Honing netting crack processing control method

A control method and technology for honing textures, applied in honing machine tools, metal processing equipment, manufacturing tools, etc., can solve the problems of misalignment of textures at the commutation point, asymmetry of texture distortion, and unstable depth index of texture grooves and other problems, to achieve the effect of reducing the trial grinding cycle, stabilizing the index, and improving the adjustment accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

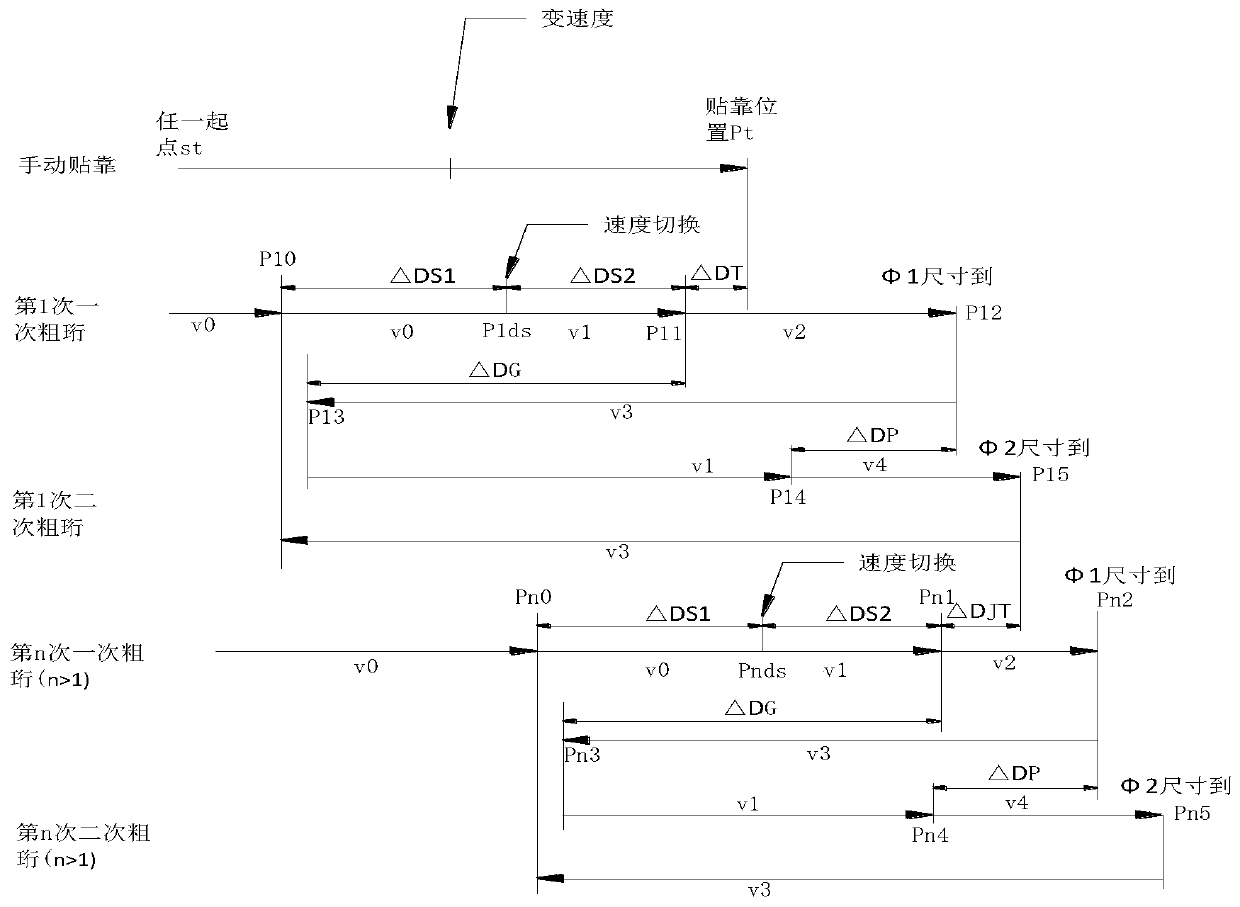

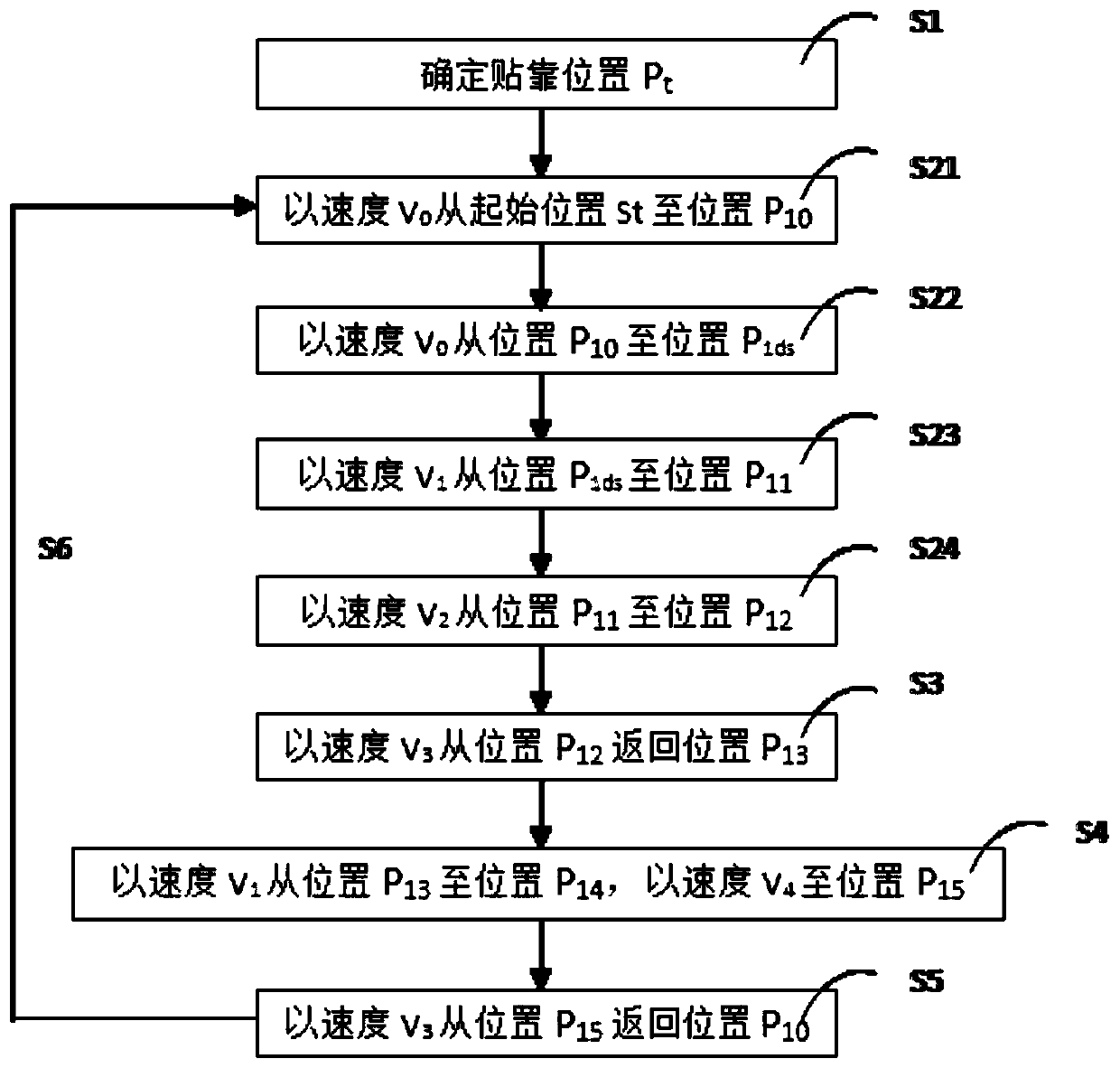

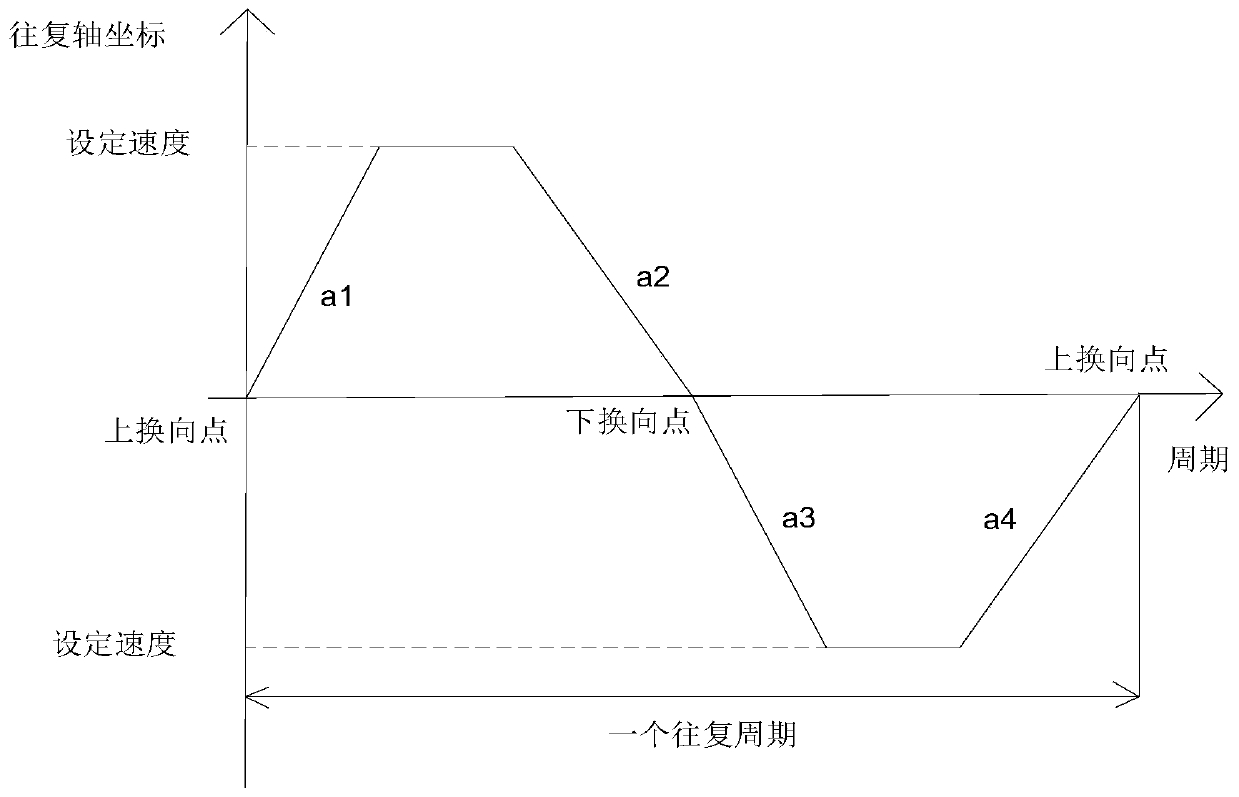

[0050] Such as figure 1 , 2 As shown in , 3, a method for controlling honing texture processing, the four stages of acceleration and deceleration in a reciprocating cycle of the honing head adopt different accelerations, and the feeding of the sand bar is controlled by speed, wherein the speed control of the feeding of the sand bar includes the following step:

[0051] S1. Set the abutment force and abutment speed, and determine the abutment position P by setting the abutment force t ;The current abutment speed is inversely proportional to the current abutment force;

[0052] S2, a rough honing: the sand bar starts from the starting position S t at fast forward speed V 0 advance to the abutment position with the P t The distance is the position P of the protection gap △DS 10 , and then change the speed to advance to the abutment position P t The distance is the position P of the elastic deformation correction value △DT 11 , at the working speed V 2 Processing set size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com