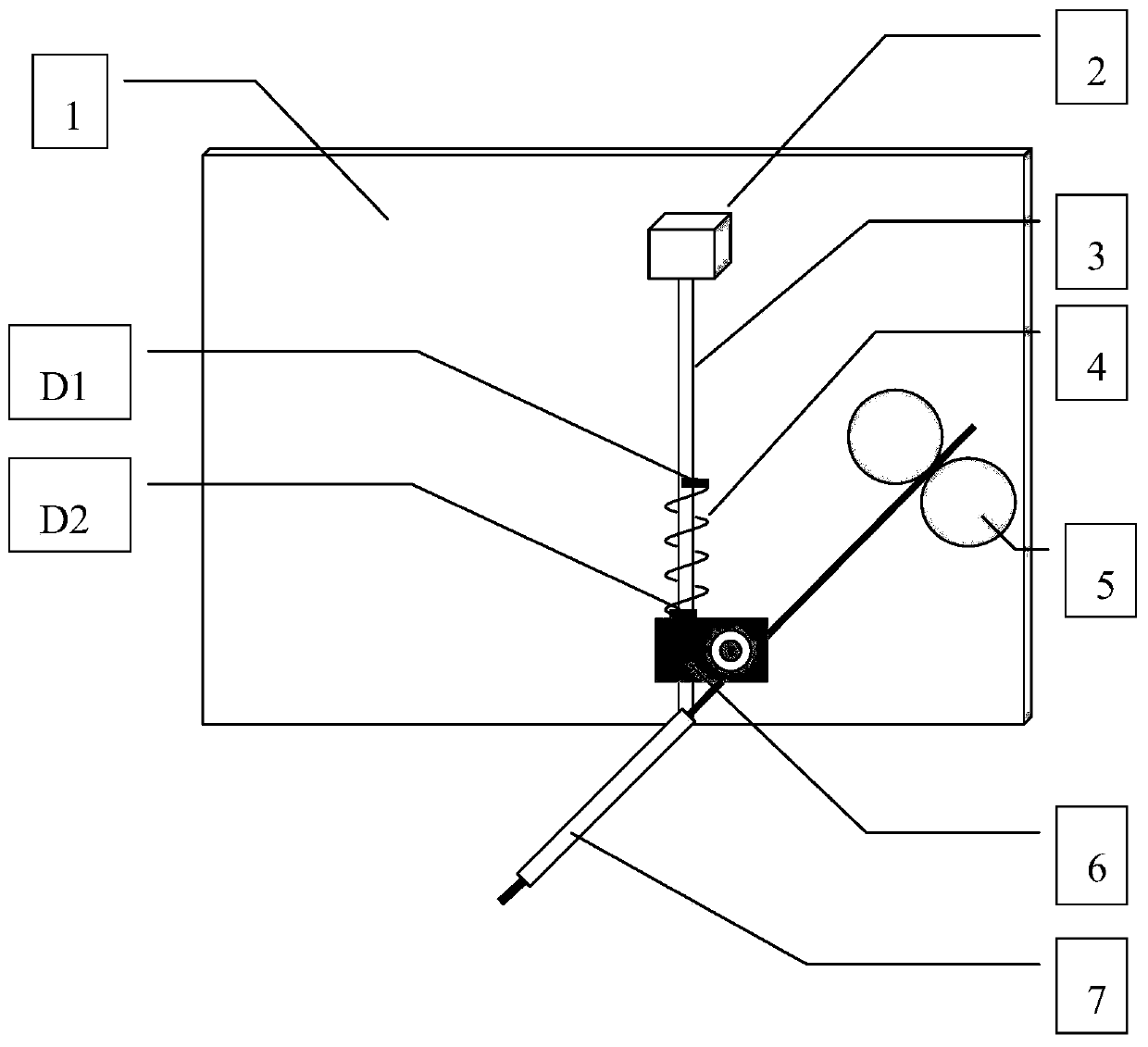

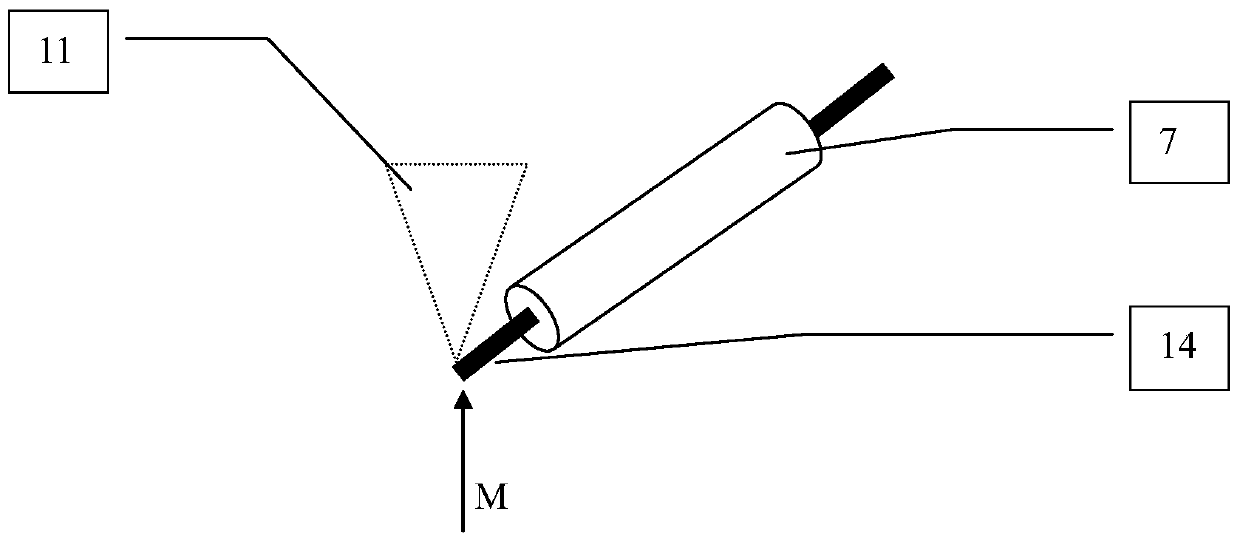

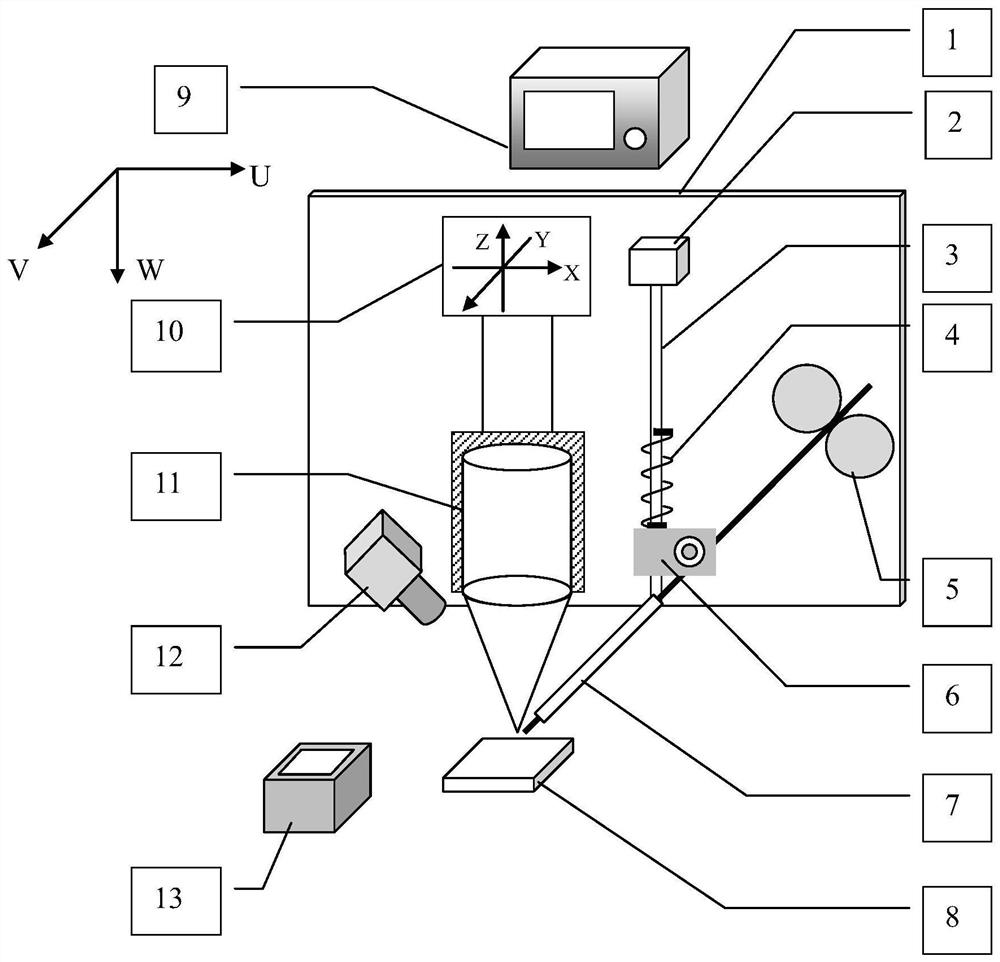

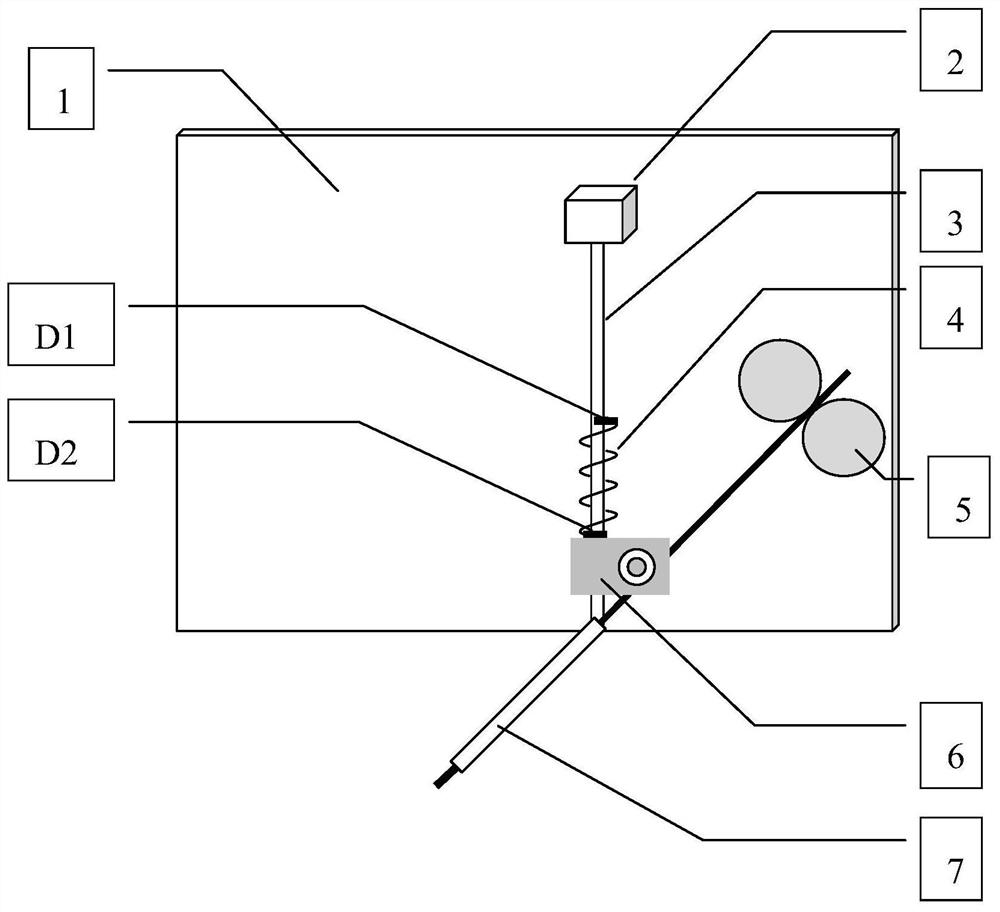

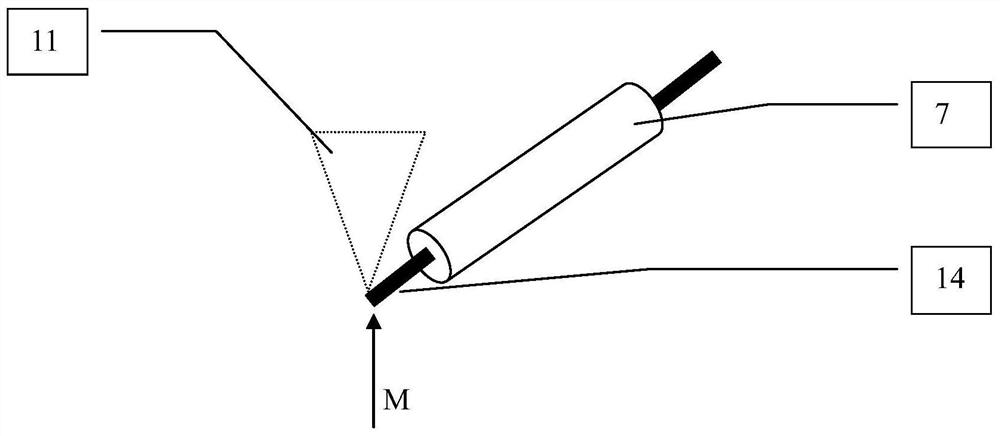

Laser welding tinning device and welding method

ActiveCN110961751AMake up for the influence of welding effectReduce processing fixture requirementsSolder feeding devicesSoldering auxillary devicesLaser processingLoop control

The invention designs a laser welding tinning device and a welding method. The tinning device comprises a back plate, a laser position correcting device, a camera, a laser machining head, a pushing wheel pair, a connecting rod, a tin feeding nozzle, a displacement sensor, an angle sensor, a balance spring, a controller and a residue box, wherein the angle sensor detects a swing angle of the connecting rod, the displacement sensor detects the vertical movement position of the connecting rod, the controller calculates the movement speed and the acceleration of the detection head according to thedisplacement amount and an angle change value of the detection head, during laser welding, laser working height closed-loop control is carried out by utilizing the position of the detection head, tinwire feeding speed closed-loop control is carried out by utilizing stress of the detection head, and closed-loop control that laser follows the position of a tin wire is carried out by utilizing theangle of the detection head, influence of the welding spot height difference on the welding effect can be made up, the product machining fixing requirement is lowered, and the application range of laser welding is expanded. The tinning device is advantaged in that mechanical collision or burning of a processing base material can be prevented, the process is stable, and the qualified rate is improved.

Owner:WUHAN BESKYS TECH CO LTD

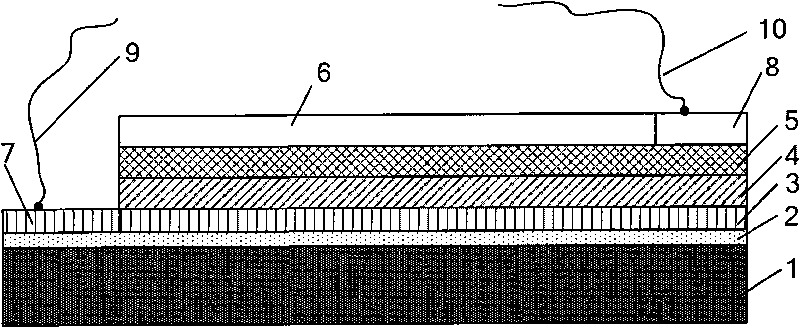

Solid electrolyte SO2 gas sensor and manufacturing method thereof

InactiveCN101726526AEnhanced interface bindingHigh sensitivityTelevision system detailsImpedence networksPhysical chemistryThin membrane

The invention relates to the field of SO2 gas sensors and discloses a solid electrolyte SO2 gas sensor and a manufacturing method thereof. The solid electrolyte SO2 gas sensor comprises a silicon substrate, and a SiO2 insulated layer, a conductive film, a Sn / SnF2 thin film, a LaF3 solid electrolyte thin film and a Pt net which are arranged on the silicon substrate in sequence. The conductive film is connected with a first lead; and the Pt net is connected with a second lead. In the technical scheme, the conductive film is an Al film; and the manufacturing method adopts an MEMS (Micro Electromechanical System) technology and has simple process and convenient realization.

Owner:XI AN JIAOTONG UNIV

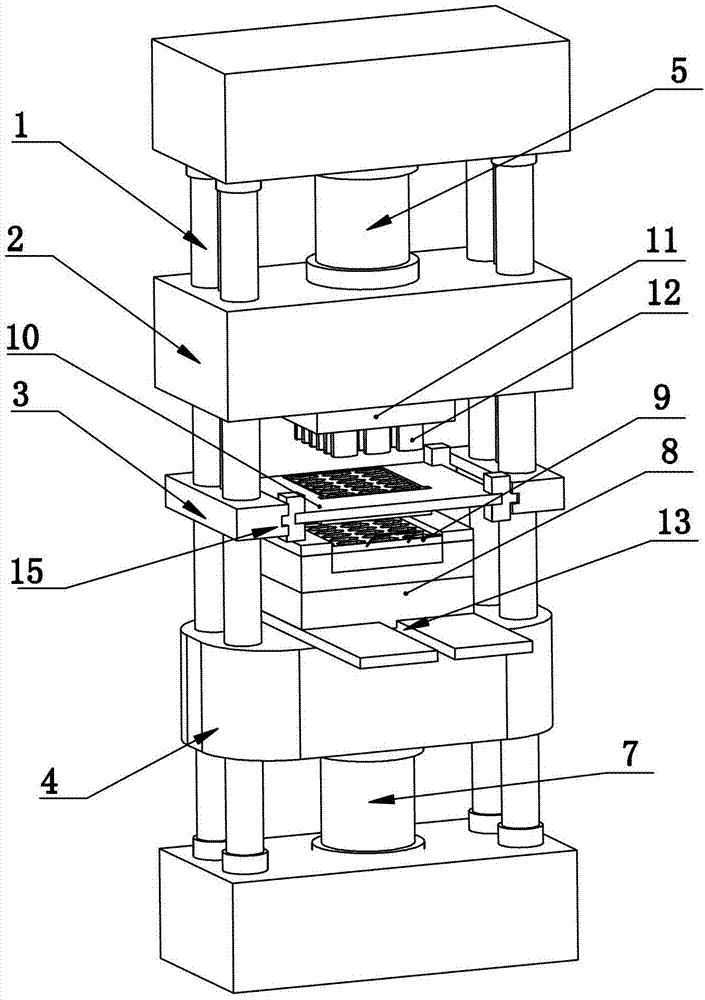

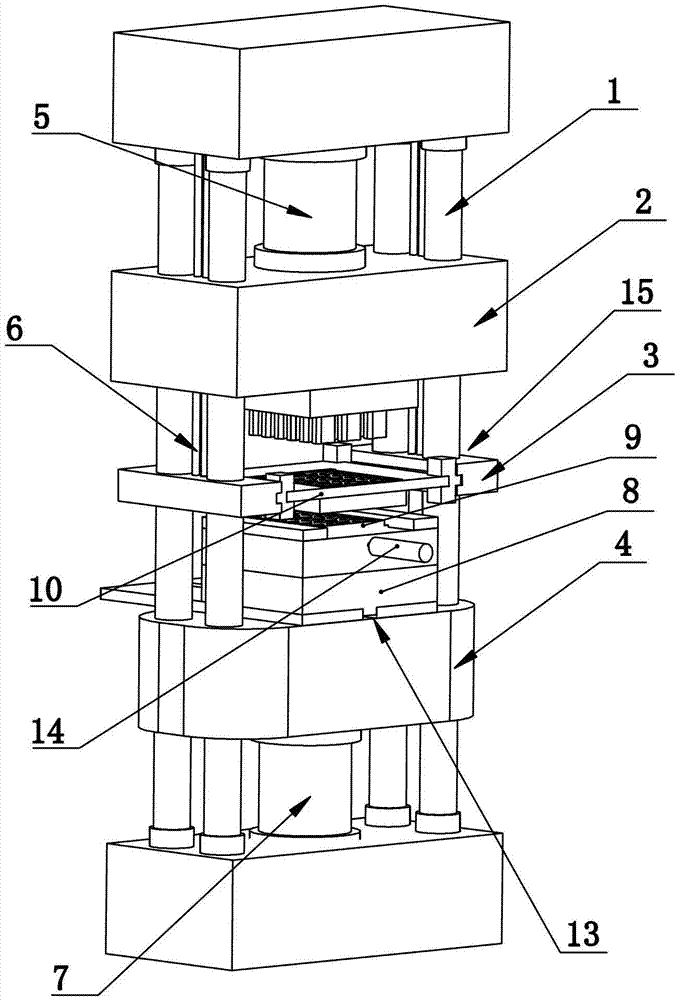

Processing technology for disc-type brake lining

The invention relates to a processing technology for a disc-type brake lining, which comprises processing equipment for the disc-type brake lining. The processing technology for the disc-type brake lining comprises the following steps of: 1) placing a steel backing of the disc-type brake lining on a position corresponding to a friction sheet forming cavity of an intermediate die on a carriage; 2) adding the powder material of the friction sheet into the friction sheet forming cavity; 3) enabling a heating die head to enter the friction sheet forming cavity to carry out hot extrusion forming on the powder material of the friction sheet; and 4) ejecting the processed and shaped friction sheet by the heating die head to fall on the carriage. The technical scheme of the processing technology for the disc-type brake lining, which is disclosed by the invention, has the effect of higher processing efficiency, and the processed disc-type brake lining has a firmer structure.

Owner:ZHEJIANG MINGTAI AUTO SPARE PARTS

Antistatic release film

InactiveCN104129128AStable processing technologyGood transparencySynthetic resin layered productsPolyesterAntistatic agent

Belonging to the technical field of high polymer materials, the invention in particular relates to an antistatic release film. The antistatic release film includes a polyester film, an antistatic layer on single side or double sides of the polyester film, and a release layer on the antistatic layer. The anti-static release film comprises the following components by weight: 30-60 parts of polyphenylene ethylene, 80-100 parts of adhesive resin, and 5-15 parts of an anti-adhesion agent. Compared with the prior art, according to the technical scheme provided by the invention, the antistatic layer has stable processing technology, excellent transparency and good adhesion, and the surface resistance is less than 108 omega cm.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Polishing method for mirror effect of amorphous alloy

The invention provides a polishing method for a mirror effect of amorphous alloy. The polishing method comprises the following steps that S1, grinding liquid containing single crystal diamond particles with a particle diameter of 10-20um is adopted, and first grinding is carried on a first grinding machine; S2, grinding liquid containing single crystal diamond particles with a particle diameter of2-6um is adopted, and second grinding is carried on a second grinding machine; S3, polishing liquid containing silicon dioxide particles with a particle diameter of 70-100um is adopted, and an amorphous alloy product is polished on a polishing machine; and S4, after the amorphous alloy product is ultrasonically cleaned with alkaline cleaning solution, the product is dried. According to the polishing method for the mirror effect of the amorphous alloy, grinding and polishing of the surface of the amorphous alloy product can be carried out through three processes of coarse grinding, fine grinding and polishing, and a better machining surface can be obtained under the mechanical friction action of abrasive with particles with uniformity and good dispersibility; and the machining process is simple and stable, the grinding and polishing time is short, the removal rate is high, the cost is low, and the qualification rate is high.

Owner:上海驰声新材料有限公司

Fotiaoqiang frozen conditioning bag and processing process thereof

InactiveCN106376937AScientific and reasonable processing technologyStable processing technologyFood scienceAdditive ingredientBamboo shoot

The invention discloses a fotiaoqiang frozen conditioning bag and a processing process thereof, wherein the recipe comprises the following ingredients: 25 to 32 parts of beef tendons, 25 to 35 parts of sea cucumbers, 8 to 14 parts of abalones, 18 to 24 parts of fish maws, 18 to 24 parts of sliced conchs, 13 to 18 parts of pleurotus eryngii, 12 to 16 parts of winter bamboo shoots, 8 to 12 parts of dried scallop meat, 8 to 10 parts of quail eggs, 4 to 5 parts of yellow rice wine and 95 to 105 parts of safflower puree; the processing process is also disclosed. The fotiaoqiang frozen conditioning bag has the advantages that the processing process is scientific and reasonable; the industrial production is realized; the processing process is easy to master; the product quality of the obtained frozen conditioning bag is stable; the shelf life at normal temperature is long; after being bought by consumers, the food is cooked after stewing for 10 to 15 minutes in the frozen state; the eating is convenient and fast; the taste is delicious; the fragrance is durable; the taste enjoyment degree is higher than that of a traditional method; in addition, the product has high nutrition value; after the product is often eaten, the body immunity can be improved; the sleeping is improved; the sub-health status is further improved.

Owner:NEW HOPE LIUHE

Jacket formula for rubber jacketed flame-proof cable and production method thereof

InactiveCN101314654BTightly boundGood flexibilityRubber insulatorsPlastic/resin/waxes insulatorsParaffin waxThiourea

The invention discloses a fire-retardant cable sheath material formulation and the preparation method thereof. The formulation comprises, by weight parts, 15 to 30 parts of chloroprene rubber, 15 to 30 parts of chlorinated polyethylene, 0.5 to 3.0 parts of zinc oxide, 0.5 to 3.0 parts of magnesium oxide, 0.2 to 1.0 parts of ethylene thiourea, 0.5 to 2.0 parts of dibenzothiazyl disulfide, 0.1 to 0.5 parts of tetramethylthiuram disulfide, 0.5 to 2.0 parts of N-phenyl-2-naphthylamine, 0.5 to 2.0 parts of stearic acid, 0.5 to 3.5 parts of paraffin, 1.0 to 5.0 parts of dioctyl phthalate, 5.0 to 15parts of carbon black with high abrasion resistance, 5.0 to 15 parts of semi-reinforced carbon black, 3.5 to 10 parts of calcium carbonate, 2.5 to 8 parts of bis(pentabromophenyl) ether, 1.0 to 3.0 parts of antimony trioxide, and 1.0 to 8.0 parts of aluminum hydroxide. The preparation method mainly comprises the following steps: plasticating, blending, mixing, thin-passing and calendaring and extruding the sheath.

Owner:JIANGXI CABLE

Application of novel rice husk culture medium in industrial cultivation of white enokitake

InactiveCN110679391ALight weightHigh densityCultivating equipmentsMushroom cultivationSoybean hullsEngineering

The invention discloses application of a novel rice husk culture medium in industrial cultivation of white enokitake and relates to the technical field of edible mushroom culture. Raw materials in theculture medium include rice husk, corncob, rice bran, bran, dry bean residue, brewer's grain, soybean hull and shell powder. The rice husk is added as a part of the raw materials of the enokitake culture medium to replace part of corncob, so that the advantages of good storage condition, high supporting performance, high breathability and low cost are realized, the rice husk is effectively utilized and greatly consumed, comprehensive utilization of the rice husk is promoted actively, the objective of enokitake culture cost is lowered, and the problem that corncob alternative materials lower in cost need to be found due to the fact that constantly-rising price of the corncob used for enokitake culture and the problems of great resource waste, huge economic loss and serious environment pollution caused by the fact that the rice husk is taken as waste in many places are solved.

Owner:江苏华绿生物科技股份有限公司

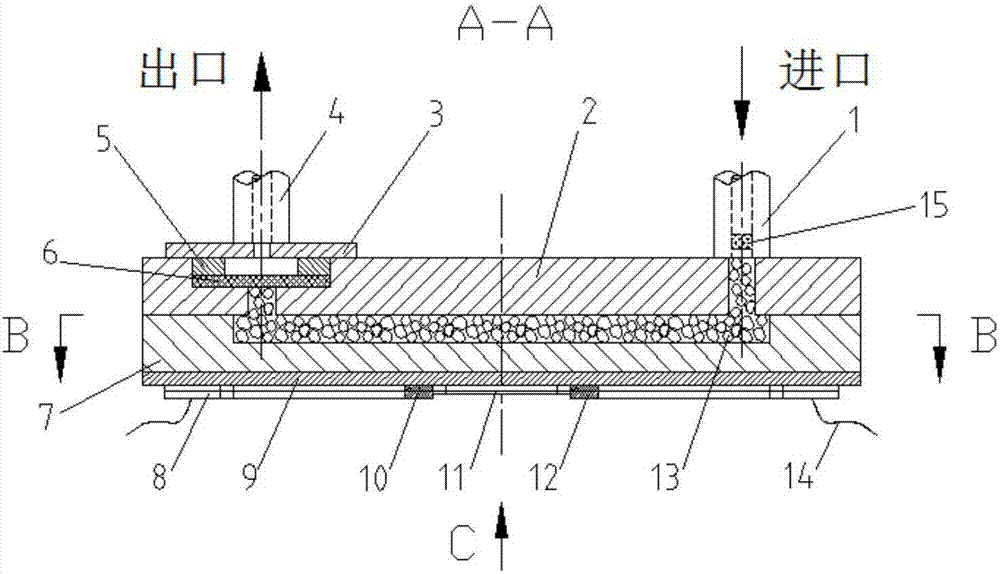

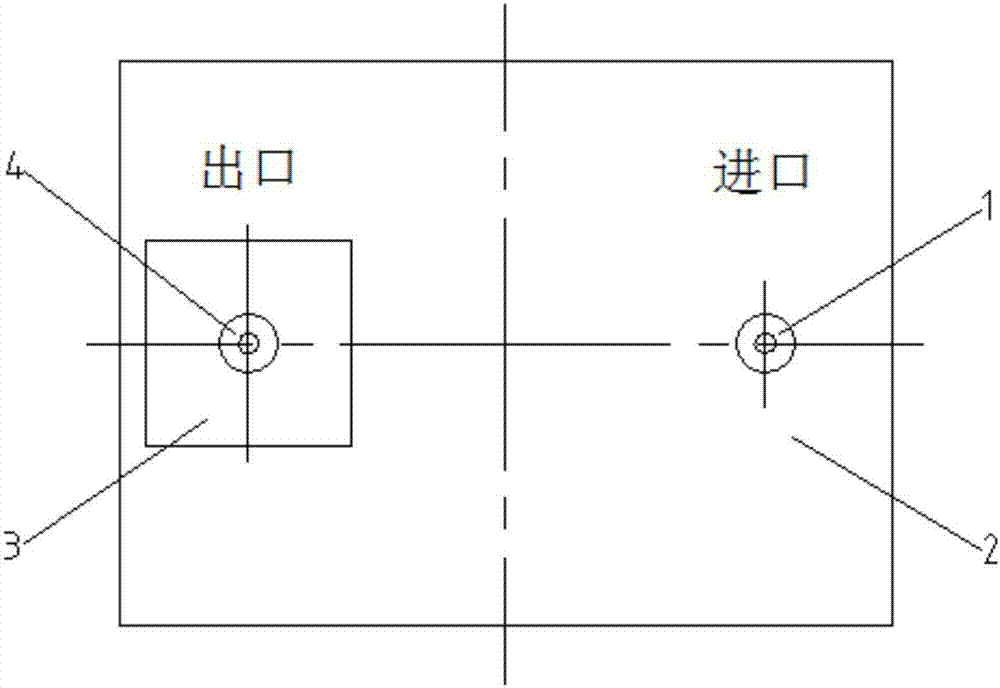

Miniature gas enricher and preparation method thereof

ActiveCN107014666AMiniaturizationHigh enrichment ratePreparing sample for investigationMiniaturizationEngineering

The invention discloses a miniature gas enricher and a preparation method thereof. The miniature gas enricher comprises a filling layer and a packaging layer covered on the filling layer, wherein a symmetrically distributed miniature spitting channel is processed on the upper surface of the filling layer; absorbing grains are filled in the channel; an air inlet and an air outlet which are communicated with the miniature spitting channel are formed on the packaging layer; a counter bore which is used for fixing a filtering layer is formed at the air outlet; an inlet adapter and an outlet adapter are hermetically arranged corresponding to the air inlet and the air outlet; a SiO2 dielectric layer is arranged on the filling layer; a pair of quick heating elements and a pair of sensitive temperature measurers are respectively arranged on the SiO2 dielectric layer. The enriched gas enters from the inlet adapter, is concentrated and enriched under the physical absorption effect of the absorbing grains and then passes through the filtering layer and is discharged from the outlet adapter. The miniature gas enricher disclosed by the invention can realize miniaturization and has the characteristics of high enriching rate, low power consumption, low cost, easiness in processing, stable materials, easiness in integration, and the like. The thick-film technology of the heating element is simple and the cost is low.

Owner:XI AN JIAOTONG UNIV +1

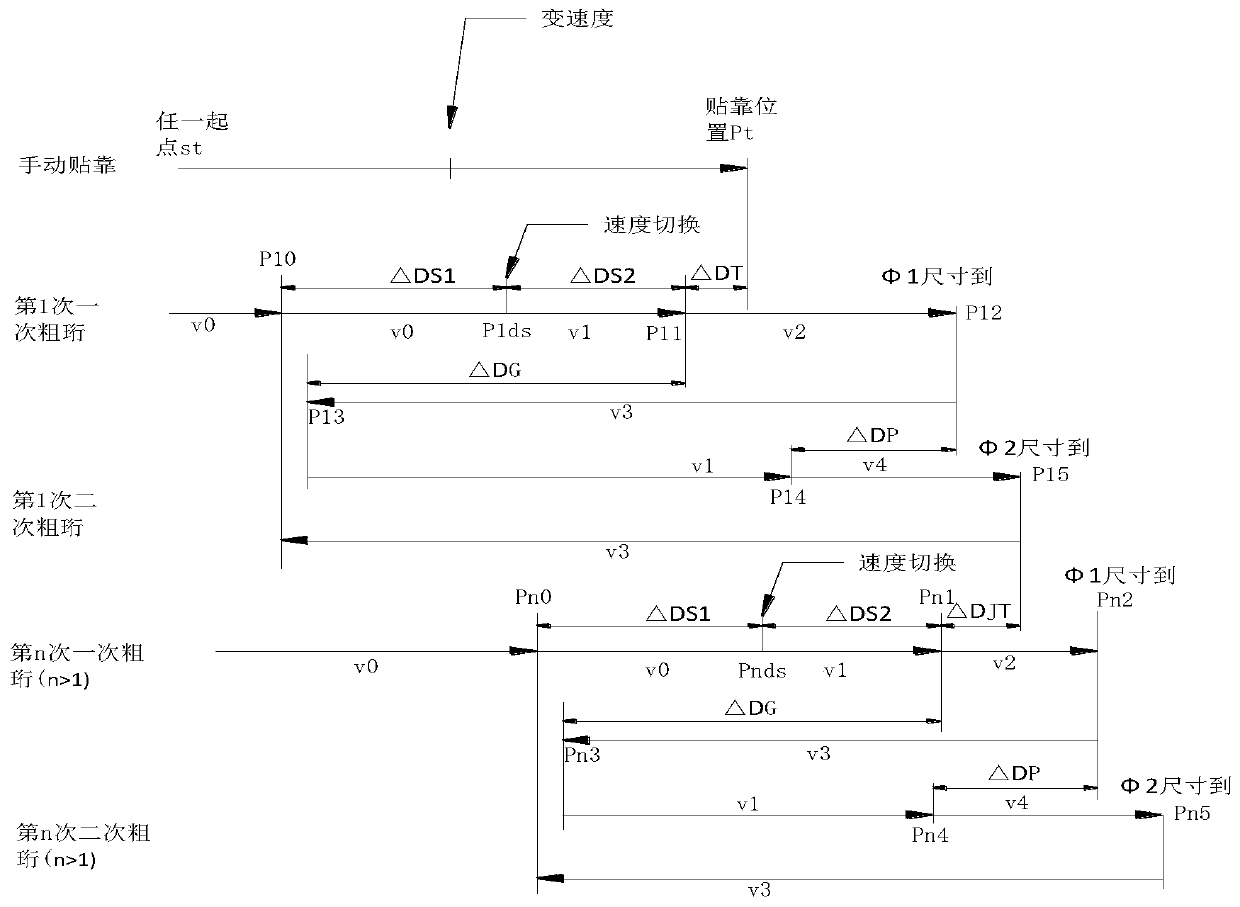

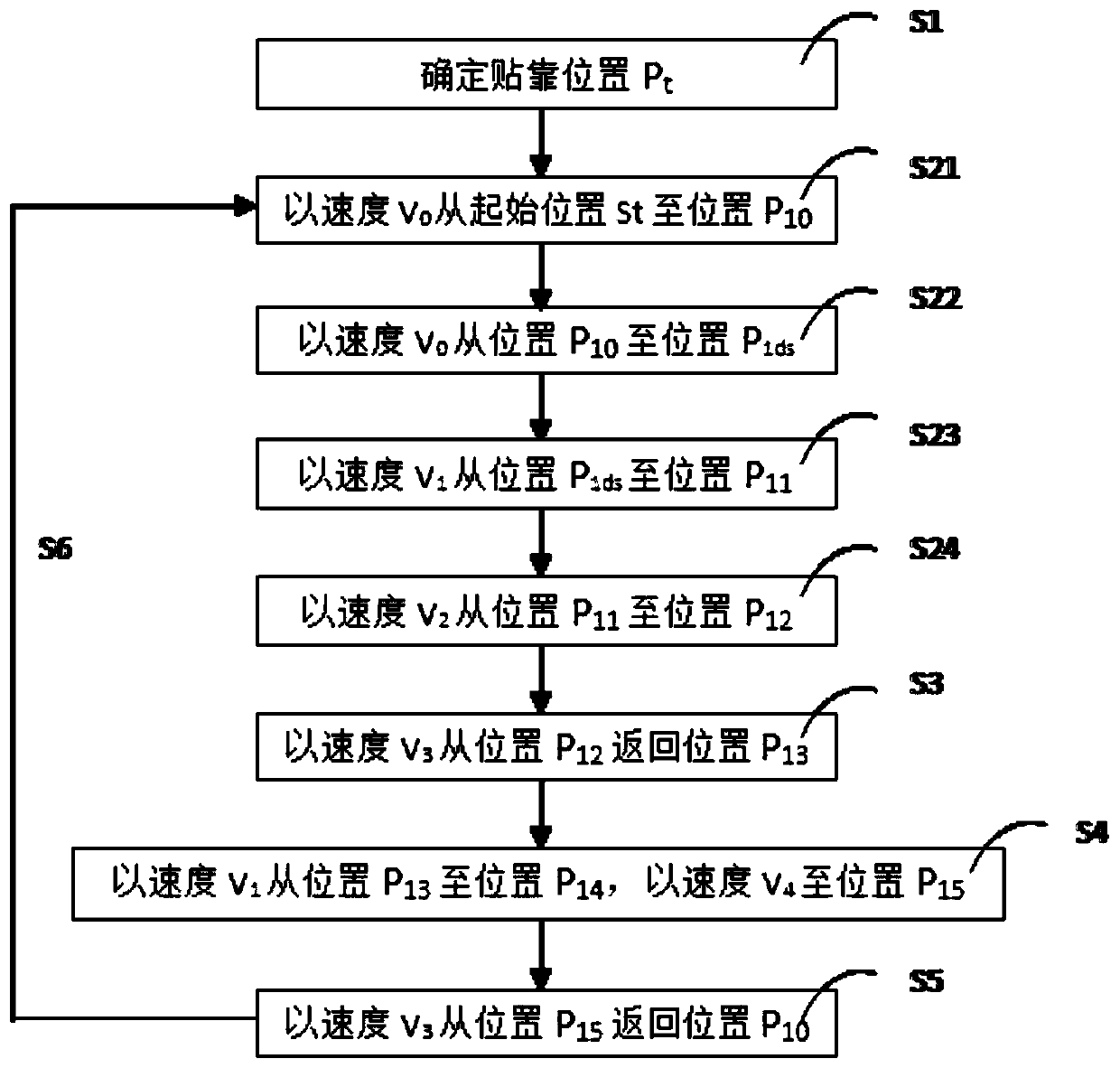

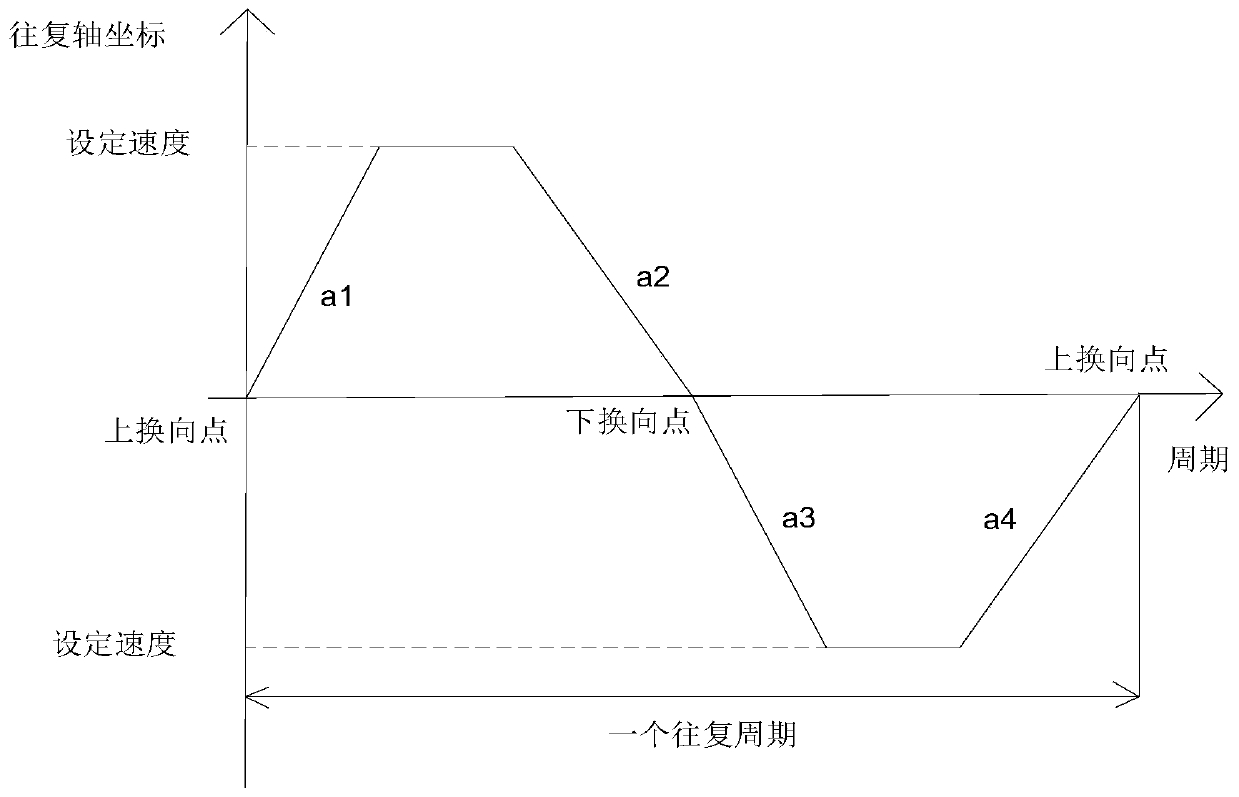

Honing netting crack processing control method

ActiveCN110900320AControl Sophisticated ImplementationRealize quantitative adjustmentHoning machinesStructural engineeringIndustrial engineering

The invention provides a honing netting crack processing control method. A honing head has different accelerations in four acceleration and deceleration stages within a reciprocating cycle and honingsticks are controlled to feed by speed. A primary processing course comprises primary rough honing, honing stick returning, secondary rough honing and finishing of rough honing. The distance between two adjacent honing sticks is as same as the one-stroke rotating distance of the honing stick. According to the honing netting crack processing control method provided by the invention, the honing sticks are controlled to feed by speed, so that the problem that the cutting pressure is affected by a contact area of the honing sticks and a workpiece in fixed pressure control is avoided. Meanwhile, bymatching different accelerations with honing stick distribution, netting crack angle, stroke distance and rotating speed reasonably, the honing netting crack at a reversing position is straightened.

Owner:NINGXIA YINCHUAN DAHE CNC MACHINE

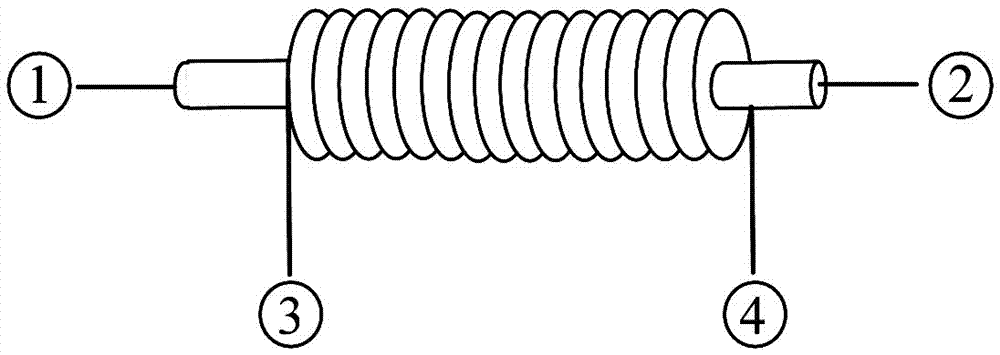

PCB-based GMI sensor probe and preparation method for the same

The present invention discloses a PCB-based GMI sensor probe and a preparation method for the same. The GMI sensor probe comprises a PCB and a signal pick-up coil, wherein the PCB is provided with an etching-formed groove; the groove is provided with amorphous wires; and the two sides of the PCB in the groove are provided with a row of through holes respectively. The signal pick-up coil is formed in such a way that the conductive wires pass the through holes sequentially and alternately winds on the front face and the back face of the PCB. The preparation method includes the following steps: etching the surface of the PCB to develop a groove; placing amorphous wires in the groove; forming two rows of through holes on both sides of the groove on the PCB; and forming a signal pick-up coil by letting the conductive wires pass the through holes sequentially and alternately wind on the front face and the back face of the PCB. The sensor probe and the preparation method for the same of the invention have the advantages of possessing a simple and stable process, are low in cost, flexible and convenient in application.

Owner:NAT UNIV OF DEFENSE TECH

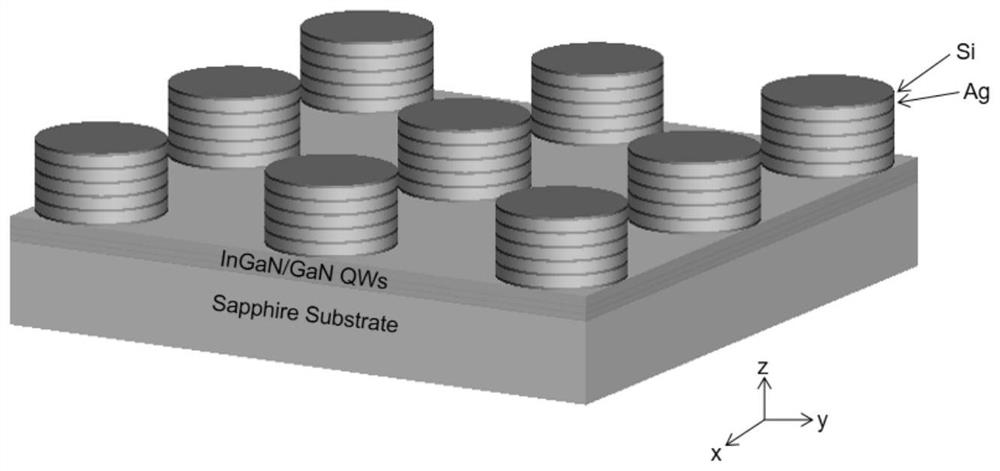

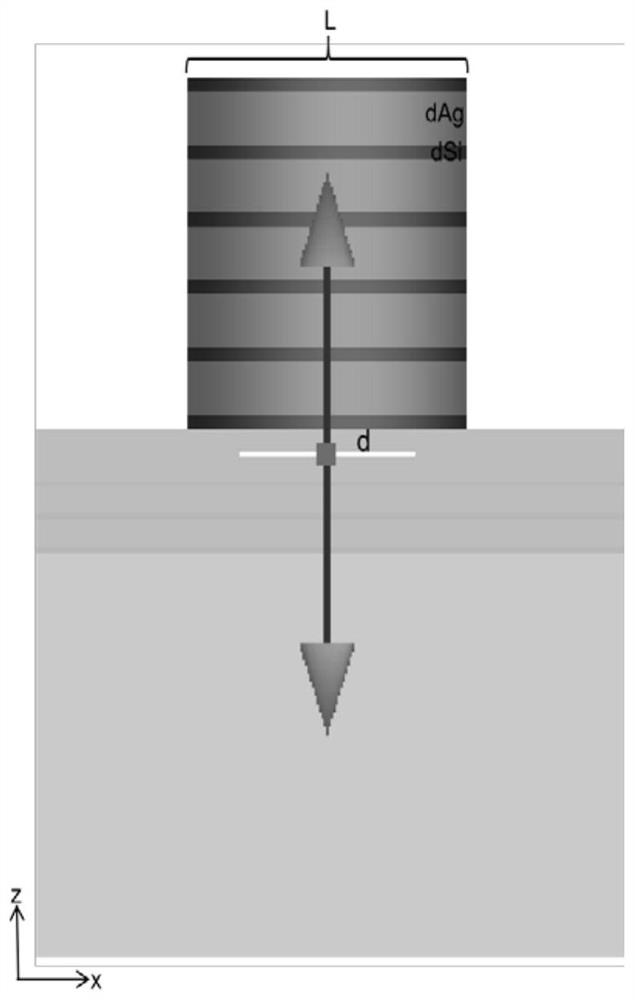

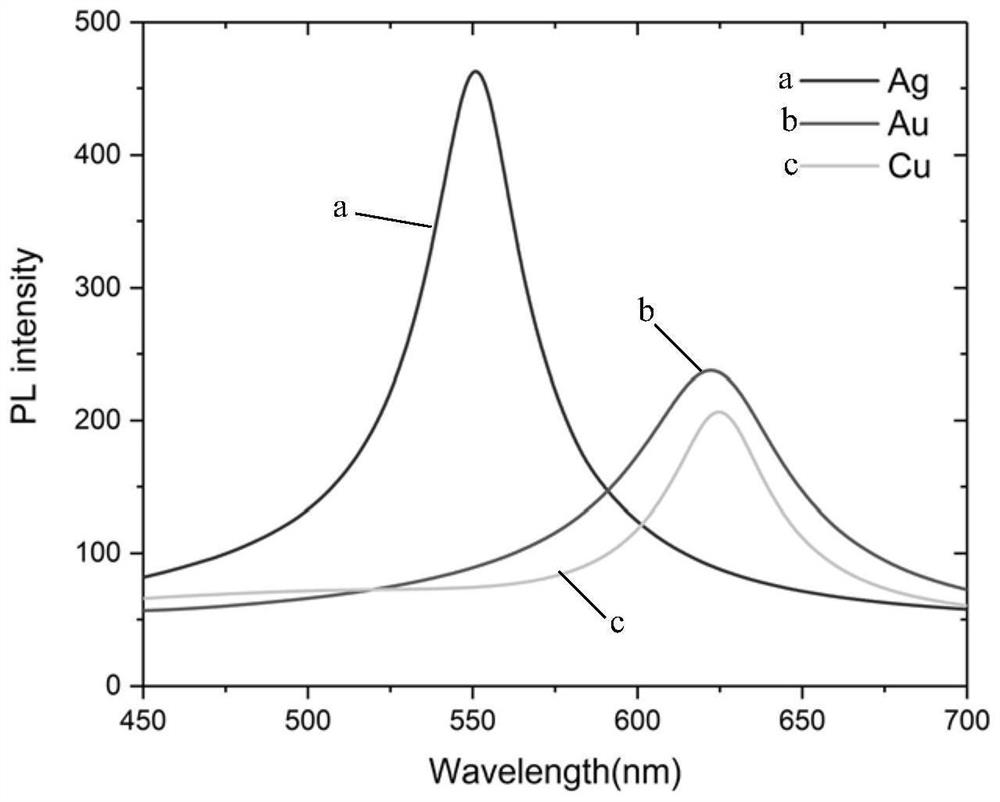

LED based on patterned substrate and preparation method thereof

The invention discloses an LED based on a patterned substrate and a preparation method thereof. The LED based on the patterned substrate structurally and sequentially comprises a sapphire substrate with two polished sides, three pairs of InGaN / GaN layer quantum wells, a barrier layer made of GaN, five pairs of Ag / Si layer hyperbolic metamaterials and a surface protection layer Si layer from bottomto top. On the basis of a traditional LED, a plurality of layers of hyperbolic metamaterials are added, so that the LED luminous efficiency of the patterned substrate reaches 180 times and is far higher than that of the traditional LED, and the LED is simple in technological process, low in cost, stable in processing technology and easy to produce in batches. Therefore, the LED and the preparation method a great application prospect in LED research.

Owner:NANJING UNIV OF POSTS & TELECOMM

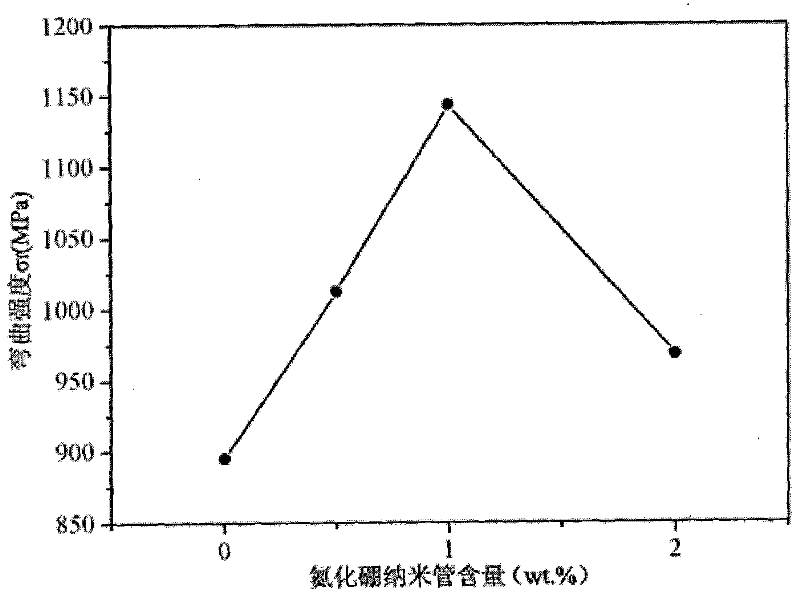

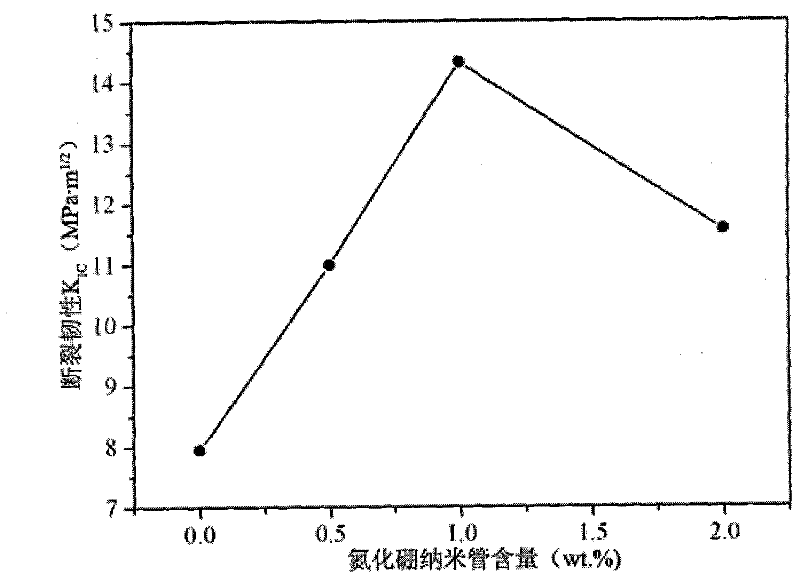

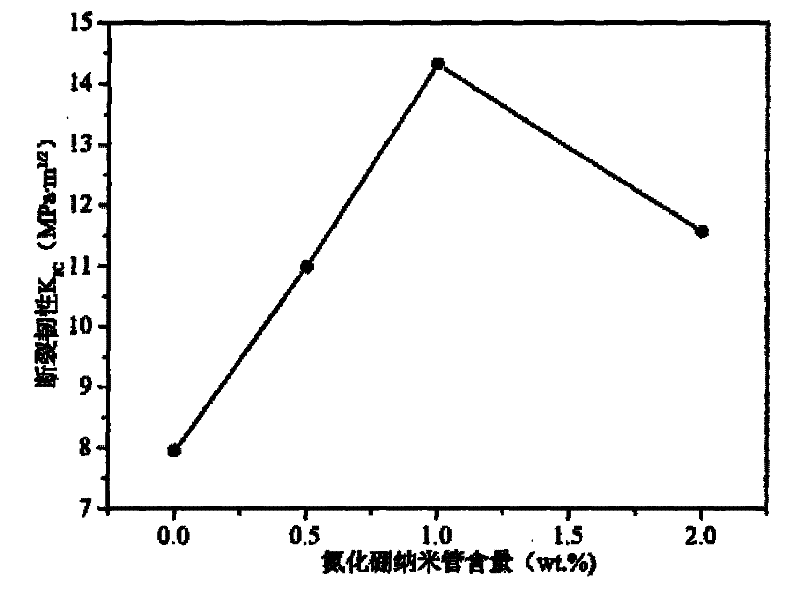

Method for producing boron nitride nano tube reinforced and toughened zirconium oxide ceramic

The invention discloses a method for producing boron nitride nano tube reinforced and toughened zirconium oxide ceramic, which comprises the following operations of: weighing boron nitride nano tube, zirconium oxide powder and zirconium oxide grinding balls, measuring anhydrous ethanol and pouring the anhydrous ethanol into a ball milling tank, and performing ball milling; drying the mixed slurryin an oven after ball milling, screening the dried mixed slurry, filling the screened powder into an alumina crucible, and pre-sintering the powder in a muffle furnace; filling the pre-sintered powder into a graphite mould, sintering the powder in a multifunctional sintering furnace, and naturally cooling the sintered powder to room temperature; and obtaining a finished product by mechanical processing of the sintered body such as grinding, cutting and the like. The method has the advantages of low cost, stable processing process, simple operation treatment, high production efficiency, high mechanical property of the product and the like. Under the same process condition, the bending strength of the zirconium oxide ceramic added with the boron nitride nano tube reaches 1,143.3MPa and is improved by 28 percent compared with pure zirconium oxide ceramic; and the fracture toughness reaches 14.3MPa.m1 / 2 and is improved by 80 percent compared with the pure zirconium oxide ceramic.

Owner:SHANDONG UNIV

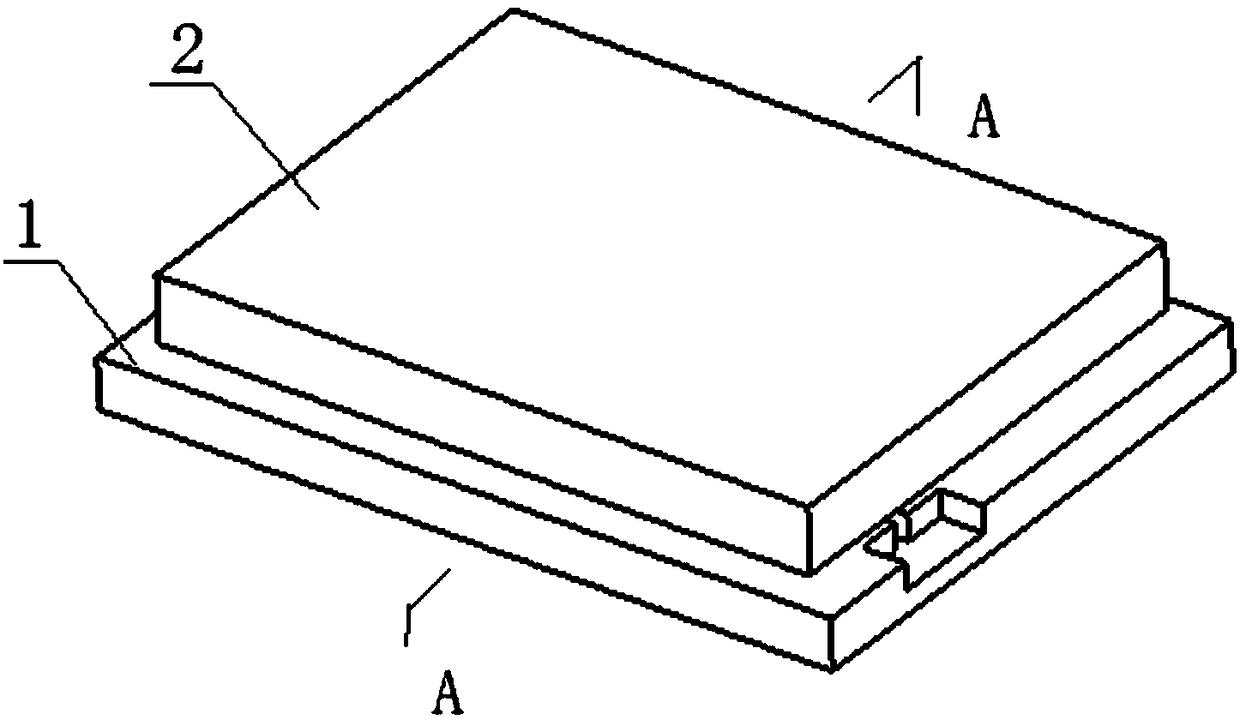

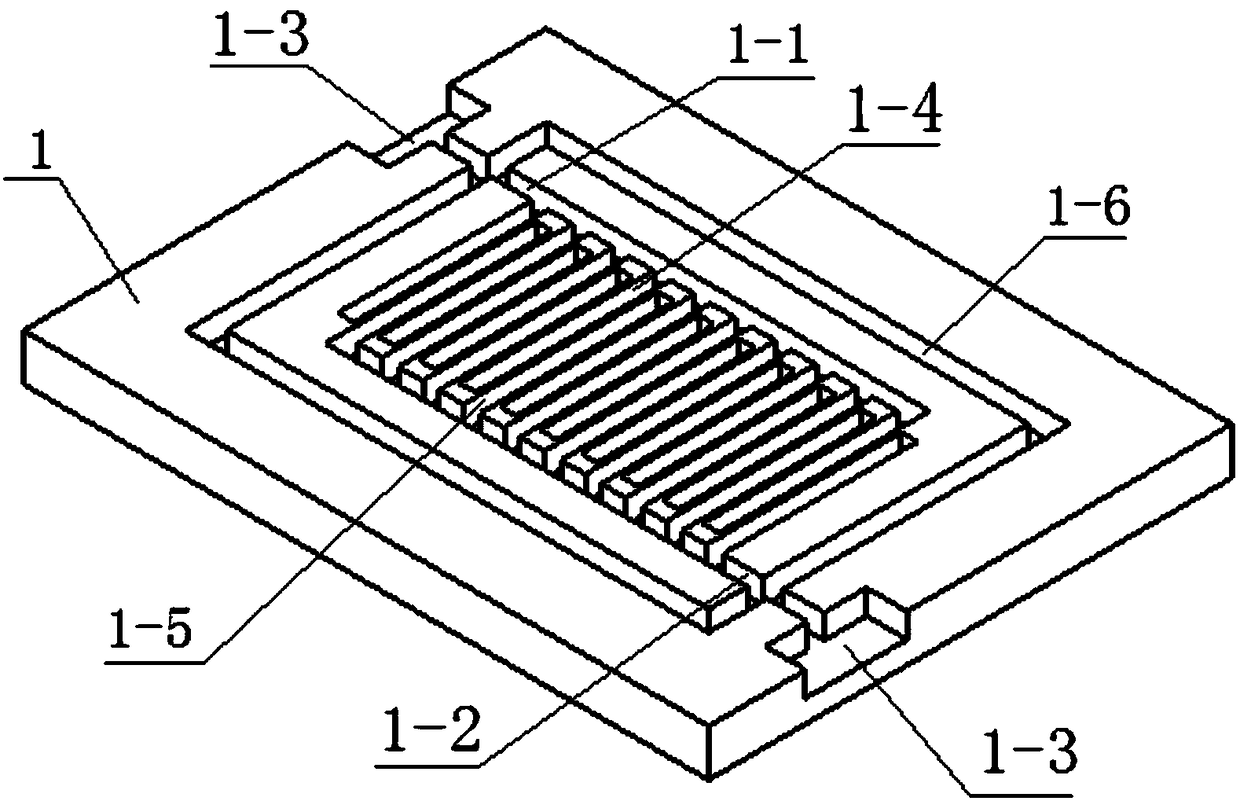

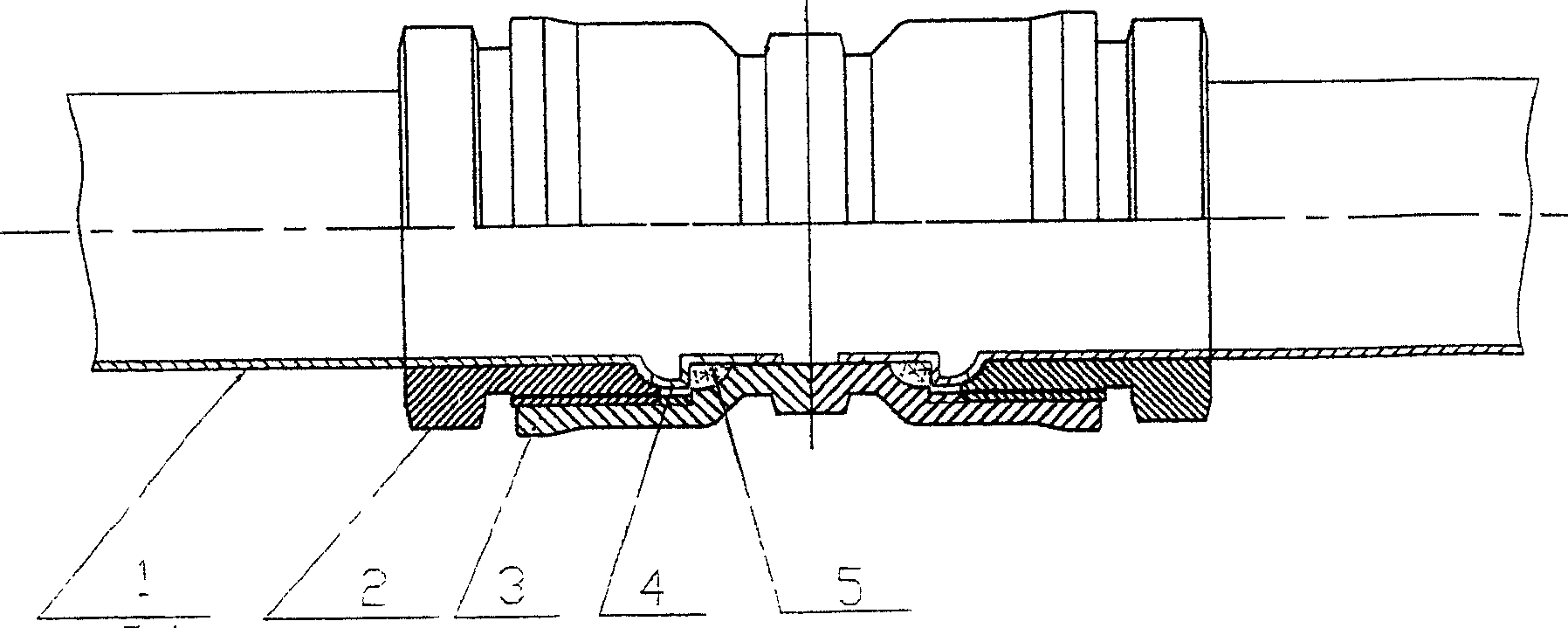

Hard-shell encapsulation structure of lithium-ion battery and processing method of hard-shell encapsulation structure

ActiveCN109326744ADisadvantages affecting electrochemical performanceGuaranteed qualityFinal product manufactureSmall-sized cells cases/jacketsInterference fitEngineering

The invention discloses a hard-shell encapsulation structure of a lithium-ion battery and a processing method of the hard-shell encapsulation structure. The encapsulation structure is formed by a substrate, a fence and a buckling cover, wherein the substrate is provided with positive and negative lug leading-out grooves and expansion grooves of leading-out ends of the positive and negative lug leading-out grooves; the substrate between the two lug leading-out grooves is provided with two groups of radial grooves into which positive and negative pole-plate current collectors are embedded alternately and which are uniformly spaced; the peripheries of the positive and negative lug leading-out grooves of the substrate are provided with rectangular fence embedment grooves; the bottom surface ofthe fence is provided with bosses which are in interference fit with the fence embedment grooves; the bosses are provided with cambered-surface grooves which are corresponding to the corresponding lug leading-out grooves respectively; and the buckling cover is in interference fit with the outer edge of the fence. The substrate, the fence and the buckling cover in the formation of the hard-shell encapsulation are prepared from a photosensitive resin material and are printed for one-time molding through a photocuring 3d (three-dimensional) printer; molded parts of the hard-shell encapsulation structure are photosensitive resin primary-color transparent bodies; and the radial grooves are in transition fit with the embedded laser-cut positive and negative current collectors, namely an aluminum sheet and a pure copper sheet. The hard-shell encapsulation structure has the outstanding advantages of being convenient to process and assemble, saving working time and being suitable for scale production.

Owner:深圳光韵达机电设备有限公司

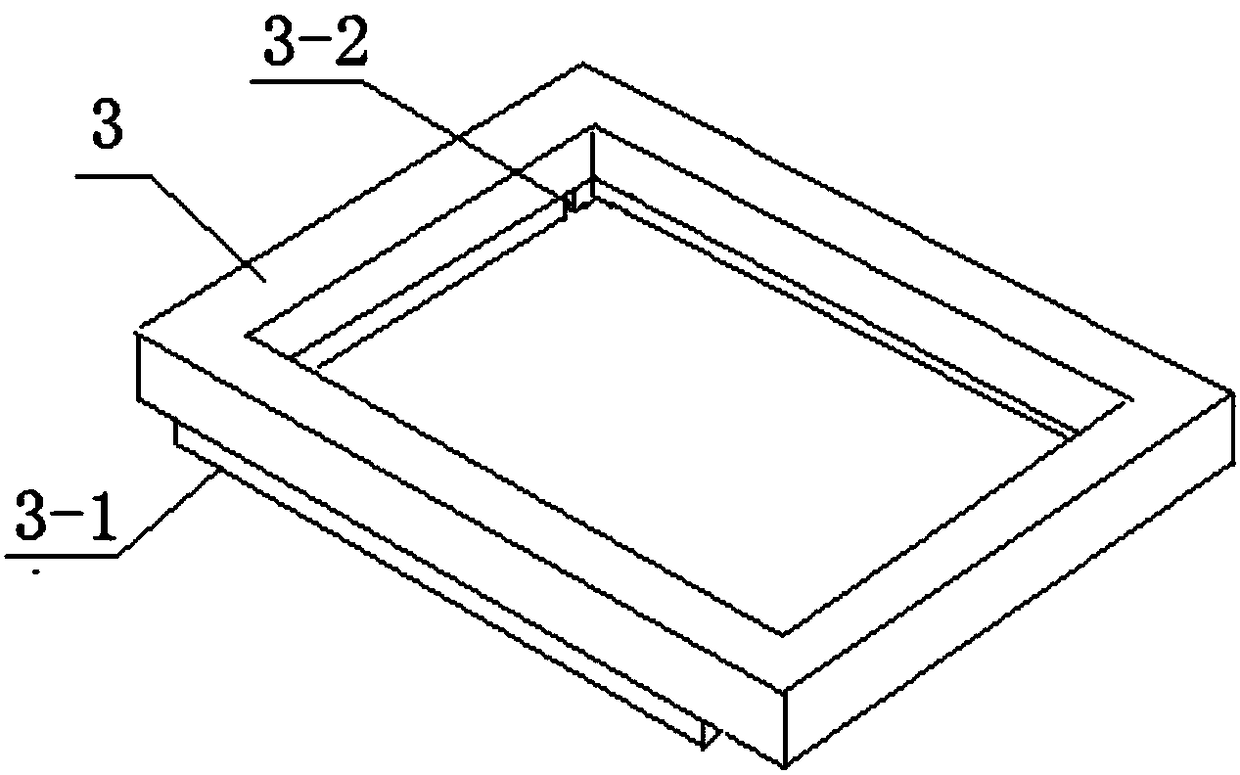

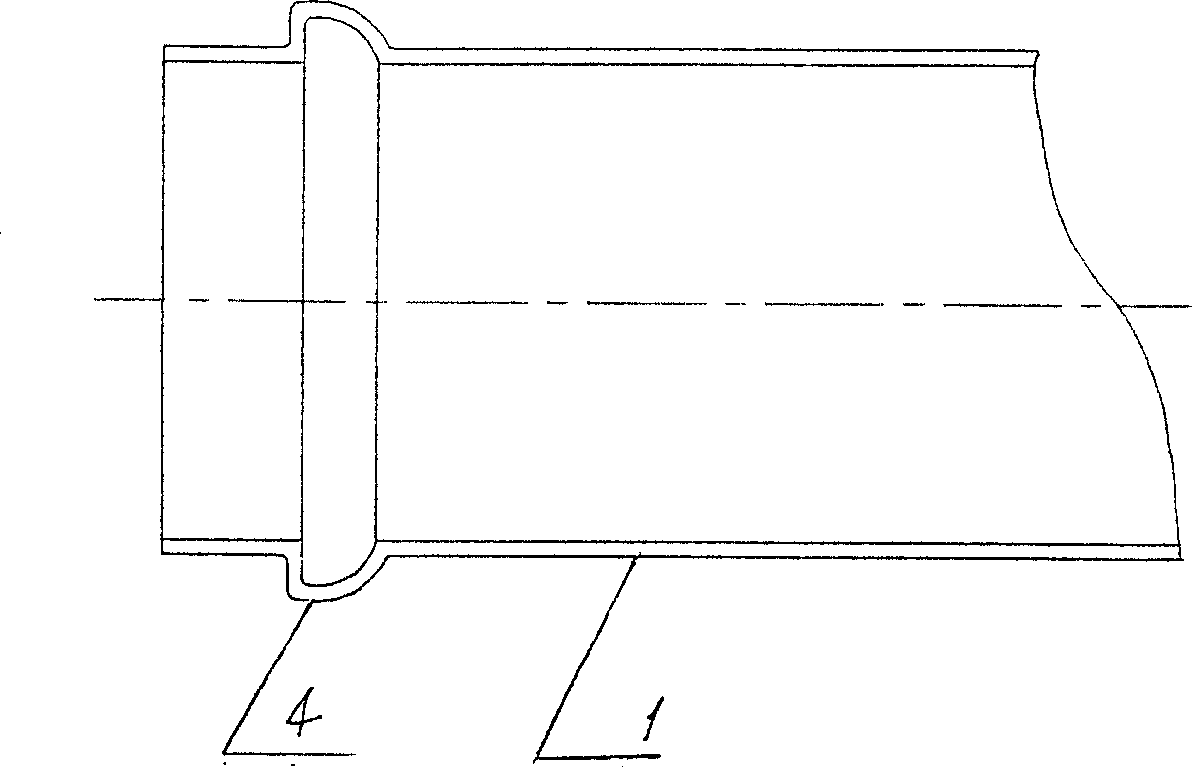

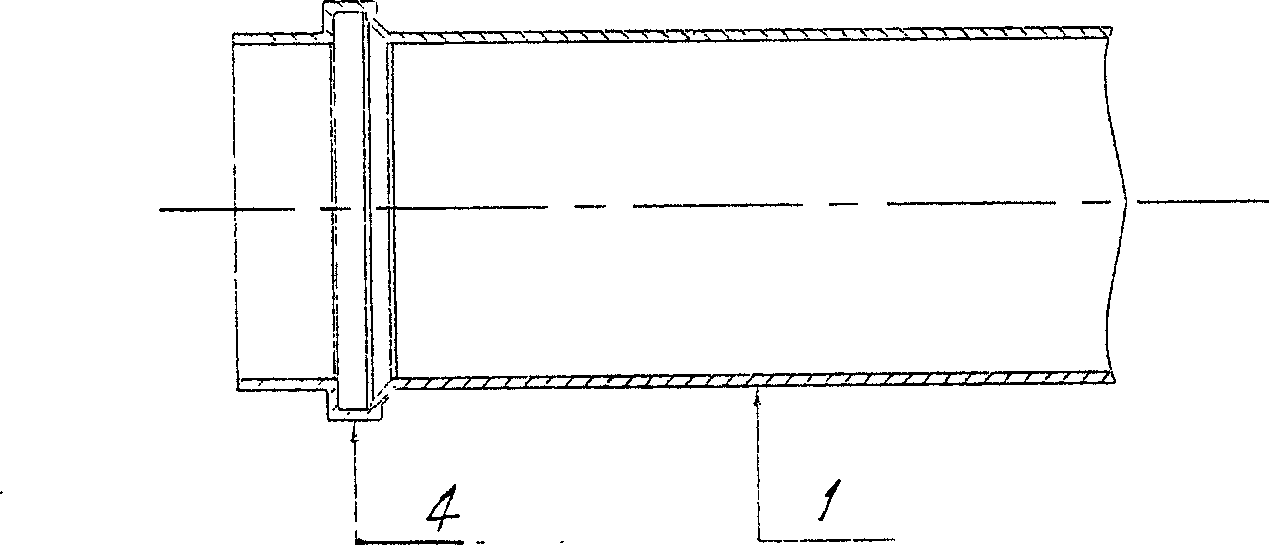

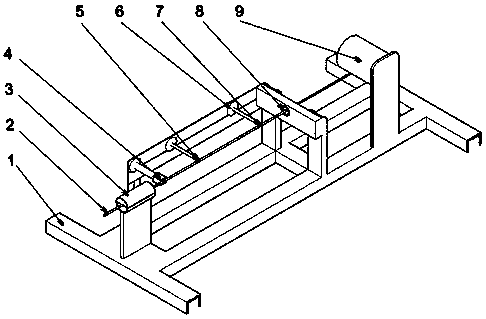

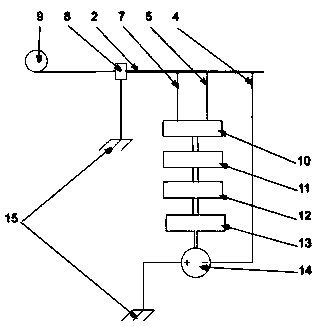

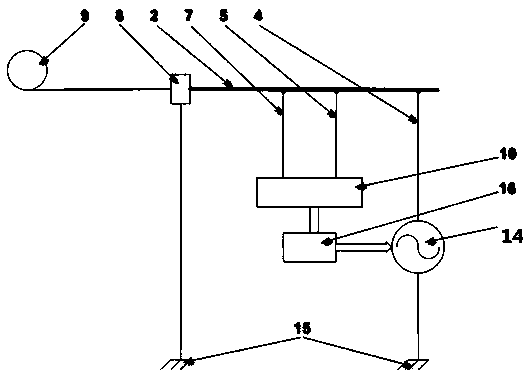

Fan convex ring thin wall metal pipe, its processing method and special equipment

InactiveCN100464105CStable processing technologySimple and fast operationJoints with sealing surfacesBobbinMolding machine

Provided is a fan convex ring thin wall metal pipe, wherein the convex ring and the pipe fitting are connected together. The cross sectional shape is vertical angle sector or five-edge trapezium, wherein the convex ring edge line of the vertical angle sector near the connecting end is a vertical line and the opposite connecting end is the fan-shaped arc line, and that, the convex ring edge line of the five-edge trapezium near the connecting end is a vertical line and the opposite connecting end is the edgefold line. The processing method adopts the cart roll forming machine to shape the machining pipe fitting convex ring through the rolling method, namely using the internal mold core of the bobbin roller as the male die. The outside diameter of the internal mold core of the bobbin roller must be smaller than the inside diameter of the machining fittings. When the external mold core of the bobbin roller is used as the cavity die, the inside diameter of the external mold core of the bobbin roller must be larger than the outside diameter of the machining fitting convex ring. The processed fittings are put into the inner of the external mold core of the bobbin roller and the internal mold core of the bobbin roller is inserted to the processed fittings. The position of the male die and the cavity die convex ring are corresponding each other, wherein the male die and the cavity die rotate separately. At the same time, the male die applies force to the radial direction of the fittings shaped to the convex ring through rolling. The advantages of the invention are that: it has stable processing technology, simple operation, rigidly controlled quality of the processing fittings, and excellent rounding of the convex ring in favor of assemble, good tightness of the fittings, high pull strength.

Owner:金洲

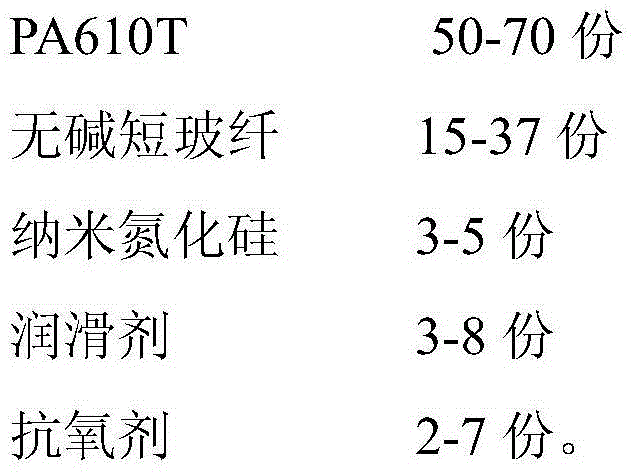

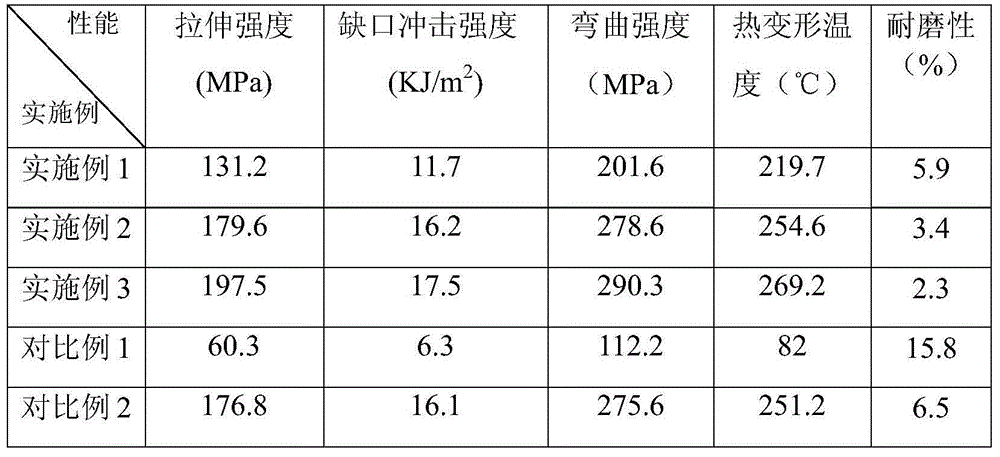

Heatproof wear-resistant alkali-free short glass fiber-reinforced nylon PA610T composition and preparation method thereof

The invention relates to a heatproof wear-resistant alkali-free short glass fiber-reinforced nylon PA610T composition and a preparation method thereof. The composition is prepared from, by weight, 50 to 70 parts of PA610T, 15 to 37 parts of alkali-free short glass fiber, 3 to 5 parts of nanometer silicon nitride, 3 to 8 parts of a lubricant and 2 to 7 parts of an anti-oxidant. The preparation method comprises the following steps: weighing nylon, nanometer silicon nitride, the anti-oxidant and the lubricant according to the above-mentioned weight parts, carrying out uniformly mixing, pouring an obtained mixture into a hopper of an extruder and adding the alkali-free short glass fiber into a side feed inlet; starting the extruder and a vacuum pump and carrying out extrusion and granulation via the double screw-extruder so as to obtain am alkali-free short glass fiber-reinforced nylon PA610T composition; and drying the composition in a baking oven with a temperature of 90 to 110 DEG C for 2 to 6 h so as to obtain the heatproof wear-resistant alkali-free short glass fiber-reinforced nylon PA610T composition for subsequent usage. Compared with the prior art, the invention has the following advantages: the preparation method is simple and stable; the alkali-free short glass fiber and auxiliary agents are uniformly dispersed in nylon resin; compatibility of the short glass fiber and nylon resin is good; and the obtained composition has ideal mechanical properties and excellent heatproof and wear-resistant performance.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Laser welding tinning device and welding method

ActiveCN110961751BMake up for the influence of welding effectReduce processing fixture requirementsSolder feeding devicesSoldering auxillary devicesLaser processingLoop control

The present invention designs a laser welding tinning device and welding method. The tinning device includes a back plate, a laser position correction device, a camera, a laser processing head, a push wheel pair, a connecting rod, a tin feeding nozzle, a displacement sensor, an angle sensor, a balance Spring, controller, residue box, the angle sensor detects the swing angle of the connecting rod, the displacement sensor detects the up and down movement position of the connecting rod, and the controller calculates the moving speed and acceleration of the detecting head according to the displacement and angle change value of the detecting head; laser welding When using the position of the probe head for closed-loop control of the laser working height, closed-loop control of the feeding speed of the tin wire by using the force of the probe head, and closed-loop control of the position of the laser following the tin wire by using the probe head angle, it can make up for the height difference of the solder joints. The impact of the effect reduces the fixed requirements for product processing and expands the application range of laser welding. It can prevent mechanical collision or burn the processing base material, the process is stable, and the rate of qualified products is improved.

Owner:WUHAN BESKYS TECH CO LTD

Preparation method of novel colored BIPV (building integrated photovoltaics)

The invention relates to the field of photovoltaic modules, in particular to a preparation method of a novel colored BIPV (building integrated photovoltaics), which comprises the following steps: S1, plating a plurality of layers of optical films on the surface of a glass substrate, and controlling the visible light transmittance to be 30-90%, the reflectivity to be 70-10% and the absorptivity to be less than 0.5%; s2, separating the plated optical film from the glass substrate, and taking out the thin film layer; s3, grinding the thin film layer until the powder granularity reaches 10-60 microns to prepare the semitransparent color pigment; s4, uniformly mixing and stirring the pigment and the transparent glaze, and selecting different mixing proportions of the pigment and the transparent glaze according to the requirements of appearance and transmittance; s5, coating front plate glass of the BIPV with the prepared pigment through a silk-screen printing process; and S6, carrying out high-temperature sintering on the front plate glass coated with the pigment to obtain the colored glass front sheet. The color is rich in variety, is coordinated with the color of the building appearance, and greatly reduces the loss of the photoelectric conversion efficiency of the photovoltaic module.

Owner:宸亚(兰考县)科技有限公司

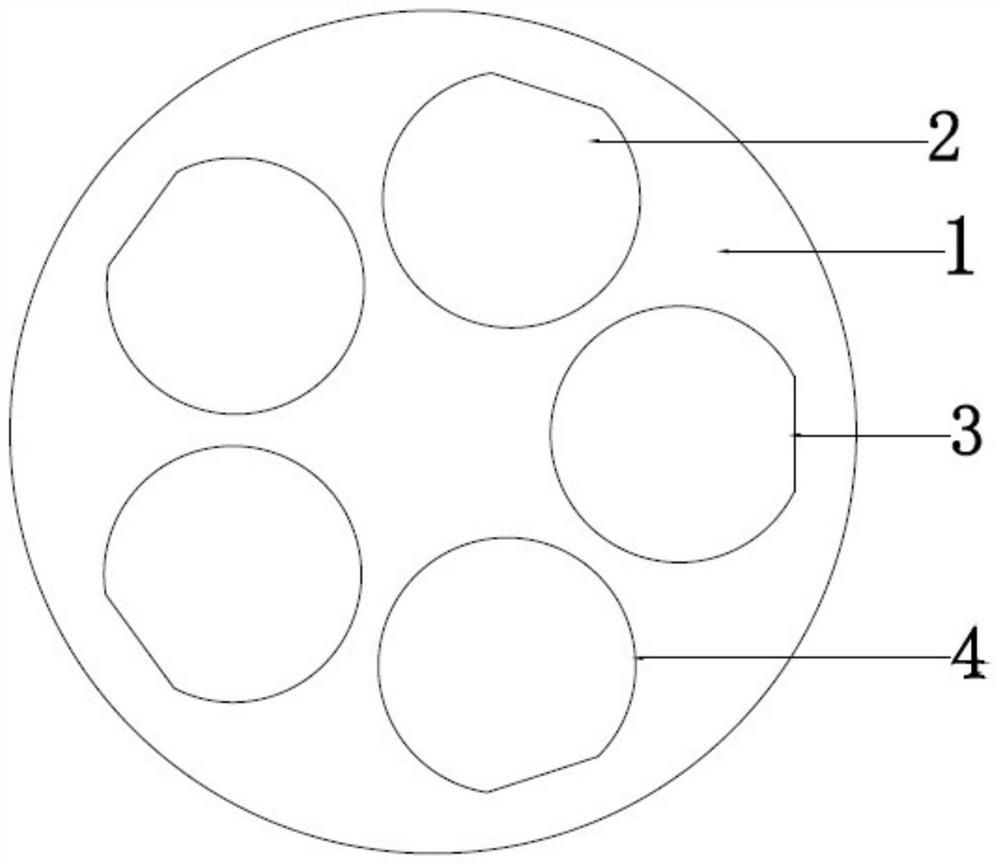

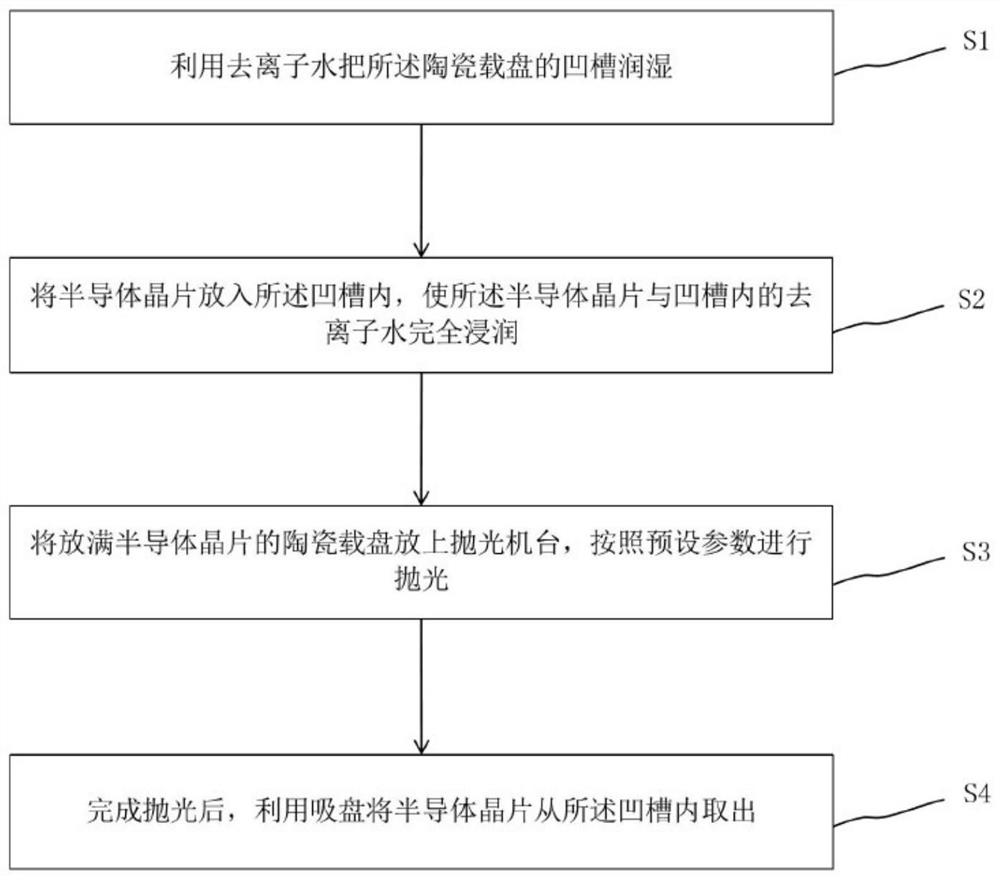

Ceramic carrier plate for polishing semiconductor wafers

InactiveCN113211306ASimple structureSimple processing technologyLapping machinesWork carriersWaferingMachining process

The invention discloses an integral polishing ceramic carrier plate for wax-free polishing of semiconductor wafers. The ceramic carrier plate comprises a plate body and a groove located on the plate body, the groove and the plate body are integrated, the top of the groove is flush with the plate body, the groove is distributed on the periphery of the upper end of the plate body and is in a rotational symmetry shape, and the groove is used for bearing the semiconductor wafers. The problems that the temperature is low in the polishing process of the semiconductor wafers and the removal rate cannot be increased are solved, meanwhile, it is guaranteed that the wafers cannot slide and shake in the machining process, and the machining quality of the wafers is guaranteed.

Owner:FUJIAN JING AN OPTOELECTRONICS CO LTD

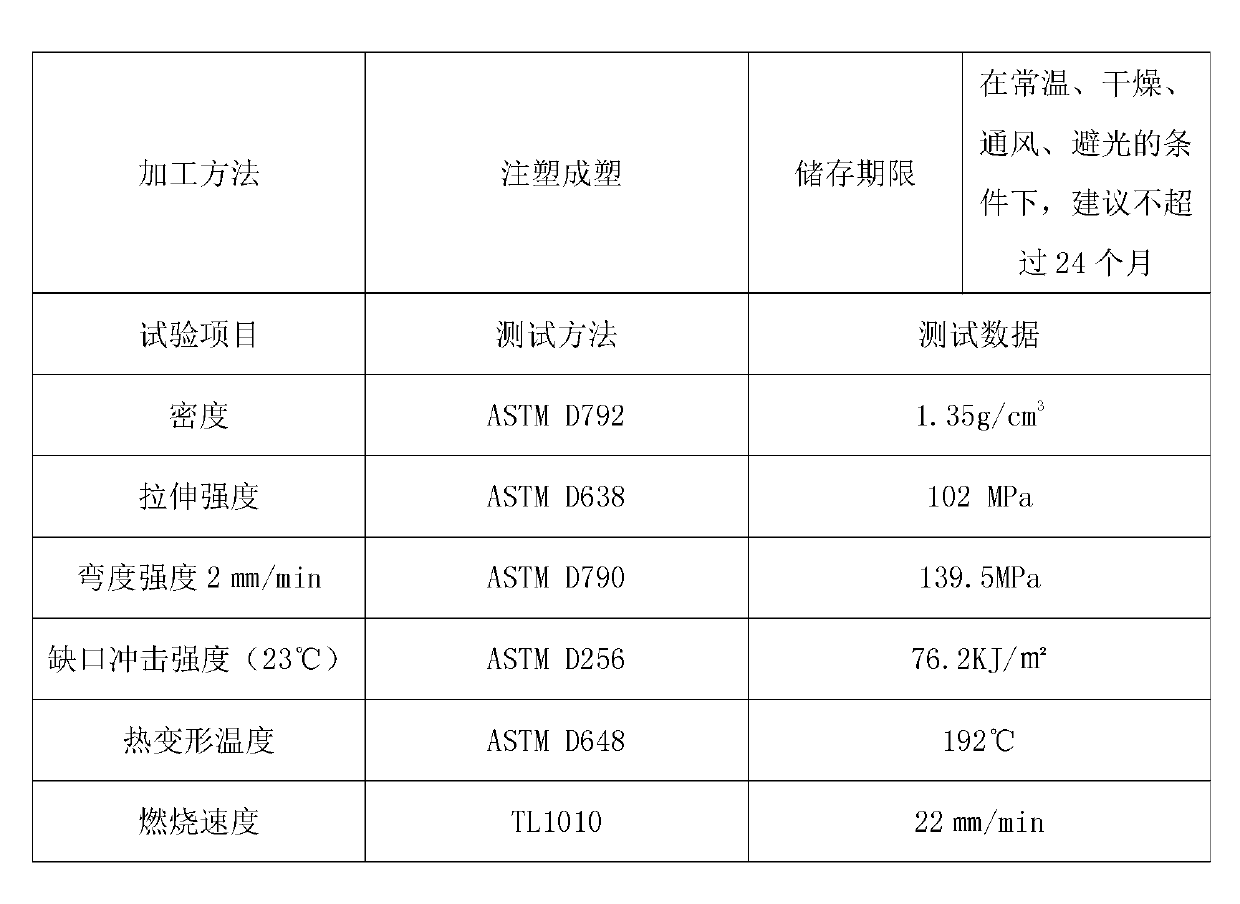

Plastic socket, manufacturing method thereof and application of plastic socket on automobile

The invention discloses a plastic socket, a manufacturing method thereof and application of the plastic socket on an automobile. The manufacturing method mainly comprises the steps of: modifying nylon PA66, then adding the nylon PA66 as a raw material into a heated injection machine, and obtaining a final accepted product by setting the injection pressure, speeds, injection time and injection glue quantities of different sections of the injection machine and simultaneously setting that the final dwell pressure and pressure holding speed achieve the optimal injection technique. The socket disclosed by the invention is easy to mold in an injection manner, easy to demold, stable in machining technology, and high in qualification rate; the production efficiency is improved; the production cost is reduced; and the injected product socket is high in surface gloss, good in fire resistance, good in toughness, high in strength and stable in performance, and can be applied to the automobile.

Owner:ANHUI KAIDI ELECTRIC

A kind of preparation method of high melting point metal wire

ActiveCN108568456BPrecise control of processing temperatureConsistent drawing processTemperatue controlElectrical resistance and conductanceManufactured material

The invention discloses a preparation method of a high-melting-point metal and alloy wire, and belongs to the field of processing of materials. The preparation method of the high-melting-point metal and alloy wire comprises the following specific steps: electrifying a drawn wire with alternating current and direct current so that the drawn wire is self-heated to reach a thermal machining temperature under the effect of current and a wire drawing process can be carried out at a large cross sectional area deformation ratio; meanwhile arranging a two-potential testing end in a wire heating section and measuring a potential value of a specific section of the drawn wire; accurately measuring the temperature of the wire according to the characteristics of resistance and temperature of the measured wire; and the heating power of the drawn wire is controlled by adjustment of fed current. Therefore, it can be ensured that wire drawing is carried out at a checked process temperature of the material. The method has the characteristics of high production efficiency, small product crystalline grains, zero raw material loss in a production process and the like.

Owner:KUNMING UNIV OF SCI & TECH

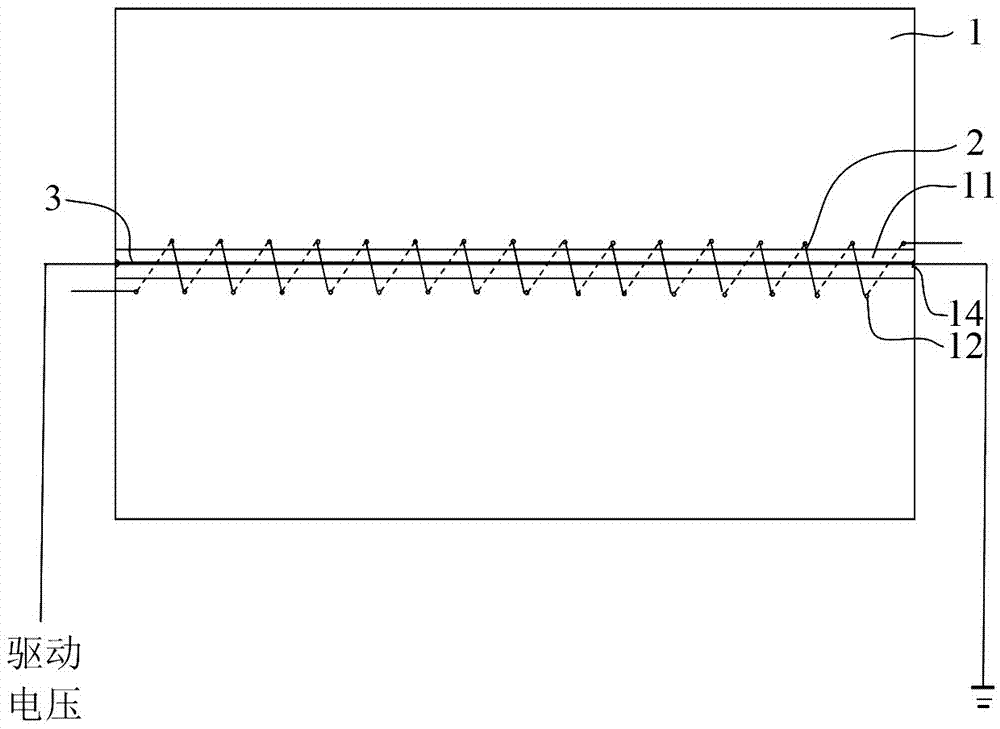

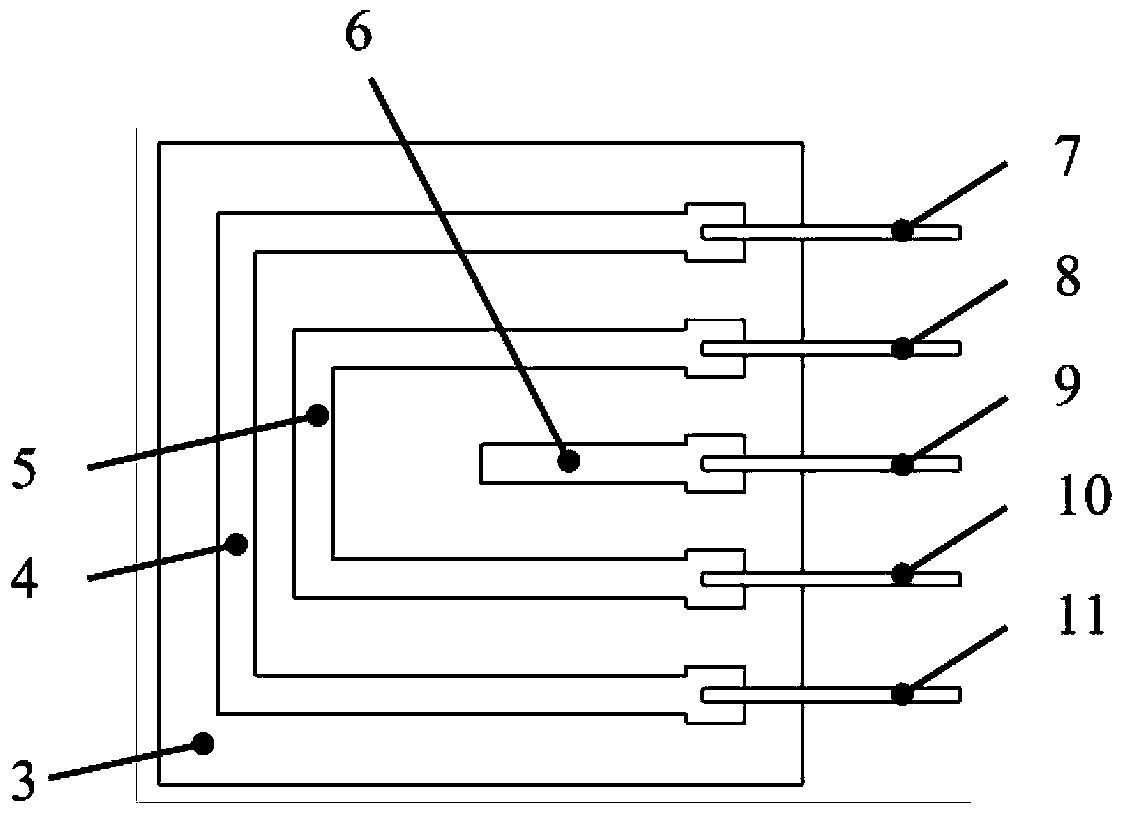

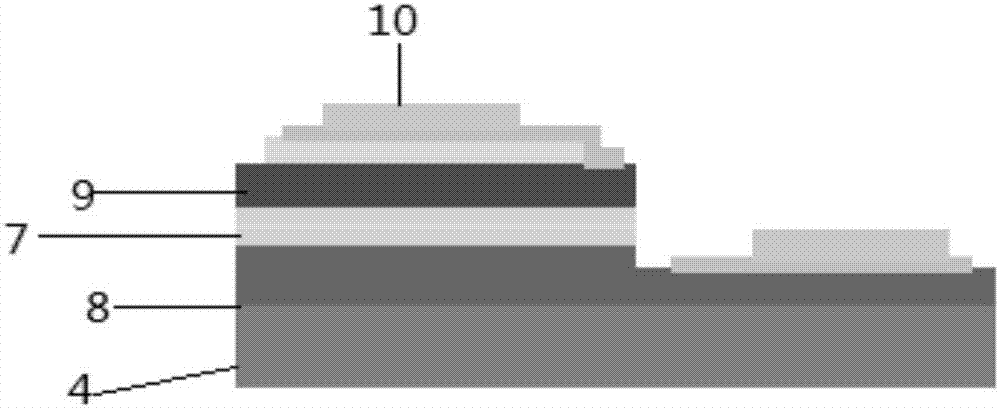

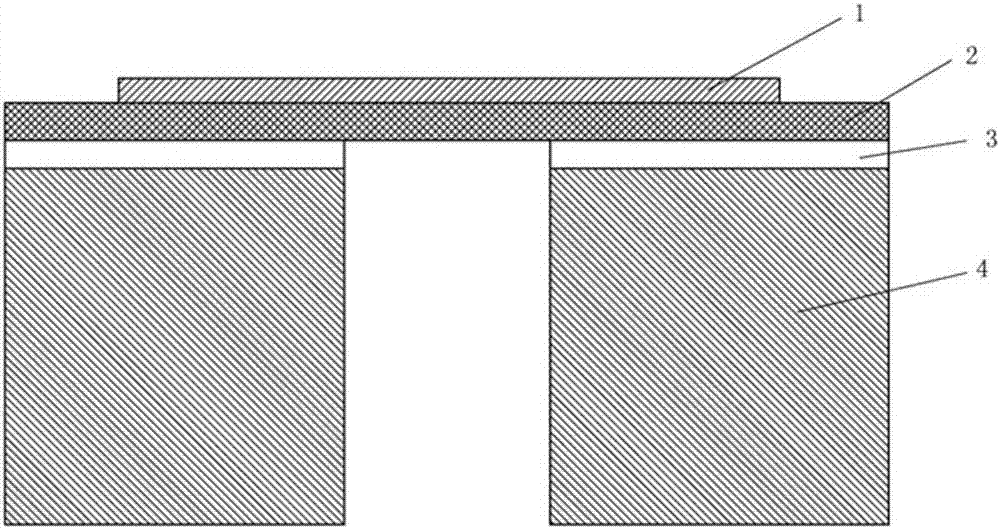

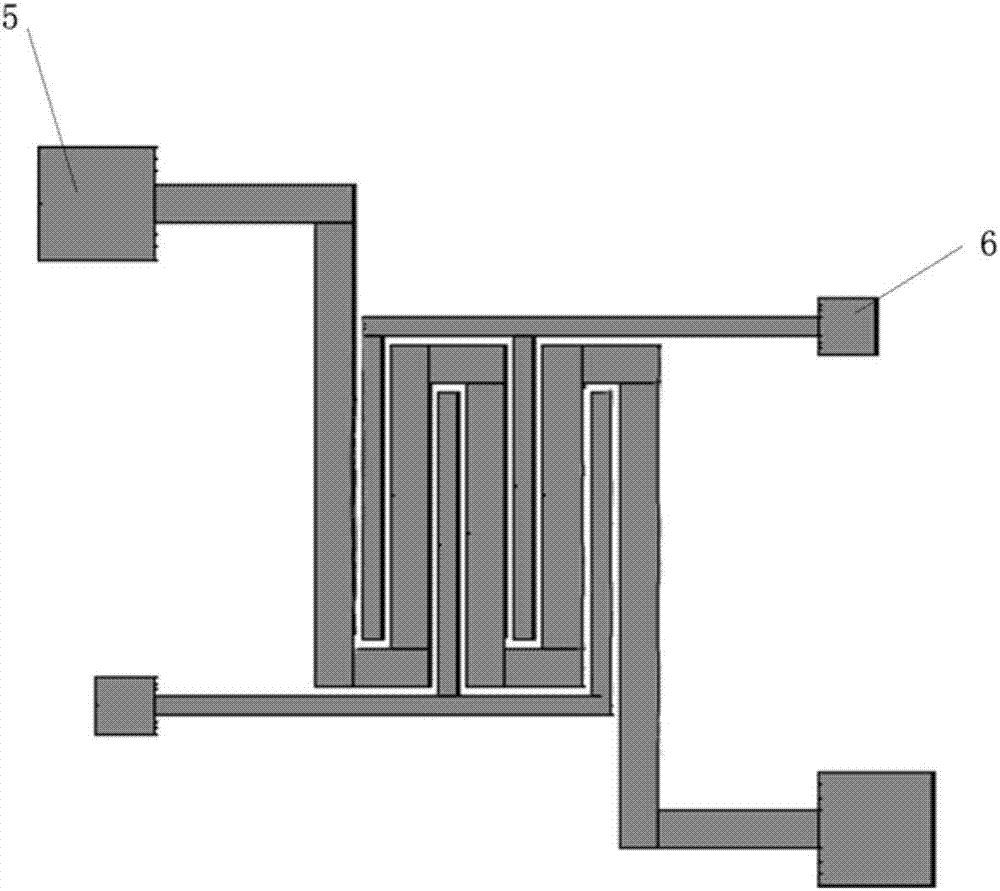

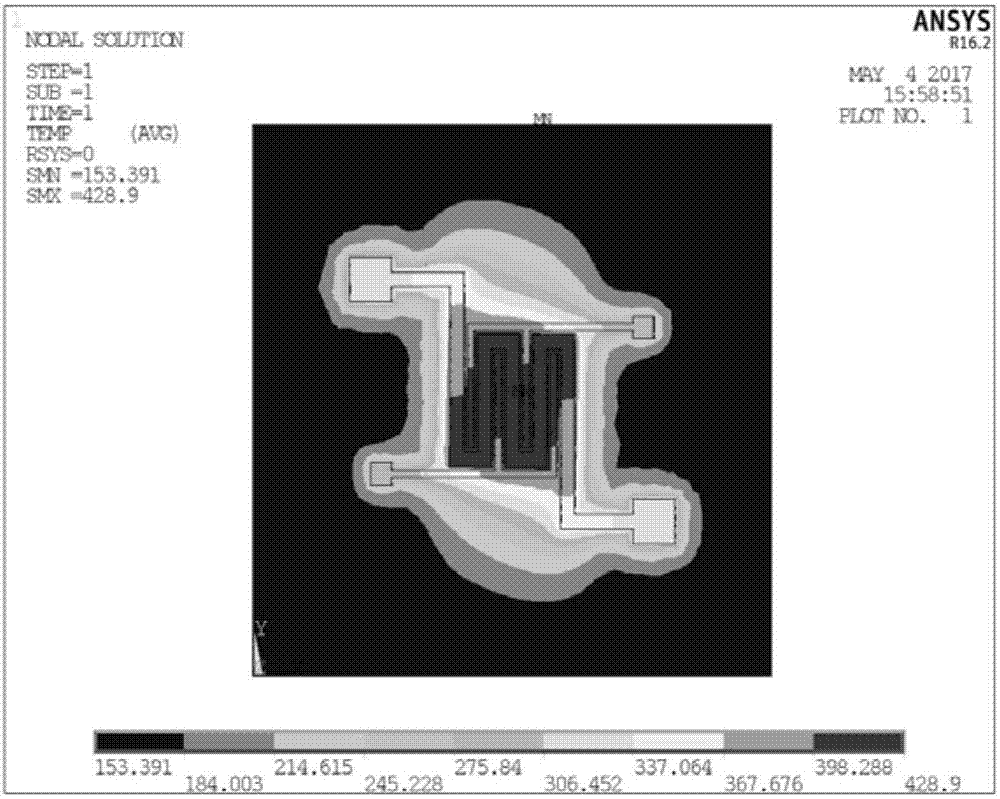

A temperature control system for mems devices

ActiveCN107656562BProcess stabilityStable processing technologyAuxillary controllers with auxillary heating devicesTemperature controlSignal processing circuits

The invention belongs to the technical field of sensors, in particular to a temperature control system used for an MEMS device. The temperature control system is characterized in that temperature detection electrodes and heating electrodes are distributed on surfaces of upper and lower substrates of the MEMS device; and a temperature detection circuit transmits electric signals detected by means of the temperature detection electrodes to a signal processing circuit, the signal processing circuit judges whether operating temperatures of the surfaces of the upper and lower substrates of the MEMSdevice are appropriate, and the signal processing circuit controls the operating temperatures of the surfaces of the upper and lower substrates of the MEMS device through controlling intensities of control electric signals input to the heating electrodes. The temperature control system provided by the invention can eliminate temperature performance and temperature hysteresis of the MEMS device.

Owner:XIAN FLIGHT SELF CONTROL INST OF AVIC

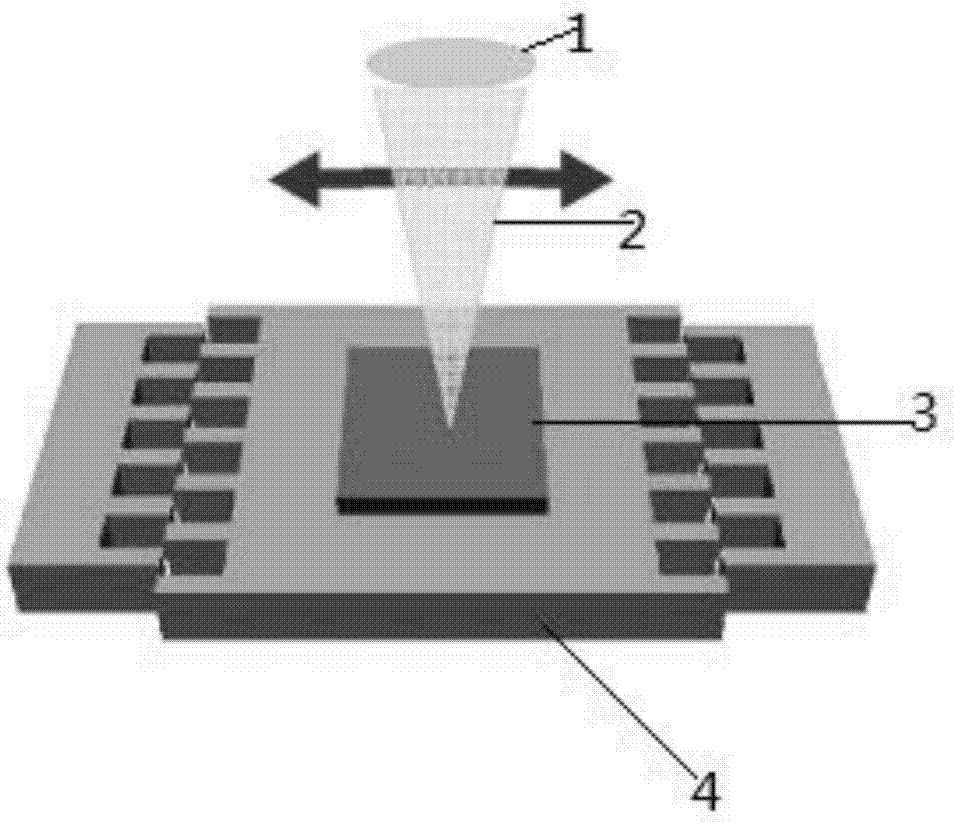

Variable light distribution device based on silicon-based nitride and preparation method thereof

ActiveCN107188112AEasy to prepareAchieve integrationTelevision system detailsImpedence networksLateral movementLight source

The invention discloses a variable light distribution device based on silicon-based nitride and a preparation method thereof. The variable light distribution device comprises a lens, a quantum well GaN, P-GaN, N-GaN, an EL electrode, a GaN-based LED light source, an electrostatic MEMS (Micro-Electro-Mechanical System) micro performer and a Si substrate. The GaN-based LED light source is grown on the Si substrate. The lens is completely adhered right above the GaN-based LED light source. The electrostatic MEMS micro performer comprises a comb-shaped structure composed of fixed combs and movable combs. The fixed combs are connected with the Si substrate. The movable combs and the GaN-based LED light source are fixed together. The LED light source is arranged right above the movable combs. Through application of a voltage, the GaN-based LED light source carries out lateral movement on the Si substrate plane under the drive of a comb-shaped driver. When the GaN-based LED light source moves to an optical axis direction of the lens in parallel, collimated beams passing through the GaN-based LED light source are deflected according to an angle forming certain proportion with the Si substrate plane. The device can be applied to fields such as directional illumination, free space optical communication and a robot optical sensor.

Owner:NANJING UNIV OF POSTS & TELECOMM

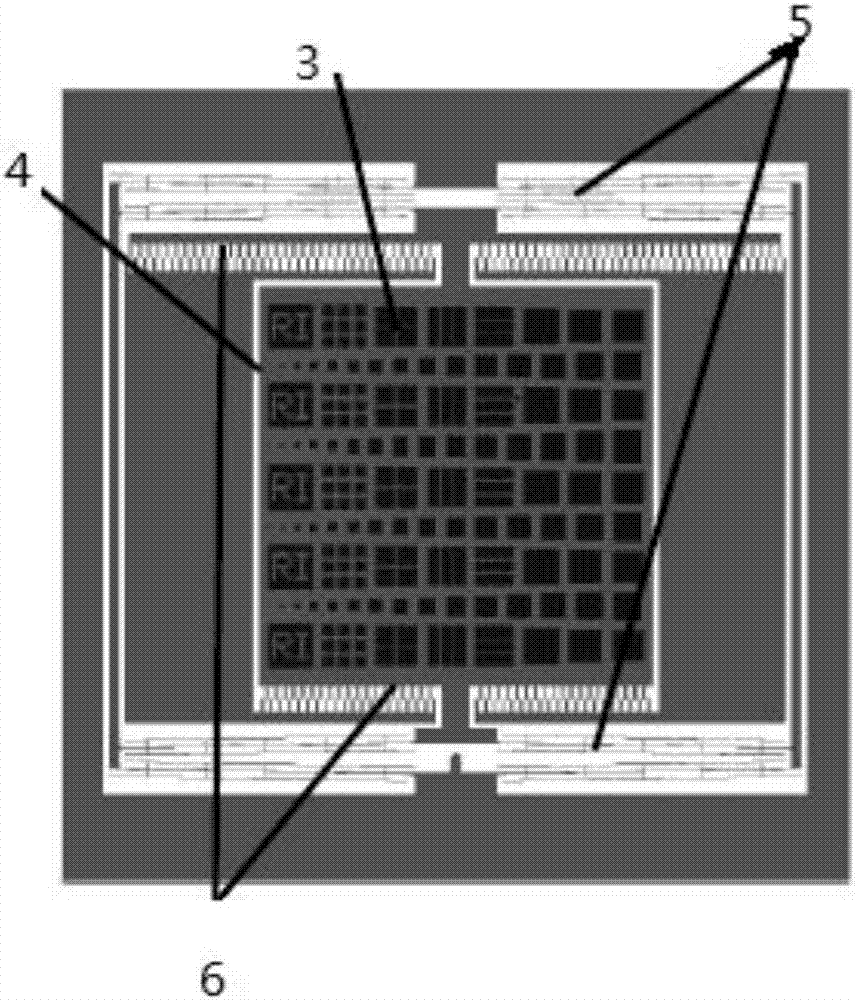

Micro heating plate based on porous silicon insulation layer and preparation method thereof

ActiveCN107404775AUniform contact areaGood insulation performanceOhmic-resistance electrodesHeating element materialsInsulation layerElectrical performance

A micro heating plate based on a porous silicon insulation layer and a preparation method thereof are provided, which belong to the technical field of silicon-based heating plates for gas sensors. The micro heating plate includes, sequentially from top to bottom, an electrode group, a porous silicon layer, a silicon dioxide layer, and a silicon base. The electrode group includes a heating electrode and a signal electrode. The heating electrode is snake-shaped. The signal electrode is an interdigital electrode. The interdigital bulges of the signal electrode are in the depressed portions of the snake shape of the heating electrode. The heating electrode and the signal electrode do not contact each other. A novel porous silicon insulation layer material replaces the existing silicon dioxide and silicon nitride insulation layer material. The silicon base released by a bulk silicon processing technology is used, and the silicon base is prepared through backside silicon etching. The contact area between the insulation layer and the air is increased. Dissipation of heat on the heating plate can be greatly reduced. The micro heating plate has the advantages of small size, high sensitivity, low cost, low power consumption, easy batch production, strong mechanical and electrical performance, stable processing technology, and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com